Thickness Dependence of Toughness in Ultra-Heavy Low-Alloyed Steel Plate after Quenching and Tempering

Abstract

:1. Introduction

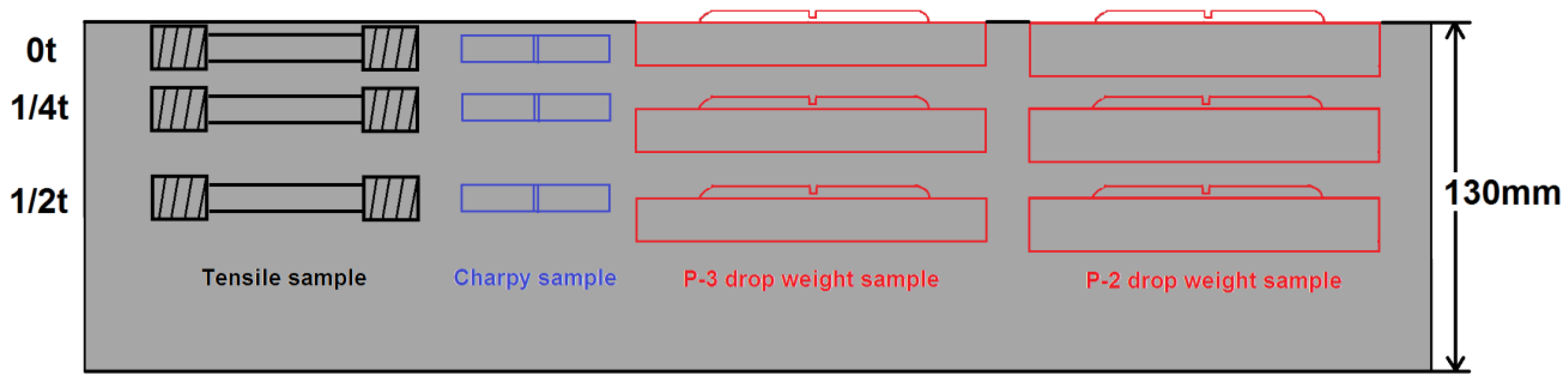

2. Materials and Methods

3. Results

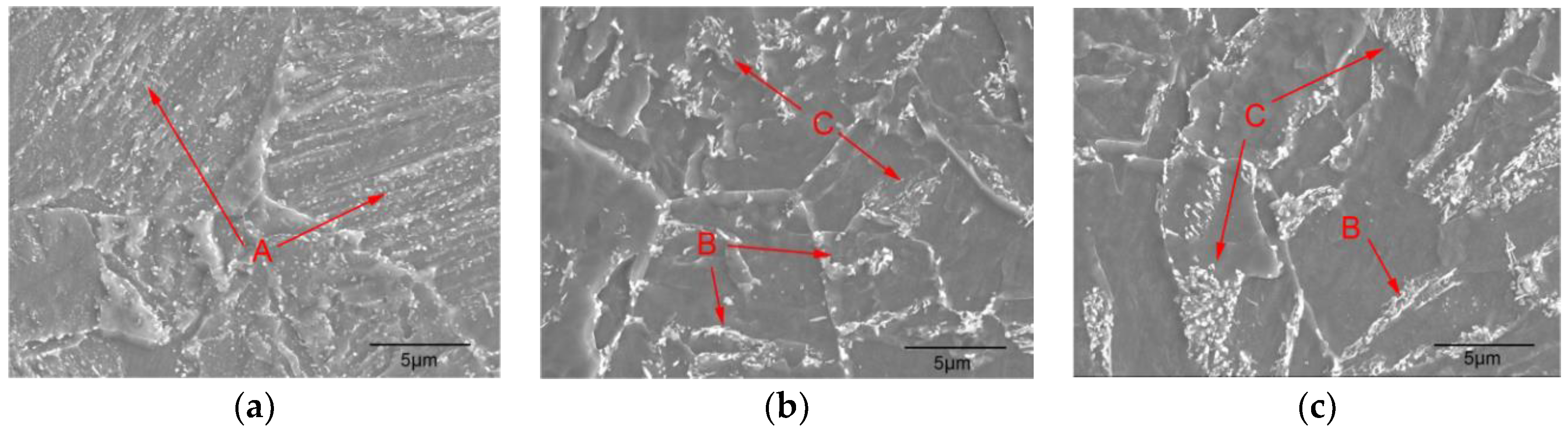

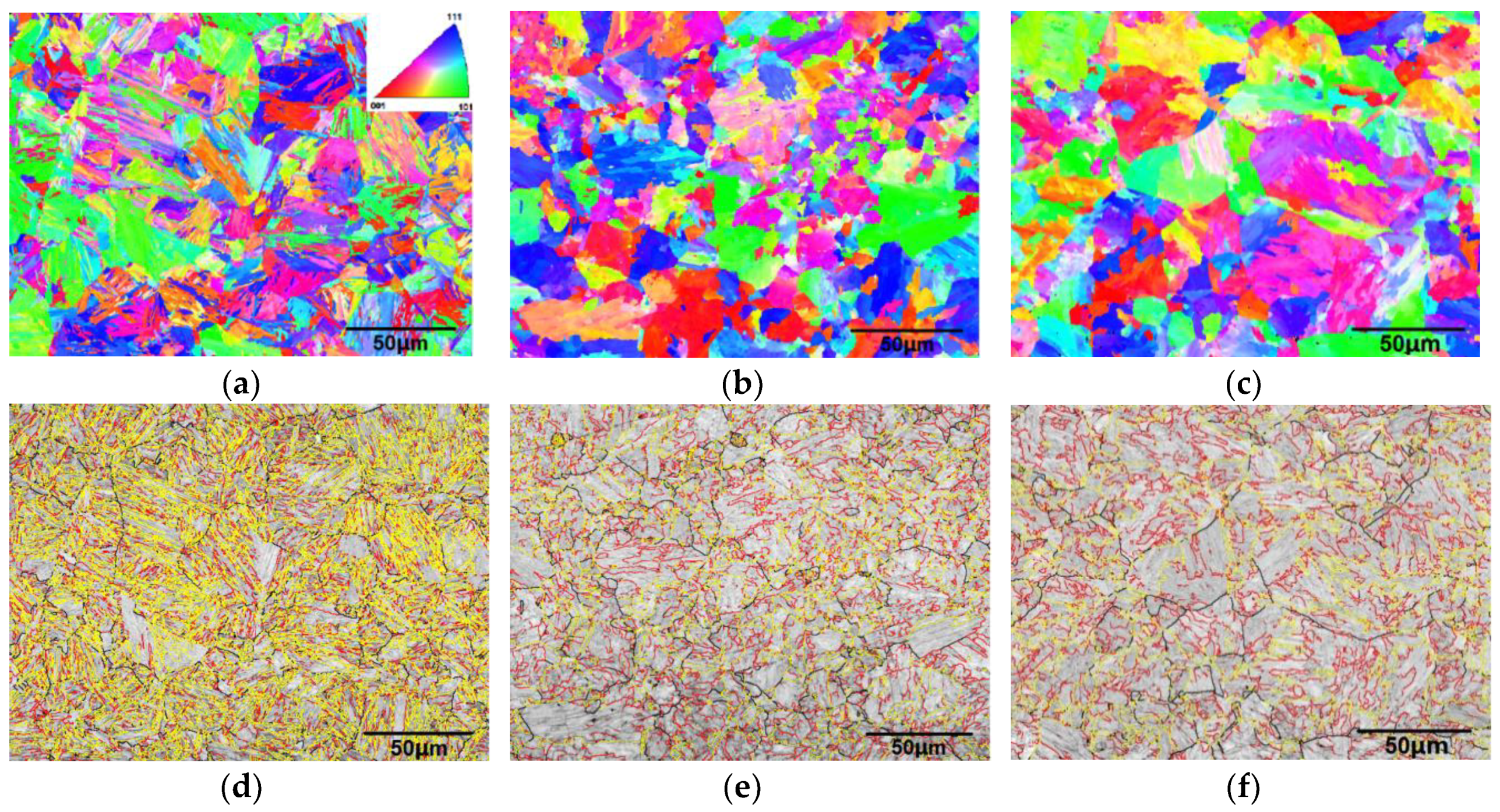

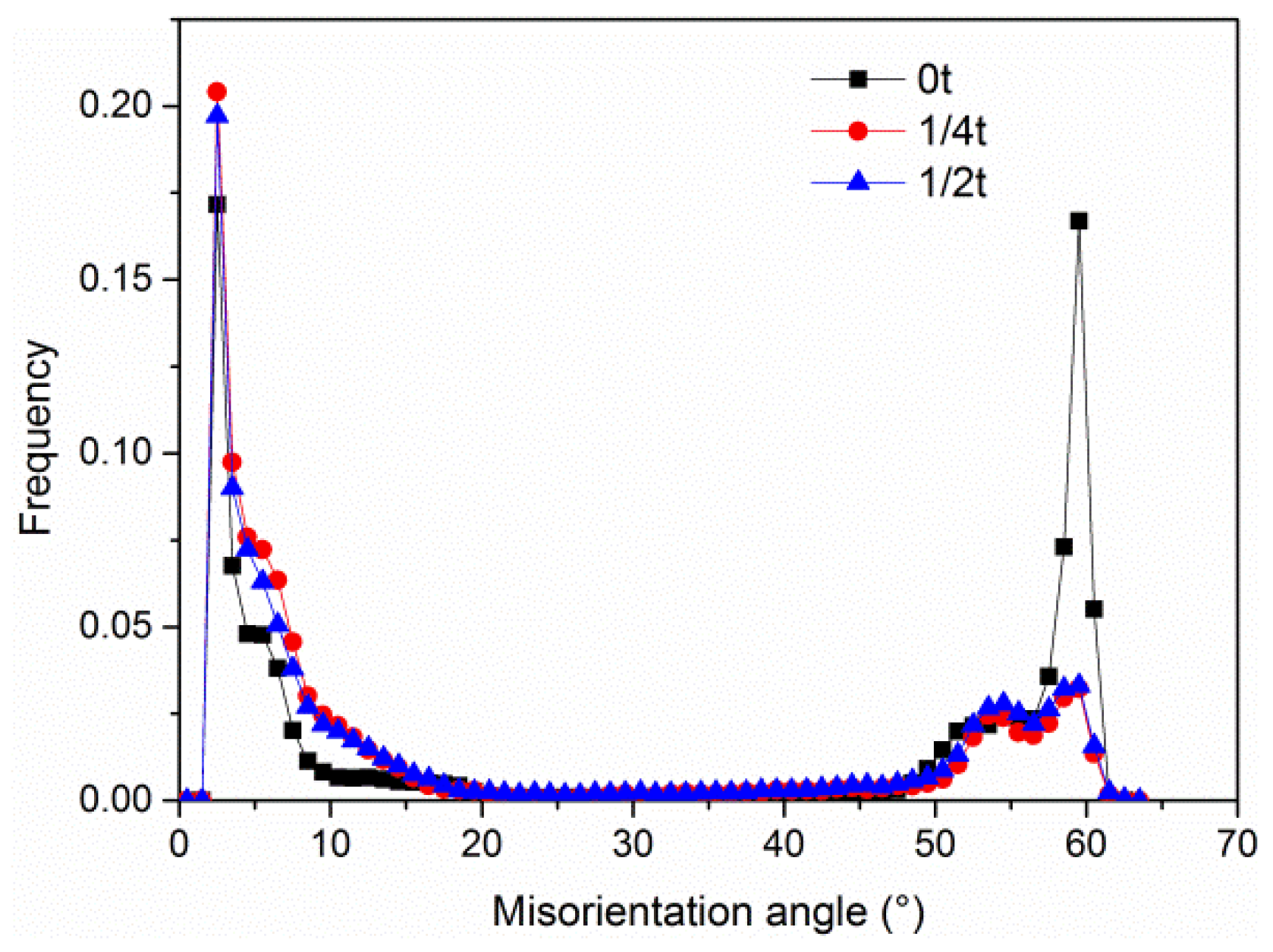

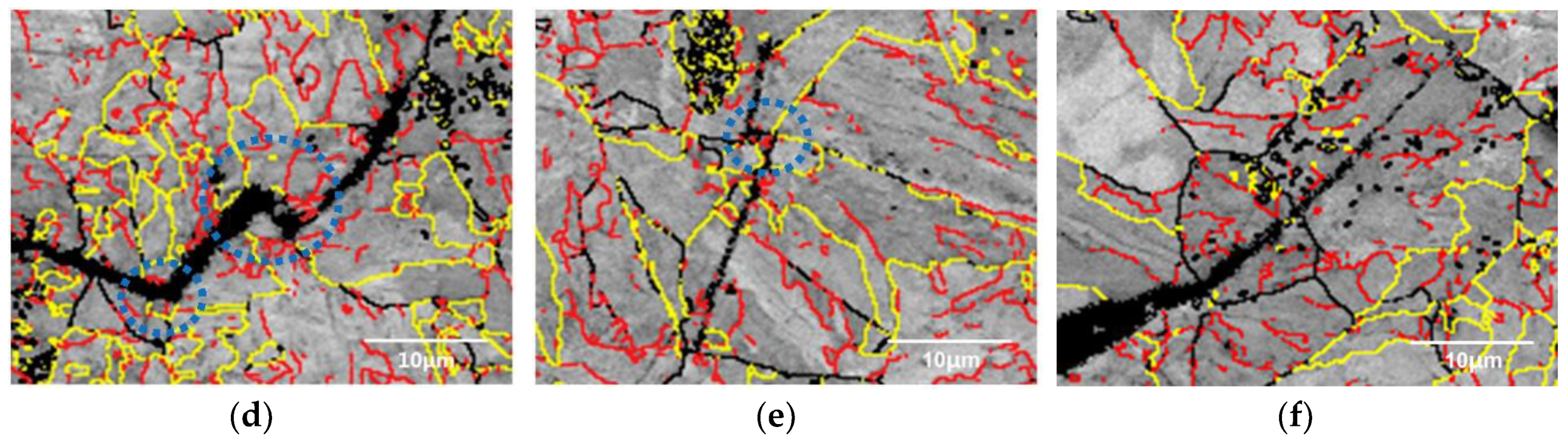

3.1. Microstructure

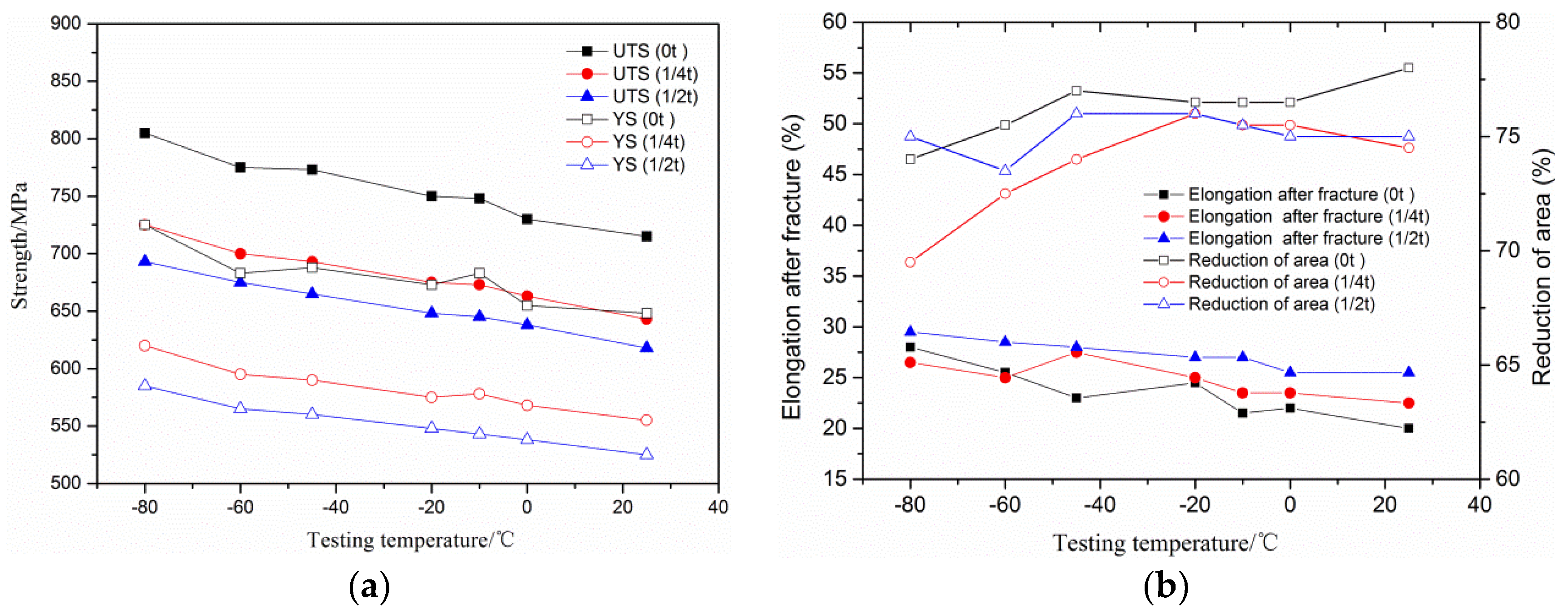

3.2. Tensile Properties

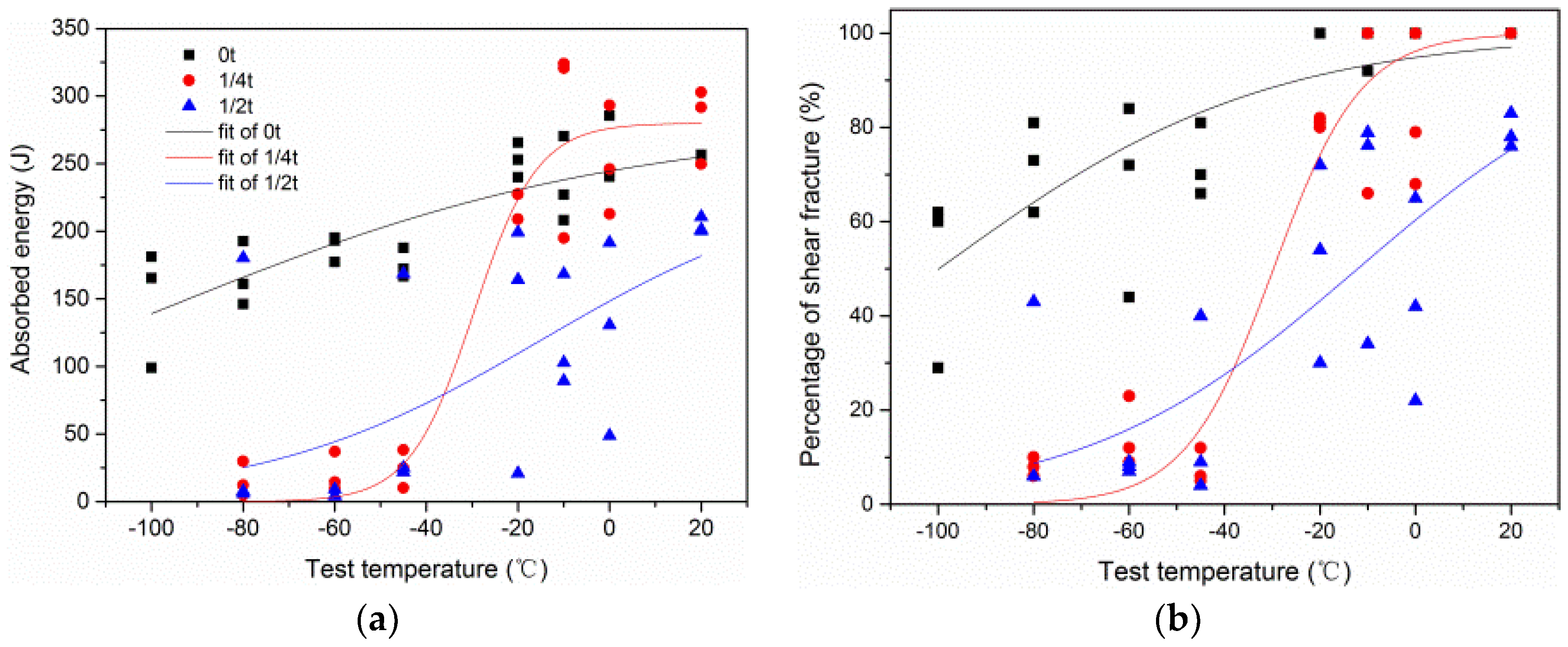

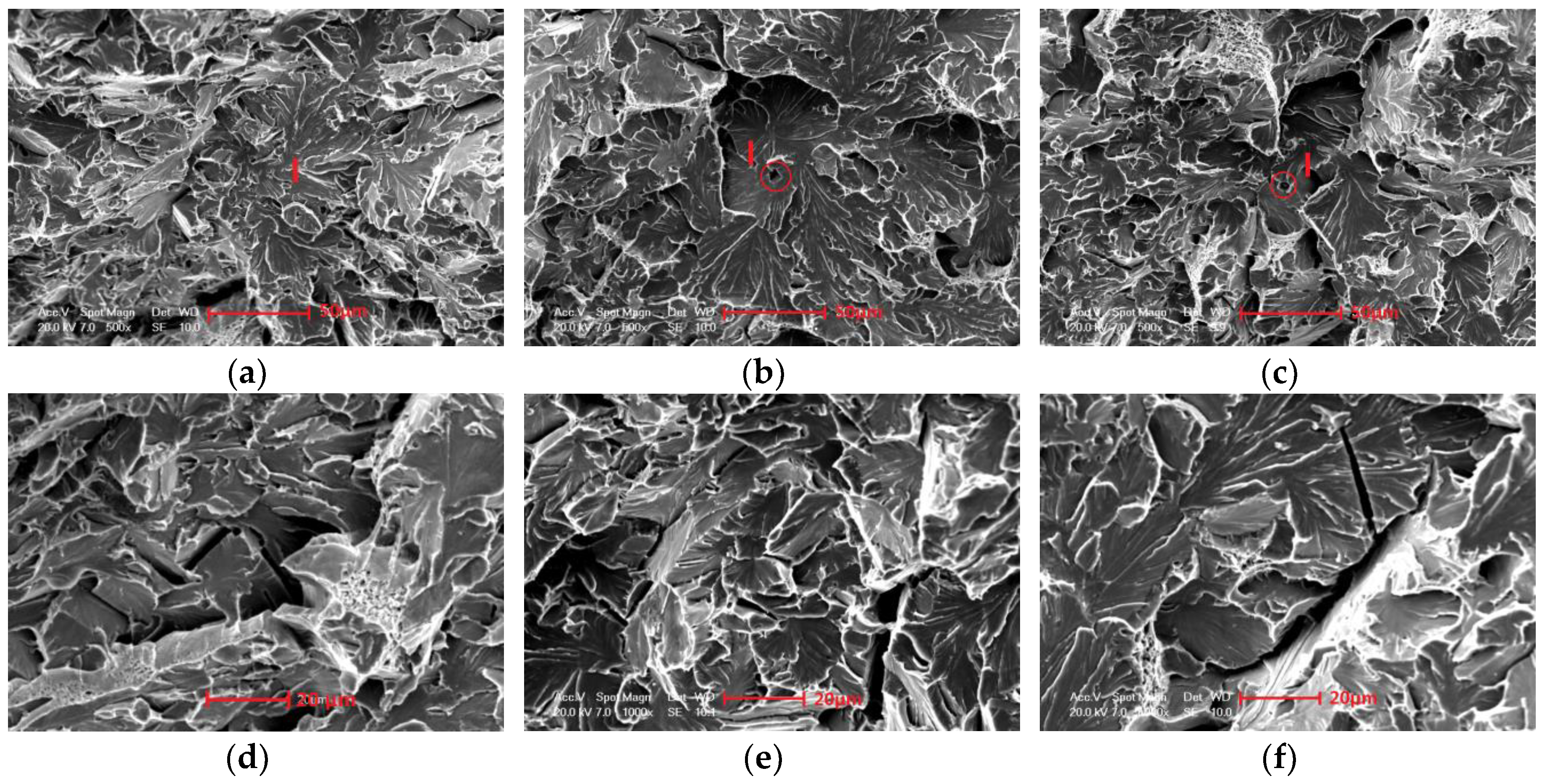

3.3. Impact Toughness

3.4. Instrumented Charpy Impact

3.5. Pellini Drop Weight Tests

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Buchmayr, B. Thermomechanical Treatment of Steels—A Real Disruptive Technology Since Decades. Steel Res. Int. 2017, 88, 1700182. [Google Scholar] [CrossRef]

- Tsuyama, S. Thick Plate Technology for the Last 100 Years: A World Leader in Thermo Mechanical Control Process. ISIJ Int. 2015, 55, 67–78. [Google Scholar] [CrossRef] [Green Version]

- Yen, H.; Chiang, M.; Lin, Y.; Chen, D.; Huang, C.; Lin, H. High-Temperature Tempered Martensite Embrittlement in Quenched-and-Tempered Offshore Steels. Metals 2017, 7, 253. [Google Scholar] [CrossRef]

- Zhou, T.; Yu, H.; Wang, S. Microstructural Characterization and Mechanical Properties across Thickness of Ultra-Heavy Steel Plate. Steel Res. Int. 2017, 88, 1700132. [Google Scholar] [CrossRef]

- Hu, J.; Du, L.; Xie, H.; Gao, X.; Misra, R. Microstructure and mechanical properties of TMCP heavy plate microalloyed steel. Mater. Sci. Eng. A 2014, 607, 122–131. [Google Scholar] [CrossRef]

- Zhou, T.; Yu, H.; Wang, S. Effect of microstructural types on toughness and microstructural optimization of ultra-heavy steel plate: EBSD analysis and microscopic fracture mechanism. Mater. Sci. Eng. A 2016, 658, 150–158. [Google Scholar] [CrossRef]

- Wang, X.L.; Wang, Z.Q.; Ma, X.P.; Subramanian, S.V.; Xie, Z.J.; Shang, C.J.; Li, X.C. Analysis of impact toughness scatter in simulated coarse-grained HAZ of E550 grade offshore engineering steel from the aspect of crystallographic structure. Mater. Charact. 2018, 140, 312–319. [Google Scholar] [CrossRef]

- Petrov, R.; Kestens, L.; Wasilkowska, A.; Houbaert, Y. Microstructure and texture of a lightly deformed TRIP-assisted steel characterized by means of the EBSD technique. Mater. Sci. Eng. A 2007, 447, 285–297. [Google Scholar] [CrossRef]

- Gourgues, A.F.; Flower, H.M.; Lindley, T.C. Electron backscattering diffraction study of acicular ferrite, bainite, and martensite steel microstructures. Mater. Sci. Technol. 2000, 16, 26–40. [Google Scholar] [CrossRef]

- Dieter, G.E.; Bacon, D.J. Mechanical Metallurgy; McGraw-Hill: New York, NY, USA, 1986. [Google Scholar]

- Tanguy, B.; Besson, J.; Piques, R.; Pineau, A. Ductile to brittle transition of an A508 steel characterized by Charpy impact test Part I: Experimental results. Eng. Fract. Mech. 2005, 72, 49–72. [Google Scholar] [CrossRef] [Green Version]

- Tavares, S.S.M.; Silva, M.B.; de Macêdo, M.C.S.; Strohaecker, T.R.; Costa, V.M. Characterization of fracture behavior of a Ti alloyed supermartensitic 12%Cr stainless steel using Charpy instrumented impact tests. Eng. Fail. Anal. 2017, 82, 695–702. [Google Scholar] [CrossRef]

- Schindler, H.J.; Morf, U. A closer look at estimation of fracture toughness from Charpy V-notch tests. Int. J. Press. Vessels Pip. 1993, 55, 203–212. [Google Scholar] [CrossRef]

- Chaouadi, R.; Fabry, A. On the utilization of the instrumented Charpy impact test for characterizing the flow and fracture behavior of reactor pressure vessel steels. In European Structural Integrity Society; Elsevier: Amsterdam, The Netherlands, 2002; Volume 30, pp. 103–117. [Google Scholar]

- Kim, H.; Park, J.; Kang, M.; Lee, S. Interpretation of Charpy impact energy characteristics by microstructural evolution of dynamically compressed specimens in three tempered martensitic steels. Mater. Sci. Eng. A 2016, 649, 57–67. [Google Scholar] [CrossRef]

- Wallin, K.; Karjalainen-Roikonen, P.; Suikkanen, P. Crack arrest toughness estimation for high strength steels from sub-sized instrumented Charpy-V tests. In Proceedings of the 26th International Ocean and Polar Engineering Conference, Rhodes, Greece, 26 June–2 July 2016; pp. 85–91. [Google Scholar]

- Wiesner, C.S. Predicting structural crack arrest behaviour using small-scale material characterisation tests. J. Press. Vessels Pip. 1996, 69, 185–196. [Google Scholar] [CrossRef]

- Hertzberg, R.W. Deformation and Fracture Mechanics of Engineering Materials; Wiley: Hoboken, NJ, USA, 1989. [Google Scholar]

- Chen, J.; Cao, R. Micromechanism of Cleavage Fracture of Metals: A Comprehensive Microphysical Model for Cleavage Cracking in Metals; Butterworth-Heinemann: Oxford, UK, 2014. [Google Scholar]

- Zhang, X.Z.; Knott, J.F. Cleavage fracture in bainitic and martensitic microstructures. Acta Mater. 1999, 47, 3483–3495. [Google Scholar] [CrossRef]

- Bowen, P.; Druce, S.G.; Knott, J.F. Effects of microstructure on cleavage fracture in pressure vessel steel. Acta Metall. 1986, 34, 1121–1131. [Google Scholar] [CrossRef]

- Filho, W.W.A.B.; Carvalho, A.L.M.A.; Bowen, P.B. Micromechanisms of cleavage fracture initiation from inclusions in ferritic welds. Part I. Quantification of local fracture behaviour observed in notched testpieces. Mater. Sci. Eng. A 2007, 460, 436–452. [Google Scholar] [CrossRef]

- Naylor, J.P. The influence of the lath morphology on the yield stress and transition temperature of martensitic- bainitic steels. Metall. Trans. A 1979, 10, 861–873. [Google Scholar] [CrossRef]

- Bush, M.E.; Kelly, P.M. Strengthening mechanisms in bainitic steels. Acta Metall. 1971, 19, 1363–1371. [Google Scholar] [CrossRef]

- Fan, L.; Zhou, D.; Wang, T.; Li, S.; Wang, Q. Tensile properties of an acicular ferrite and martensite/austenite constituent steel with varying cooling rates. Mater. Sci. Eng. A 2014, 590, 224–231. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cu + Ni + Cr | Mo | V + Nb |

|---|---|---|---|---|---|---|---|

| 0.088 | 0.22 | 1.40 | 0.009 | 0.0002 | 0.63 | 0.27 | 0.060 |

| Thickness Position | Impact Toughness | TNDT (°C) | ||||

|---|---|---|---|---|---|---|

| USE (J) | T68J (°C) | T0.89mm (°C) | FATT (°C) | P-2 | P-3 | |

| 0 t | 271 | <−100 | <−100 | −100 | −40 | −40 |

| 1/4 t | 287 | −38 | −37 | −30 | −25 | −25 |

| 1/2 t | 211 | −43 | −46 | −15 | −10 | −5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Zhang, H.; Li, J. Thickness Dependence of Toughness in Ultra-Heavy Low-Alloyed Steel Plate after Quenching and Tempering. Metals 2018, 8, 628. https://doi.org/10.3390/met8080628

Liu H, Zhang H, Li J. Thickness Dependence of Toughness in Ultra-Heavy Low-Alloyed Steel Plate after Quenching and Tempering. Metals. 2018; 8(8):628. https://doi.org/10.3390/met8080628

Chicago/Turabian StyleLiu, Huibin, Hanqian Zhang, and Jinfu Li. 2018. "Thickness Dependence of Toughness in Ultra-Heavy Low-Alloyed Steel Plate after Quenching and Tempering" Metals 8, no. 8: 628. https://doi.org/10.3390/met8080628

APA StyleLiu, H., Zhang, H., & Li, J. (2018). Thickness Dependence of Toughness in Ultra-Heavy Low-Alloyed Steel Plate after Quenching and Tempering. Metals, 8(8), 628. https://doi.org/10.3390/met8080628