Modeling and Simulation of the Static Recrystallization of 5754 Aluminium Alloy by Cellular Automaton

Abstract

:1. Introduction

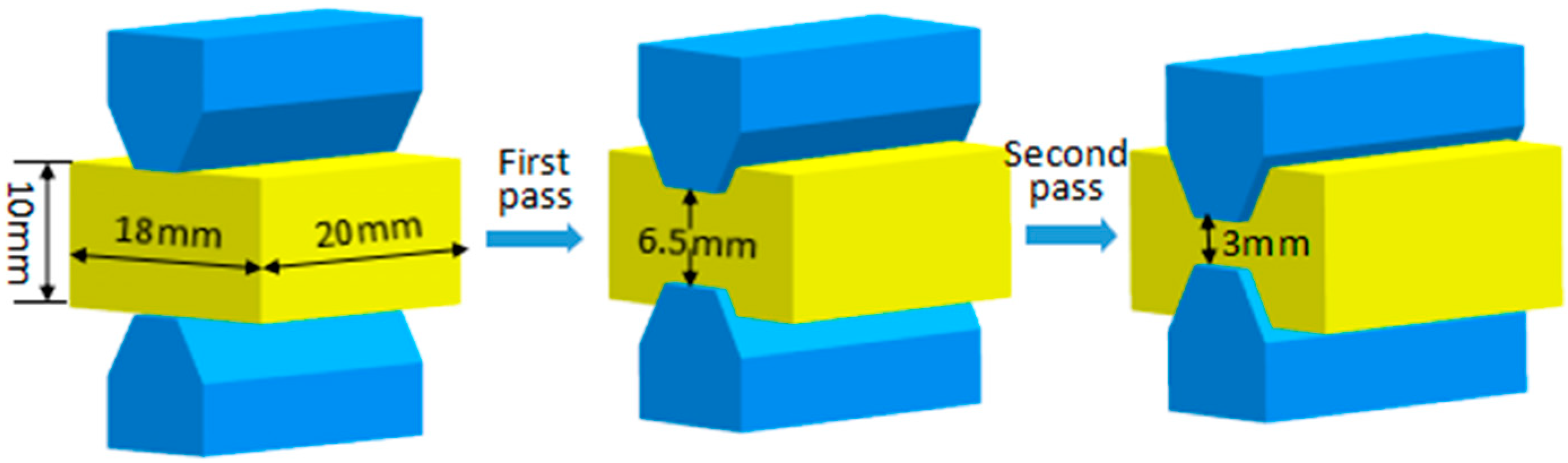

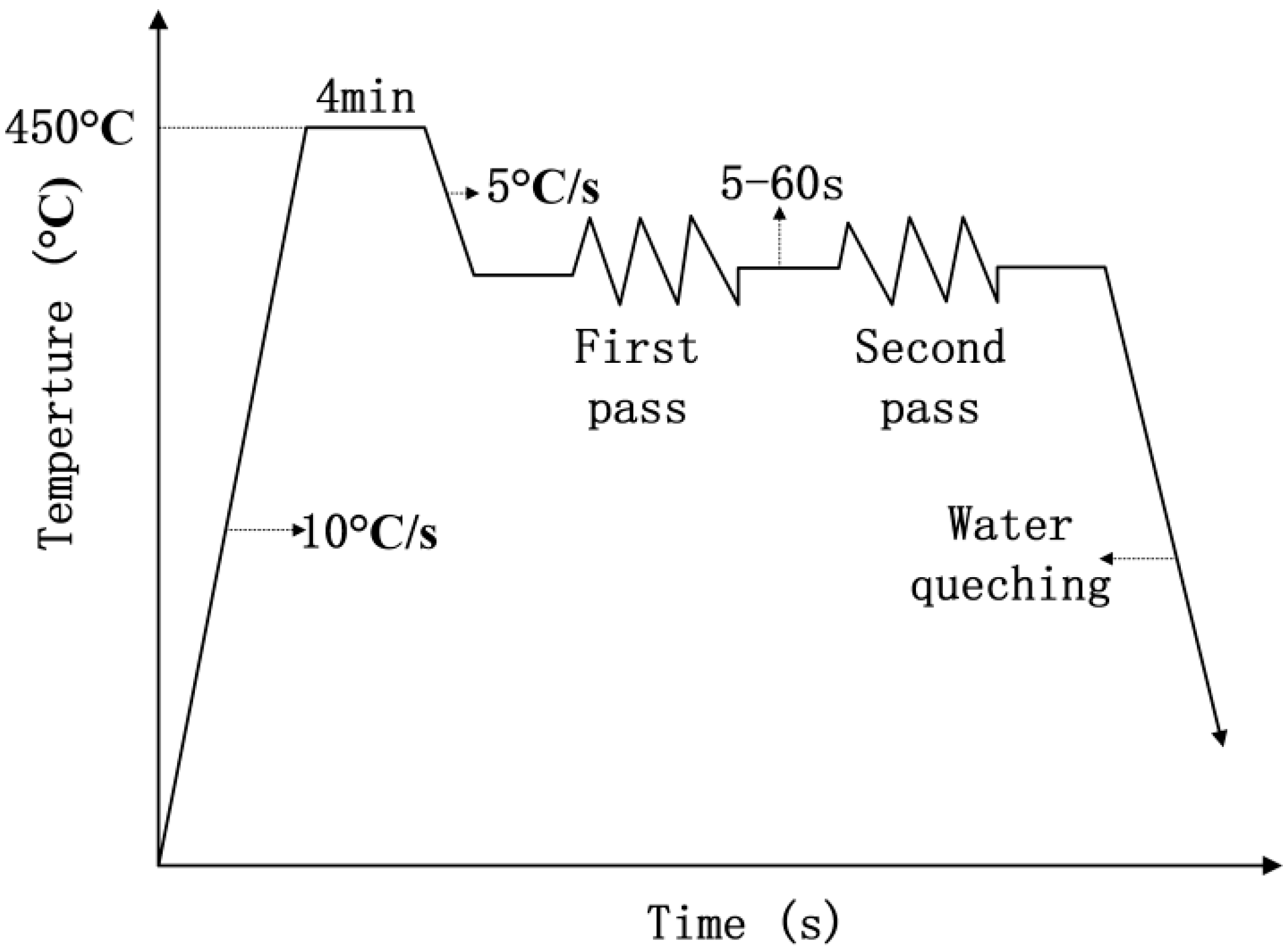

2. Experimental Procedure and Materials

3. Results and Discussion

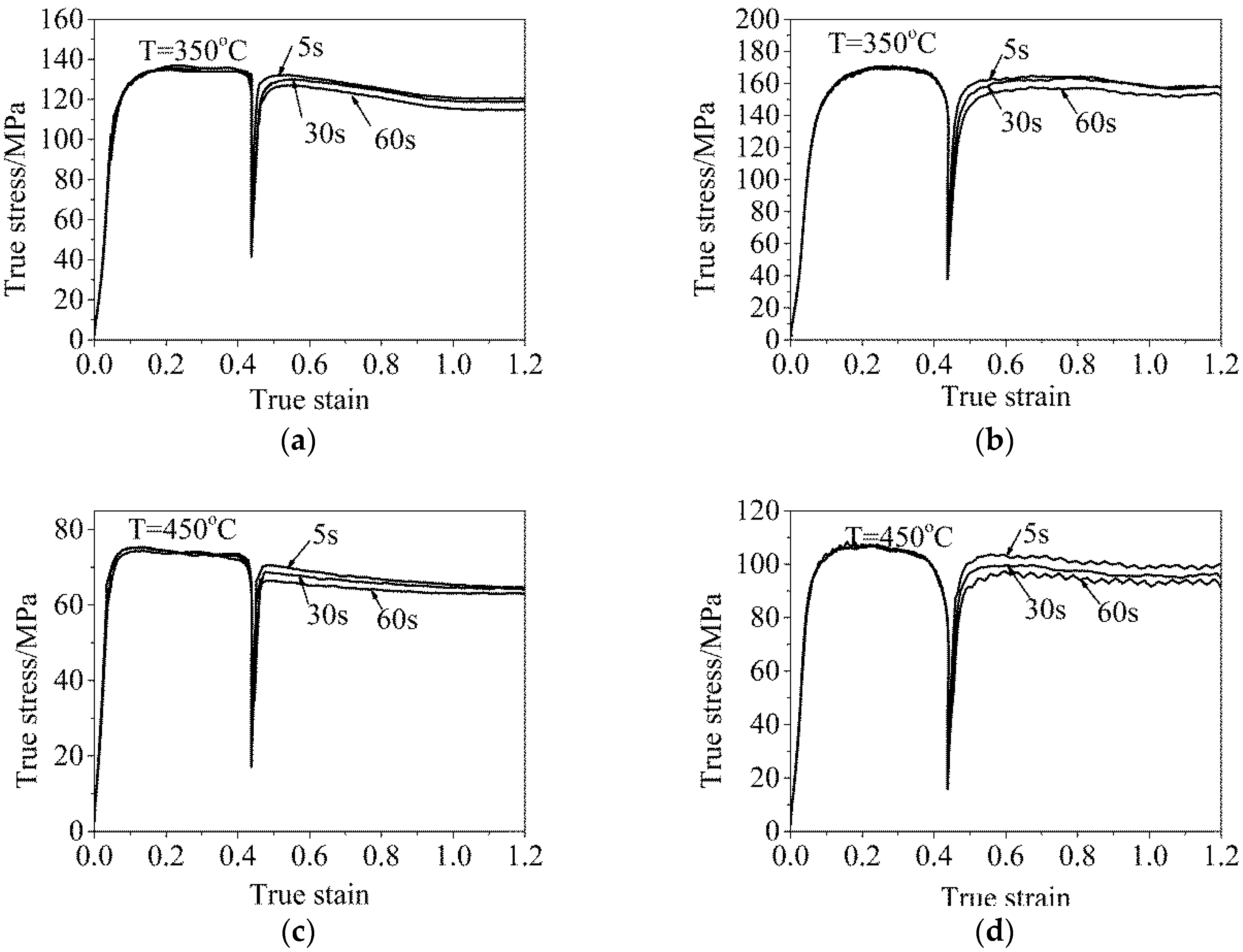

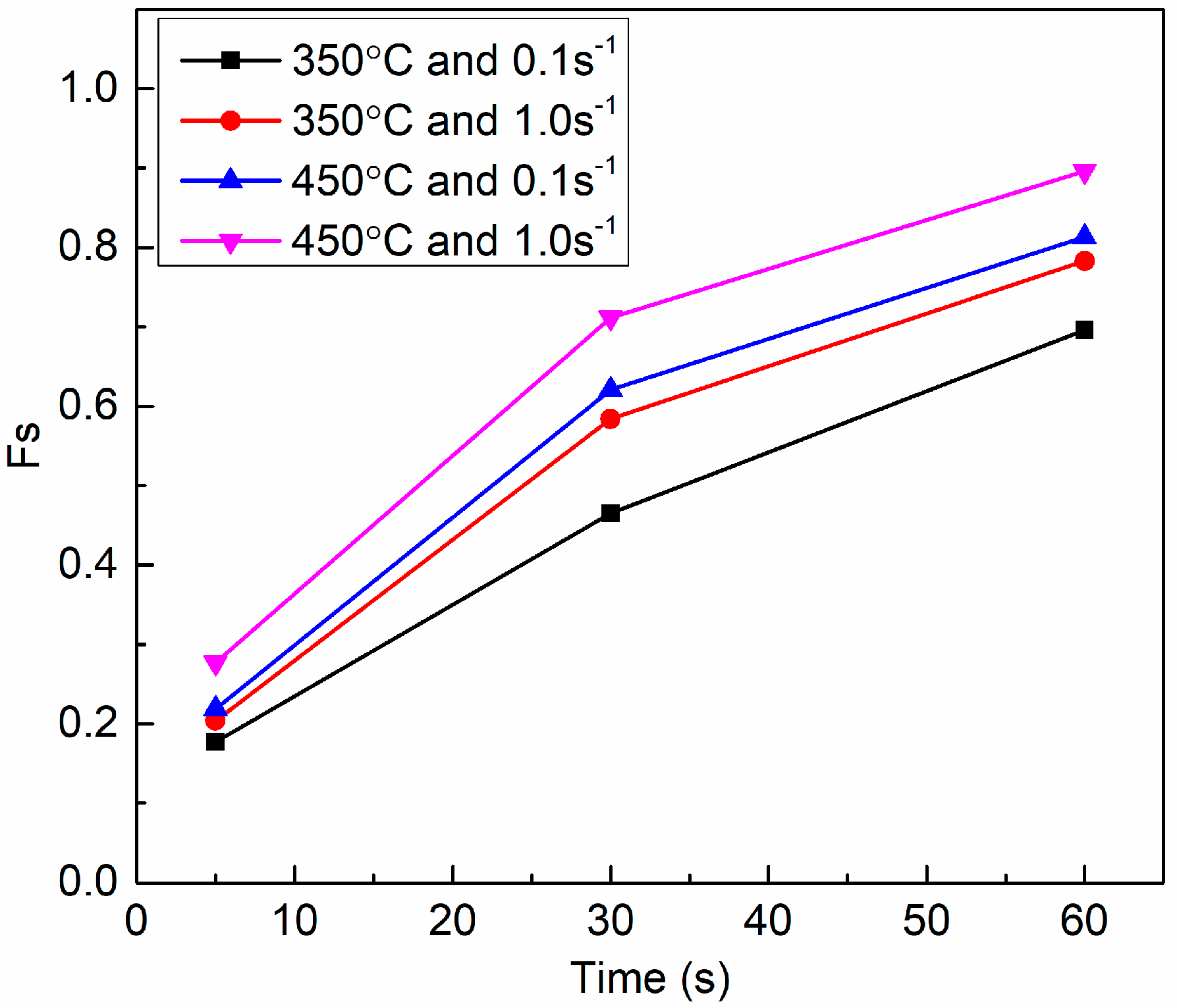

3.1. Static Softening Behavior of 5754 Aluminium Alloy

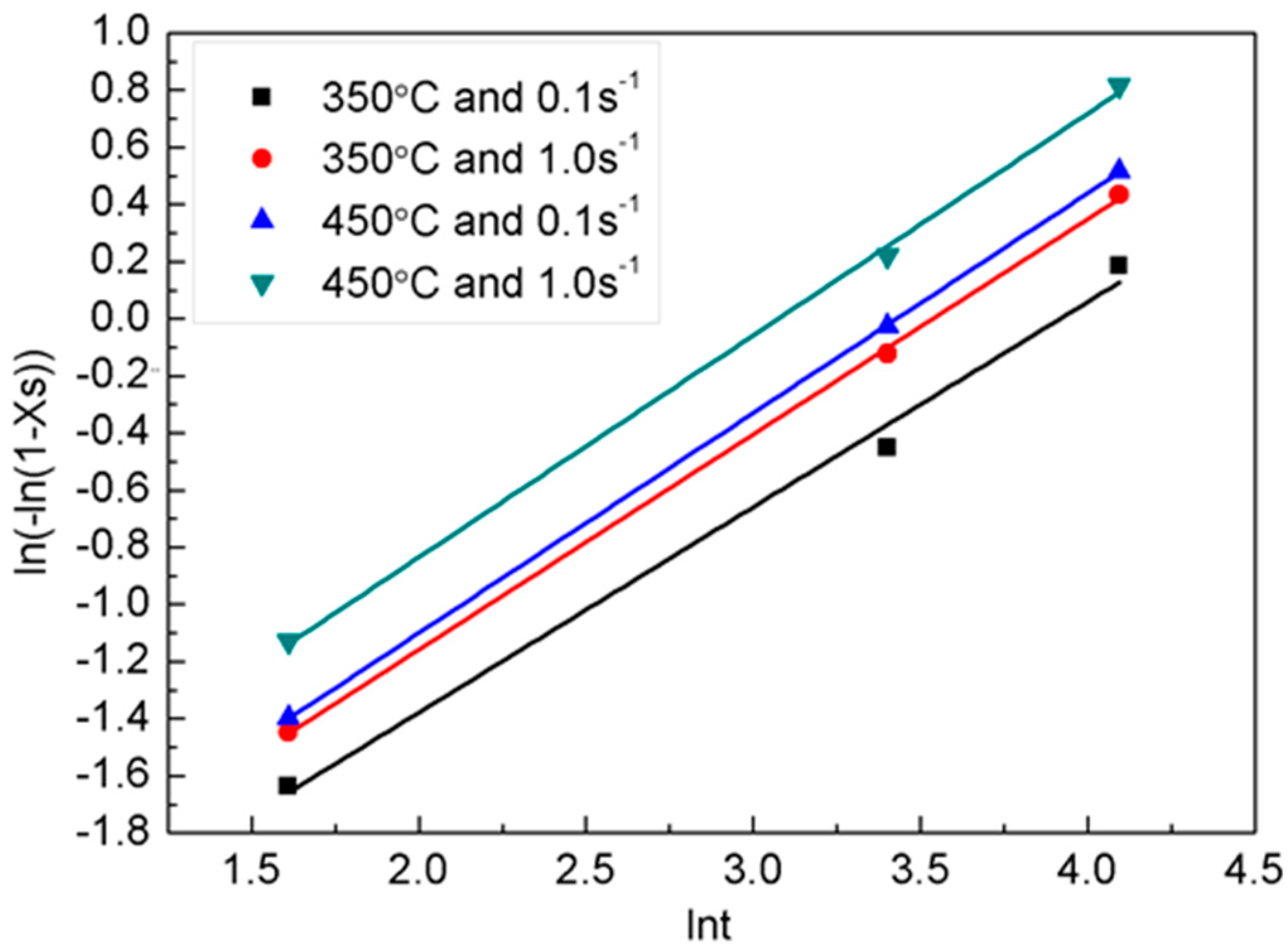

3.2. SRX Kinetic Model of 5754 Aluminium Alloy

3.3. The Simulation of Static Recrystallization of 5754 Aluminium Alloy

3.3.1. Deformation-Stored Energy

3.3.2. Nucleation Model for Static Recrystallization

3.3.3. Grain Growth Model

3.4. The Construction of CA Model

4. Simulation Results of the CA Model

4.1. The Initial Microstructure

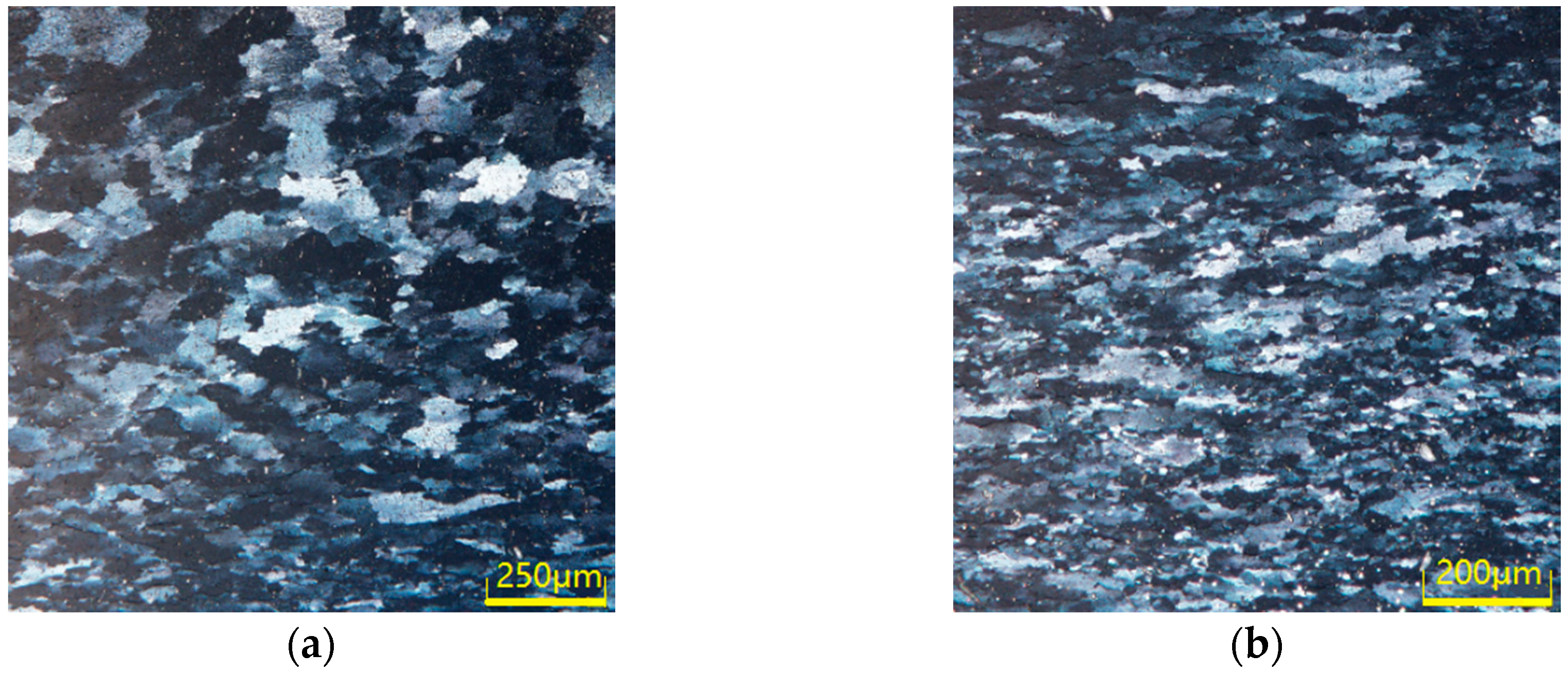

4.2. Deformation Temperature Effect

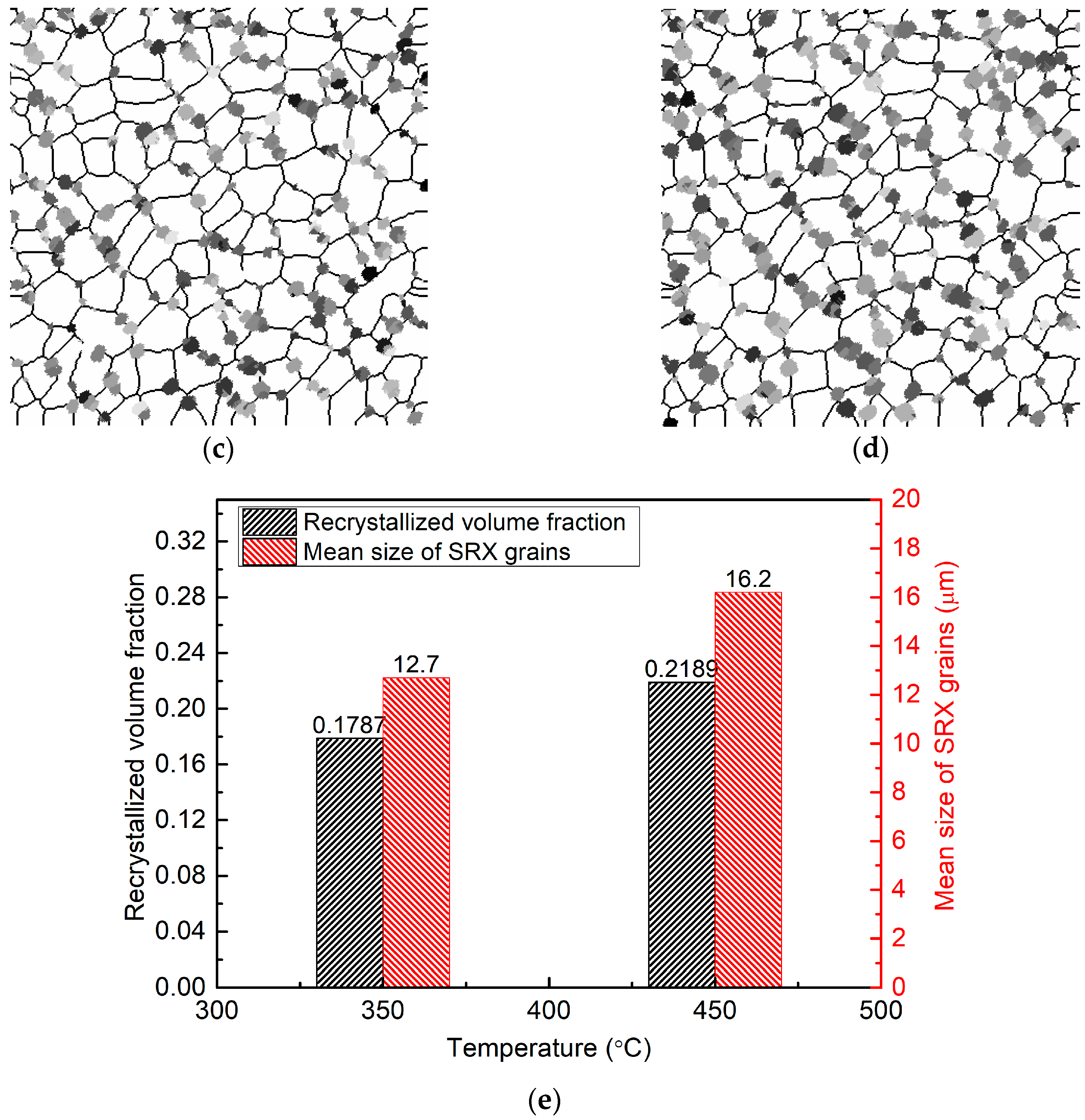

4.3. Strain Rate Effect

4.4. Delay Time Effect

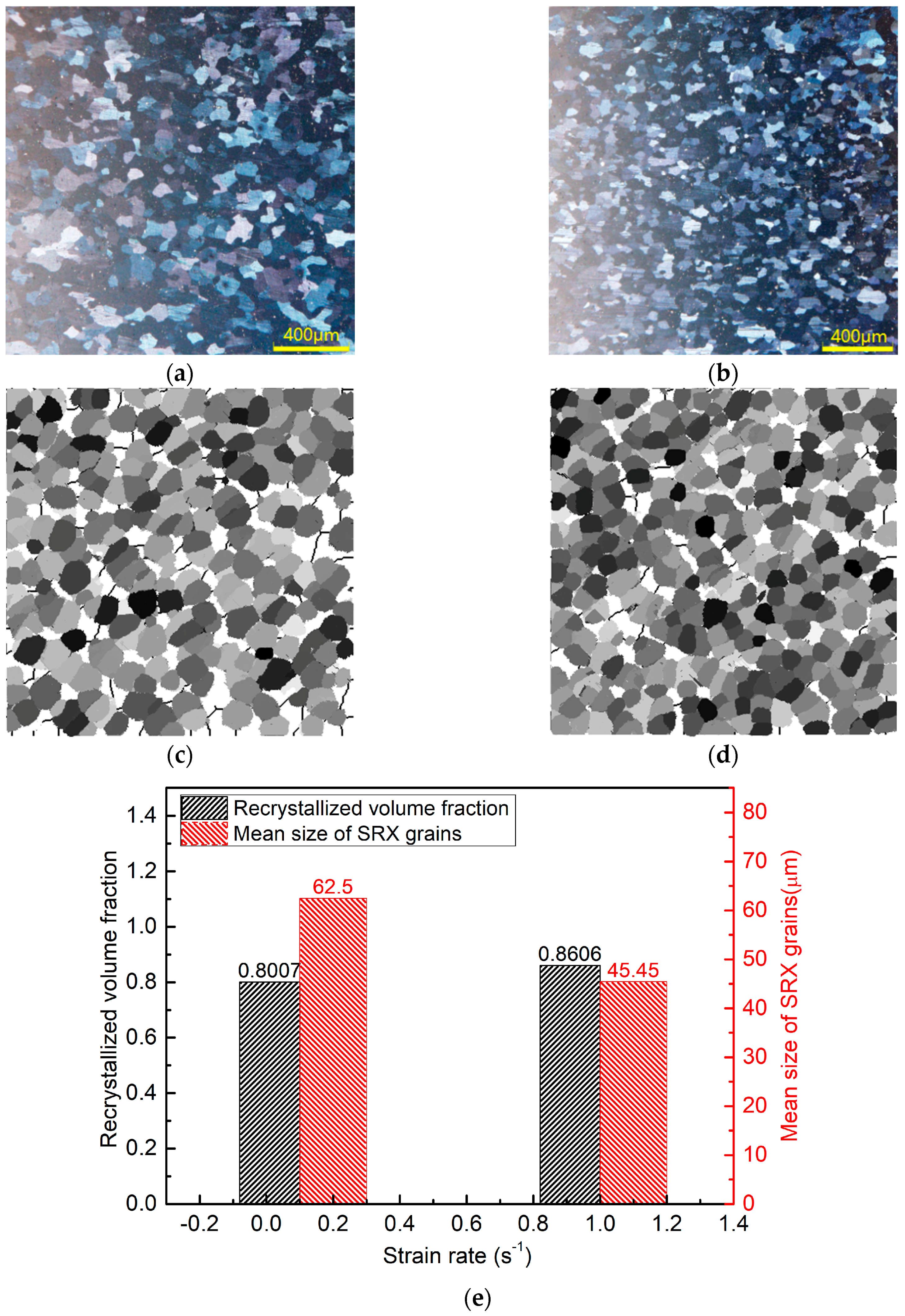

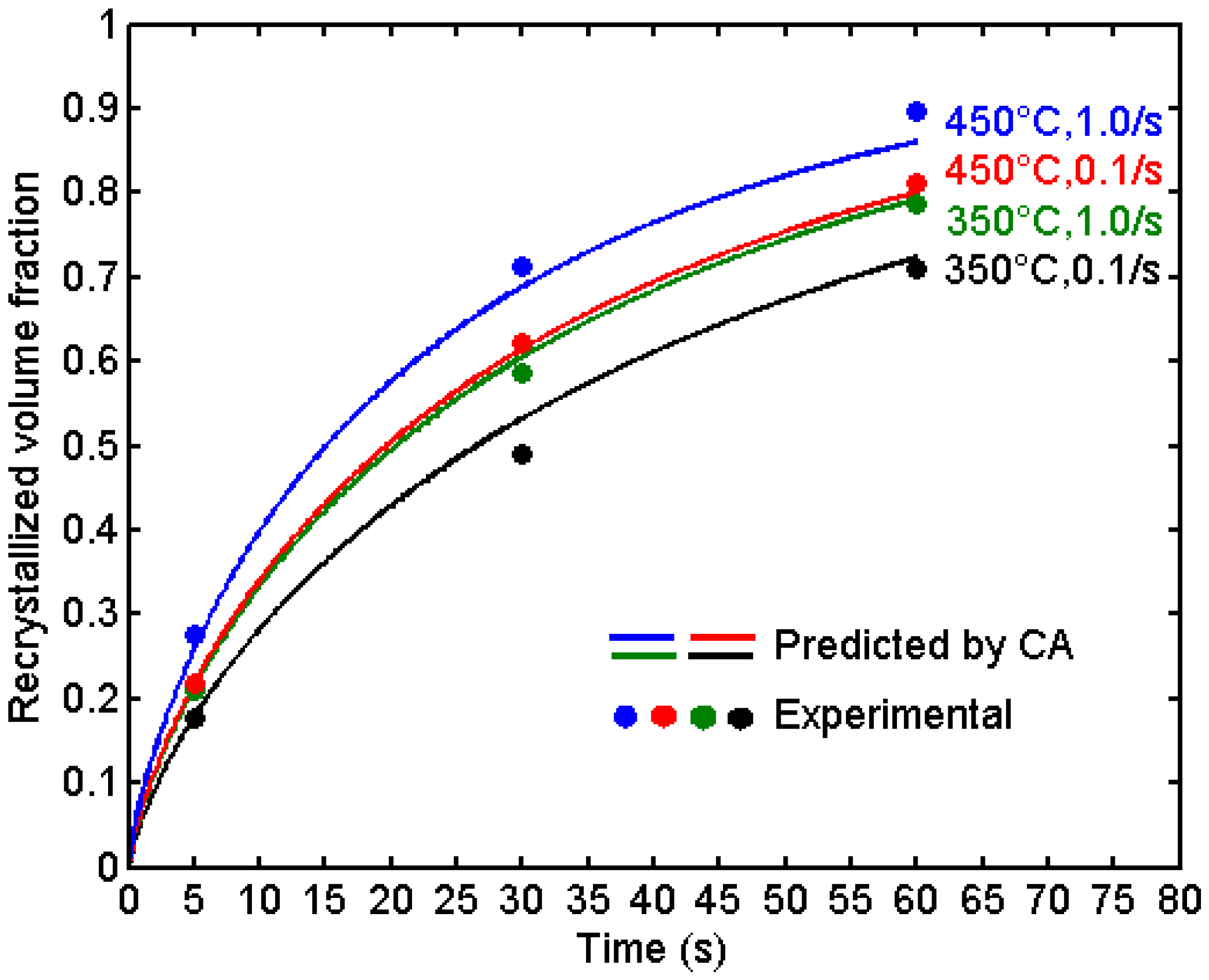

4.5. Validation of the CA Model

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huang, C.Q.; Deng, J.; Wang, S.X.; Liu, L.L. An Investigation on the Softening Mechanism of 5754 Aluminum Alloy during Multistage Hot Deformation. Metals 2017, 7, 107. [Google Scholar] [CrossRef]

- Sang, D.; Li, Y. The Hot Deformation Activation Energy of 7050 Aluminum Alloy under Three Different Deformation Modes. Metals 2016, 6, 49. [Google Scholar] [CrossRef]

- Huang, C.-Q.; Liu, L.-L. Application of the Constitutive Model in Finite Element Simulation: Predicting the Flow Behavior for 5754 Aluminum Alloy during Hot Working. Metals 2017, 7, 331. [Google Scholar]

- Brand, A.J.; Kalz, S.; Kopp, R. Microstructural simulation in hot rolling of aluminium alloys. Comput. Mater. Sci. 1996, 7, 242–246. [Google Scholar] [CrossRef]

- Yanagida, A.; Yanagimoto, J. Formularization of softening fractions and related kinetics for static recrystallization using inverse analysis of double compression test. Mater. Sci. Eng. A 2008, 487, 510–517. [Google Scholar] [CrossRef]

- Llanos, L.; Pereda, B.; Lopez, B.; Rodriguez-Ibabe, J.M. Hot deformation and static softening behavior of vanadium microalloyed high manganese austenitic steels. Mater. Sci. Eng. A 2016, 651, 358–369. [Google Scholar] [CrossRef]

- Jiang, F.; Zhang, H.; Li, L.; Chen, J. The kinetics of dynamic and static softening during multistage hot deformation of 7150 aluminum alloy. Mater. Sci. Eng. A 2012, 552, 269–275. [Google Scholar] [CrossRef]

- Pouraliakbar, H.; Pakbaz, M.; Firooz, S.; Jandaghi, M.R.; Khalaj, G. Study on the dynamic and static softening phenomena in Al-6Mg alloy during two-stage deformation through interrupted hot compression test. Measurement 2016, 77, 50–53. [Google Scholar] [CrossRef]

- Mukhopadhyay, P.; Loeck, M.; Gottstein, G. A cellular operator model for the simulation of static recrystallization. Acta Mater. 2007, 55, 551–564. [Google Scholar] [CrossRef]

- Beygelzimer, Y.E.; Spuskanyuk, A.V. The thick yield surface: Idea and approach for investigating its structure. Philos. Mag. A 1999, 79, 2437–2459. [Google Scholar] [CrossRef]

- Raabe, D. Cellular automata in materials science with particular reference to recrystallization simulation. Annu. Rev. Mater. Res. 2002, 32, 53–76. [Google Scholar] [CrossRef]

- Lin, Y.C.; Liu, Y.X.; Chen, M.S.; Huang, M.H.; Ma, X.; Long, Z.L. Study of static recrystallization behavior in hot deformed Ni-based superalloy using cellular automaton model. Mater. Des. 2016, 99, 107–114. [Google Scholar] [CrossRef]

- Zheng, C.; Xiao, N.; Li, D.; Li, Y. Microstructure prediction of the austenite recrystallization during multi-pass steel strip hot rolling: A cellular automaton modeling. Comput. Mater. Sci. 2009, 44, 507–514. [Google Scholar] [CrossRef]

- Kugler, G.; Turk, R. Study of the influence of initial microstructure topology on the kinetics of static recrystallization using a cellular automata model. Comput. Mater. Sci. 2006, 37, 284–291. [Google Scholar] [CrossRef]

- Salehi, M.S.; Serajzadeh, S. Simulation of static recrystallization in non-isothermal annealing using a coupled cellular automata and finite element model. Comput. Mater. Sci. 2012, 53, 145–152. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, S.; Hu, L.; Zhao, Y.; Sun, D. Investigation on primary static recrystallization in NiTiFe shape memory alloy subjected to cold canning compression by coupling crystal plasticity finite element method with cellular automaton. Model. Simul. Mater. Sci. Eng. 2017, 25. [Google Scholar] [CrossRef]

- Sitko, M.; Pietrzyk, M.; Madej, L. Time and length scale issues in numerical modelling of dynamic recrystallization based on the multi space cellular automata method. J. Comput. Sci. 2016, 16, 98–113. [Google Scholar] [CrossRef]

- Chen, M.S.; Yuan, W.Q.; Li, H.B.; Zou, Z.H. Modeling and simulation of dynamic recrystallization behaviors of magnesium alloy AZ31B using cellular automaton method. Comput. Mater. Sci. 2017, 136, 163–172. [Google Scholar] [CrossRef]

- Wang, L.; Fang, G.; Qian, L. Modeling of Dynamic Recrystallization of Magnesium Alloy using Cellular Automata Considering Initial Topology of Grains. Mater. Sci. Eng. A 2017, 711, 268–283. [Google Scholar] [CrossRef]

- Azarbarmas, M.; Aghaie-Khafri, M. A New Cellular Automaton Method Coupled with a Rate-dependent (CARD) Model for Predicting Dynamic Recrystallization Behavior. Metall. Mater. Trans. A 2018, 49, 1916–1930. [Google Scholar] [CrossRef]

- Li, X.; Li, X.; Zhou, H.; Zhou, X.; Li, F.; Liu, Q. Simulation of dynamic recrystallization in AZ80 magnesium alloy using cellular automaton. Comput. Mater. Sci. 2017, 140, 95–104. [Google Scholar] [CrossRef]

- Chen, M.S.; Yuan, W.Q.; Lin, Y.C.; Li, H.B.; Zou, Z.H. Modeling and simulation of dynamic recrystallization behavior for 42CrMo steel by an extended cellular automaton method. Vacuum 2017, 146, 142–151. [Google Scholar] [CrossRef]

- Zheng, B.; Ertorer, O.; Li, Y.; Zhou, Y.; Mathaudhu, S.N.; Tsao, C.Y.A.; Lavernia, E.J. High strength, nano-structured Mg-Al-Zn alloy. Mater. Sci. Eng. A 2011, 528, 2180–2191. [Google Scholar] [CrossRef]

- Filatov, Y.A.; Yelagin, V.I.; Zakharov, V.V. New Al-Mg-Sc alloys. Mater. Sci. Eng. A 2000, 280, 97–101. [Google Scholar] [CrossRef]

- Matsuda, K.; Ikeno, S.; Terayama, K.; Matsui, H.; Sato, T.; Uetani, Y. Comparison of precipitates between excess Si-type and balanced-type Al-Mg-Si alloys during continuous heating. Metall. Mater. Trans. A 2005, 36, 2007–2012. [Google Scholar] [CrossRef]

- Lohmar, J.; Bambach, M.; Hirt, G. Comparison of Semi-empirical and Dislocation Density based Material Equations for Fast Modeling of Multistage Hot Working of Steel. Procedia Eng. 2014, 81, 268–273. [Google Scholar] [CrossRef]

- Jiang, F.; Zhang, H.; Su, J.; Sun, Y. Constitutive characteristics and microstructure evolution of 7150 aluminum alloy during isothermal and non-isothermal multistage hot compression. Mater. Sci. Eng. A 2015, 636, 459–469. [Google Scholar] [CrossRef]

- Zhemchuzhnikova, D.А.; Lebyodkin, M.A.; Lebedkina, T.A.; Kaibyshev, R.O. Unusual behavior of the Portevin-Le Chatelier effect in an AlMg alloy containing precipitates. Mater. Sci. Eng. A 2015, 639, 37–41. [Google Scholar] [CrossRef]

- Ma, P.C.; Zhang, D.; Zhuang, L.Z.; Zhang, J.S. Effect of alloying elements and processing parameters on the Portevin-Le Chatelier effect of Al-Mg alloys. Int. J. Miner. Metall. Mater. 2015, 22, 175–183. [Google Scholar] [CrossRef]

- Fernández, A.I.; López, B.; RodríGuez-Ibabe, J.M. Relationship between the austenite recrystallized fraction and the softening measured from the interrupted torsion test technique. Scr. Mater. 1999, 40, 543–549. [Google Scholar] [CrossRef]

- Sheppard, T.; Duan, X. Modelling of static recrystallisation by combining FEM with empirical models. J. Mater. Process. Technol. 2002, 130, 250–253. [Google Scholar] [CrossRef]

- Toloui, M.; Serajzadeh, S. Modelling recrystallization kinetics during hot rolling of AA5083. J. Mater. Process. Technol. 2007, 184, 345–353. [Google Scholar] [CrossRef]

- Ivasishin, O.M.; Shevchenko, S.V.; Vasiliev, N.L.; Semiatin, S.L. A 3-D Monte-Carlo (Potts) model for recrystallization and grain growth in polycrystalline materials. Mater. Sci. Eng. A 2006, 433, 216–232. [Google Scholar] [CrossRef]

- Hallberg, H.K. Approaches to Modeling of Recrystallization. Metals 2011, 1, 16–48. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.W.; Im, Y.T. Numerical modeling of dynamic recrystallization during nonisothermal hot compression by cellular automata and finite element analysis. Int. J. Mech. Sci. 2010, 52, 1277–1289. [Google Scholar]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: New York, NY, USA, 2004; pp. 219–224. [Google Scholar]

- Kremeyer, K. Cellular Automata Investigations of Binary Solidification. J. Comput. Phys. 1998, 142, 243–262. [Google Scholar] [CrossRef]

- Ulam, S. Sets, Numbers, and Universes: Selected Works; MIT Press: Cambridge, MA, USA, 1974. [Google Scholar]

| Chemical Elements | Mg | Mn | Si | Fe | Cr | Zn | Ti | Cu | Al |

|---|---|---|---|---|---|---|---|---|---|

| Content (wt. %) | 3.1 | 0.50 | 0.40 | 0.40 | 0.30 | 0.20 | 0.15 | 0.10 | Balance |

| Parameter | ||||||

|---|---|---|---|---|---|---|

| Value | 2.6 × 10−10 | 26 | 8 × 10−14 | 1.38 × 10−23 | 0.33 | 0.5 |

| Parameter | |||

|---|---|---|---|

| Value | 1.56966 × 106 | 73,220.3 | 108,000 |

| Temperature/°C | Strain Rate/s−1 | CA Model/ | Experiment/ |

|---|---|---|---|

| 450 °C | 0.1 | 62.50 | 64.17 |

| 1.0 | 45.45 | 47.91 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, C.; Jia, X.; Zhang, Z. Modeling and Simulation of the Static Recrystallization of 5754 Aluminium Alloy by Cellular Automaton. Metals 2018, 8, 585. https://doi.org/10.3390/met8080585

Huang C, Jia X, Zhang Z. Modeling and Simulation of the Static Recrystallization of 5754 Aluminium Alloy by Cellular Automaton. Metals. 2018; 8(8):585. https://doi.org/10.3390/met8080585

Chicago/Turabian StyleHuang, Changqing, Xiaodong Jia, and Zhiwu Zhang. 2018. "Modeling and Simulation of the Static Recrystallization of 5754 Aluminium Alloy by Cellular Automaton" Metals 8, no. 8: 585. https://doi.org/10.3390/met8080585

APA StyleHuang, C., Jia, X., & Zhang, Z. (2018). Modeling and Simulation of the Static Recrystallization of 5754 Aluminium Alloy by Cellular Automaton. Metals, 8(8), 585. https://doi.org/10.3390/met8080585