Research on Influential Mechanism of HAZ Impact Toughness for Shipbuilding Steel with Mg Addition

Abstract

:1. Introduction

2. Materials and Methods

- —welding current, A,

- —welding voltage, V,

- —welding speed, cm/s.

3. Results

3.1. Impact Testing

3.2. Impact Fracture

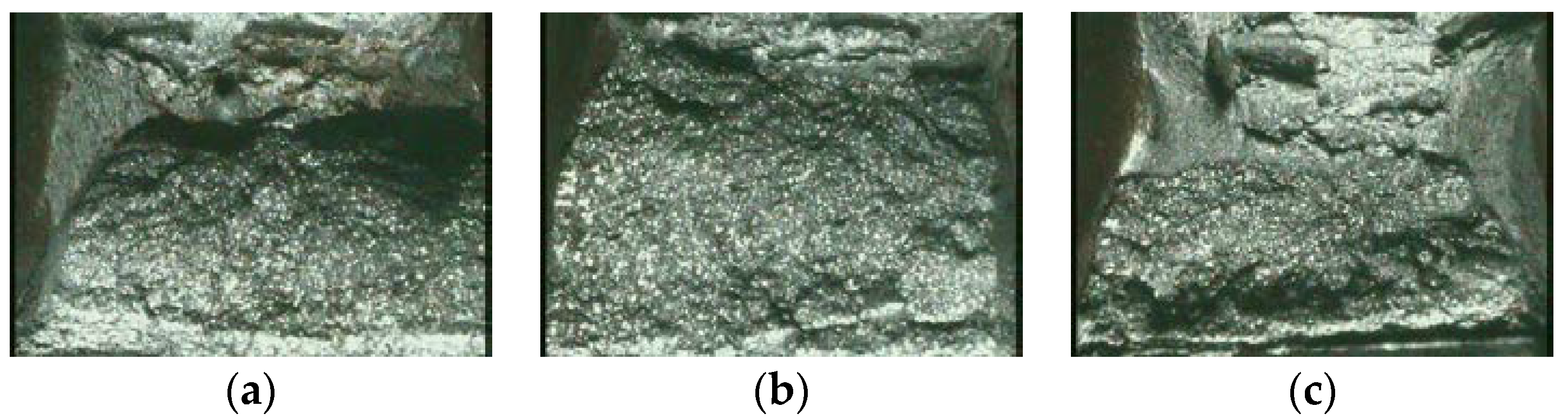

3.2.1. Macroscopic Feature

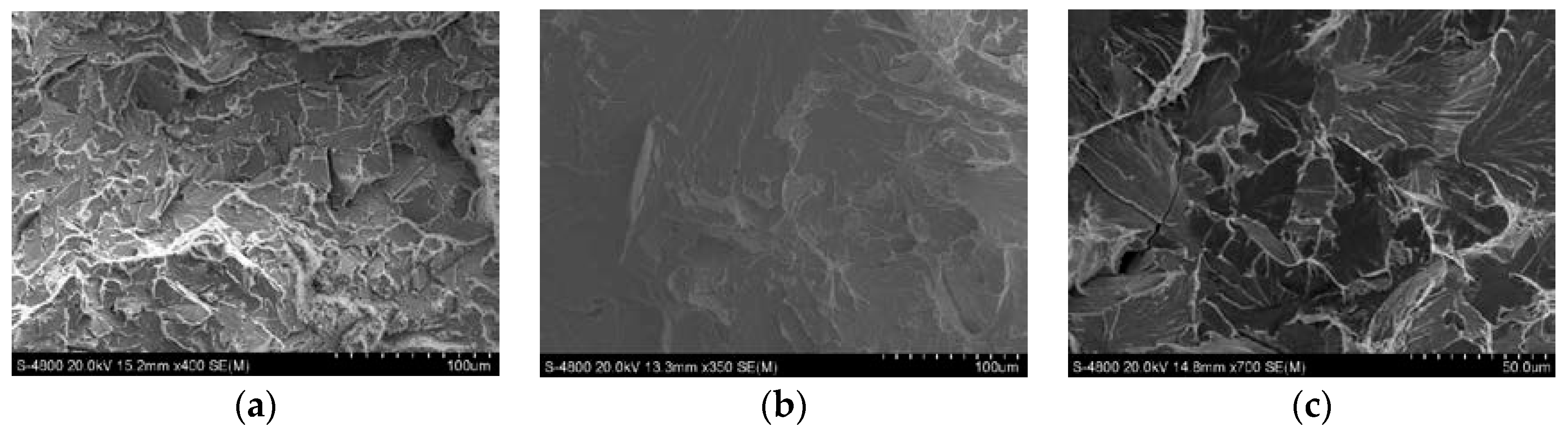

3.2.2. Microscopic Feature

4. Discussion

4.1. Influence of Welding Heat Input

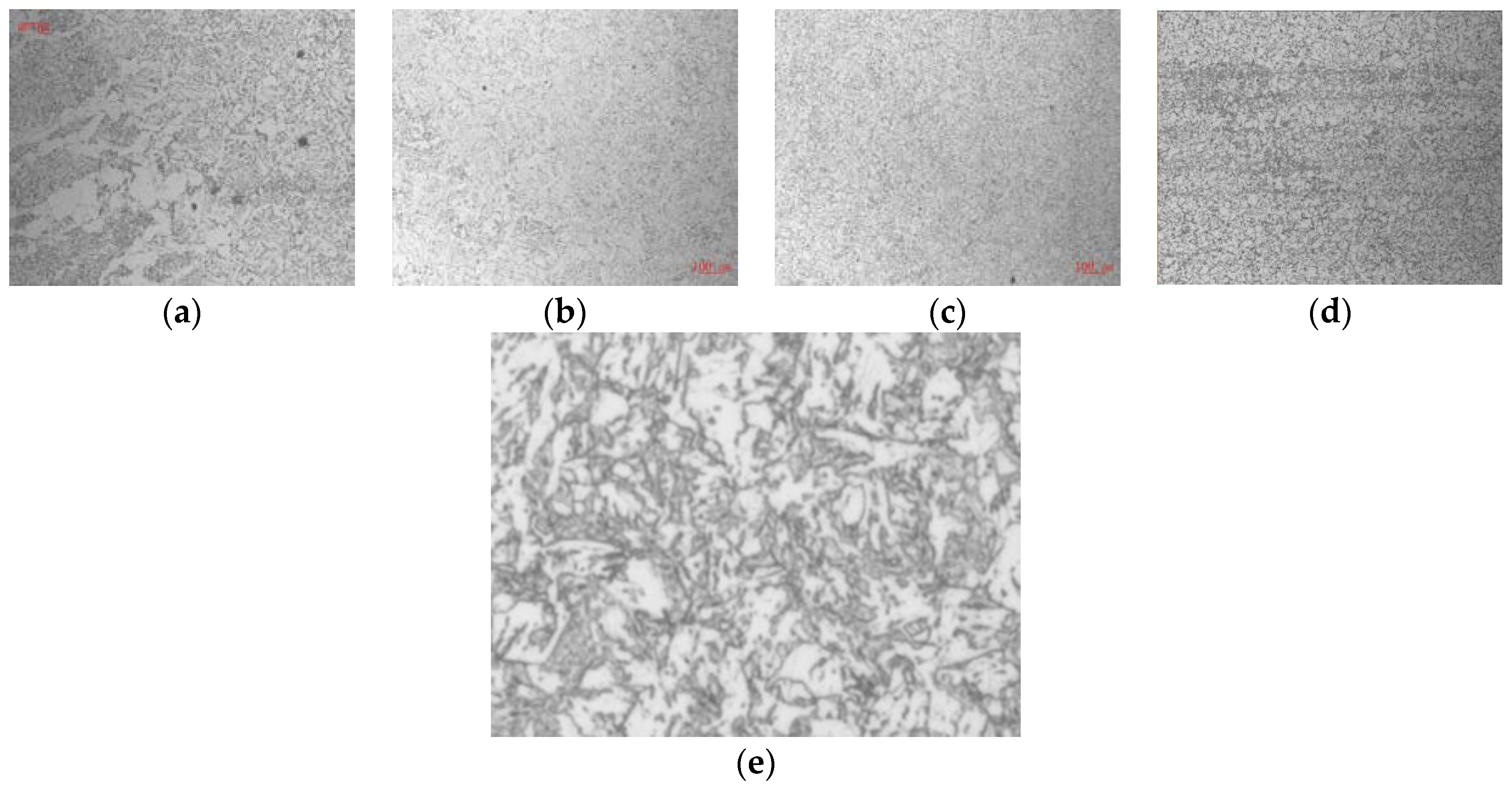

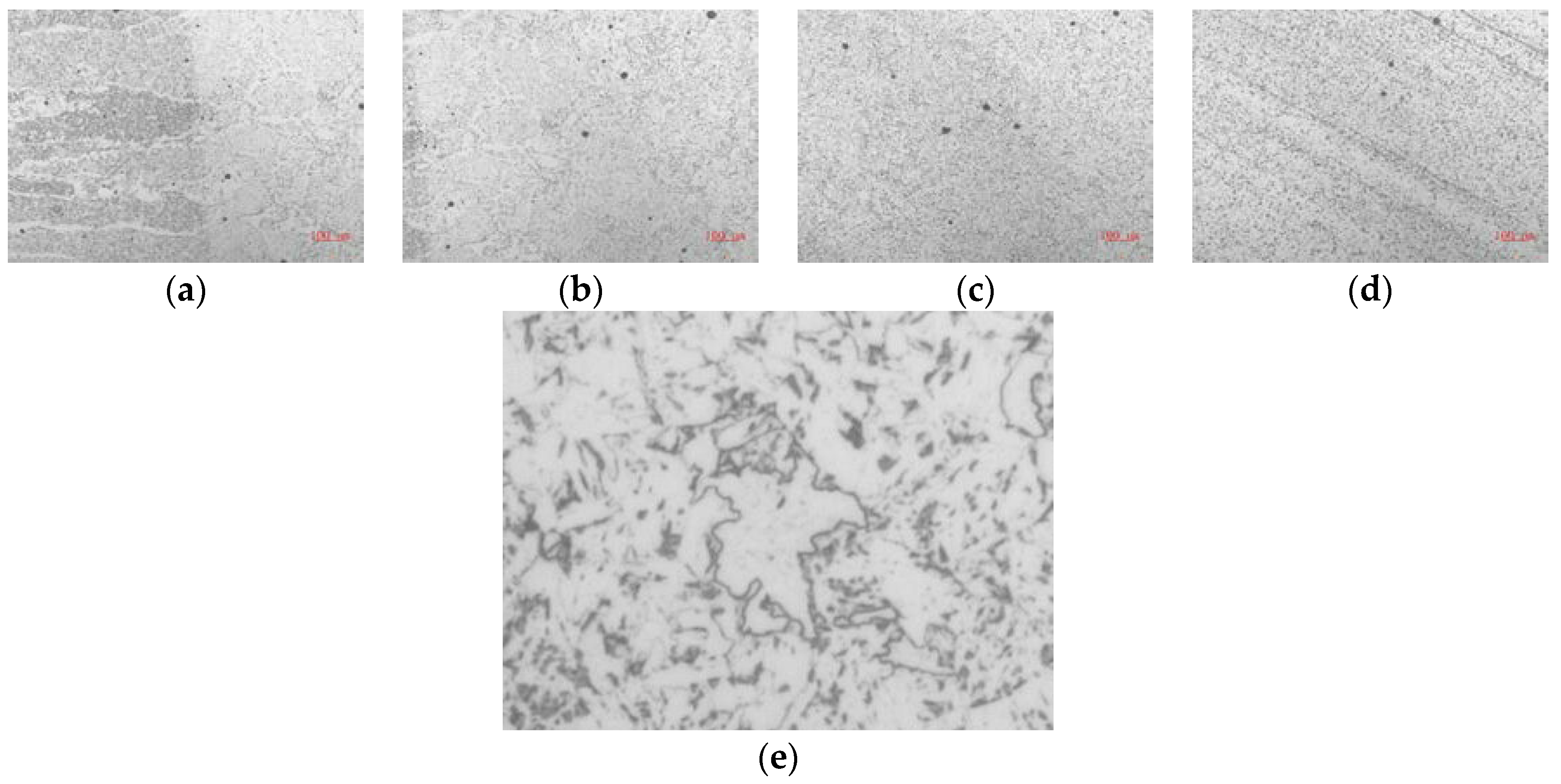

4.2. Analysis of Metallographic Structures

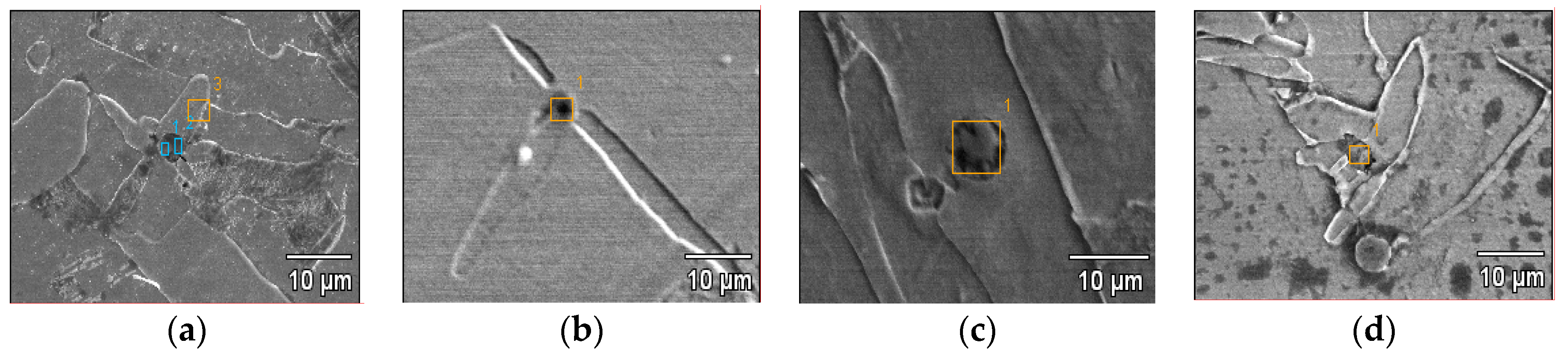

4.3. Analysis of Inclusions

5. Conclusions

- (1)

- The HAZ of three kinds of thickness plates induced much IAF; with Mg addition, the inclusion dimension had been reduced effectively, and the IAF induced ability of the inclusions had also been improved. If the original metallographic microstructure of steel was coarse, the pinning effect of the inclusions would be reduced significantly, and the microstructure of HAZ would be coarsened and the impact toughness of HAZ would be decreased, so there is a certain matching relationship between the metallographic microstructure and the inclusion dimension.

- (2)

- Mg is not the primary cause of the IAF inducing, but Mg can effectively reduce the size of inclusions, and thus increase the inclusion ability of IAF inducing.

- (3)

- The difference of HAZ impact toughness with different welding heat input and different impact temperature is significant; considering the influence of welding heat input and metallographic microstructure on the impact toughness of HAZ, the welding heat load had a far greater effect than the metallographic microstructure on the ductile–brittle transition temperature.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Takamura, J.; Mizoguchi, S. Role of oxides in steels perform ances metallurgy of oxides in steels. In Proceedings of the ISIJ Sixth International Iron and Steel Congress, Nagoya, Japan, 21–26 October 1990; pp. 591–597. [Google Scholar]

- Mizoguchi, S.; Takamura, J. Control of oxides as inoculants metallurgy of oxides in steels. In Proceedings of the ISIJ Sixth International Iron and Steel Congress, Nagoya, Japan, 21–26 October 1990; pp. 598–604. [Google Scholar]

- Hitoshi, H. Effect of Ti and alloying elements on microstructure and toughness of simulated HAZ of 780 MPa class steels. Tetsu-to-Hagane 2004, 90, 271–277. [Google Scholar]

- Shu, W.; Wang, X.; Li, S.; He, X. Nucleation and growth of intragranular acicular ferrite and its effect on grain refinement of the heat-affected-zone. Acta Metall. Sin. 2011, 47, 435–441. [Google Scholar]

- Hong, S.G.; Kang, K.J.; Park, C.G. Strain-induced precipitation of NbC in Nb and Nb-Ti microalloyed HSLA steels. Scr. Mater. 2002, 46, 163–168. [Google Scholar] [CrossRef]

- Vega, M.I.; Medina, S.F.; Quispe, A.; Gomez, M.; Gomez, P.P. Influence of TiN particle precipitation state on static recrystallisation in structural steels. ISIJ Int. 2005, 45, 1878–1886. [Google Scholar] [CrossRef]

- Kanazawa, S.; Nakashima, A.; Okamoto, K.; Kanaya, K. Improved toughness of weld fussion zone by fine TiN particles and development of a steel for large heat input welding. Tetsu-to-Hagane 1975, 61, 2589–2603. [Google Scholar] [CrossRef]

- Kasamatsu, Y. Effect of titanium and nitrogen on toughness of heat-affected zone of steel plate with tensile strength of 50 kg/mm2 in high heat input welding. Tetsu-to-Hagane 1979, 65, 1232–1241. [Google Scholar] [CrossRef]

- Song, M.; Song, B.; Hu, C.; Xin, W.B.; Song, G.Y. Effect of Ti--Mg complex deoxidation on the microstructure and impact properties of HAZ in steel. Chin. J. Eng. 2015, 37, 883–888. [Google Scholar]

- Zhu, K.; Yang, Z. Effect of Mg addition on the ferrite grain boundaries misorientation in HAZ of low carbon steel. J. Mater. Sci. Technol. 2011, 27, 252–256. [Google Scholar] [CrossRef]

- Sun, Z.; Huang, J.; Zhang, H.; Zhao, X.; Li, Q. Microstructures and mechanical properties of joints of mi-croalloyed EH40 ship steel with high heat-input welding. Trans. China Weld. Inst. 2008, 29, 42–43. [Google Scholar]

- Sohn, S.S.; Hong, S.; Lee, J.; Suh, B.-C.; Kim, S.-K.; Lee, B.-J.; Kim, N.J.; Lee, S. Effects of Mn and Al contents on cryogenic-temperature tensile and Charpy impact properties in four austenitic high-Mn steels. Acta Mater. 2015, 100, 39–52. [Google Scholar] [CrossRef]

- Hwang, B.; Lee, C.G. Influence of thermomechanical processing and heat treatments on tensile and Charpy impact properties of B and Cu bearing high-strength low-alloy steels. Mater. Sci. Eng. A 2010, 527, 4341–4346. [Google Scholar] [CrossRef]

- You, Y.; Wang, X.; Shang, C. Influence of austenitizing temperature on the microstructure and impact toughness of a high strength low alloy HLSA100 steel. Acta Metall. Sin. 2012, 48, 1290–1298. [Google Scholar] [CrossRef]

- Sung, H.K.; Shin, S.Y.; Cha, W.; Oh, K.; Lee, S.; Kim, N.J. Effects of acicular ferrite on charpy impact properties in heat affected zones of oxide-containing API X80 linepipe steels. Mater. Sci. Eng. A 2011, 528, 3350–3357. [Google Scholar] [CrossRef]

- Tao, P.; Yu, H.; Fan, Y.; Fu, Y. Effects of cooling method after intercritical heat treatment on microstructural characteristics and mechanical properties of as-cast high-strength low-alloy steel. Mater. Des. 2014, 54, 914–923. [Google Scholar] [CrossRef]

- Li, L.; Cao, F.; Wang, Y.; Zhang, X.; Lu, C. Analysis on low temperature impact toughness and fracture morphologies of X90 pipeline steel. Heat Treat. Met. 2015, 40, 190–193. [Google Scholar]

- Luo, K.Y.; Wang, C.Y.; Sun, G.F.; Cui, C.Y.; Sheng, J.; Lu, J.Z. Investigation and microstructural analyses of massive LSP impacts with coverage area on crack initiation location and tensile properties of AM50 magnesium alloy. Mater. Sci. Eng. A 2016, 650, 110–118. [Google Scholar] [CrossRef]

- Chatterjee, A.; Chakrabarti, D.; Moitra, A.; Mitra, R.; Bhaduri, A.K. Effect of deformation temperature on the ductile–brittle transition behavior of a modified 9Cr-1Mo steel. Mater. Sci. Eng. A 2015, 630, 58–70. [Google Scholar] [CrossRef]

- Bai, X.; Wu, S.; Liaw, P.K. Influence of thermo-mechanical embrittlement processing on microstructure and mechanical behavior of a pressure vessel steel. Mater. Des. 2016, 89, 759–769. [Google Scholar] [CrossRef]

- Nazari, A.; Milani, A.A.; Khalaj, G. Modeling ductile to brittle transition temperature of functionally graded steels by ANFIS. Appl. Math. Model. 2012, 36, 3903–3915. [Google Scholar] [CrossRef]

- Chen, X.M.; Song, S.H.; Weng, L.Q.; Liu, S.J.; Wang, K. Relation of ductile-to-brittle transition temperature to phosphorus grain boundary segregation for a Ti-stabilized interstitial free steel. Mater. Sci. Eng. A 2011, 528, 8299–8304. [Google Scholar] [CrossRef]

- Kumar, S.; Nath, S.K. Effect of heat input on impact toughness in transition temperatureregion of weld CGHAZ of a HY 85 steel. J. Mater. Proc. Technol. 2016, 236, 216–224. [Google Scholar] [CrossRef]

- Goto, H.; Miyazawa, K.; Yamaguchi, K.; Ogibayashi, S.; Tanaka, K. Effect of cooling rate on oxide precipitation during solidification of low carbon steels. ISIJ Int. 1994, 34, 414–419. [Google Scholar] [CrossRef]

- Goto, H.; Miyazawa, K.; Tanaka, K. Effect of oxygen Content on size distribution of oxides in steel. ISIJ Int. 1995, 35, 286–291. [Google Scholar] [CrossRef]

- Shen, D.; Yuan, Z. Factors influencing the DBTT of 2.25CrMo steel. J. Wuhan Univ. Sci. Technol. 2011, 34, 410–413. [Google Scholar]

- Yang, L.; Liu, J.; Bao, Y. Researches on X70 cleanliness in refine and continuous casting process. J. Univ. Sci. Technol. Beijing 2007, 29, 97–100. [Google Scholar]

- Li, C.; Bao, Y.; Liu, J. Investigation of reasonable cleanliness for high-grade linepipe steel scale production. J. Univ. Sci. Technol. Beijing 2007, 29, 10–13. [Google Scholar]

| Composition | C | Si | Mn | S | P | Al | Ti | Mo | V | Nb | Mg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| content | 0.08 | 0.20 | 1.40 | 0.005 | 0.015 | 0.01 | 0.015 | 0.07 | 0.04 | 0.04 | 0.005 |

| Thickness (mm) | Input Line Energy (KJ/cm) | Welding Speed (m/h) | Welding Wire Diameter (mm) | Welding Wire Kinds | Fore Wire | Hind Wire | ||

|---|---|---|---|---|---|---|---|---|

| Current | Voltage | Current | Voltage | |||||

| (A) | (V) | (A) | (V) | |||||

| 16 | 50 | 19.6 | 4.0 | 10Mn2 | 780 | 35 | ||

| 25 | 100 | 24 | 5.0 + 5.0 | 10Mn2 + SJ501 | 1000 | 41 | 700 | 37 |

| 40 | 150 | 22.7 | 5.0 + 5.0 | 10Mn2 + SJ501 | 1200 | 44 | 1000 | 42 |

| Thickness/mm | Input Line Energy/kJ/cm | Impact Temperature/°C | Impact Absorbed Energy/J | Averaged Value/J | ||

|---|---|---|---|---|---|---|

| 16 | 50 | −20 | 197.3 | 166.7 | 172.0 | 178.7 |

| −40 | 89.6 | 49.0 | 74.3 | 71.0 | ||

| 25 | 100 | −20 | 42.5 | 91.4 | 38.6 | 57.5 |

| −40 | 51.8 | 30.2 | 17.4 | 33.1 | ||

| 40 | 150 | −20 | 198.9 | 189.5 | 197.6 | 195.3 |

| −40 | 32.9 | 35.7 | 27.5 | 32.0 | ||

| Thickness of Steel Plate | 0–5 μm | 5–10 μm | 10–15 μm | 15–20 μm |

|---|---|---|---|---|

| 16 mm | 83 | 14 | 16 | 14 |

| 25 mm | 100 | 20 | 8 | 2 |

| 40 mm | 67 | 26 | 6 | 10 |

| Total Scan Area S1 (mm2) | Number of Microscopic Inclusions | Number of Microscopic Inclusions per Unit Area (/mm2) | Total Area of Microscopic Inclusions S2 (mm2) | S2/S1 (%) | |

|---|---|---|---|---|---|

| Normal (without Mg) | 35.4 | 2042 | 57.7 | 0.023 | 0.065 |

| Experiment (with Mg) | 30.0 | 2211 | 73.7 | 0.017 | 0.057 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.-r.; Sun, L.-g.; Zhu, L.-g.; Liu, Y.-s.; Li, Y.-g. Research on Influential Mechanism of HAZ Impact Toughness for Shipbuilding Steel with Mg Addition. Metals 2018, 8, 584. https://doi.org/10.3390/met8080584

Li H-r, Sun L-g, Zhu L-g, Liu Y-s, Li Y-g. Research on Influential Mechanism of HAZ Impact Toughness for Shipbuilding Steel with Mg Addition. Metals. 2018; 8(8):584. https://doi.org/10.3390/met8080584

Chicago/Turabian StyleLi, Hui-rong, Li-gen Sun, Li-guang Zhu, Yun-song Liu, and Yun-gang Li. 2018. "Research on Influential Mechanism of HAZ Impact Toughness for Shipbuilding Steel with Mg Addition" Metals 8, no. 8: 584. https://doi.org/10.3390/met8080584