Processing of Magnesium-Based Metal Matrix Nanocomposites by Ultrasound-Assisted Particle Dispersion: A Review

Abstract

:1. Introduction

1.1. Ultrasound Equipment

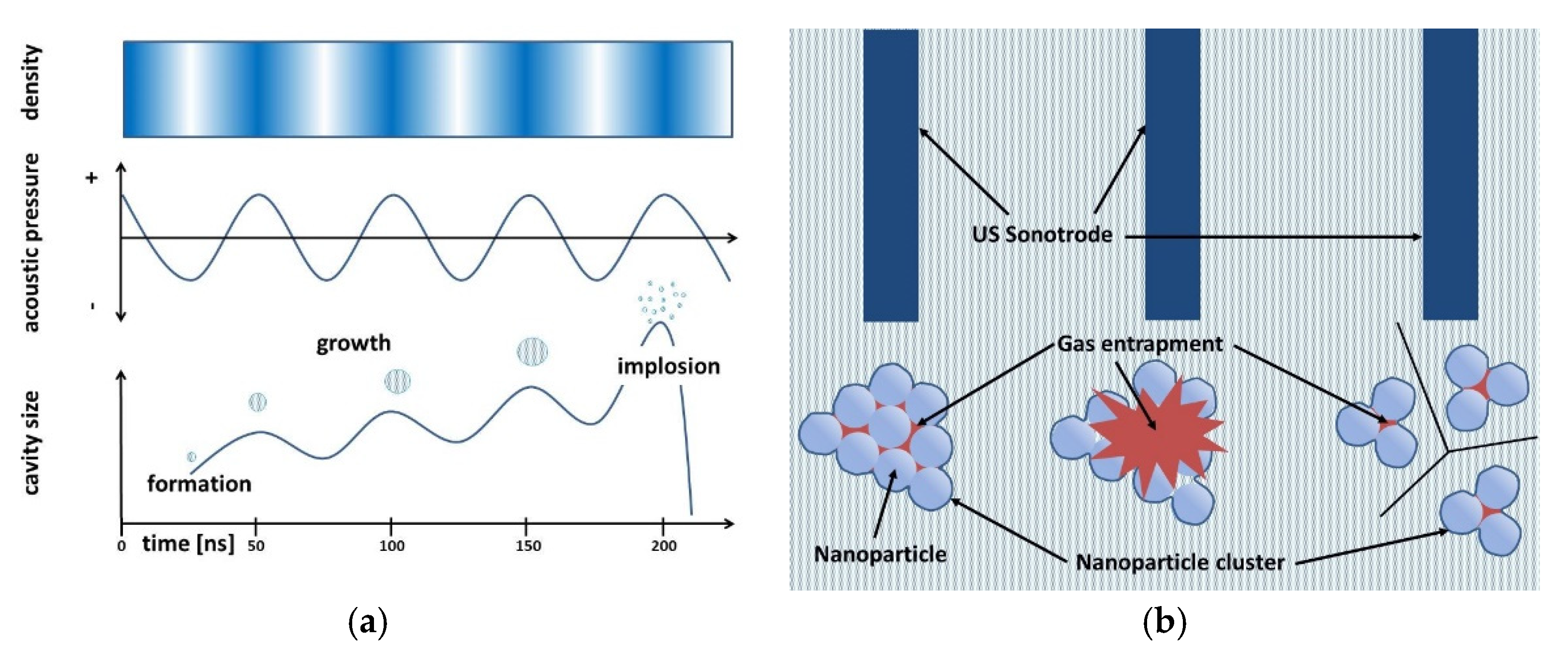

1.2. Cavitation

- Cavities that pulsate and keep the content of vapour gas constant.

- Cavities that grow during pulsation, due to tensile stresses and diffusion of the gas only into the cavity.

- Cavities that collapse under compressive stresses, producing plenty of small cavities and massive local pressure.

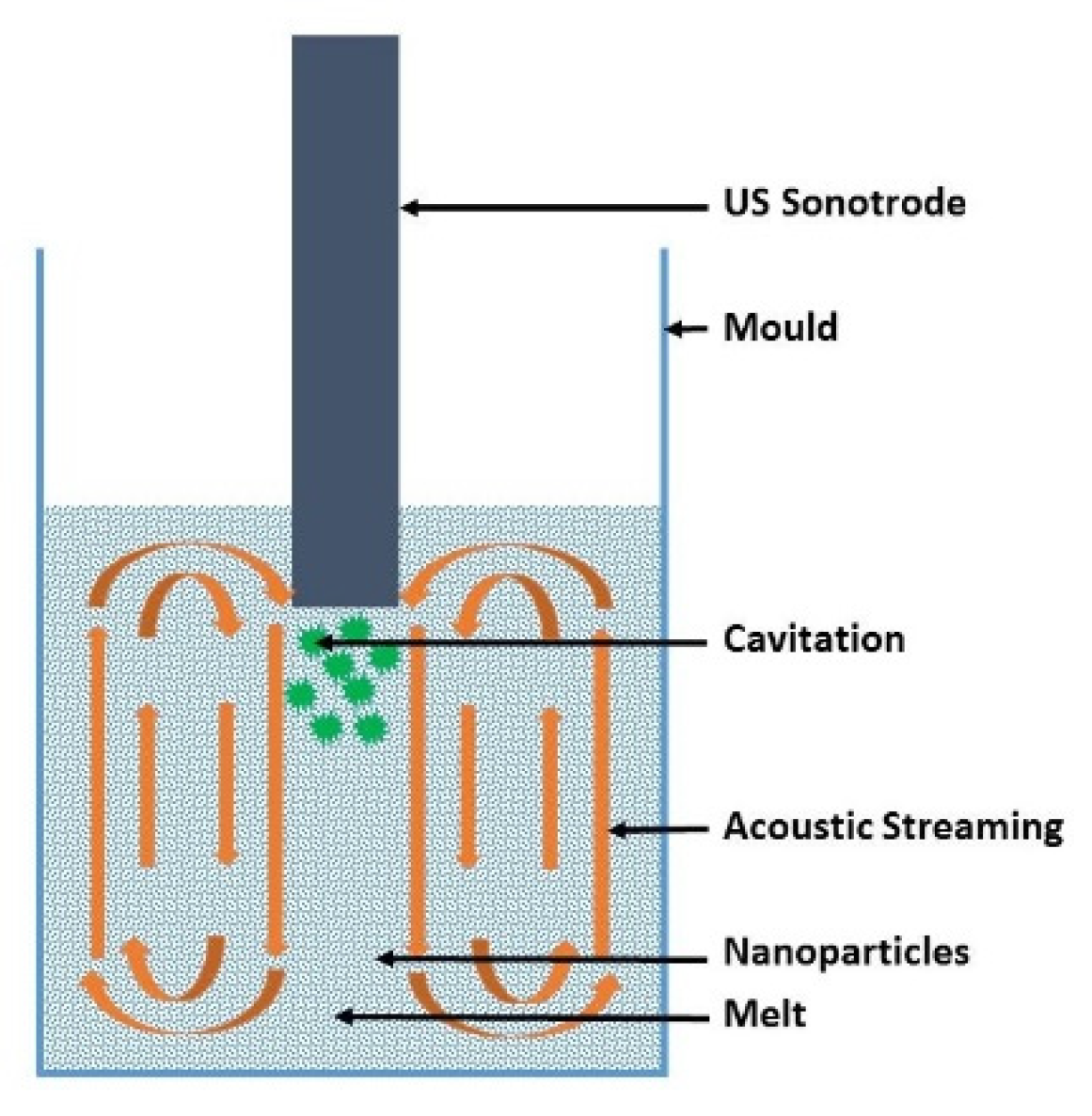

1.3. Acoustic Streaming

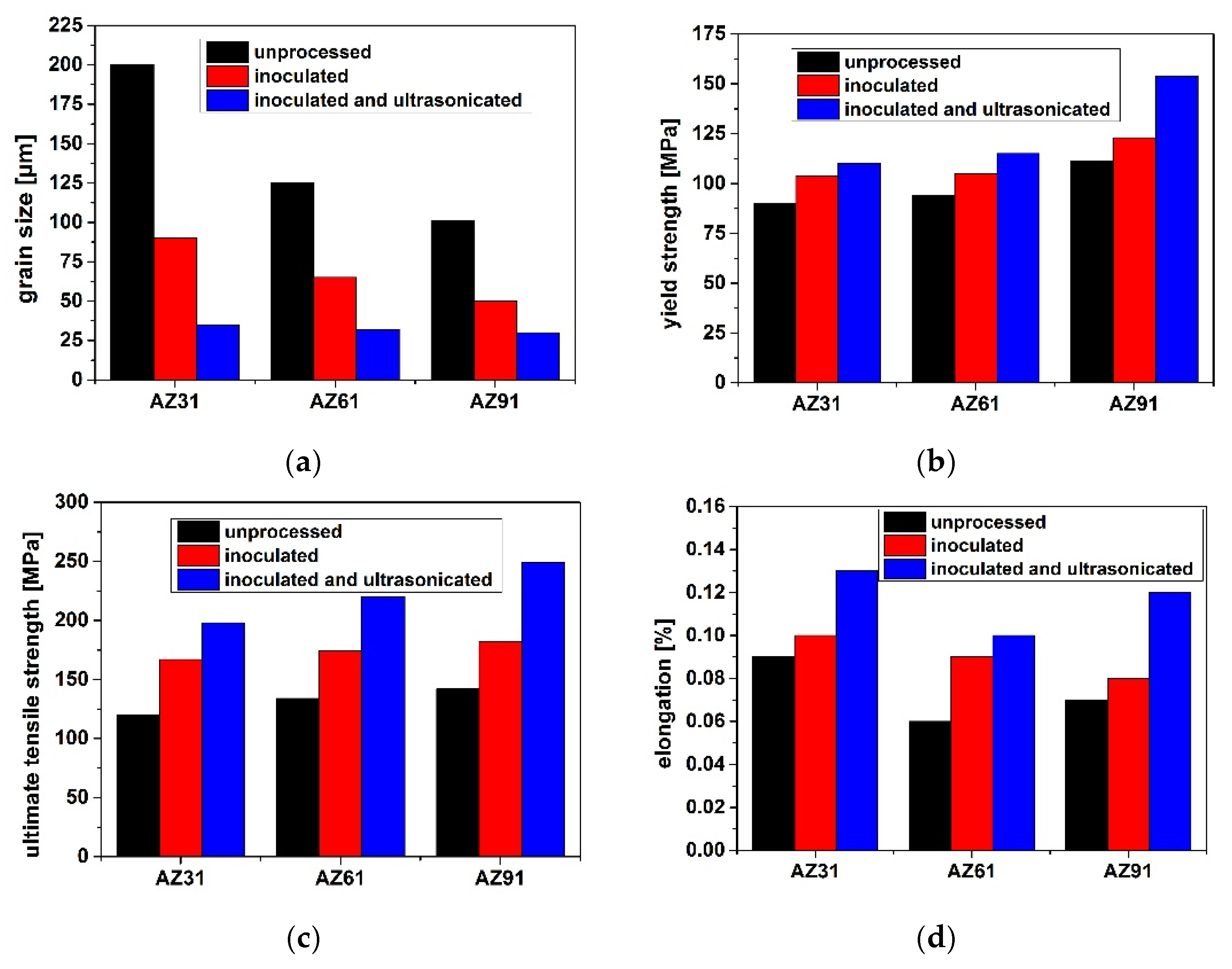

1.4. Effect of Ultrasound on Magnesium Alloys

2. Nanocomposites Processing

2.1. In Situ Processing

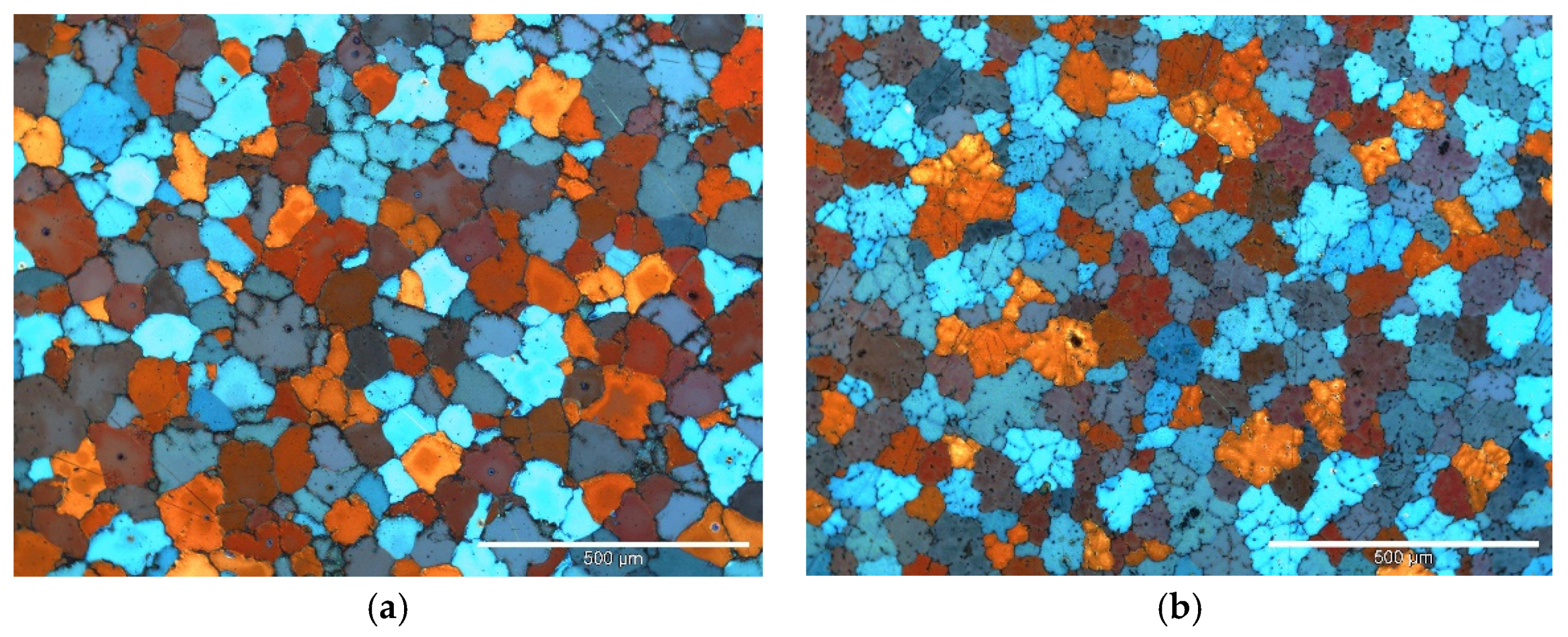

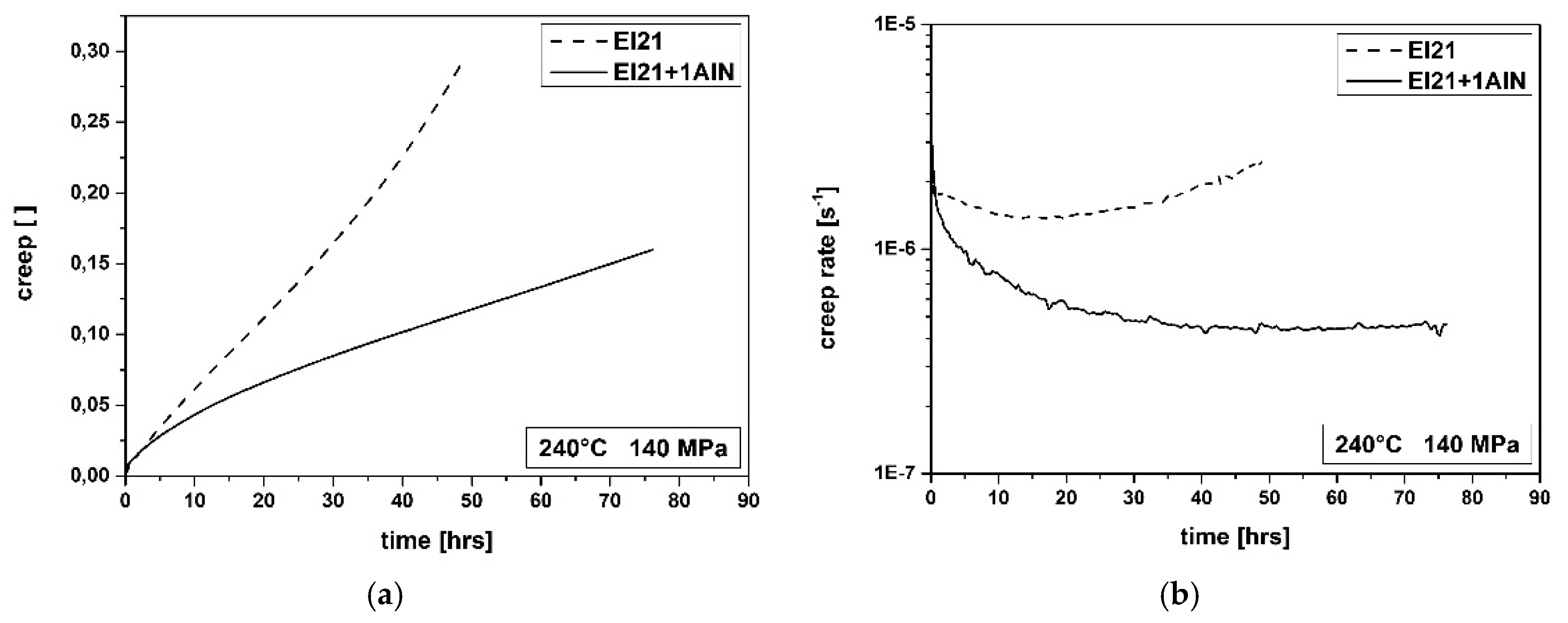

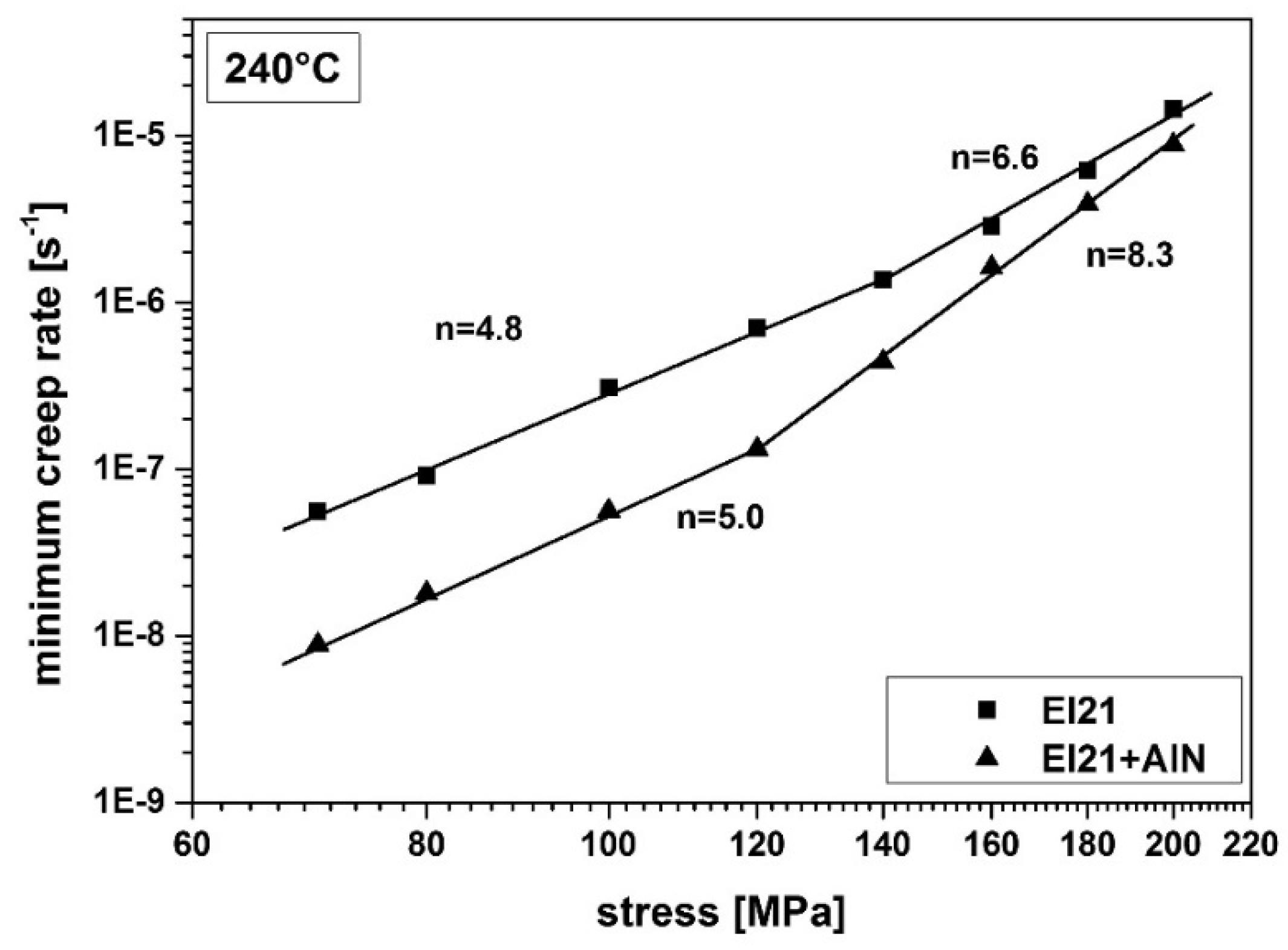

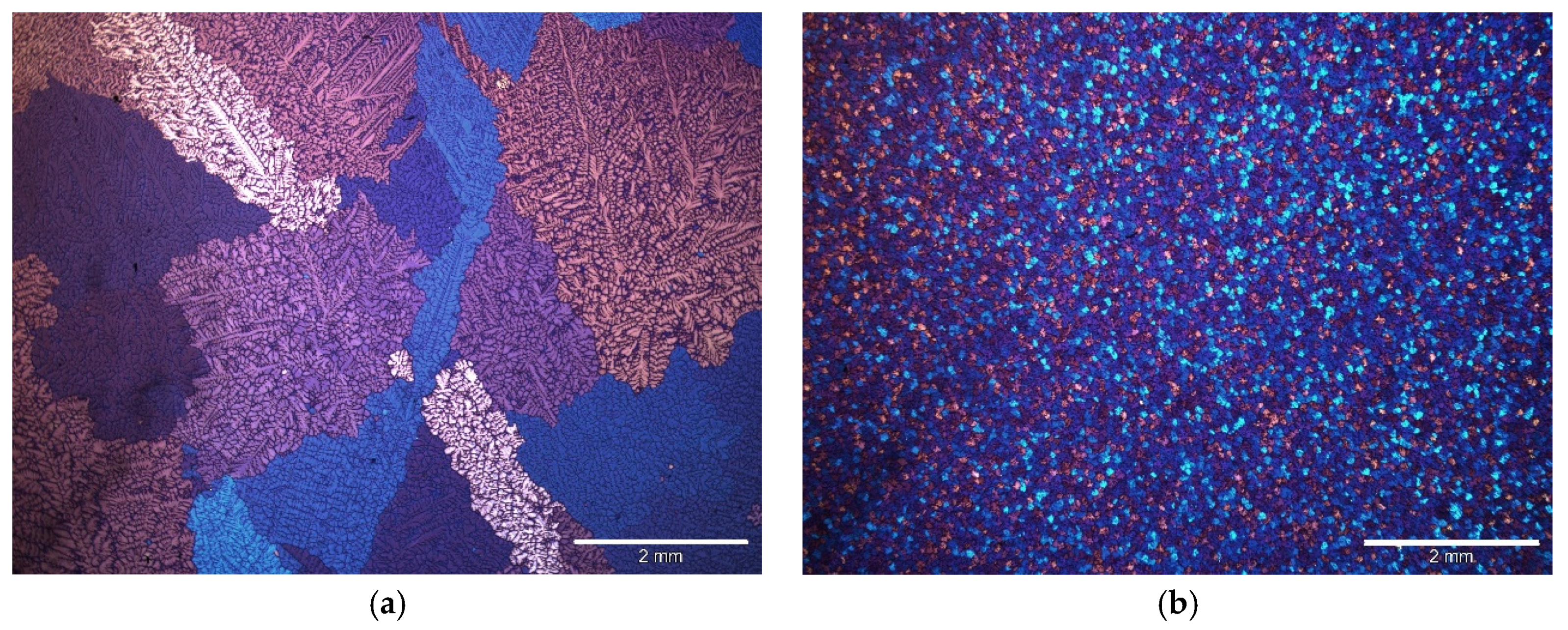

2.2. AlN Reinforcement

2.3. Al2O3 Reinforcement

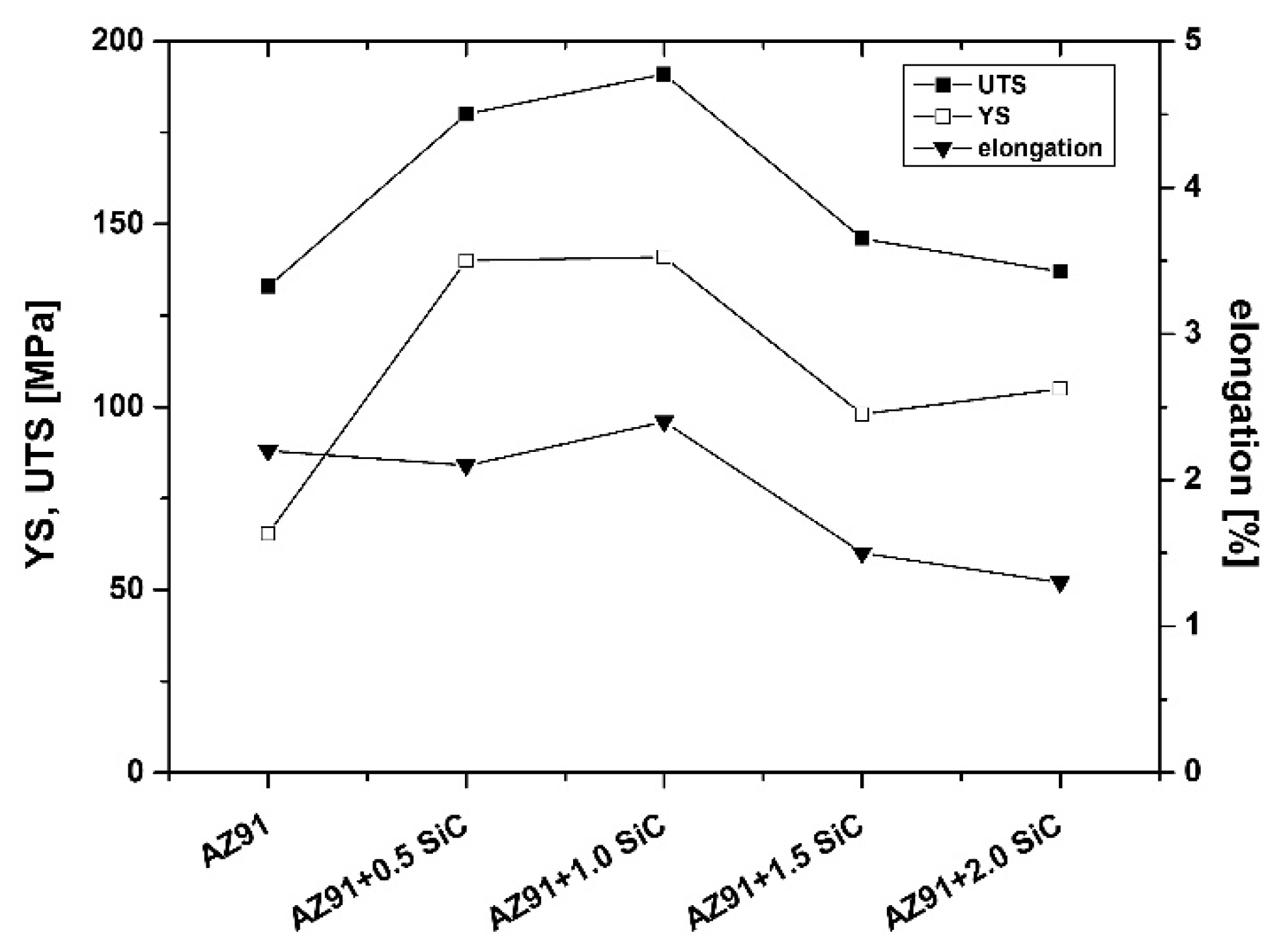

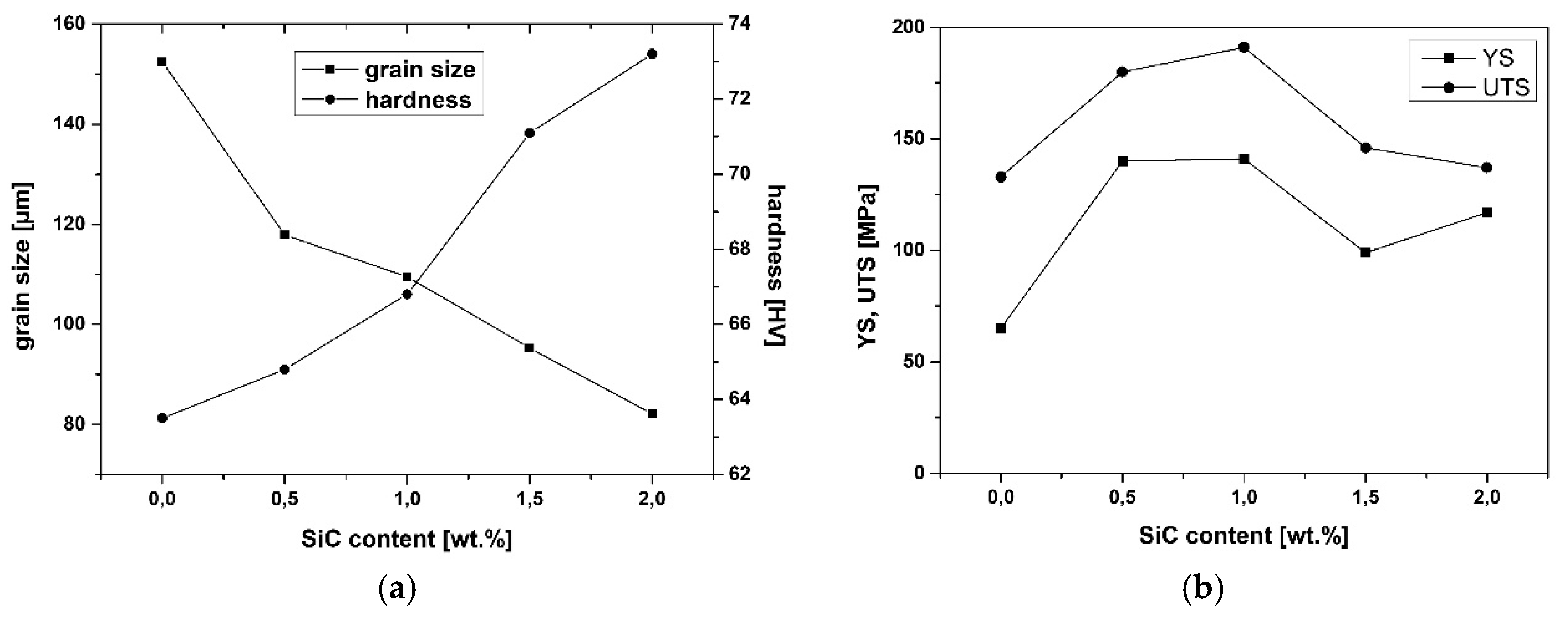

2.4. SiC Reinforcement

2.5. TiB2 Reinforcement

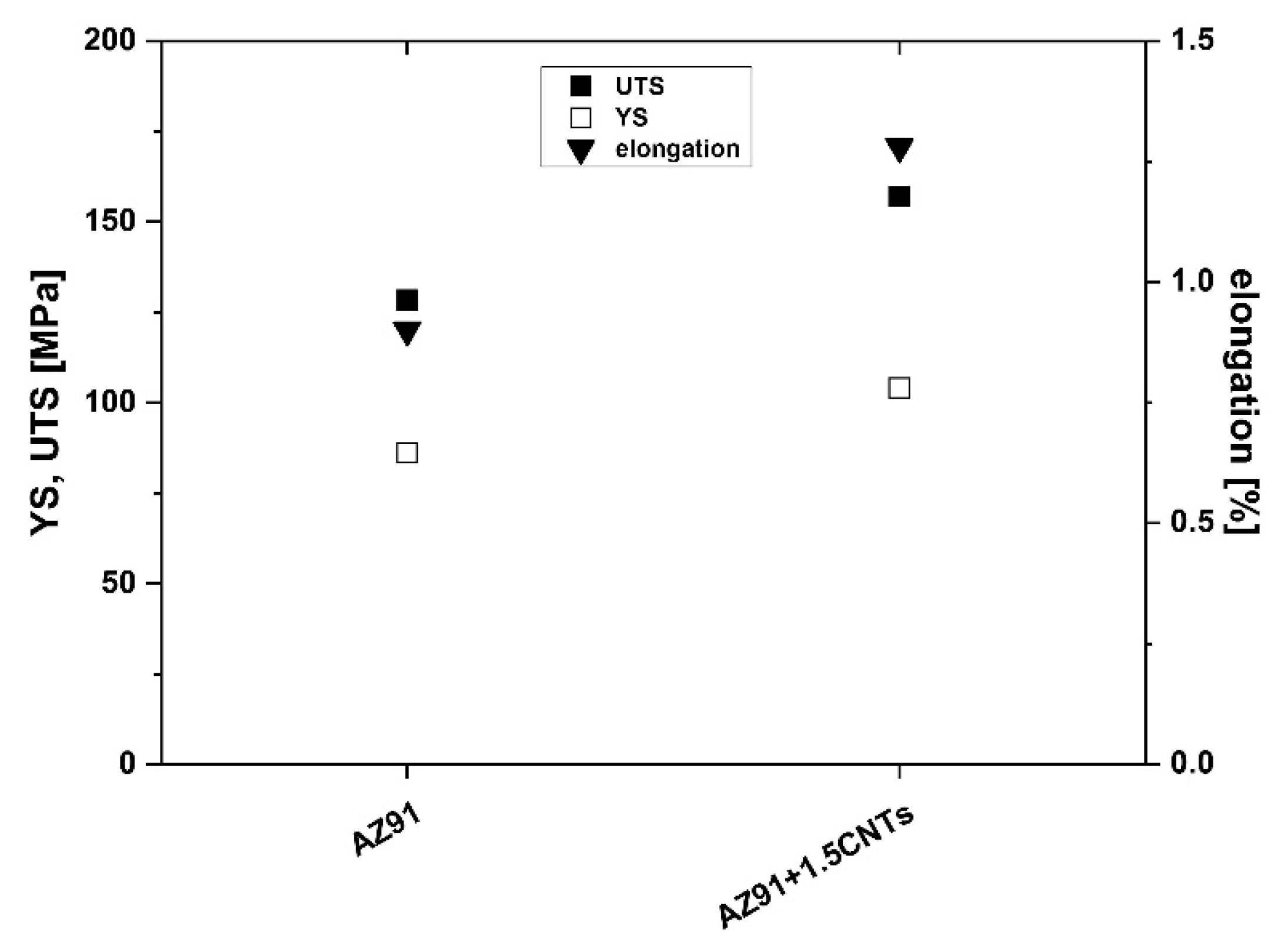

2.6. Graphene, Carbon Black, and CNT Reinforcement

3. Conclusions

Conflicts of Interest

References

- Zhu, S.M.; Gibson, M.A.; Easton, M.A.; Nie, J.F. The relationship between microstructure and creep resistance in die-cast magnesium-rare earth alloys. Scr. Mater. 2010, 63, 698–703. [Google Scholar] [CrossRef]

- Zhu, S.M.; Easton, M.A.; Gibson, M.A.; Dargusch, M.S.; Nie, J.F. Analysis of the creep behaviour of die-cast Mg–3Al–1Si alloy. Mater. Sci. Eng. 2013, A578, 377–382. [Google Scholar] [CrossRef]

- Kubásek, J.; Vojtěch, D.; Martínek, M. Structural characteristics and elevated temperature mechanical properties of AJ62 Mg alloy. Mater. Charact. 2013, 86, 270–282. [Google Scholar] [CrossRef]

- Dieringa, H.; Huang, Y.; Wittke, P.; Klein, M.; Walther, F.; Dikovits, M.; Poletti, C. Compression creep response of magnesium alloy DieMag422 containing barium compared with the commercial creep-resistant alloys AE42 and MRI230D. Mater. Sci. Eng. 2013, 585, 430–438. [Google Scholar] [CrossRef]

- Huang, Y.; Dieringa, H.; Kainer, K.U.; Hort, N. Understanding effects of microstructural inhomogeneity on creep response—New approaches to improve the creep resistance in magnesium alloys. J. Magnes. Alloys 2014, 2, 124–132. [Google Scholar] [CrossRef]

- Eskin, D.G.; Eskin, G.I. Ultrasonic Treatment of Light Alloy Melts, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Suslick, K.S.; Cline, R.E.; Hammerton, D.A. The sonochemical hot spot. J. Am. Chem. Soc. 1986, 108, 5641–5642. [Google Scholar] [CrossRef]

- Eskin, G.I. Cavitation mechanism of ultrasonic melt degassing. Ultrason. Sonochem. 1995, 2, S137–S141. [Google Scholar] [CrossRef]

- Eskin, G.I. Ultrasonic Treatment of Light Alloy Metallic Melts; Gordon and Breach Science Publishers: Amsterdam, The Netherlands, 1998. [Google Scholar]

- Suslick, K.S.; Matula, T.J. Ultrasonic physical mechanisms and chemical effects. In Wiley Encyclopedia of Electrical and Electronics Engineering; Webster, J., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1999. [Google Scholar]

- Zarembo, L.K. Part III: Acoustic streaming. In High-Intensity Ultrasonic Fields; Rozenberg, L.D., Ed.; Springer Science and Business Media: New York, NY, USA, 1971. [Google Scholar]

- Ishiwata, Y.; Komarov, S.; Takeda, Y. Investigation of acoustic streaming in aluminum melts exposed to high-intensity ultrasonic irradiation. In Proceedings of the 13th International Conference on Aluminum Alloys (ICAA13), Pittsburgh, PA, USA, 3–7 June 2012. [Google Scholar]

- Eskin, G.I. Crystallization of ingots of magnesium alloys with ultrasonic treatment of the melt. Metallurgist 2003, 47, 265–272. [Google Scholar] [CrossRef]

- Eskin, G.I. Principles of ultrasonic treatment: Application for light alloys melts. Adv. Perform. Mater. 1997, 4, 223–232. [Google Scholar] [CrossRef]

- Chen, Y.-J.; Hsu, W.-N.; Shih, J.-R. The effect of ultrasonic treatment on microstructural and mechanical properties of cast magnesium alloys. Mater. Trans. 2009, 50, 401–408. [Google Scholar] [CrossRef]

- Chen, G.; Zhou, T.; Yan, H.; Li, K. Effects of ultrasonic field on microstructure and properties of semi-solid AZ91D magnesium alloy. J. Wuhan Univ. Technol. 2010, 25, 555–560. [Google Scholar]

- Aghayani, M.K.; Niroumand, B. Effects of ultrasonic treatment on microstructure and tensile strength of AZ91 magnesium alloy. J. Alloys Comp. 2011, 509, 114–122. [Google Scholar] [CrossRef]

- Bhingole, P.P.; Patel, B.; Chaudhari, G.P. Ultrasonic processing and microstructural analysis of AZ91 magnesium alloy. Mater. Sci. Forum 2012, 702–703, 975–978. [Google Scholar] [CrossRef]

- Bhingole, P.; Chaudhari, G. Effect of ultrasonic treatment on the grain refinement and mechanical properties of AZ91 magnesium alloy. Mater. Sci. Forum 2012, 710, 463–468. [Google Scholar] [CrossRef]

- Bhingole, P.P.; Chaudhari, G.P.; Nath, S.K. Processing, microstructure and properties of ultrasonically processed in situ MgO–Al2O3–MgAl2O4 dispersed magnesium alloy composites. Composites 2014, A66, 209–217. [Google Scholar] [CrossRef]

- Muley, S.V.; Singh, S.P.; Sinha, P.; Bhingole, P.P.; Chaudhari, G.P. Microstructural evolution in ultrasonically processed in situ AZ91 matrix composites and their mechanical and wear behaviour. Mater. Des. 2014, 53, 475–481. [Google Scholar] [CrossRef]

- Cao, G.; Choi, H.; Oportus, J.; Konishi, H.; Li, X. Study on tensile properties and microstructure of cast AZ91D/AlN nanocomposites. Mater. Sci. Eng. 2008, A494, 127–131. [Google Scholar] [CrossRef]

- Katsarou, L.; Mounib, M.; Lefebvre, W.; Vorozhtsov, S.; Pavese, M.; Badini, C.; Molina-Aldareguia, J.M.; Cepeda Jimenez, C.; Pérez Prado, M.T.; Dieringa, H. Microstructure, mechanical properties and creep of magnesium alloy Elektron21 reinforced with AlN nanoparticles by ultrasound-assisted stirring. Mater. Sci. Eng. 2016, A659, 84–92. [Google Scholar] [CrossRef]

- Dieringa, H.; Katsarou, L.; Buzolin, R.; Szakács, G.; Horstmann, M.; Wolff, M.; Mendis, C.; Vorozhtsov, S.; StJohn, D. Ultrasound assisted casting of an AM60 based metal matrix nanocomposite, its properties, and recyclability. Metals 2017, 7, 388. [Google Scholar] [CrossRef]

- Mounib, M.; Pavese, M.; Badini, C.; Lefebvre, W.; Dieringa, H. Reactivity and microstructure of Al2O3-reinforced magnesium-matrix composites. Adv. Mater. Sci. Eng. 2014. [Google Scholar] [CrossRef]

- Kumar, H.; Chaudhari, G.P. Creep behavior of AS41 alloy matrix nano-composites. Mater. Sci. Eng. A 2014, 607, 435–444. [Google Scholar] [CrossRef]

- Shiying, L.; Feipeng, G.; Qiongyuan, Z.; Wenzhen, L. Mechanical properties and microstructures of nano-sized SiC particle reinforced AZ91D nanocomposites fabricated by high intensity ultrasonic assisted casting. Mater. Sci. Forum 2009, 618–619, 449–452. [Google Scholar]

- Cao, G.; Choi, H.; Konishi, H.; Kou, S.; Lakes, R.; Li, X. Mg–6Zn/1.5%SiC nanocomposites fabricated by ultrasonic cavitation-based solidification processing. J. Mater. Sci. 2008, 43, 5521–5526. [Google Scholar] [CrossRef]

- Cao, G.; Konishi, H.; Li, X. Mechanical properties and microstructure of SiC-reinforced Mg-(2,4)Al-1Si nanocomposites fabricated by ultrasonic cavitation based solidification processing. Mater. Sci. Eng. 2008, A486, 357–362. [Google Scholar] [CrossRef]

- Cao, G.; Konishi, H.; Li, X. Mechanical properties and microstructure of Mg/SiC nanocomposites fabricated by ultrasonic cavitation based nanomanufacturing. J. Manuf. Sci. Eng. 2008, 130, 031105. [Google Scholar] [CrossRef]

- Nie, K.B.; Wang, X.J.; Wu, K.; Hu, X.S.; Zheng, M.Y.; Xu, L. Microstructure and tensile properties of micro-SiC particles reinforced magnesium matrix composites produced by semisolid stirring assisted ultrasonic vibration. Mater. Sci. Eng. 2011, A528, 8709–8714. [Google Scholar] [CrossRef]

- Jia, X.Y.; Liu, S.Y.; Gao, F.P.; Zhang, Q.Y.; Li, W.Z. Magnesium matrix nanocomposites fabricated by ultrasonic assisted casting. Int. J. Cast Metals Res. 2009, 22, 196–199. [Google Scholar] [CrossRef]

- Wang, Z.-H.; Wang, X.-D.; Zhao, Y.-X.; Du, W.-B. SiC nanoparticles reinforced magnesium matrix composites fabricated by ultrasonic method. Trans. Nonferrous Metals Soc. China 2010, 20, s1029–s1032. [Google Scholar] [CrossRef]

- De Cicco, M.; Konishi, H.; Cao, G.; Choi, H.S.; Turng, L.-S.; Perepezko, J.H.; Kou, S.; Lakes, R.; Li, X. Strong, ductile magnesium-zinc nanocomposites. Metall. Mater. Trans. 2009, A40, 3038–3045. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Peng, J.-Y.; Xu, J.-Q.; Choi, H.; Li, X.-C. Achieving uniform distribution and dispersion of a high percentage of nanoparticles in metal matrix nanocomposites by solidification processing. Scr. Mater. 2013, 69, 634–637. [Google Scholar] [CrossRef]

- Song, S.; Zhou, X.; Li, L.; Ma, W. Numerical simulation and experimental validation of SiC nanoparticle distribution in magnesium melts during ultrasonic cavitation based processing of magnesium matrix composites. Ultrason. Sonochem. 2015, 24, 43–54. [Google Scholar] [CrossRef] [PubMed]

- Choi, H.; Sun, Y.; Slater, B.P.; Konishi, H.; Li, X. AZ91D/TiB2 Nanocomposites Fabricated by Solidification Nanoprocessing. Adv. Eng. Mater. 2012, 14, 291–295. [Google Scholar] [CrossRef]

- Bhingole, P.P.; Chaudhari, G.P. Synergy of nano carbon black inoculation and high intensity ultrasonic processing in cast magnesium alloys. Mater. Sci. Eng. A 2012, 556, 954–961. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Konishi, H.; Fehrenbacher, A.; Ma, C.; Xu, J.-Q.; Choi, H.; Xu, H.-F.; Pfefferkorn, F.E.; Li, X.-C. Novel nanoprocessing route for bulk graphene nanoplatelets reinforced metal matrix nanocomposites. Scr. Mater. 2012, 67, 29–32. [Google Scholar] [CrossRef]

- Liu, S.-Y.; Gao, F.-P.; Zhang, Q.-Y.; Zhu, X.; Li, W.-Z. Fabrication of carbon nanotubes reinforced AZ91D composites by ultrasonic processing. Trans. Nonferrous Met. Soc. China 2010, 20, 1222–1227. [Google Scholar] [CrossRef]

- Mussi, R.G.S.; Motegi, T.; Tanabe, F.; Kawamura, H.; Anzai, K.; Shiba, D.; Suganuma, M. Effect of ultrasonic vibration on the dispersion of carbon nano-fibre reinforcement through semi-solid az91d magnesium alloy. Solid State Phenom. 2006, 116–117, 392–396. [Google Scholar] [CrossRef]

- Nie, K.B.; Wang, X.J.; Xu, L.; Wu, K.; Hu, X.S.; Zheng, M.Y. Influence of extrusion temperature and process parameter on microstructures and tensile properties of a particulate reinforced magnesium matrix nanocomposite. Mater. Des. 2012, 36, 199–205. [Google Scholar] [CrossRef]

| Property | AZ91 | AZ91 + 3Si | AZ91 + 5Si |

|---|---|---|---|

| Grain size [µm] | 73 | 51 | 40 |

| Hardness [VHN] | 65.2 ± 3 | 97.4 ± 3 | 108.2 ± 4 |

| Property | Temperature [°C] | Elektron21 | Elektron21 + 1 wt % AlN |

|---|---|---|---|

| CYS [MPa] | RT | 92.4 ± 0.8 | 88.0 ± 1.0 |

| UCS [MPa] | RT | 316.8 ± 1.5 | 315.7 ± 0.8 |

| E [%] | RT | 21.6 ± 0.8 | 22.1 ± 0.6 |

| TYS [MPa] | RT | 115 ± 5 | 107 ± 3 |

| UTS [MPa] | RT | 229 ± 10 | 226 ± 3 |

| E [%] | RT | 12 ± 3 | 14 ± 1 |

| TYS [MPa] | 240 °C | 86 ± 7 | 80 ± 2 |

| UTS [MPa] | 240 °C | 214 ± 15 | 217 ± 8 |

| E [%] | 240 °C | 28 ± 1 | 27 ± 1 |

| Property | AM60 | AM60 + AlN |

|---|---|---|

| Grain size [µm] | 1277.0 ± 301.3 | 84.9 ± 6.2 |

| Hardness [HV5] | 48.0 ± 4.0 | 46.4 ± 6.0 |

| Density [g/cm3] | 1.7848 ± 0.0004 | 1.783 ± 0 |

| Porosity [%] | - | 0.919 |

| Yield strength ][[MPa] | 44.9 ± 6.9 | 91.2 ± 3.8 |

| UTS [MPa] | 109.3 ± 19.2 | 235.1 ± 6.4 |

| Elongation [%] | 6.4 ± 3.4 | 15.4 ± 4.2 |

| Alloy | Al | Zn | Mn | Nd | Gd | Zr | Mg |

|---|---|---|---|---|---|---|---|

| AZ91 | 8.71 | 0.66 | 0.22 | - | - | - | Bal. |

| El21 | - | 0.2–0.5 | - | 2.6–3.1 | 1.0–1.7 | Satur. | Bal. |

| Material | YS [MPa] | UTS [MPa] | E [%] |

|---|---|---|---|

| Mg | 20 | 89.6 | 14.0 |

| Mg-0.5SiC | 28.3 | 120.7 | 15.5 |

| Mg-1SiC | 30.3 | 124.1 | 14.2 |

| Mg-2SiC | 35.9 | 131.0 | 12.6 |

| Mg-4SiC | 47.6 | 106.9 | 5.5 |

| Material | YS [MPa] | UTS [MPa] | E [%] |

|---|---|---|---|

| AZ91 | 104 | 174 | 3.6 |

| AZ91 + 0.5SiC | 124 | 216 | 6.6 |

| Material | YS [MPa] | UTS [MPa] | E [%] |

|---|---|---|---|

| Mg-4Zn | 44 ± 2 | 112 ± 14 | 5 ± 1 |

| Mg-4Zn + 1.5 SiC | 67 ± 4 | 199 ± 6 | 10 ± 1 |

| Mg-6Zn | 51 ± 4 | 136 ± 19 | 5 ± 1 |

| Mg-6Zn + 1.5 SiC | 79 ± 5 | 194 ± 15 | 7 ± 1 |

| Mg-8Zn * | 81 | 152 | 3 |

| Mg-8Zn + 3 SiC * | 111 | 222 | 7 |

| Material | YS [MPa] | UTS [MPa] | E [%] |

|---|---|---|---|

| AZ91 | 88 ± 3 | 162 ± 5 | 2.88 ± 0.12 |

| AZ91 + 1 TiB2 | 104 ± 1 | 180 ± 0 | 3.33 ± 0.05 |

| AZ91 + 2.7 TiB2 | 107 ± 1 | 188 ± 7 | 4.27 ± 0.61 |

| Reference | Sonotrode Material and Depth of It in the Melt (mm) | Frequency (kHz) | Power (kW) | Ultrasonic Intensity (kW/cm2) or Amplitude (µm) | Supplier of Ultrasonic Generator | Sonication Time (min) |

|---|---|---|---|---|---|---|

| [20] | Ti6Al4V - | 20 | max 1.5 | 4.3 kW/cm2 | VCX 1500, Sonics and Materials, USA | 3 |

| [21] | - 20 | 20 | 1.5 | - | VCX 1500, Sonics and Materials, USA | 3 |

| [22] | Nb (Ø = 35) 32 | 17.5 | 3.5 | - | Advanced Sonics, LLC, Oxford, CT, USA | 15 |

| [23] | Ti (Ø = 35) 10 | 20 | 0.3 | - | UIP1500hd, Hielscher, Germany | 5 |

| [24] | Ti (Ø = 35) 10 | 20 | 0.3 | - | UIP1500hd, Hielscher, Germany | 5 |

| [25] | Ti (Ø = 35) 10 | 20 | 0.3 | - | UIP1500hd, Hielscher, Germany | 5 |

| [26] | Ti6Al4V | 20 | max 1.5 | 60 µm | VCX 1500, Sonics and Materials, USA | 3 |

| [27] | Ti (Ø = 45) - | 20 | max 4.0 | - | - | 10 |

| [28] | C103 Nb (Ø = 35) 32 | 17.5 | 3.5 | 40 µm | Advanced Sonics, LLC, Oxford, CT, USA | 45 + 15 |

| [29] | Nb (Ø = 34.9) 25-31 | 17.5 | 3.5 | - | Advanced Sonics, LLC, Oxford, CT, USA | 40 + 15 |

| [30] | Nb (Ø = 31.8) 31.8 | 17.5 | max 4.0 | - | Advanced Sonics, LLC, Oxford, CT, USA | - |

| [31] | - 20 | 20 | 0.35 | - | - | 20 or 30 |

| [32] | - | 20 | 4 | - | - | 10 |

| [33] | - 20 | 20 | 0.6 | - | - | 30 |

| [34] | Nb (Ø = 31.8) 31.8 | 17.5 | max 4.0 | - | Advanced Sonics, LLC, Oxford, CT, USA | - |

| [35] | (Ø = 12.7) 6 | 20 | - | 60 µm | - | - |

| [37] | Nb (Ø = 12.7) 12.7 | 20 | max 3.0 | 60 µm | Misonix Inc., USA | 15 |

| [38] | Ti6Al4V | 20 | - | 48 µm | VCX 1500, Sonics and Materials, USA | 3 |

| [39] | C103 Nb | - | - | 60 µm | - | 15 |

| [40] | Ti-alloy (Ø = 40) 35 | 20 | max 1.4 | - | - | 15 |

| [41] | - | - | - | 11–20 µm | - | 1–20 |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dieringa, H. Processing of Magnesium-Based Metal Matrix Nanocomposites by Ultrasound-Assisted Particle Dispersion: A Review. Metals 2018, 8, 431. https://doi.org/10.3390/met8060431

Dieringa H. Processing of Magnesium-Based Metal Matrix Nanocomposites by Ultrasound-Assisted Particle Dispersion: A Review. Metals. 2018; 8(6):431. https://doi.org/10.3390/met8060431

Chicago/Turabian StyleDieringa, Hajo. 2018. "Processing of Magnesium-Based Metal Matrix Nanocomposites by Ultrasound-Assisted Particle Dispersion: A Review" Metals 8, no. 6: 431. https://doi.org/10.3390/met8060431

APA StyleDieringa, H. (2018). Processing of Magnesium-Based Metal Matrix Nanocomposites by Ultrasound-Assisted Particle Dispersion: A Review. Metals, 8(6), 431. https://doi.org/10.3390/met8060431