Optimization of Sintering Time and Holding Time for 3D Printing of Fe-Based Metallic Glasses

Abstract

1. Introduction

2. Experiment

2.1. Preparation of Fe-Based Metallic Glass Slurry

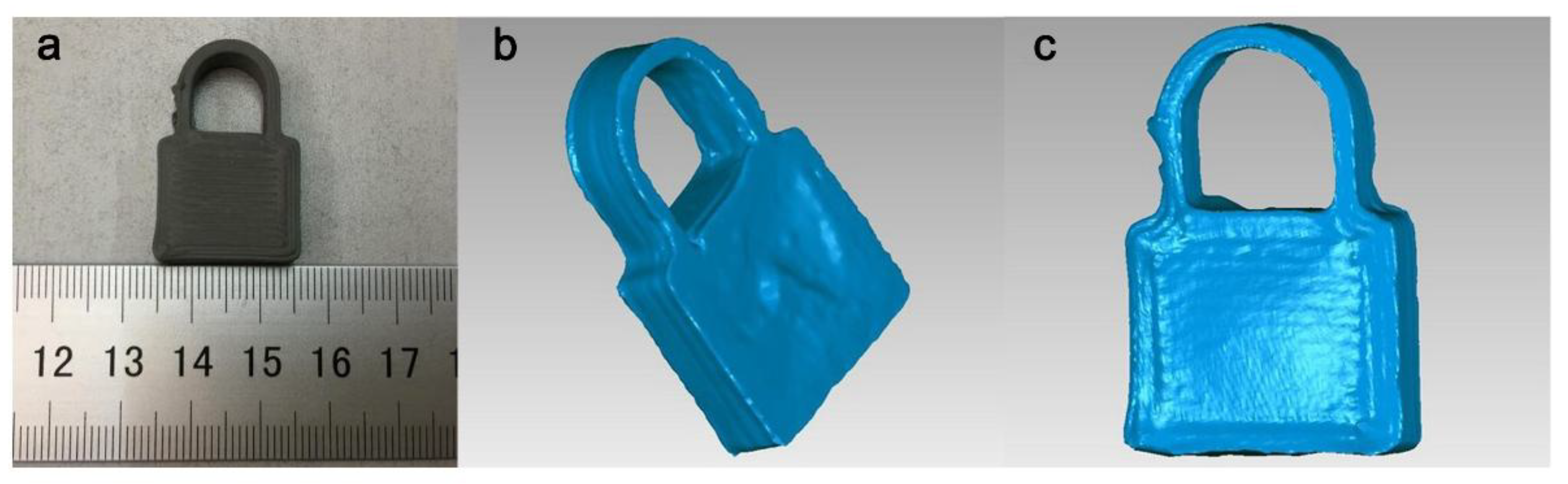

2.2. 3D Printing and Deformation Analysis of Fe-Based Metallic Glass Parts

2.3. Sintering of 3D-Printed Fe-Based Metallic Glass Parts

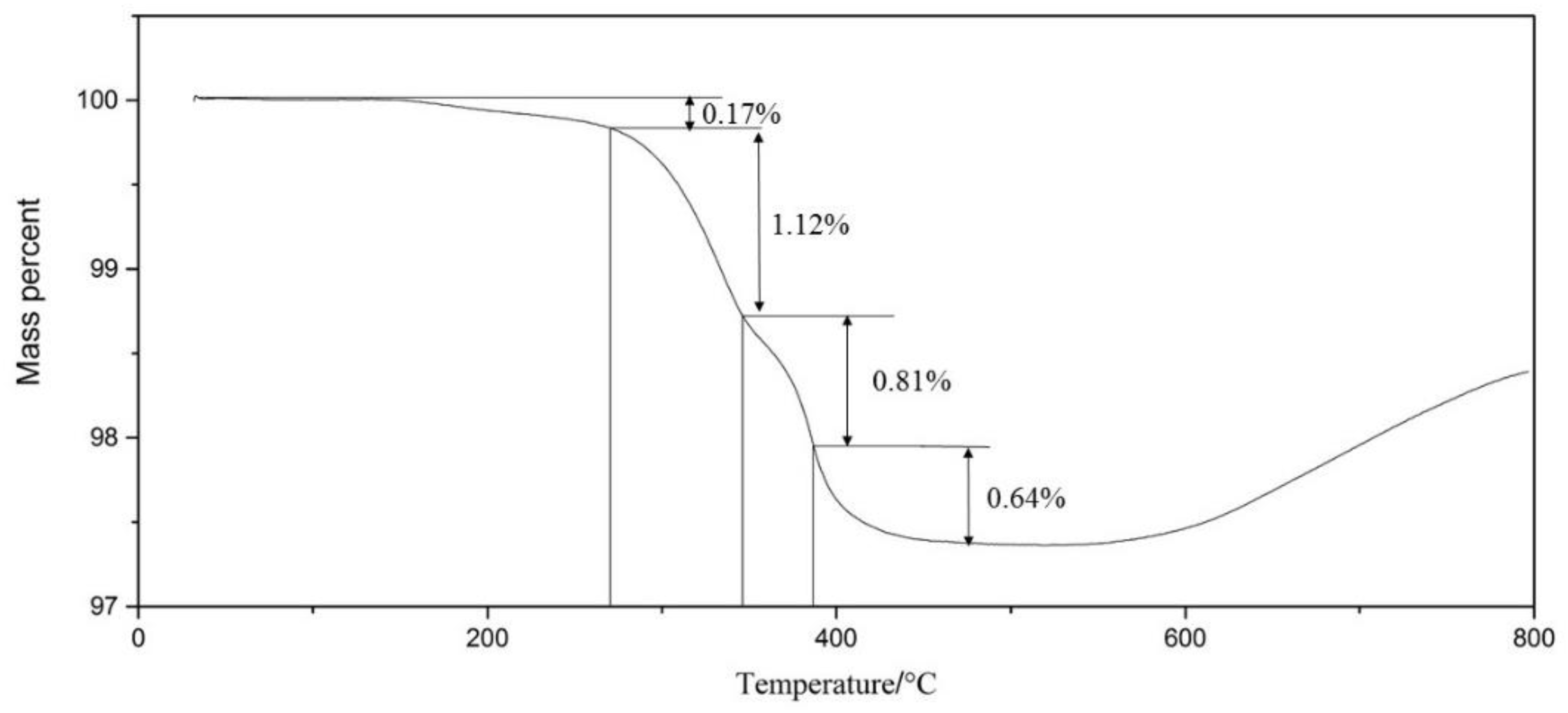

3. Results and Discussion

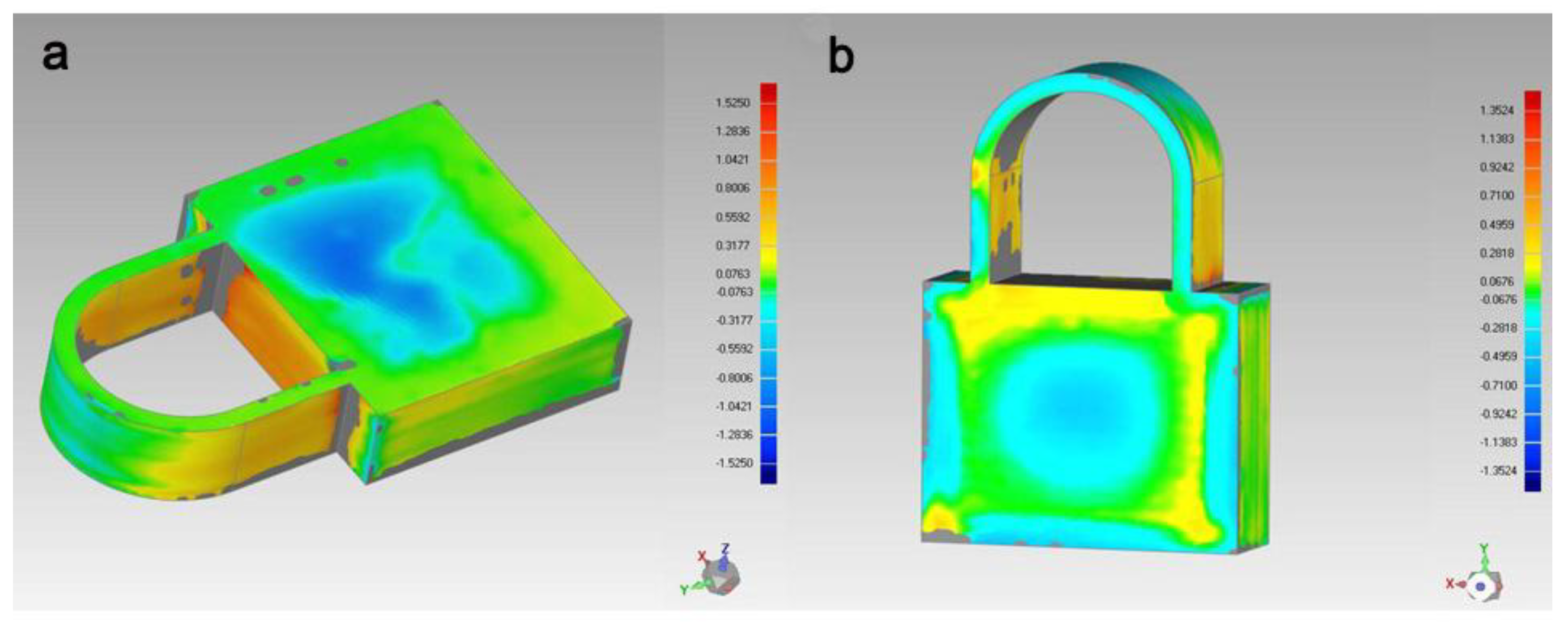

3.1. Analysis of Deformation of 3D-Printed Fe-Based Metallic Glass Parts

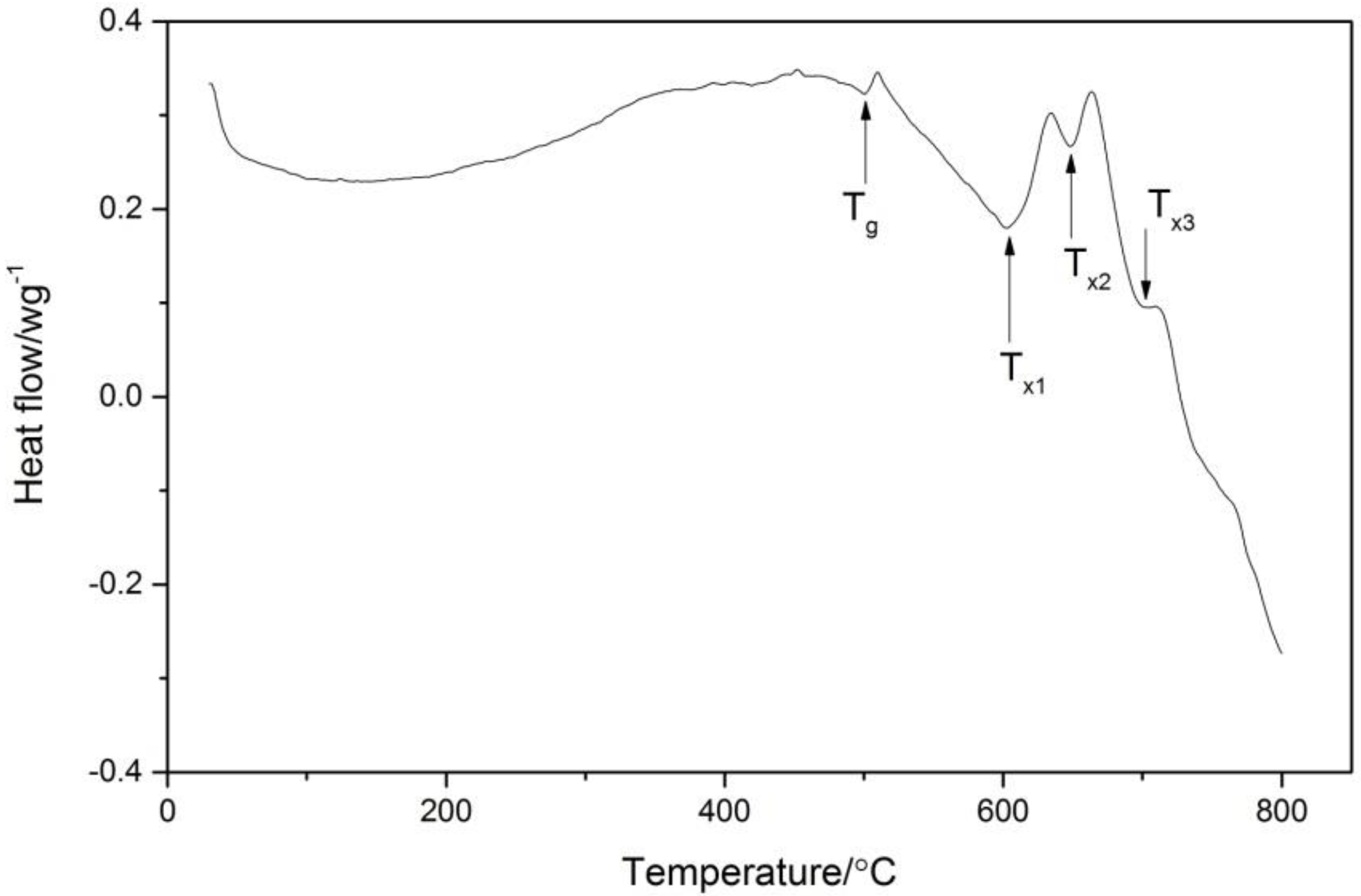

3.2. Differential Thermal Analysis of Fe-Based Metallic Glass Powder

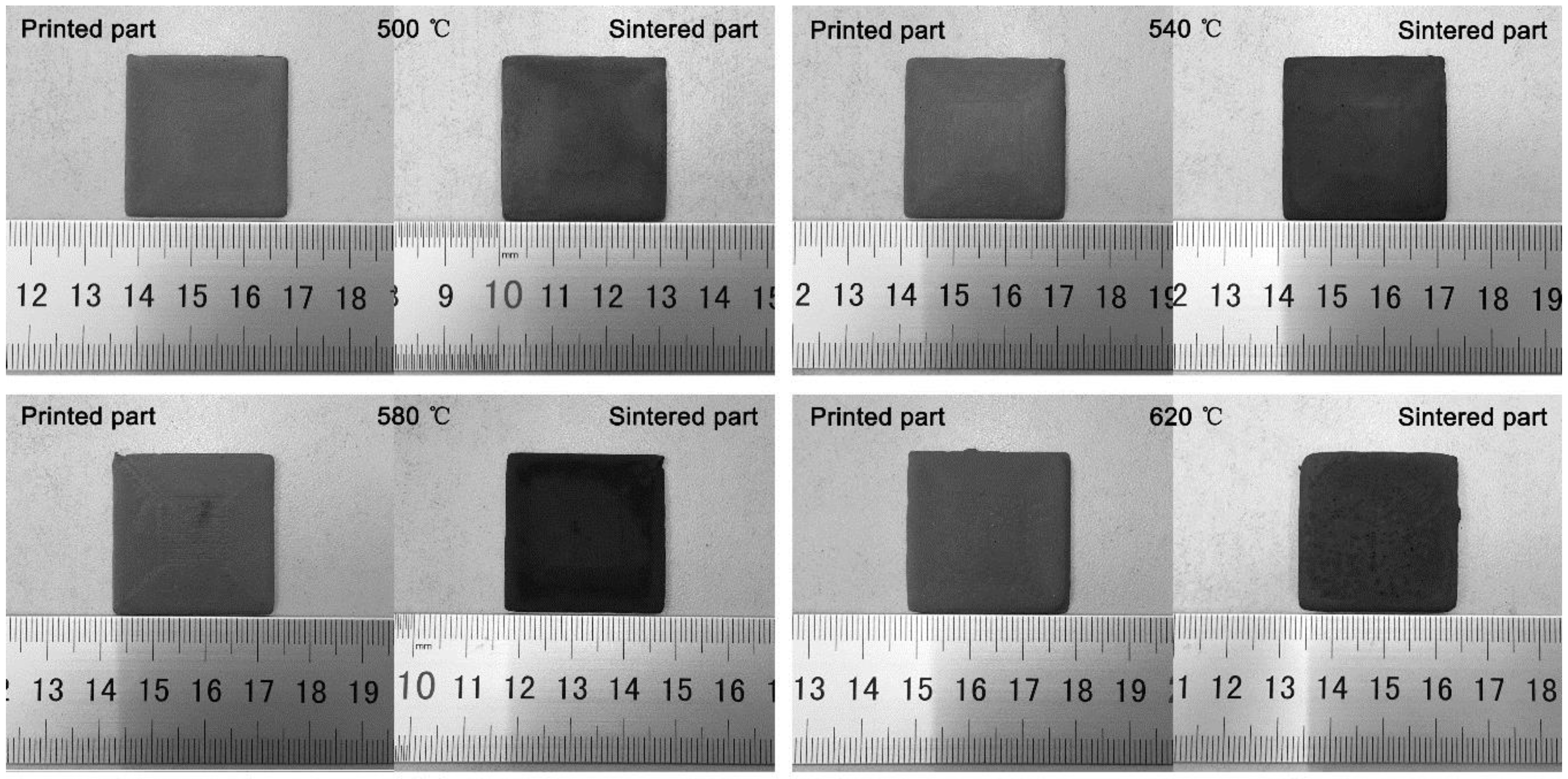

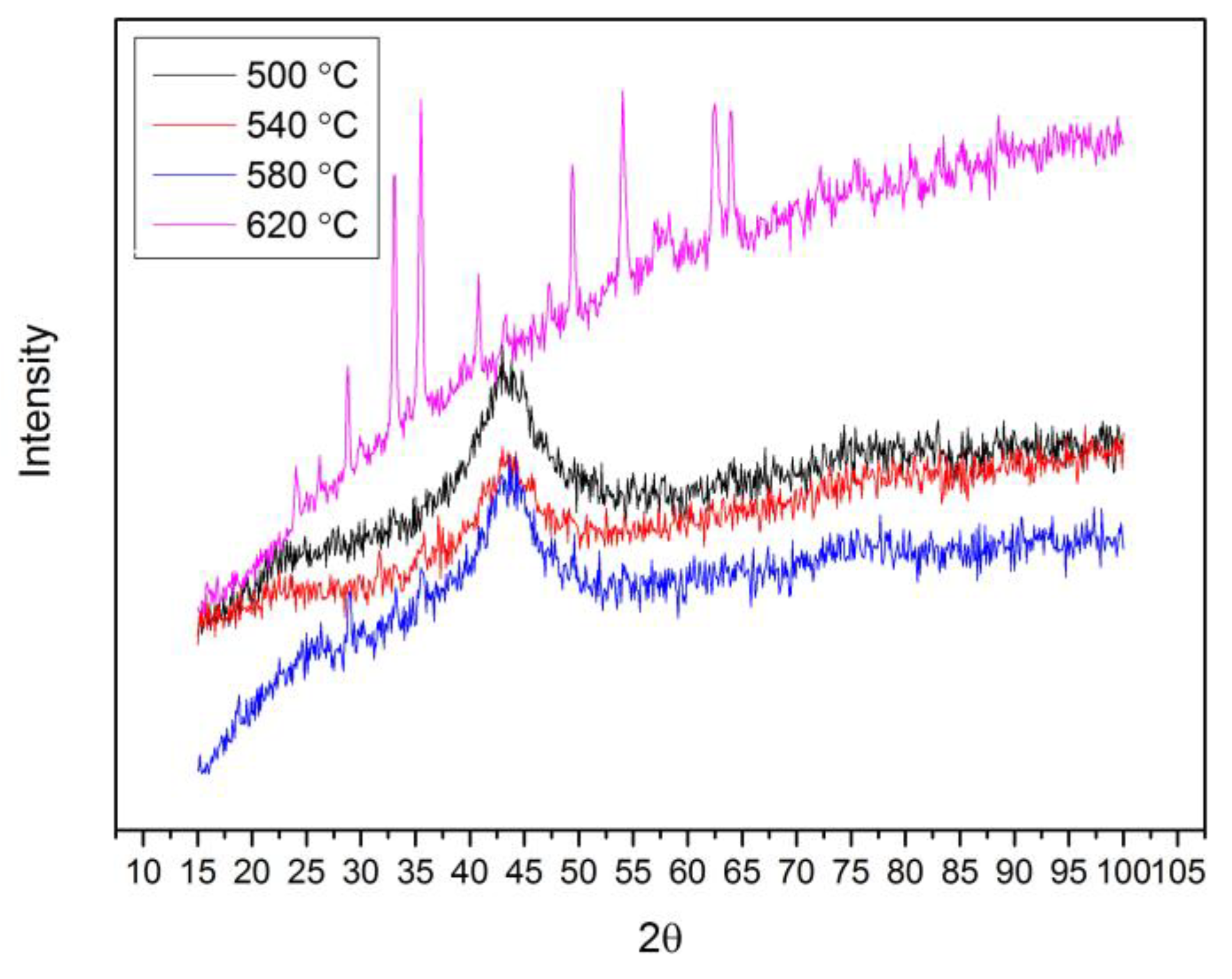

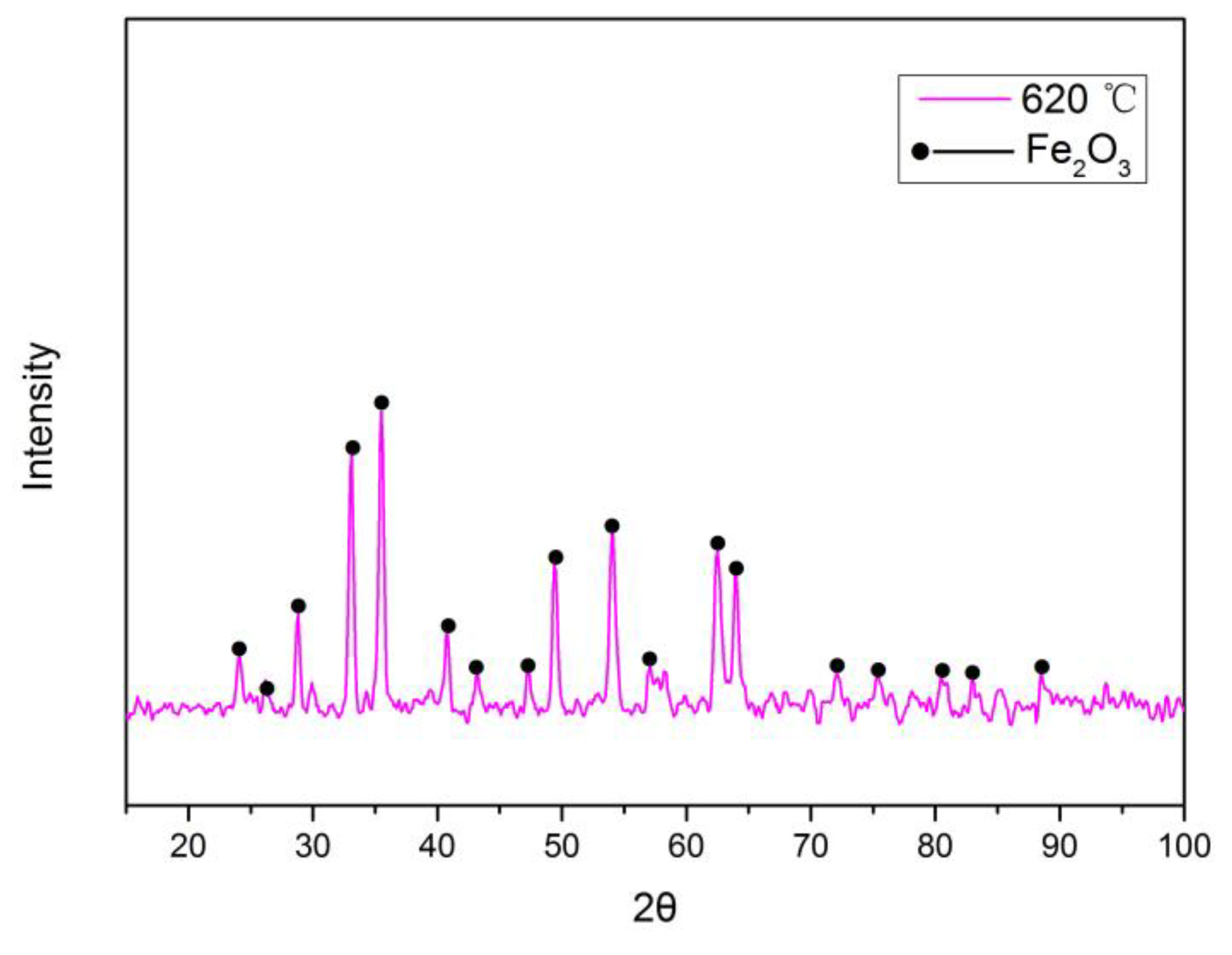

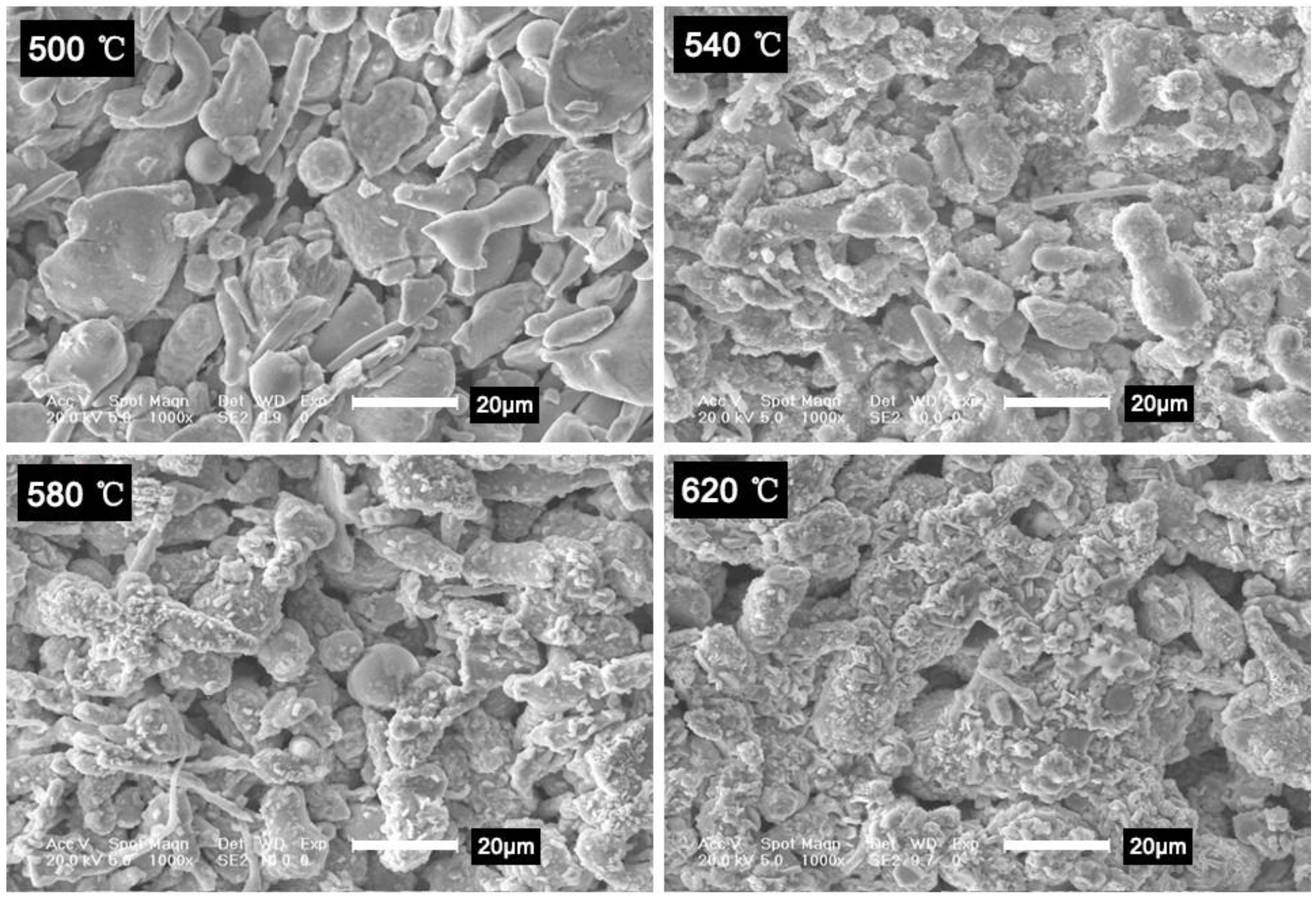

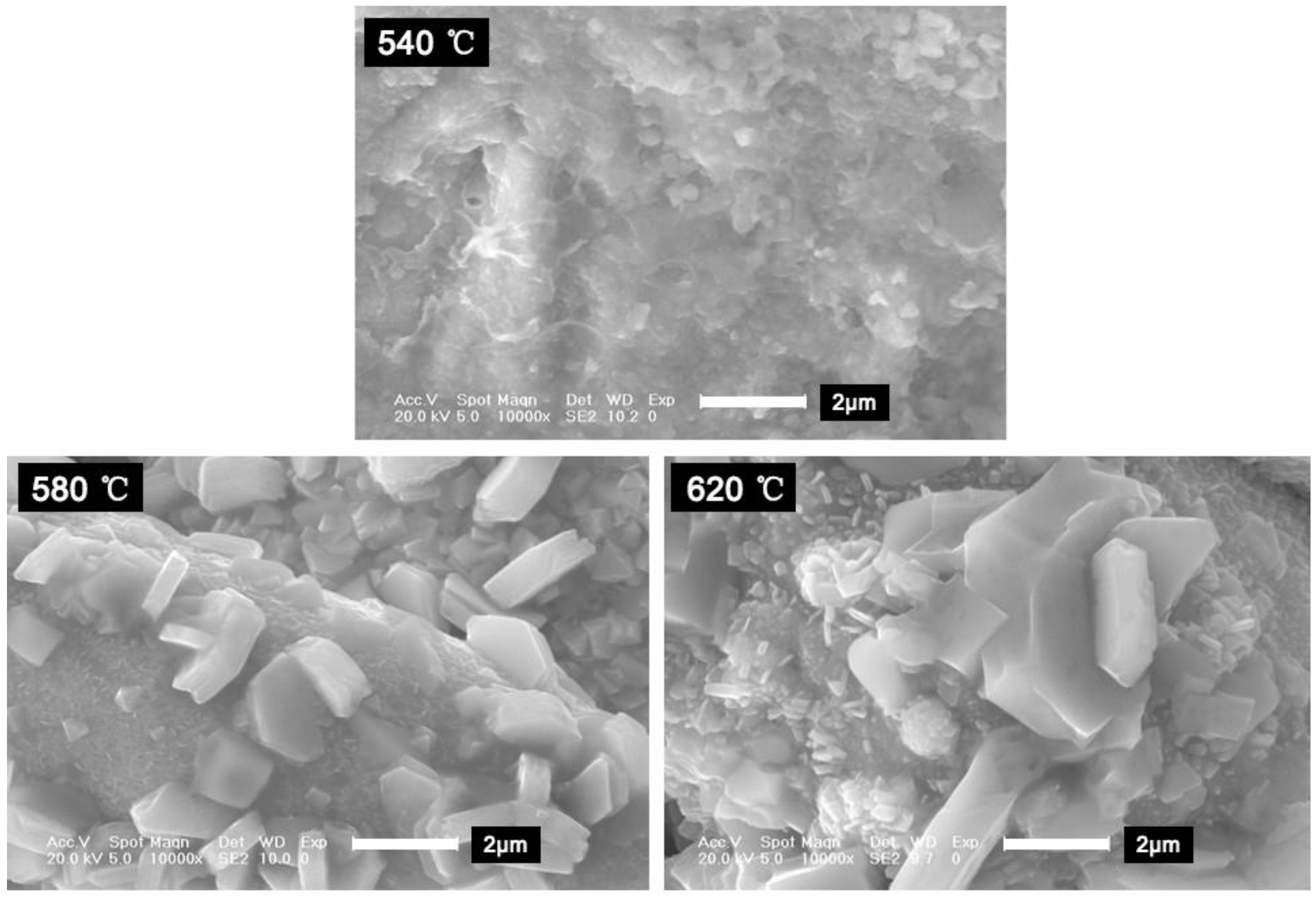

3.3. Effect of Sintering Temperature on Properties of 3D-Printed Fe-Based Metallic Glass Parts

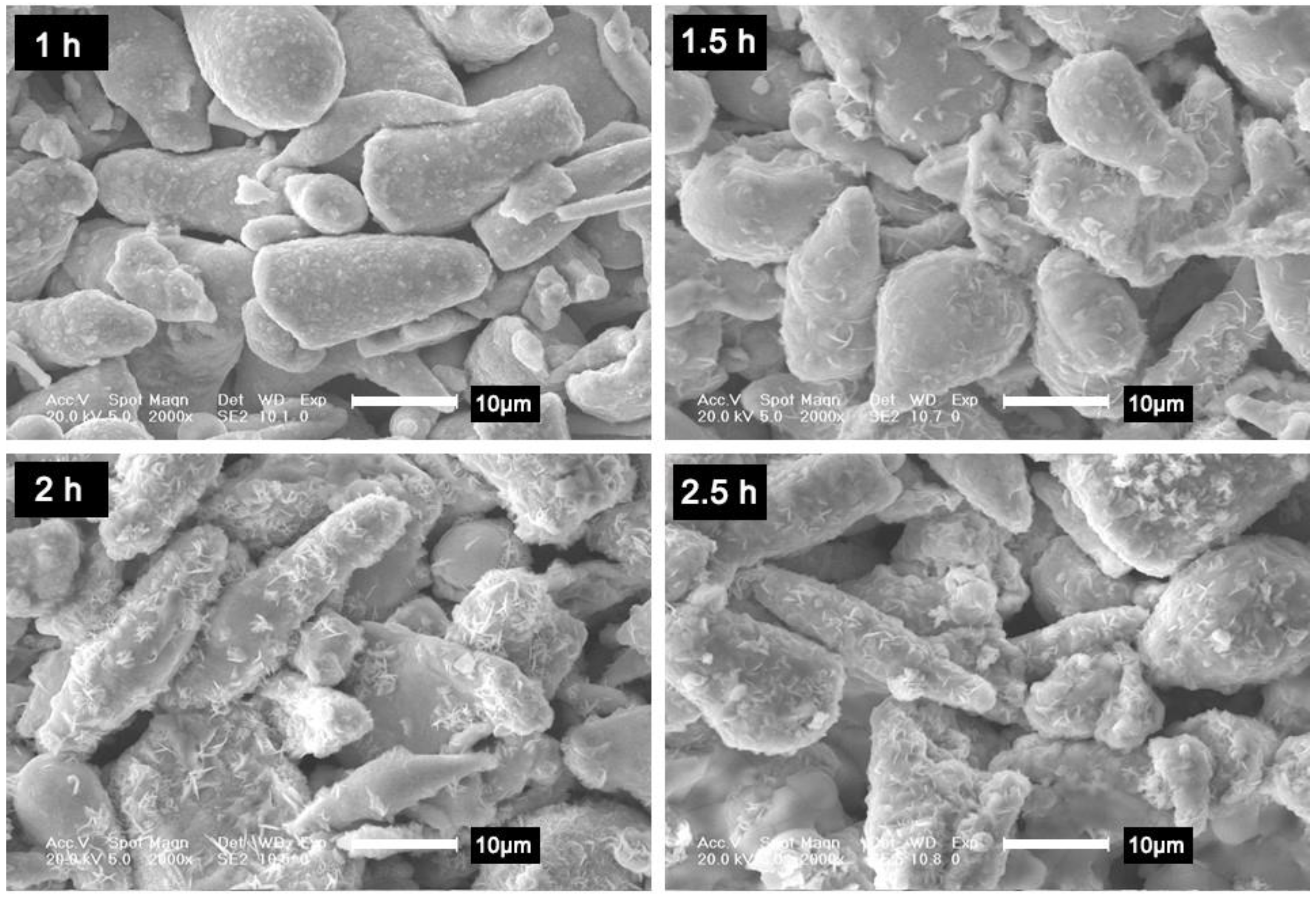

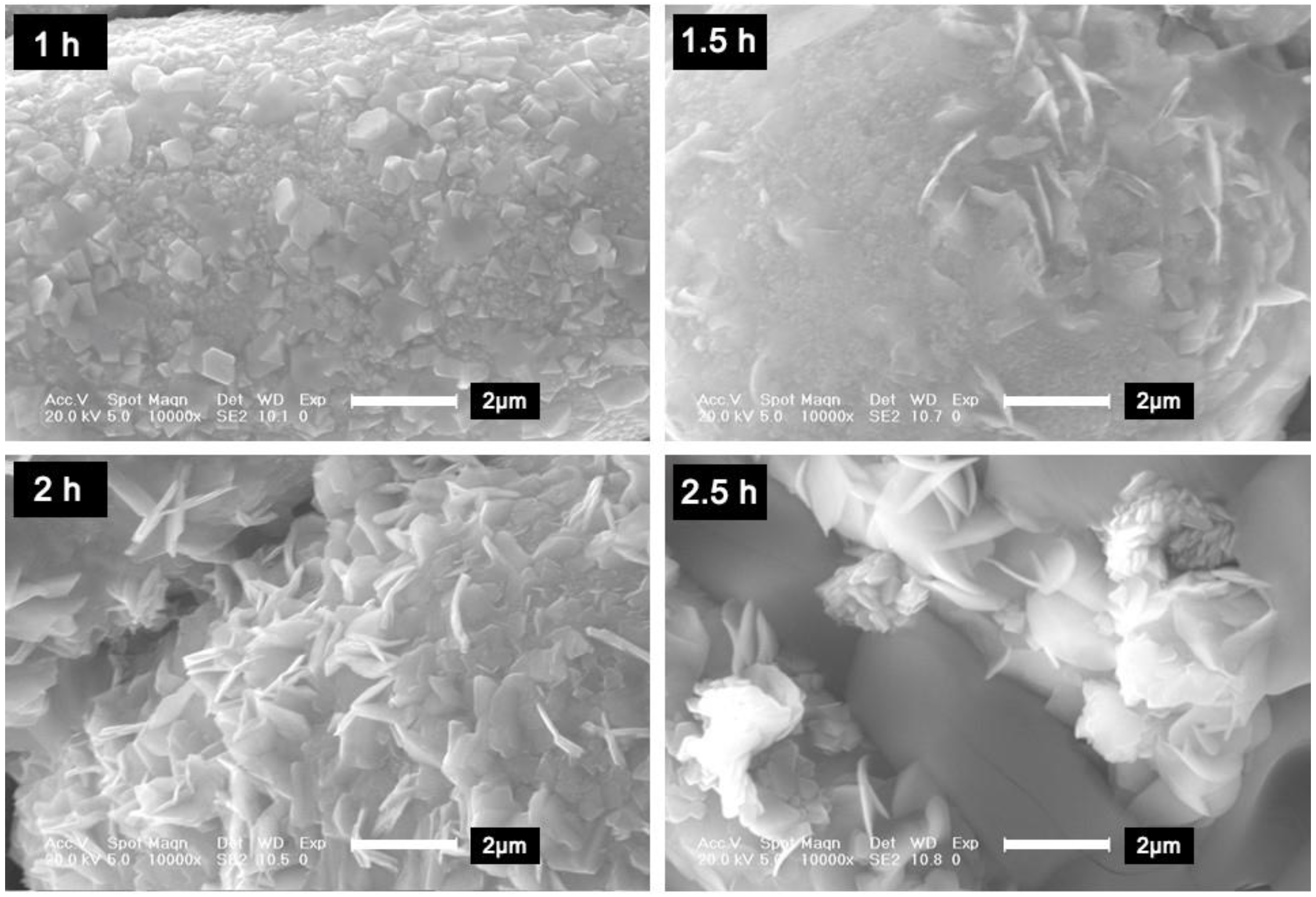

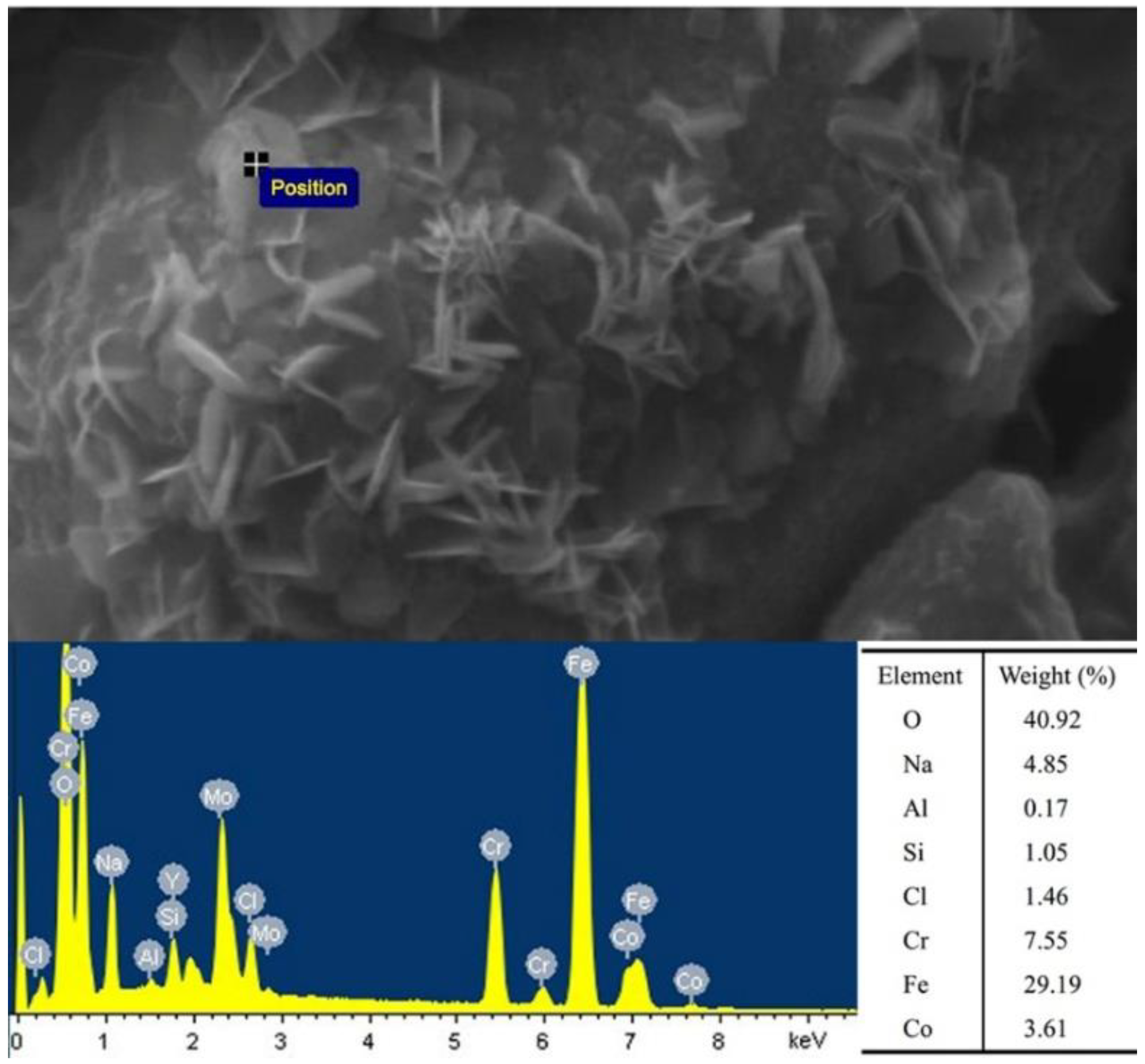

3.4. Effect of Holding Time on Properties of 3D-Printed Fe-Based Metallic Glass Parts

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gu, X.J.; Poon, S.J.; Shiflet, G.J. Mechanical properties of iron-based bulk metallic glasses. J. Mater. Res. 2011, 22, 344–351. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Inoue, A. Iron-based bulk metallic glasses. Int. Mater. Rev. 2013, 58, 131–166. [Google Scholar] [CrossRef]

- Ghidelli, M.; Idrissi, H.; Gravier, S.; Blandin, J.-J.; Raskin, J.-P.; Schryvers, D.; Pardoen, T. Homogeneous flow and size dependent mechanical behavior in highly ductile Zr 65 Ni 35 metallic glass films. Acta Mater. 2017, 131, 246–259. [Google Scholar] [CrossRef]

- Wu, Y.; Li, H.X.; Gao, J.E.; Wang, H.; Liu, X.J.; Miller, M.K.; Bei, H.; Gao, Y.F.; Lu, Z.P. Nanocrystallization in a cu-doped fe-based metallic glass. J. Alloys Compd. 2016, 688, 822–827. [Google Scholar] [CrossRef]

- Schroers, J. Processing of bulk metallic glass. Adv. Mater. 2010, 22, 1566–1597. [Google Scholar] [CrossRef] [PubMed]

- Pauly, S.; Löber, L.; Petters, R.; Stoica, M.; Scudino, S.; Kühn, U.; Eckert, J. Processing metallic glasses by selective laser melting. Mater. Today 2013, 16, 37–41. [Google Scholar] [CrossRef]

- Williams, E.; Lavery, N. Laser processing of bulk metallic glass: A review. J. Mater. Process. Technol. 2017, 247, 73–91. [Google Scholar] [CrossRef]

- Jung, H.Y.; Choi, S.J.; Prashanth, K.G.; Stoica, M.; Scudino, S.; Yi, S.; Kühn, U.; Kim, D.H.; Kim, K.B.; Eckert, J. Fabrication of Fe-based bulk metallic glass by selective laser melting: A parameter study. Mater. Des. 2015, 86, 703–708. [Google Scholar] [CrossRef]

- Li, N.; Zhang, J.; Xing, W.; Ouyang, D.; Liu, L. 3D printing of Fe-based bulk metallic glass composites with combined high strength and fracture toughness. Mater. Des. 2018, 143, 285–296. [Google Scholar] [CrossRef]

- Cesarano, J., III; Segalman, R.; Calvert, P. Robocasting provides moldless fabrication from slurry deposition. Ceram. Ind. 1998, 148, 94–102. [Google Scholar]

- Lewis, J.A. Direct ink writing of 3D functional materials. Adv. Funct. Mater. 2006, 16, 2193–2204. [Google Scholar] [CrossRef]

- Zhu, D.B.; Xu, A.P. Dual-phase materials extrusion process for rapid fabrication of ceramic dental crown. Adv. Mater. Res. 2010, 97–101, 4050–4053. [Google Scholar] [CrossRef]

- Hong, S.; Sanchez, C.; Du, H.; Kim, N. Fabrication of 3D printed metal structures by use of high-viscosity cu paste and a screw extruder. J. Electr. Mater. 2015, 44, 836–841. [Google Scholar] [CrossRef]

- Li, Y.; Li, L.; Li, B. Direct ink writing of three-dimensional (K, Na)NbO3-based piezoelectric ceramics. Materials 2015, 8, 1729–1737. [Google Scholar] [CrossRef] [PubMed]

- Ren, X.; Shao, H.; Lin, T.; Zheng, H. 3D gel-printing—An additive manufacturing method for producing complex shape parts. Mater. Des. 2016, 101, 80–87. [Google Scholar] [CrossRef]

- Morissette, S.L.; Lewis, J.A.; Cesarano Iii, J.; Dimos, D.B.; Baer, T.; Hackley, V.A. Solid freeform fabrication of aqueous alumina-poly(vinyl alcohol) gelcasting suspensions. J. Am. Ceram. Soc. 2000, 83, 2409. [Google Scholar] [CrossRef]

- Wu, W.; Du, H.; Sui, H.; Guo, X.; Wang, B.; Li, G.; Zhao, J. Printing parameters and strengthening mechanism of pneumatic injection additive manufacturing with iron powder slurry. Int. J. Adv. Manuf. Technol. 2017, 94, 3809–3817. [Google Scholar] [CrossRef]

- Fu, K.; Wang, Y.; Yan, C.; Yao, Y.; Chen, Y.; Dai, J.; Lacey, S.; Wang, Y.; Wan, J.; Li, T.; et al. Graphene oxide-based electrode inks for 3D-printed lithium-ion batteries. Adv. Mater. 2016, 28, 2587–2594. [Google Scholar] [CrossRef] [PubMed]

- Jain, R.A. The manufacturing techniques of various drug loaded biodegradable poly(lactide-co-glycolide) (plga) devices. Biomaterials 2000, 21, 2475–2490. [Google Scholar] [CrossRef]

- Jakus, A.E.; Secor, E.B.; Rutz, A.L.; Jordan, S.W.; Hersam, M.C.; Shah, R.N. Three-dimensional printing of high-content graphene scaffolds for electronic and biomedical applications. ACS Nano 2015, 9, 4636–4648. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Yang, F.; Zhao, H.; Gao, Q.; Xia, B.; Fu, J. Research on the printability of hydrogels in 3D bioprinting. Sci. Rep. 2016, 6, 29977. [Google Scholar] [CrossRef] [PubMed]

- Jakus, A.E.; Taylor, S.L.; Geisendorfer, N.R.; Dunand, D.C.; Shah, R.N. Metallic printing: Metallic architectures from 3D-printed powder-based liquid inks (adv. Funct. Mater. 45/2015). Adv. Funct. Mater. 2015, 25, 7099. [Google Scholar] [CrossRef]

- Wu, W.; Du, H.; Sui, H.; Sun, B.; Wang, B.; Yu, Z.; Ni, H.; Li, G.; Zhao, J. Study of printing parameters of pneumatic-injection 3D printing of Fe-based metallic glass. J. Non-Cryst. Solids 2018, 489, 50–56. [Google Scholar] [CrossRef]

- Ghidelli, M.; Gravier, S.; Blandin, J.-J.; Pardoen, T.; Raskin, J.-P.; Mompiou, F. Compositional-induced structural change in ZrxNi100−x thin film metallic glasses. J. Alloys Compd. 2014, 615, S348–S351. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, W.; Liu, W.; Du, H.; Wang, B.; Li, G.; Sun, B.; Zhang, S.; Zhao, J. Optimization of Sintering Time and Holding Time for 3D Printing of Fe-Based Metallic Glasses. Metals 2018, 8, 429. https://doi.org/10.3390/met8060429

Wu W, Liu W, Du H, Wang B, Li G, Sun B, Zhang S, Zhao J. Optimization of Sintering Time and Holding Time for 3D Printing of Fe-Based Metallic Glasses. Metals. 2018; 8(6):429. https://doi.org/10.3390/met8060429

Chicago/Turabian StyleWu, Wenzheng, Wei Liu, Haidong Du, Bofan Wang, Guiwei Li, Bin Sun, Shuo Zhang, and Ji Zhao. 2018. "Optimization of Sintering Time and Holding Time for 3D Printing of Fe-Based Metallic Glasses" Metals 8, no. 6: 429. https://doi.org/10.3390/met8060429

APA StyleWu, W., Liu, W., Du, H., Wang, B., Li, G., Sun, B., Zhang, S., & Zhao, J. (2018). Optimization of Sintering Time and Holding Time for 3D Printing of Fe-Based Metallic Glasses. Metals, 8(6), 429. https://doi.org/10.3390/met8060429