Fabrication Technology and Material Characterization of Hot Rolled Cylindrical Fe-6.5 wt. % Si Bars

Abstract

:1. Introduction

2. Materials and Methods

2.1. Starting Materials

2.2. Rolling Equipment

2.3. Characterization of Microstructure and Mechanical Properties

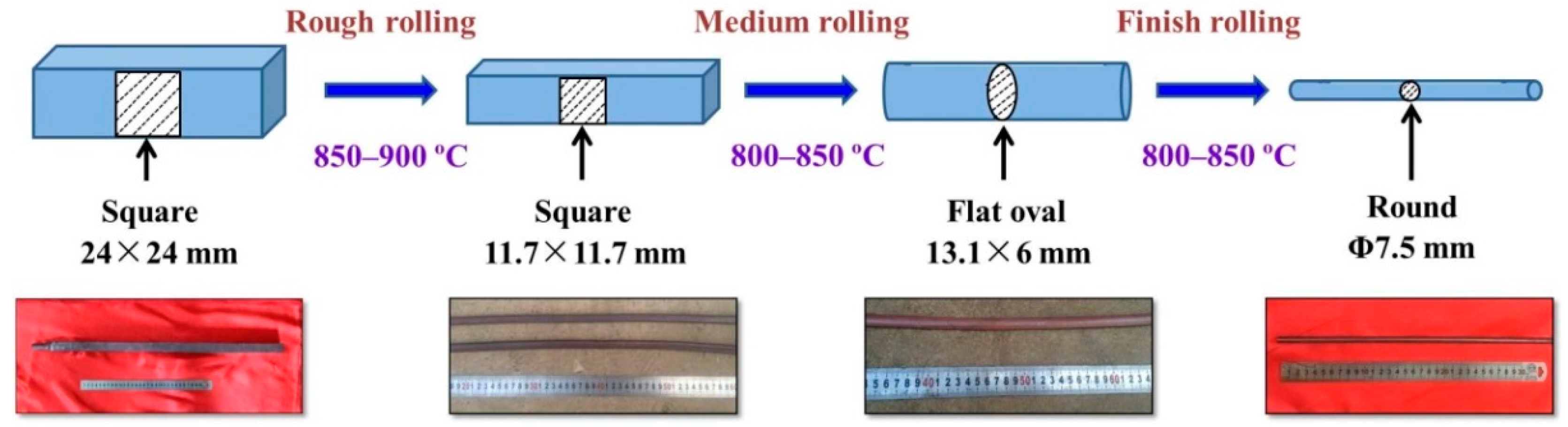

3. Fabrication of Fe-6.5 wt. % Si Bars by the Hot Bar Rolling Technique

3.1. Rolling Temperature and Roll Pass

3.2. Rolling Groove and Deformation Ratio

3.3. Rolling Gap

4. Results and Discussion

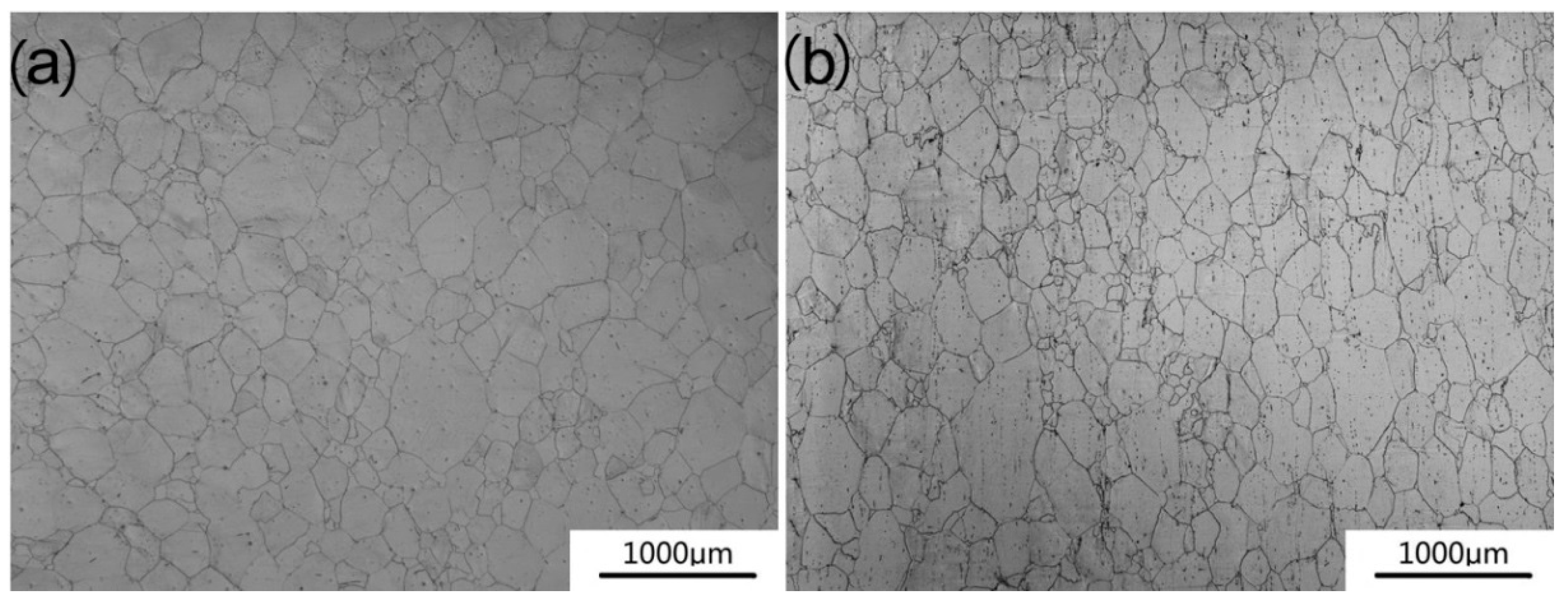

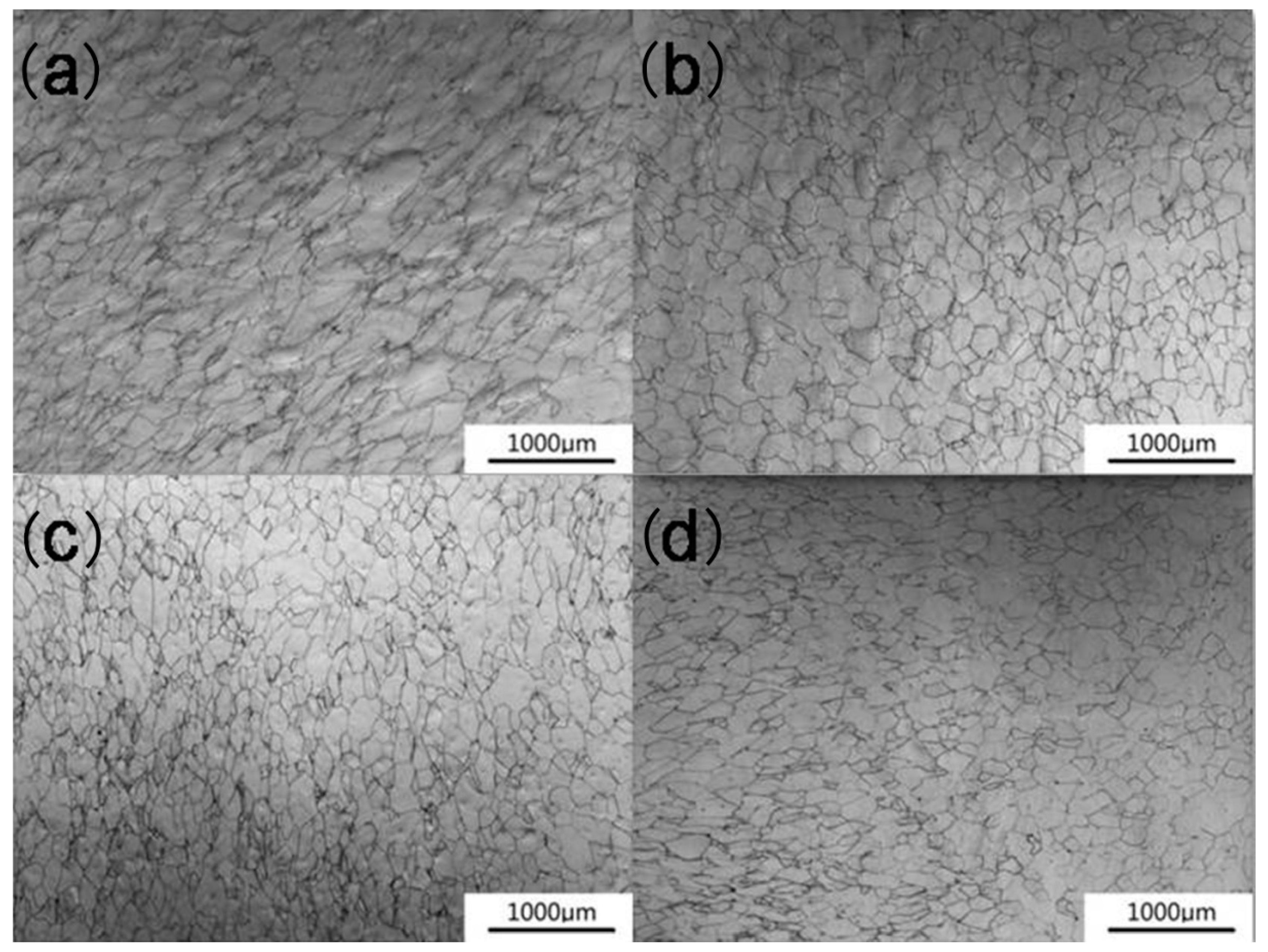

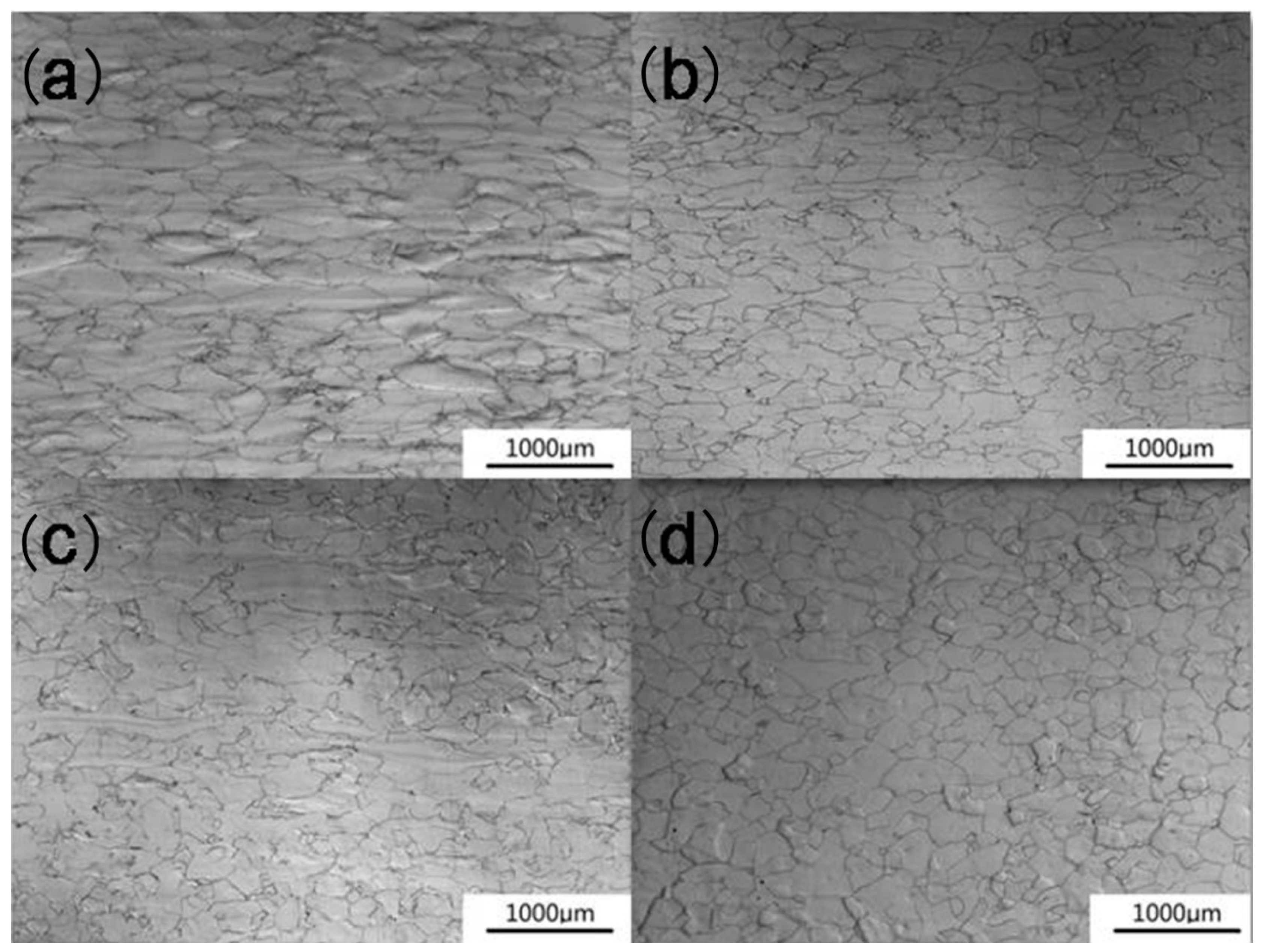

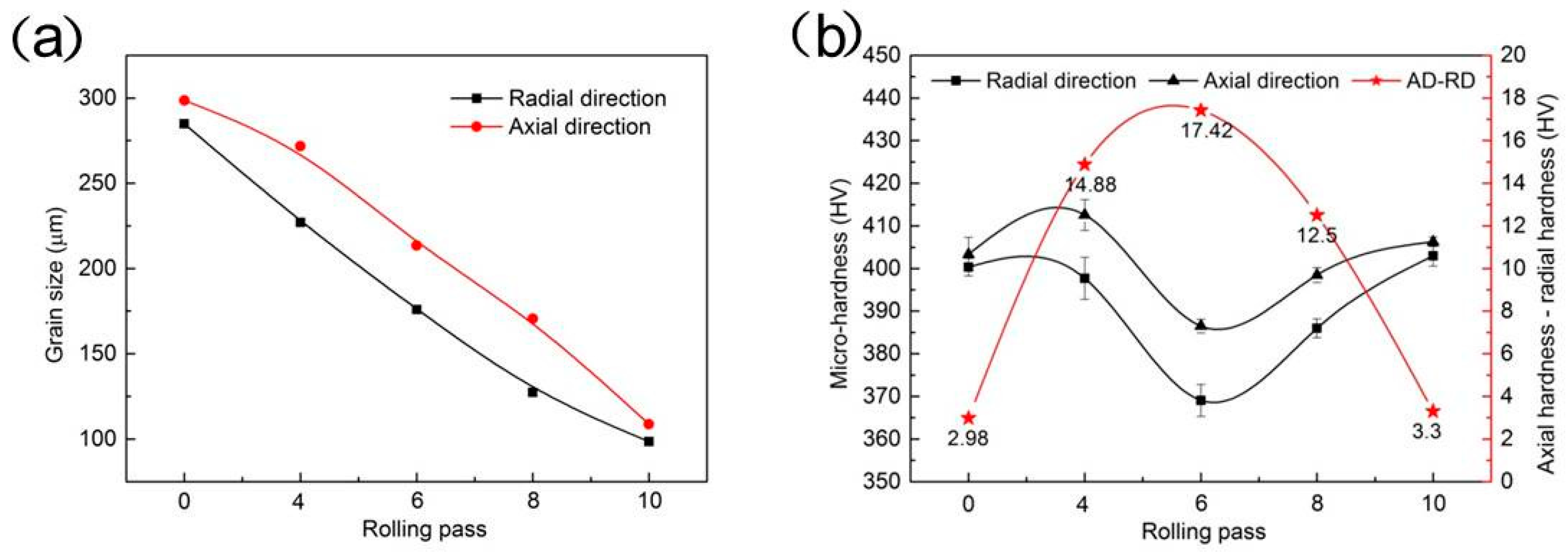

4.1. Microstructure Evolution

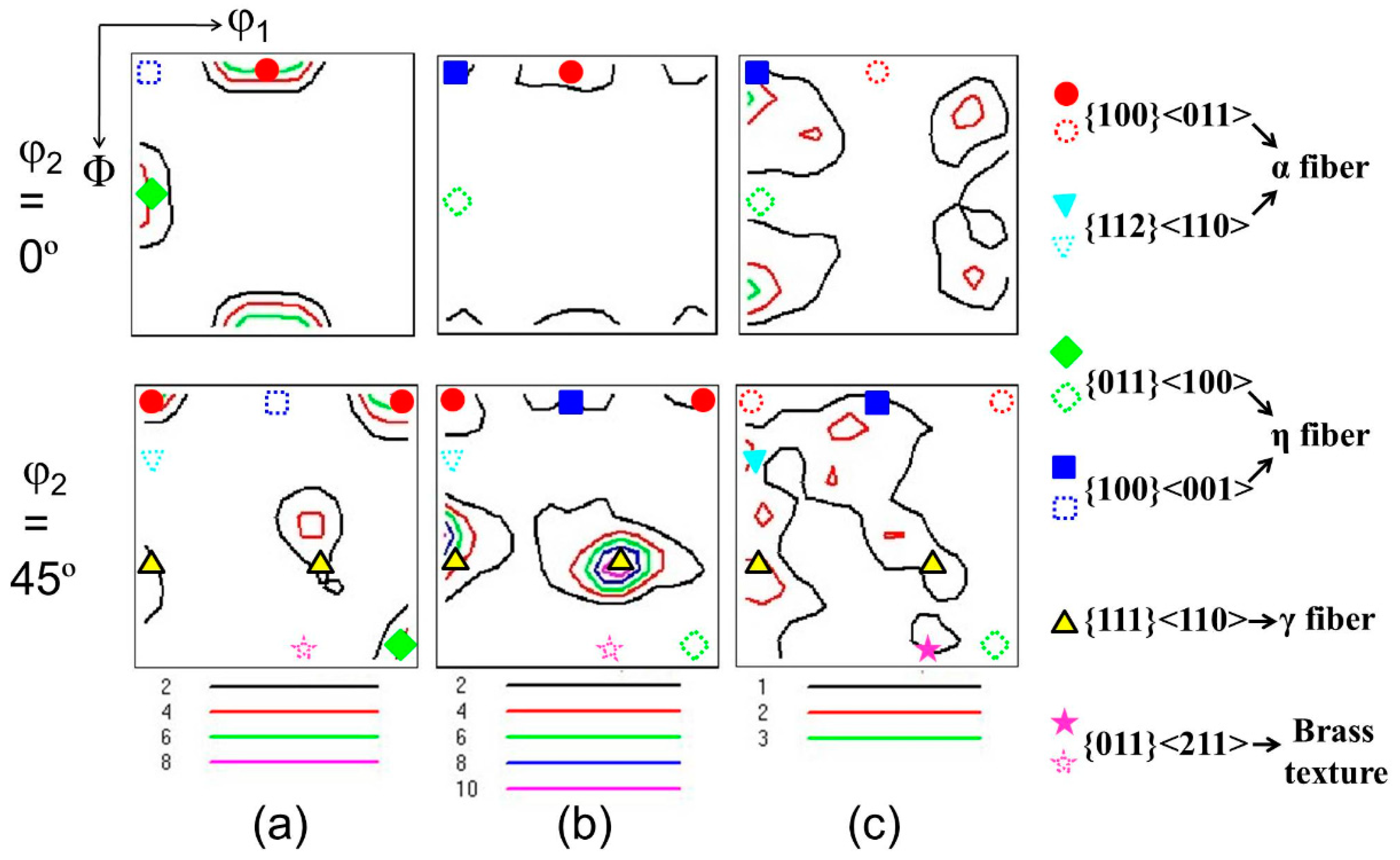

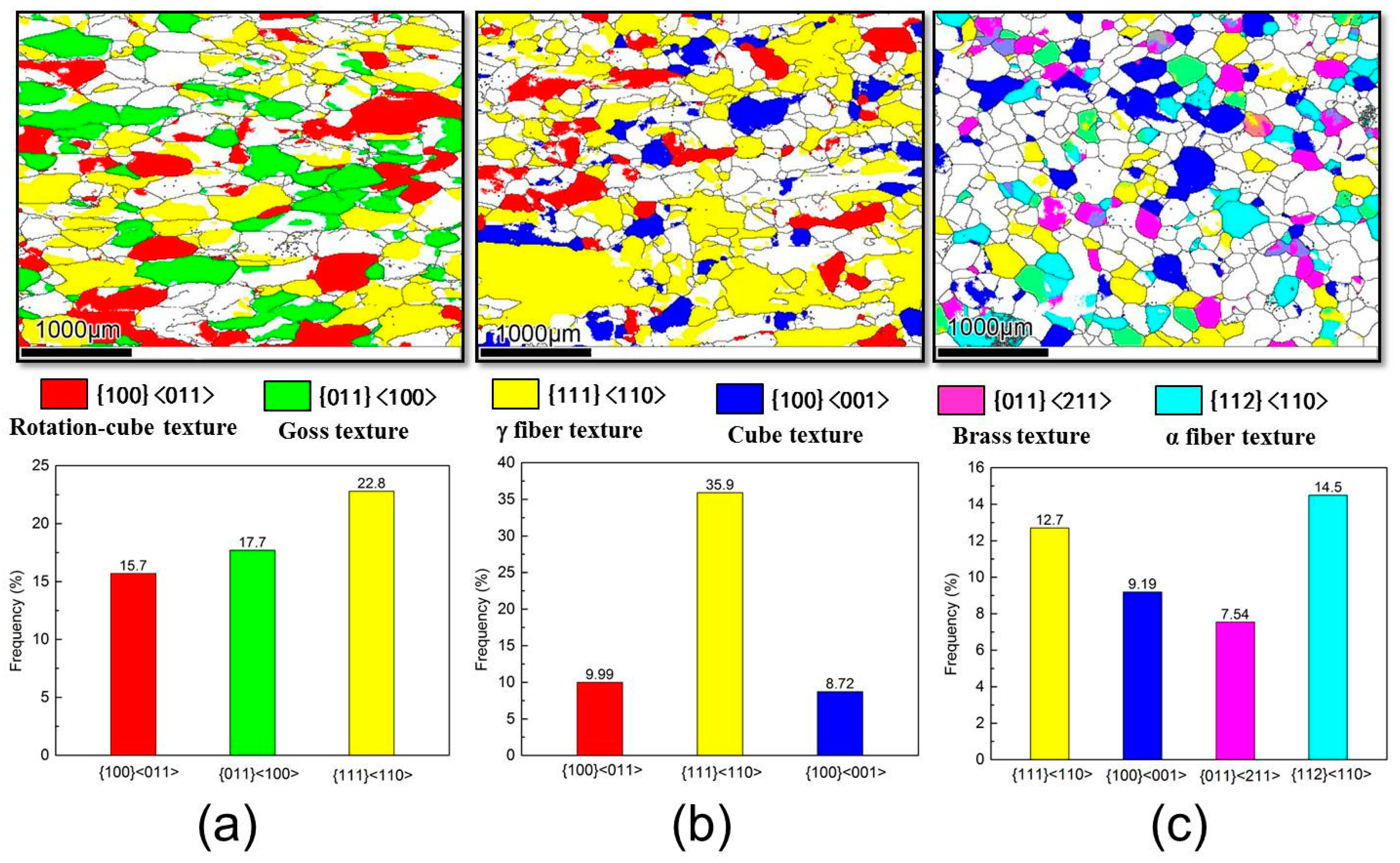

4.2. Texture Evolution

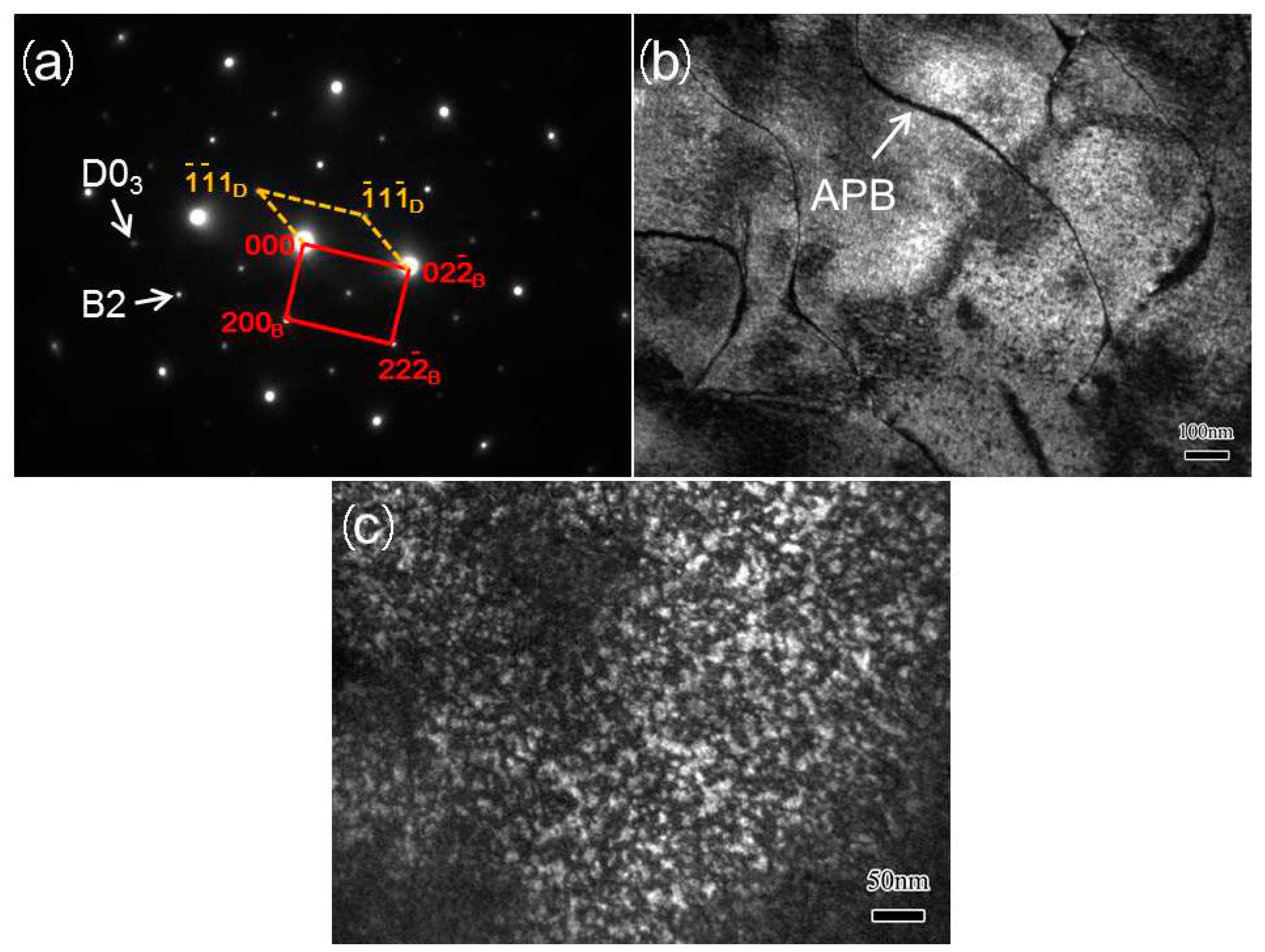

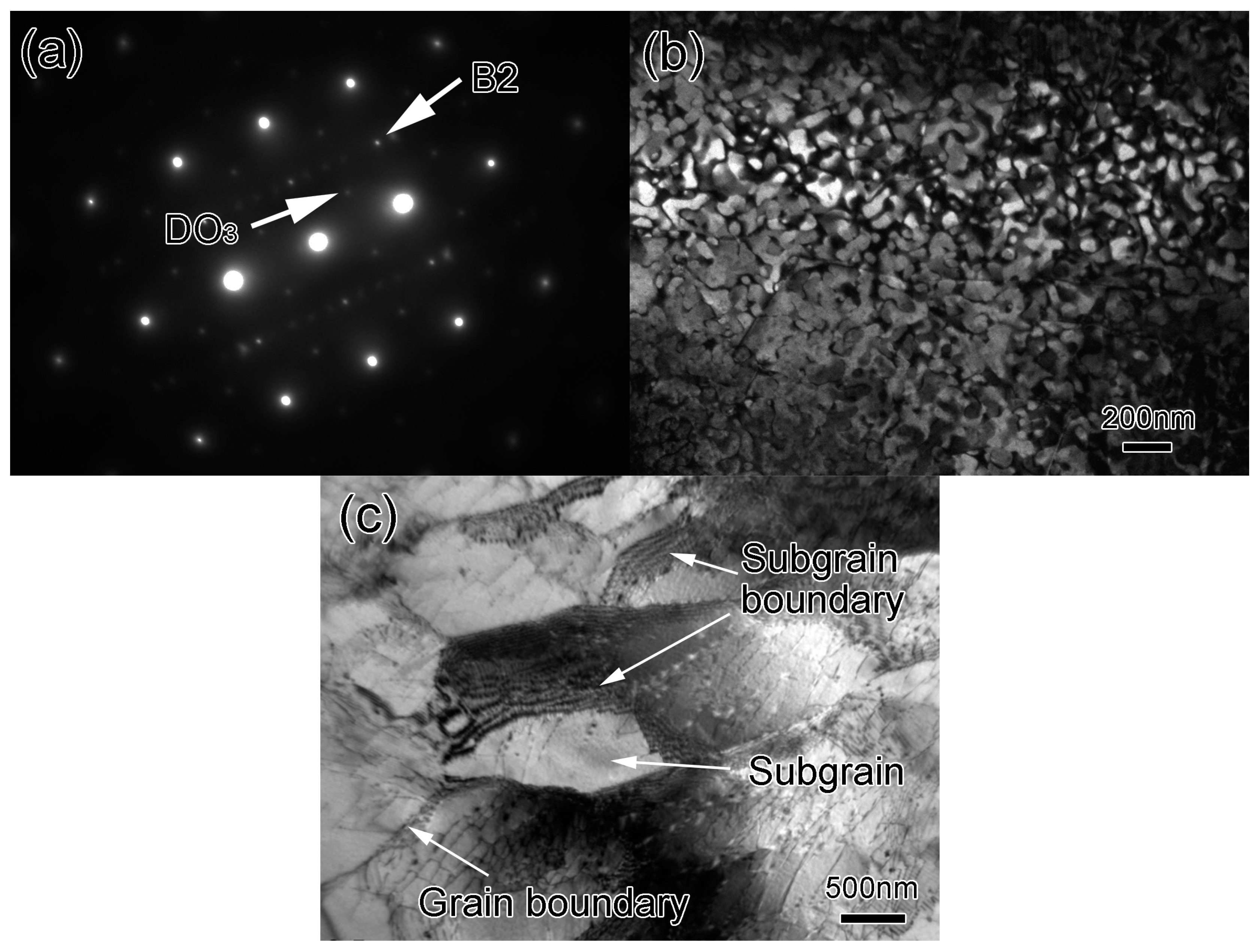

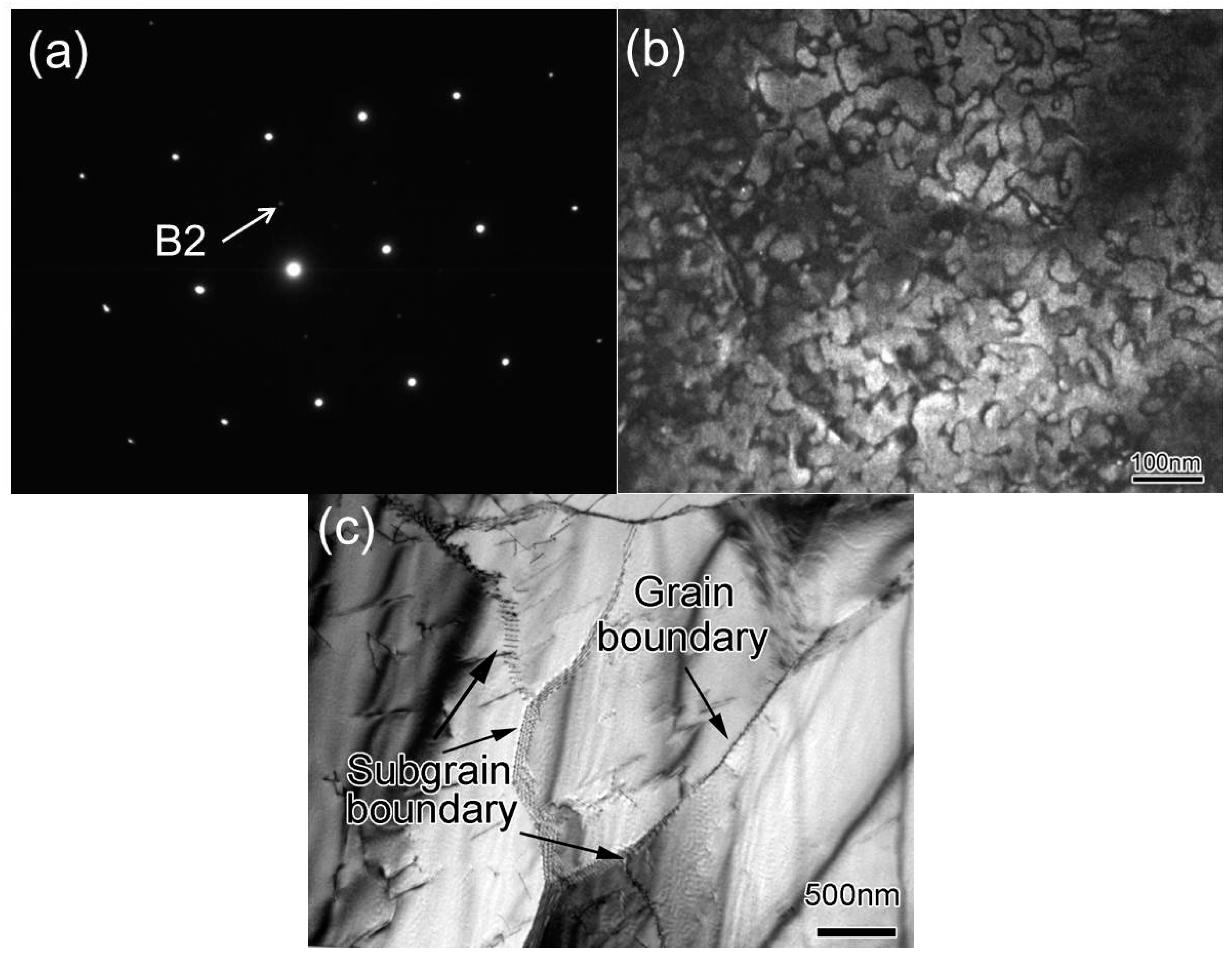

4.3. Ordered Structure Evolution

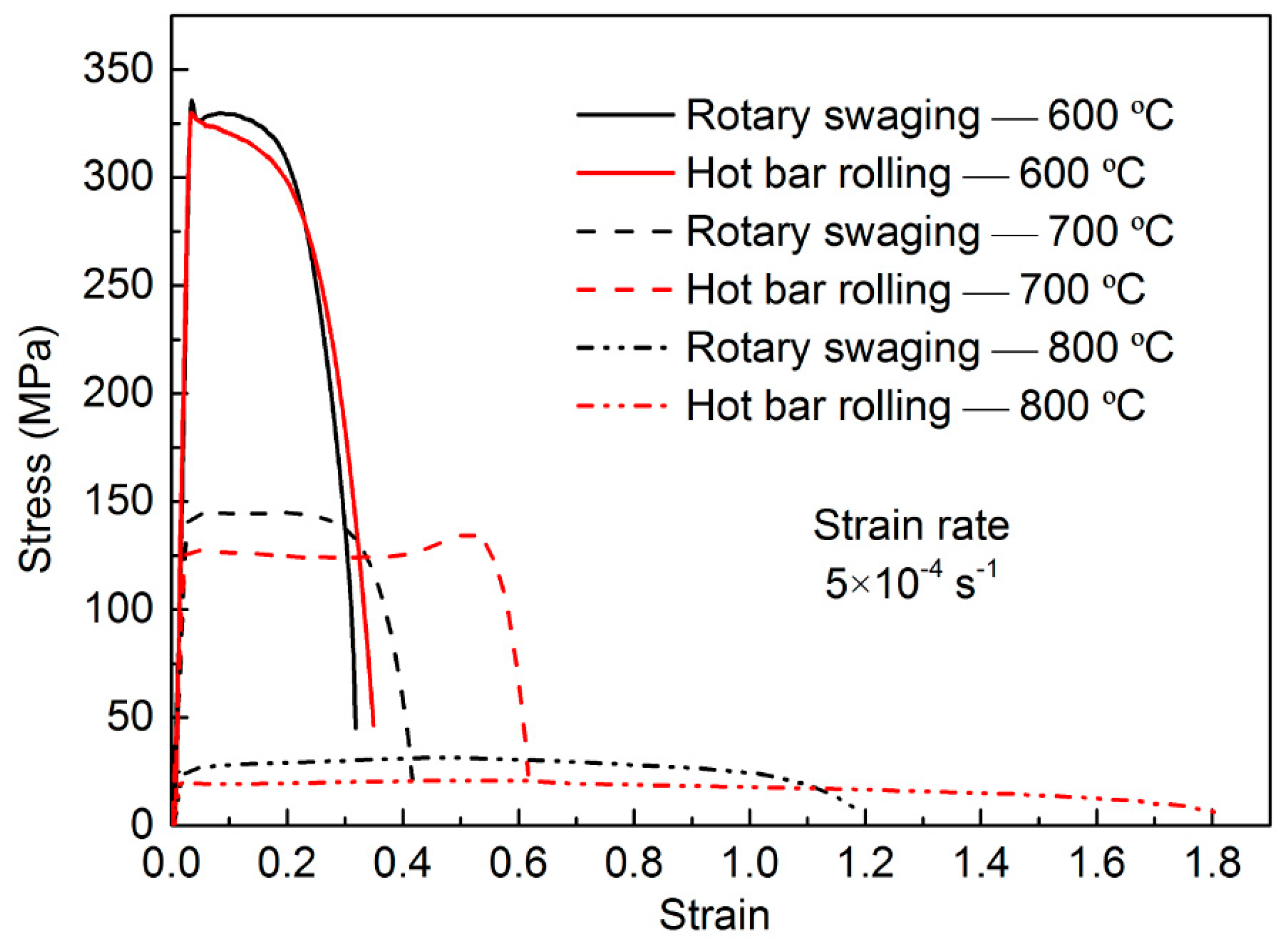

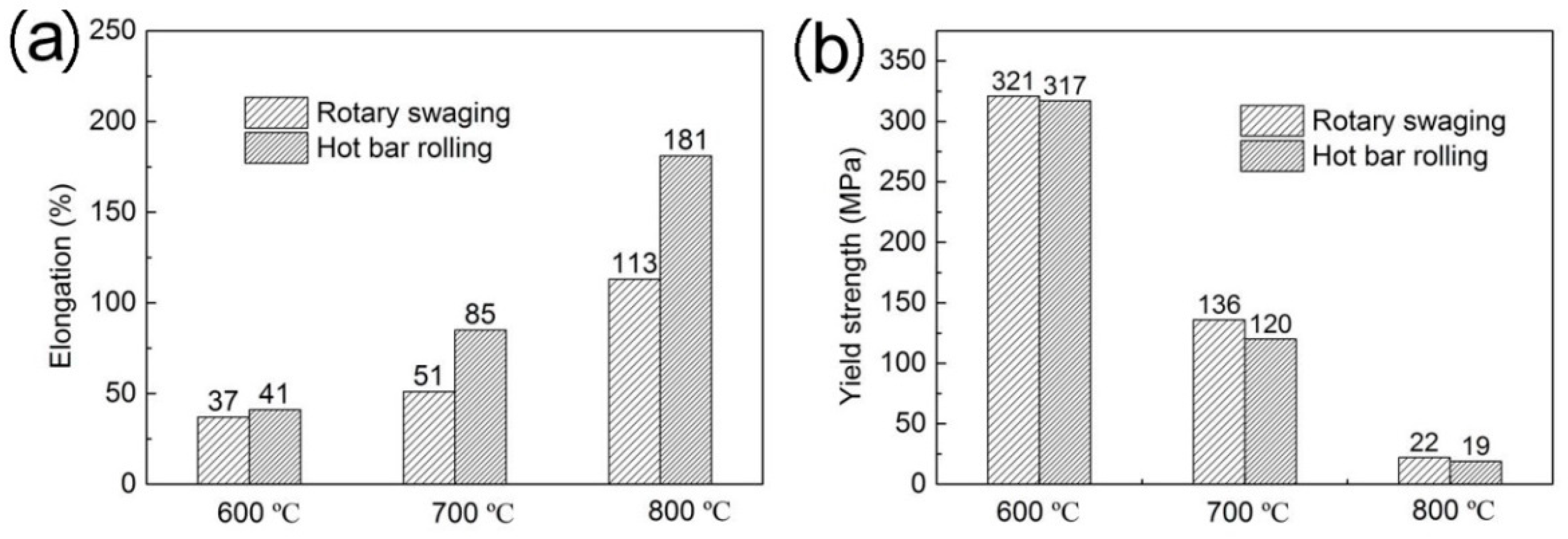

4.4. Mechanical Properties

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Arai, K.; Tsuya, N. Ribbon-form silicon-iron alloy containing around 6.5 percent silicon. IEEE. Trans. Magn. 1980, 16, 126–129. [Google Scholar] [CrossRef]

- Narita, K.; Teshima, N.; Mori, Y.; Enokizono, M. Recent researches on high silicon-iron alloys. IEEE. Trans. Magn. 1981, 17, 2857–2862. [Google Scholar] [CrossRef]

- Raviprasad, K.; Tenwick, M.; Davies, H.A.; Chattopadhyay, K. The nature of ordered structures in melt spun iron-silicon alloys. Scr. Metall. 1986, 20, 1265–1270. [Google Scholar] [CrossRef]

- Raviprasad, K.; Chattopadhyay, K. The influence of critical points and structure and microstructural evolution in iron rich Fe-Si alloys. Acta Metall. 1993, 41, 609–624. [Google Scholar] [CrossRef]

- Takada, Y.; Abe, M.; Masuda, S.; Inagaki, J. Commercial scale production of Fe-6.5 wt. % Si sheet and its magnetic properties. J. Appl. Phys. 1988, 64, 5367–5369. [Google Scholar] [CrossRef]

- Ros-Yanez, T.; Houbaert, Y.; Gómez Rodrı́guez, V. High-silicon steel produced by hot dipping and diffusion annealing. J. Appl. Phys. 2002, 91, 7857–7859. [Google Scholar] [CrossRef]

- He, X.D.; Li, X.; Sun, Y. Microstructure and magnetic properties of high silicon electrical steel produced by electron beam physical vapor deposition. J. Magn. Magn. Mater. 2008, 320, 217–221. [Google Scholar] [CrossRef]

- Machado, R.; Kasama, A.H.; Jorge, A.M.; Kiminami, C.S.; Fo, W.B.; Bolfarini, C. Evolution of the texture of spray-formed Fe-6.5 wt. % Si-1.0 wt. % Al alloy during warm-rolling. Mater. Sci. Eng. A 2007, 449–451, 854–857. [Google Scholar] [CrossRef]

- Lima, C.C.; Da Silva, M.C.A.; Sobral, M.D.C.; Coelho, R.E.; Bolfarini, C. Effects of order–disorder reactions on rapidly quenched Fe-6.5% Si alloy. J. Alloys Compd. 2014, 586, S314–S316. [Google Scholar] [CrossRef]

- Fish, G.E.; Chang, C.F.; Bye, R. Frequency dependence of core loss in rapidly quenched Fe-6.5 wt. % Si. J. Appl. Phys. 1988, 64, 5370–5372. [Google Scholar] [CrossRef]

- Liang, Y.F.; Wang, S.; Li, H.; Jiang, Y.M.; Ye, F. Fabrication of Fe-6.5 wt. % Si ribbons by melt spinning method on large scale. Adv. Mater. Sci. Eng. 2015, 2015, 1–5. [Google Scholar] [CrossRef]

- Wang, S.; Jiang, Y.M.; Liang, Y.F.; Ye, F.; Lin, J.P. Magnetic properties and core loss behavior of Fe-6.5 wt. % Si ribbons prepared by melt spinning. Adv. Mater. Sci. Eng. 2015, 2015, 1–6. [Google Scholar] [CrossRef]

- Li, R.; Shen, Q.; Zhang, L.; Zhang, T. Magnetic properties of high silicon iron sheet fabricated by direct powder rolling. J. Magn. Magn. Mater. 2004, 281, 135–139. [Google Scholar] [CrossRef]

- Liang, Y.F.; Ye, F.; Lin, J.P.; Wang, Y.L.; Chen, G.L. Effect of annealing temperature on magnetic properties of cold rolled high silicon steel thin sheet. J. Alloys Compd. 2010, 491, 268–270. [Google Scholar] [CrossRef]

- Patterson, E.E.; Field, D.P.; Zhang, Y. Characterization of twin boundaries in an Fe-17.5Mn-0.56C twinning induced plasticity steel. Mater. Charact. 2013, 85, 100–110. [Google Scholar] [CrossRef]

- Liang, Y.F.; Ye, F.; Lin, J.P.; Wang, Y.L.; Zhang, L.Q.; Chen, G.L. Effect of heat treatment on mechanical properties of heavily cold-rolled Fe-6.5 wt. % Si alloy sheet. Sci. China Technol. Sci. 2010, 53, 1008–1011. [Google Scholar] [CrossRef]

- Di Giulio, M. Transformer with Magnetic Core of Coiled Wires. International Patent Application No. WO 00/44006, 21 January 2000. [Google Scholar]

- Yang, W.; Li, H.; Yang, K.; Liang, Y.F.; Yang, J.; Ye, F. Hot drawn Fe-6.5 wt. %Si wires with good ductility. Mater. Sci. Eng. B 2014, 186, 79–82. [Google Scholar] [CrossRef]

- Lee, Y. Rod and Bar Rolling: Theory and Applications; CRC Press: Austin, TX, USA, 2004; ISBN 9780824756499. [Google Scholar]

- Liang, Y.F.; Lin, J.P.; Ye, F.; Li, Y.J.; Wang, Y.L.; Chen, G.L. Microstructure and mechanical properties of rapidly quenched Fe-6.5 wt. % Si alloy. J. Alloys Compd. 2010, 504, S476–S479. [Google Scholar] [CrossRef]

- Cheng, Z.Y.; Liu, J.; Zhu, J.C.; Xiang, Z.D.; Jia, J.; Bi, Y.J. Microstructure, texture evolution and magnetic properties of Fe-6.5 wt. %Si and Fe-6.5 wt. %Si-0.5 wt. %Cu alloys during rolling and annealing treatment. Metals 2018, 8, 144. [Google Scholar] [CrossRef]

- Said, A.; Lenard, J.G.; Ragab, A.R.; Elkhier, M.A. The temperature, roll force and roll torque during hot bar rolling. J. Mater. Process. Technol. 1999, 88, 147–153. [Google Scholar] [CrossRef]

- Kwon, H.C.; Im, Y.T. Interactive computer-aided-design system for roll pass and profile design in bar rolling. J. Mater. Process. Technol. 2002, 123, 399–405. [Google Scholar] [CrossRef]

- Song, R.B. The Technology of Rolling; Metallurgical Industry Press: Beijing, China, 2014; ISBN 978-7-5024-6506-3. [Google Scholar]

- Wen, S.B.; Han, C.Y.; Zhang, B.; Liang, Y.F.; Ye, F.; Lin, J.P. Flow behavior characteristics and processing map of Fe-6.5 wt. %Si alloys during hot compression. Metals 2018, 8, 186. [Google Scholar] [CrossRef]

- Zhang, H.; Li, H.; Yang, K.; Liang, Y.F.; Ye, F. Optimization of heat treatment process of Fe-6.5% Si sheet. Acta Metall. Sin. 2013, 49, 1445–1451. [Google Scholar] [CrossRef]

- Hölscher, M.; Raabe, D.; Lücke, K. Relationship between rolling textures and shear textures in fcc and bcc metals. Acta. Mater. 1994, 42, 879–886. [Google Scholar] [CrossRef]

- Dillamore, I.L.; Roberts, W.T. Rolling textures in fcc and bcc metals. Acta. Mater. 1964, 12, 281–293. [Google Scholar] [CrossRef]

- Dong, N.L. The evolution of recrystallization textures from deformation textures. Scr. Metall. Mater. 1994, 32, 1689–1694. [Google Scholar] [CrossRef]

- Li, K.; Yang, P. The formation of strong {100} texture by dynamic strain-induced boundary migration in hot compressed Ti-5Al-5Mo-5V-1Cr-1Fe alloy. Metals 2017, 7, 412. [Google Scholar] [CrossRef]

- Marcinkowski, M.J.; Brown, N. Direct observation of antiphase boundaries in the Fe3Al superlattice. J. Appl. Phys. 1962, 33, 537–552. [Google Scholar] [CrossRef]

- Yu, J.H.; Shin, J.S.; Bae, J.S.; Lee, Z.H.; Lee, T.D. The effect of heat treatments and Si contents on B2 ordering reaction in high-silicon steels. Mater. Sci. Eng. A 2001, 307, 29–34. [Google Scholar] [CrossRef]

- Jung, H.; Kim, J. Influence of cooling rate on iron loss behavior in 6.5 wt % grain-oriented silicon steel. J. Magn. Magn. Mater. 2014, 353, 76–81. [Google Scholar] [CrossRef]

- Li, H.; Liang, Y.F.; Yang, W.; Ye, F.; Lin, J.P.; Xie, J.X. Disordering induced work softening of Fe-6.5 wt. % Si alloy during warm deformation. Mater. Sci. Eng. A 2015, 628, 262–268. [Google Scholar] [CrossRef]

- Haghdadi, N.; Zarei-Hanzaki, A.; Farabi, E.; Cizek, P.; Beladi, H.; Hodgson, P.D. Strain rate dependence of ferrite dynamic restoration mechanism in a duplex low-density steel. Mater. Des. 2017, 132, 360–366. [Google Scholar] [CrossRef]

- Haghdadi, N.; Cizek, P.; Beladi, H.; Hodgson, P.D. A novel high-strain-rate ferrite dynamic softening mechanism facilitated by the interphase in the austenite/ferrite microstructure. Acta Mater. 2017, 126, 44–57. [Google Scholar] [CrossRef]

- Gourdet, S.; Montheillet, F. A model of continuous dynamic recrystallization. Acta Mater. 2003, 51, 2685–2699. [Google Scholar] [CrossRef]

- Callister, W.D., Jr.; Rethwisch, D.G. Fundamentals of Materials Science and Engineering: An Integrated Approach; John Wiley and Sons: Hoboken, NJ, USA, 2012; ISBN 0-471-39551-X. [Google Scholar]

- Yang, W. Fabrication and Properties of Wires of Fe-6.5% Si Electrical Steel. Master’s Thesis, University of Science and Technology, Beijing, China, 2013. [Google Scholar]

- Li, H.; Liang, Y.F.; Ye, F. Effect of heat treatment on ordered structures and mechanical properties of Fe-6.5 mass% Si alloy. Mater. Trans. 2015, 56, 759–765. [Google Scholar] [CrossRef]

| C | Si | Mn | S | P | Ti | B | Fe |

|---|---|---|---|---|---|---|---|

| 0.009 | 6.510 | 0.015 | 0.0009 | 0.054 | 0.005 | 0.0004 | Bal |

| Rolling Stage | Pass | Groove | Area (mm2) | Elongation Coefficient | Deformation Ratio |

|---|---|---|---|---|---|

| ‒ | 0 | Square | S0 = 576.0 | ‒ | ‒ |

| Rough rolling | 1 | Hexagon | S1 = 409.5 | μ1 = S0/S1 = 1.41 | L0/L1 = 41% |

| 2 | Square | S2 = 269.0 | μ2 = S1/S2 = 1.52 | L1/L3 = 52% | |

| 3 | Flat oval | S3 = 182.8 | μ3 = S2/S3 = 1.47 | L2/L3 = 47% | |

| 4 | Square | S4 = 136.9 | μ4 = S3/S4 = 1.33 | L3/L4 = 33% | |

| Medium rolling | 5 | Flat oval | S5 = 102.6 | μ5 = S4/S5 = 1.33 | L4/L5 = 33% |

| 6 | Square | S6 = 81 | μ6 = S5/S6 = 1.27 | L5/L6 = 27% | |

| 7 | Flat oval | S7 = 64.5 | μ7 = S6/S7 = 1.26 | L6/L7 = 26% | |

| 8 | Round | S8 = 56.7 | μ8 = S7/S8 = 1.14 | L7/L8 = 14% | |

| Finish rolling | 9 | Flat oval | S9 = 49.1 | μ9 = S8/S9 = 1.15 | L8/L9 = 15% |

| 10 | Round | S10 = 44.2 | μ10 = S9/S10 = 1.11 | L9/L10 = 11% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, S.; Xue, S.; Han, C.; Liu, B.; Liang, Y.; Ye, F. Fabrication Technology and Material Characterization of Hot Rolled Cylindrical Fe-6.5 wt. % Si Bars. Metals 2018, 8, 371. https://doi.org/10.3390/met8050371

Wen S, Xue S, Han C, Liu B, Liang Y, Ye F. Fabrication Technology and Material Characterization of Hot Rolled Cylindrical Fe-6.5 wt. % Si Bars. Metals. 2018; 8(5):371. https://doi.org/10.3390/met8050371

Chicago/Turabian StyleWen, Shibo, Shaowei Xue, Chaoyu Han, Binbin Liu, Yongfeng Liang, and Feng Ye. 2018. "Fabrication Technology and Material Characterization of Hot Rolled Cylindrical Fe-6.5 wt. % Si Bars" Metals 8, no. 5: 371. https://doi.org/10.3390/met8050371

APA StyleWen, S., Xue, S., Han, C., Liu, B., Liang, Y., & Ye, F. (2018). Fabrication Technology and Material Characterization of Hot Rolled Cylindrical Fe-6.5 wt. % Si Bars. Metals, 8(5), 371. https://doi.org/10.3390/met8050371