Microstructure and Mechanical Characterization of a Dissimilar Friction-Stir-Welded CuCrZr/CuNiCrSi Butt Joint

Abstract

:1. Introduction

2. Materials and Methods

2.1. Friction Stir Welding Process

2.2. Microstructural Characterization

2.3. Mechanical Testing

3. Results

3.1. Microstructure of Dissimilar CuCrZr/CuNiCrSi Butt Joints

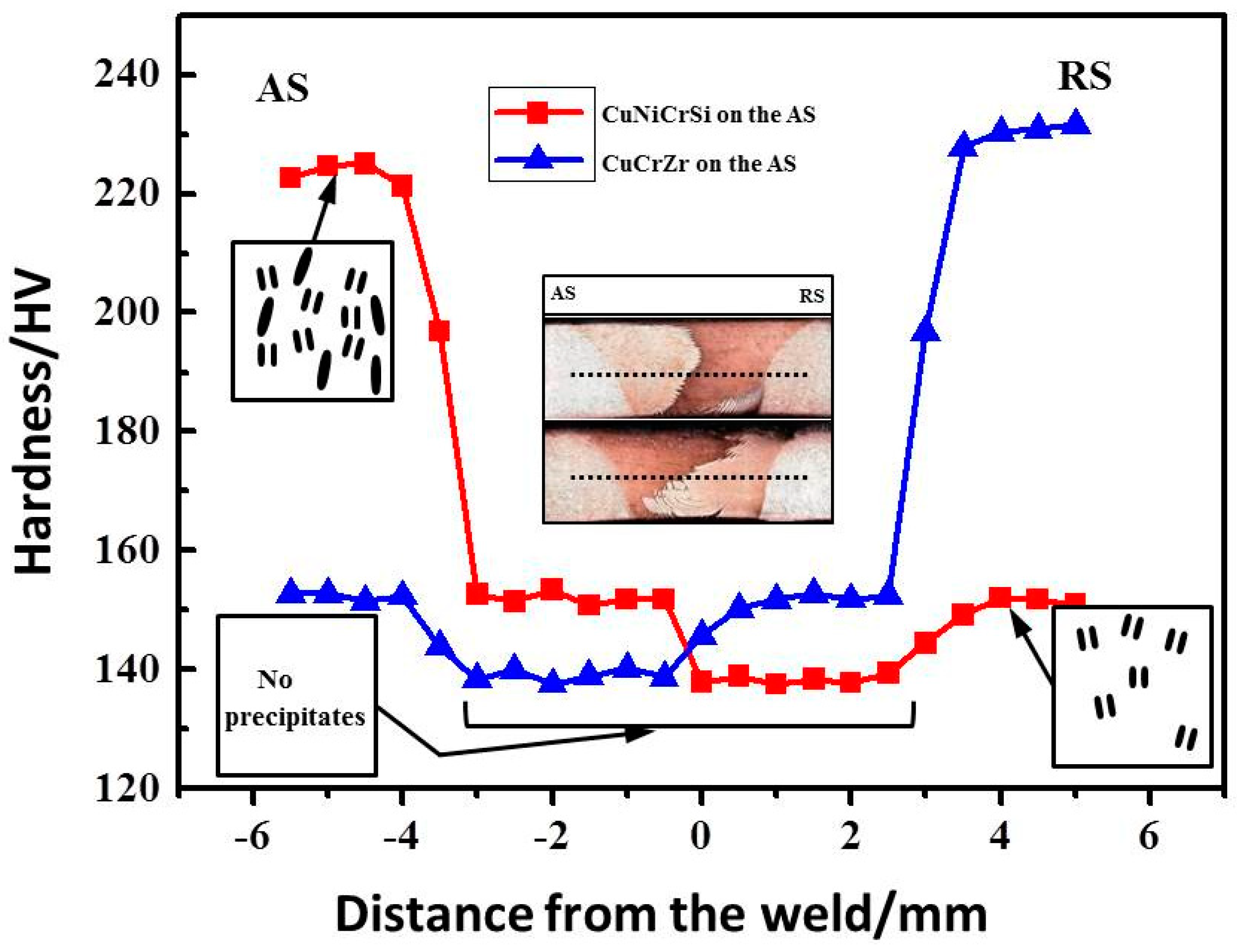

3.2. Mechanical Characterization of CuCrZr/CuNiCrSi Butt Joints

4. Discussion

4.1. The Analysis of Microstructure of Dissimilar CuCrZr/CuNiCrSi Butt Joints

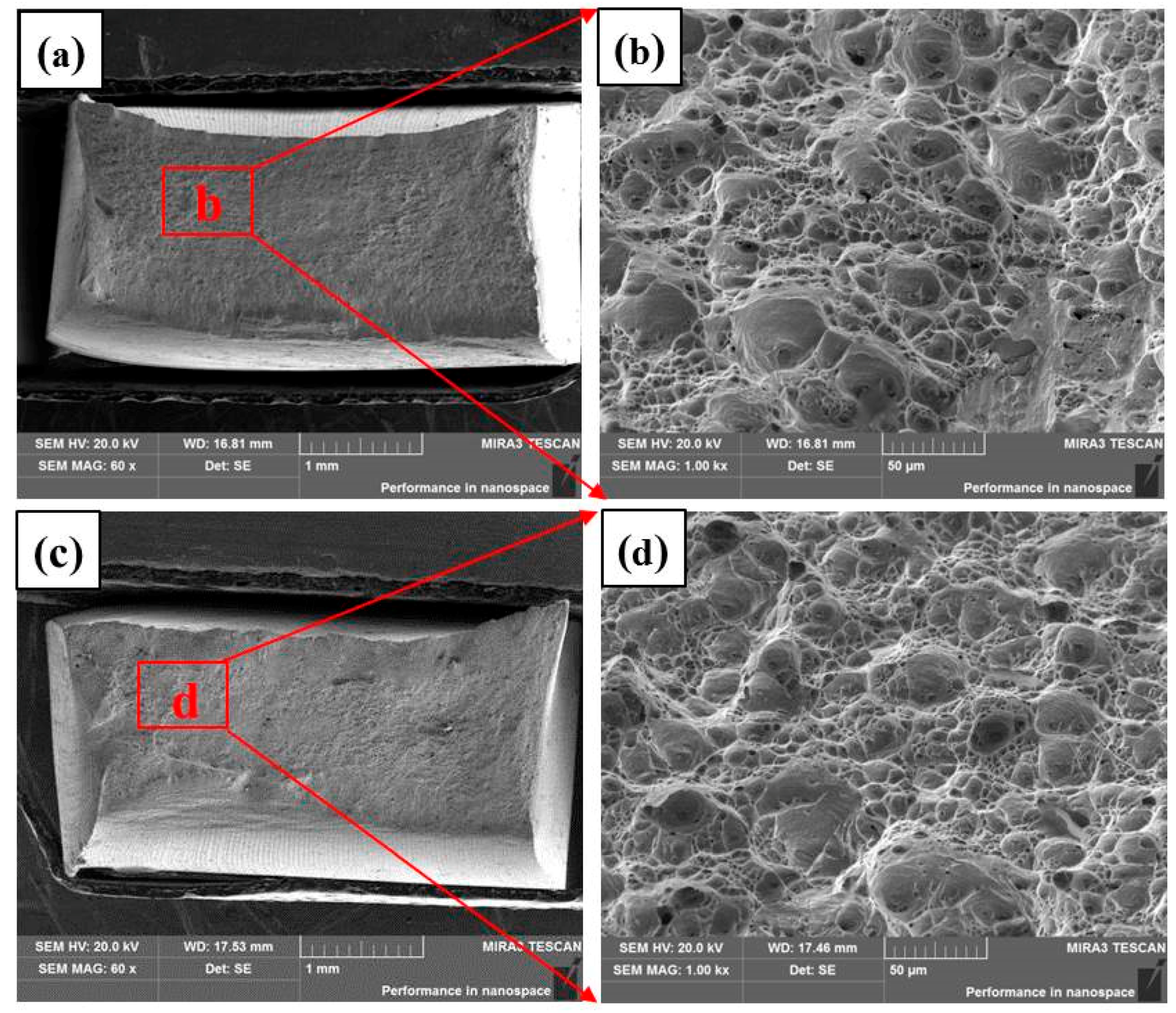

4.2. The Relationship of Microstructure and Mechanical Characterization

5. Conclusions

- (I)

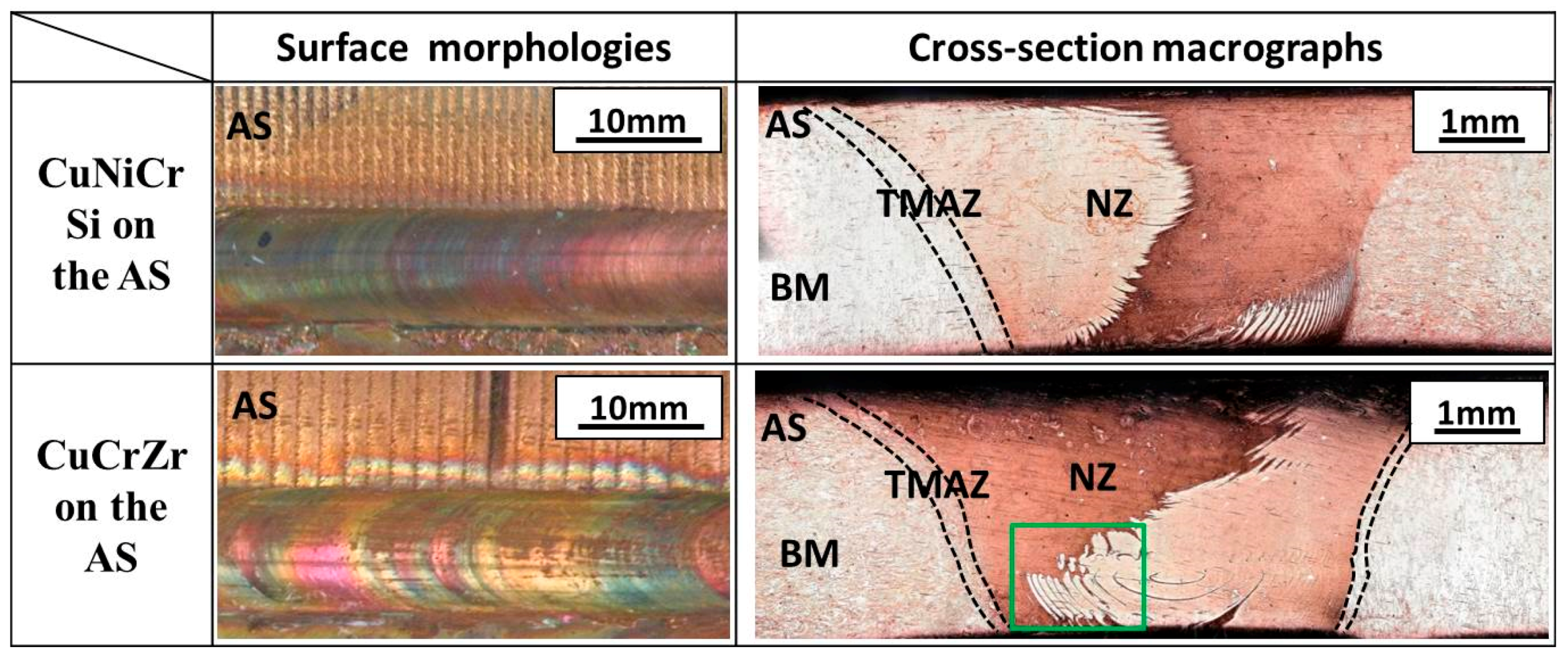

- Defect-free joints are obtained under the constant welding speed of 150 mm/min and constant rotational speeds of 1400 rpm. The area of retreating materials in the NZ is bigger when the CuCrZr alloy was placed on the AS.

- (II)

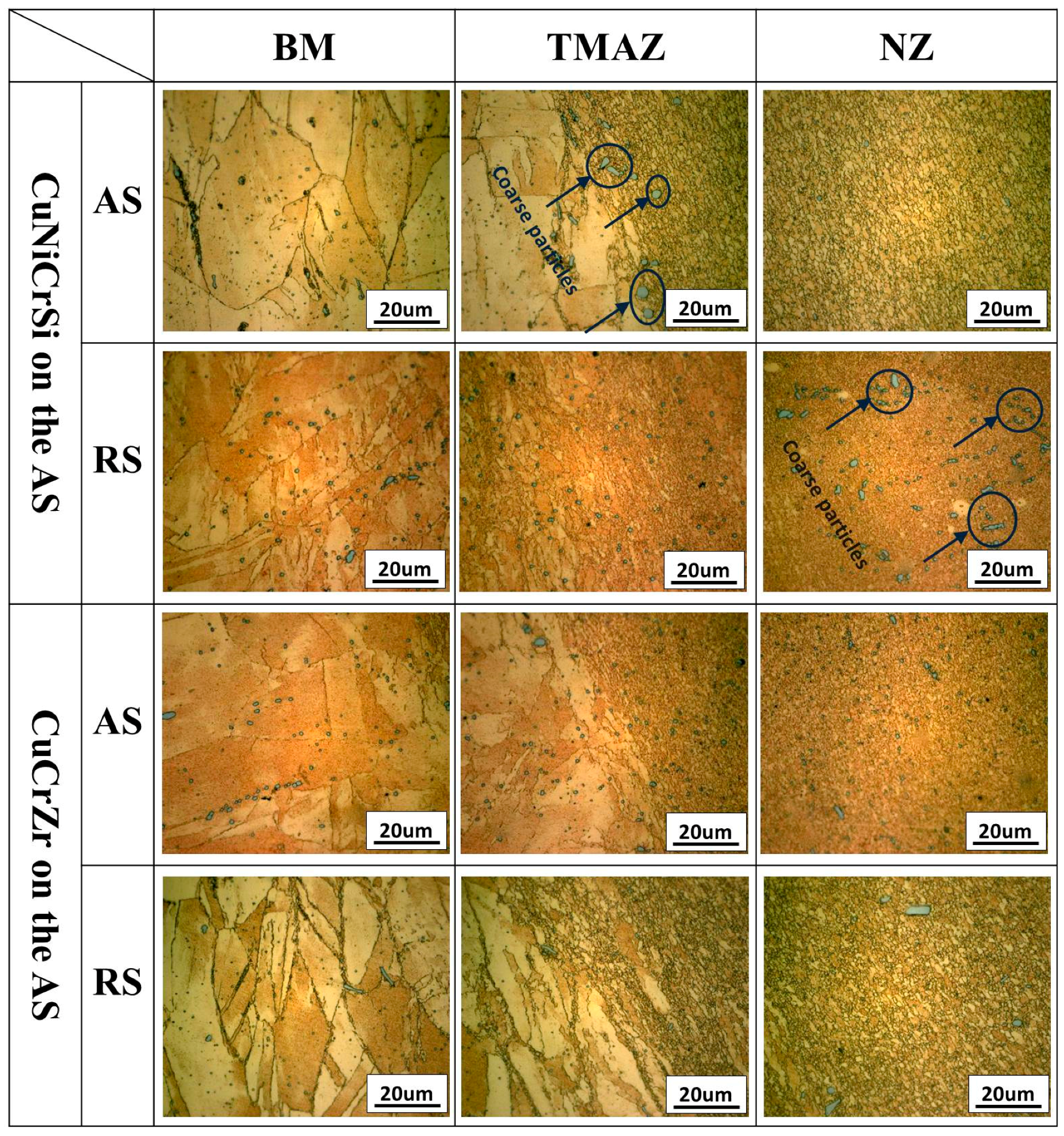

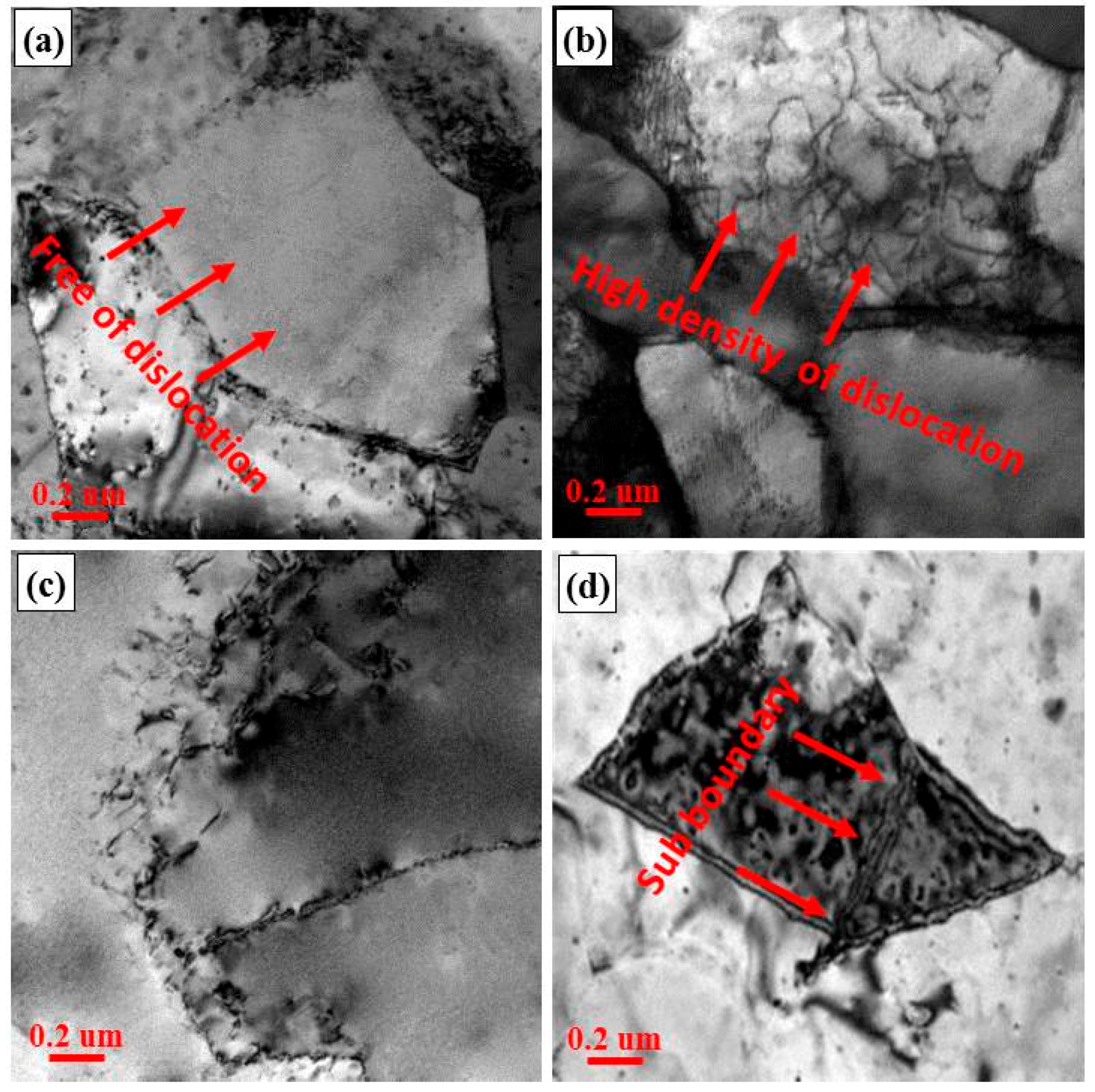

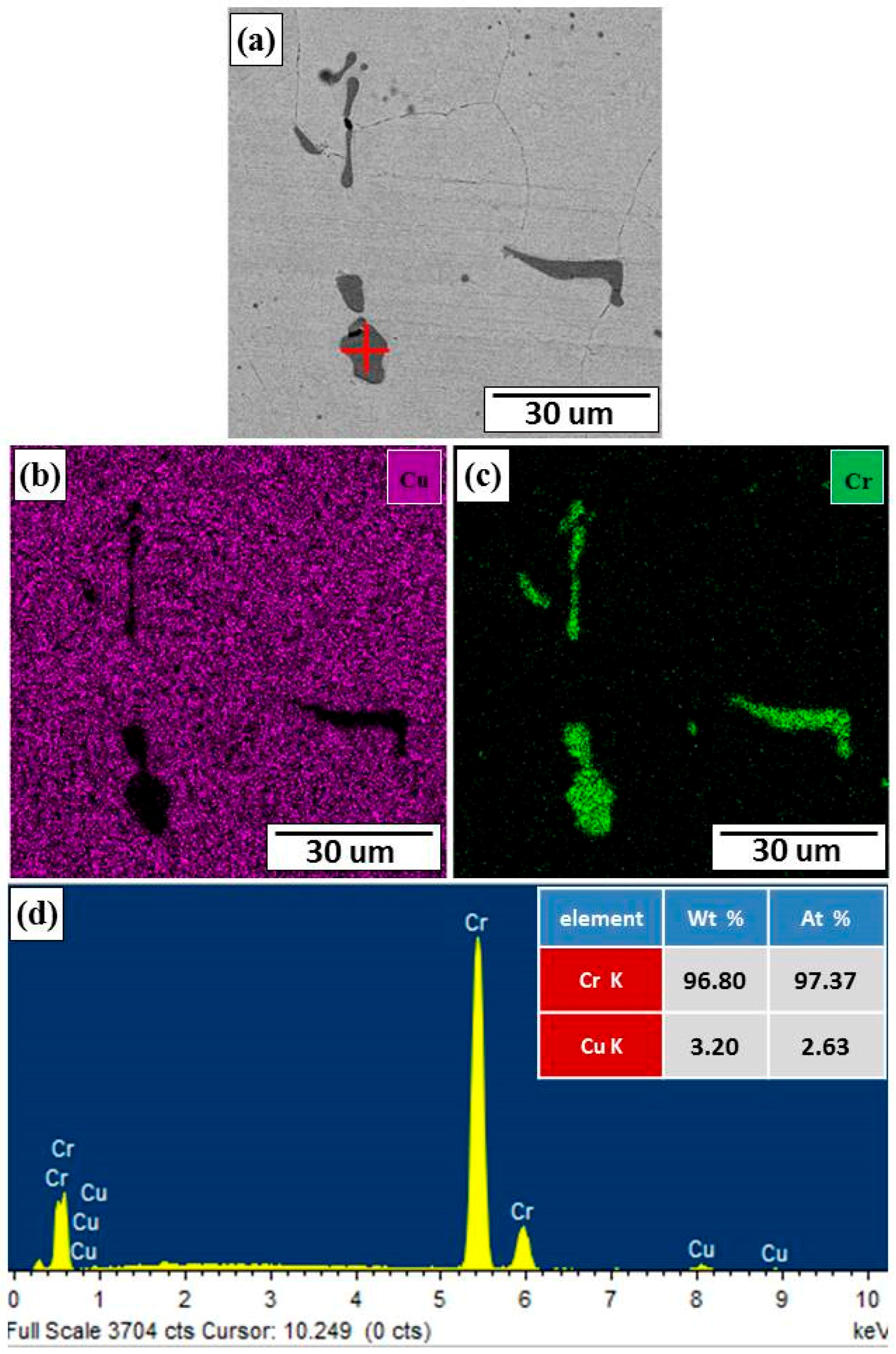

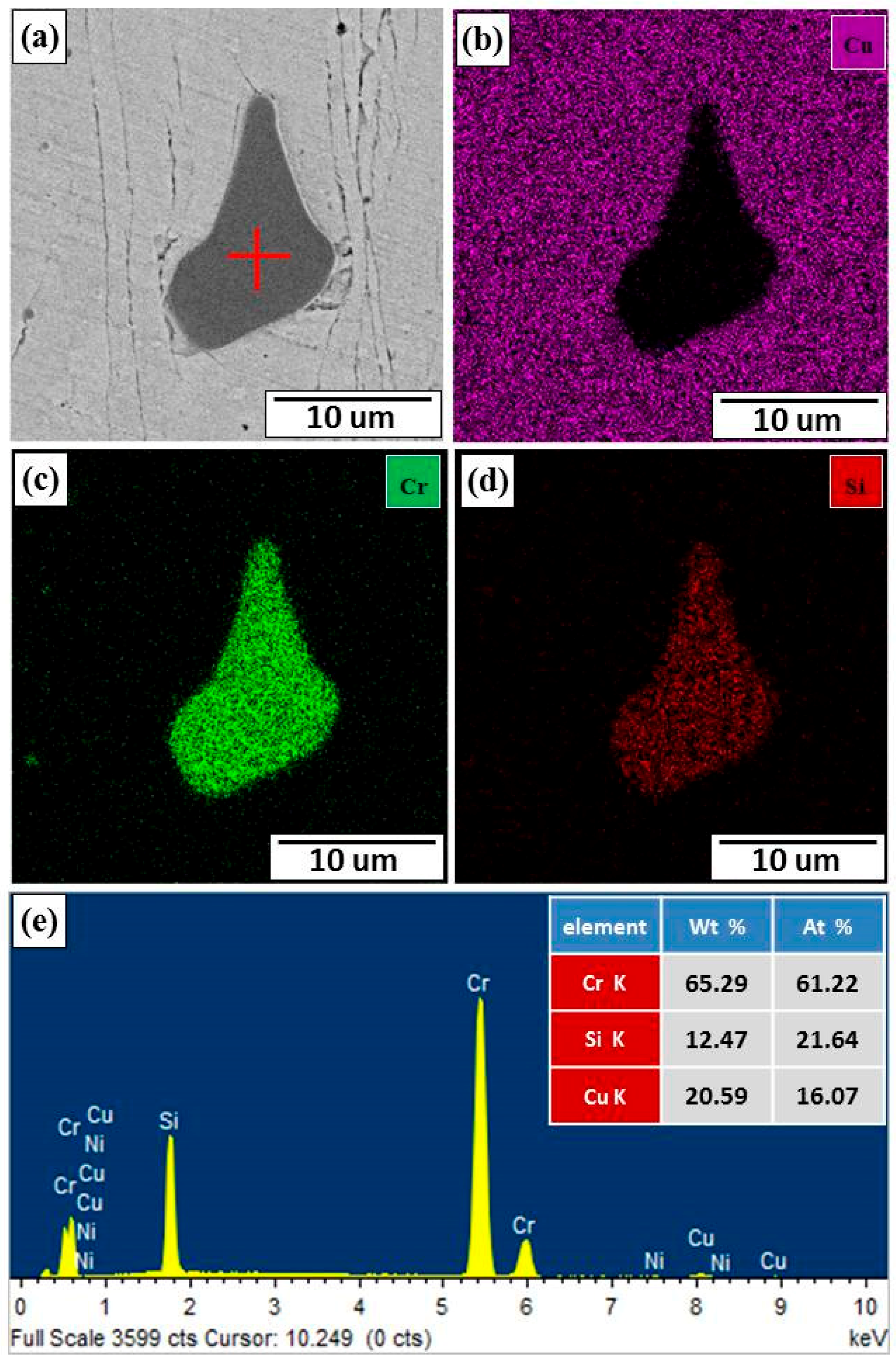

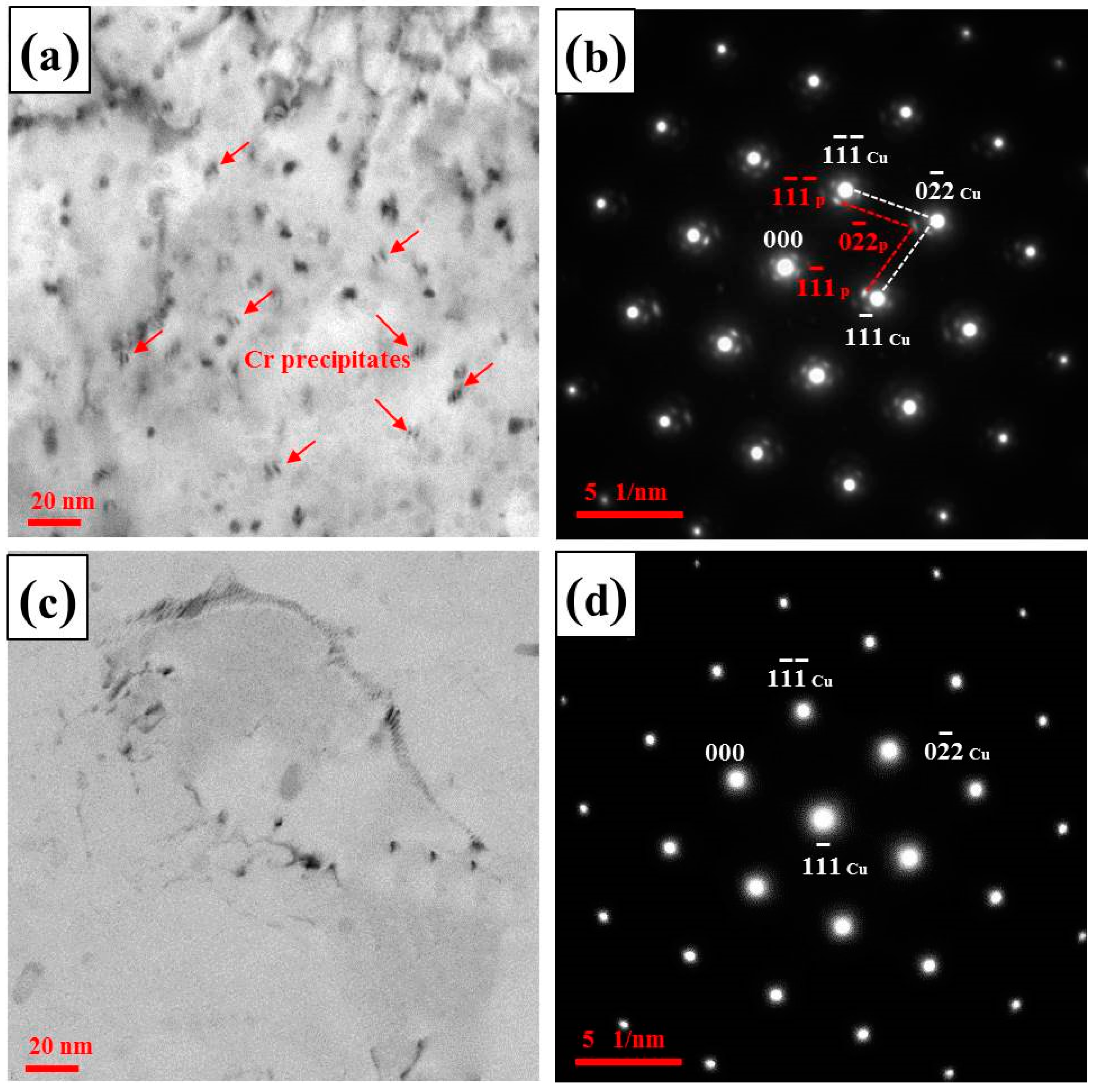

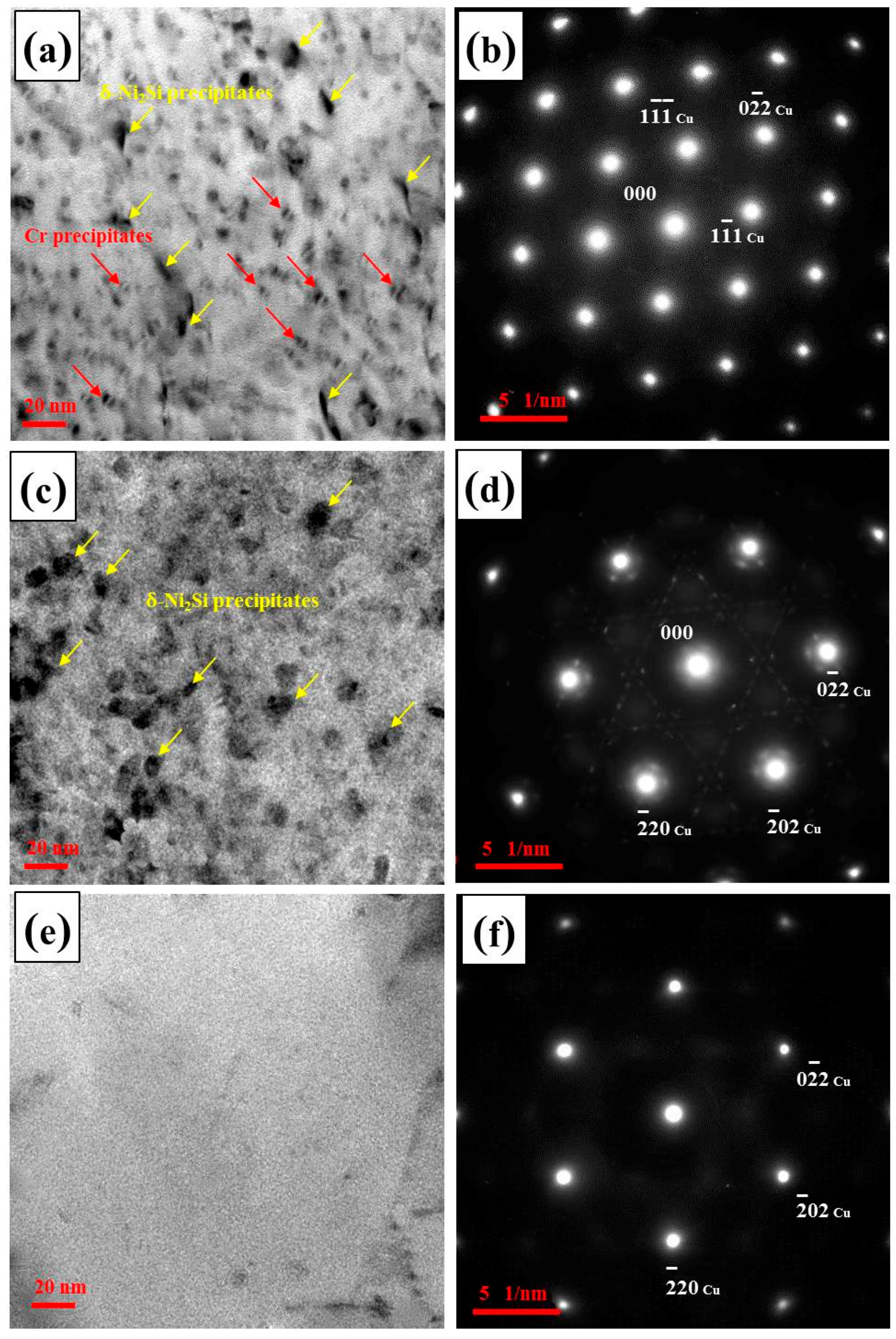

- Considerable numbers of coarse particles are found to distribute randomly in both BM and NZ. In CuCrZr-NZ, Cr solute-rich particles are detected, while concentration of Cr and Si element with larger density is found in CuNiCrSi-NZ.

- (III)

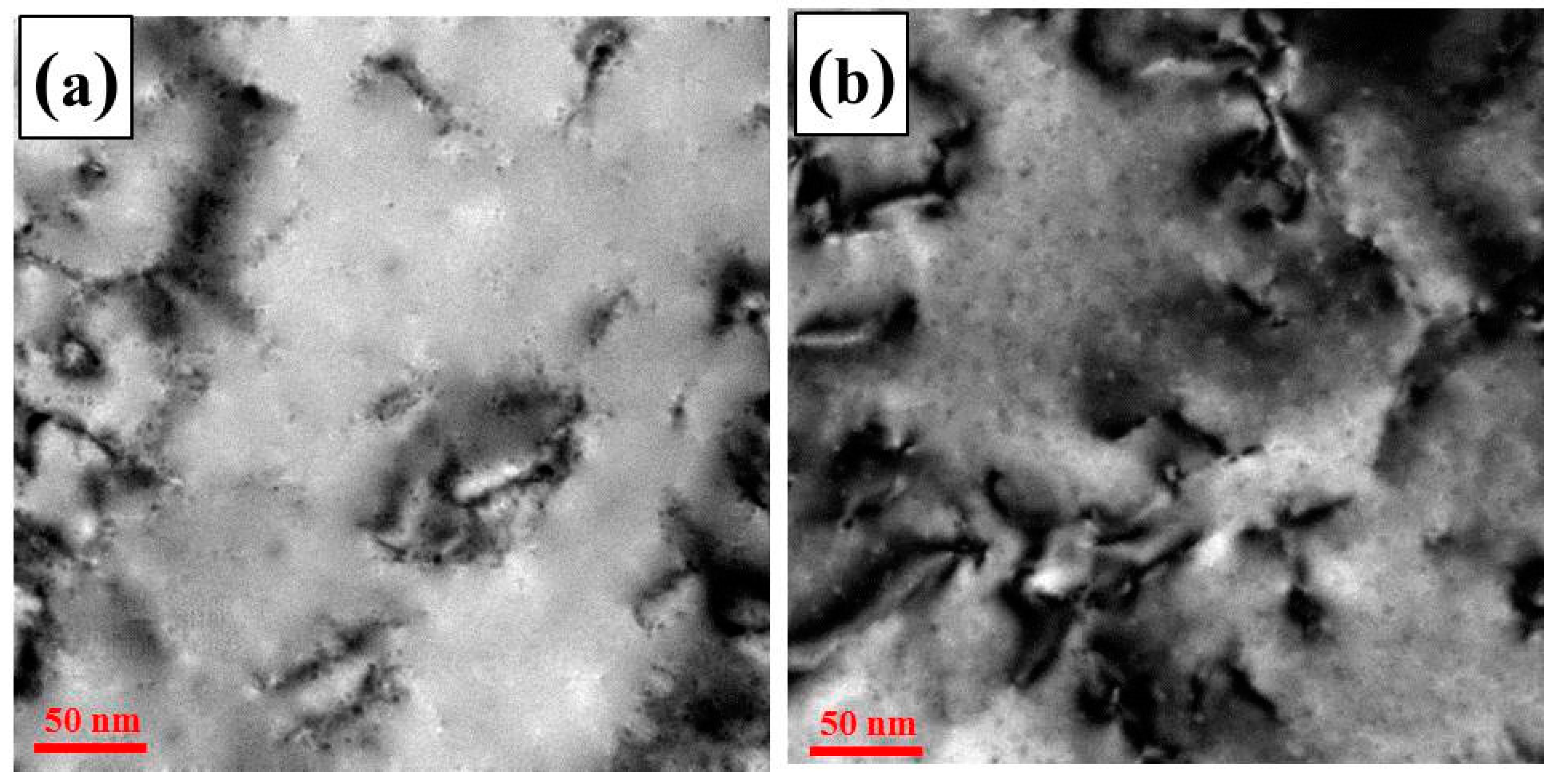

- The Cr and δ-Ni2Si precipitates are observed in CuNiCrSi-BM while only Cr precipitates are found in CuCrZr-BM. All these precipitates are dissolved in both CuCrZr-NZ and CuNiCrSi-NZ due to the high temperature, leading to the lower micro-hardness and tensile strength of joints when compared to base metals.

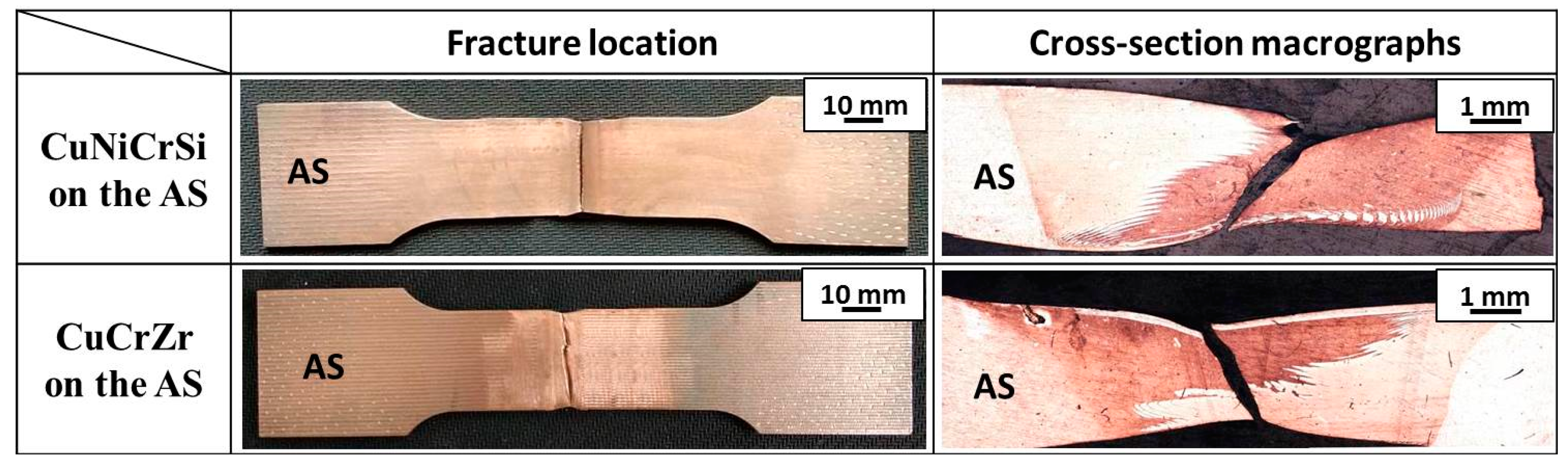

- (IV)

- When the CuNiCrSi alloy was located on the AS, the fracture occurred in the CuCrZr-NZ due to the existence of larger density of coarse particles. However, failure was found at the mixed zone of CuNiCrSi-NZ and CuCrZr-NZ when the CuCrZr alloy was located on AS.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mishnev, R.; Shakhova, I.; Belyakov, A.; Kaibyshev, R. Deformation microstructures, strengthening mechanisms, and electrical conductivity in a Cu-Cr-Zr alloy. Mater. Sci. Eng. A 2015, 629, 29–40. [Google Scholar] [CrossRef]

- Gholami, M.; Vesely, J.; Altenberger, I.; Kuhn, H.A.; Janecek, M.; Wollmann, M.; Wagner, L. Effects of microstructure on mechanical properties of CuNiSi alloys. J. Alloy. Compd. 2017, 696, 201–212. [Google Scholar] [CrossRef]

- Shueh, C.; Chan, C.K.; Chang, C.C.; Sheng, I.C. Investigation of vacuum properties of CuCrZr alloy for high-heat-load absorber. Nuclear Instrum. Methods Phys. Res. 2017, 841, 1–4. [Google Scholar] [CrossRef]

- Lipa, M.; Durocher, A.; Tivey, R.; Huber, T.; Schedler, B.; Weigert, J. The use of copper alloy CuCrZr as a structural material for actively cooled plasma facing and in vessel components. Fusion Eng. Des. 2005, 75, 469–473. [Google Scholar] [CrossRef]

- Zhang, L.J.; Bai, Q.L.; Ning, J.; Wang, A.; Yang, J.N.; Yin, X.Q.; Zhang, J.X. A comparative study on the microstructure and properties of copper joint between MIG welding and laser-MIG hybrid welding. Mater. Des. 2016, 110, 35–50. [Google Scholar] [CrossRef]

- Kanigalpula, P.K.C.; Pratihar, D.K.; Jha, M.N.; Derose, J.; Bapat, A.V.; Pal, A.R. Experimental investigations, input-output modeling and optimization for electron beam welding of Cu-Cr-Zr alloy plates. International J. Adv. Manuf. Technol. 2015, 85, 711–726. [Google Scholar] [CrossRef]

- Thomas, W.M.; Nicholas, E.; Needham, J.; Murch, M.; Temple-Smith, P.; Dawes, C. Improvements Relating to Friction Welding. Patent EP 0,653,265, 17 May 1995. [Google Scholar]

- Amarnath, V.; Karuppuswamy, P.; Balasubramanian, V. Comparative study of joining processes of high conductivity electrolytic tough pitch copper used in automotive industries. Int. J. Veh. Struct. Syst. 2017, 9, 1. [Google Scholar] [CrossRef]

- Lin, J.W.; Chang, H.C.; Wu, M.H. Comparison of mechanical properties of pure copper welded using friction stir welding and tungsten inert gas welding. J. Manuf. Process. 2014, 16, 296–304. [Google Scholar] [CrossRef]

- Mironov, S.; Inagaki, K.; Sato, Y.S.; Kokawa, H. Microstructural evolution of pure copper during friction-stir welding. Philos. Mag. 2015, 95, 367–381. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Saeid, T. Prediction of mechanical properties in friction stir welds of pure copper. Mater. Des. 2013, 52, 1077–1087. [Google Scholar] [CrossRef]

- Liu, H.J.; Shen, J.J.; Huang, Y.X.; Kuang, L.Y.; Liu, C.; Li, C. Effect of tool rotation rate on microstructure and mechanical properties of friction stir welded copper. Sci. Technol. Weld. Join. 2009, 14, 577–583. [Google Scholar] [CrossRef]

- Shen, J.J.; Liu, H.J.; Cui, F. Effect of welding speed on microstructure and mechanical properties of friction stir welded copper. Mater. Des. 2010, 31, 3937–3942. [Google Scholar] [CrossRef]

- Xue, P.; Xiao, B.L.; Zhang, Q.; Ma, Z.Y. Achieving friction stir welded pure copper joints with nearly equal strength to the parent metal via additional rapid cooling. Scr. Mater. 2011, 64, 1051–1054. [Google Scholar] [CrossRef]

- Sahlot, P.; Jha, K.; Dey, G.K.; Arora, A. Quantitative wear analysis of H13 steel tool during friction stir welding of Cu-0.8%Cr-0.1%Zr alloy. Wear 2017, 378–379, 82–89. [Google Scholar] [CrossRef]

- Jha, K.; Kumar, S.; Nachiket, K.; Bhanumurthy, K.; Dey, G.K. Friction Stir Welding (FSW) of Aged CuCrZr Alloy Plates. Metall. Mater. Trans. A 2018, 49, 223–234. [Google Scholar] [CrossRef]

- Lai, R.; He, D.; He, G.; Lin, J.; Sun, Y. Study of the Microstructure Evolution and Properties Response of a Friction-Stir-Welded Copper-Chromium-Zirconium Alloy. Metals 2017, 7, 381. [Google Scholar] [CrossRef]

- Akramifard, H.R.; Shamanian, M.; Sabbaghian, M.; Esmailzadeh, M. Microstructure and mechanical properties of Cu/SiC metal matrix composite fabricated via friction stir processing. Mater. Des. 2014, 54, 838–844. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, G.; Chen, Q.; Zhang, G.; Shi, Q. Simulation of material plastic flow driven by non-uniform friction force during friction stir welding and related defect prediction. Mater. Des. 2016, 108, 400–410. [Google Scholar] [CrossRef]

- Guo, J.F.; Chen, H.C.; Sun, C.N.; Bi, G.; Sun, Z.; Wei, J. Friction stir welding of dissimilar materials between AA6061 and AA7075 Al alloys effects of process parameters. Mater. Des. 2014, 56, 185–192. [Google Scholar] [CrossRef]

- Su, J.Q.; Nelson, T.W.; Mishra, R.; Mahoney, M. Microstructural investigation of friction stir welded 7050-T651 aluminium. Acta Mater. 2003, 51, 713–729. [Google Scholar] [CrossRef]

- Su, J.Q.; Nelson, T.W.; Sterling, C.J. Microstructure evolution during FSW/FSP of high strength aluminum alloys. Mater. Sci. Eng. A 2005, 405, 277–286. [Google Scholar] [CrossRef]

- Pang, Y.; Xia, C.; Wang, M.; Li, Z.; Xiao, Z.; Wei, H.; Sheng, X.; Jia, Y.; Chen, C. Effects of Zr and (Ni, Si) additions on properties and microstructure of Cu-Cr alloy. J. Alloy. Compd. 2014, 582, 786–792. [Google Scholar] [CrossRef]

- Holzwarth, U.; Pisoni, M.; Scholz, R.; Stamm, H.; Volcan, A. On the recovery of the physical and mechanical properties of a CuCrZr alloy subjected to heat treatments simulating the thermal cycle of hot isostatic pressing. J. Nuclear Mater. 2000, 279, 19–30. [Google Scholar] [CrossRef]

- Holzwarth, U.; Stamm, H. The precipitation behaviour of ITER-grade Cu-Cr-Zr alloy after simulating the thermal cycle of hot isostatic pressing. J. Nuclear Mater. 2000, 279, 31–45. [Google Scholar] [CrossRef]

- Lei, Q.; Xiao, Z.; Hu, W.; Derby, B.; Li, Z. Phase transformation behaviors and properties of a high strength Cu-Ni-Si alloy. Mater. Sci. Eng. A 2017, 697, 37–47. [Google Scholar] [CrossRef]

- Lockyer, S.A.; Noble, F.W. Precipitate structure in a Cu-Ni-Si alloy. J. Mater. Sci. 1994, 29, 218–226. [Google Scholar] [CrossRef]

- Sato, Y.S.; Kokawa, H.; Enomoto, M.; Jogan, S. Microstructural evolution of 6063 aluminum during friction-stir welding. Metall. Mater. Trans. A 1999, 30, 2429–2437. [Google Scholar] [CrossRef]

- Rhodes, C.G.; Mahoney, M.W.; Bingel, W.H.; Spurling, R.A.; Bampton, C.C. Effects of friction stir welding on microstructure of 7075 aluminum. Scr. Mater. 1997, 36, 69–75. [Google Scholar] [CrossRef]

| Alloy | Cu | Al | Mg | Cr | Ni | Zr | Fe | Si |

|---|---|---|---|---|---|---|---|---|

| CuCrZr | Bal | 0.25 | 0.1 | 0.8 | - | 0.3 | 0.09 | 0.04 |

| CuNiCrSi | Bal | - | - | 0.5 | 2.0 | - | ≤0.15 | 0.5 |

| Conditions | Grain Size/µm | |||

|---|---|---|---|---|

| CuNiCrSi-BM | CuNiCrSi-NZ | CuCrZr-BM | CuCrZr-NZ | |

| CuNiCrSi on the AS | 48 ± 2.5 | 1.5 ± 0.2 | 31 ± 4.1 | 0.8 ± 0.2 |

| CuCrZr on the AS | 47 ± 4.2 | 1.4 ± 0.5 | 30 ± 3.6 | 0.9 ± 0.3 |

| Conditions | UTS (MPa) | ε (%) | Failture Location |

|---|---|---|---|

| CuNiCrSi-BM | 725 ± 8 | 9.5 ± 1.1 | - |

| CuCrZr-BM | 550 ± 10 | 11.5 ± 0.6 | - |

| CuNiCrSi on the AS | 405 ± 7 | 25.0 ± 0.8 | CuCrZr-NZ |

| CuCrZr on the AS | 450 ± 8 | 24.3 ± 0.4 | Mixed zone |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; He, D.; Xue, F.; Lai, R.; He, G. Microstructure and Mechanical Characterization of a Dissimilar Friction-Stir-Welded CuCrZr/CuNiCrSi Butt Joint. Metals 2018, 8, 325. https://doi.org/10.3390/met8050325

Sun Y, He D, Xue F, Lai R, He G. Microstructure and Mechanical Characterization of a Dissimilar Friction-Stir-Welded CuCrZr/CuNiCrSi Butt Joint. Metals. 2018; 8(5):325. https://doi.org/10.3390/met8050325

Chicago/Turabian StyleSun, Youqing, Diqiu He, Fei Xue, Ruilin Lai, and Guoai He. 2018. "Microstructure and Mechanical Characterization of a Dissimilar Friction-Stir-Welded CuCrZr/CuNiCrSi Butt Joint" Metals 8, no. 5: 325. https://doi.org/10.3390/met8050325

APA StyleSun, Y., He, D., Xue, F., Lai, R., & He, G. (2018). Microstructure and Mechanical Characterization of a Dissimilar Friction-Stir-Welded CuCrZr/CuNiCrSi Butt Joint. Metals, 8(5), 325. https://doi.org/10.3390/met8050325