Abstract

Rigid perpetual joining of materials is one of the main demands in most of the manufacturing and assembling industries. AISI D2 cold work tool steels is commonly known as non-weldable metal that a high quality joint of this kind of material can be hardly achieved and almost impossible by conventional welding. In this study, a novel thixowelding technology was proposed for joining of AISI D2 tool steel. The effect of joining temperature, holding time and post-weld heat treatment on microstructural features and mechanical properties were also investigated. Acceptable joints without defect were achieved through the welding temperature of 1300 °C, while the welding at lower temperature resulted in a series of cracks across the entire joint that led to spontaneous fracture after joining. Tensile test results showed that maximum joint tensile strength of 271 MPa was achieved at 1300 °C and 10 min holding time, which was 35% of that of D2 base metal. Meanwhile, tensile strength of the joined parts after heat treatment showed a significant improvement over the non-heat treated condition with 560 MPa, i.e., about 70% of that of the strength value of the D2 base metal. This improvement in the tensile strength attributed to the dissolution of some amounts of eutectic chromium carbides and changes in the microstructure of the matrix. The joints are fractured at the diffusion zone, and the fracture exhibits a typical brittle characteristic. The present study successfully confirmed that by avoiding dendritic microstructure, as often resulted from the fusion welding, high joining quality components obtained in the semi-solid state. These results can be obtained without complex or additional apparatuses that are used in traditional joining process.

1. Introduction

Recently, AISI D2 tool steel get significant attention in the wide applications of industrial sector owing to its attractive properties. Unfortunately, a high-quality joint of this type of material can be hardly achieved and almost impossible by conventional welding methods owing to its high carbon and alloying elements content with an enormous amount of carbides. The existing fusion welding technique is the most commonly used process and has been widely practiced in industries. In this process, the welding is used with preheating and post-weld heat treatment (PWHT) to avoid solidification cracking and residual stresses that induced by the phase transformations throughout the welding. The most critical part in the process is the heat affected zone (HAZ), which can be very hard and brittle, along with susceptive to cracking if the tools are not heat-treated correctly.

In addition, fusion welding technologies are characterized by high temperature gradients that results in high thermal stresses and a fast solidification, which lead to the occurrence of segregation phenomena. Furthermore, the interface morphology is characteristically dendritic and the natural progression of solidification commonly leads to interior structural defects, such as shrinkage porosities and non-homogenous microstructure []. Therefore, an innovative route that can avoid the above mentioned problems inherent in fusion welding is required. Thixojoining is a possible technique that can weld the AISI D2 cold-work tool steel free from the above mentioned problems, as the process is carried at the semisolid state where the mechanisms of solidification and heat flow are different from other welding processes [,,].

During the last 30 years, several authors have shown that the thixojoining process has the potential to be used for a wide range of metal production processes. Notwithstanding some technical and technological differences between the available semi-solid joining processes, they can be classified into four categories: (1) joining metals by using semisolid slurries, (2) addition of functional features, (3) semisolid stir joining, and (4) semisolid diffusion joining [].

The first method involves the utilization of a thixotropic metal as filler applied into the joint groove for the purpose of joining materials. This kind of joining has the distinctive advantage of allowing a controlled flow during deposition process. Moreover, the applied temperatures and thermal gradients are considered smaller if compared with fusion welding. Earlier research work in the 1990s has demonstrated the feasibility of the process when Mendez and Brown used Sn-5 wt. % Pb as a filler and applied it on the joint groove to join bars of Sn-15 wt. % Pb model alloy. The microstructure of the joint cross-sectional area showed excellent metallurgical joining with the interface connection and smooth and homogeneous welding between the bars and filler metal without defects or adverse effects in the heating zone [].

Other researchers have more investigations in the field of semisolid joining revealed the possibility of producing prototype components by combining the forming operation with the simultaneous insertion of additional components []. One special approach that takes advantage of the material’s high flowability is the addition of functional features to a forged part. With this technology, it is possible to shorten conventional process chains and to create a new generation of components. Kiuchi et al. [] studied the possibility of joining aluminum with aluminum and steel alloys. They found that thixojoining of simple insert shape with bulk material is promising approach. With decreasing of liquid fraction, there was increasing in joint strength. This clarifies the significant merits compared with conventional casting due to formation of intermetallic compounds and diffusion between base and insert materials. The big challenge of improvement this technique for other materials is accessible inserting component in mushy matrix with destruction of joint geometry by remelting or deformation.

Further investigations in Semisolid stir joining (SSSJ) showed the applicability of this type of joining process to improve and overcome the difficulties accompanied with current joining techniques which were based on friction stir welding. Recently, there was trend toward carrying out a vacuum-free SSSJ process that enables using low joining temperature when applied to a semisolid base or filler metal. Hosseini et al. [] have also carried out extensive experiments on semisolid stir joining (SSSJ) for AZ91 alloy by using mechanical stirring and a Mg-25 wt. % Zn interlayer. The results showed the significant effect of mechanical stirring rate on the joint-strength. This supposes that the formed oxide layer has been disrupted due to stirring effect and consequently improve metallurgical bonds. They claimed that this method can be used as an alternative joining for Mg-based alloys.

More investigations to achieve joint with high-quality globular structure were undertaken by Mohammed et al. [,,] in semisolid diffusion joining (SSDJ). Their research explored the possibilities of joining semisolid AISI D2 tool steel with functional elements of the same material as well as with other materials such as AISI 304 stainless steel by using a peculiar characteristic of the metals’ liquid components. In their proposed method, when the interfaces of two metals are pasted together, the liquid components present in both sides of these “semisolid metals” penetrate and diffuse through the interface and then solidify together as one body. The experimental results showed that, the use of this technique can make homogeneous properties with high surface quality without any evidence of porosity or microcracking.

The semisolid metal joining (SSMJ) process can be used for processing different net near net shape components with complicated shape and geometries where other joining processes cannot be utilized for many reasons such as: low melting temperature, poor mechanical properties, and insufficient plastic deformation. Several applications have been considered based on this new joining method like heating radiator components, car shock absorber, slider system components and roller way elements. In addition, this joining technology can be used for joining craft glass and stones to plates and bars with different shapes. The products can be utilized in decoration various wall plates and floor panels. Furthermore, metal/glass joining products have great capabilities to add other functional properties to materials to produce lubricated, corrosion-proof, antiwear or heatresistant items [].

The thixojoining is new semi-solid-based process that should take their place among other joining processes. Nevertheless, it takes little considerations by researcher and investigators. This new specific area needs continuous studies and works to overcome the related problem and propose solutions and suggestions especially for high grade alloys and materials. In this work, the thixowelding process was applied to join AISI D2 cold work tool steels by using a direct partial remelting method (DPRM) method. The objectives of the present research are to study the microstructure evolution and mechanical properties of the joints under different welding conditions.

2. Experimental Section

2.1. Materials and Sample Preparation

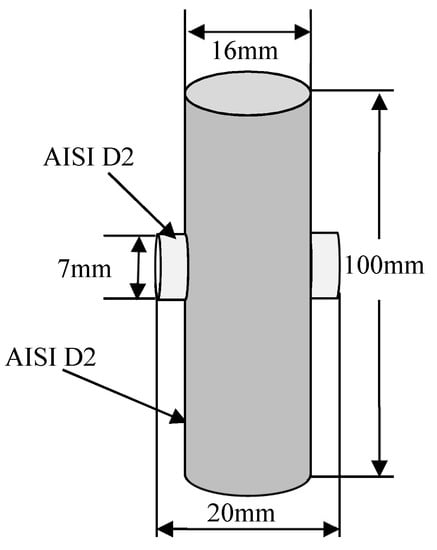

AISI D2 cold-work tool steel used in this study which was supplied after a soft annealing process, i.e., heating to 850 °C followed by cooling at 10 °C/h to 650 °C and finally air cooling. The chemical composition of the studied AISI D2 cold-work tool steel was determined by using X-ray fluorescence (XRF) (S8 TIGER ECO, Bruker, Karlsruhe, Germany) as shown in Table 1. The base blank of AISI D2 was cut Ø 16× 100 mm while the length of the pin insert was 18 mm with diameter of 7 mm as shown in Figure 1. Each specimen was disposed of rust and scale by submerging in pickling solution, washed with acetone, and finally rinsed using distilled water.

Table 1.

Chemical composition of AISI D2 cold-work tool steel (in Weight Percent).

Figure 1.

Schematic drawing of the AISI D2 parts combination.

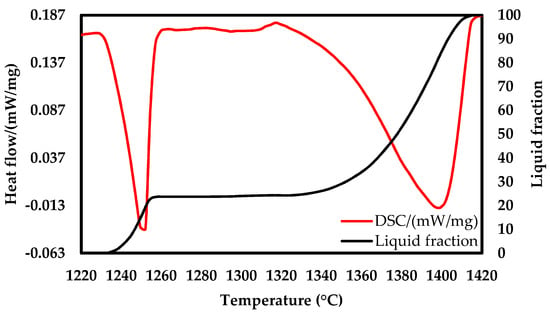

The temperatures of liquidus and solidus, in addition to liquid fraction, were estimated by carrying out differential scanning calorimetry test (DSC). Small pieces samples (less than 20 mg) were cut from the as-received material for testing with The Netzsch-STA 449 F3 simultaneous thermogravimeter (TGA-DSC) (STA 449F3, NETZSCH, Bavaria, Germany). The samples were heated at a rate of 10 °C/min in nitrogen atmosphere to prevent oxidation. The common tangent procedure is adopted to estimate the liquid fraction. Finding out the fraction of liquid was done by integrating of partial areas under the heating curves as shown in Figure 2.

Figure 2.

Liquid fraction vs. temperature and heating flow vs temperature curves of the AISI D2 tool steel calculated by differential scanning calorimetry (DSC).

2.2. Thixo Welding Process

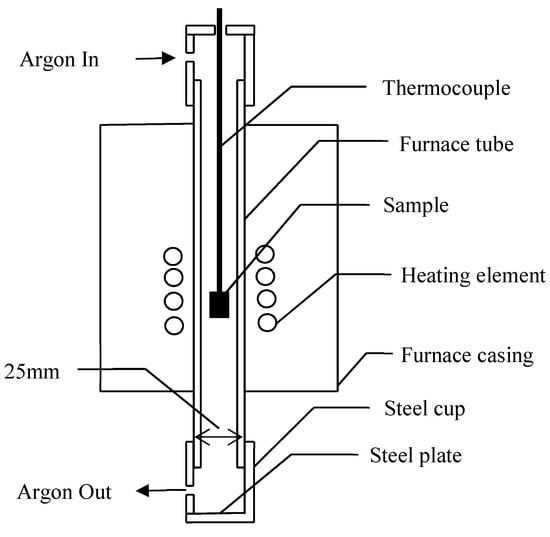

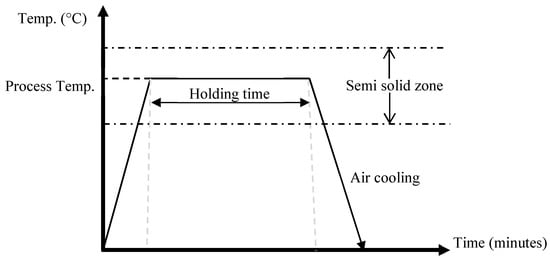

High temperature carbolite furnace was utilised to carry out the thixo welding of AISI D2 tool steel as shown in Figure 3. The furnace is vertical type and protected with argon gas. The moment that furnace reached the pre-selected temperature (1250, 1275, and 1300 °C), the sample was lowered into the furnace by use chromehromel wire for 0, 5 and 10 min respectively then it was allowed to cool slowly at room temperature as shown in Figure 4. To investigate the influence of post welding heat treatment on the microstructure and mechanical properties of the welded plates, specimens were heat treated by heating the specimens to 850–900 °C followed by slow rates of furnace cooling (22 °C/h), when a steel cools to 650 °C, air cooling can be used to bring the steel to room temperature.

Figure 3.

Schematic drawing of the furnace set-up.

Figure 4.

Temperature profile of direct partial remelting experiment.

2.3. Metallography

The thixowelded joint samples were polished and then etched by using Villela reagent (1 g picric acid, 5 mL hydrochloric acid, and 95 mL ethyl alcohol) to reveal their microstructures. The microstructures of the joints were characterized by Optics microscopy (BX51-P, Olympus, Tokyo, Japan), scanning electron microscopy (SEM) (LEO 1455 VP SEM, Zeiss, Oberkochen, Germany) equipped with energy dispersive X-ray spectroscopy (EDX) (Oxford 7353, Oxford Instruments, Wiesbaden, Germany). X-ray diffraction (XRD) (Bruker D8 Discover, Bruker, Karlsruhe, Germany) analyses were carried out to analyze the phases present in the steel specimen before and after the thixojoining. It also gives an idea about the characteristics of joints and if there is any harmful phase or brittle phase have formed during thixojoining.

2.4. Test of Mechanical Properties

The mechanical characterization of the joints was measured using tensile strength and hardness tests. The tensile tests were carried out on using Zwick universal testing machine (ProLine Z005/Z100, Zwick, Ulm, Germany) with a cross-head speed of 0.5 mm/min at room temperature according to ASTM E8M Standards. The fracture morphologies of failed specimens were then observed by scanning electron microscopy (SEM). Vickers micro-hardness testing (FH5, Tinius Olsen, Horsham, PA, USA) was performed on the polished specimens of the transverse section of joints as well as the base material and insert to compare the phases present in the joint and the joining parameters on the base metal. The profiles of micro-hardness were constructed across the sample’s horizontal section of the D2 tool steel base metal, the weld zone and the insert by using a load of 10 g for 30 s along the lines perpendicular to the joint interface. Hardness measurements were carried out by using Vickers micro-hardness tester FH5.

3. Results and Discussion

3.1. Microstructure and Joint Quality

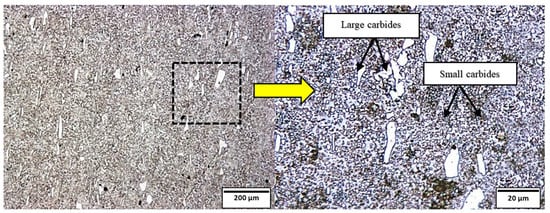

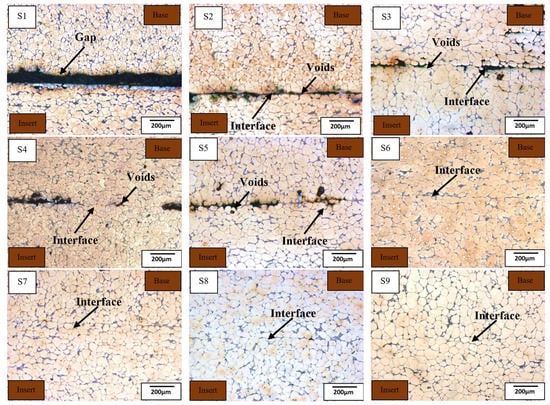

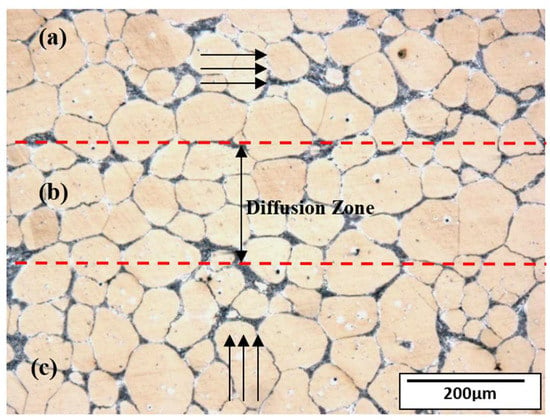

The microstructure of as-received AISI D2 consists of ferritic matrix parallel to working direction in which different surplus of large-coarse and fine carbides are distributed as shown in Figure 5. The revealed microstructure refers to annealed tool steel [] and indicates that the heat treatment was carried out as recommended. The optical microscopy examination performed on the welded joints at various conditions is shown in Figure 6. From the complete weld section at 1250 °C heating temperature with 0, 5 and 10 min holding time, large gap can been seen and big cracks at the joint interface can be observed. With the increase of welding temperature to 1275 °C with 0 and 5 min holding time, a series of cracks resulted and the weld seam could not be well joined, as shown in Figure 6S4,S5. In addition, big fractures across the entire joint were shown with little and local interactions were lactated at different zones in the interface resulting in spontaneous fracture after joining. However, when the holding time is adequate (10 min) the weldability is relatively good and there is no macroscopic voids and fractures across the entire joint which is occupied by eutectic liquid, as shown in Figure 6S6. Meanwhile, by further increasing the welding temperature to 1300 °C, strong thixojoint can be produced. Further, fine and small boundary can be observed as transition zone between two alloys. No presence of porosity and micro-cracking at this zone and the joint shape was smooth and not corrugated, as shown in Figure 6S7–S9. The thixoweld joint was characterised by visible full penetration that indicate perfect thixojoning between base blank and the insert along the bounding border. Higher amount of the interfacial reactions has been produced between two base metals []. The structure is distinguished by two features that can be determined by grain direction, as illustrated in arrows direction in Figure 7. The direction of the grains are in bands in the forming direction and as a single pin of AISI D2 was inserted perpendicular into a base blank of AISI D2 to illustrate two distinct features. The interfacial reactions during heating have accelerated the diffusion of elements through the interface and propagated the eutectic liquid across the joined surfaces that resulted in good thixojoint of the interface at both side of steels.

Figure 5.

Optical microstructure of as received AISI D2 tool steel.

Figure 6.

Microstructure of the thixojoined samples processed at different conditions: (S1) 1250 °C/0 min, (S2) 1250 C/5 min, (S3) 1250 °C/10 min, (S4) 1275 °C/0 min, (S5) 1275 °C/5 min, (S6) 1275 °C/10 min, (S7) 1300 °C/0 min, (S8) 1300 °C/5 min, (S9) 1300 °C/10 min.

Figure 7.

Microstructure of thixo-weld-joint of (a) base metal, (b) diffusion zone (c) insert, after subjecting to 1300 °C heating temperature for 10 min.

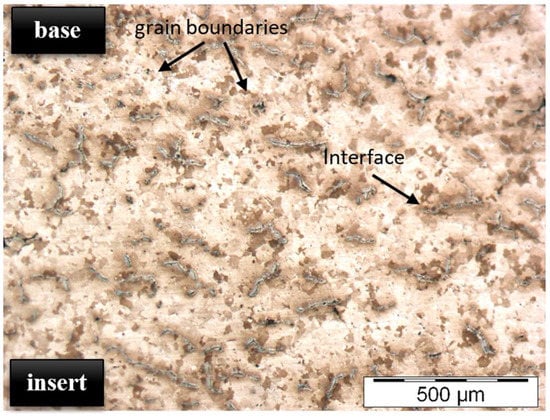

Additionally, the properties of the thixojoining can be improved by subsequent heat- treatment. It is clearly visible that the changes in the microstructure patterns of the thixojoining occur after the heat treatment as shown in Figure 8. It is obviously to see that the primary distribution of grain boundary is decreased substantially and some amounts of eutectic carbides dissolve in the matrix. It means that the primary grain boundaries have distinctly pinning effect on growth of grain size in the heat treated condition []. The heat treated structures of the thixojoined parts only show improved contrast between solid and liquid phases, whereby the big solids appeared in little liquid matrix.

Figure 8.

Microstructure of thixojoint parts after application of 1300 °C for 10 min and subjected to heat treatment.

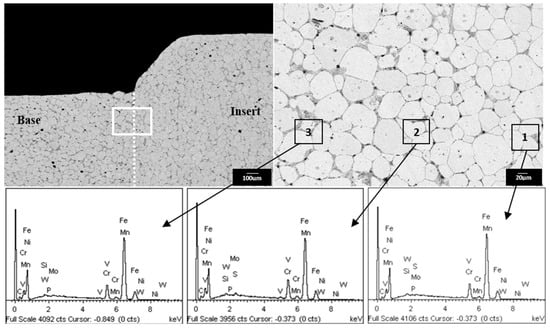

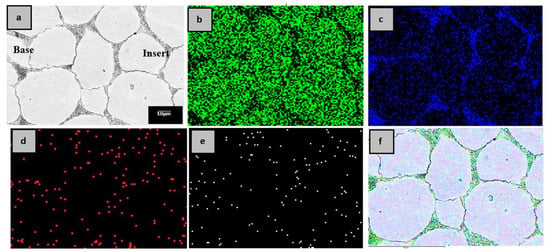

The samples were also examined using SEM in order to get a complete assessment if there is any harmful or brittle phase have formed during thixojoining. Figure 9 shows the Scanning electron images of the microstructures of the thixojoint parts and the EDS spectra corresponding to the analyzed phases. While, SEM-EDX elemental mapping techniques was also performed on both sides at the periphery of the joint in order to determine the composition of the region near the diffusion zone of the joined part, as shown in Figure 10. Regarding to Figure 9 and Figure 10, the EDX results confirm that the contact area was identical in microstructure, composition, and properties with the base and insert. On the basis of element distribution, it can be deduced that the both sides at the periphery of the joint display a uniform and homogeneous distribution in the structure due thermal diffusion driving force []. Along with this result, it was observed that the intermetallic compounds were not incorporated into the joining region, providing further evidence of the reliability of this process.

Figure 9.

SEM micrographs of thixojoined part at 1300 °C with EDX of point (1) for base metal, (2) for diffusion area and (3) for insert.

Figure 10.

SEM-EDX elemental mapping of thixojoined part at 1300 °C of results near joint: (a) SEM micrograph, (b) Fe, (c) Cr, (d) C, (e) V, (f) all four elements.

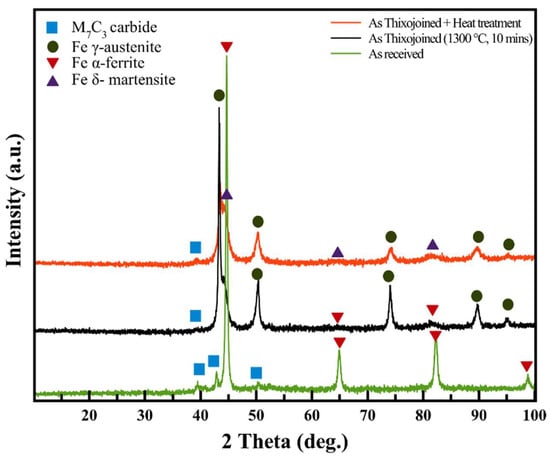

X-ray diffraction test has been carried out for more characterisation of thixojoint as displayed in Figure 11. The analysis of the diffraction patterns of as-received tool steel found peaks corresponding to the ferrite phase and iron-chromium carbide (M7C3). From the other side, the thixoweld at 1300 °C is characterised by three peaks refer to austenite and ferrite phases in addition to M7C3 carbides. The presence of austenite is primarily connected with the increasing of carbon in the solid solution that stabilizing the austenite []. Higher contents of these elements have a significant effect on the martensite temperature and consequently the transformation of austenite to martensite is very difficult. In addition, when relatively fast cooling from the solidus–liquidus range is applied there is relatively better stability for the austenitic phase at room temperature [].

Figure 11.

XRD patterns for AISI D2-AISI D2 joining processed at different conditions.

Meanwhile, analysis of the XRD patterns of the joined parts after post welding heat treatment condition revealed a change of the structure character over the non-heat treated condition as shown in Figure 10. As can be observed that, the microstructures are composed of different amounts of retained austenite, martensite and chromium carbides. Retained austenite was recognised using crystallographic data for austenite, while martensite was recognised with data for ferrite because of similarity in the crystal structure and slight differences in lattice constants. The decomposition of metastable austenite in the structure was probably caused by the changes of carbon content. The effect of slow cooling give rise to dissolution of a large number of carbide particles causing in an augmentation of retained austenite after post welding heat treatment condition. During the thermal exposure, carbon migrates and diffused deeper to the grain boundaries while some amounts of eutectic chromium carbides dissolve in the matrix. It means that the primary grain boundaries have distinctly pinning effect on growth of grain size in the heat treated condition []. Based on these findings, no harmful or brittle phase was detected by XRD patterns at the thixoweld zone and these observations were in good agreement with microstructure examinations.

3.2. Mechanical Properties

3.2.1. Tensile Test and Fracture-surface Investigation

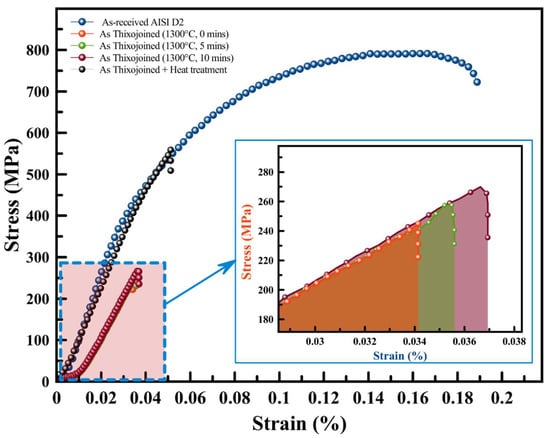

For the tensile strength, six samples were prepared using different joining parameters (the first three specimens with 1250 °C heating temperature was neglected). It is believed that the supplied heat input not providing sufficient diffusion within the joint interface even when the holding time was long. Typical stress-strain curves for the different test conditions are shown in Figure 12. With high thixowelding temperature, the produced interface is free from voids and pores due to high diffusion rates of different elements across this area. Consequently, when this high temperature accompany with long holding time, high tensile strength could be achieved. It is well known that the strength of a joint primarily depends on the quality of its microstructure. As can be observed, the tensile strength graph shows a relatively identical shape of the applied heating temperature to 1300 °C at 0, 5 and 10 min to give 241 MPa, 253 MPa and 271 MPa respectively. A minimum tensile strength of 241 MPa is recorded for the applied heating temperature of 1300 °C at 0 min. At 5 min a slight increment in tensile strength was recoded. Meanwhile, with 10 min. holding time there was remarkable improvement in tensile strength due to fact that diffusion rate is highly affected by both of temperature and time for non-steady state diffusion. The tensile value of the D2 as-supplied material (791 MPa) is more than two times if compared with the as-thixojoind value of 271 MPa. This is actually an interesting result which was achieved by a process which is simpler than conventional processes. Meanwhile, tensile strength of the joined parts after post welding heat treatment condition showed a significant improvement over the non-heat treated condition which is 560 MPa, i.e., about 70% the strength value of D2 base metal. This improvement of strength is linked to such factors as the size, distribution and dissolvement of carbides, relative proportions of austenite and martensite phases, and grain size. This explanation is also corroborated by microscopic studies which resulted in improved contrast between solid and liquid phases, whereby the big solids appeared in little liquid matrix where primary distribution of grain boundary is decreased substantially and some amounts of eutectic carbides dissolve in the matrix.

Figure 12.

Typical stress-strain curves for the different test conditions.

The mechanical properties of similar substrates will have an important effect on the joints properties because the temperature attained by each substrate markedly depends on the properties of the materials and on the selected joining parameters. According to the Arrhenius equation, an increase in the temperature will occasion an exponential enhancement in the diffusivity of solute []. Consequently, the heating temperature for the material will have a substantial impact on the joint properties. Weak joint may be produced if heating temperature is set on low level, even though if it is combined with high holding time. This resulted in inadequate diffusion along the interface because the elements do not have enough energy to migrate and diffuse within diffusion transition zone.

where D is the diffusivity, D* is temperature-independent preexponential (m2/s), Qd is the activation energy for diffusion (J/mol or eV/atom), R is the gas constant (8.31 J/(mol·K) or 8.62×10−5 eV/(atom·K)) and T is absolute temperature (K).

D = D* exp (−Qd / RT)

It is worth mentioning that the joining strength increases with the increase of holding time at the initial stage of the joining process due to the better coalescence of mating surfaces to ensures complete diffusion of atoms and attains a maximum strength value []. In general, in non-steady state diffusion, the concentration of diffusion species is function of both of time and position (Fick’s second law). It is thus expected with the aid of more suitable holding time, joints with highly desirable microstructure can be obtained and in turn, highly reliable bonded joints with good performance can be anticipated. Moreover, holding time has an effect on the quantity of atomic diffusion and the creep of the protrusions (i.e., elemental diffusion of the joined alloy can be improved by increasing the holding time) [].

where ∂C/∂t is the change in solute concentration with time at a given position in the base metal, which could provide an indication of isothermal solidification rate, and D is the diffusion coefficient, and ∂2C/∂x2 is the change in concentration gradient with distance.

∂C/∂t = D (∂2C/∂x2)

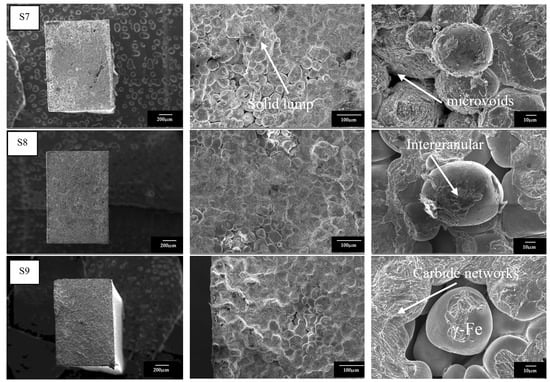

Figure 13 displays the SEM morphology of the thixojoint that achieved with various joining conditions. Through observing the fracture surfaces created by the tensile test, it was found that the fracture appearance of the welded joint at 1300 °C was not completely along the interface between base metal and insert. The fractures were characterised by brittleness, where intergranular fracture mode is illustrative. The fracture path, which is typically dimpled, is located around liquid-solid zone and grain boundary. The close-up of the fracture path reveals a “cobbled” surface appearance, which could indicate that during solidification the fracture occurred through the liquid with the re-solidified grains then becoming exposed as “cobbles”, a phenomenon also seen in 7075 Al alloy []. The brittleness was a result of coarse fracture with big solid lump that refer to unbroken structure. The solid γ (Fe) particles, mainly with globular shape, surrounded by the carbide networks which is a typical characteristic with respect to semi-solid microstructure of D2 tool steel. The fracture then appears to have quickly propagated along the grain boundaries and the weak liquidus–solidus interface of the lumps []. From the results it is believed that there is a good metallurgical joining at interface; this kind of compound fracture mechanism means that the rupture is not along the interface.

Figure 13.

Fractured surface of welded joints of samples processed at various conditions: (S7) 1300 °C/0 min, (S8) 1300 °C/5 min, (S9) 1300 °C/10 min.

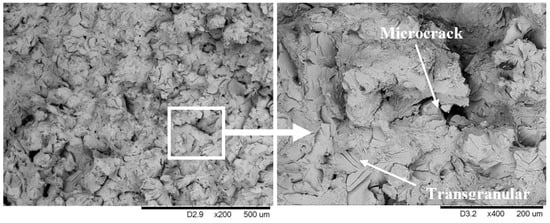

Figure 14 shows fractured surface of welded joints obtained after post welding heat treatment. As can be understood from this figure, post welding heat treatment changes the fracture mode to predominantly transgranular fracture, with few intergranular facets. On the contrary, in the tensile test of the non treated condition, disbanding of the solid particles has occurred as well as several microcracks with nano wide which are found out in fracture surface. Stress applied on the sample during the tensile tests led to the formation of big cracks out of small pores and in turn, fractures occurred when these cracks grew. It is worth mentioning that the main parameter responsible for the low ductility is the grain boundary. The liquid phase appearance in grain boundaries, results in formation of porosities after solidification, which reduces ductility. It is thus expected with the presence of grain boundary leads to long soft zones which distort discriminatory during plastic deformation [,]. It is attractive to note that post-joining heat treatment is one of the key parameters for improving the mechanical properties of thixojoined parts (although this would have cost-implications and could reduce the attractiveness of the process).

Figure 14.

Fractured surface of welded joints after post welding heat treatment.

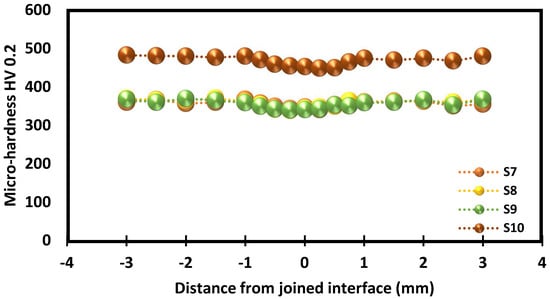

3.2.2. Hardness Measurements

Micro-hardness profiles were obtained for the AISI D2 tool steel base metal, the weld zone and the insert by using a load of 10 g for 30 s. Figure 15 presents the micro-hardness profile against distance from the interface and illustrates the variations of the HV value along the lines perpendicular to the joint interface. The hardness measurement of the base metal, the weld zone and the insert is fluctuated in the range 350 Hv to 370 Hv. This indicated that the hardness value of the welded joints was almost similar to those of base metal and insert. This indicated that the hardness profile gives a good impression of joint microstructure and the degree of homogenization, this looks very promising. However, the thixoweld-joint of AISI D2 exhibits different hardness values if compare to as supplied material. This exposure to thixojoining temperature also results in the phase change to metastable austenite. While the remaining interspaces are filled by precipitated eutectic carbides on the grain boundaries and in the lamellar network. As can be seen from this figure, almost the similar trend is observed in the microhardness profiles of all samples. Figure 15 clarifies small decrement in hardness values at same temperature with high holding time. The behaviour may be attributing to grain growth with increasing holding time during evolution of microstructures. [,]. These results evidenced that diffusion has occurred and weld zone micro-hardness was free from harmful or brittle phases. In the case of post welding heat treatment condition (S10), hardness measurements were somewhat higher than for the non-heat treated samples. This higher hardness can be attributed to the some amounts of eutectic chromium carbides dissolve in matrix during slow cooling. It means that the primary grain boundaries have distinctly pinning effect on growth of grain size in the heat treated condition []. In addition, the phase transformation is probably the reason of hardness increase to the (490 Hv). This value is higher in comparison with material hardness in the initial state after thixojoining processing. During the isothermal heat treatment at higher temperatures, particular decomposition of the austenite and ferrite phases to the martensitic phases was achieved and the carbides of chromium and retained austenite were included in the structure, as shown in XRD analysis. In tool steels with high alloy content, high hardenability may cause martensite to form during air cooling. Hardenability is the topic which relates alloying to the phase transformations that occur on cooling [].

Figure 15.

Hardness distributions of D2–D2 tool steel thixowelded joints at various conditions: (S7) 1300 °C/0 min, (S8) 1300 °C/5 min, (S9) 1300 °C/10 min, (S10) 1300 °C/10 min + post welding heat treatment.

4. Conclusions

The novel thixojoining process of AISI D2 similar tool steel was carried out by using the direct partial re-melting technique, and this was investigated through this research. The effect of joining temperature, holding time and post-weld heat treatment on microstructural characteristics and mechanical properties of AISI D2 tool steel joints have been studied. The summarised conclusions can be listed as below:

- Adequate and defectless thixoweld-joint were successfully produced with thixowelding temperature of 1300 °C, while lower welding temperature caused a series of cracks across the entire joint resulting in spontaneous fracture after joining. While post weld heat treatment, resulted in improved contrast between solid and liquid phases, whereby the big solids appeared in little liquid matrix where primary distribution of grain boundary is decreased substantially and some amounts of eutectic carbides dissolve in the matrix.

- According to the X-ray line scan analyses across the joint interface confirms a uniform elemental distribution in the structure while the X-ray diffraction pattern of the thixowelded area was free from any brittle or harmful phases.

- Maximum tensile streghth of 271 MPa was achieved at 1300 °C and 10 min holding time, which was 35% that of D2 base metal. Meanwhile, tensile strength of the joined parts after heat condition showed a significant improvement over the non-heat treated condition which was 560 MPa, i.e., about 70% that of as received AISI D2 tool steel base metal.

- The fracture of joints was located along the interface between base metal and insert with typical brittle characteristics (intergranular). Meanwhile, the joints after heat condition are fractured at the diffusion zone, and the fracture exhibits typical brittle characteristic (tranasgranular).

- The hardness measurement of the base metal, the weld zone and the insert is fluctuated in the range of 350 Hv to 370 Hv. This indicated that the hardness value of the welded joints was almost similar to those of base metal and insert. While the hardness measurements of the (thixojoining + heat treated) condition (490 Hv) was somewhat higher than for the non-heat treated samples. This is more related to the phase transformation (austenite and ferrite phases to the martensitic phases). Moreover, some amounts of eutectic chromium carbides dissolve in the matrix.

Acknowledgments

The authors would like to thank Universiti Kebangsaan Malaysia (UKM) and the Ministry of Higher Education (MoHE), Malaysia, for the financial support under Research Grants AP-2012-014.

Author Contributions

M.N.A. and M.Z.O. conceived and designed the experiments; M.N.A. performed the experiments; M.N.A., M.Z.O., S.A.-Z., K.S.A., M.A.A. analyzed the data; M.N.A. wrote the paper. All authors discussed the result and contributed to the final manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sekharbabu, R.; Rafi, H.K.; Rao, K.P. Characterization of D2 tool steel friction surfaced coatings over low carbon steel. Mater. Des. 2013, 50, 543–550. [Google Scholar] [CrossRef]

- Mohammed, M.N.; Omar, M.Z.; Sajuri, Z.; Salleh, M.S.; Alhawari, K.S. Trend and Development of Semisolid Metal Joining Processing. Adv. Mater. Sci. Eng. 2015, 2015. [Google Scholar] [CrossRef]

- Chegeni, A.A.; Kapranos, P. An Experimental Evaluation of Electron Beam Welded Thixoformed 7075 Aluminum Alloy Plate Material. Metals 2017, 7, 569. [Google Scholar] [CrossRef]

- Mohammed, M.N.; Omar, M.Z.; Salleh, M.S.; Alhawari, K.S.; Kapranos, P. Semisolid Metal Processing Techniques for Nondendritic Feedstock Production. Sci. World J. 2013, 2013. [Google Scholar] [CrossRef] [PubMed]

- Mendez, P.F.; Brown, S.B. Method and Apparatus for Metal Solid Freeform Fabrication Utilizing Partially Solidified Metal Slurry. Patent number: 5,893,404, 13 April 1999. [Google Scholar]

- Kiuchi, M.; Yanagimoto, J.; Sugiyama, S. Application of mushy/semi-solid joining—Part 3. J. Mater. Process. Technol. 2003, 140, 163–166. [Google Scholar] [CrossRef]

- Hosseini, V.A.; Aashuri, H.; Kokabi, A.H. Characterization of newly developed semisolid stir welding method for AZ91 magnesium alloy by using Mg–25%Zn interlayer. Mater. Sci. Eng. A 2013, 565, 165–171. [Google Scholar] [CrossRef]

- Mohammed, M.N.; Omar, M.Z.; Syarif, J.; Sajuri, Z.; Salleh, M.S.; Alhawari, K.S. Semi-Solid Joining of D2 Cold-Work Tool Steel. Solid State Phenom. 2015, 217–218, 355–360. [Google Scholar] [CrossRef]

- Mohammed, M.N.; Omar, M.Z.; Alhawari, K.S.; Abdelgnei, M.A.; Saud, S.N. The Interface Morphology of Thixo-Joined Dissimilar Steels. Solid State Phenom. 2016, 256, 243–250. [Google Scholar] [CrossRef]

- Mohammed, M.N.; Omar, M.Z.; Salleh, M.S.; Alhawari, K.S. Study on Thixojoining Process Using Partial Remelting Method. Adv. Mater. Sci. Eng. 2013, 2013, 1–8. [Google Scholar] [CrossRef]

- Omar, M.Z.; Alfan, A.; Syarif, J.; Atkinson, H.V. Microstructural investigations of XW-42 and M2 tool steels in semi-solid zones via direct partial remelting route. J. Mater. Sci. 2011, 46, 7696–7705. [Google Scholar] [CrossRef]

- Vigraman, T.; Narayanasamy, R.; Ravindran, D. Microstructure and mechanical property evaluation of diffusion-bonded joints made between SAE 2205 steel and AISI 1035 steel. Mater. Des. 2012, 35, 156–169. [Google Scholar] [CrossRef]

- Püttgen, W.; Hallstedt, B.; Bleck, W.; Uggowitzer, P.J. On the microstructure formation in chromium steels rapidly cooled from the semi-solid state. Acta Mater. 2007, 55, 1033–1042. [Google Scholar] [CrossRef]

- Aisman, D.; Jirkova, H.; Kucerova, L.; Masek, B. Metastable structure of austenite base obtained by rapid solidification in a semi-solid state. J. Alloys Compd. 2011, 509, S312–S315. [Google Scholar] [CrossRef]

- Rogal, Ł.; Dutkiewicz, J. Heat Treatment of Thixo-Formed Hypereutectic X210CrW12 Tool Steel. Metall. Mater. Trans. A 2012, 43, 5009–5018. [Google Scholar] [CrossRef]

- Wikstrom, N.P.; Egbewande, A.T.; Ojo, O.A. High temperature diffusion induced liquid phase joining of a heat resistant alloy. J. Alloys Compd. 2008, 460, 379–385. [Google Scholar] [CrossRef]

- Cao, J.; Liu, J.; Song, X.; Lin, X.; Feng, J. Diffusion bonding of TiAl intermetallic and Ti3AlC2 ceramic: Interfacial microstructure and joining properties. Mater. Des. 2014, 56, 115–121. [Google Scholar] [CrossRef]

- Mohammadi, H.; Ketabchi, M. Investigation of microstructural and mechanical properties of 7075 al alloy prepared by SIMA method. Iran. J. Mater. Sci. Eng. 2013, 10, 32–43. [Google Scholar]

- Guo, J.F.; Chen, H.C.; Sun, C.N.; Bi, G.; Sun, Z.; Wei, J. Friction stir welding of dissimilar materials between AA6061 and AA7075 Al alloys effects of process parameters. Mater. Des. 2014, 56, 185–192. [Google Scholar] [CrossRef]

- Mohammed, M.N.; Omar, M.Z.; Syarif, J.; Sajuri, Z.; Salleh, M.S.; Alhawari, K.S. Microstructural evolution during DPRM process of semisolid ledeburitic D2 tool steel. Sci. World J. 2013, 2013. [Google Scholar] [CrossRef] [PubMed]

- Omar, M.Z.; Atkinson, H.V.; Kopranos, P. Semi-solid metal processing—A processing method under low flow loads. J. Kejuruter. 2007, 19, 137–146. [Google Scholar]

- Mohammed, M.N.; Omar, M.Z.; Syarif, J.; Sajuri, Z.; Salleh, M.S.; Alhawari, K.S. Microstructural properties of semisolid welded joints for AISI D2 Tool Steel. J. Kejuruter. 2014, 26, 31–34. [Google Scholar] [CrossRef]

- Aisman, D.; Jirkova, H.; Masek, B. The influence of deformation and cooling parameters after transition through semi-solid state on structure development of ledeburite steel. J. Alloys Compd. 2012, 536, S204–S207. [Google Scholar] [CrossRef]

- Roberts, G.; Krauss, G.; Kennedy, R. Tool Steels, 5th ed.; ASM International: Geauga County, OH, USA, 1998. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).