Effect of Process Parameters on Fatigue and Fracture Behavior of Al-Cu-Mg Alloy after Creep Aging

Abstract

:1. Introduction

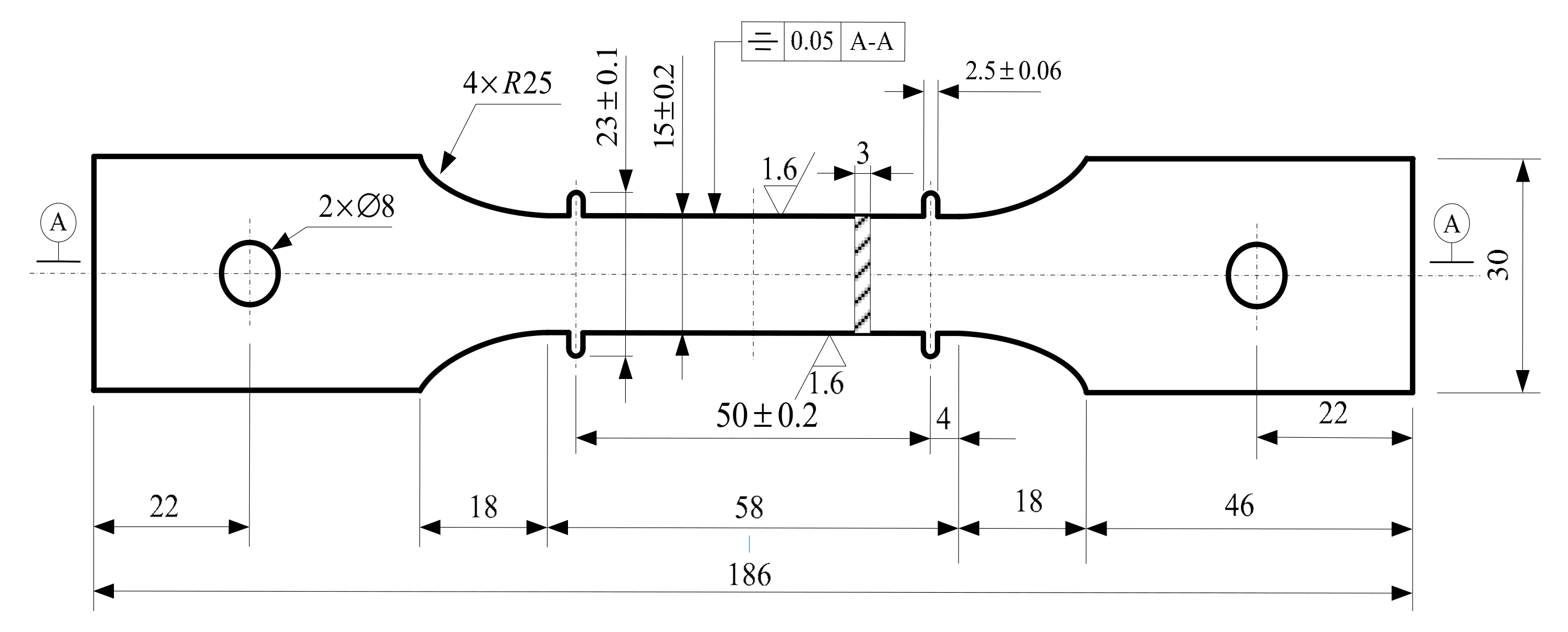

2. Experimental

2.1. Samples and Heat Treatment

2.2. Tensile and Fatigue Testing

2.3. Microstructural Analysis

3. Results and Discussion

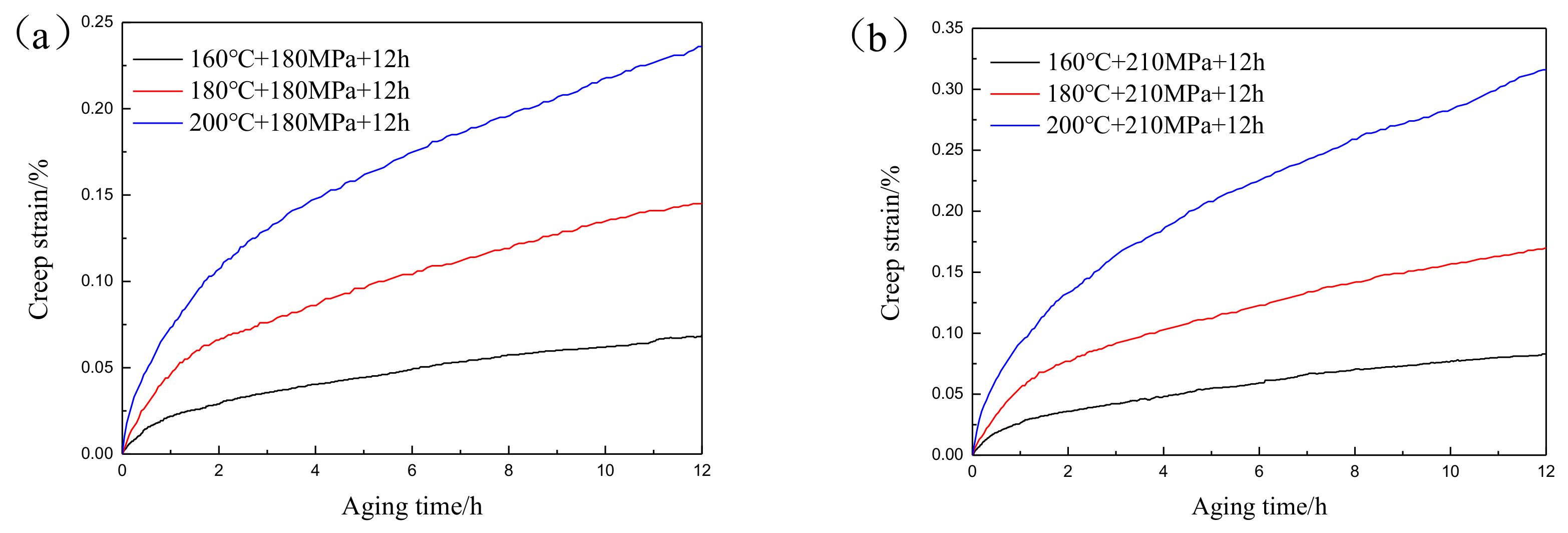

3.1. Creep Behavior of Alloy

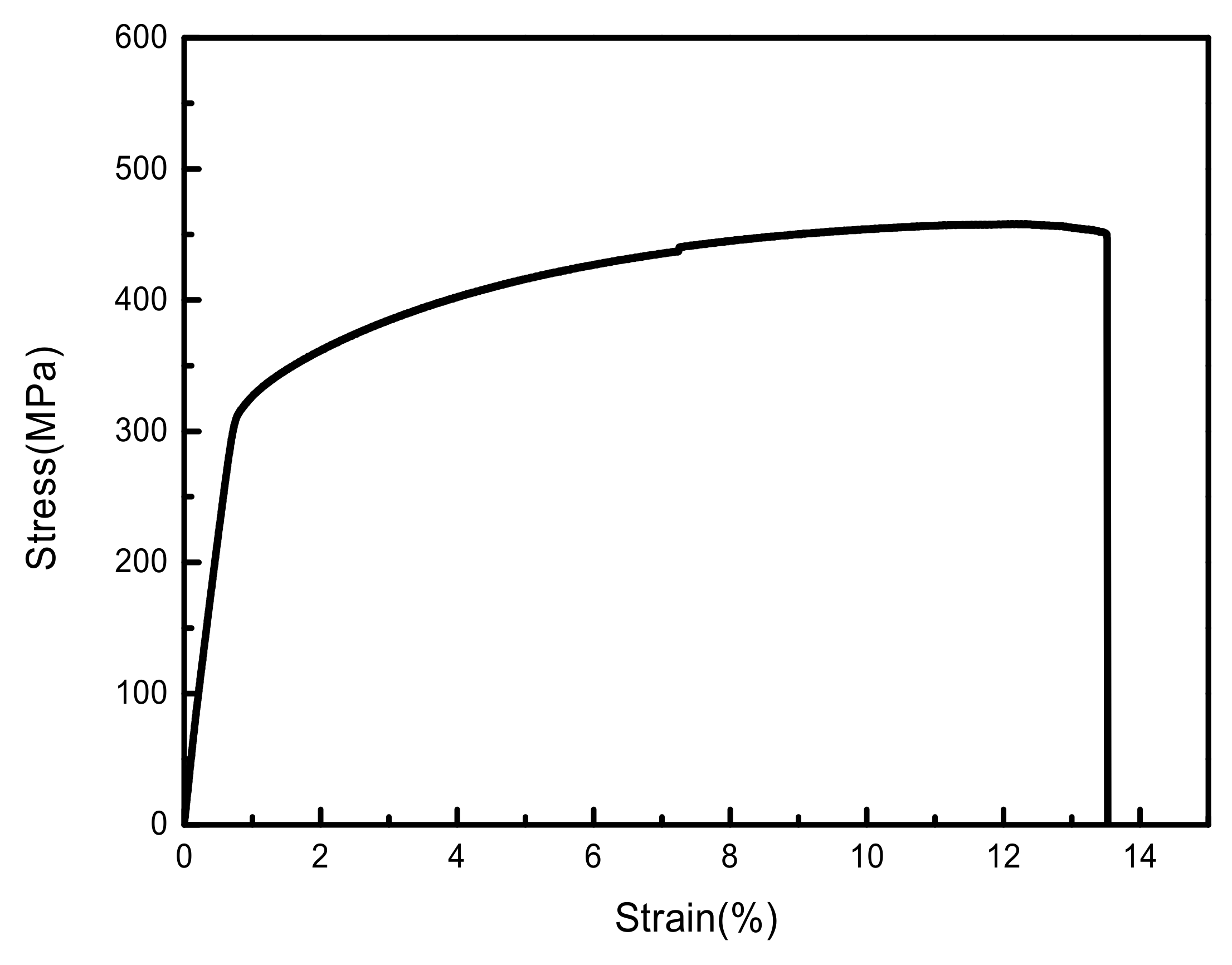

3.2. Mechanical Properties of Alloy

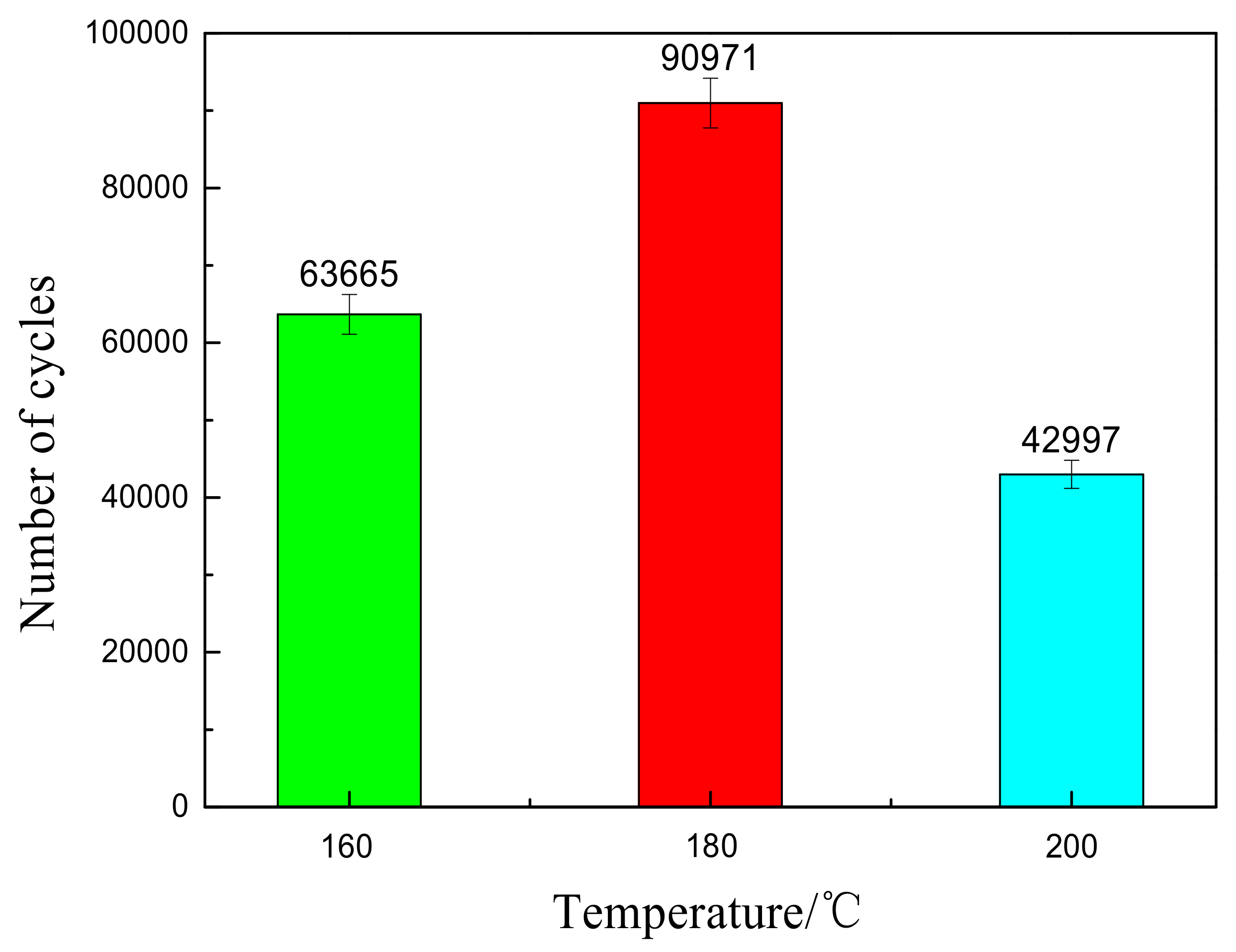

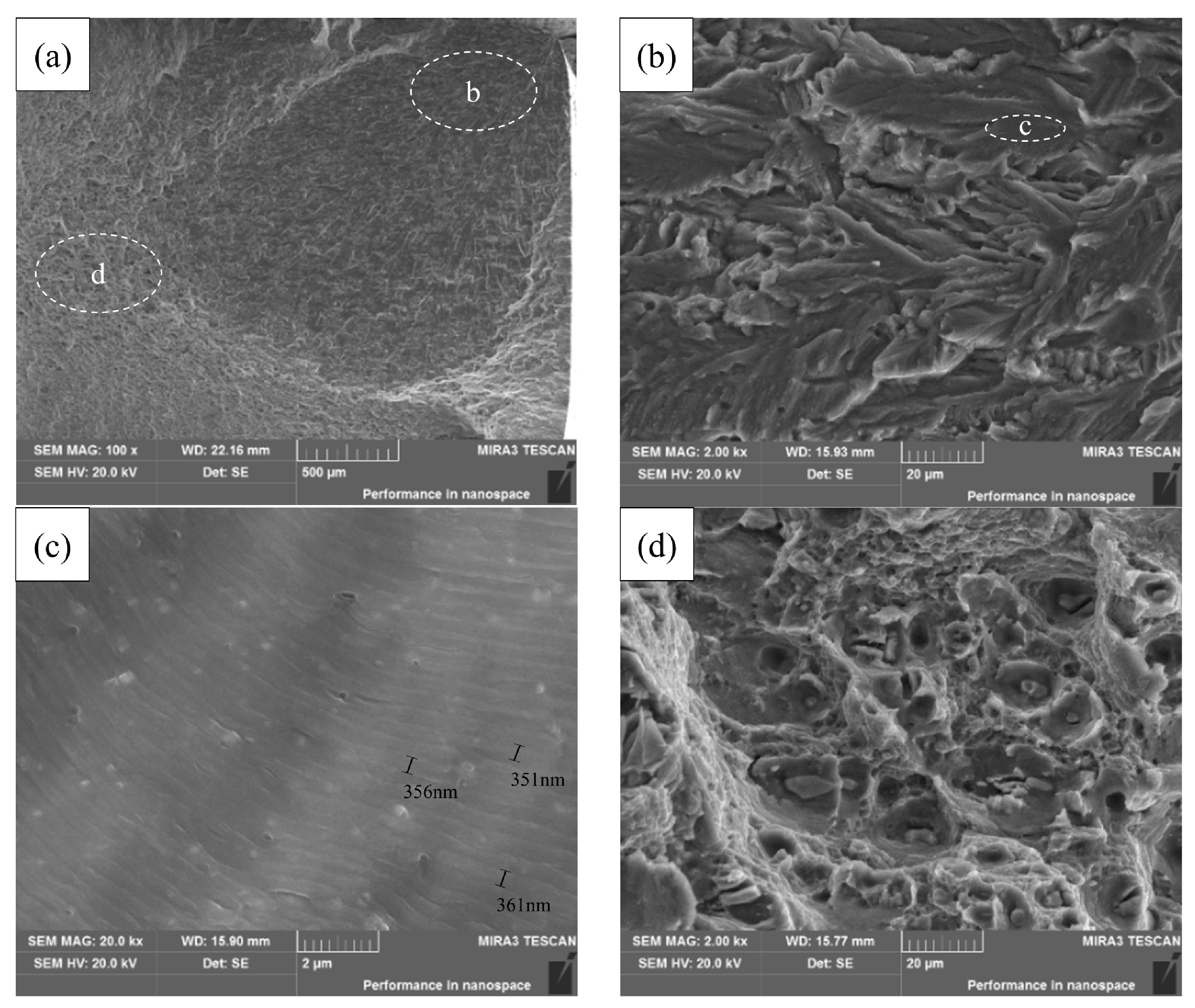

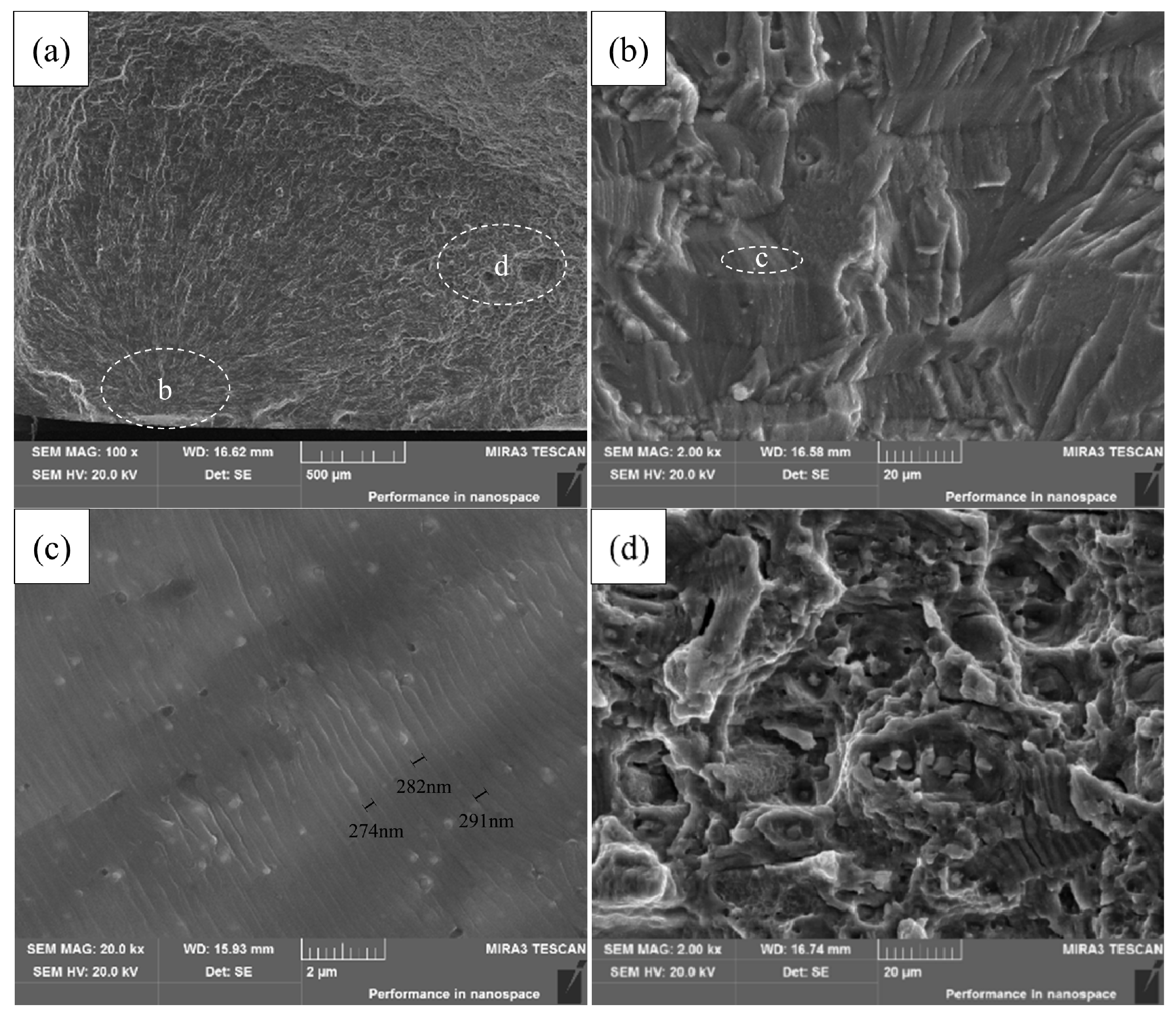

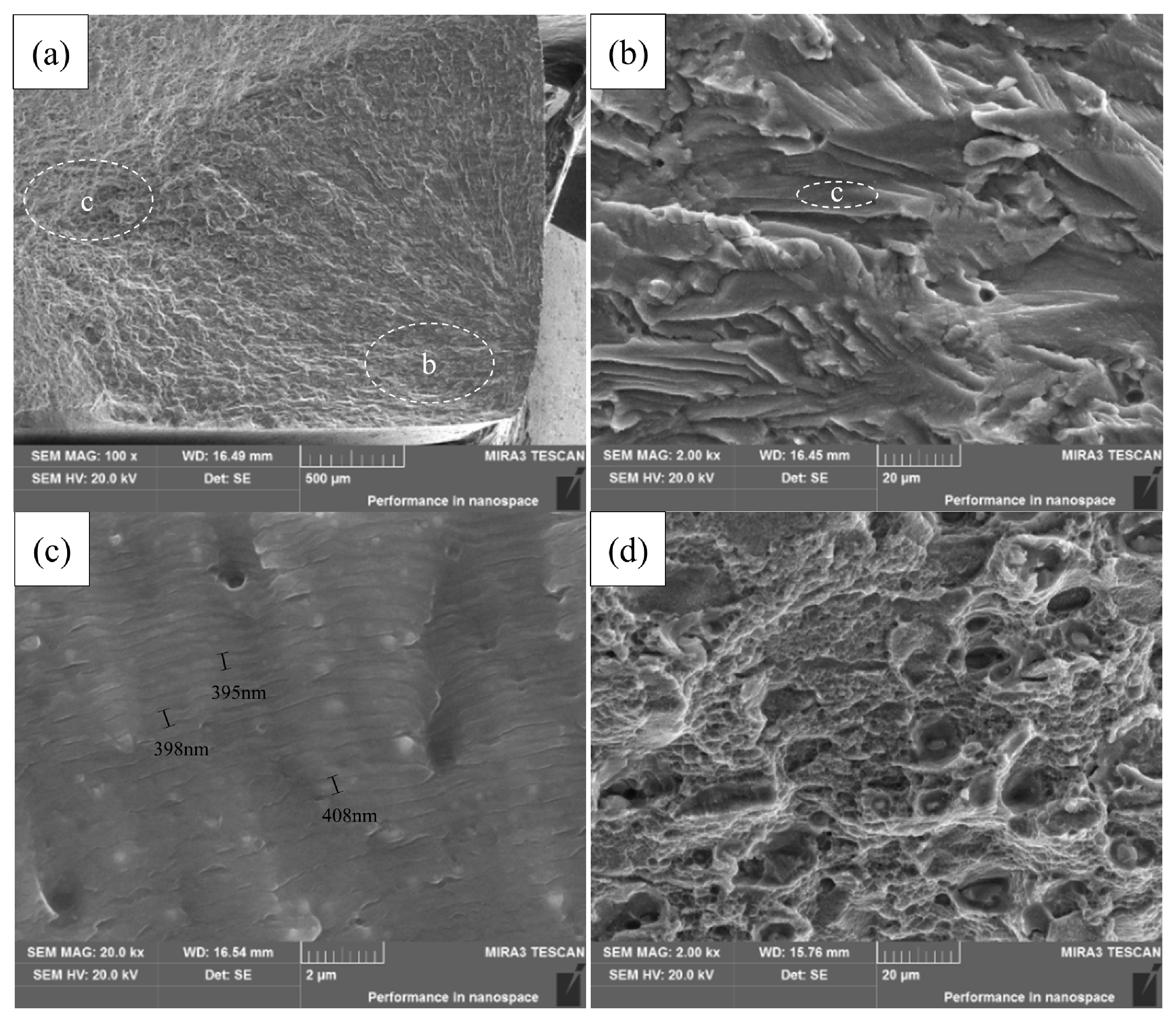

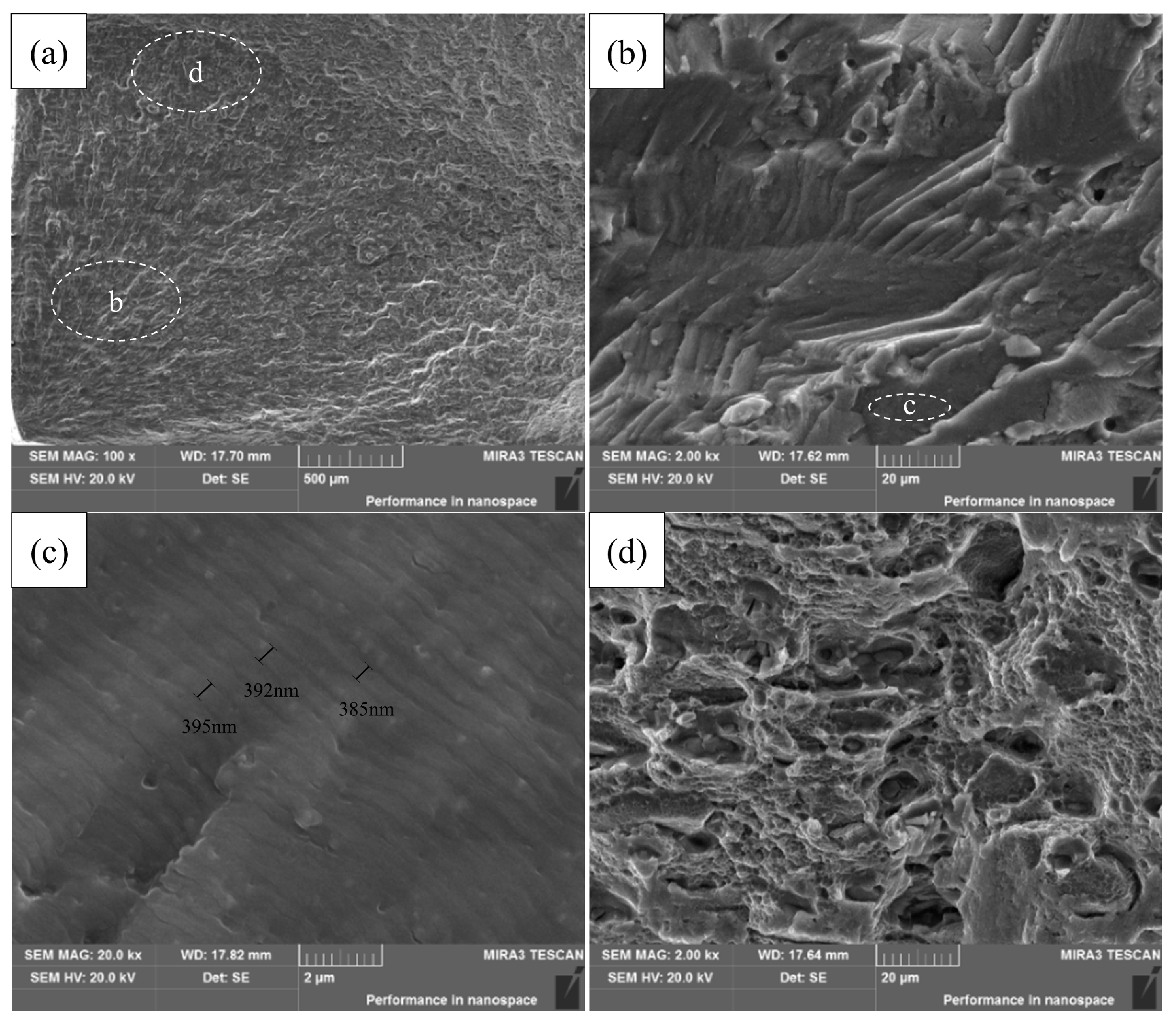

3.3. Effect of Aging Temperature on Fatigue Fracture of Alloy

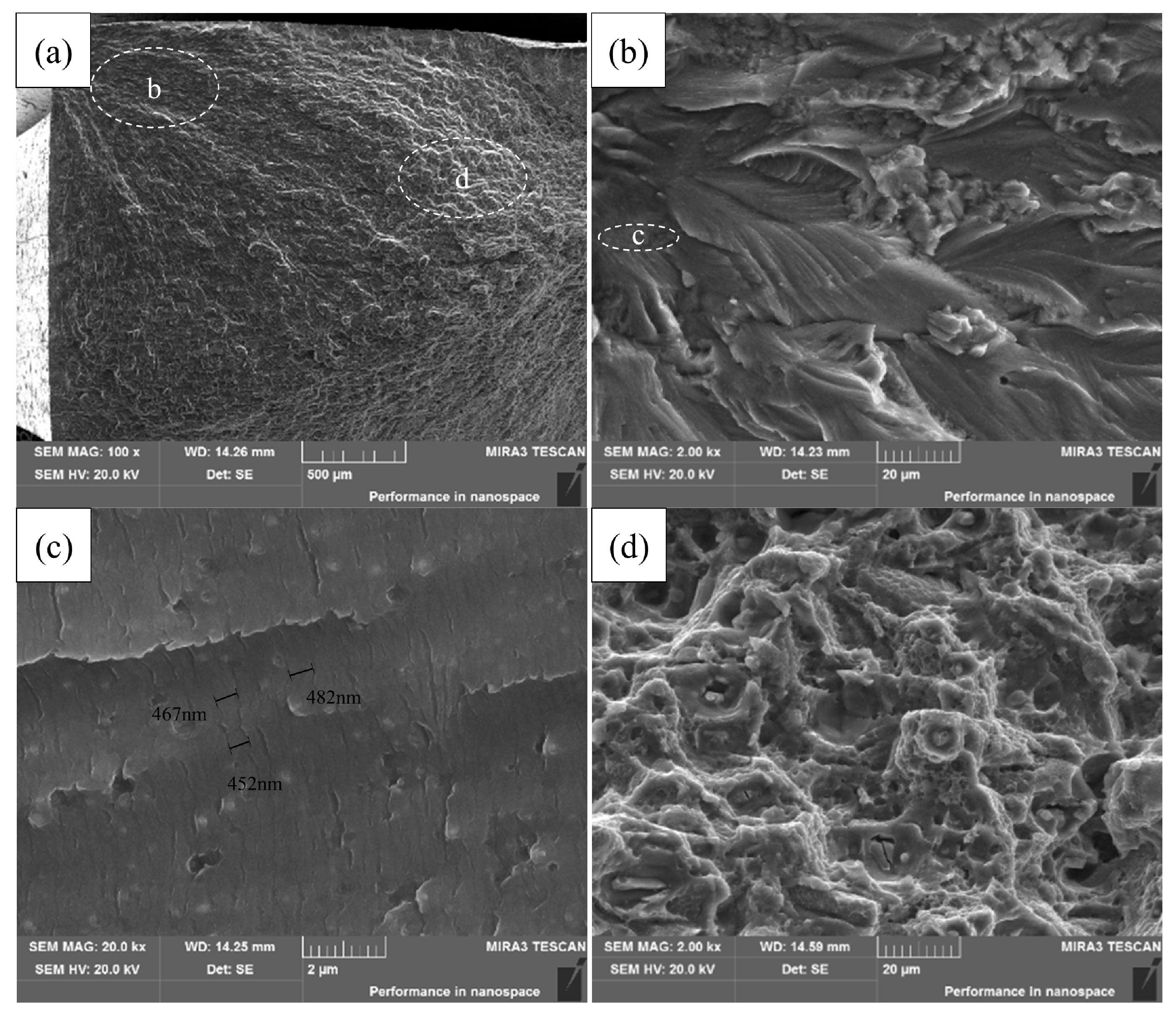

3.4. Effect of Stress on Fatigue Fracture of Alloy

3.5. Relationship between Microstructure and Fatigue Fracture Behavior of Alloy

3.5.1. Effect of Aging Temperature

3.5.2. Effect of Stress

- (1)

- During the creep aging process, the strengthening phases in the grain interior can precipitate under the combined impact of stress and temperature. These precipitation phases in the matrix impede the dislocations movement and improve the strength and anti-plastic deformation of alloy until they eventually reduce the deformation damage during the fatigue process and prolong fatigue life.

- (2)

- The precipitation phases in the grain interior are semi-coherent or incoherent with the matrix, causing dislocations passing round the precipitation phases and leaving a dislocations loop. It makes dislocations unable to slip repeatedly in grains, which leads to the dislocations easily slipping to the grain boundary. The precipitation phase is not conducive to the crack growth and the reduction of deformation damage.

- (3)

- The precipitation-free zone (PFZ) and coarse particles along the grain boundaries will reduce the strength of grain boundaries, so that the dislocations are more likely to slip at the grain boundary. These can increase the stress concentration of grain boundaries, forming cracks easily along the grain boundaries.

4. Conclusions

- (1)

- With the increase of temperature and stress, the creep strain of the alloy is improved. As the temperature rises, the tensile strength and yield strength first increase, and then decrease. The mechanical properties of alloy are improved after creep aging, but stress has a weak effect on the mechanical properties.

- (2)

- The process parameters can obviously impact the fatigue life of the alloy. The fatigue life first increases, and then decreases with the rise of both temperature and stress. Both overhigh temperature and stress can shorten the fatigue life. The best fatigue life is 90971 cycles at 180 °C under 180 MPa in this study.

- (3)

- The precipitation characteristics of alloy are the main reason for the fatigue life change of the alloy. When the precipitation phases are fine and dispersed, the strength and anti-plastic deformation of the alloy are improved, and fatigue life increases. However, when the precipitation phases become coarse, the precipitation phases cannot be cut by dislocation, so the fatigue life dropped. Besides, the PFZ at the grain boundary is a weak part of alloy, where the fatigue life decreases with a wide PFZ.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Zhan, L.; Lin, J.; Dean, T.A. A review of the development of creep age forming: Experimentation, modelling and applications. Int. J. Mach. Tool Manuf. 2011, 51, 1–17. [Google Scholar] [CrossRef]

- Xu, Y.; Zhan, L.; Li, W. Effect of pre-strain on creep aging behavior of 2524 aluminum alloy. J. Alloys Compd. 2017, 691, 564–571. [Google Scholar] [CrossRef]

- Yang, Y.; Zhan, L.; Shen, R.; Yin, X.; Li, X.; Li, W.; Huang, M.; He, D. Effect of pre-deformation on creep age forming of 2219 aluminum alloy: Experimental and constitutive modelling. Mater. Sci. Eng. A 2017, 683, 227–235. [Google Scholar] [CrossRef]

- Lei, C.; Yang, H.; Li, H.; Shi, N.; Zhan, L. Dependences of microstructures and properties on initial tempers of creep aged 7050 aluminum alloy. J. Mater. Process. Technol. 2017, 239, 125–132. [Google Scholar] [CrossRef]

- Xu, Y.; Zhan, L.; Ma, Z.; Huang, M.; Wang, K.; Sun, Z. Effect of heating rate on creep aging behavior of Al-Cu-Mg alloy. Mater. Sci. Eng. A 2017, 688, 488–497. [Google Scholar] [CrossRef]

- Ho, K.C.; Lin, J.; Dean, T.A. Modelling of springback in creep forming thick aluminum sheets. Int. J. Plast. 2004, 20, 733–751. [Google Scholar] [CrossRef]

- Zhan, L.; Lin, J. , Dean, T.A.; Huang, M. Experimental studies and constitutive modelling of the hardening of aluminium alloy 7055 under creep age forming conditions. Int. J. Mech. Sci. 2011, 53, 595–605. [Google Scholar] [CrossRef]

- Xu, F.; Zhang, J.; Deng, Y.; Zhang, X. Precipitation orientation effect of 2124 aluminum alloy in creep aging. Trans. Nonferrous Met. Soc. China 2014, 24, 2067–2071. [Google Scholar] [CrossRef]

- Yang, Y.; Zhan, L.; Li, J. Constitutive modeling and springback simulation for 2524 aluminum alloy in creep age forming. Trans. Nonferrous Met. Soc. China 2015, 25, 3048–3055. [Google Scholar] [CrossRef]

- Chen, Y.; Pan, S.; Zhou, M.; Yi, D.; Xu, D.; Xu, Y. Effects of inclusions, grain boundaries and grain orientations on the fatigue crack initiation and propagation behavior of 2524-T3 Al alloy. Mater. Sci. Eng. A 2013, 580, 150–158. [Google Scholar] [CrossRef]

- Siddiqui, R.A.; Abdul-Wanhab, S.A.; Pervez, T. Effect of aging time and aging temperature on fatigue and fracture behavior of 6063 aluminum alloy under seawater influence. Mater. Des. 2008, 29, 70–79. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Z.; Li, Y.; Xia, Q.; Zhou, J. Enhanced fatigue crack propagation resistance of an Al-Cu-Mg alloy by artificial aging. Mater. Sci. Eng. A 2008, 527, 4070–4075. [Google Scholar]

- Chen, X.; Liu, Z.; Lin, M.; Ning, A.; Zeng, S. Enhanced Fatigue Crack Propagation Resistance in an Al-Zn-Mg-Cu Alloy by Retrogression and Reaging Treatment. J. Mater. Eng. Perform. 2012, 21, 2345–2353. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, J.; Deng, Y. Creep forming heat treatment technology of Al-Cu-Mg alloy. Chin. J. Nonferrous Met. 2016, 26, 1607–1614. (In Chinese) [Google Scholar]

- Chen, Y.; Deng, Y.; Wan, L.; Jin, K.; Xiao, Z. Microstructures and Properties of 7050 Aluminum Alloy Sheet During Creep Aging. J. Mater. Eng. 2012, 2, 71–76. (In Chinese) [Google Scholar]

- Quan, L.; Zhao, G.; Gao, S.; Muddle, B.C. Effect of pre-stretching on microstructure of aged 2524 aluminium alloy. Trans. Nonferrous Met. Soc. China 2011, 21, 1957–1962. [Google Scholar] [CrossRef]

- Marceau, R.; Sha, G.; Ferragut, R.; Dupasquier, A.; Ringer, S. Solute clustering in Al-Cu-Mg alloys during the early stages of elevated temperature ageing. Acta Mater. 2010, 58, 4923–4939. [Google Scholar] [CrossRef]

- Starke, E.A.; Sraley, J.T. Application of modern aluminum alloys to aircraft. Prog. Aerosp. Sci. 1996, 32, 131–172. [Google Scholar] [CrossRef]

- Huda, Z.; Zaharinie, T.; Min, G. Temperature effects on material behavior of aerospace aluminum alloys for subsonic and supersonic aircraft. J. Aerosp. Eng. 2010, 23, 124–128. [Google Scholar] [CrossRef]

- Zheng, Z.; Cai, B.; Zhai, T.; Li, S. The behavior of fatigue crack initiation and propagation in AA2524-T34 alloy. Mater. Sci. Eng. A 2011, 528, 2017–2022. [Google Scholar] [CrossRef]

- Li, W.; Zhan, L.; Liu, L.; Xu, Y. The effect of creep aging on the fatigue fracture behavior of 2524 aluminum alloy. Metals 2016, 6, 215. [Google Scholar] [CrossRef]

- Xu, Y.; Zhan, L.; Xu, L.; Huang, M. Experimental research on creep aging behavior of Al-Cu-Mg alloy with tensile and compressive stresses. Mater. Sci. Eng. A 2017, 682, 54–62. [Google Scholar] [CrossRef]

- Bray, G.H.; Glazov, M.; Rioj, R.J.; Lib, D.; Gangloffb, R.P. Effect of artificial aging on the fatigue crack propagation resistance of 2000 series aluminum alloys. Int. J. Fatigue 2001, 23, 265–276. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, J.; Wang, S.; Yuan, D.; Yin, M.; Wu, C. The structure and the properties of S-phase in AlCuMg alloys. Acta Mater. 2011, 59, 7396–7405. [Google Scholar] [CrossRef]

- Ratchev, P.; Verlinden, B.; Smet, P.; Houtte, P. Precipitation hardening of an Al-4.2 wt % Mg-0.6 wt % Cu alloy. Acta Mater. 1998, 46, 3523–3533. [Google Scholar] [CrossRef]

- Sha, G.; Marceau, R.K.W.; Gao, X.; Muddle, B.C.; Ringer, S.P. Nanostructure of aluminium alloy 2024: Segregation, clustering and precipitation processes. Acta Mater. 2011, 59, 1659–1670. [Google Scholar] [CrossRef]

- Kamp, N.; Gao, N.; Starink, M.J.; Sinclair, I. Influence of grain structure and slip planarity on fatigue crack growth in low alloying artificially aged 2xxx aluminium alloys. Int. J. Fatigue 2007, 29, 869–878. [Google Scholar] [CrossRef]

- Liu, M.; Liu, Z.; Bai, S.; Xia, P.; Ying, P.; Zeng, S. Solute cluster size effect on the fatigue crack propagation resistance of an underaged Al-Cu-Mg alloy. Int. J. Fatigue 2016, 84, 104–112. [Google Scholar] [CrossRef]

| Cu | Mg | Mn | Fe | Zn | Ti | Cr | Si | Al |

|---|---|---|---|---|---|---|---|---|

| 4.26 | 1.36 | 0.57 | 0.037 | 0.024 | 0.01 | 0.002 | 0.089 | Bal. |

| Temperature/°C | Stress/MPa | Creep Strain/% | Steady-State Creep/s−1 |

|---|---|---|---|

| 160 | 180 | 0.068 | 3.3 × 10−3 |

| 210 | 0.082 | 4.02 × 10−3 | |

| 180 | 180 | 0.145 | 7.58 × 10−3 |

| 210 | 0.169 | 8.42 × 10−3 | |

| 200 | 180 | 0.235 | 1.033 × 10−2 |

| 210 | 0.315 | 1.46 × 10−2 |

| Temperature/°C | Stress/MPa | Tensile Strength/MPa | Yield Strength/MPa | Elongation/% |

|---|---|---|---|---|

| 160 | 0 | 482.6 ± 2.5 | 331.6 ± 3.4 | 19.9 ± 0.3 |

| 160 | 180 | 497.5 ± 4.1 | 362.4 ± 5.6 | 21.6 ± 0.5 |

| 160 | 210 | 496.6 ± 3.0 | 358.6 ± 3.6 | 21.6 ± 0.4 |

| 180 | 0 | 495.6 ± 2.7 | 443.4 ± 3.4 | 10.1 ± 0.4 |

| 180 | 180 | 504.2 ± 4.5 | 463.2 ± 4.8 | 10.1 ± 0.3 |

| 180 | 210 | 501.4 ± 2.8 | 461.1 ± 3.1 | 10.4 ± 0.3 |

| 200 | 0 | 465.6 ± 3.6 | 372.6 ± 4.2 | 8.8 ± 0.5 |

| 200 | 180 | 472.7 ± 3.5 | 417.3 ± 4.6 | 8.9 ± 0.4 |

| 200 | 210 | 475.2 ± 2.1 | 419.9 ± 2.6 | 8.9 ± 0.3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhan, L.; Wu, X.; Wang, X.; Yang, Y.; Liu, G.; Xu, Y. Effect of Process Parameters on Fatigue and Fracture Behavior of Al-Cu-Mg Alloy after Creep Aging. Metals 2018, 8, 298. https://doi.org/10.3390/met8050298

Zhan L, Wu X, Wang X, Yang Y, Liu G, Xu Y. Effect of Process Parameters on Fatigue and Fracture Behavior of Al-Cu-Mg Alloy after Creep Aging. Metals. 2018; 8(5):298. https://doi.org/10.3390/met8050298

Chicago/Turabian StyleZhan, Lihua, Xintong Wu, Xun Wang, Youliang Yang, Guiming Liu, and Yongqian Xu. 2018. "Effect of Process Parameters on Fatigue and Fracture Behavior of Al-Cu-Mg Alloy after Creep Aging" Metals 8, no. 5: 298. https://doi.org/10.3390/met8050298

APA StyleZhan, L., Wu, X., Wang, X., Yang, Y., Liu, G., & Xu, Y. (2018). Effect of Process Parameters on Fatigue and Fracture Behavior of Al-Cu-Mg Alloy after Creep Aging. Metals, 8(5), 298. https://doi.org/10.3390/met8050298