High Speed Finish Turning of Inconel 718 Using PCBN Tools under Dry Conditions

Abstract

1. Introduction

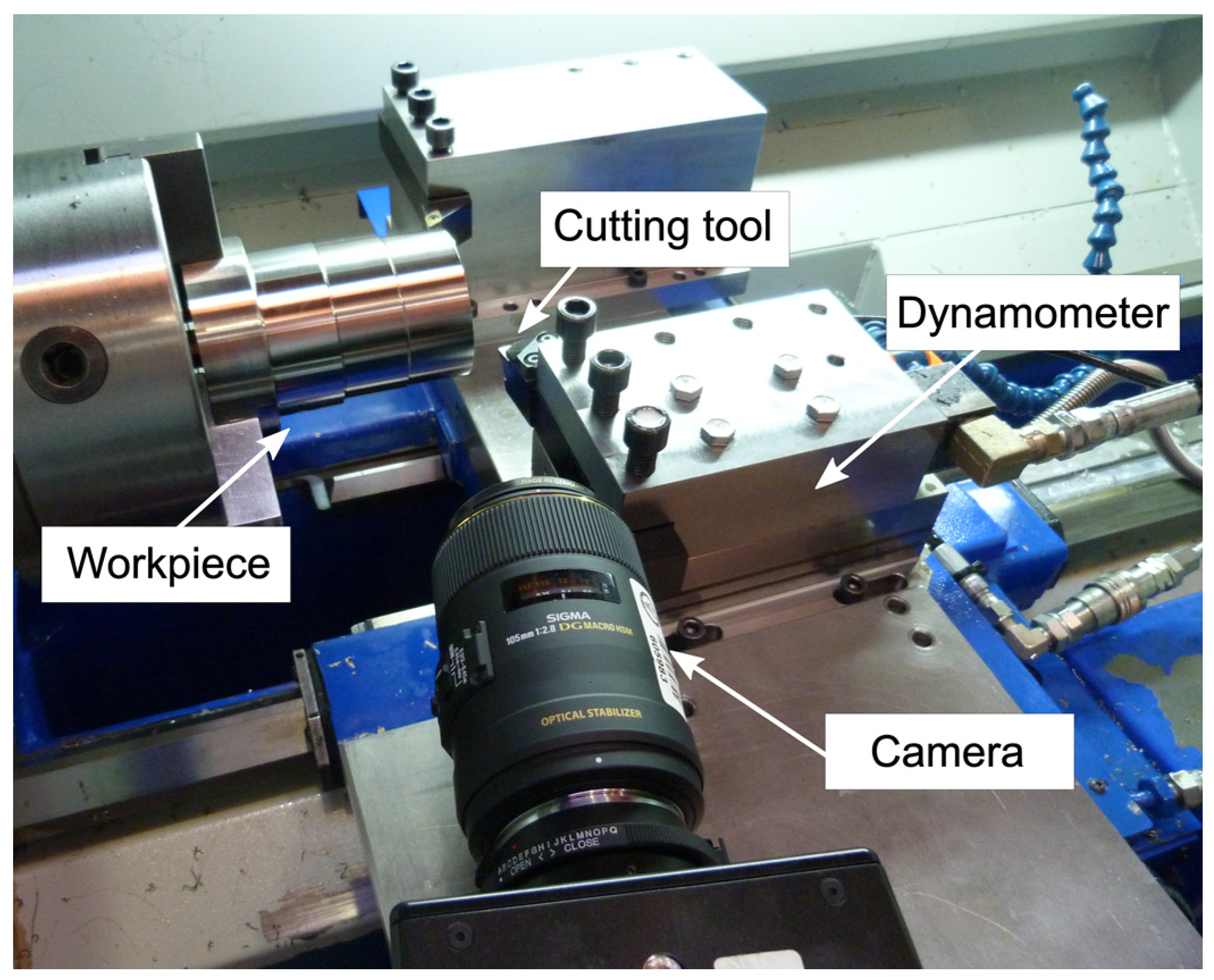

2. Experimental Setup

2.1. Working Material and Cutting Tools

2.2. Experimental Setup and Measuring Instruments

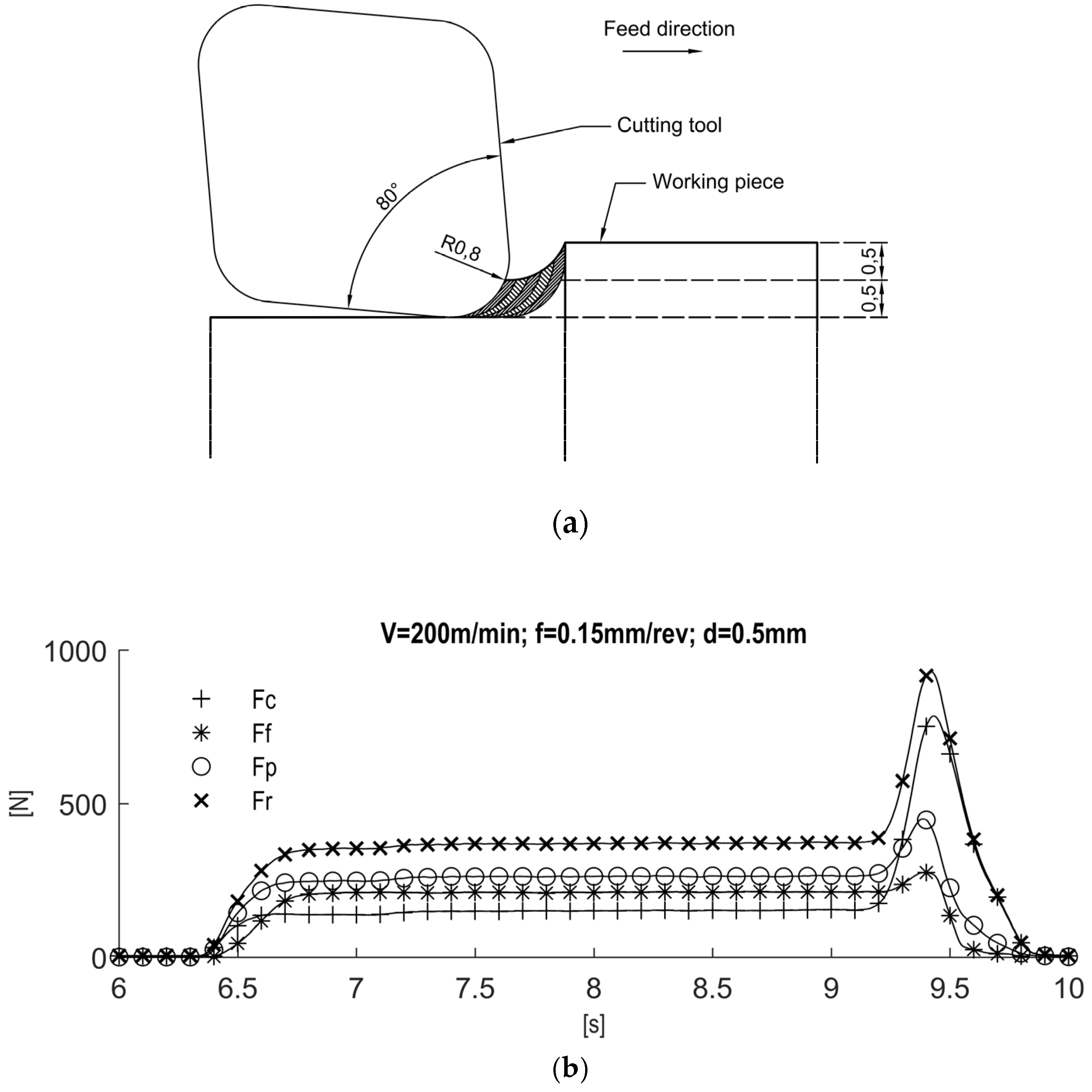

2.3. Experimental Procedure

3. Results

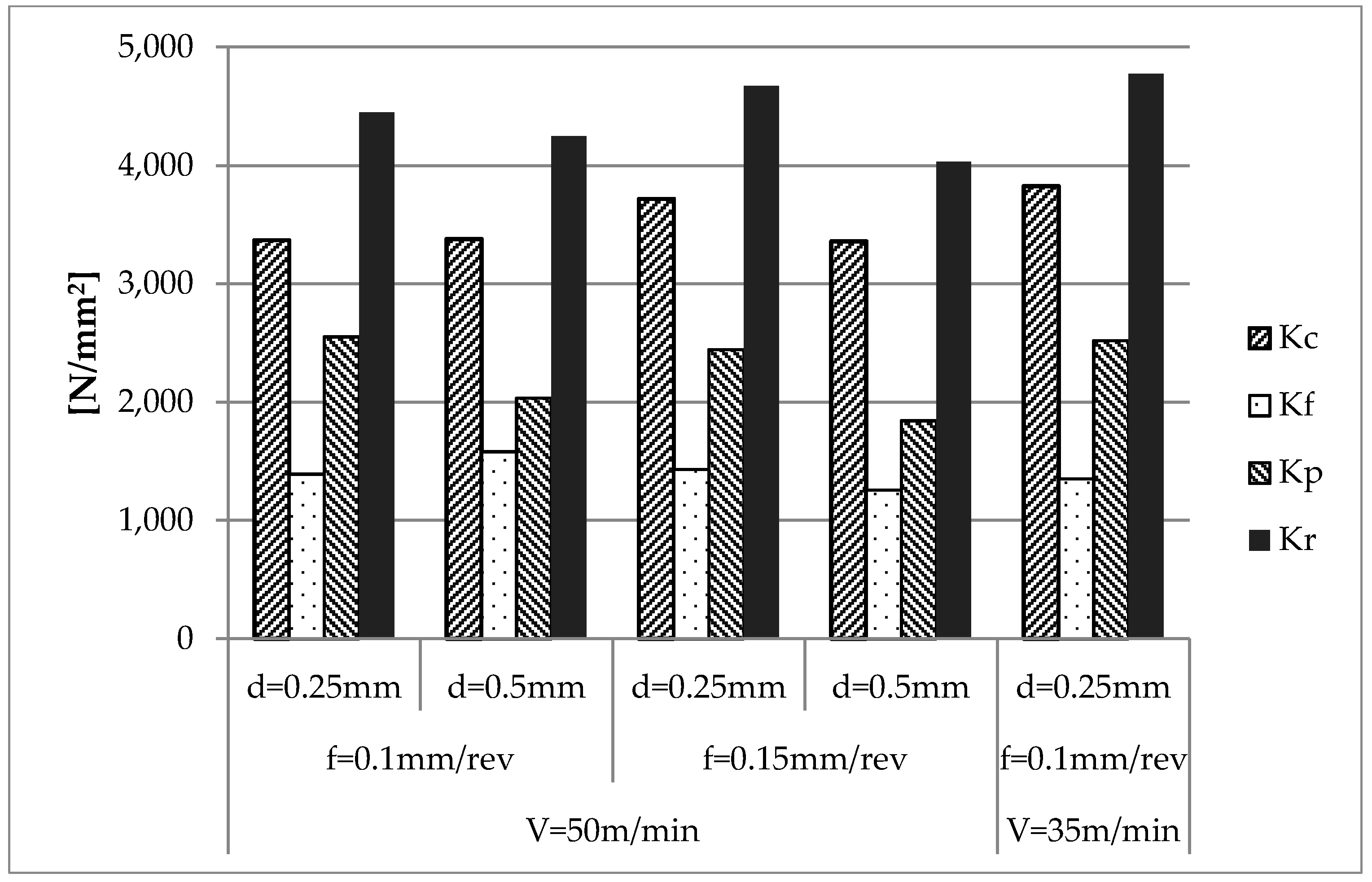

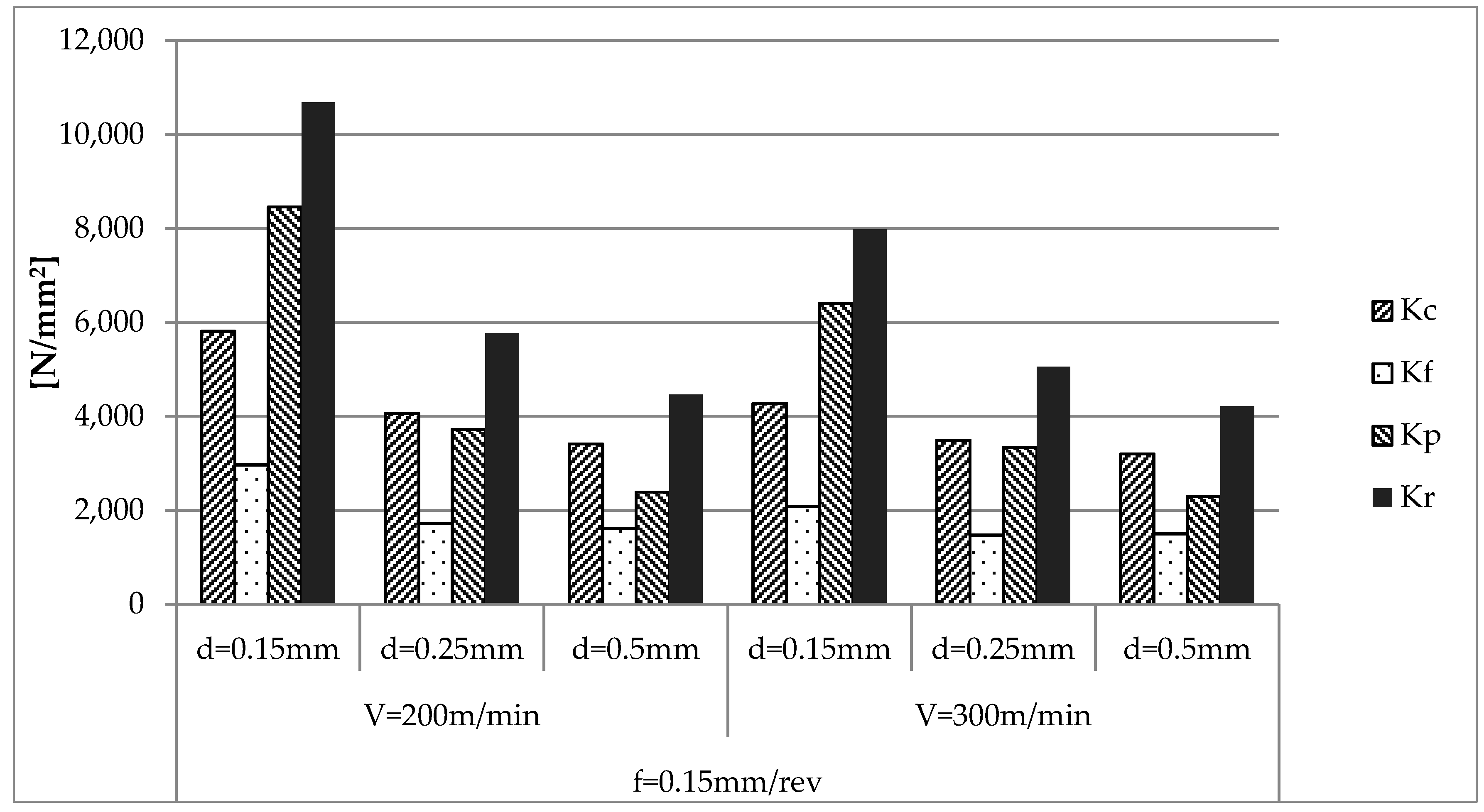

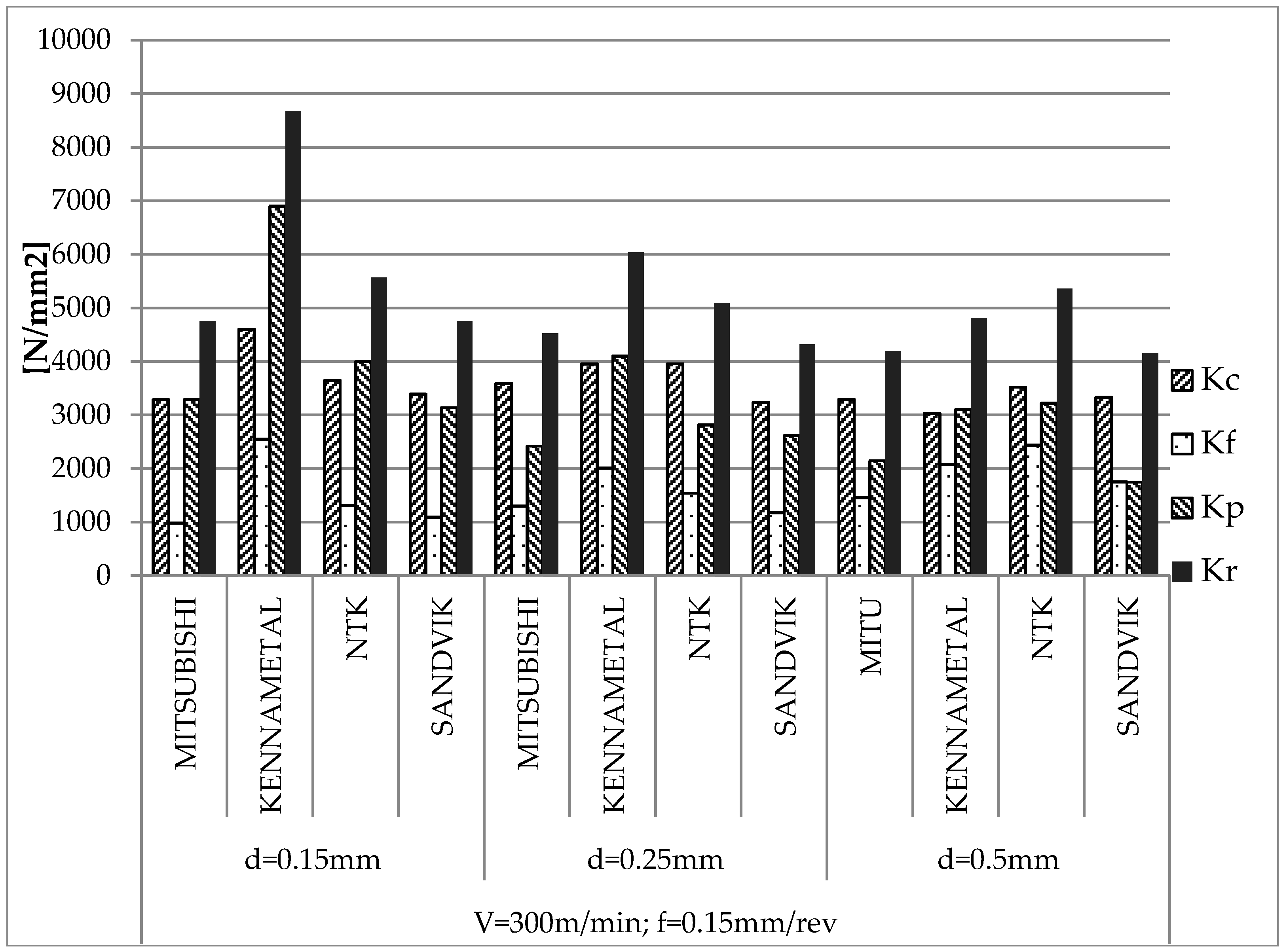

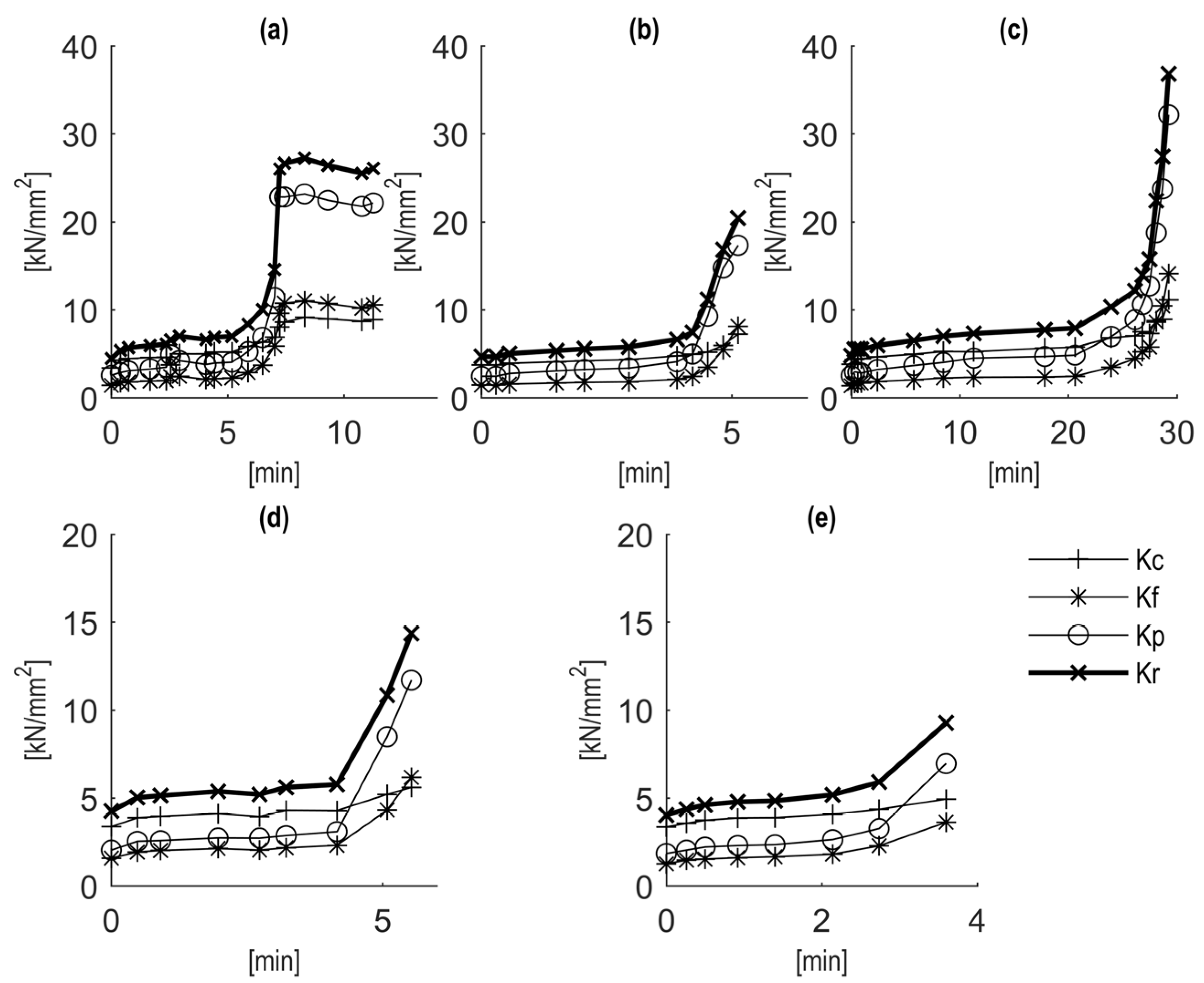

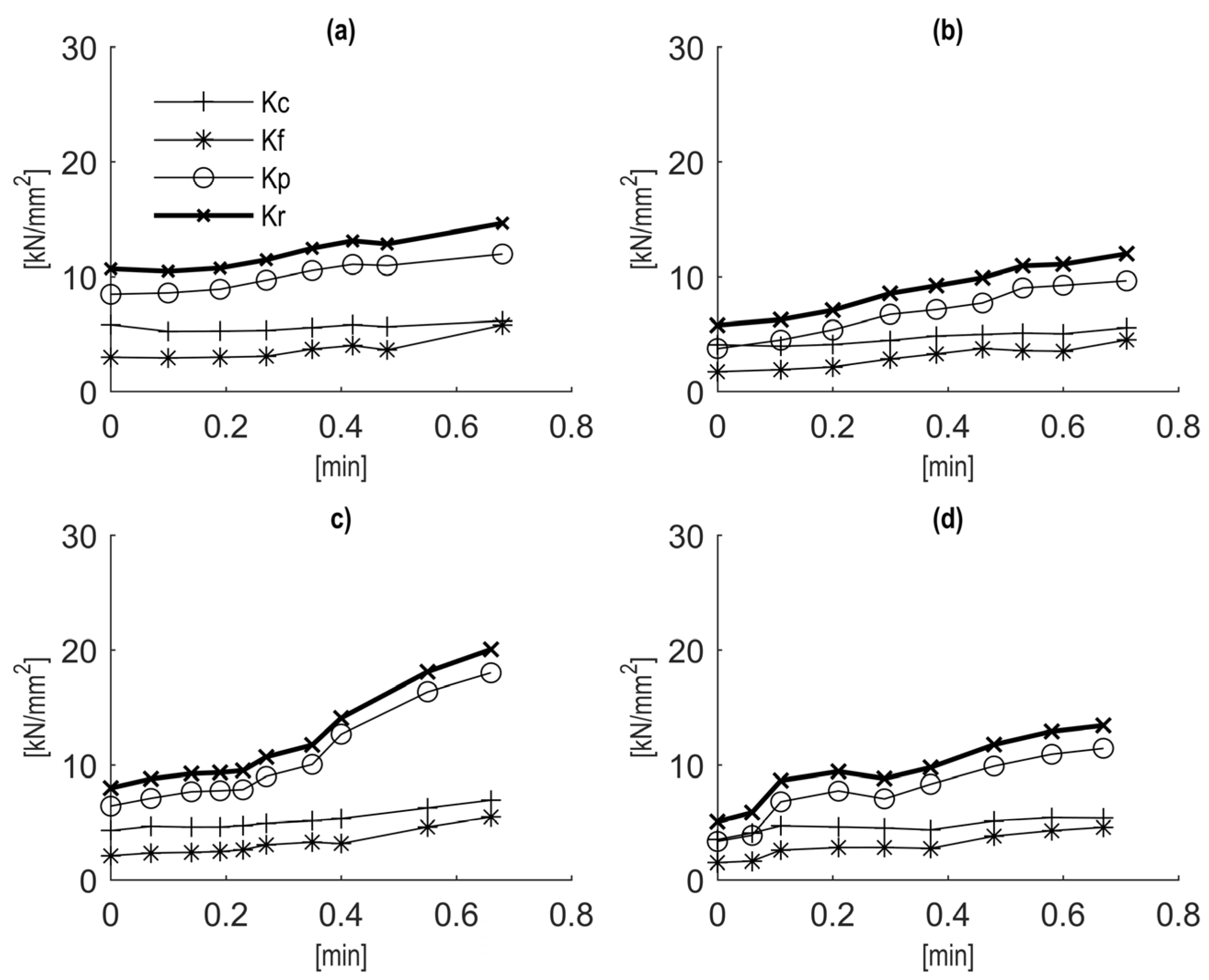

3.1. Experimental Results: Cutting Force Components

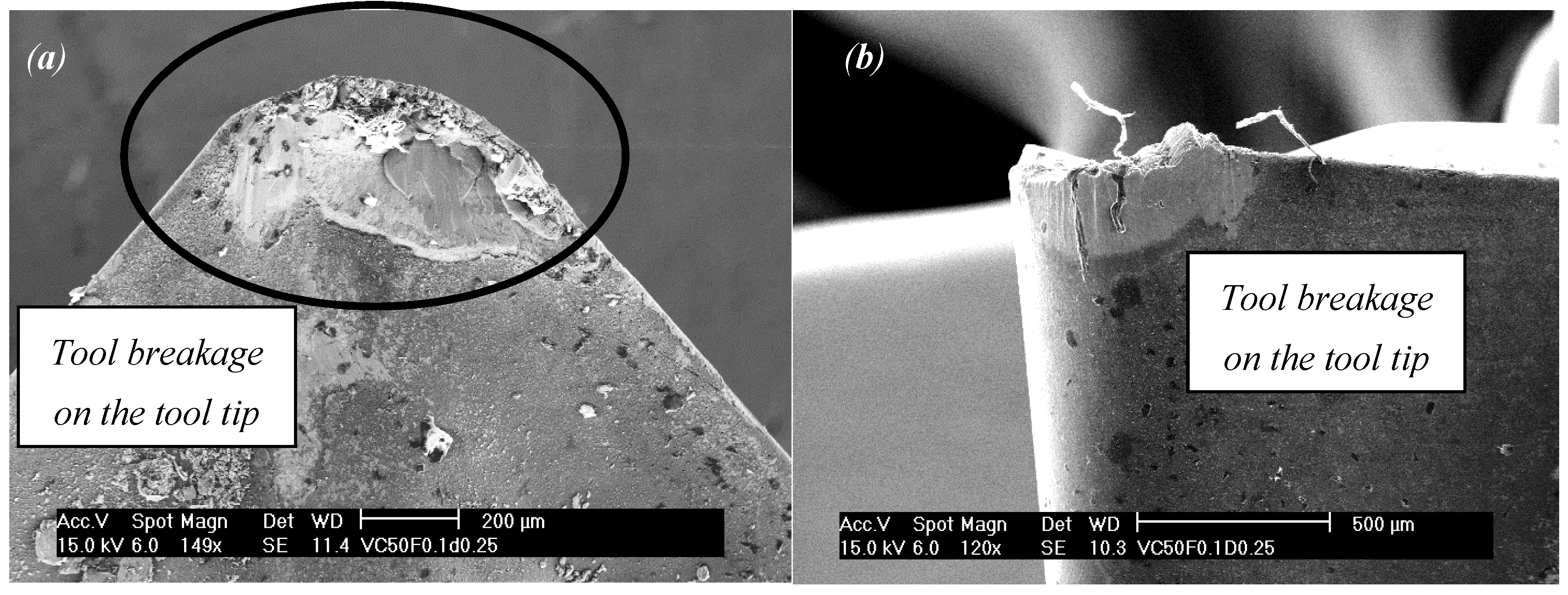

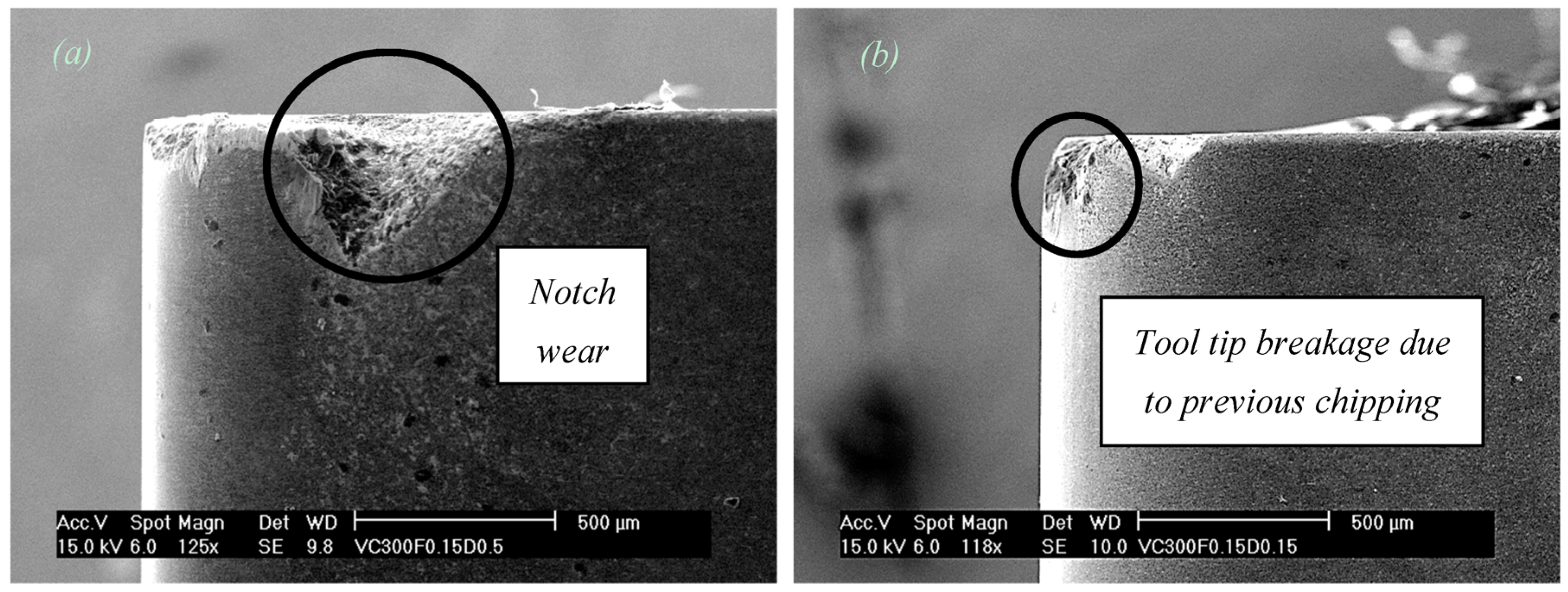

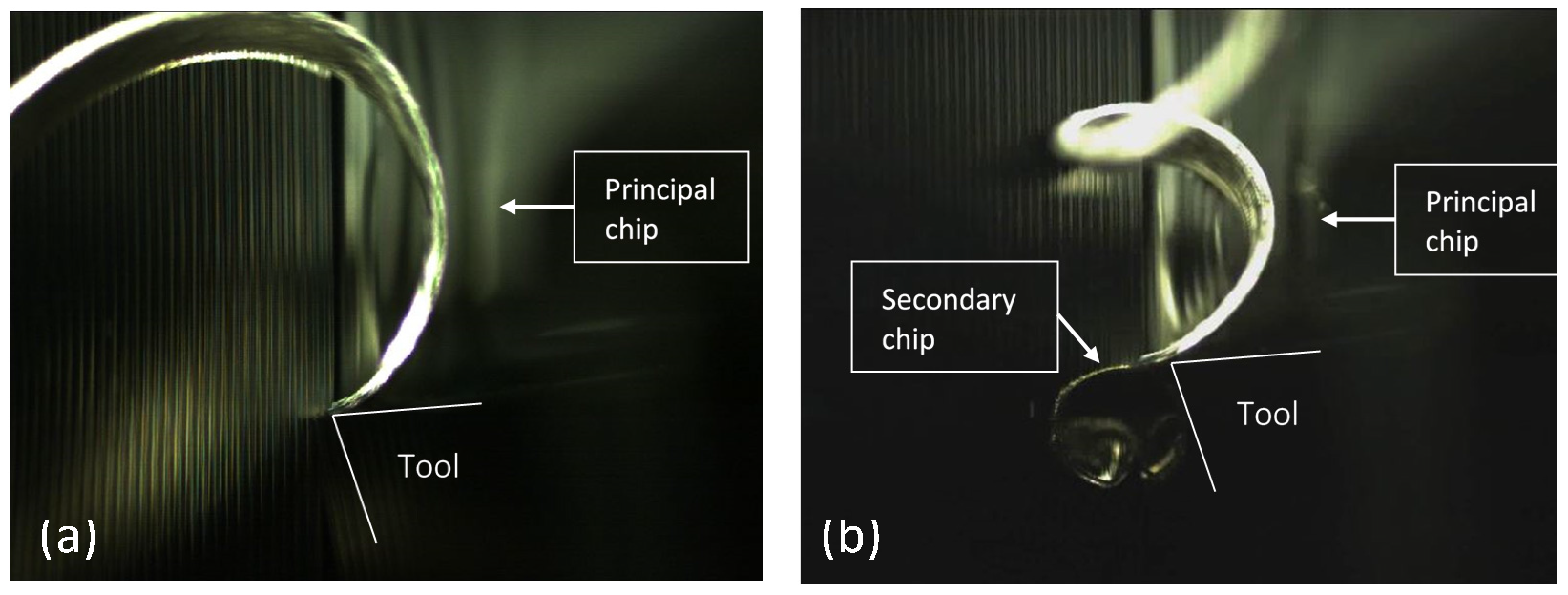

3.2. Experimental Results: Tool Wear

- (1)

- PCBN inserts have a much shorter life than carbide tools.

- (2)

- PCBN tools with a more robust edge geometry (chamfered honing and round honing with a radius of 35 µm) have a longer duration than tools with round honing with a radius of 35 µm.

- (3)

- An increase in depth of pass significantly reduces tool life.

- (4)

- Increased cutting speed increases the temperature and improves the stability of the cut but has very little effect on the durability of PCBN tools.

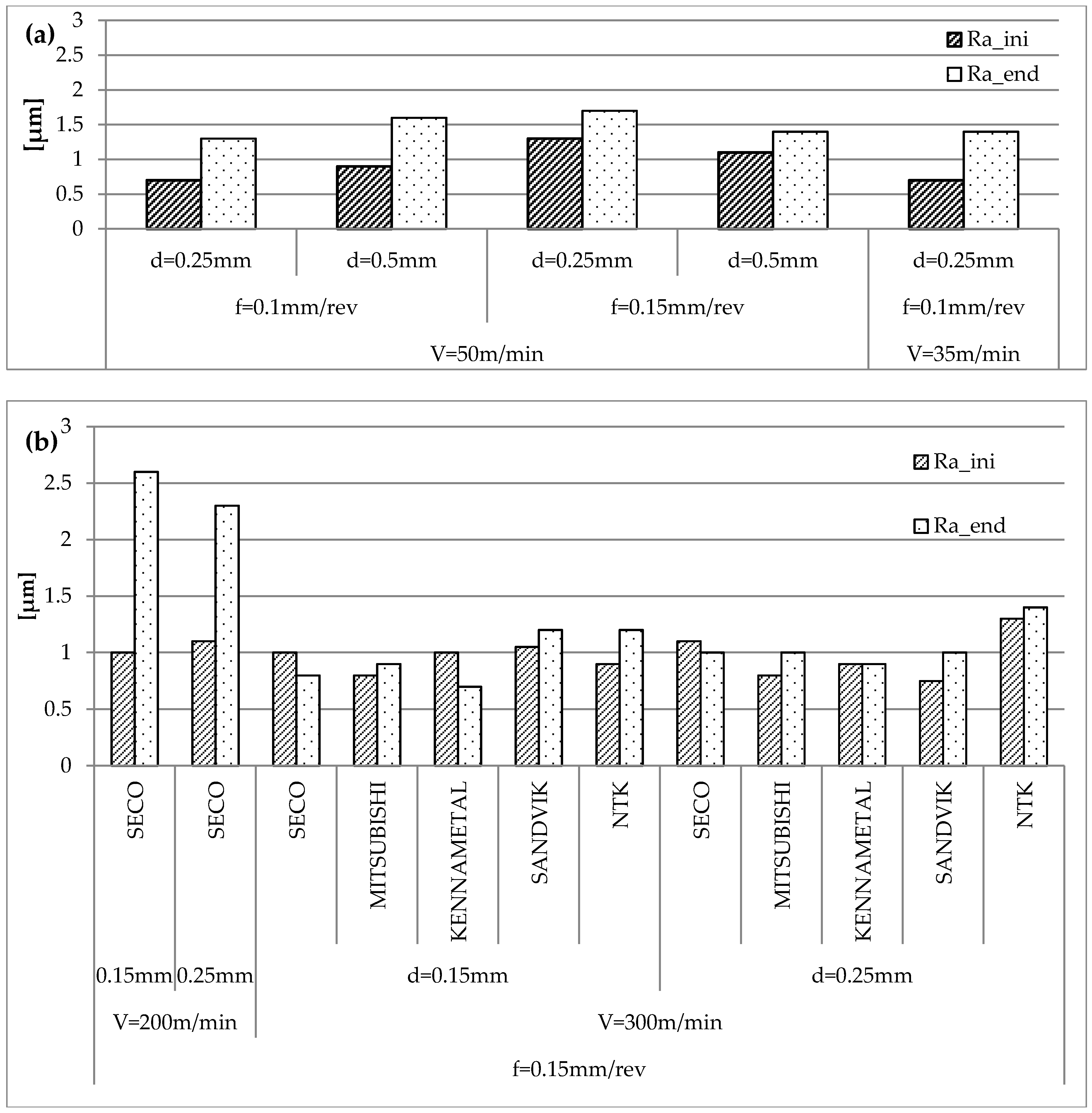

3.3. Experimental Results: Surface Finish

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| CBN | cubic boron nitride |

| d | depth of pass |

| f | feed rate |

| Fc | Cutting force |

| Ff | Feed force |

| Fp | Back force |

| Fr | Resultant force |

| Kc | Specific cutting force |

| Kf | Specific feed force |

| Kp | Specific back force |

| Kr | Specific resultant force |

| PCBN | Polycrystalline cubic boron nitride |

| SEM | Scanning electron microscopy |

| Smach/t | Machined surfaced per unit time |

| Sedge | Machined surface per cutting edge |

| T | Tool life |

| V | Cutting speed |

References

- Reed, R. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar] [CrossRef]

- Choudhury, I.A.; El-Baradie, M.A. Machinability of nickel-base super alloys: A general review. J. Mater. Process. Technol. 1998, 77, 278–284. [Google Scholar] [CrossRef]

- Polvorosa, R.; Suárez, A.; de Lacalle, L.N.L.; Cerrillo, I.; Wretland, A.; Veiga, F. Tool wear on nickel alloys with different coolant pressures: Comparison of Alloy 718 and Waspaloy. J. Manuf. Process. 2017, 26, 44–56. [Google Scholar] [CrossRef]

- Kitagawa, T.; Kubo, A.; Maekawa, K. Temperature and wear of cutting tools in high-speed machining of Inconel 718 and Ti6Al6V2Sn. Wear 1997, 202, 142–148. [Google Scholar] [CrossRef]

- Rahman, M.; Seah, W.K.H.; Teo, T.T. The machinability of inconel 718. J. Mater. Process. Technol. 1997, 63, 199–204. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Wang, Z.M.; Machado, A.R. The machinability of nickel-based alloys: A review. J. Mater. Process. Technol. 1999, 86, 1–16. [Google Scholar] [CrossRef]

- Olovsjö, S.; Nyborg, L. Influence of microstructure on wear behaviour of uncoated WC tools in turning of Alloy 718 and Waspaloy. Wear 2012, 282–283, 12–21. [Google Scholar] [CrossRef]

- Bhatt, A.; Attia, H.; Vargas, R.; Thomson, V. Wear mechanisms of WC coated and uncoated tools in finish turning of Inconel 718. Tribol. Int. 2010, 43, 1113–1121. [Google Scholar] [CrossRef]

- Fernández-Valdivielso, A.; López De Lacalle, L.N.; Urbikain, G.; Rodriguez, A. Detecting the key geometrical features and grades of carbide inserts for the turning of nickel-based alloys concerning surface integrity. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2016, 230, 3725–3742. [Google Scholar] [CrossRef]

- Costes, J.P.; Guillet, Y.; Poulachon, G.; Dessoly, M. Tool-life and wear mechanisms of CBN tools in machining of Inconel 718. Int. J. Mach. Tools Manuf. 2007, 47, 1081–1087. [Google Scholar] [CrossRef]

- M’Saoubi, R.; Larsson, T.; Outeiro, J.; Guo, Y.; Suslov, S.; Saldana, C.; Chandrasekar, S. Surface integrity analysis of machined Inconel 718 over multiple length scales. CIRP Ann. Manuf. Technol. 2012, 61, 99–102. [Google Scholar] [CrossRef]

- Calleja, A.; Barrio, H.G.; Teijeiro, R.P.; Marcaide, D.L. Multitasking machines: Evolution, resources, processes and scheduling. DYNA 2017, 92, 637–642. [Google Scholar] [CrossRef]

- Tanaka, H.; Sugihara, T.; Enomoto, T. High Speed Machining of Inconel 718 Focusing on Wear Behaviors of PCBN Cutting Tool. Procedia CIRP 2016, 46, 545–548. [Google Scholar] [CrossRef]

- Soo, S.L.; Khan, S.A.; Aspinwall, D.K.; Harden, P.; Mantle, A.L.; Kappmeyer, G.; Pearson, D.; M’Saoubi, R. High speed turning of Inconel 718 using PVD-coated PCBN tools. CIRP Ann. Manuf. Technol. 2016, 65, 89–92. [Google Scholar] [CrossRef]

- Díaz-Álvarez, J.; Tapetado, A.; Vázquez, C.; Miguélez, H. Temperature measurement and numerical prediction in machining inconel 718. Sensors 2017, 17, 1531. [Google Scholar] [CrossRef] [PubMed]

- Goindi, G.S.; Sarkar, P. Dry machining: A step towards sustainable machining—Challenges and future directions. J. Clean. Prod. 2017, 165, 1557–1571. [Google Scholar] [CrossRef]

- Devillez, A.; Schneider, F.; Dominiak, S.; Dudzinski, D.; Larrouquere, D. Cutting forces and wear in dry machining of Inconel 718 with coated carbide tools. Wear 2007, 262, 931–942. [Google Scholar] [CrossRef]

- Pereira, O.; Martín-Alfonso, J.E.; Rodríguez, A.; Calleja, A.; Fernández-Valdivielso, A.; López de Lacalle, L.N. Sustainability analysis of lubricant oils for minimum quantity lubrication based on their tribo-rheological performance. J. Clean. Prod. 2017, 164, 1419–1429. [Google Scholar] [CrossRef]

- Cantero, J.L.; Díaz-Álvarez, J.; Miguélez, M.H.; Marín, N.C. Analysis of tool wear patterns in finishing turning of Inconel 718. Wear 2013, 297, 885–894. [Google Scholar] [CrossRef]

- Davoudinejad, A.; Noordin, M.Y. Effect of cutting edge preparation on tool performance in hard-turning of DF-3 tool steel with ceramic tools. J. Mech. Sci. Technol. 2014, 28, 4727–4736. [Google Scholar] [CrossRef]

| Element | Ni | Cr | Fe | Nb | Mo | Ti | Al | Co. | Si | Cu | Mn | C |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| % | 53.02 | 18.49 | 18.12 | 5.40 | 3.06 | 0.96 | 0.55 | 0.10 | 0.06 | 0.05 | 0.06 | 0.03 |

| Manufacturer (Grade) | Substrate Composition | Cutting Edge Geometry | Nose Radius | Coating |

|---|---|---|---|---|

| Seco (TS2000) | Carbide | Round honing: radius 25 µm | 0.4 | TiAlN + TiN coated |

| Seco (CBN170) | PCBN (65% CBN, ceramic binder). | Round honing: radius 25 µm | 0.8 | Without coating |

| Sandvik (7015) | PCBN (50% CBN, ceramic binder). | Round honing: radius 35 µm | 0.8 | TiN coated. |

| NTK (JP2) | Confidential information | Chamfer honing: Honing width 50 µm, Honing angle: −20°. | 0.8 | TiN coated. |

| Mitsubishi (MB8025) | PCBN (60% CBN, ceramic binder). | Chamfer honing: Honing width 50 µm, Honing angle: −15°. | 0.8 | Without coating |

| Kennametal (KB5625) | PCBN (medium-CBN content, ceramic binder). | Round honing: radius 25 µm | 0.8 | TiAlN coated |

| Set of Tests Number | Tool Material (Tool Grade) | Cutting Speed (m/min) | Feed (mm/rev) | Depth of Pass (mm) |

|---|---|---|---|---|

| Set 1 | Carbide tool (TS2000, Seco) | 35 | 0.1 | 0.25 |

| 50 | 0.1 | 0.25 | ||

| 0.5 | ||||

| 0.15 | 0.25 | |||

| 0.5 | ||||

| Set 2 | PCBN (CBN170, Seco) | 200 | 0.15 | 0.15 |

| 0.25 | ||||

| 0.5 | ||||

| 300 | 0.15 | 0.15 | ||

| 0.25 | ||||

| 0.5 | ||||

| Set 3 | PCBN (MB8025, Mitsubishi) | 300 | 0.15 | 0.15 |

| 0.25 | ||||

| 0.5 | ||||

| PCBN (KB5625, Kennametal) | 300 | 0.15 | 0.15 | |

| 0.25 | ||||

| 0.5 | ||||

| PCBN (7015, Sandvik) | 300 | 0.15 | 0.15 | |

| 0.25 | ||||

| 0.5 | ||||

| JP2 (NTK) | 300 | 0.15 | 0.15 | |

| 0.25 | ||||

| 0.5 |

| Tool Material (Tool Grade) | Cutting Speed (m/min) | Feed (mm/rev) | Depth of Pass (mm) | Tool Life (min) | Machined Surface Per Unit Time (mm2/s) | Machined Surface per Cutting Edge (mm2/edge) |

|---|---|---|---|---|---|---|

| Carbide tool (TS2000, Seco) | 35 | 0.1 | 0.25 | 28.7 | 58.33 | 100,450 |

| 50 | 0.1 | 0.25 | 10.1 | 83.33 | 50,500 | |

| 0.5 | 6 | 83.33 | 30,000 | |||

| 0.15 | 0.25 | 5.4 | 125 | 40,500 | ||

| 0.5 | 3.9 | 125 | 29,250 | |||

| PCBN (CBN170, Seco) | 200 | 0.15 | 0.15 | 0.8 | 500 | 24,000 |

| 0.25 | 0.8 | 500 | 24,000 | |||

| 0.5 | 0.2 | 500 | 6000 | |||

| 300 | 0.15 | 0.15 | 0.8 | 750 | 36,000 | |

| 0.25 | 0.7 | 750 | 31,500 | |||

| 0.5 | 0.2 | 750 | 9000 | |||

| PCBN (MB8025, Mitsubishi) | 300 | 0.15 | 0.15 | 1.4 | 750 | 63,000 |

| 0.25 | 0.5 | 750 | 22,500 | |||

| 0.5 | 0.3 | 750 | 13,500 | |||

| PCBN (KB5625, Kennametal) | 300 | 0,15 | 0.15 | 0.7 | 750 | 31,500 |

| 0.25 | 0.4 | 750 | 18,000 | |||

| 0.5 | 0.3 | 750 | 13,500 | |||

| PCBN (7015, Sandvik) | 300 | 0,15 | 0.15 | 1.6 | 750 | 72,000 |

| 0.25 | 0.7 | 750 | 31,500 | |||

| 0.5 | 0.4 | 750 | 18,000 | |||

| JP2 (NTK) | 300 | 0,15 | 0.15 | 1.6 | 750 | 72,000 |

| 0.25 | 0.7 | 750 | 31,500 | |||

| 0.5 | 0.7 | 750 | 31,500 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cantero, J.L.; Díaz-Álvarez, J.; Infante-García, D.; Rodríguez, M.; Criado, V. High Speed Finish Turning of Inconel 718 Using PCBN Tools under Dry Conditions. Metals 2018, 8, 192. https://doi.org/10.3390/met8030192

Cantero JL, Díaz-Álvarez J, Infante-García D, Rodríguez M, Criado V. High Speed Finish Turning of Inconel 718 Using PCBN Tools under Dry Conditions. Metals. 2018; 8(3):192. https://doi.org/10.3390/met8030192

Chicago/Turabian StyleCantero, José Luis, José Díaz-Álvarez, Diego Infante-García, Marcos Rodríguez, and Víctor Criado. 2018. "High Speed Finish Turning of Inconel 718 Using PCBN Tools under Dry Conditions" Metals 8, no. 3: 192. https://doi.org/10.3390/met8030192

APA StyleCantero, J. L., Díaz-Álvarez, J., Infante-García, D., Rodríguez, M., & Criado, V. (2018). High Speed Finish Turning of Inconel 718 Using PCBN Tools under Dry Conditions. Metals, 8(3), 192. https://doi.org/10.3390/met8030192