The Application of 40Ti-35Ni-25Nb Filler Foil in Brazing Commercially Pure Titanium

Abstract

1. Introduction

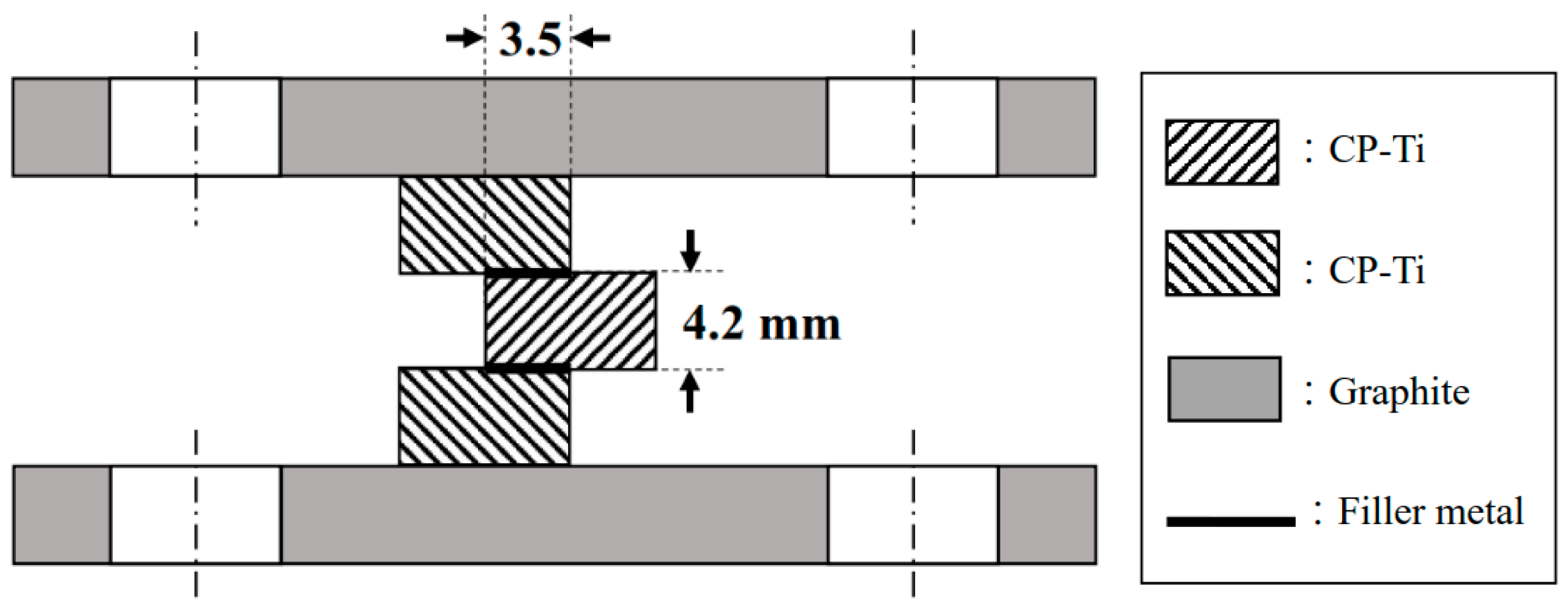

2. Materials and Experimental Procedures

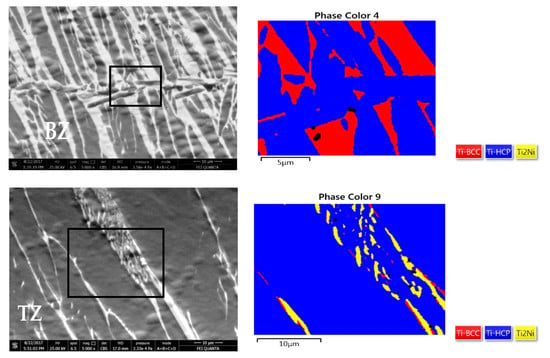

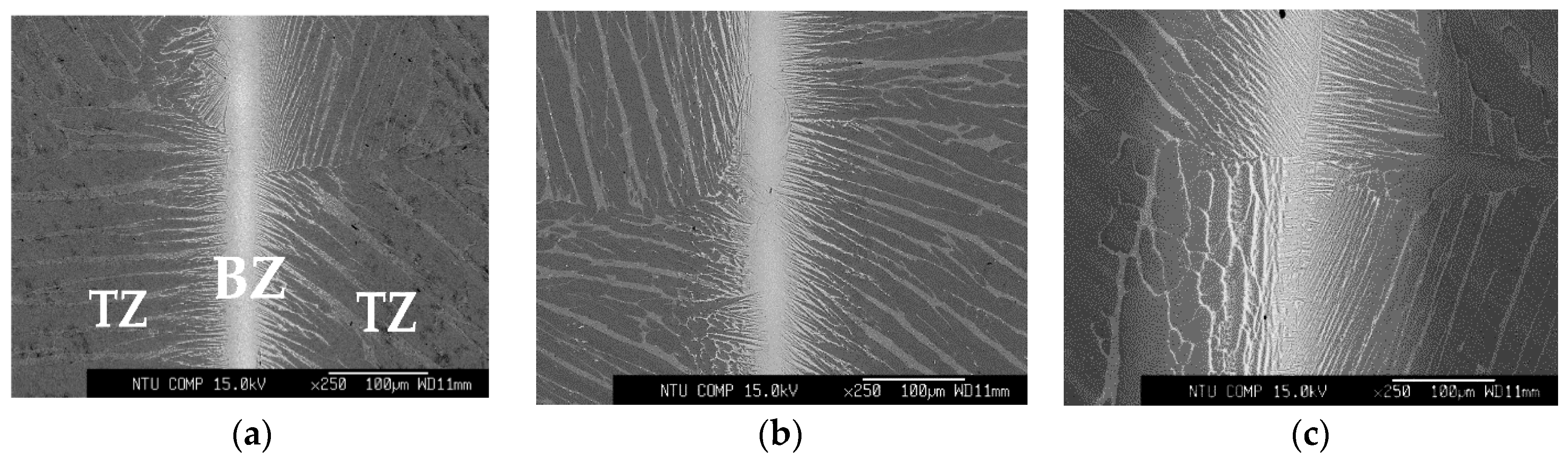

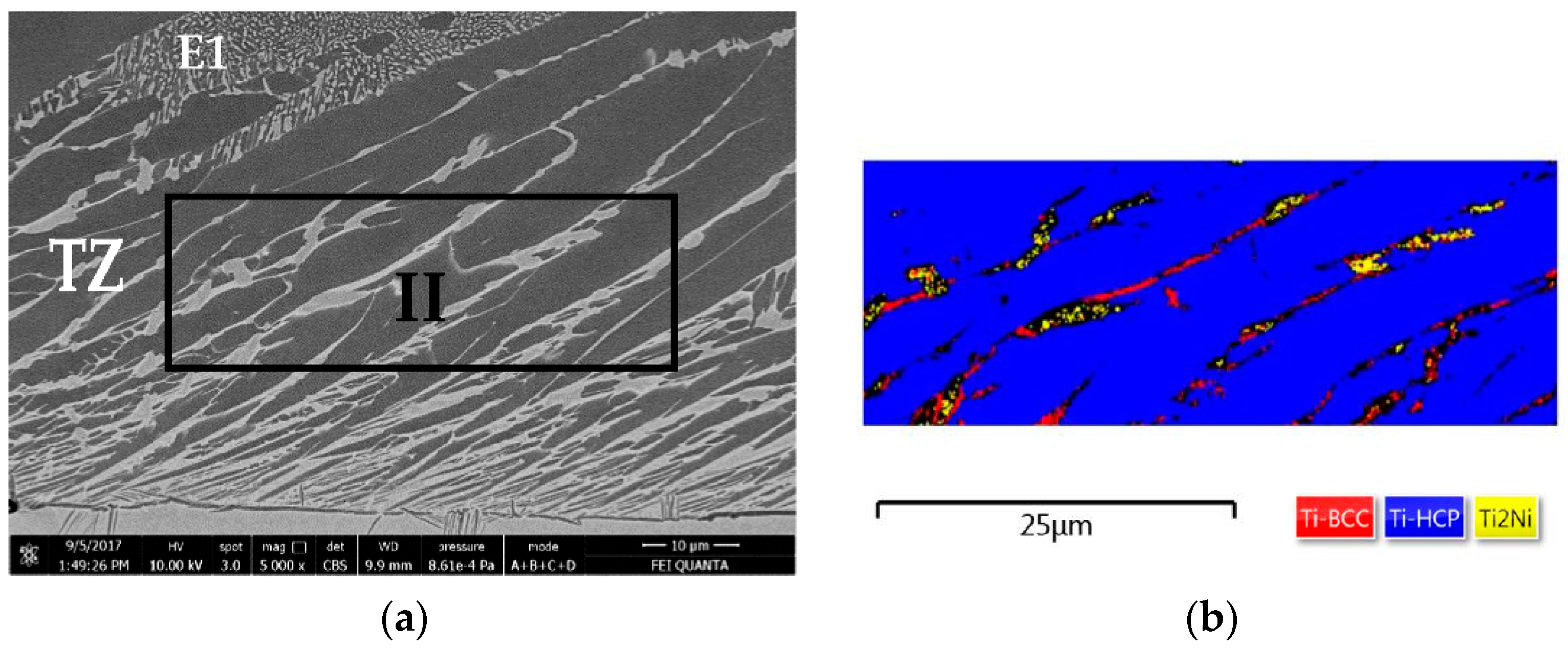

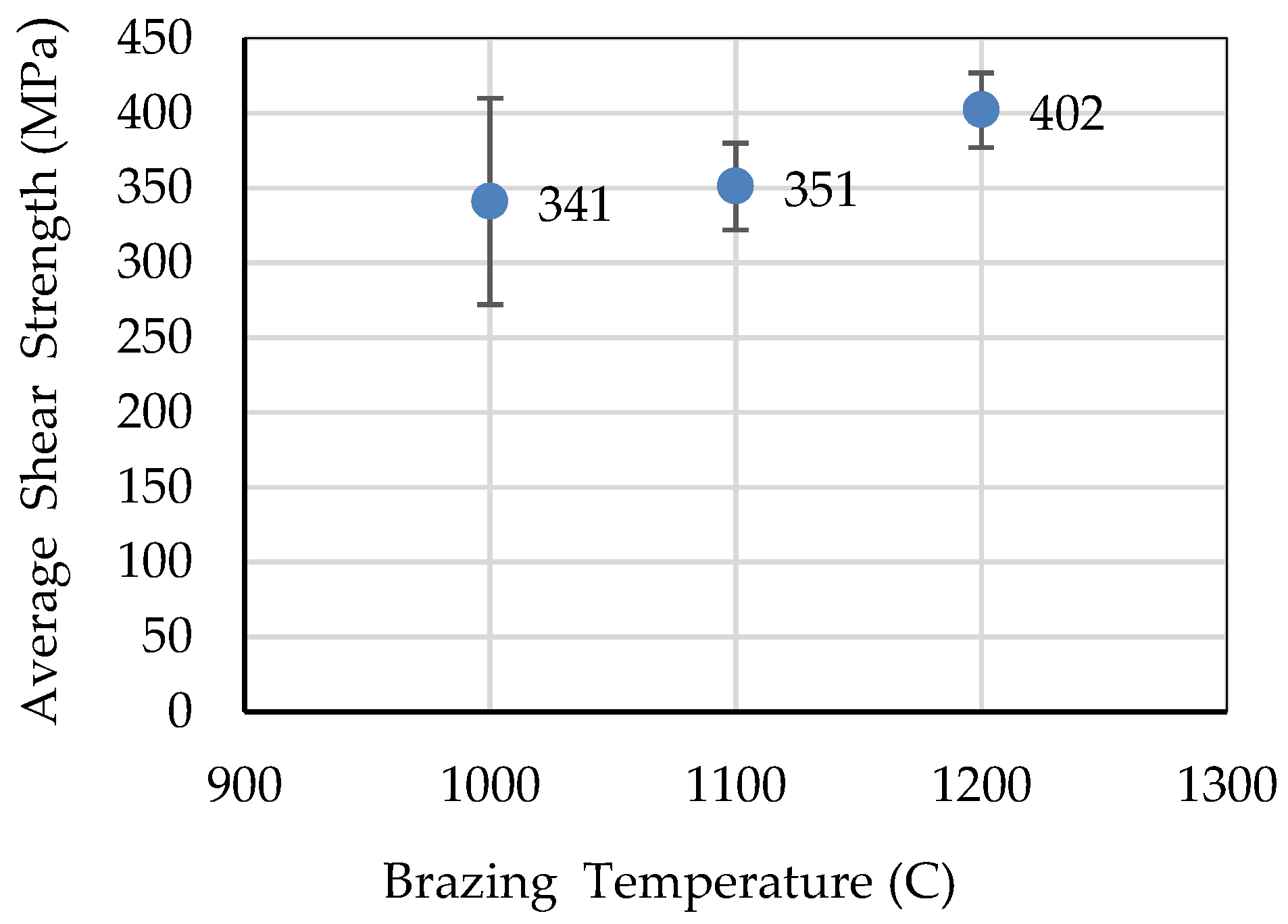

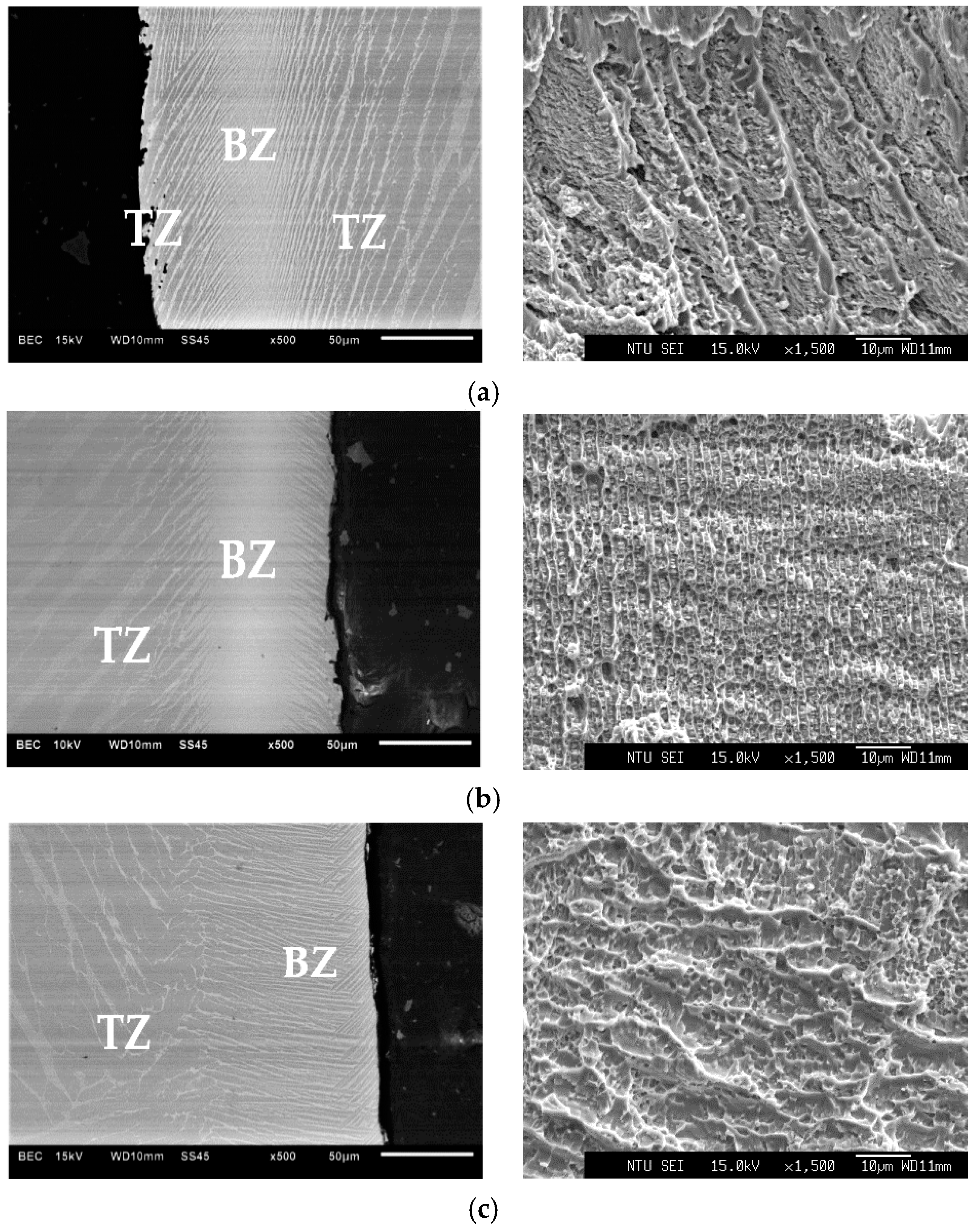

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Davis, J.R. ASM Handbook Volume 2 Properties and Selection: Nonferrous Alloys and Special-Purpose Materials; ASM International: Cleveland, OH, USA, 1990; pp. 661–669. [Google Scholar]

- Smith, W.F. Structure and Properties of Engineering Alloys; McGraw-Hill Book, Co.: New York, NY, USA, 1993; pp. 433–484. [Google Scholar]

- Attar, H.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Manufacture by selective laser melting and mechanical behavior of commercially pure titanium. Mater. Sci. Eng. A 2014, 593, 170–177. [Google Scholar] [CrossRef]

- Attar, H.; Bonisch, M.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Selective laser melting of in situ titanium–titanium boride composites: Processing, microstructure and mechanical properties. Acta Mater. 2014, 76, 13–22. [Google Scholar] [CrossRef]

- Okulov, I.V.; Wendrock, H.; Volegov, A.S.; Attar, H.; Kühn, U.; Skrotzki, W. High strength beta titanium alloys: New design approach. Mater. Sci. Eng. A 2015, 628, 297–302. [Google Scholar] [CrossRef]

- Roger, R.; Collings, E.W.; Welsch, G. Materials Properties Handbook: Titanium Alloys; ASM International: Cleveland, OH, USA, 1993; pp. 1–3. [Google Scholar]

- Walter, J.L.; Jackson, M.R.; Sims, C.T. Titanium and Its Alloys: Principles of Alloying Titanium; ASM International: Cleveland, OH, USA, 1988; pp. 23–33. [Google Scholar]

- Yeh, T.Y.; Shiue, R.K.; Chang, C.S. Microstructural evolution of brazed CP-Ti using the clad Ti-20Zr-20Cu-20Ni foil. Metall. Mater. Trans. A 2013, 44, 9–14. [Google Scholar] [CrossRef]

- Yeh, T.Y.; Shiue, R.K.; Chang, C.S. Microstructural observation of brazed Ti-15-3 alloy using the clad Ti-20Zr-20Cu-20Ni foil. ISIJ Int. 2013, 53, 726–728. [Google Scholar] [CrossRef][Green Version]

- Humpston, G.; Jacobson, D.M. Principles of Soldering and Brazing; ASM International: Cleveland, OH, USA, 1993; pp. 31–69. [Google Scholar]

- Okulov, I.V.; Volegov, A.S.; Attar, H.; Bonisch, M.; Ehtemam-Haghighi, S.; Calin, M. Composition optimization of low modulus and high-strength TiNb-based alloys for biomedical application. J. Mech. Behav. Biomed. Mater. 2017, 65, 866–871. [Google Scholar] [CrossRef] [PubMed]

- Ehtemam-Haghighi, S.; Prashanth, K.G.; Attar, H.; Chaubey, A.K.; Cao, G.H.; Zhang, L.C. Evaluation of mechanical and wear properties of Ti-xNb-7Fe alloys designed for biomedical applications. Mater. Des. 2016, 111, 592–599. [Google Scholar] [CrossRef]

- Massalski, T.B. Binary Alloy Phase Diagrams; ASM International: Cleveland, OH, USA, 1990. [Google Scholar]

- Shiue, R.K.; Wu, S.K.; Chen, Y.T. Strong bonding of infrared brazed α2-Ti3Al and Ti-6Al-4V using Ti-Cu-Ni fillers. Intermetallics 2010, 18, 107–114. [Google Scholar] [CrossRef]

- Zou, Z.H.; Zeng, F.H.; Wu, H.B.; Liu, J.; Li, Y.; Gu, Y.; Yuan, T.C.; Zhang, F.Q. The Joint strength and fracture mechanisms of TC4/TC4 and TA0/TA0 brazed with Ti-25Cu-15Ni braze alloy. J. Mater. Eng. Perform. 2017, 26, 2079–2085. [Google Scholar] [CrossRef]

- Gey, N.; Humbert, M. Specific analysis of EBSD data to study the texture inheritance due to the β → α phase transformation. J. Mater. Sci. 2003, 38, 1289–1294. [Google Scholar] [CrossRef]

- Kurpaska, L.; Jozwik, I.; Jagieiski, J. Study of sub-oxide phases at metal-oxide interface in oxidized pure zirconium and Zr-1.0% Nb alloy by using SEM/FIB/EBSD techniques. J. Nucl. Mater. 2016, 476, 56–62. [Google Scholar] [CrossRef]

- Lin, C.Z.; Shiue, R.K. Vacuum brazing niobium using the clad 50Ti-35Ni-15Nb foil. Int. J. Refract. Met. Hard Mater. 2018, 71, 206–210. [Google Scholar] [CrossRef]

- Villars, P.; Prince, A.; Okamoto, H. Handbook of Ternary Alloy Phase Diagrams Volume 10; ASM International: Cleveland, OH, USA, 1997; pp. 12805–12808. [Google Scholar]

- Lide, D. CRC Handbook of Chemistry and Physics, 74th ed.; CRC Press: Ann Arbor, MI, USA, 1993; pp. 12–151. [Google Scholar]

- Chang, C.T.; Du, Y.C.; Shiue, R.K.; Chang, C.S. Infrared brazing of high-strength titanium alloys by Ti-15Cu-15Ni and Ti-15Cu-25Ni filler foils. Mater. Sci. Eng. A 2006, 420, 155–164. [Google Scholar] [CrossRef]

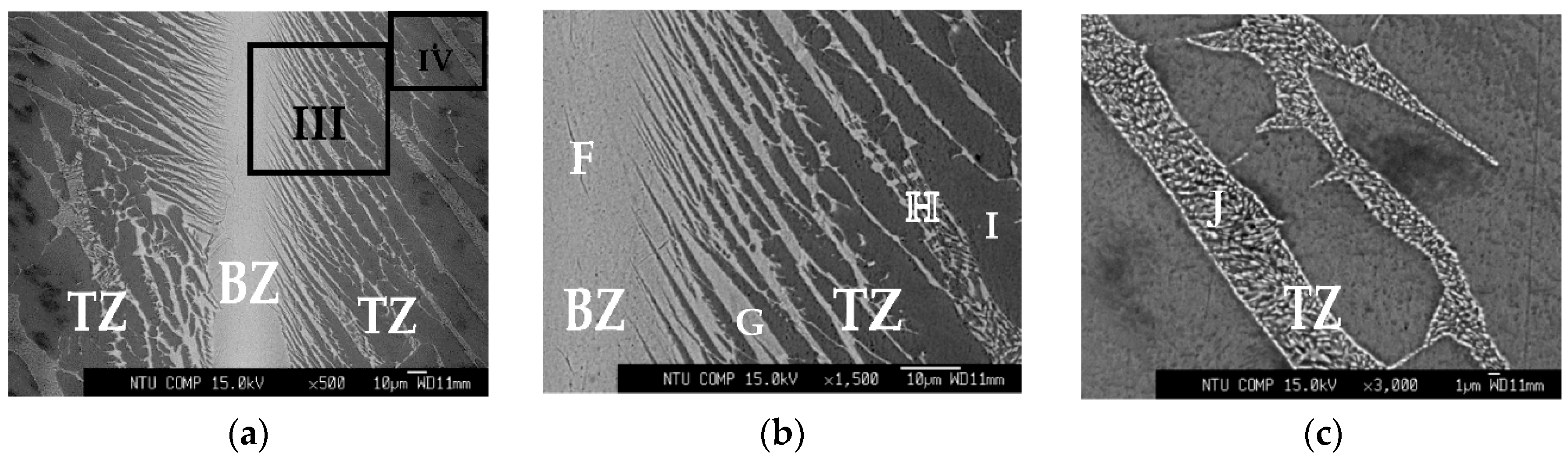

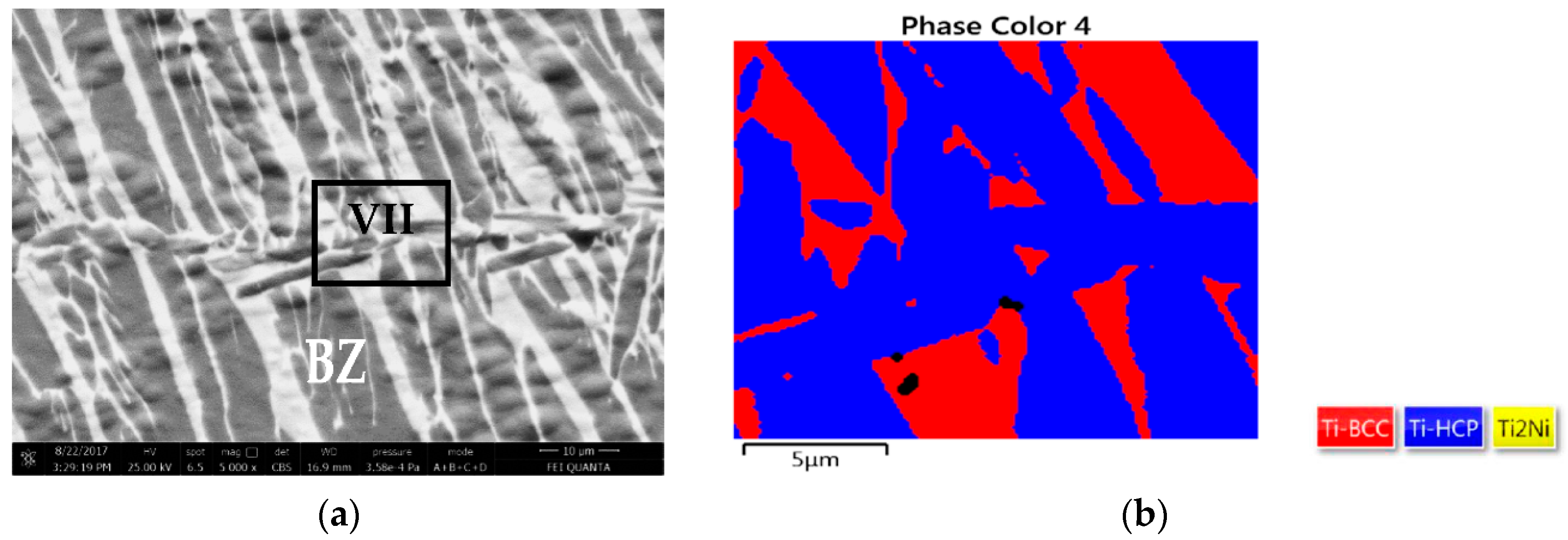

| at % | A | B | C | D | E |

|---|---|---|---|---|---|

| Nb | 10.0 | 8.4 | 0.9 | 1.7 | 0.3 |

| Ni | 4.3 | 4.3 | 29.0 | 0.1 | 8.5 |

| Ti | 85.7 | 87.3 | 70.1 | 98.2 | 91.2 |

| Phase | β-Ti | retained β-Ti | Ti2Ni | α-Ti | eutectoid |

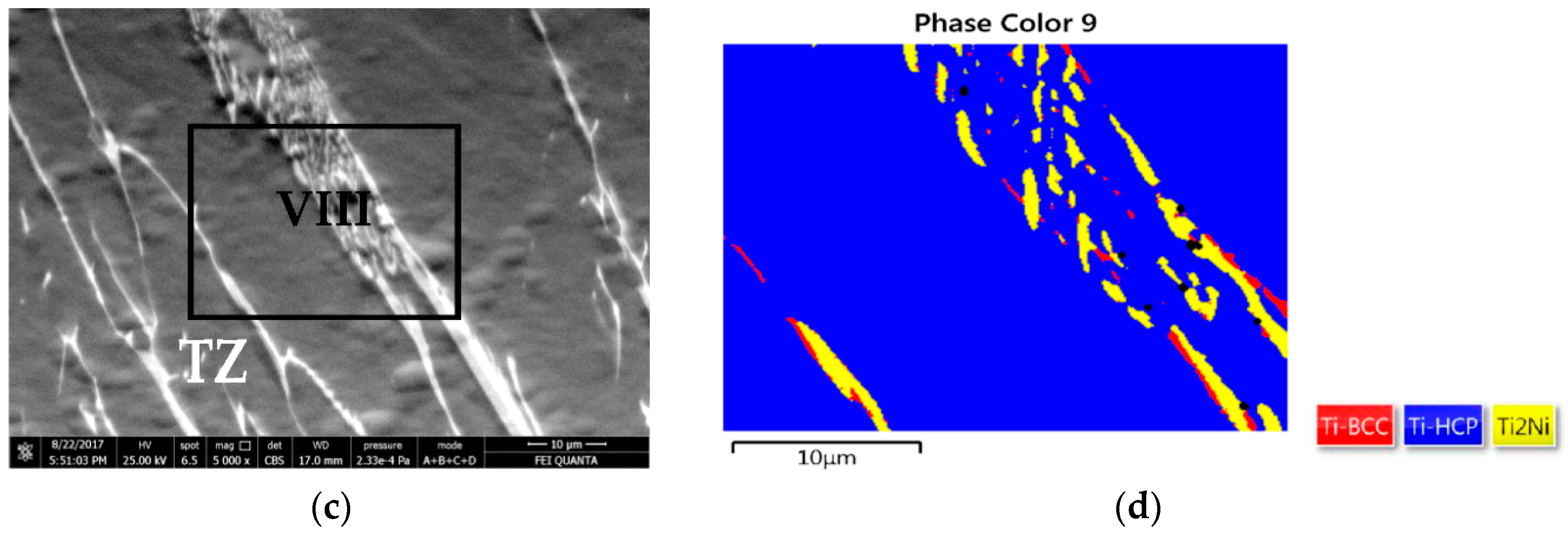

| at % | F | G | H | I | J |

|---|---|---|---|---|---|

| Nb | 11.5 | 8.3 | 0.2 | 1.2 | 0.1 |

| Ni | 1.8 | 5.4 | 15.0 | 0.1 | 9.3 |

| Ti | 86.7 | 86.3 | 84.8 | 98.7 | 90.6 |

| Phase | β-Ti | retained β-Ti | eutectoid | α-Ti | eutectoid |

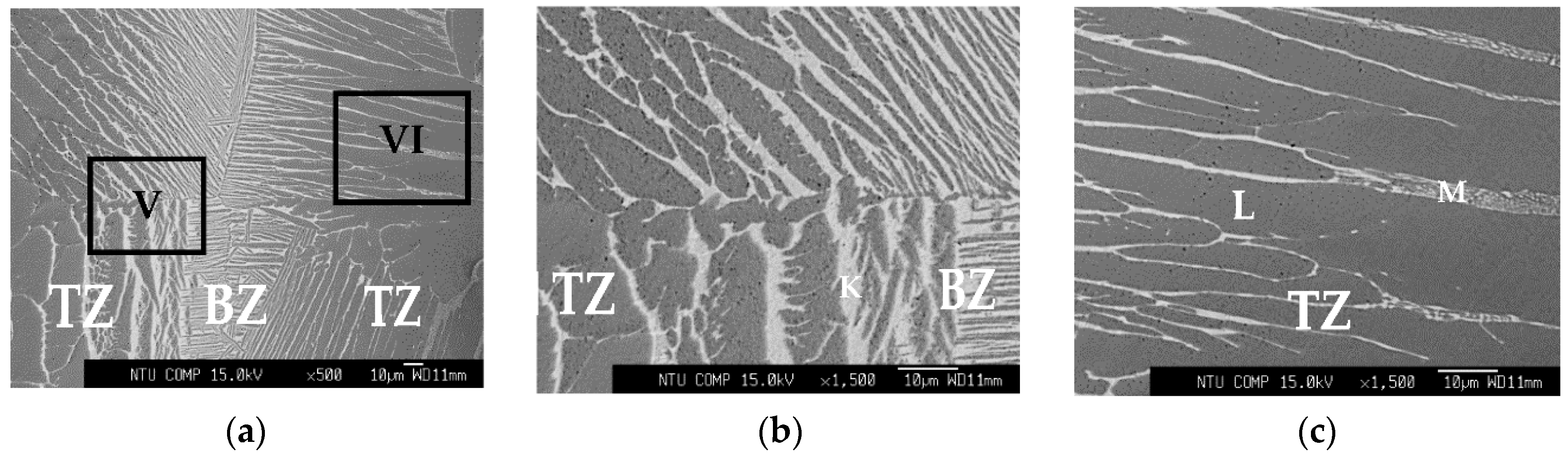

| at % | K | L | M |

|---|---|---|---|

| Nb | 10.5 | 2.3 | 0.3 |

| Ni | 4.6 | 0.2 | 8.4 |

| Ti | 84.9 | 97.5 | 91.3 |

| Phase | retained β-Ti | α-Ti | eutectoid |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.-B.; Kao, C.-S.; Tsay, L.-W.; Shiue, R.-K. The Application of 40Ti-35Ni-25Nb Filler Foil in Brazing Commercially Pure Titanium. Metals 2018, 8, 154. https://doi.org/10.3390/met8030154

Wang S-B, Kao C-S, Tsay L-W, Shiue R-K. The Application of 40Ti-35Ni-25Nb Filler Foil in Brazing Commercially Pure Titanium. Metals. 2018; 8(3):154. https://doi.org/10.3390/met8030154

Chicago/Turabian StyleWang, Shan-Bo, Chuan-Sheng Kao, Leu-Wen Tsay, and Ren-Kae Shiue. 2018. "The Application of 40Ti-35Ni-25Nb Filler Foil in Brazing Commercially Pure Titanium" Metals 8, no. 3: 154. https://doi.org/10.3390/met8030154

APA StyleWang, S.-B., Kao, C.-S., Tsay, L.-W., & Shiue, R.-K. (2018). The Application of 40Ti-35Ni-25Nb Filler Foil in Brazing Commercially Pure Titanium. Metals, 8(3), 154. https://doi.org/10.3390/met8030154