Abstract

This work shows a sequence of numerical models for the simulation of the Presta joining process: a well-established industrial process for manufacturing assembled camshafts. The operation is divided into two sub-steps: the rolling of the shaft to widen the cam seat and the joining of the cam onto the shaft. When manufactured, the connection is tested randomly by loading it with a static torque. Subsequently, there are three numerical models using the finite element method. Additionally, a material model of finite strain viscoplasticity with nonlinear kinematic hardening is used throughout the whole simulation process, which allows a realistic representation of the material behavior even for large deformations. In addition, it enables a transfer of the deformation history and of the internal stresses between different submodels. This work also shows the required parameter identification and the associated material tests. After comparing the numerical results with experimental studies of the manufacturing process for steel-steel connections, the models are used to extend the joining process to the utilization of aluminum shafts.

1. Introduction

In materials science and continuum mechanics, research is done on the development of complex constitutive models that are able to reproduce the elastic-viscoplastic material behavior of metals at large deformations. Nonetheless, there still is a lack of usage of those models in industrial applications, where detailed and complex simulation models are necessary, for example to analyze production processes and the resulting behavior of the produced structures. Moreover, increasing requirements of being lightweight and having durability have to be taken into account. Thus, numerically-efficient implementations of material models with high prediction accuracy and applicability in multi-stage forming processes are required. In this contribution, a phenomenological material model of finite strain viscoplasticity with nonlinear kinematic hardening introduced by Shutov and Kreißig [1] is applied to an industrial multi-stage manufacturing process: the Presta joining process (PJP).

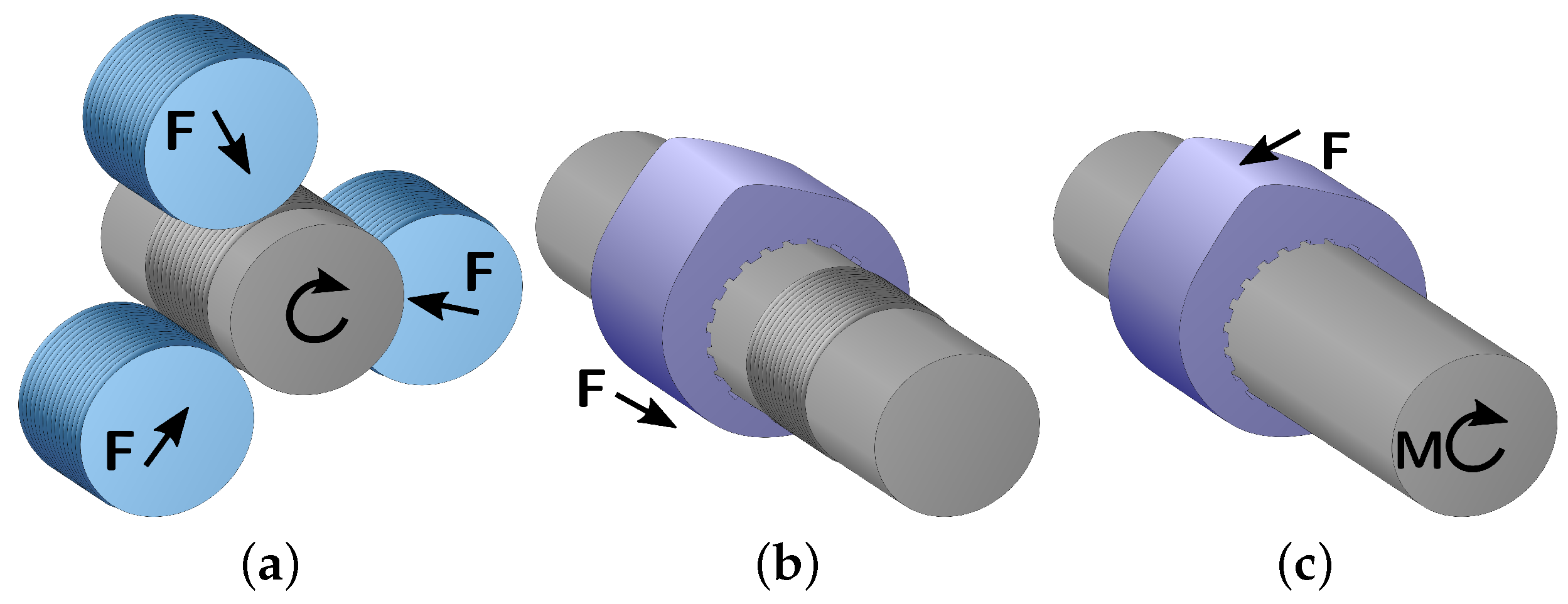

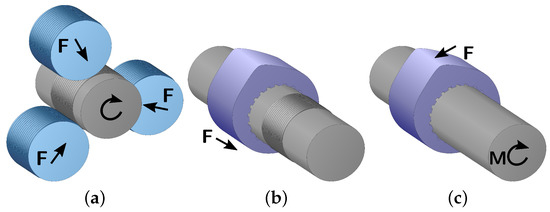

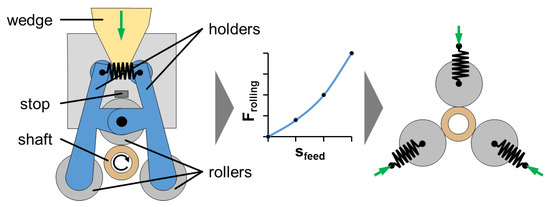

PJP is the world’s leading process in the series production of assembled camshafts [2]. Compared to conventional cast or forged camshafts, the process allows up to 30% reduced weight. This causes a significant inertia reduction of the rotating camshafts [2,3]. During the multi-step manufacturing process, a shaft-hub connection between a shaft and cams is created. In the first step, a local widening of the shaft at the latter cam seat position is created by forming it with rollers with an approximately sinusoidal cross-sectional profile. Due to the rotation of the shaft between three rollers, a circumferentially-oriented profile is formed (Figure 1a). On the shaft, the peaks of the resulting profile have an increasing diameter with respect to the original diameter. In the second sub-step, a cam with an inner profile oriented parallel to the shaft axis is forced onto the widened cam seat (Figure 1b). Thus, the inner profile of the cam and the circumferentially-oriented profile of the shaft are oriented orthogonally to each other, which causes large local plastic deformations during the joining process and creates a tight press and form fit. In a subsequent quality control step, randomly-selected camshafts are tested within a static torsional test (Figure 1c). Thereby, the maximum transmittable torque of the connection is evaluated.

Figure 1.

Scheme of the PJP: (a) rolling of the shaft to create a local widening; (b) the joining process that forces the cam onto the widened cam seat; (c) loading of the connection to evaluate the maximum transmittable torque.

The PJP process is well known experimentally, but still has a large development potential. So far, it has only been applied to camshafts consisting of steel-steel connections. Corresponding analyses by the help of the finite element method (FEM) have already been conducted and showed good agreement with the experimentally-obtained results of the different manufacturing steps (see [4,5,6]). Therein, the application of the phenomenological material model of finite strain viscoplasticity enabled the transfer of the deformation history at the change of simulation models. In this paper, the extension of PJP to the application aluminum shafts is regarded, which provides further weight reduction and in some cases an improved bearing of the camshaft. Thereby, the phenomenological material model of finite strain viscoplasticity is applied to both the steel cam and the aluminum shaft. Experimental tests and the parameter identification procedure to obtain material parameters of the aluminum alloy are presented in this paper. Moreover, the FEM models of the three sub-steps, i.e., rolling, joining and testing by a static torque, are described and applied to the aluminum-shaft/steel-cam connection. Thereby, the producibility of this connection and the final resistance to a static torque loading are analyzed.

2. Materials and Methods

2.1. Material Modeling

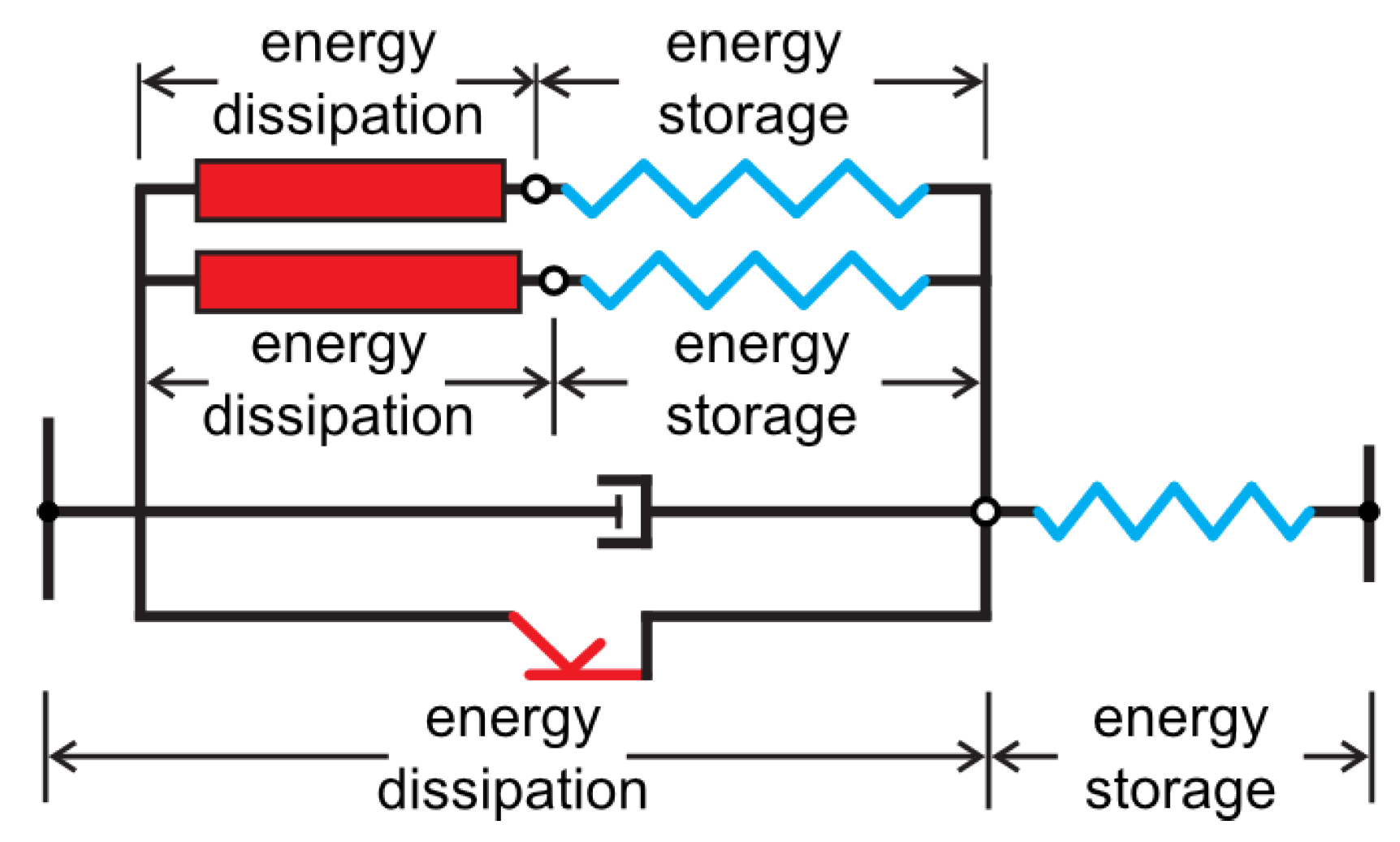

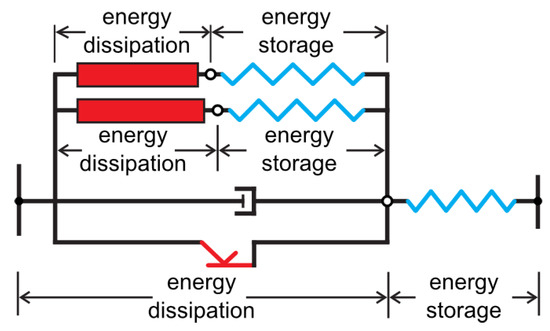

The phenomenological material model of finite strain viscoplasticity with nonlinear kinematic hardening introduced by Shutov and Kreißig [1] has been extended to a formulation providing multiple backstresses in Shutov et al. [7] (Figure 2). This material model is able to properly reproduce the material behavior at large deformations [4,7,8].

Figure 2.

Rheological model of the material model with two backstresses (endochronic Maxwell elements), cf. [7,9].

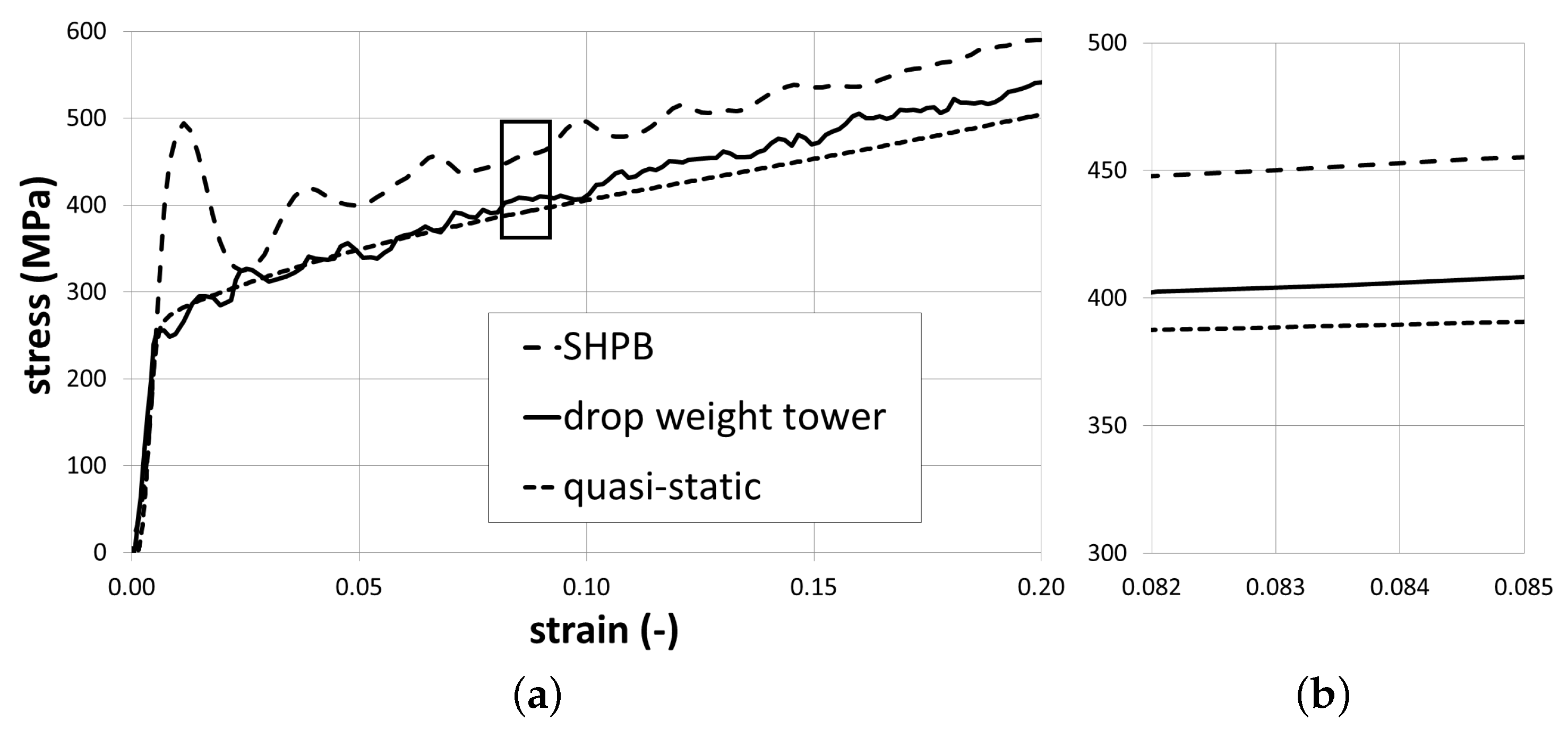

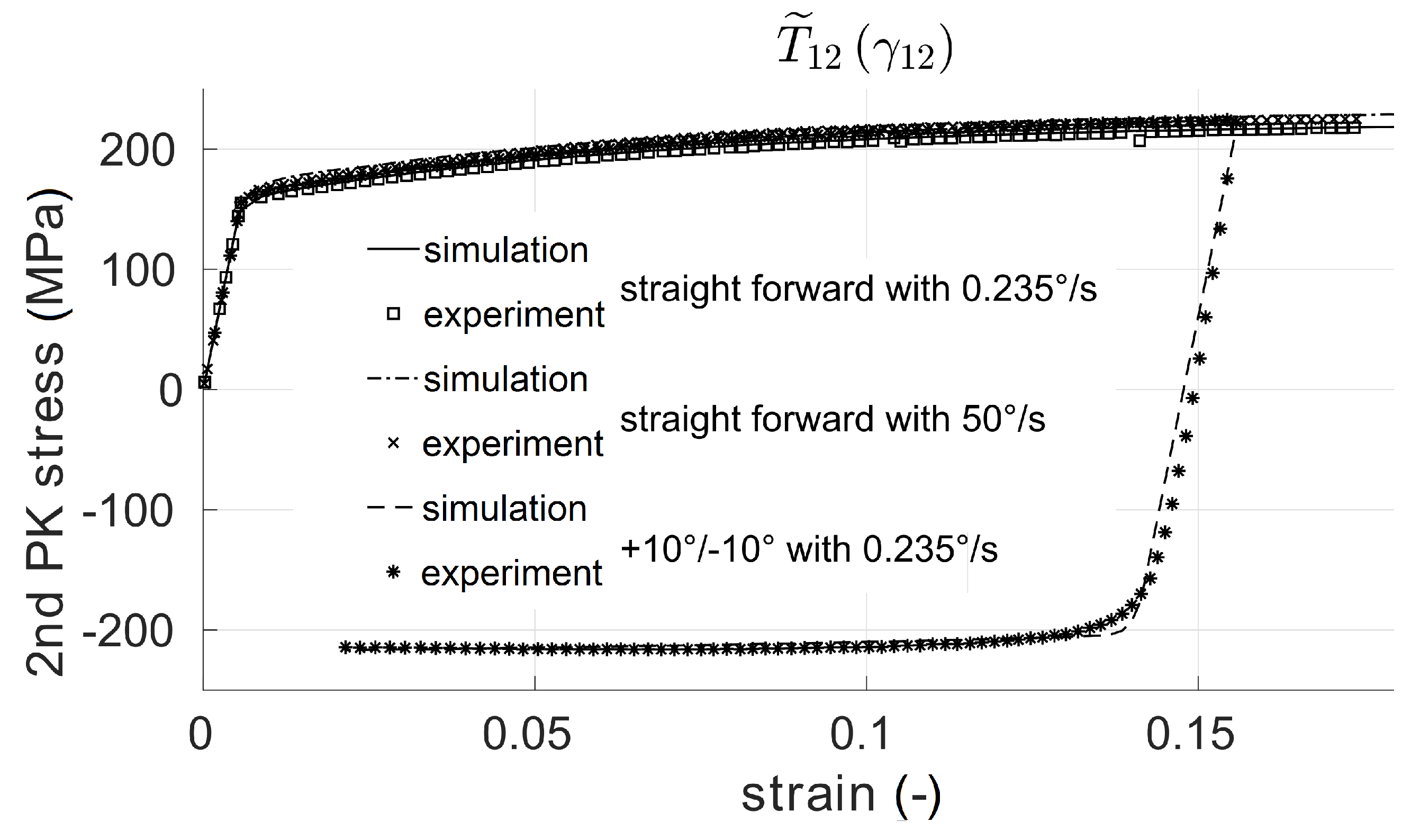

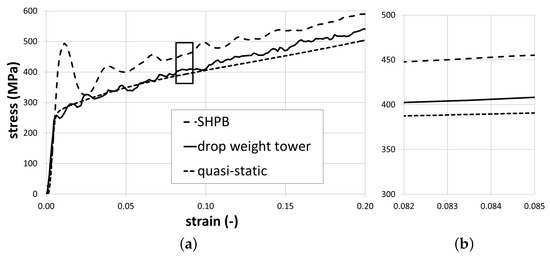

The formulation used in the numerical models of the joining process contains an elastic region, a von Mises yield criterion, rate-dependent yielding of the Perzyna type, two isotropic hardening mechanisms of the Voce type and two backstresses of the Armstrong–Frederick type. Altogether, the model includes 13 material parameters. This work uses the strategy for parameter identification of Shutov et al. [7]. The shear modulus G, the bulk modulus K and the yield stress are determined by analyzing the elastic region of the experimentally-determined stress-strain curves or by using standardized table values. Next, the parameters representing the strain rate dependency—the viscosity and the parameter m of the Perzyna rule—are identified by analyzing the different overstresses that occur at different strain rates (cf. Figure 3b). The remaining eight parameters representing the kinematic and isotropic hardening are identified by adapting the material model to experimentally-obtained stress strain curves (cyclic torsion tests on thin hollow tubes; see Section 2.2). The optimization procedure was realized by the help of the nonlinear least-squares solver lsqnonlin provided by MATLAB.

Figure 3.

(a) Compression tests of aluminum AA6082 at three different strain rates (quasi-static 10−3 s−1, drop weight tower 3 × 102 s−1 and SHPB 1.6 × 103 s−1) for the identification of the strain rate dependence; (b) detailed view of the three different stress levels used to calculate the related viscous overstresses.

2.2. Experimental Methods

To experimentally study the mechanical behavior of the aluminum alloy AA6082 (obtained from Bikar-Aluminium GmbH, Korbußen, Germany), cylindrical specimens with a height of 4 mm and a diameter of 4 mm were used in the conventional peak aged condition. The material samples were uniaxially deformed under quasi-static compressive loading conditions at room temperature (RT) with an initial strain rate of 10−3 s−1 (Figure 3). Additionally, the mechanical behavior under dynamic compression load was characterized. Here, a drop weight tower testing machine was used with a mass of 600 kg. The impact velocity was 1.4 , which results in an effective initial strain rate of 3 × 102 s−1 (Figure 3). For testing at even higher strain rates, a split-Hopkinson pressure bar (SHPB) setup was used. The SHPB system contains a gas launcher, the striker, incident and transmitter bars and a shock absorber, which are mounted on a flat base. The samples are positioned between the incident and transmitter bars. The gas launcher is charged with a pressurized gas to accelerate the striker bar with an initial impact velocity of 7 . This results in an initial strain rate of 1.6 × 103 s−1, which is the same order of magnitude of strain rates like the rolling process (Figure 3). More detailed information on the experimental setups can be taken from previous studies [10,11].

For both drop weight tower and SHPB tests, force data were determined from the strain gauge data recorded on the elastic deforming on the plunger, as well as on the incident and transmitter bars. The deformation of all compression tests was documented with a high-speed camera. To determine the surface strain fields, an optical digital image correlation (DIC) system (Aramis by GOM) was used. The measured displacements and loads were related to initial sample height and cross-section in order to determine engineering strains and stresses, respectively. Then, true (logarithmic) strains and stresses were calculated from the engineering data. For the statistics, three samples were tested for each strain rate.

Furthermore, torsion tests on thin-walled hollow tubes were conducted in a Schenk PTT250 K1 machine. The deformed part of the samples had an outer diameter of 19 mm and an inner diameter of 16 mm. The gauge length was 4 mm. The flow curves were characterized at three different angular velocities: 0.235° s−1, 10° s−1 and 50° s−1. In addition, the strain hardening behavior of the materials was analyzed by varying the deformation paths at an angular velocity of 0.235° s−1: (i) +10°/−10°; (ii) +10°/−8°; (iii) +10°/−5°.

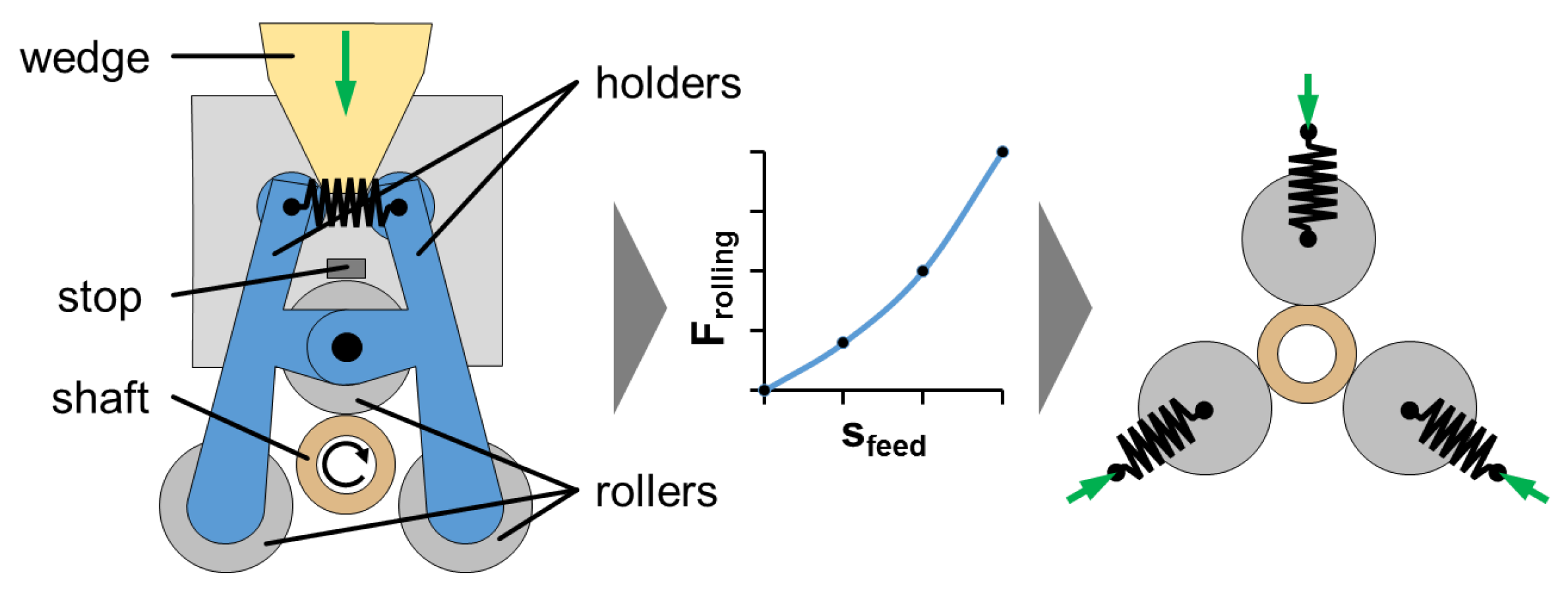

2.3. Rolling of the Shaft

The rolling of the shaft is performed by three rollers arranged in a rolling tool by an angle of 120° (Figure 4). This angle varies slightly over the rolling process by ±1°.

Figure 4.

The rolling tool with the two holders, the three rollers and the shaft in the middle; cf. [4].

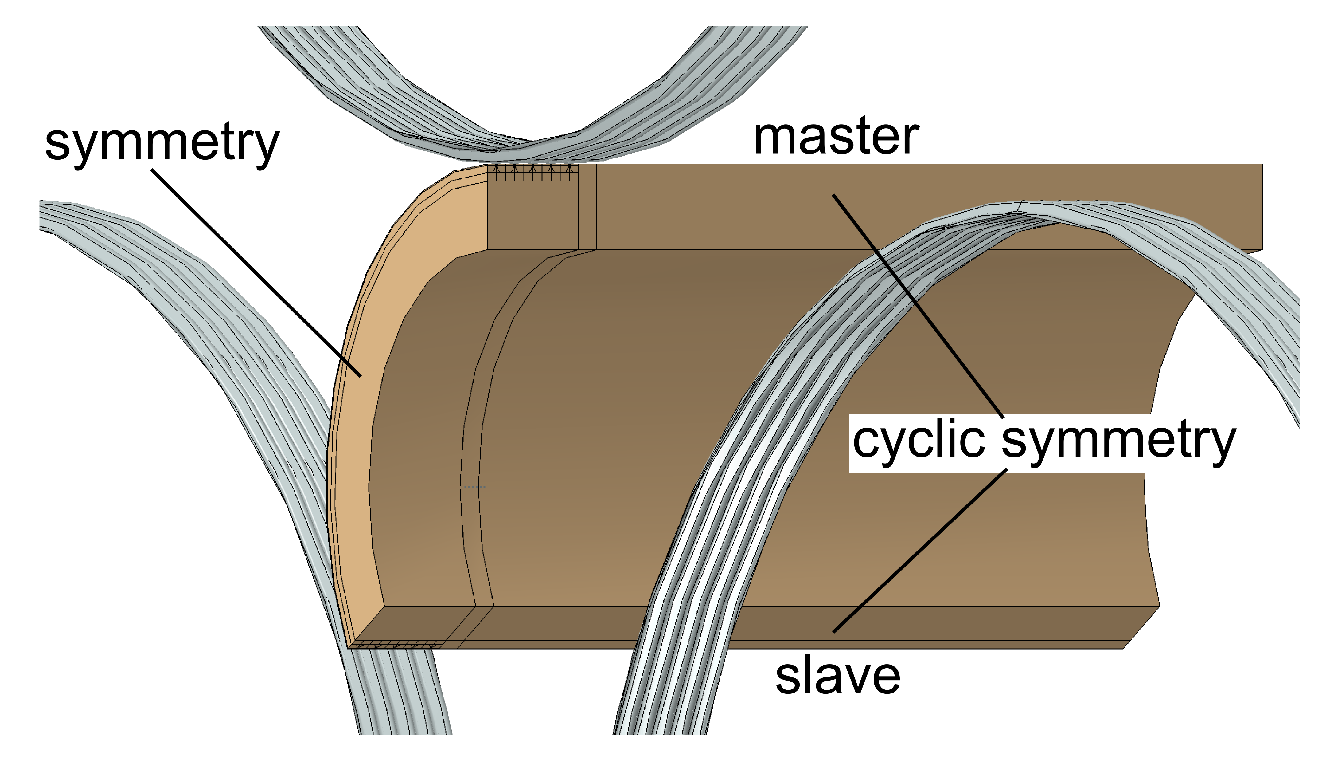

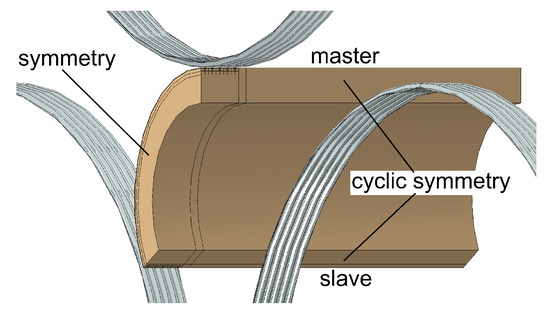

This arrangement is used in the geometrical model of the rolling process by reducing the volume to a section of 120 degrees and applying cyclically-symmetric boundary conditions. The variation of the rollers’ arrangement has not been considered in the model to maintain cyclic symmetry. Additionally, the cam seat is cut into halves in the axial direction. Hence, the geometry of the numerical model includes just a sixth of the shaft geometry (Figure 5). The stiffness of the holders of the rolling tool is represented in the numerical model by multi-linear springs; see Scherzer et al. [4]. Thus, the radial displacement of the rollers is controlled by the stiffnesses of the holders and of the shaft.

Figure 5.

Geometry of the numerical model of the rolling process with axially- and cyclically-symmetric boundary conditions; cf. [4].

The numerical model is calculated using the commercial FEM software ABAQUS 6.14 standard (implicit). The phenomenological material model of finite strain viscoplasticity is implemented by using ABAQUS’ user interface for the implementation of material subroutines (UMAT) and employing an efficient implicit integration scheme introduced by Shutov [12]. For the calculation of ABAQUS specific values, the so-called wrapper technology described in Besdo et al. [13] is applied. The model uses linear eight-node brick elements C3D8 with full integration.

The model of the rolling process has been evaluated in Scherzer et al. [4] by comparing experimental and calculated data of the reaction forces of the holders over the whole process with the traditional usage of steel shafts and steel cams. Additionally, the rolled profile has been measured and compared to the computed shaft profile.

2.4. The Joining Process

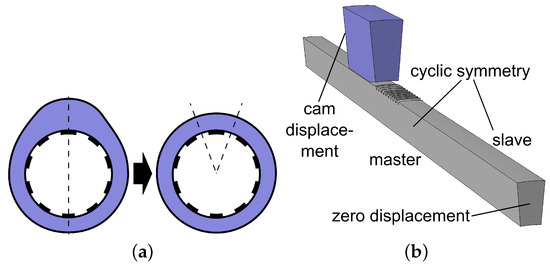

The inner profile oriented parallel to the shaft axis of the cam is forced onto the widened cam seat in the joining process. This inner profile of the cam requires a fine tangential mesh in the regions of shifting inner diameters. In contrast, the mesh of the shaft in the first simulation step is very coarse compared to its cross-sectional mesh because the resulting shaft profile after the rolling process is almost axisymmetric. Hence, for the second simulation step, a new mesh is required. Additionally, if the outer profile is simplified to a circular contour, it can be reduced to a model including only one tooth of the inner profile (Figure 6a).

Figure 6.

(a) Simplification of the cam’s outer profile to a circular contour; (b) geometry of the numerical model of the joining process reduced to one tooth of the inner-profile; cf. [5].

Normally, the change of numerical models together with the change of geometry would cause a loss of information on the internal stresses and the deformation history of the rolling process. Thus, at the start of the joining step, the shaft would be free of stresses and the state variables of the material model would be at the initial state of undeformed material. The variables store the deformation history of the process and include the right Cauchy–Green tensors and representing intermediate configurations (see Figure 2), the inelastic arc length s and its dissipative part . However, in Shutov et al. [14], the invariance of the phenomenological material model of finite strain viscoplasticity under an isochoric change of the reference configuration has been introduced. This invariance can be shown by transforming the internal state variables of the material model by , which is the deformation gradient from the old to the new reference configuration.

Further, this concept has been extended to non-isochoric changes of the reference configuration and applied to the PJP in Scherzer et al. [6]. Hence, the internal state variables at the end of the rolling simulation (i.e., with a certain loading state) are transformed to the undeformed reference configuration at the start of the joining simulation (described by a deformation gradient equal to the unit tensor). As Equation (1) shows, the relative deformation gradient required for the transformation equals the deformation gradient of the rolling step .

At the start of every ABAQUS simulation, the deformation gradient also is equal to the unit tensor. Thus, in the first increment of the calculation, the model of the joining step with the new geometry, mesh and a transformed set of internal variables recovers the internal stresses of the rolling process.

Just like the rolling model, the numerical model of the joining step has been evaluated and tested by comparing its results to experimental data of the traditional Presta connection using steel shafts and steel cams. The computed joining force curve is especially in a good agreement with the curves measured during actual series production [5].

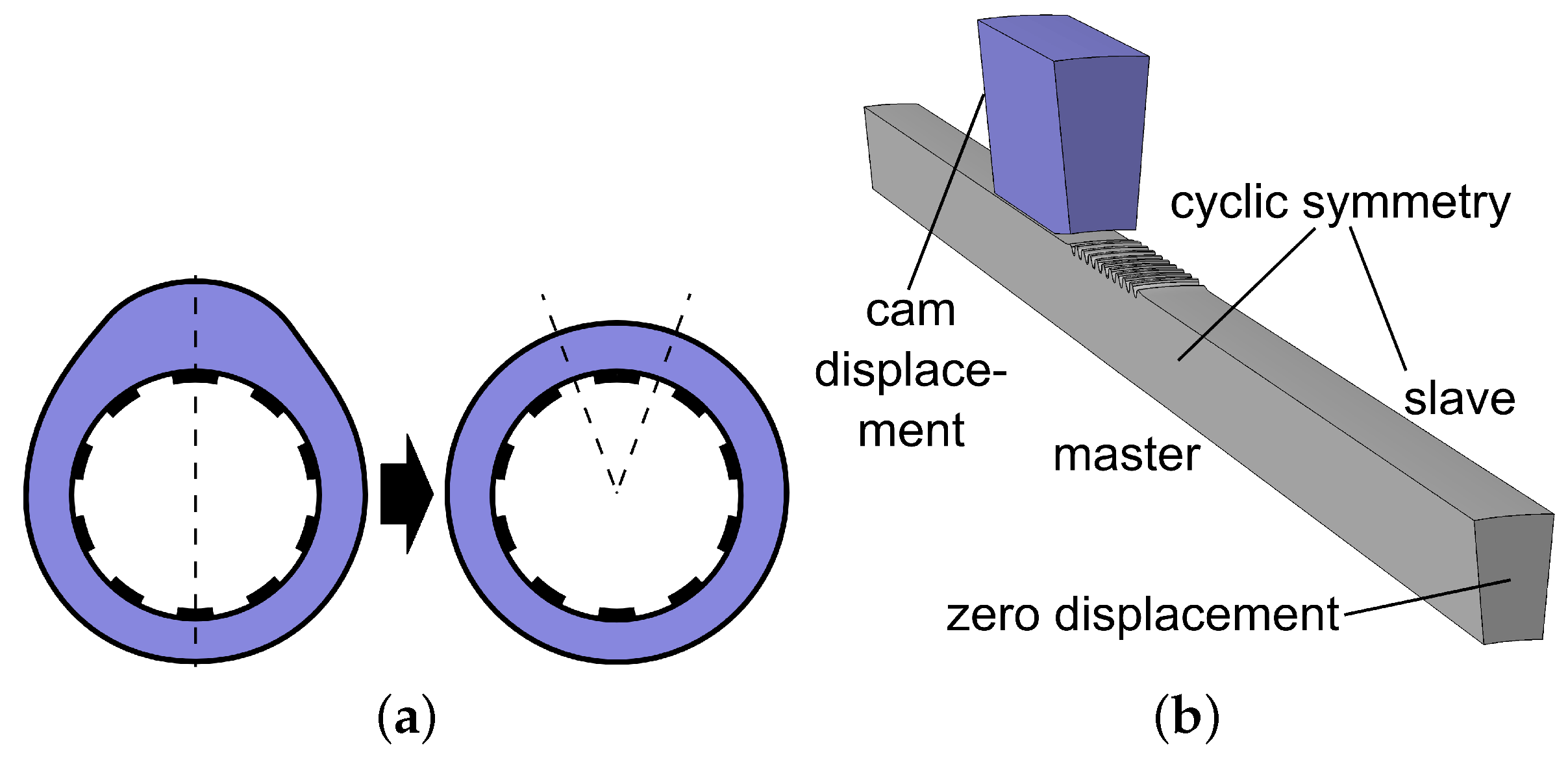

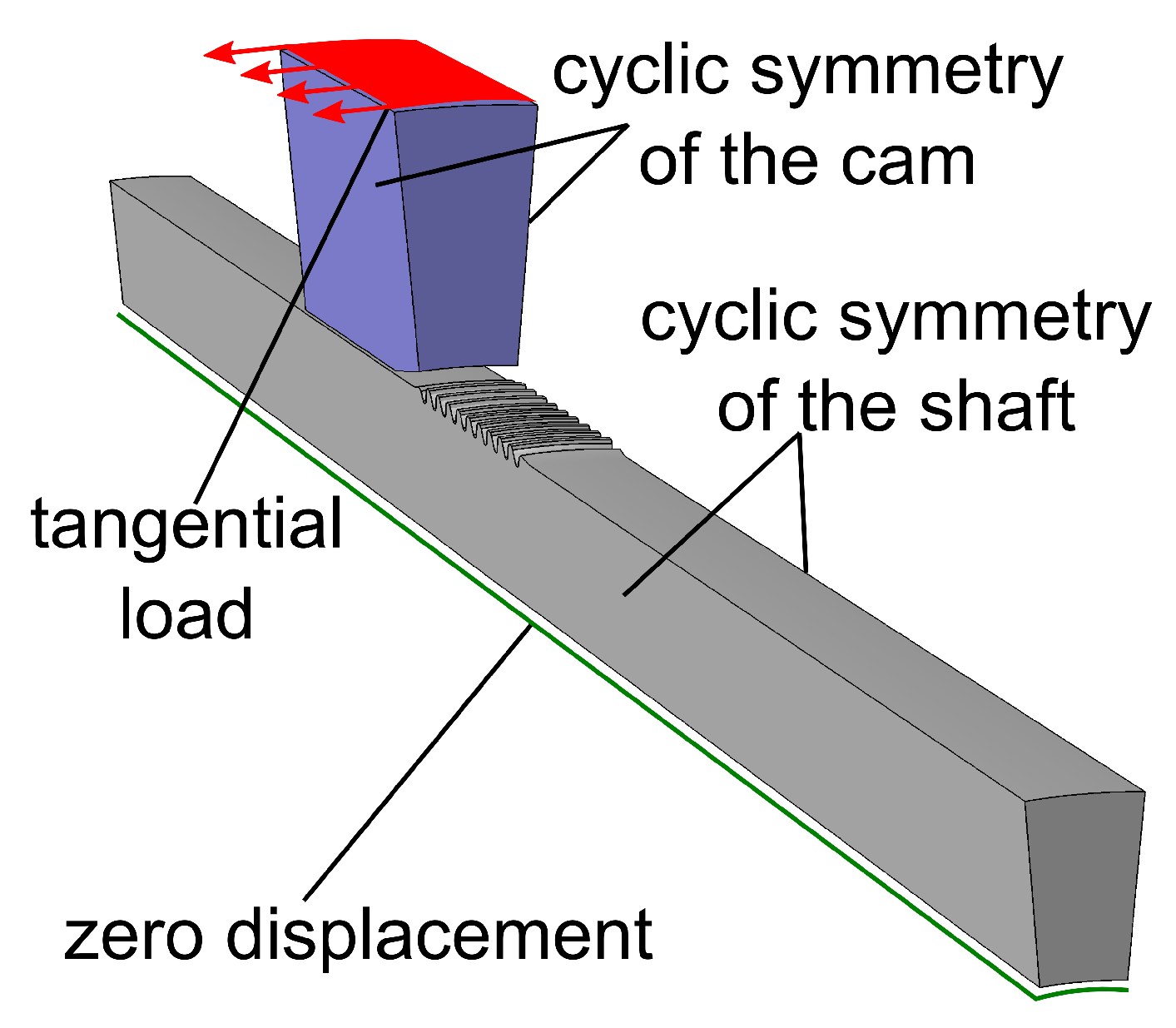

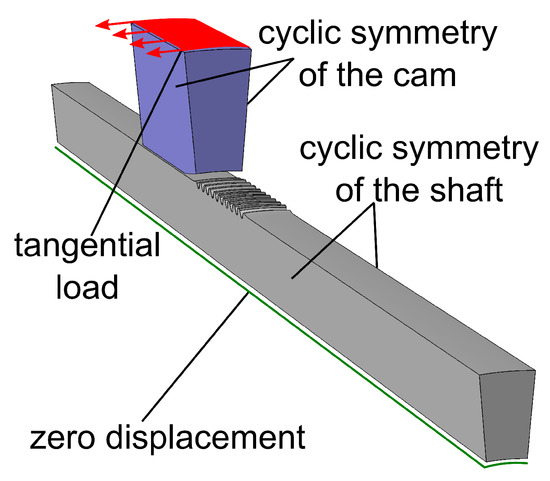

2.5. Loading of the Presta Connection

The last step of the simulation package of the PJP is a numerical model for applying a static load in the model to compute the maximum transmittable torque of the connection. In contrast to the model change between the rolling and the joining, the load step uses the same geometrical model and mesh as the previous model. Hence, the numerical model uses the restart option of ABAQUS to continue the calculation after the joining step. This approach automatically maintains the deformation history and internal stresses of the previous steps. Thus, the geometrical entities remain the same as in the joining model (Figure 7).

Figure 7.

Geometry of the numerical model of the load step with cyclically-symmetric boundary conditions for each of the single parts to enable relative displacement between them.

However, the boundary conditions have to be adapted. The axial position of the cam relative to the shaft is fixed by the friction between the single parts. The tangential twist of the shaft is prevented by a zero displacement boundary condition at its inner surface. The tangential load is applied to the top of the cam and increases linearly until the simulation is aborted because of the cam’s displacement (Figure 7).

The cyclic symmetry boundary condition of ABAQUS cannot be applied in this simulation model because of the relative tangential movement between the two parts. ABAQUS allows just one cyclic symmetry boundary condition per model, and this is only applicable to a single master surface (set) and one related slave surface (set). This causes problems when tangential displacements occur. Therefore, the displacements (described in cylindrical coordinates) of every single node at the slave surface become coupled with the corresponding displacement of the master surface. This method has been implemented in the Python script controlling the model.

3. Results

3.1. Material Tests and Parameter Identification for the Aluminum Alloy AA6082

The single numerical models have been developed and verified with the traditional Presta connection of steel cams and steel shafts. Next, the simulation sequence is utilized to achieve the extension of the PJP to the usage of aluminum shafts. To describe the material behavior of AA6082, both literature data and the data given in Section 2.2 are employed. In Section 2.1 it is shown how the material parameters have to be determined. Shutov et al. [7] determined the following numerical parameters: the shear modulus G, the bulk modulus K and the yield stress (Table 1). Moreover, the viscosity and the parameter m of the Perzyna rule were identified using the different viscous overstresses obtained by the compression tests (Figure 3 and Table 1).

Table 1.

Material parameters G, K and describing the elastic material behavior and the parameters and m describing the strain rate dependency of the aluminum alloy AA6082.

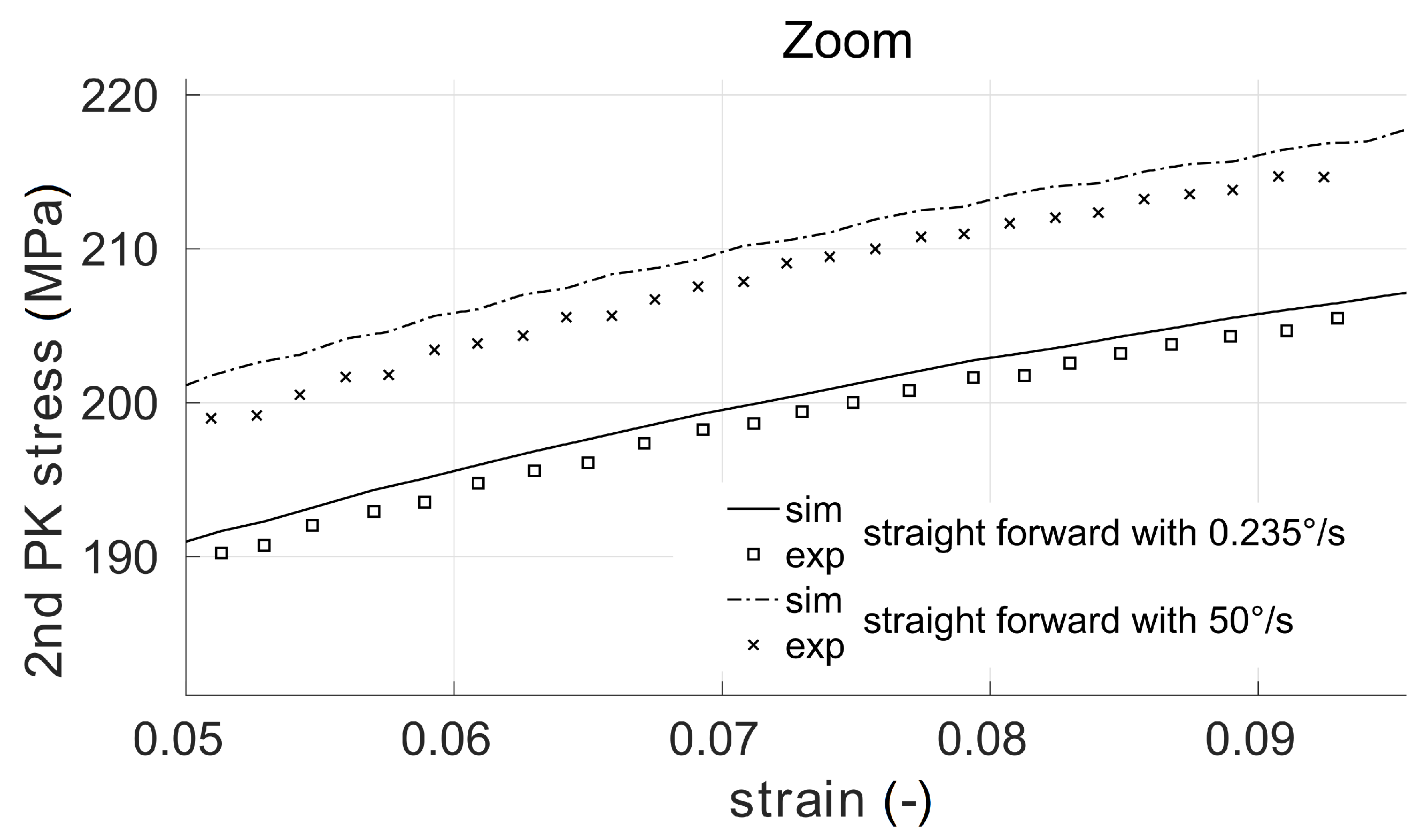

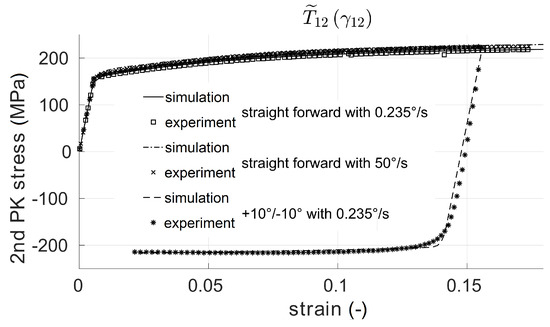

Finally, the remaining eight hardening parameters were identified. This was performed in an optimization using MATLAB with the experimental data of the torsion tests (Table 2 and Figure 8 and Figure 9).

Table 2.

Material parameters , , , , , , and describing the plastic hardening of the aluminum alloy AA6082.

Figure 8.

Results of the parameter identification of the hardening effects comparing the calculated stresses (lines) with the stresses from experimental data (dots) of the torsion tests.

Figure 9.

The magnified view of Figure 8 shows the different overstresses at different strain rates.

3.2. Application of the Simulation Sequence on AA6082

Next, the simulation of the rolling process is executed by varying the rollers’ cross-sectional profile, the preloading of the holders and the geometric dimensions of the shaft. Here, existing geometrical sets of thyssenkrupp Presta have been used to obtain a fitting arrangement for the AA6082 alloy. For the eventually chosen geometric constraints, the rolling simulation of the AA6082 alloy shows a very good rolling profile. This can be assessed by comparing the resulting shaft profile with the given profile of the roller. Here, the profile is shaped completely without causing plastic deformations at the inner radius of the shaft.

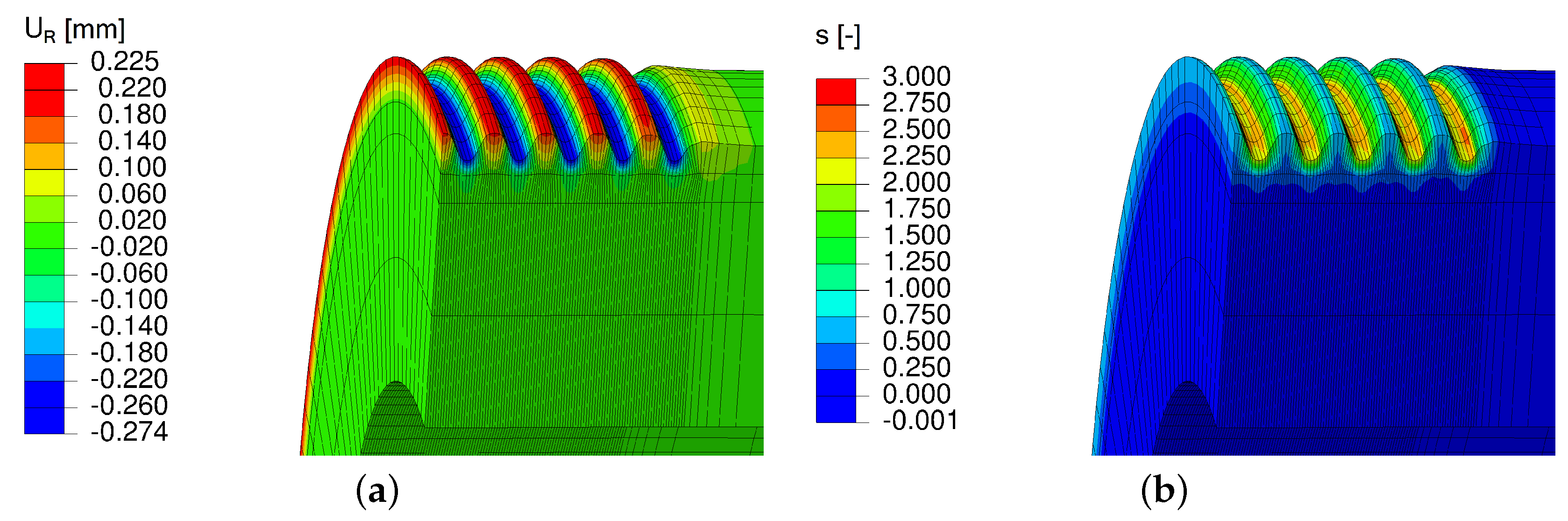

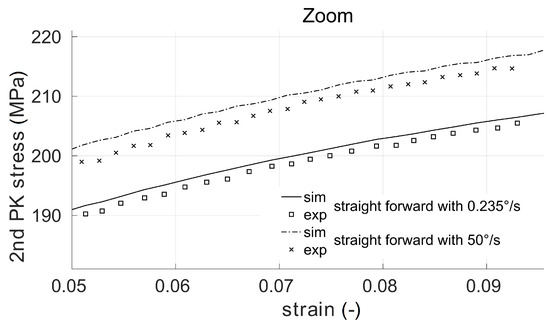

Thus, an adequate local widening has been achieved, which is required for the joining process. As Figure 10 shows, the mesh in the tangential and radial directions is coarse compared to the mesh refinement in the axial direction in order to save computational cost. Fortunately, this partially coarse mesh has a small impact on the convergence of the simulation results since the deformation is approximately axisymmetric and comparably small in the direction of the long edges of the elements.

Figure 10.

(a) Plot of the radial displacement after widening the shaft made from AA6082 through rolling; (b) plot of the inelastic arc length s, which can be interpreted as the degree of plastic deformation or as the effective plastic strain.

The phenomenological material model of finite strain viscoplasticity includes the internal state variable s (inelastic arc length) [7], which can be seen as the degree of plastic deformation or as the effective plastic strain. This variable increases monotonically with plastic deformation and independently of the loading path. Thus, it can be used to figure out the zone of plastic deformation (Figure 10b).

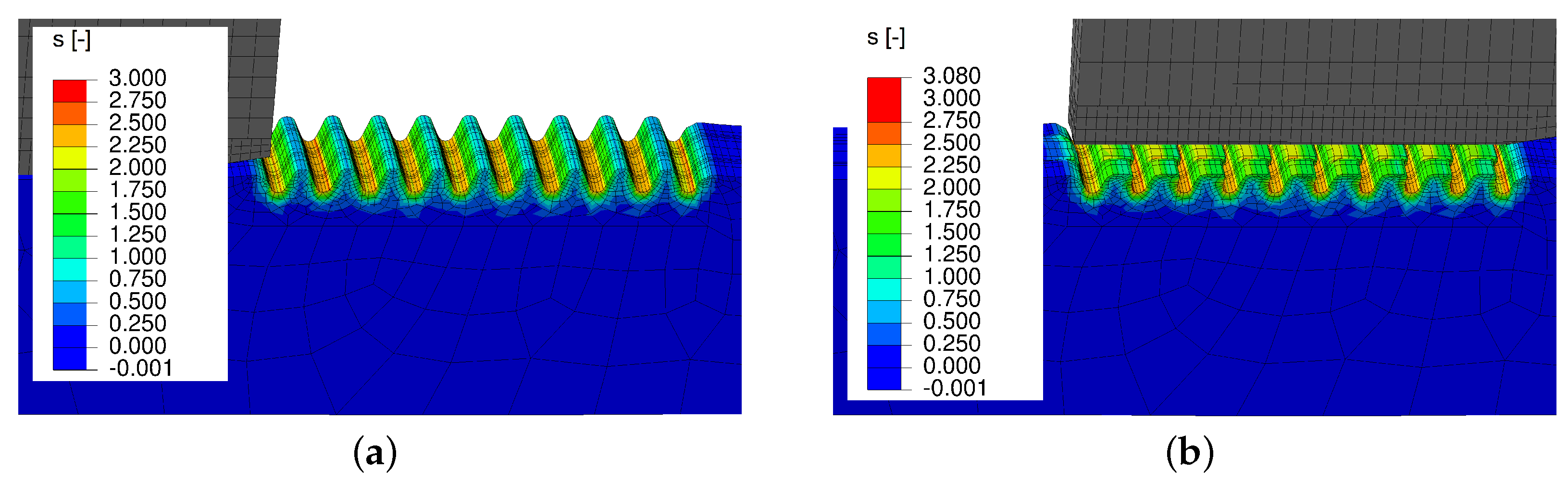

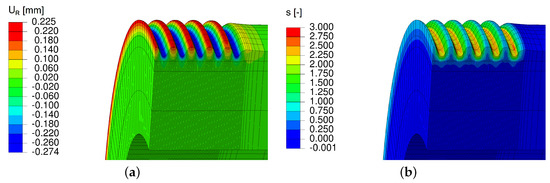

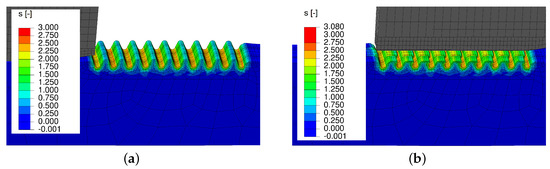

Since the internal state variables are transferred at the change of models, the plot of the inelastic arc length s at the start of the joining process in Figure 11a is equivalent to the plot at the end of the rolling step in Figure 10b, although there is a new geometric model and a new mesh. More details on the transformation procedure can be found in Scherzer et al. [6].

Figure 11.

Comparison of the degree of plastic deformation before and after the joining step. (a) The transferred inelastic arc length s at the start of the joining step with the new geometry and the new mesh; (b) the inelastic arc length s at the end of the joining step with the deformed shaft profile and a cut through the cam. Furthermore, this plot shows the deformed grooves of the cam seat.

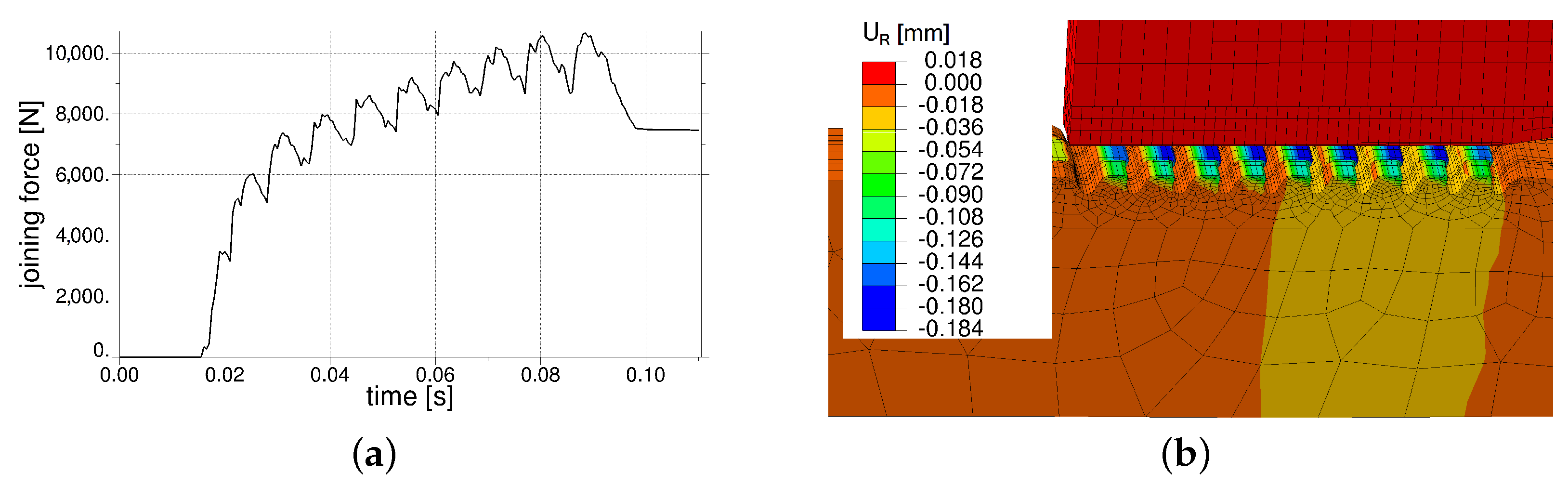

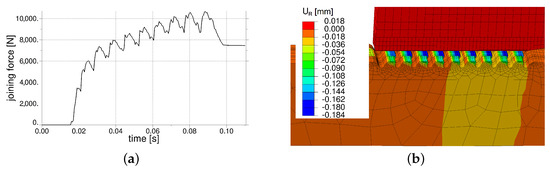

After the cam with its inner profile is forced onto the shaft profile, the degree of deformation is increased slightly compared to the initial value of the rolling step (Figure 11b). In the series production, the quality of the connection is measured continuously by monitoring the limits of the joining force (Figure 12a). Besides the form fit due to the plastic deformation in the joining process, there is an additional press fit that results from the elastic compression of the shaft and the elastic decompression of the cam (Figure 12b).

Figure 12.

(a) Calculated progression of the joining force over time for the joining of the cam onto the aluminum shaft. The single grooves of the rolled profile cause small peaks in the force path. The force grows over the joining process due to the increasing friction surface. (b) Radial displacement of the joining step showing the compression of the shaft and the decompression of the cam.

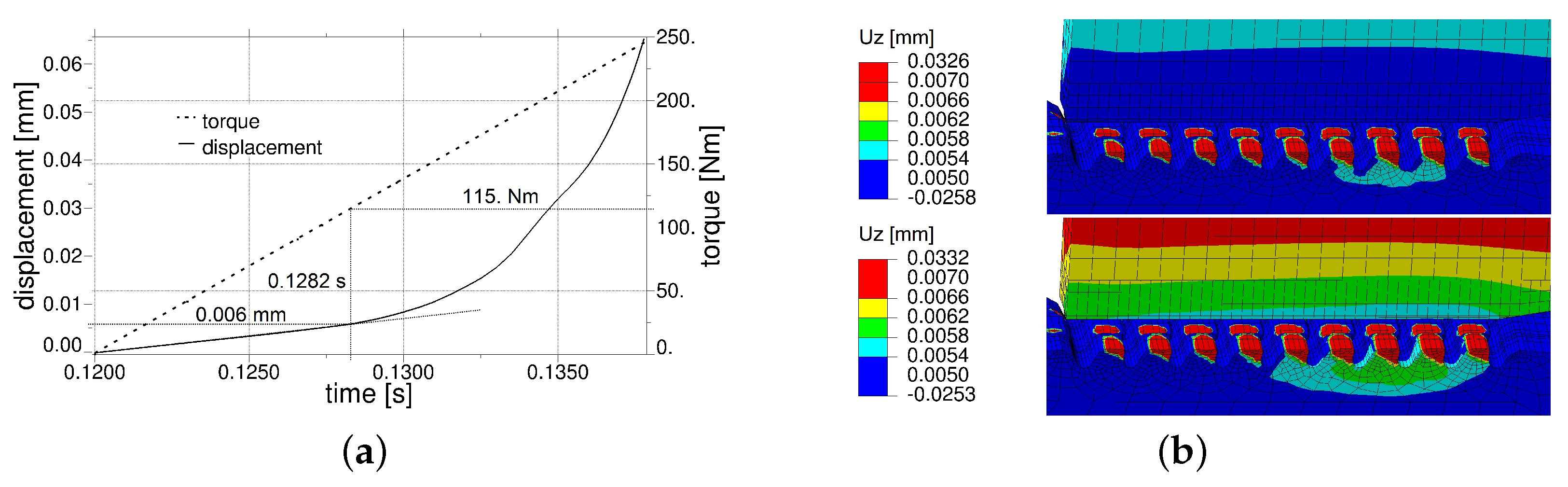

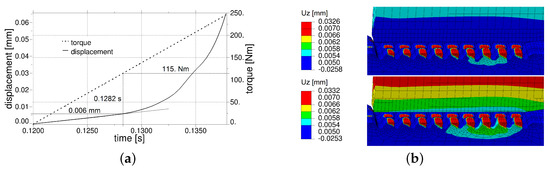

Next, the connection is tested numerically by applying a linear increasing static torque in the loading simulation (cf. Section 2.5). Thereby, the maximum transmittable torque of the connection is determined by evaluating the progression of the cam’s tangential displacement over loading time (Figure 13a).

Figure 13.

(a) Linearly-increasing torque with the related tangential displacement of the cam and the determination of the maximum transmittable torque of the connection; (b) the tangential displacement of the loading model at = 0.128 s (top) and = 0.129 s (bottom).

The connection remains intact as long as the displacement increases linearly. In this state, the contact zone between the cam and the shaft is almost zero (Figure 13b (top)). The connection fails as soon as as a critical torque is achieved. There are a further increase of the torque causes plastic deformations in the contact zone, an increasing relative displacement between the cam and the shaft (Figure 13b (bottom)) and a nonlinear progression of the corresponding tangential displacement curve. The transition point between linear and nonlinear curve shape is employed to identify the critical torque (Figure 13a). Hence, the maximum transmittable torque of the steel-aluminum connection is approximately 115 Nm (Figure 13a).

4. Discussion

This approach connects three numerical models to a sequence to enable simulations of the PJP. Because of the large deformations that occur during the process, it is necessary to use an appropriate material model. Here, a phenomenological material model of finite strain viscoplasticity has been used. To enable a proper reproduction of the material behavior, it is necessary to perform material tests and an identification of the material parameters. The quality of the resulting set of parameters depends on the complexity of the material tests. For technical reasons, the chosen set of material tests is a combination of torsion and compression tests. Hence, adding more experiments would improve the quality of material parameters.

The rolling of the shaft produces an approximately axisymmetric profile. This means that there is a small gradient of deformation in the tangential direction, and thus, a relatively coarse mesh has been used tangentially. This coarse mesh allows the calculation of the model in an acceptable time span.

The joining process simulation is based on a simplification of the outer contour of the cam. Further investigations with the simulation of the full geometry of the cam could show the influence of this simplification on the joining force. Additionally, localization effects in the deformation of the cam and the rolled profile of the shaft could be investigated.

The maximum transmittable torque obtained in the loading simulation results from a static test of the connection. For the usage in combustion engines there are high demands on the fatigue strength of the connection. The connection shown in this approach most likely does not meet these requirements because it is based on an existing geometrical configuration used for steel-steel connections. An adjustment of the geometrical design, with the aim of improving fatigue behavior, is a key topic of future investigations.

5. Summary

This work combines the simulation models of the rolling of the shaft and of the joining step with a simulation sequence for the joining process and adds a third simulation step for testing the connection by loading it with a static torque. The included usage of the phenomenological material model of finite strain viscoplasticity makes it necessary to perform precise material tests. The underlying experimental methods and the identification of the material parameters have been described.

Finally, the simulation package has been used to test numerically if the usage of aluminum shafts is theoretically possible. Indeed, the numerical results demonstrate the technical feasibility of such an extension of the PJP under the aspect of static loads.

However, considering the application of aluminum shafts in combustion engines, the shafts also have to meet the requirements of fatigue strength. Therefore, several changes in the dimensioning of the shaft, the cam and their attachments have to be made. Moreover, the shaft design shown in this work will be manufactured and tested in the near future. If the experimental tests of this connection verify the computed results, the required design changes can be investigated and implemented.

6. Conclusions

Industrial research often uses built-in material models of commercial FEM software. Possible reasons for this are the required implementations of the models and the expensive material tests to obtain the material parameters. This work proves the concept of the use of a phenomenological material model of finite strain viscoplasticity in an industrial manufacturing process. Additionally, the transfer of the deformation history from the rolling simulation to the joining step has proven the concept of the change of the reference configuration to perform in multi-step analyses.

Altogether, this work has shown the feasibility of the application of aluminum in the PJP by numerical simulations. The next steps of investigation include the validation of numerical results by manufacturing sample camshafts with aluminum shafts, as well as the change of the geometrical design of the shaft and of the cam to meet the requirements of fatigue strength. The simulation sequence shown in this approach may well be an essential help in the process of this development.

Acknowledgments

The research shown in this work originates from the publicly-supported collaborative research center SFB 692 “High-strength aluminum based lightweight materials for safety components”, which is supported by the German Research Foundation (DFG). Furthermore, this research is carried out in close cooperation with thyssenkrupp Presta GmbH in Chemnitz. The underlying project is a transfer project with the goal to show possible industrial applications of previous research results of the collaborative research center.

Author Contributions

Sebastian Fritsch designed and performed the experiments and wrote the relating section “Experimental Methods”. Robert Scherzer analyzed the data, developed the numerical models, performed the numerical investigations and wrote the remaining parts of the paper. All authors discussed the results and helped with writing the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| DIC | Digital image correlation |

| FEM | Finite element method |

| PJP | Presta joining process |

| SFB | Sonderforschungsbereich (engl. collaborative research center) |

| SHPB | Split-Hopkinson pressure bar |

| UMAT | User subroutine to define a material’s mechanical behavior in ABAQUS |

References

- Shutov, A.V.; Kreißig, R. Finite strain viscoplasticity with nonlinear kinematic hardening: Phenomenological modeling and time integration. Comput. Methods Appl. Mech. Eng. 2008, 197, 2015–2029. [Google Scholar] [CrossRef]

- Meusburger, P. Lightweight design in engine construction by use of assembled camshafts. MTZ Worldw. 2006, 67, 10–12. [Google Scholar] [CrossRef]

- Lengwiler, A. Fehlerfortpflanzung, Simulation und Optimierung von Prozessketten Anhand der Gebauten Nockenwelle; Eidgenössische Technische Hochschule ETH Zürich: Zürich, Switzerland, 2011. [Google Scholar]

- Scherzer, R.; Silbermann, C.B.; Ihlemann, J. FE-simulation of the Presta joining process for assembled camshafts—Local widening of shafts through rolling. IOP Conf. Ser. Mater. Sci. Eng. 2016, 118, 12039. [Google Scholar] [CrossRef]

- Scherzer, R.; Silbermann, C.B.; Landgraf, R.; Ihlemann, J. FE-simulation of the Presta joining process for assembled camshafts—Modelling of the joining process. IOP Conf. Ser. Mater. Sci. Eng. 2017, 181, 12030. [Google Scholar] [CrossRef]

- Scherzer, R.; Ihlemann, J. Simulation of the Presta process—Transfer of deformation history. PAMM. (accepted 2017).

- Shutov, A.V.; Kuprin, C.; Ihlemann, J.; Wagner, M.X.; Silbermann, C. Experimentelle Untersuchung und numerische Simulation des inkrementellen Umformverhaltens von Stahl 42CrMo4. Materialwiss. Werkst. 2010, 41, 765–775. [Google Scholar] [CrossRef]

- Shutov, A.V.; Kreißig, R. Regularized strategies for material parameter identification in the context of finite strain plasticity. Tech. Mech. 2010, 30, 280–295. [Google Scholar]

- Kießling, R.; Landgraf, R.; Scherzer, R.; Ihlemann, J. Introducing the concept of directly connected rheological elements by reviewing rheological models at large strains. Int. J. Solids Struct. 2016, 97, 650–667. [Google Scholar] [CrossRef]

- Winter, S.; Schmitz, F.; Clausmeyer, T.; Tekkaya, A.E.; Wagner, M.F.-X. High temperature and dynamic testing of AHSS for an analytical description of the adiabatic cutting process. IOP Conf. Ser. Mater. Sci. Eng. 2017, 181, 12026. [Google Scholar] [CrossRef]

- Pouya, M.; Winter, S.; Fritsch, S.; Wagner, M.F.-X. A numerical and experimental study of temperature effects on deformation behavior of carbon steels at high strain rates. IOP Conf. Ser. Mater. Sci. Eng. 2017, 181, 12022. [Google Scholar] [CrossRef]

- Shutov, A.V. Efficient implicit integration for finite-strain viscoplasticity with a nested multiplicative split. Comput. Methods Appl. Mech. Eng. 2016, 306, 151–174. [Google Scholar] [CrossRef]

- Besdo, D.; Hohl, C.; Ihlemann, J. ABAQUS implementation and simulation results of the MORPH constitutive model. Const. Models Rubber IV 2005, 4, 223–228. [Google Scholar]

- Shutov, A.V.; Pfeiffer, S.; Ihlemann, J. On the simulation of multi-stage forming processes: Invariance under change of the reference configuration. Materialwiss. Werkst. 2012, 43, 617–625. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).