The Potential of Recycling the High-Zinc Fraction of Upgraded BF Sludge to the Desulfurization Plant and Basic Oxygen Furnace

Abstract

1. Introduction

2. Materials and Methods

2.1. Technical-Scale Experiments

2.1.1. Material Characterization and Agglomeration

2.1.2. Smelting Reduction Experiments

2.2. Industrial-Scale Trials

2.3. Low-Sulfur Binders in Cold-Bonded Briquettes

3. Results and Discussion

3.1. Technical-Scale Smelting Reduction Experiments

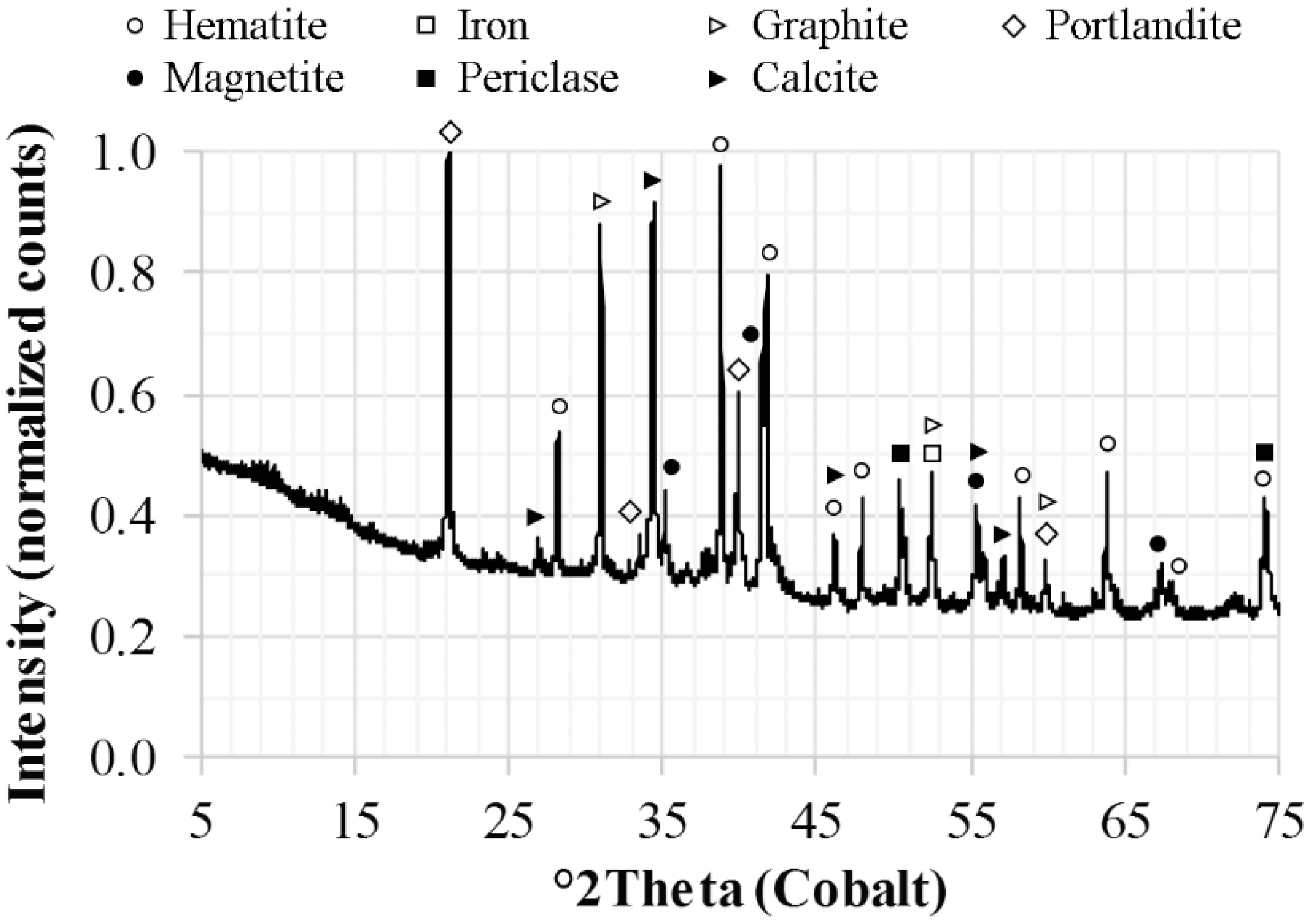

3.1.1. Characterization of the Agglomerates

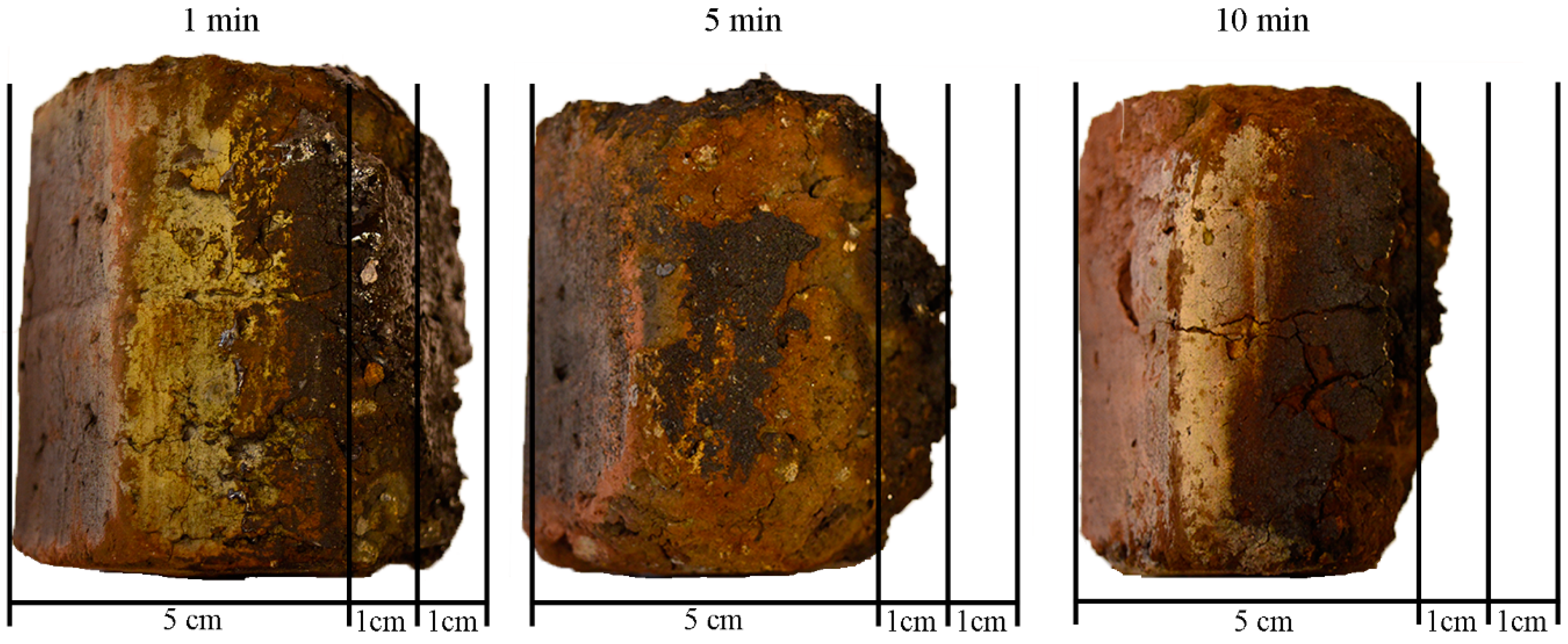

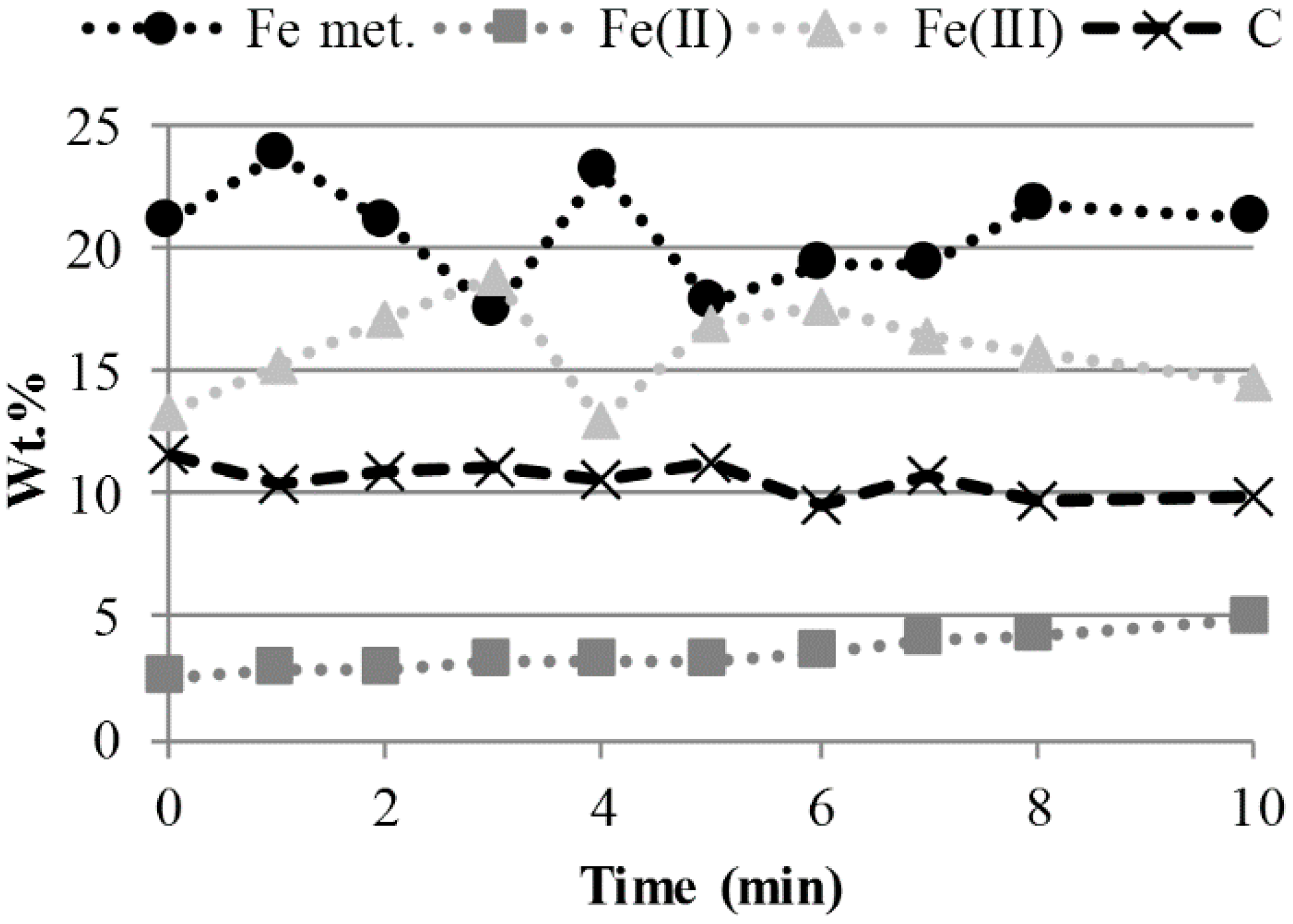

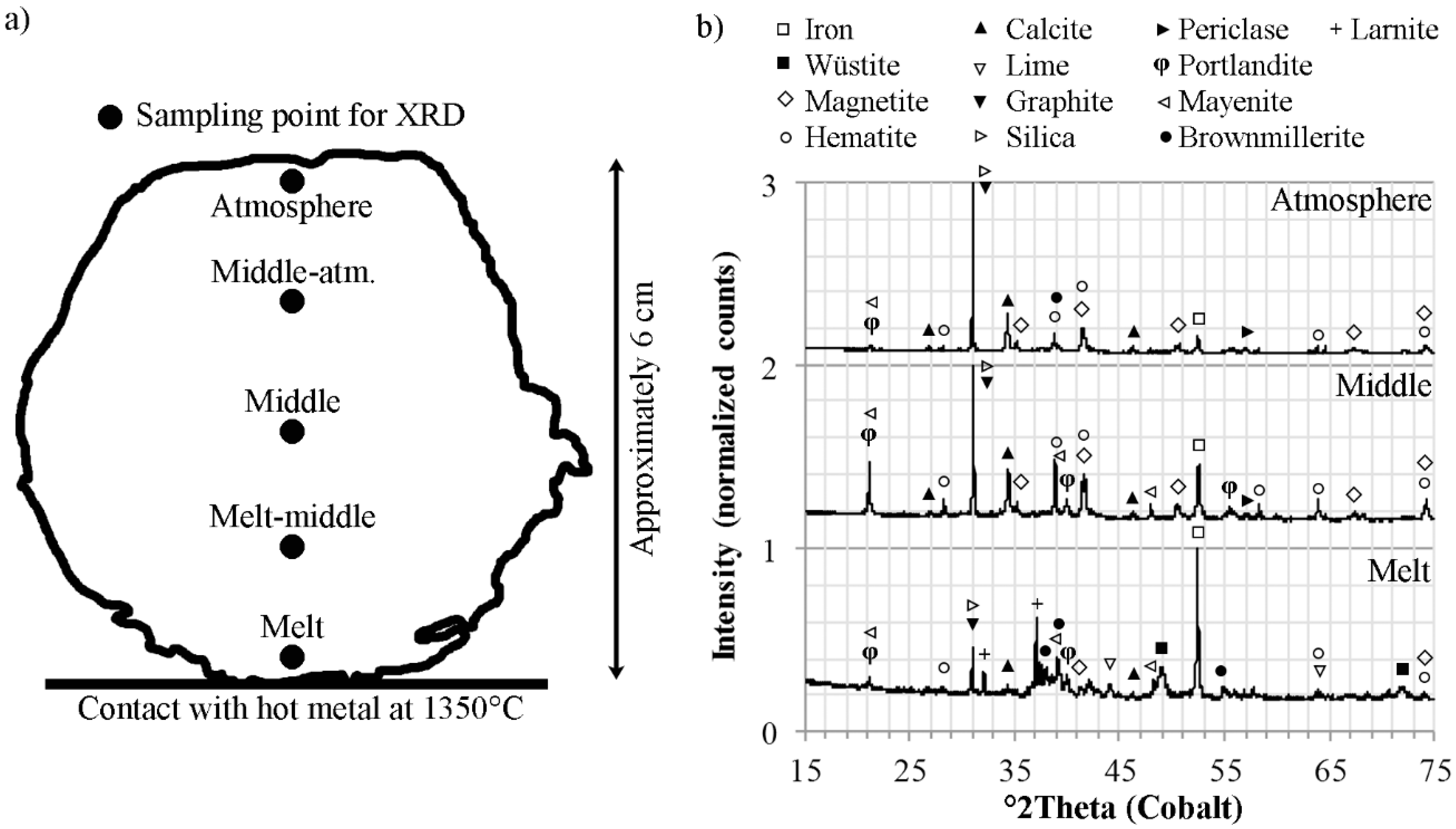

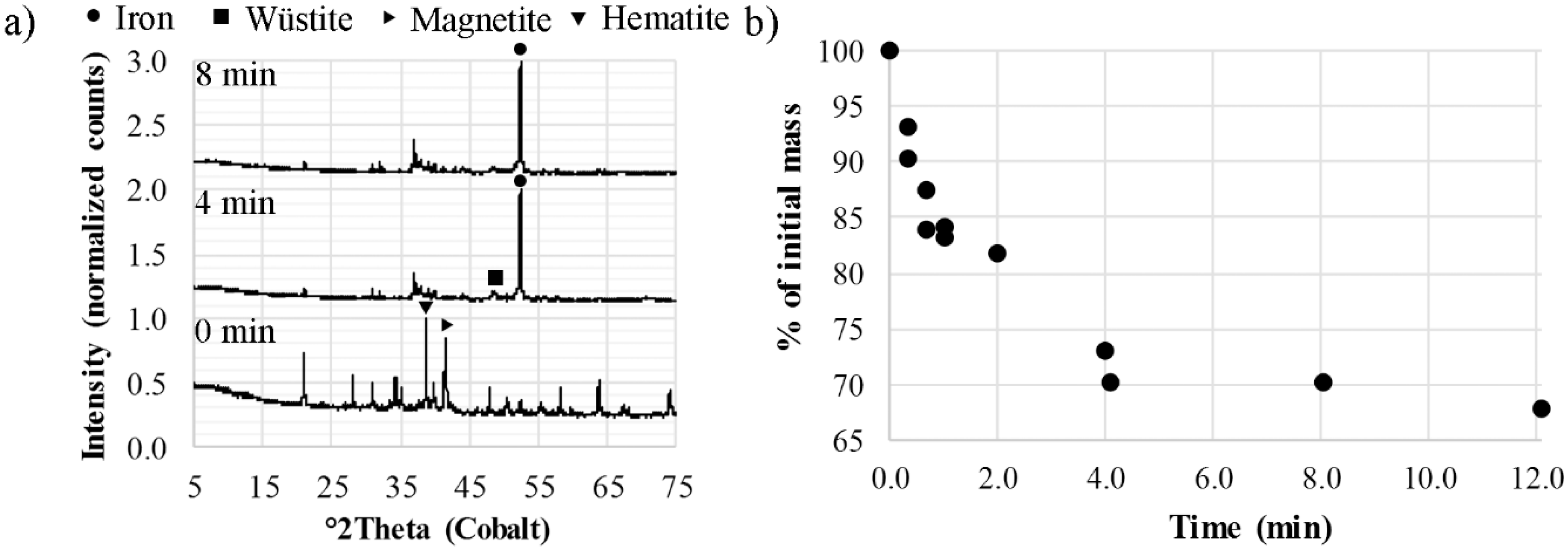

3.1.2. Smelting Reduction of Cold-Bonded Briquettes

3.1.3. Smelting Reduction of Cold-Bonded Pellets

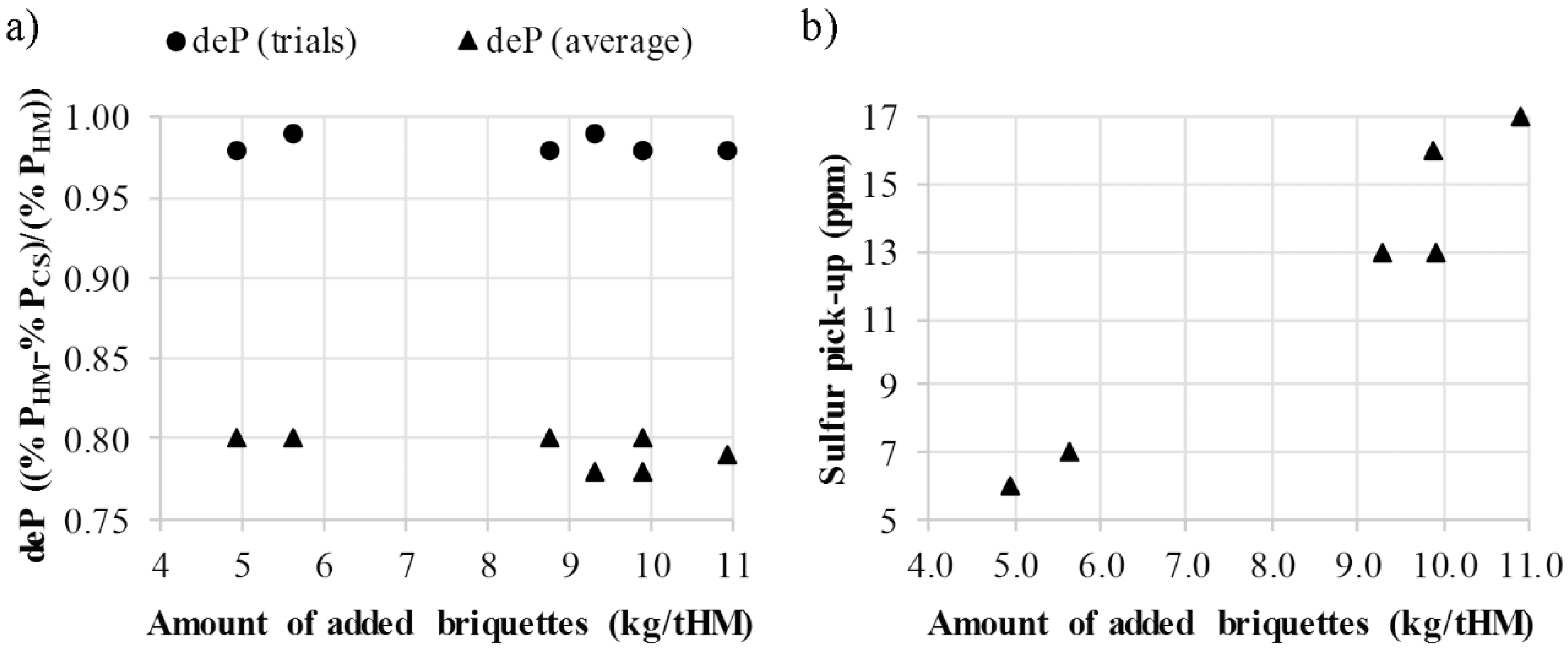

3.2. Industrial-Scale Trials

3.2.1. Desulfurization Plant

3.2.2. Basic Oxygen Furnace

3.3. Low-Sulfur Binders in Cold-Bonded Briquettes

4. Conclusions

- The endothermic reactions occurring upon heating of the briquette lowered the heating and reduction rate, which hindered the melt-in.

- The pellets, being smaller than the briquettes, were fully reduced after eight minutes in contact with the HM but still showed melt-in problems.

- The HM deS plant could be used to recycle up to 2.3 kg of briquettes per tHM, which was the maximum amount tested in the study.

- Recycling briquettes together with the cooling scrap charged to the BOF enabled recycling of 10.9 kg of briquettes per tHM. The recycling rate was limited by the sulfur pick-up in the crude steel.

Author Contributions

Funding

Conflicts of Interest

References

- Senk, D.; Gudenau, H.W.; Geimer, S.; Gorbunova, E. Dust injection in Iron and Steel Metallurgy. ISIJ Int. 2006, 46, 1745–1751. [Google Scholar] [CrossRef]

- Geerdes, M.; Chaigneau, R.; Kurunov, I.; Lingiardi, O.; Ricketts, J. Modern Blast Furnace Ironmaking: An Introduction, 3rd ed.; IOS Press BV: Amsterdam, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Butterworth, P.; Linsley, K.; Aumonier, J. Hydrocyclone treatment of blast furnace slurry within British Steel. Rev. Métall. 1996, 93, 807–816. [Google Scholar] [CrossRef]

- Honingh, S.; Van Weert, G.; Reuter, M.A. Turning Blast Furnace Dust into a Source of Zinc and Lead Units: A Progres Report on Testwork at Corus Ijmuiden. In Proceedings of the Fourth International Symposium on Recycling of Metals and Engineered Materials, Pittsburgh, PA, USA, 22–25 October 2000; TMS: Pittsburgh, PA, USA, 2000. [Google Scholar]

- Itoh, Y.; Fieser, A.H. Zinc removal from blast furnace dust. Iron Steel Eng. 1982, 59, 33–36. [Google Scholar]

- Uno, S.; Umetsu, Y.; Ohmizu, M.; Munakata, S. Dezincing equipment and operation based on wet classification of wet-cleaned BF dust. Nippon Steel Tech. Rep. (Overseas) 1979, 13, 80–85. [Google Scholar]

- Jeon, J.G.; Jin, S.J. Posco’s Achievement for the Recycling of Sludge. SEAISI Q. 2002, 31, 53–59. [Google Scholar]

- Makkonen, H.T.; Heino, J.; Laitila, L.; Hiltunen, A.; Pöyliö, E.; Härkki, J. Optimisation of steel plant recycling in Finland: Dusts, scales and sludge. Resour. Conserv. Recycl. 2002, 35, 77–84. [Google Scholar] [CrossRef]

- Su, F.; Lampinen, H.-O.; Robinson, R. Recycling of Sludge and Dust to the BOF Converter by Cold Bonded Pelletizing. ISIJ Int. 2004, 44, 770–776. [Google Scholar] [CrossRef]

- Tang, F.; Yu, S.; Peng, F.; Hou, H.; Qian, F.; Wang, X. Novel concept of recycling sludge and dust to BOF converter through dispersed in-situ phase induced by composite ball explosive reaction. Int. J. Miner. Metall. Mater. 2017, 24, 863–868. [Google Scholar] [CrossRef]

- Agrawal, R.K.; Pandey, P.K. Productive recycling of basic oxygen furnace sludge in integrated steel plant. J. Sci. Ind. Res. 2005, 64, 702–706. [Google Scholar]

- Singh, A.K.P.; Raju, M.T.; Jha, U. Recycling of Basic Oxygen Furnace (BOF) sludge in iron and steel works. Int. J. Environ. Technol. Manag. 2011, 14, 19–32. [Google Scholar] [CrossRef]

- Tikka, J.; Lindfors, N.; Bäcklund, E. Learning from nature: The tornado process. In Proceedings of the 6th International Heavy Minerals Conference, Hluhluwe, South Africa, 10–14 September 2007; SAIMM: Johannesburg, South Africa, 2007. [Google Scholar]

- Dos Santos, D.M.; Mourão, M.B. High-temperature reduction of iron oxides by solid carbon or carbon dissolved in liquid iron-carbon alloy. Scand. J. Metall. 2004, 33, 229–235. [Google Scholar] [CrossRef]

- Bryk, C.; Lu, W.K. Reduction phenomena in composites of iron-ore concentrates and coals. Ironmak. Steelmak. 1986, 13, 70–75. [Google Scholar]

- Shivaramakrishna, N.; Sarkar, S.B.; Prasad, K.K. The Role of Internal Coal in the Reduction of Composite Pellets. SEAISI Q. 1996, 25, 82–95. [Google Scholar]

- El-Hussiny, N.A.; Shalabi, M.E.H. A self-reduced intermediate product from iron and steel plants waste materials using a briquetting process. Powder Technol. 2010, 205, 217–223. [Google Scholar] [CrossRef]

- Ding, Y.L.; Warner, N.A. Smelting reduction of carbon-chromite composite pellets Part 1: Reduction kinetics and mechanism. Trans. Inst. Min. Metall. Sect. C Min. Process. Extr. Metall. 1997, 106, C55–C63. [Google Scholar]

- Wang, G.; Xue, Q.G.; She, X.F.; Wang, J.S. Reduction-melting behaviors of boron-bearing iron concentrate/carbon composite pellets with addition of CaO. Int. J. Miner. Metall. Mater. 2015, 22, 926–932. [Google Scholar] [CrossRef]

- Materic, V.; Smedley, S.I. High Temperature Carbonation of Ca(OH)2. Ind. Eng. Chem. Res. 2011, 50, 5927–5932. [Google Scholar] [CrossRef]

- Ding, Y.L.; Warner, N.A. Smelting reduction of carbon-chromite composite pellets Part 2: Dissolution kinetics and mechanism. Trans. Inst. Min. Metall. Sect. C Min. Process. Extr. Metall. 1997, 106, C64–C68. [Google Scholar]

- Iwamasa, P.K.; Fruehan, R.J. Effect of FeO in the Slag and Silicon in the Metal on the Desulfurization of Hot Metal. Metall. Mater. Trans. B 1997, 28B, 47–57. [Google Scholar] [CrossRef]

- Andersson, A.; Gullberg, A.; Kullerstedt, A.; Sandberg, E.; Andersson, M.; Ahmed, H.; Sundqvist-Ökvist, L.; Björkman, B. A Holistic and Experimentally-Based View on Recycling of Off-Gas Dust within the Integrated Steel Plant. Metals 2018, 8, 760. [Google Scholar] [CrossRef]

- Fernández Bertos, M.; Simons, S.J.R.; Hills, C.D.; Carey, P.J. A review of accelerated carbonation technology in the treatment of cement-based materials and sequestration of CO2. J. Hazard. Mater. 2004, 112, 193–205. [Google Scholar] [CrossRef] [PubMed]

- Robinson, R. Studies in Low-Temperature Self-Reduction of By-Products from Integrated Iron and Steelmaking. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, 2008. [Google Scholar]

| Fe | C | S | Zn |

|---|---|---|---|

| 29.6 | 19.5 | 0.31 | 1.57 |

| High-Zinc Fraction of BF Sludge | Desulfurization Scrap | Secondary Dust | Cement |

|---|---|---|---|

| 25 | 50 | 15 | 10 |

| Fine Fraction of Steel Scrap | BOF Coarse Sludge | BOF Fine Sludge | Mill Scale from Cont. Casting | Cast House Dust | Cement | Water |

|---|---|---|---|---|---|---|

| 44 | 22 | 18 | 4 | 1 | 10 | 1 |

| Binder | Fine Fraction of Steel Scrap | BOF Coarse Sludge | BOF Fine Sludge | Mill Scale from Cont. Casting | Binder |

|---|---|---|---|---|---|

| Cement 1 | 45.0 | 22.5 | 18.0 | 4.5 | 10.0 |

| Quicklime | 45.0 | 22.5 | 18.0 | 4.5 | 10.0 |

| Slaked lime | 45.0 | 22.5 | 18.0 | 4.5 | 10.0 |

| Synt. organic binder | 50.0 | 25.0 | 20.0 | 5.0 | 0.03 |

| Fe Met. | Fe(II) | Fe(III) 1 | O in FeOx | CaO | SiO2 | MgO | Al2O3 |

| 21.0 | 2.5 | 13.3 | 6.4 | 23.0 | 5.8 | 2.5 | 2.2 |

| MnO | K2O | TiO2 | V2O5 | P2O5 | Na2O | Zn | C |

| 1.9 | 0.19 | 0.68 | 0.43 | 0.09 | 0.38 | 0.93 | 11.6 |

| Fetot | CaO | SiO2 | MnO | P2O5 | Al2O3 | MgO | V2O5 | C | S |

|---|---|---|---|---|---|---|---|---|---|

| 42.3 | 22.6 | 8.8 | 1.8 | 0.2 | 3.1 | 4.4 | 1.3 | 2.0 | 0.3 |

| Binder | No. of Drops (Cured in Room) | No. of Drops (Cured in CO2) | % S in Binder |

|---|---|---|---|

| Cement | 38 | / | 1.37 |

| Quicklime | 1 | 6 | 0.11 |

| Slaked lime | 1 | 5 | 0.53 |

| Synt. organic binder | 2 | 3 | 0.03 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andersson, A.; Andersson, M.; Mousa, E.; Kullerstedt, A.; Ahmed, H.; Björkman, B.; Sundqvist-Ökvist, L. The Potential of Recycling the High-Zinc Fraction of Upgraded BF Sludge to the Desulfurization Plant and Basic Oxygen Furnace. Metals 2018, 8, 1057. https://doi.org/10.3390/met8121057

Andersson A, Andersson M, Mousa E, Kullerstedt A, Ahmed H, Björkman B, Sundqvist-Ökvist L. The Potential of Recycling the High-Zinc Fraction of Upgraded BF Sludge to the Desulfurization Plant and Basic Oxygen Furnace. Metals. 2018; 8(12):1057. https://doi.org/10.3390/met8121057

Chicago/Turabian StyleAndersson, Anton, Mats Andersson, Elsayed Mousa, Adeline Kullerstedt, Hesham Ahmed, Bo Björkman, and Lena Sundqvist-Ökvist. 2018. "The Potential of Recycling the High-Zinc Fraction of Upgraded BF Sludge to the Desulfurization Plant and Basic Oxygen Furnace" Metals 8, no. 12: 1057. https://doi.org/10.3390/met8121057

APA StyleAndersson, A., Andersson, M., Mousa, E., Kullerstedt, A., Ahmed, H., Björkman, B., & Sundqvist-Ökvist, L. (2018). The Potential of Recycling the High-Zinc Fraction of Upgraded BF Sludge to the Desulfurization Plant and Basic Oxygen Furnace. Metals, 8(12), 1057. https://doi.org/10.3390/met8121057