Diffusion Bonding of 9Cr Martensitic/Ferritic Heat-Resistant Steels with an Electrodeposited Ni Interlayer

Abstract

1. Introduction

2. Material and Methods

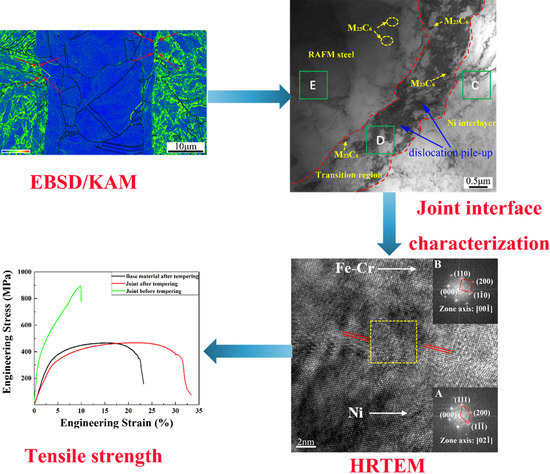

3. Results and Discussion

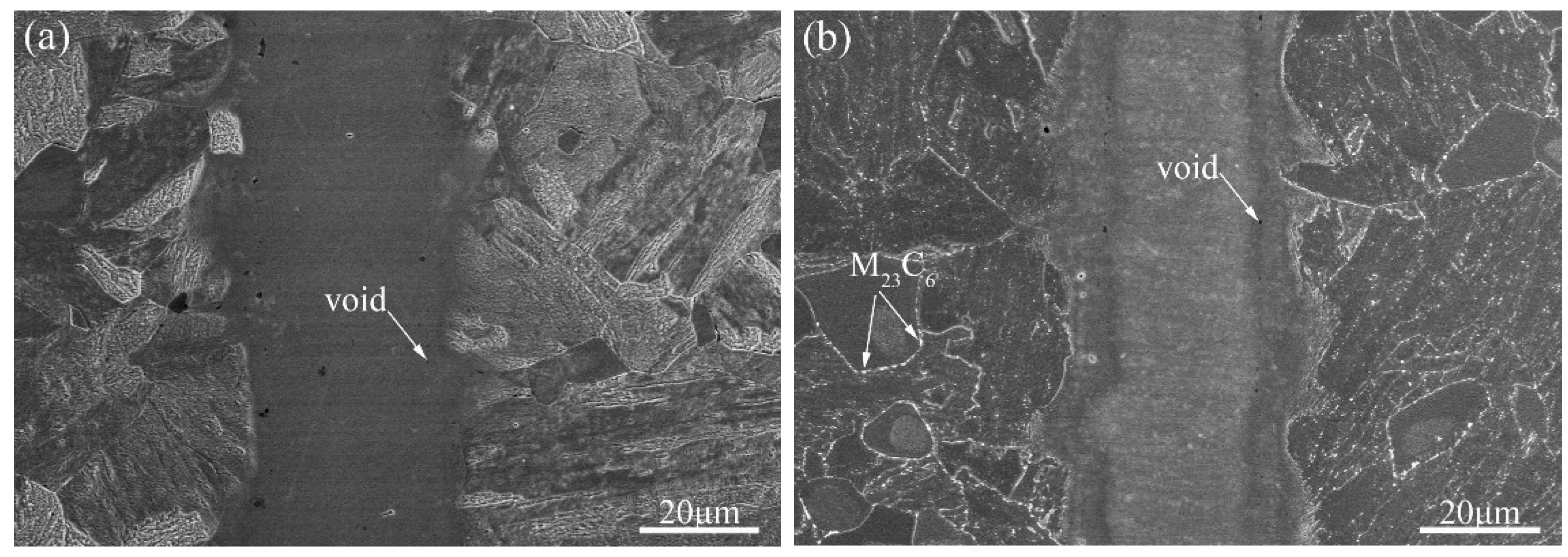

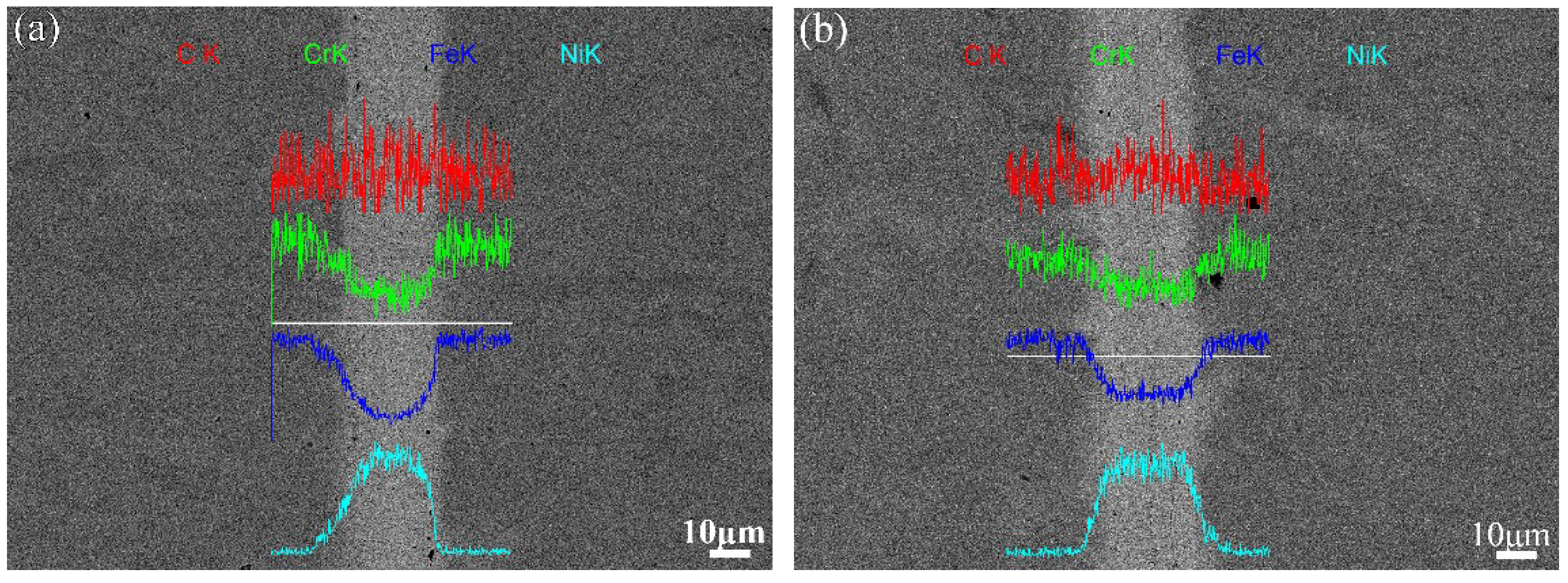

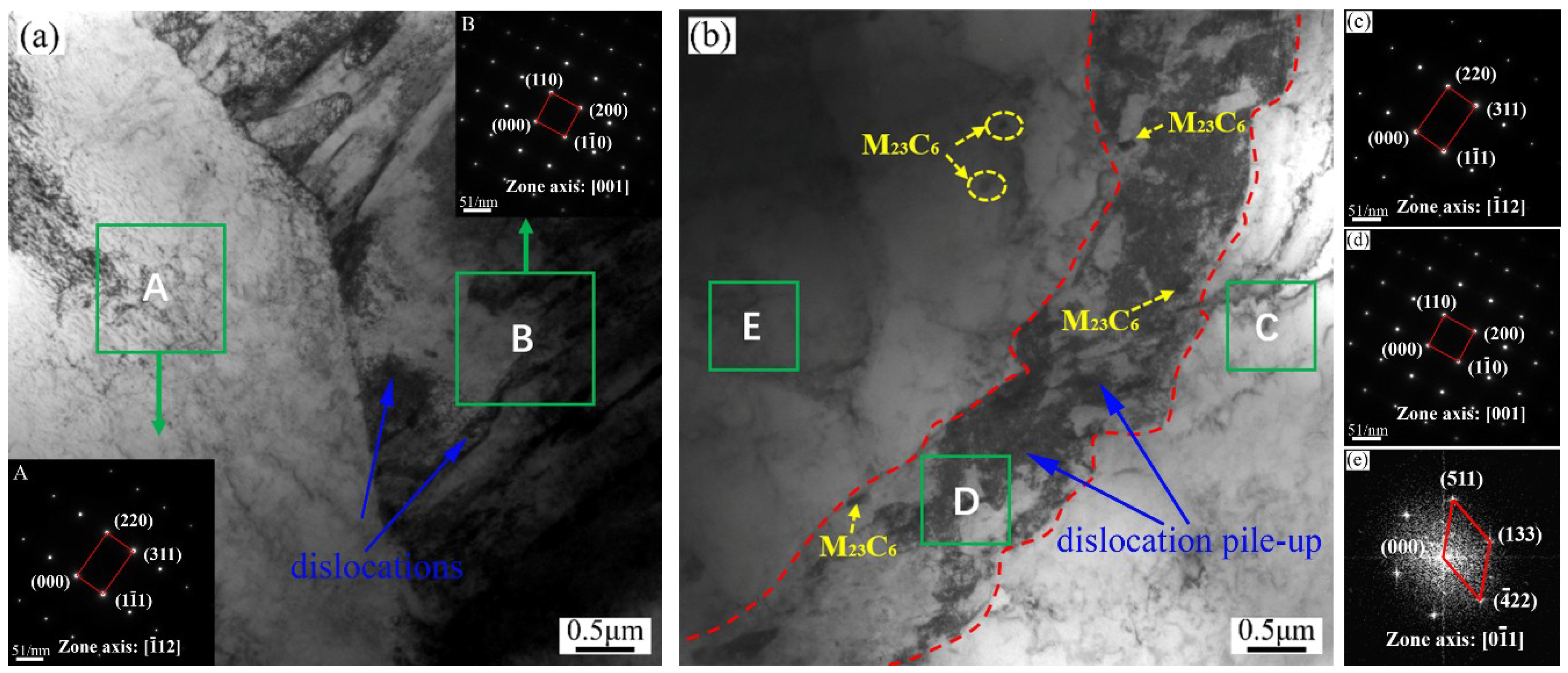

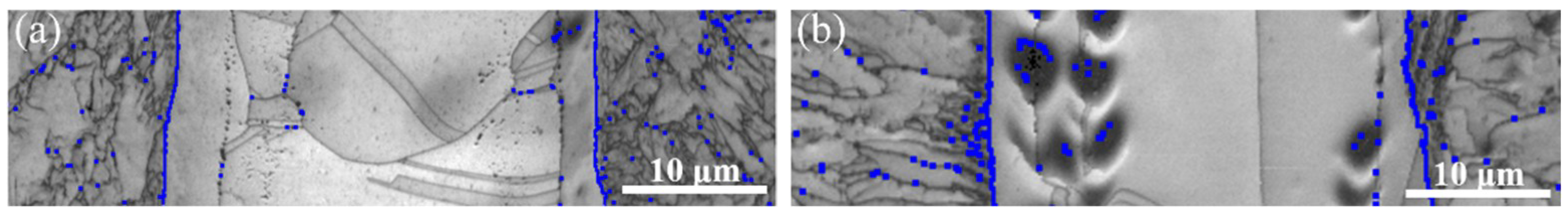

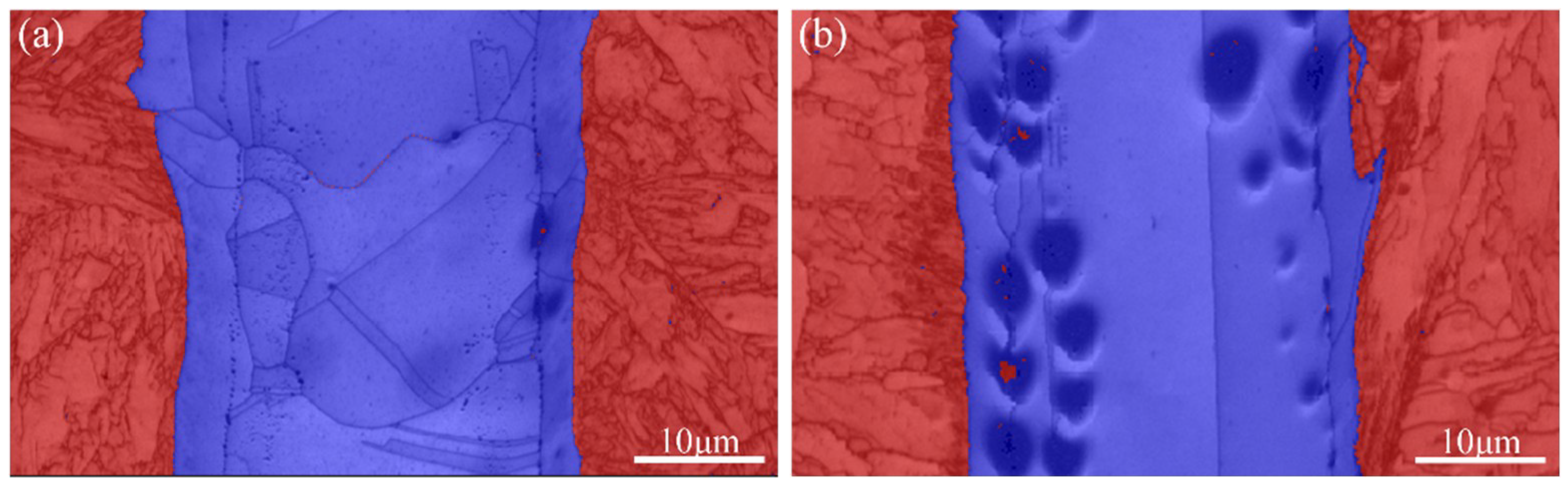

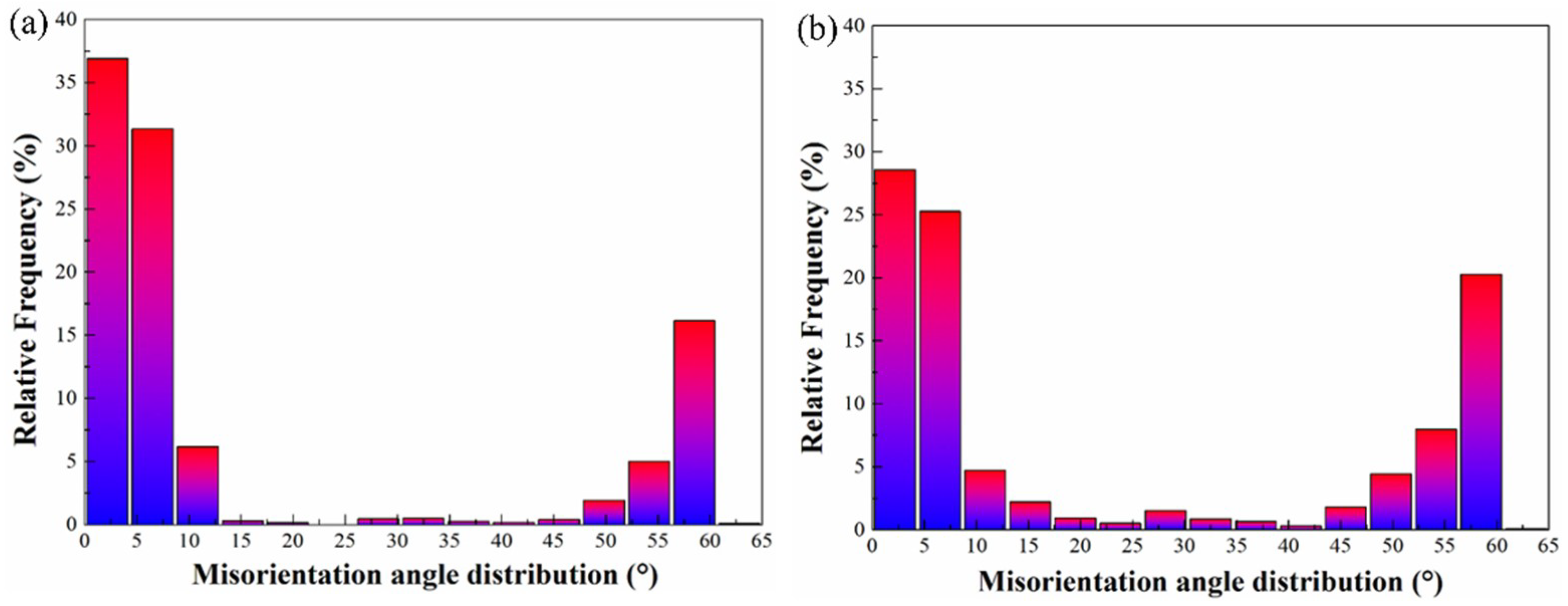

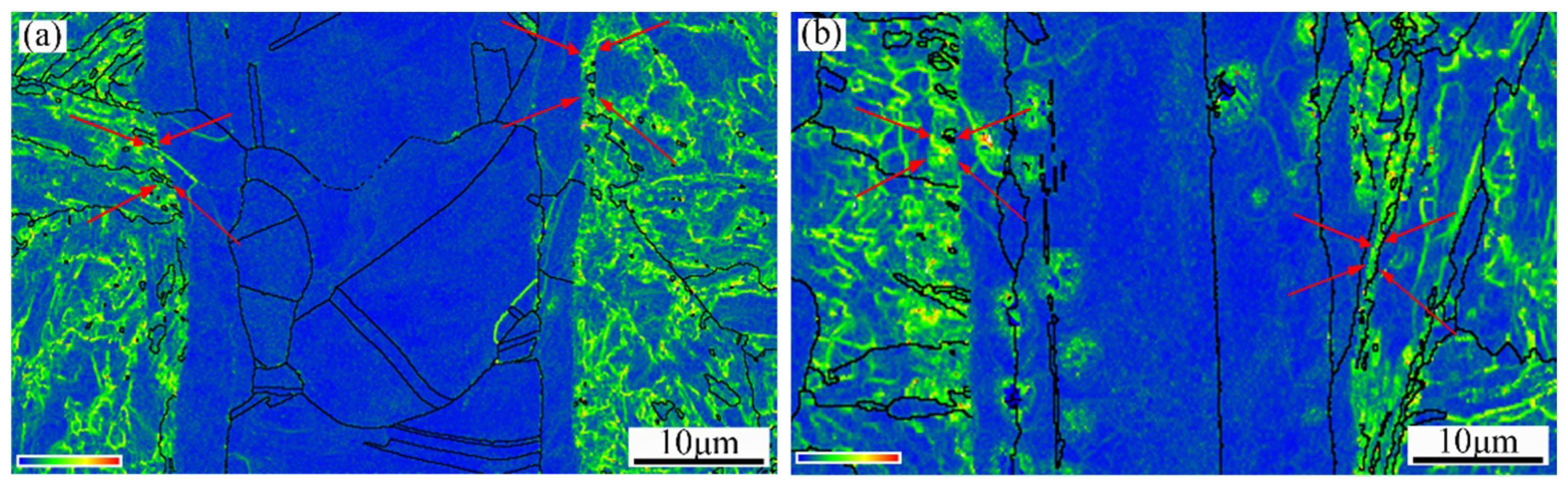

3.1. Microstructural Observation

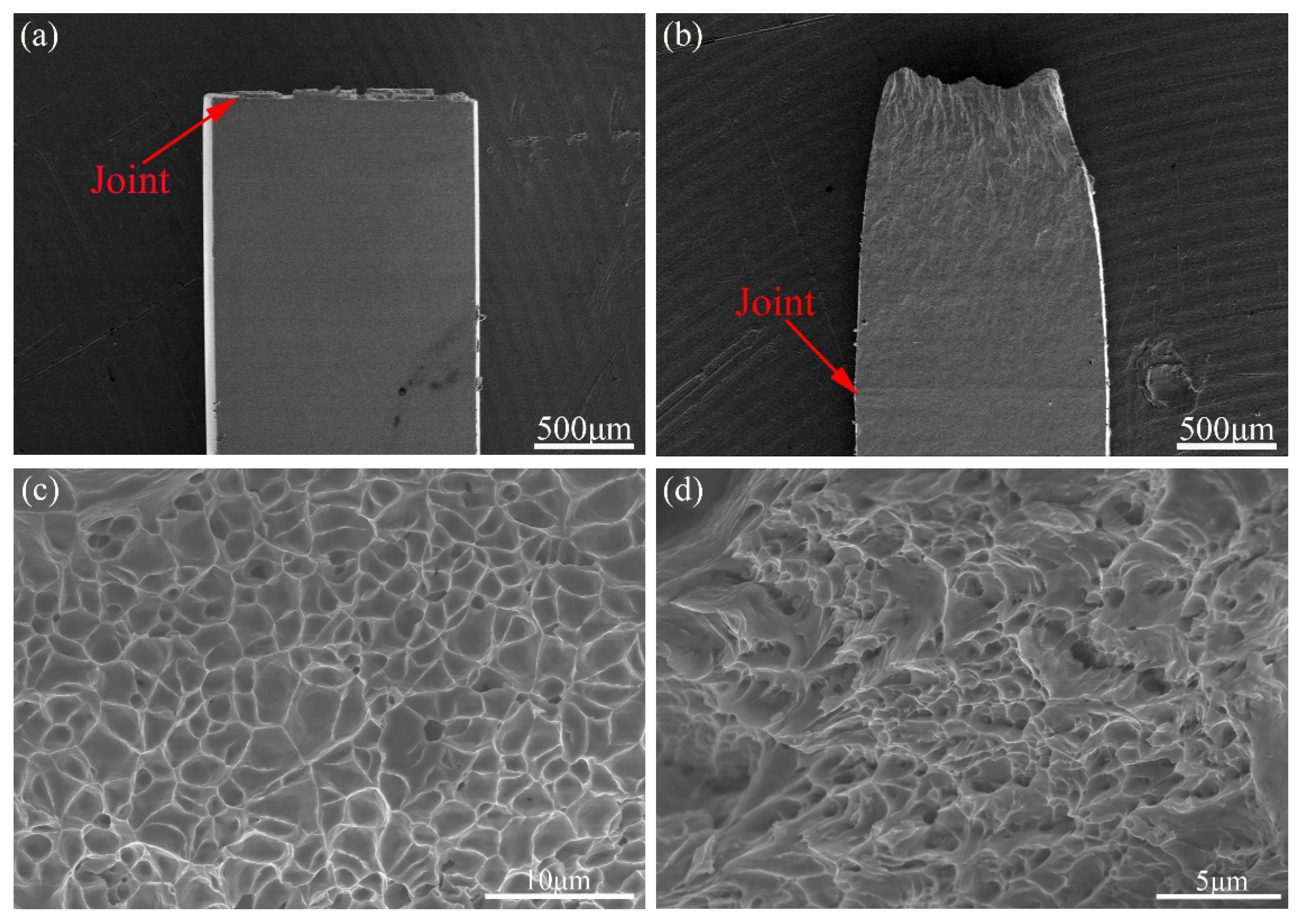

3.2. Tensile Tests of Joints

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pan, C.H. The International Thermonuclear Experimental Reactor and the future of nuclear fusion energy. Wuli 2010, 39, 375–378. [Google Scholar]

- Klueh, R.L.; Nelson, A.T. Ferritic/martensitic steels for next-generation reactors. J. Nucl. Mater. 2007, 371, 37–52. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, C.; Yu, L.; Liu, Y.; Li, H. Phase Transformation Behavior and Microstructural Control of High-Cr Martensitic/Ferritic Heat-resistant Steels for Power and Nuclear Plants: A Review. J. Mater. Sci. Technol. 2015, 31, 235–242. [Google Scholar] [CrossRef]

- Muroga, T.; Gasparotto, M.; Zinkle, S.J. Overview of materials research for fusion reactors. Fusion Eng. Des. 2002, 61, 13–25. [Google Scholar] [CrossRef]

- Baluc, N.; Gelles, D.S.; Jitsukawa, S.; Kimura, A.; Klueh, R.L.; Odette, G.R.; Schaaf, B.V.D.; Yu, J. Status of reduced activation ferritic/martensitic steel development. J. Nucl. Mater. 2007, 367, 33–41. [Google Scholar] [CrossRef]

- Mao, C.; Liu, C.; Yu, L.; Li, H.; Liu, Y. Mechanical properties and tensile deformation behavior of a reduced activated ferritic-martensitic (RAFM) steel at elevated temperatures. Mater. Sci. Eng. A 2018, 725, 283–289. [Google Scholar] [CrossRef]

- Tanigawa, H.; Gaganidze, E.; Hirose, T.; Ando, M.; Zinkle, S.J.; Lindau, R.; Diegele, E. Development of benchmark reduced activation ferritic/martensitic steels for fusion energy applications. Nucl. Fusion 2017, 57. [Google Scholar] [CrossRef]

- Aubert, P.; Tavassoli, F.; Rieth, M.; Diegele, E.; Poitevin, Y. Review of candidate welding processes of RAFM steels for ITER test blanket modules and DEMO. J. Nucl. Mater. 2011, 417, 43–50. [Google Scholar] [CrossRef]

- Hirose, T.; Shiba, K.; Ando, M.; Enoeda, M.; Akiba, M. Joining technologies of reduced activation ferritic/martensitic steel for blanket fabrication. Fusion Eng. Des. 2006, 81, 645–651. [Google Scholar] [CrossRef]

- Lee, J.S.; Park, J.Y.; Choi, B.K.; Hong, B.G.; Jung, K.J.; Jeong, Y.H. HIP joining of RAFM/RAFM steel and beryllium/RAFM steel for fabrication of the ITER TBM first wall. Met. Mater. Int. 2009, 15, 465–470. [Google Scholar] [CrossRef]

- Ku, D.Y.; Oh, S.; Ahn, M.-Y.; Yu, I.-K.; Kim, D.-H.; Cho, S.; Choi, I.-S.; Kwon, K.-B. TIG and HIP joining of Reduced Activation Ferrite/Martensitic steel for the Korean ITER–TBM. J. Nucl. Mater. 2011, 417, 67–71. [Google Scholar] [CrossRef]

- Francis, J.A.; Mazur, W.; Bhadeshia, H.K.D.H. Review Type IV cracking in ferritic power plant steels. Mater. Sci. Technol.-Lond. 2006, 22, 1387–1395. [Google Scholar] [CrossRef]

- Zhang, C.; Li, M.Q.; Li, H. Diffusion behavior at void tip and its contributions to void shrinkage during solid-state bonding. J. Mater. Sci. Technol. 2018, 34, 1449–1454. [Google Scholar] [CrossRef]

- Zhou, X.S.; Liu, Y.C.; Yu, L.M.; Liu, C.X.; Sui, G.F.; Yang, J.G. Uniaxial diffusion bonding of CLAM/CLAM steels: Microstructure and mechanical performance. J. Nucl. Mater. 2015, 461, 301–307. [Google Scholar] [CrossRef]

- Kazakov, N. Diffusion Bonding of Materials; Pergamon: Oxford, UK, 1985. [Google Scholar]

- Haneklaus, N.; Reuven, R.; Cionea, C.; Hosemann, P.; Peterson, P.F. Development of engineering parameters for low pressure diffusion bonds of 316 ss tube-to-tube sheet joints for FHR heat exchangers. In Proceedings of the TMS 2016 145th Annual Meeting & Exhibition, Nashville, TN, USA, 15–17 February 2016; pp. 583–588. [Google Scholar]

- Reuven, R.; Bolind, A.M.; Haneklaus, N.; Cionea, C.; Andreades, C.; Buster, G.; Hosemann, P.; Peterson, P.F. Ni interlayer to improve low pressure diffusion bonding of 316L ss press fit tube-to-tubesheet joints for coiled tube gas heaters. ASME J. Nucl. Radiat. Sci. 2017, 3, 030913. [Google Scholar] [CrossRef]

- Haneklaus, N.; Reuven, R.; Cionea, C.; Hosemann, P.; Peterson, P.F. Tube expansion and diffusion bonding of 316 L stainless steel tube-to-tube sheet joints using a commercial roller tube expander. J. Mater. Process. Technol. 2016, 234, 27–32. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Paul, B.K. Asme Application of Nickel Nanoparticles in Diffusion Bonding of Stainless Steel Surfaces; American Society Mechanical Engineers: New York, NY, USA, 2009; pp. 441–446. [Google Scholar]

- Zhou, X.S.; Dong, Y.T.; Liu, C.X.; Liu, Y.C.; Yu, L.M.; Chen, J.G.; Li, H.J.; Yang, J.G. Transient liquid phase bonding of CLAM/CLAM steels with Ni-based amorphous foil as the interlayer. Mater. Des. 2015, 88, 1321–1325. [Google Scholar] [CrossRef]

- Zhong, Z.; Jung, H.; Hinoki, T.; Kohyama, A. Effect of joining temperature on the microstructure and strength of tungsten/ferritic steel joints diffusion bonded with a nickel interlayer. J. Mater. Process. Technol. 2010, 210, 1805–1810. [Google Scholar] [CrossRef]

- Zhong, Z.H.; Hinoki, T.; Kohyama, A. Effect of holding time on the microstructure and strength of tungsten/ferritic steel joints diffusion bonded with a nickel interlayer. Mater. Sci. Eng. A 2009, 518, 167–173. [Google Scholar] [CrossRef]

- Kundu, S.; Chatterjee, S. Interfacial microstructure and mechanical properties of diffusion-bonded titanium–stainless steel joints using a nickel interlayer. Mater. Sci. Eng. A 2006, 425, 107–113. [Google Scholar] [CrossRef]

- Abe, F. Precipitate design for creep strengthening of 9% Cr tempered martensitic steel for ultra-supercritical power plants. Sci. Technol. Adv. Mater. 2008, 9, 013002. [Google Scholar] [CrossRef]

- Chen, J.; Liu, C.; Liu, Y.; Yan, B.; Li, H. Effects of tantalum content on the microstructure and mechanical properties of low-carbon RAFM steel. J. Nucl. Mater. 2016, 479, 295–301. [Google Scholar] [CrossRef]

- Chen, J.G.; Liu, Y.C.; Xiao, Y.T.; Liu, Y.H.; Liu, C.X.; Li, H.J. Improvement of High-Temperature Mechanical Properties of Low-Carbon RAFM Steel by MX Precipitates. Acta Metall. Sin.-Engl. Lett. 2018, 31, 706–712. [Google Scholar] [CrossRef]

- Yan, B.Y.; Liu, Y.C.; Wang, Z.J.; Liu, C.X.; Si, Y.H.; Li, H.J.; Yu, J.X. The Effect of Precipitate Evolution on Austenite Grain Growth in RAFM Steel. Materials 2017, 10, 1017. [Google Scholar] [CrossRef]

- Rabkin, E.; Klinger, L.; Izyumova, T.; Semenov, V.N. Diffusion-induced grain boundary porosity in NiAl. Scr. Mater. 2000, 42, 1031–1037. [Google Scholar] [CrossRef]

- Balluffi, R.W. Grain boundary diffusion mechanisms in metals. Metall. Trans. B 1982, 13, 527–553. [Google Scholar] [CrossRef]

- Yu, J.Q.; Yi, W.Z.; Chen, B.D.; Chen, H.J. Phase Diagram of Binary Alloys; University of Shanghai for Science and Technology: Shanghai, China, 1987. [Google Scholar]

- Peng, K.P.; Qian, K.W.; Chen, W.Z. Effect of dynamic strain aging on high temperature properties of austenitic stainless steel. Mater. Sci. Eng. A 2004, 379, 372–377. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Miyamoto, G.; Shinbo, K.; Furuhara, T. Effects of α/γ orientation relationship on VC interphase precipitation in low-carbon steels. Scr. Mater. 2013, 69, 17–20. [Google Scholar] [CrossRef]

- Kitahara, H.; Ueji, R.; Tsuji, N.; Minamino, Y. Crystallographic features of lath martensite in low-carbon steel. Acta Mater. 2006, 54, 1279–1288. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhan, D.; Qi, X.; Jiang, Z.; Zhang, H. Microstructure and mechanical properties of Cr14 ultra-high-strength steel at different tempering temperatures around 773 K. Mater. Sci. Eng. A 2017, 698, 152–161. [Google Scholar] [CrossRef]

- Shirazi, H.; Miyamoto, G.; Nedjad, S.H.; Chiba, T.; Ahmadabadi, M.N.; Furuhara, T. Microstructure evolution during austenite reversion in Fe-Ni martensitic alloys. Acta Mater. 2018, 144, 269–280. [Google Scholar] [CrossRef]

- Shi, X.; Zeng, W.; Zhao, Q.; Peng, W.; Kang, C. Study on the microstructure and mechanical properties of Aermet 100 steel at the tempering temperature around 482 °C. J. Alloys Compd. 2016, 679, 184–190. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, C.; Yang, Z.; Su, J.; Weng, Y. Analysis of fracture toughness in high Co–Ni secondary hardening steel using FEM. Mater. Sci. Eng. A 2015, 646, 1–7. [Google Scholar] [CrossRef]

- Zhou, H.W.; Fang, J.F.; Chen, Y.; Yang, L.; Zhang, H.; Lu, Y.; He, Y.Z. Internal friction studies on dynamic strain aging in P91 ferritic steel. Mater. Sci. Eng. A 2016, 676, 361–365. [Google Scholar] [CrossRef]

| Element | C | N | Cr | W | Mn | Si | V | Ta | Fe |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | 0.04 | 0.02 | 8.93 | 1.71 | 0.44 | 0.04 | 0.22 | 0.073 | Bal. |

| Specimen No. | Chemical and Parameters | Data |

|---|---|---|

| 1 | Nickel sulfate | 240 g/L |

| 2 | Nickel chloride | 40 g/L |

| 3 | Boric acid | 40 g/L |

| 4 | Ammonium chloride | 40 g/L |

| 5 | Lauryl sodium sulfate | 0.15 g/L |

| 6 | Time duration | 60 min |

| 7 | Temperature | 35 °C |

| 8 | Current density | 3 A/dm2 |

| 9 | pH value | 5.8 |

| Region | A | B | C | D | E | |

|---|---|---|---|---|---|---|

| Element | ||||||

| Fe | 50.28 | 90.26 | 51.27 | 81.26 | 90.13 | |

| Ni | 40.34 | 0.7 | 39.64 | 9.51 | 0.57 | |

| Cr | 4.86 | 8.33 | 5.47 | 7.85 | 8.85 | |

| W | 4.52 | 4.5 | 3.60 | 1.35 | 0.43 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Wang, Z.; Liu, Y.; Li, W.; Liu, C.; Li, H. Diffusion Bonding of 9Cr Martensitic/Ferritic Heat-Resistant Steels with an Electrodeposited Ni Interlayer. Metals 2018, 8, 1012. https://doi.org/10.3390/met8121012

Gao Y, Wang Z, Liu Y, Li W, Liu C, Li H. Diffusion Bonding of 9Cr Martensitic/Ferritic Heat-Resistant Steels with an Electrodeposited Ni Interlayer. Metals. 2018; 8(12):1012. https://doi.org/10.3390/met8121012

Chicago/Turabian StyleGao, Yan, Zumin Wang, Yongchang Liu, Wenchao Li, Chenxi Liu, and Huijun Li. 2018. "Diffusion Bonding of 9Cr Martensitic/Ferritic Heat-Resistant Steels with an Electrodeposited Ni Interlayer" Metals 8, no. 12: 1012. https://doi.org/10.3390/met8121012

APA StyleGao, Y., Wang, Z., Liu, Y., Li, W., Liu, C., & Li, H. (2018). Diffusion Bonding of 9Cr Martensitic/Ferritic Heat-Resistant Steels with an Electrodeposited Ni Interlayer. Metals, 8(12), 1012. https://doi.org/10.3390/met8121012