Probability-Statistical Estimation Method of Feed Influence on As-Turned Finish of Steels and Non-Ferrous Metals

Abstract

:1. Introduction

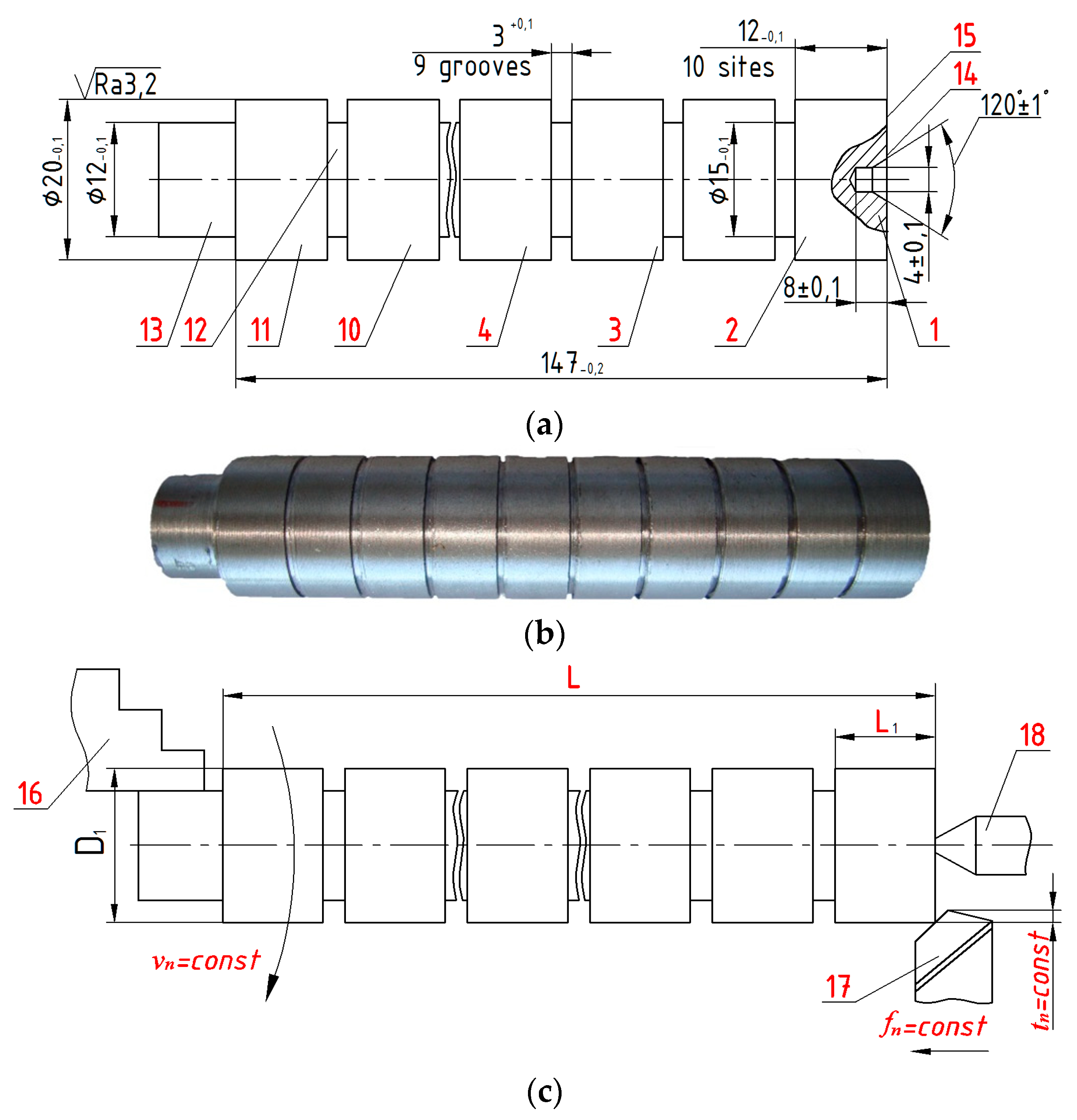

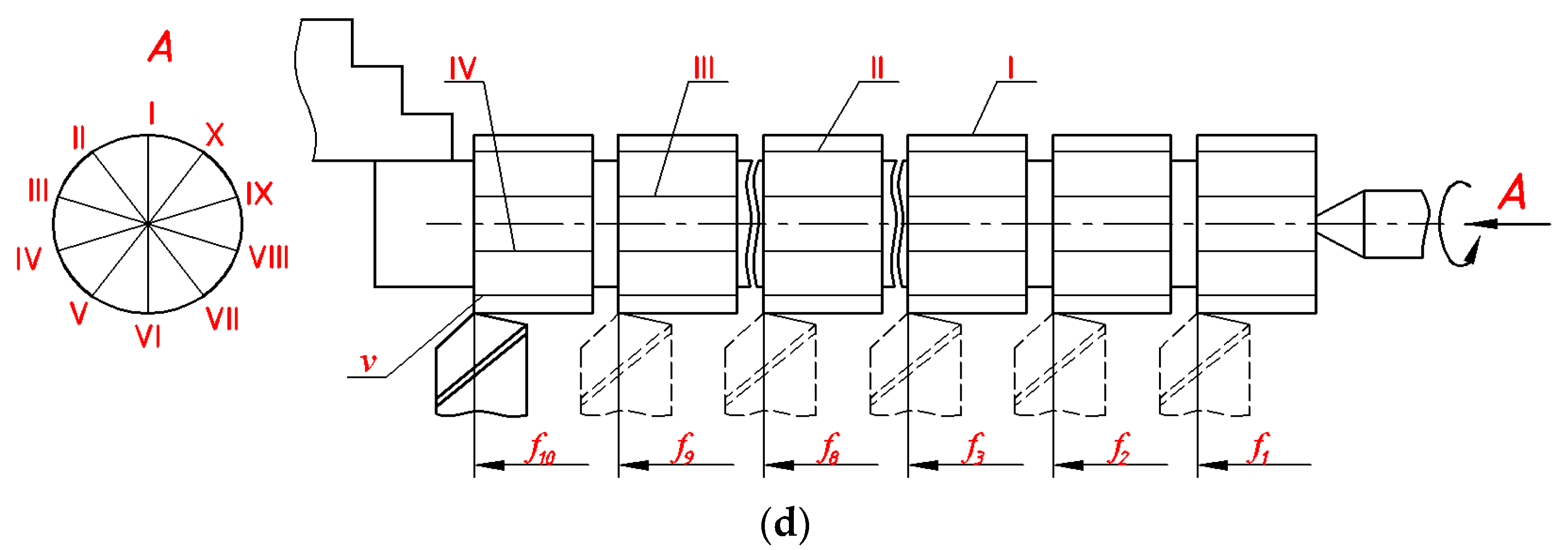

2. Materials and Methods

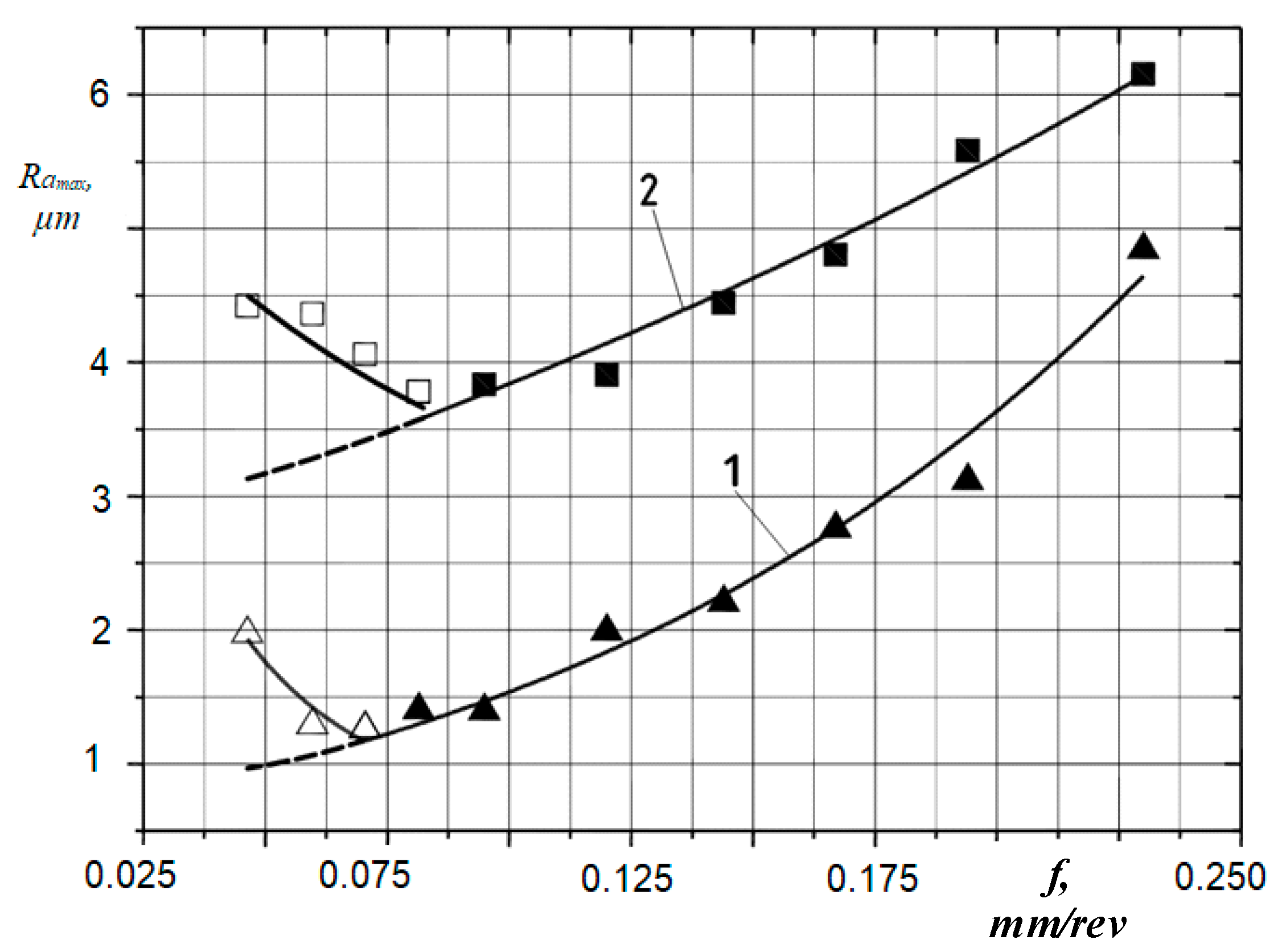

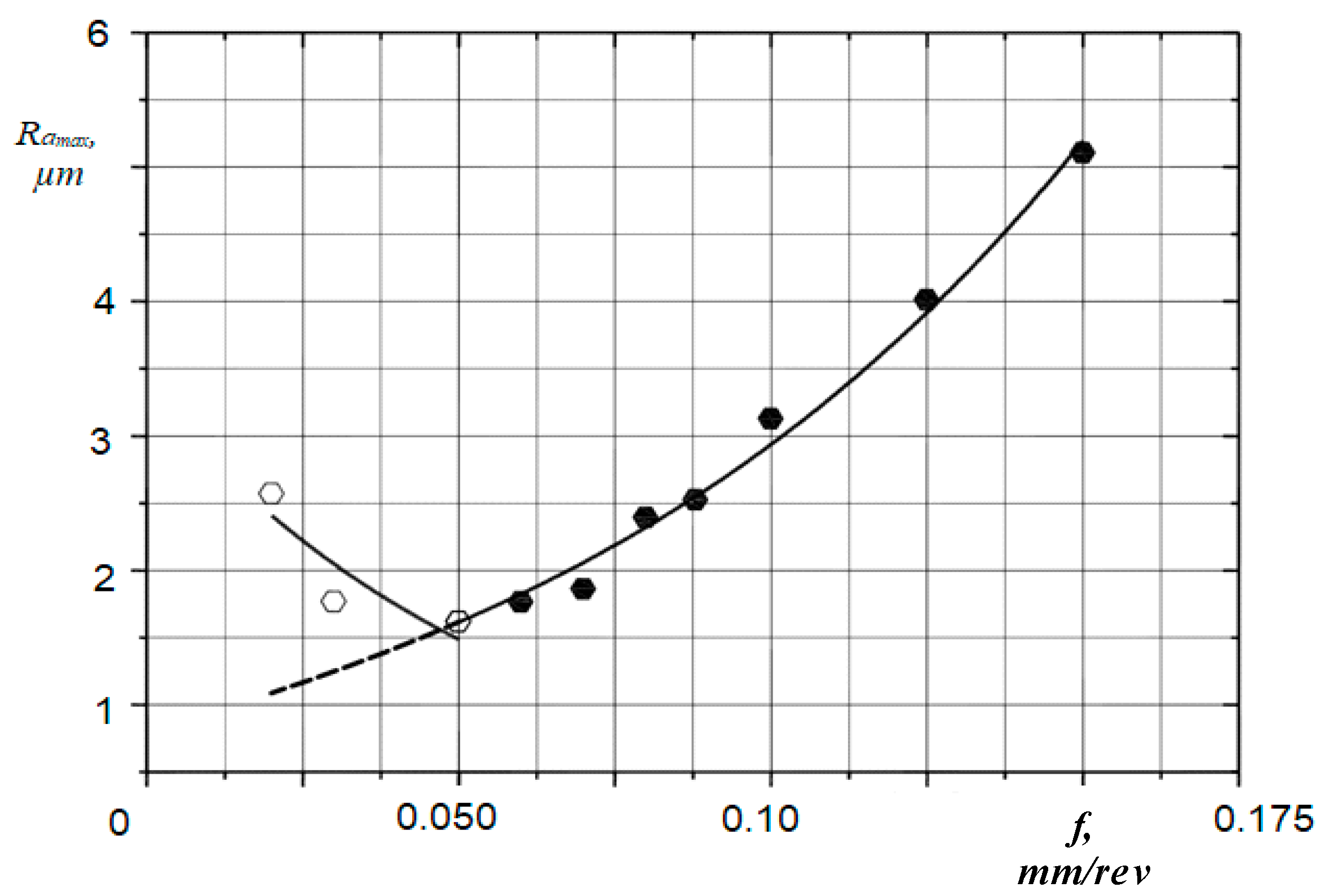

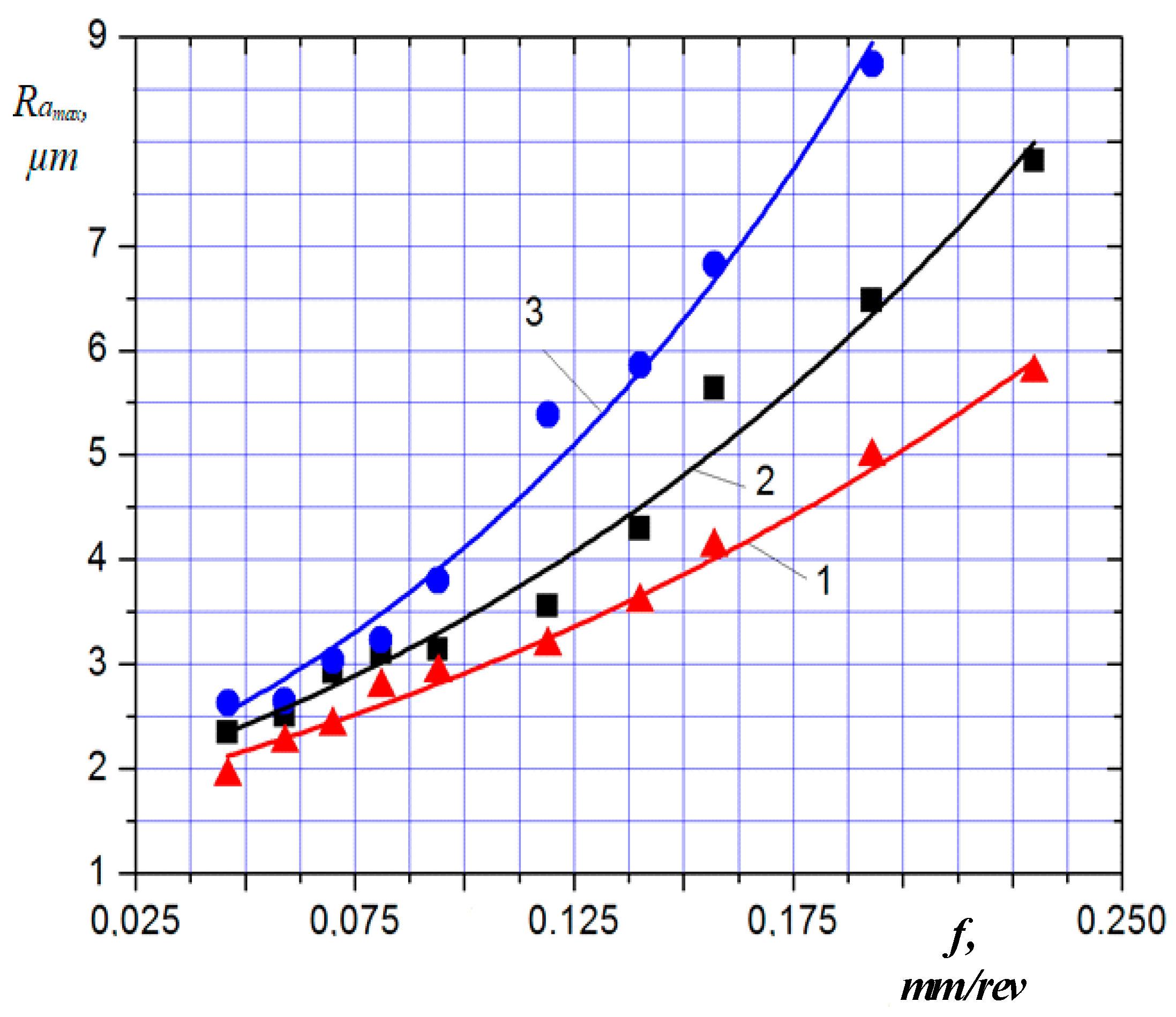

3. Approbation of the Proposed Method, Experimental Studies and Their Results

4. Analysis of Results

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Rao, P.N. Manufacturing Technology: Metal Cutting and Machine Tools; Tata McGraw-Hill Education: New York, NY, USA, 2013; 521p. [Google Scholar]

- Ryzhov, Y.V.; Suslov, A.T.; Fyedorov, V.P. Engineering Support of Machine Parts Service Characteristic; Mechanical Engineering: Moscow, Russia, 1979; 176p. [Google Scholar]

- Astakhov, V.P. Surface integrity—Definition and importance in functional performance. In Surface Integrity in Machining; Davim, J.P., Ed.; Springer Science & Business Media: Berlin, Germany, 2010; pp. 1–35. [Google Scholar]

- Reference Manual for Production-Mechanical Engineer in 2 Volumes, 4th ed.; Kosilova, A.H.; Meshcheryakov, R.K. (Eds.) Machynostroyeniye: Moscow, Russia, 1986; p. 656. [Google Scholar]

- Bobrov, V.F. Foundations of Metal Cutting Theory; Machynostroyeniye: Moscow, Russia, 1975; p. 344. [Google Scholar]

- Haskarov, D.V.; Shapovalov, V.I. Small Sample; Statistics: Moscow, Russia, 1978; p. 248. [Google Scholar]

- Kolker, Y.D. Mathematical Analysis of Machine Parts Working Accuracy; Technika: Kiev, Ukraine, 1976; p. 200. [Google Scholar]

- Kryvyi, P.D.; Dzyura, V.O.; Tymoshenko, N.M.; Krypa, V.V. Technological heredity and accuracy of the cross-section shapes of the hydro-cylinder cylindrical surfaces. In Proceedings of the ASME 2014 International Manufacturing Science and Engineering Conference Collocated with the JSME 2014 International Conference on Materials and Processing and the 42nd North American Manufacturing Research Conference, Detroit, MI, USA, 9–13 June 2014; p. 2, Paper No. MSEC2014-3946. [Google Scholar] [CrossRef]

- Dogra, M.; Sharma, V.S.; Dureja, J. Effect of tool geometry variation on finish turning—A Review. J. Eng. Sci. Technol. Rev. 2011, 4, 1–13. [Google Scholar] [CrossRef]

- Sam Paul, P.; Varadarajan, A.S.; Robinson, R. Gnanadurai Study on the influence of fluid application parameters on tool vibration and cutting performance during turning of hardened steel. Eng. Sci. Technol. Int. J. 2016, 19, 241–253. [Google Scholar] [CrossRef]

- Hughes, J.I.; Sharman, A.R.; Ridgwayk, C. The effect of cutting tool material and edge geometry on tool life and workpiece surface integrity. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2006, 220, 93–107. [Google Scholar] [CrossRef]

- Matsumoto, Y.; Hashimoto, F.; Lahoti, G. Surface integrity generated by precision hard turning. Ann. CIRP 1999, 48, 59–62. [Google Scholar] [CrossRef]

- Sasahara, H.; Obikawa, T.; Shirakashi, T. Prediction model of surface residual stress within a machined surface by combining two orthogonal plane models. Int. J. Mach. Tools Manuf. 2004, 44, 815–822. [Google Scholar] [CrossRef]

- Witenberg, Y.R. Surface Roughness and Methods of its Evaluation; Sydostroyeniye: Leningrad, Russia, 1971; p. 108. [Google Scholar]

- NCSR. AMTA Reliability Publications NO. 1-CNC Machining Centre; National Centre for System Reliability: Risley, UK, 1988. [Google Scholar]

- Lulyanov, V.S.; Rudzyt, Y.A. Surface Roughness Parameters; Izdatelstvo Standartov: Moscow, Russia, 1979; p. 162. (In Russian) [Google Scholar]

- Kryvyi, P.D.; Dzyura, V.O.; Hrytsay, I.Y.; Yatsyuk, V.A. Determination Method of Feed Effect on the Surface Roughness Machined by Cutting. Patent of Ukraine 112,248; 2 April 2015, 10 August 2016. [Google Scholar]

- Bashkov, V.M.; Katsev, P.H. Cutting Tool Durability Tests; Mashynostroyeniye: Moscow, Russia, 1985; p. 136. (In Russian) [Google Scholar]

- Filonenko, S.N. Metal Cutting; Technika: Kiev, Ukraine, 1975; p. 232. [Google Scholar]

- Knight, W.A.; Boothroyd, G. Fundamentals of Metal Machining and Machine Tools, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2005; p. 602. [Google Scholar]

- Krupa, V.V. Metal Cutting Tools with Asymmetrical Cutting Edge Location for Machining of Deep Cylinder Ports. Ph.D. Thesis, TNTU, Ternopil, Ukraine, 2015. [Google Scholar]

- Klushyn, M.I. Metal Cutting, 2nd ed.; Gosnauchtechizdat Machynostroitelnoy Literatury: Moscow, Russia, 1958; 454p. [Google Scholar]

- Lin, S.C.; Chang, M.F. A study on the effects of vibrations on the surface finish using a surface topography simulation model for turning. Int. J. Mach. Tools Manuf. 1998, 38, 763–782. [Google Scholar] [CrossRef]

- Thomas, M.; Beauchamp, Y.; Youssef, A.Y.; Masounave, J. Effect of tool vibrations on surface roughness during lathe dry turning process. Comput. Ind. Eng. 1996, 31, 637–644. [Google Scholar] [CrossRef]

- Chen, C.-C.A.; Lui, W.-C.; Duffie, N.A. A surface topography model for automated surface finishing. Int. J. Mach. Tools Manuf. 1998, 38, 543–550. [Google Scholar] [CrossRef]

- Toulfatzis, A.I.; Pantazopoulos, G.A.; David, C.N.; Sagris, D.S.; Paipetis, A.S. Machinability of Eco-Friendly Lead-Free Brass Alloys: Cutting-Force and Surface-Roughness Optimization. Metals 2018, 8, 250. [Google Scholar] [CrossRef]

- Shaw, M.C. Metal Cutting Principles; Oxford University Press: Oxford, UK, 1984; pp. 487–519. [Google Scholar]

- Thomas, T.R. Rough Surfaces; Longman Inc.: New York, NY, USA, 1982; 261p. [Google Scholar]

- ISO 3274 Geometrical Product Specifications (GPS)-Surface Texture: Profile Method-Nominal Characteristics of Contact (Stylus) Instruments; International Organization for Standardization: Geneva, Switzerland, 1996; p. 13.

- ISO 4287, Geometrical Product Specifications (GPS)-Surface Texture: Profile Method-Terms, Definitions and Surface Texture Parameters; International Organization for Standardization: Geneva, Switzerland, 1997; p. 25.

- ISO 4288, Geometrical Product Specifications (GPS)-Surface Texture: Profile Method-Rules and Procedures for the Assessment of Surface Texture; International Organization for Standardization: Geneva, Switzerland, 1996; p. 8.

- ISO 8785 Surface Imperfections-Terms, Definitions, and Parameters; International Organization for Standardization: Geneva, Switzerland, 1998; p. 20.

| Passport values, μm/rev | 50 | 60 | 75 | 90 | 100 | 125 | 150 | 175 | 200 | 250 |

| Average value, μm/rev | 46.3 | 59.8 | 70.5 | 81.5 | 94.9 | 120.0 | 144.1 | 167.5 | 193.9 | - |

| Dispersion, (μm/rev)2 | 8.46 | 20.15 | 11.64 | 21.18 | 27.8 | 29.08 | 34.55 | 52.15 | 60.78 | - |

| Mean square deviation, μm/rev | 2.91 | 4.49 | 3.41 | 4.60 | 5.27 | 5.39 | 5.87 | 7.22 | 7.80 | - |

| Parameter | Feed Passport Values—Numerator Sample Average Feed Values—Denominator, μm/rev. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cast-iron KCh 30-6 | ||||||||||

| , μm | 4.21 | 4.13 | 3.67 | 3.57 | 3.41 | 3.47 | 3.68 | 4.37 | 5.18 | 5.94 |

| , μm² | 0.005 | 0.006 | 0.017 | 0.005 | 0.020 | 0.021 | 0.065 | 0.021 | 0.018 | 0.005 |

| , μm | 4.422 | 4.362 | 4.061 | 3.782 | 3.834 | 3.905 | 4.445 | 4.805 | 5.582 | 6.152 |

| tр. | - | 2.30 | 10.88 | 18.92 | 15.18 | 13.85 | 6.05 | 21.71 | 10.89 | 51.14 |

| Change significance | - | +< | +< | +< | +< | +< | +< | >+ | >+ | >+ |

| Fр. | - | 1.32 | 3.62 | 1.19 | 4.26 | 4.47 | 13.83 | 4.47 | 38.72 | 1.19 |

| Change significance | - | – • | + • | – • | + • | + • | + • | + • | + • | – • |

| Кv. | 0.02 | 0.02 | 0.04 | 0.02 | 0.04 | 0.04 | 0.07 | 0.03 | 0.07 | 0.01 |

| Steel 45 | ||||||||||

| , μm | 1.38 | 0.99 | 0.75 | 0.93 | 1.08 | 1.36 | 1.67 | 2.39 | 2.54 | 3.85 |

| , μm² | 0.039 | 0.010 | 0.029 | 0.025 | 0.011 | 0.044 | 0.032 | 0.015 | 0.037 | 0.11 |

| , μm | 1.972 | 1.29 | 1.261 | 1.404 | 1.395 | 1.989 | 2.207 | 2.757 | 3.117 | 4.845 |

| tр. | - | 5.29 | 7.24 | 5.34 | 4.02 | 0.21 | 3.27 | 6.97 | 12.62 | 19.2 |

| Change significance | - | +< | +< | +< | >+ | >+ | >+ | >+ | >+ | >+ |

| Fр. | - | 3.9 | 1.34 | 1.56 | 3.55 | 1.13 | 1.22 | 3.85 | 1.05 | 2.82 |

| Change significance | - | + | – • | – • | + • | – • | – • | + • | – • | – • |

| Кv. | 0.14 | 0.10 | 0.23 | 0.17 | 0.10 | 0.15 | 0.11 | 0.16 | 0.08 | 0.09 |

| Parameter | Feed Passport Values, μm/rev. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 30 | 50 | 60 | 70 | 80 | 88 | 100 | 125 | 150 | |

| , μm | 2.44 | 1.52 | 1.44 | 1.58 | 1.59 | 1.72 | 2.38 | 2.54 | 3.84 | 4.66 |

| , μm² | 0.0018 | 0.0066 | 0.0035 | 0.0039 | 0.0080 | 0.05 | 0.0022 | 0.0380 | 0.0032 | 0.0220 |

| , μm | 2.567 | 1.764 | 1.617 | 1.767 | 1.858 | 2.391 | 2.521 | 3.125 | 4.01 | 5.105 |

| tр. | - | 30.11 | 41.21 | 34.17 | 25.76 | 10.28 | 1.1 | 1.5 | 59.4 | 43.17 |

| Change significance | - | +< | +< | +< | +< | +< | o | o | >+ | >+ |

| Fр. | - | 3.67 | 1.94 | 2.17 | 4.44 | 27.78 | 1.5 | 21.11 | 1.78 | 12.22 |

| Change significance | - | + • | – • | – • | + • | + • | – • | + • | – • | + • |

| Кv. | 0.02 | 0.05 | 0.04 | 0.04 | 0.06 | 0.13 | 0.01 | 0.08 | 0.01 | 0.03 |

| Parameter | Feed Passport Values—Numerator Sample Average Feed Values—Denominator, μm/rev. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Aluminium alloy D16T | ||||||||||

| , μm | 1.91 | 2.19 | 2.67 | 2.83 | 2.84 | 3.21 | 3.87 | 5.27 | 6.03 | 7.19 |

| , μm² | 0.021 | 0.011 | 0.007 | 0.008 | 0.010 | 0.013 | 0.020 | 0.015 | 0.022 | 0.043 |

| , μm | 2.345 | 2.505 | 2.921 | 3.098 | 3.14 | 3.552 | 4.294 | 5.637 | 6.475 | 7.812 |

| tр. | - | 4.19 | 13.02 | 15.68 | 15.33 | 16.27 | 25.63 | 23.81 | 59.17 | 62.26 |

| Change significance | - | >+ | >+ | >+ | >+ | >+ | >+ | >+ | >+ | >+ |

| Fр. | - | 1.91 | 2.88 | 2.63 | 2.1 | 1.62 | 1.05 | 7.38 | 1.05 | 2.05 |

| Change significance | - | - | - | - | - | - | - | + | - | - |

| Кv. | 0.07 | 0.05 | 0.03 | 0.03 | 0.04 | 0.04 | 0.04 | 0.07 | 0.02 | 0.03 |

| Brass LS 63-3 | ||||||||||

| , μm | 2.214 | 2.36 | 2.57 | 2.98 | 3.55 | 4.54 | 5.14 | 5.89 | 7.85 | - |

| , μm² | 0.019 | 0.009 | 0.024 | 0.007 | 0.007 | 0.079 | 0.058 | 0.096 | 0.088 | - |

| , μm | 2.628 | 2.645 | 3.035 | 3.231 | 3.801 | 5.383 | 5.862 | 6.82 | 8.74 | - |

| tр. | - | 0.92 | 2.17 | 4.82 | 8.43 | 12.78 | 16.71 | 19.65 | 26.75 | - |

| Change significance | - | o | >+ | >+ | >+ | >+ | >+ | >+ | >+ | - |

| Fр. | - | 24.07 | 9.13 | 25.47 | 30.42 | 2.77 | 3.78 | 2.28 | 1.21 | - |

| Change significance | - | + | + | + | + | - | + | - | - | - |

| Кv. | 0.21 | 0.04 | 0.06 | 0.03 | 0.02 | 0.06 | 0.05 | 0.05 | 0.05 | - |

| Silumin AL4 | ||||||||||

| , μm | 1.47 | 1.54 | 2.03 | 2.23 | 2.44 | 2.74 | 3.09 | 3.73 | 4.56 | 5.18 |

| , μm² | 0.023 | 0.055 | 0.016 | 0.033 | 0.025 | 0.021 | 0.028 | 0.017 | 0.020 | 0.041 |

| , μm | 1.925 | 2.244 | 2.409 | 2.775 | 2.914 | 3.175 | 3.592 | 4.121 | 4.984 | 5.787 |

| tр. | - | 0.06 | 4.12 | 4.21 | 8.69 | 11.06 | 11.19 | 13.3 | 18.52 | 15.85 |

| Change significance | - | o | >+ | >+ | >+ | >+ | >+ | >+ | >+ | >+ |

| Fр. | - | 1.62 | 1.22 | 2.39 | 5.52 | 6.57 | 4.93 | 1.23 | 1.45 | 2.97 |

| Change significance | - | - | - | - | + | + | + | - | - | - |

| Кv. | 0.29 | 0.23 | 0.20 | 0.26 | 0.06 | 0.05 | 0.06 | 0.11 | 0.09 | 0.12 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kryvyi, P.; Dzyura, V.; Tymoshenko, N.; Maruschak, P.; Nugaras, J.; Prentkovskis, O. Probability-Statistical Estimation Method of Feed Influence on As-Turned Finish of Steels and Non-Ferrous Metals. Metals 2018, 8, 965. https://doi.org/10.3390/met8110965

Kryvyi P, Dzyura V, Tymoshenko N, Maruschak P, Nugaras J, Prentkovskis O. Probability-Statistical Estimation Method of Feed Influence on As-Turned Finish of Steels and Non-Ferrous Metals. Metals. 2018; 8(11):965. https://doi.org/10.3390/met8110965

Chicago/Turabian StyleKryvyi, Petro, Volodymyr Dzyura, Nadiya Tymoshenko, Pavlo Maruschak, Justas Nugaras, and Olegas Prentkovskis. 2018. "Probability-Statistical Estimation Method of Feed Influence on As-Turned Finish of Steels and Non-Ferrous Metals" Metals 8, no. 11: 965. https://doi.org/10.3390/met8110965

APA StyleKryvyi, P., Dzyura, V., Tymoshenko, N., Maruschak, P., Nugaras, J., & Prentkovskis, O. (2018). Probability-Statistical Estimation Method of Feed Influence on As-Turned Finish of Steels and Non-Ferrous Metals. Metals, 8(11), 965. https://doi.org/10.3390/met8110965