Behaviour of Steel Grade S275JR Columns under the Influence of High-Temperature Creep

Abstract

1. Introduction

1.1. Motivation

1.2. Previous Numerical and Test Studies

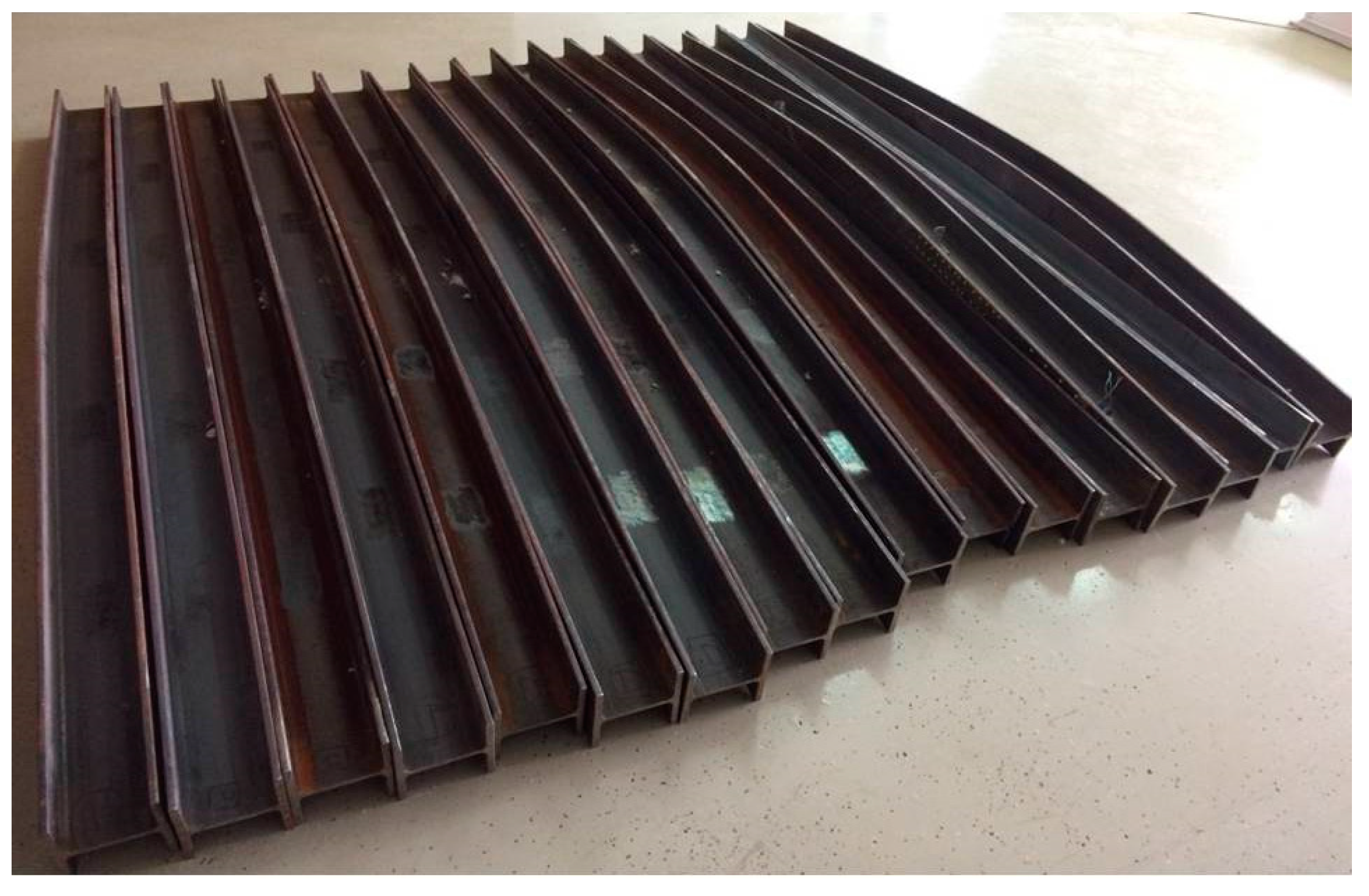

2. Experimental Study

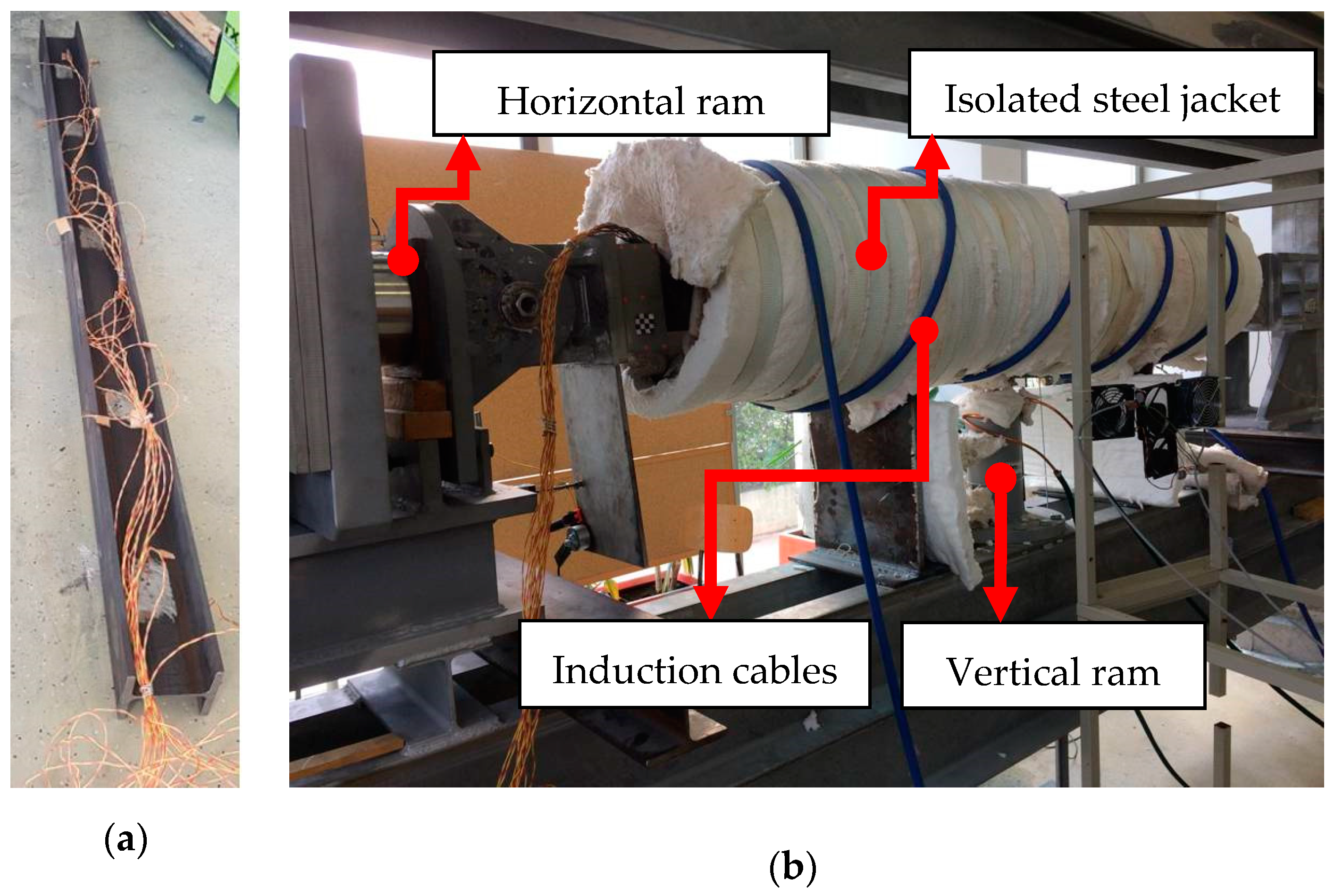

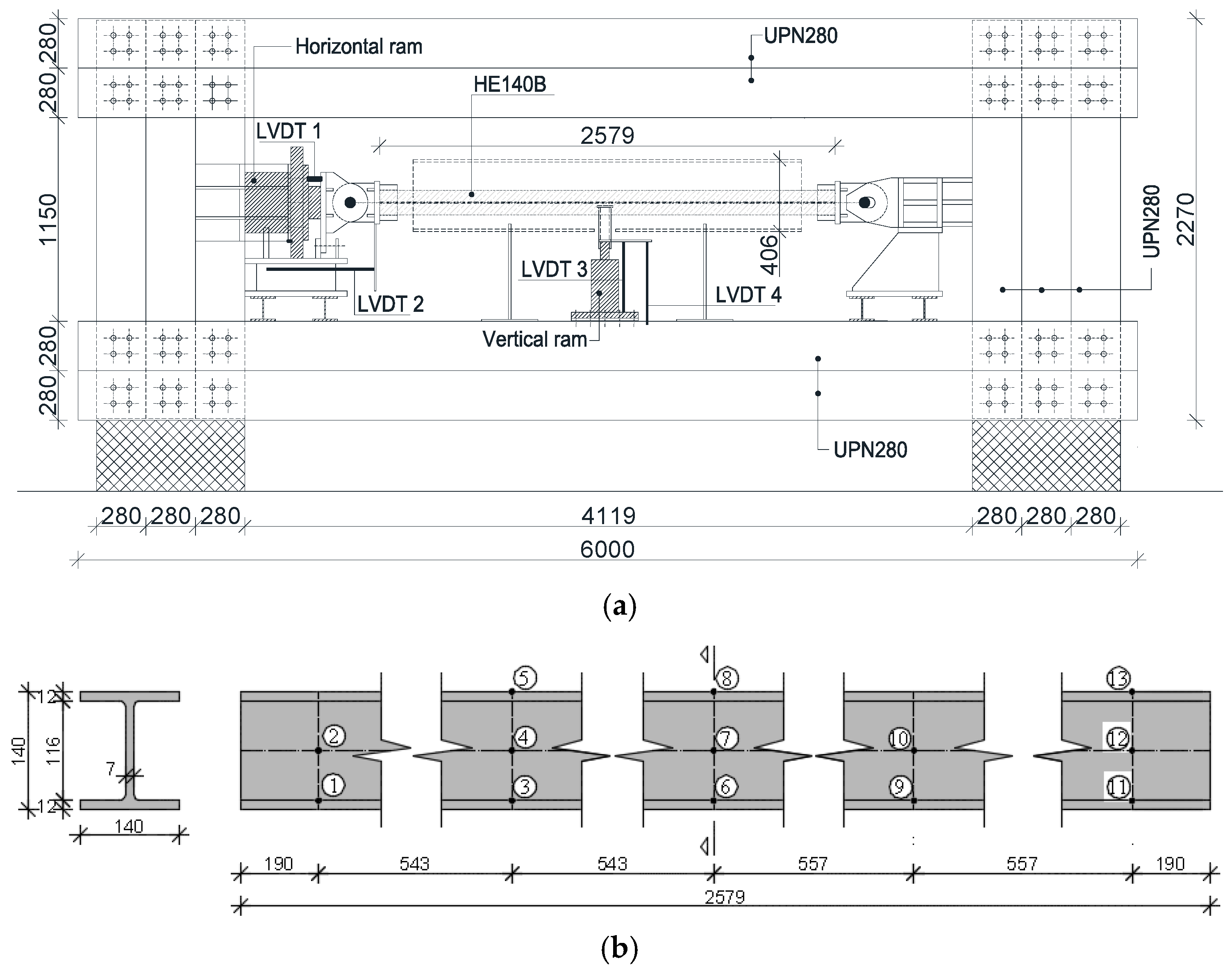

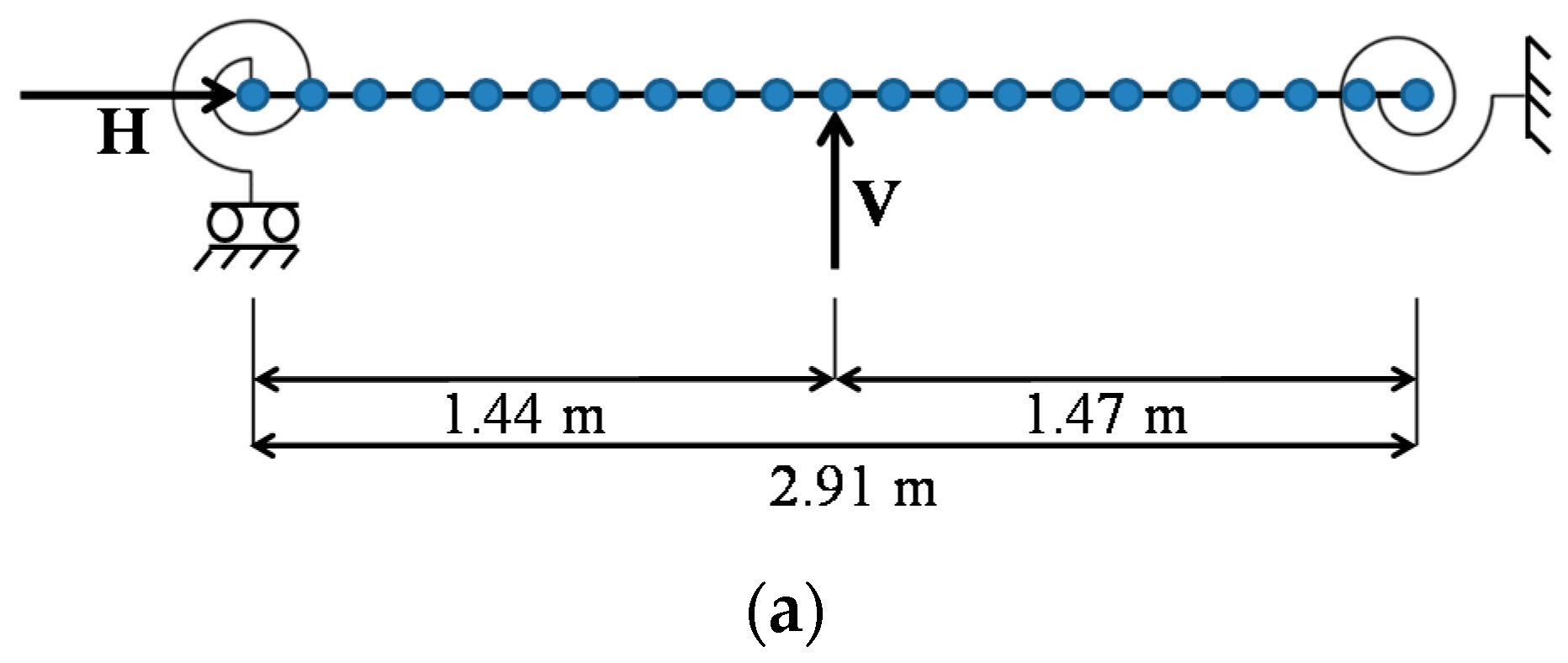

2.1. Test Setup and Methodology

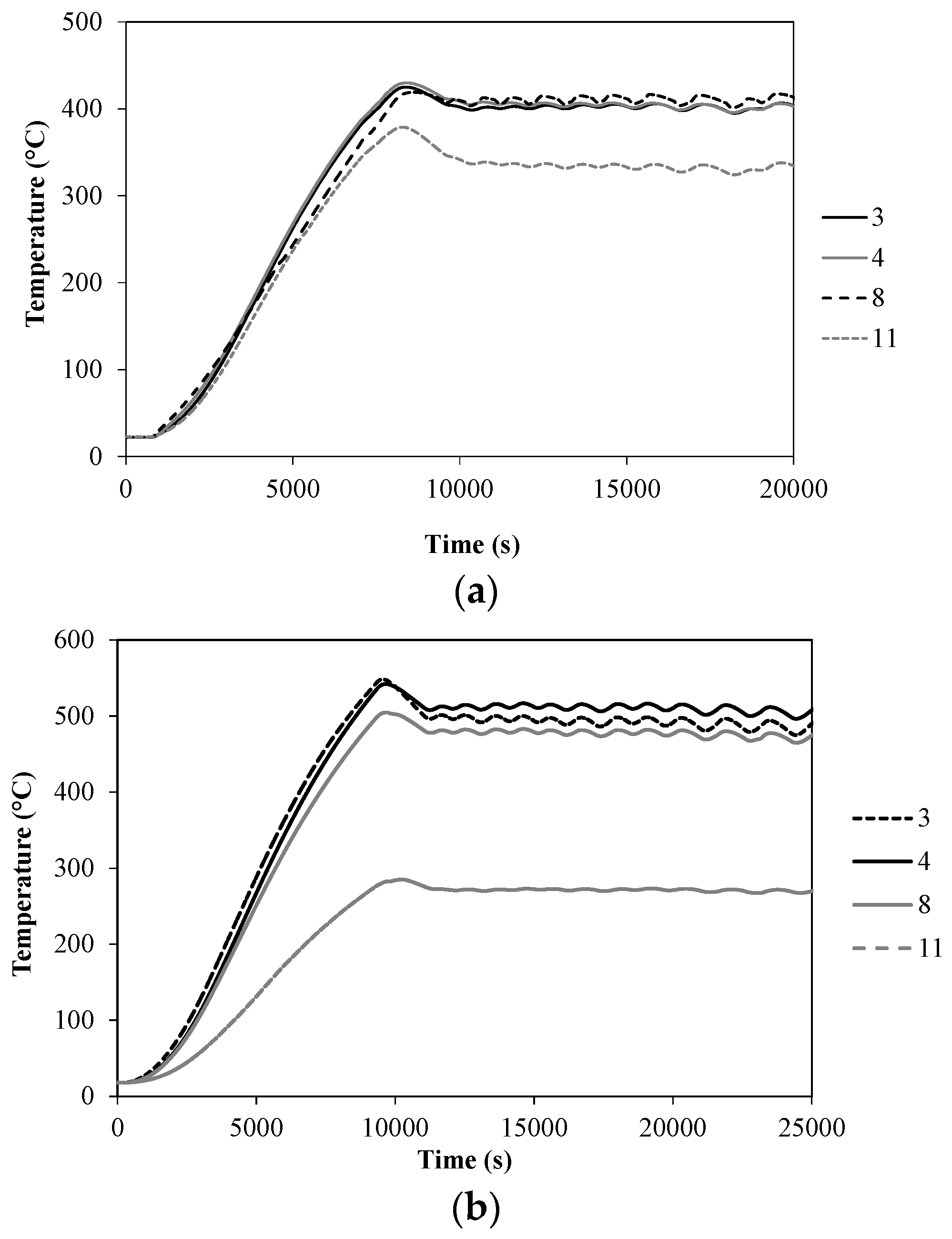

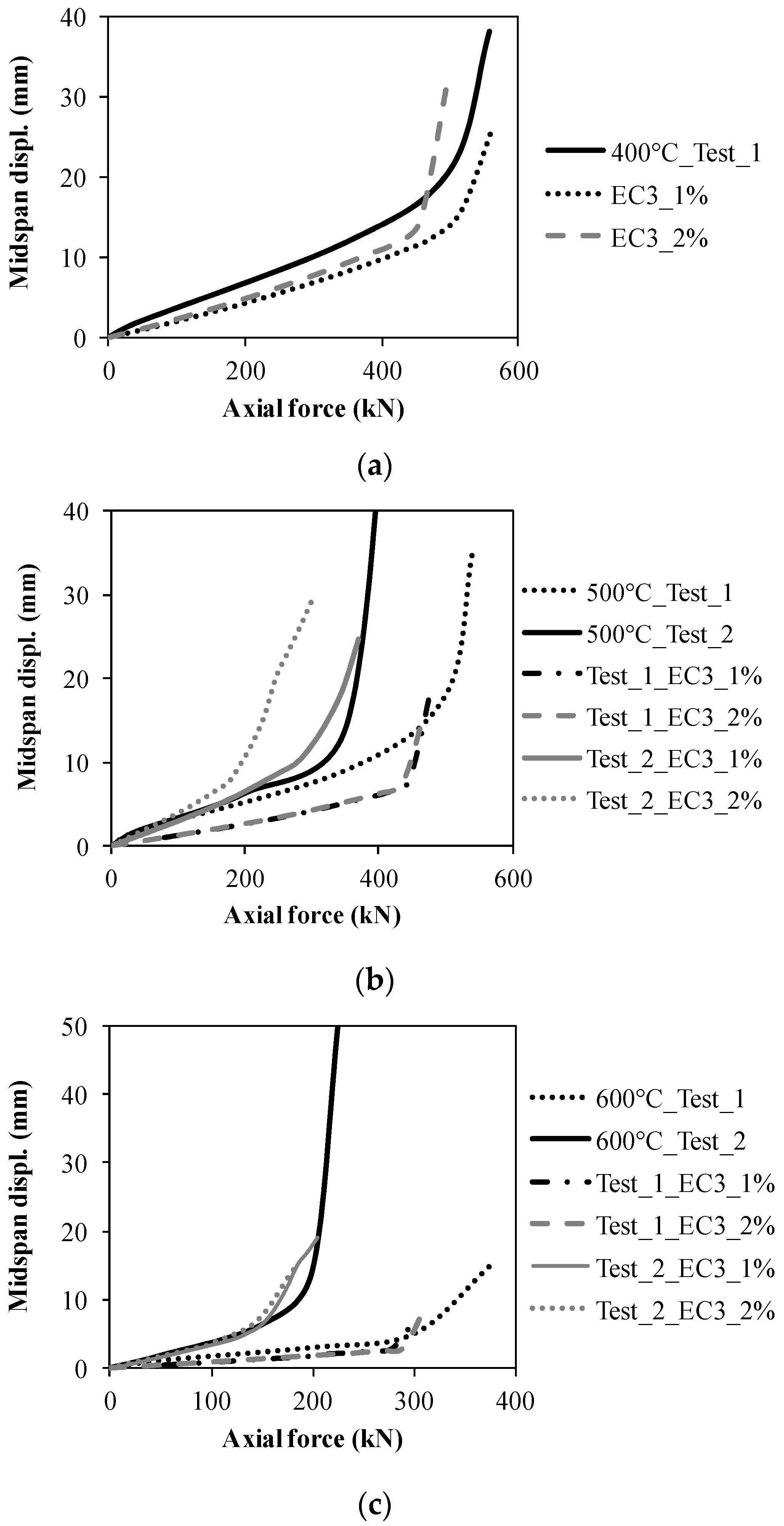

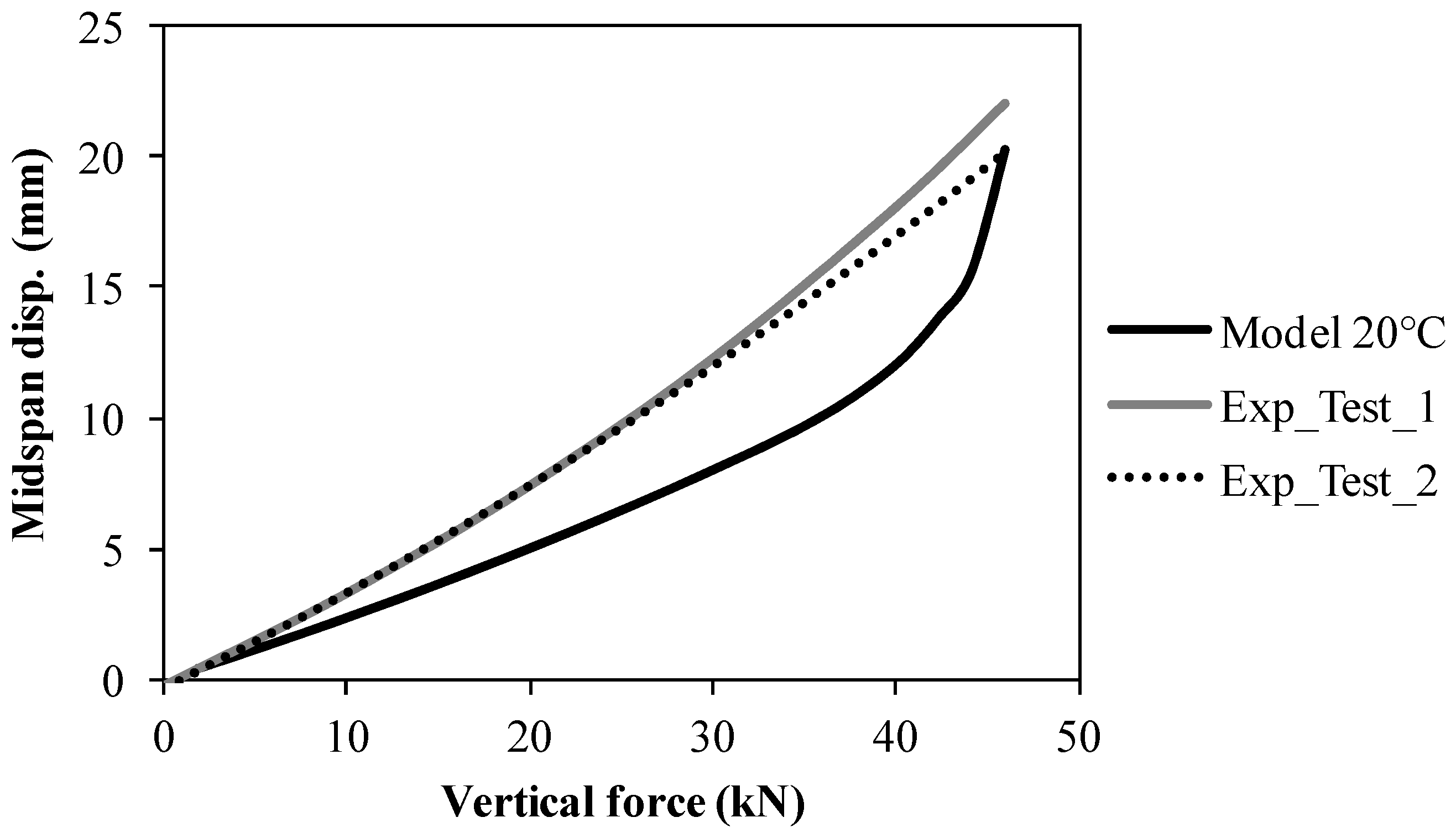

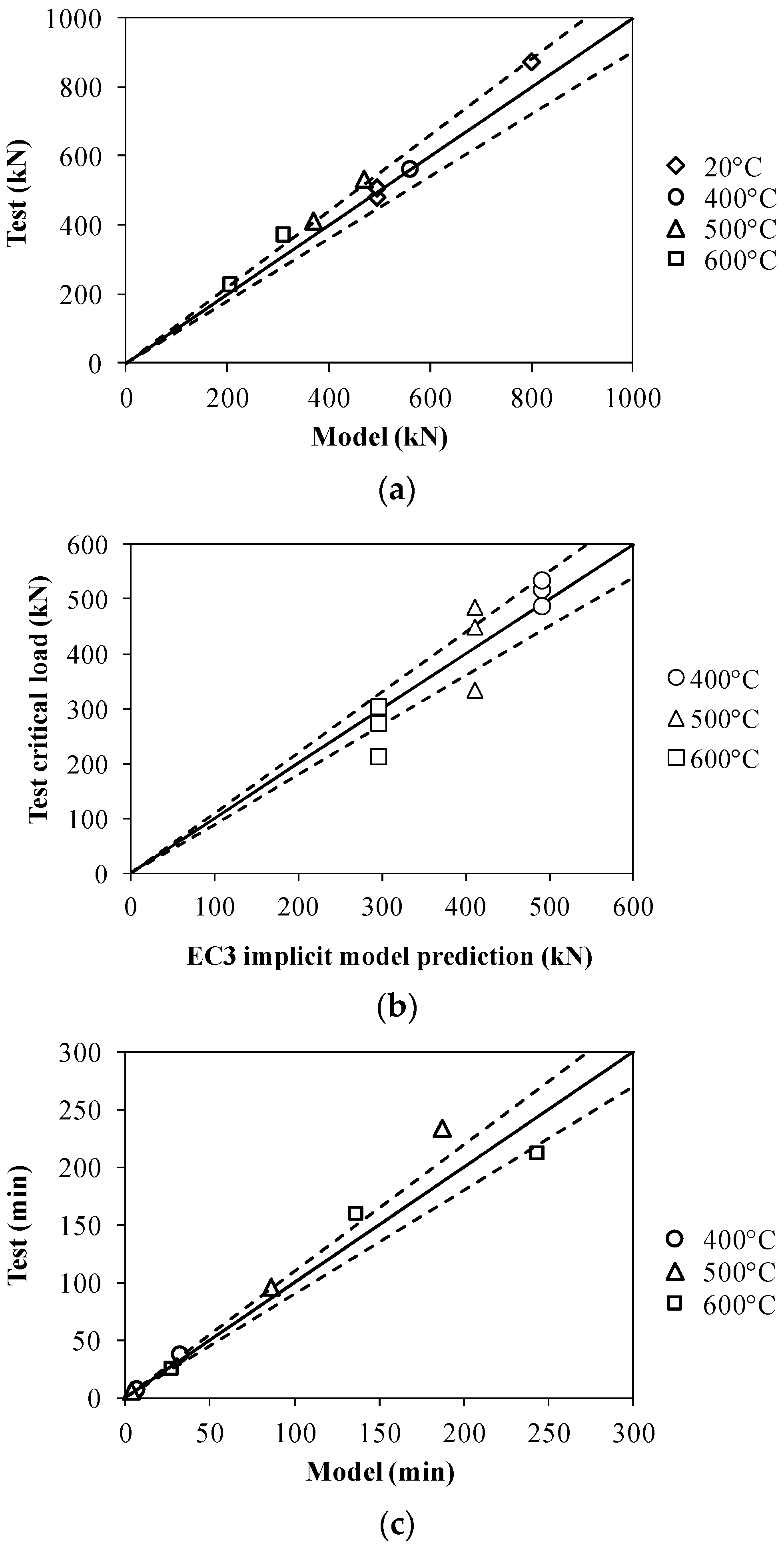

2.2. Constant-Temperature Capacity Tests

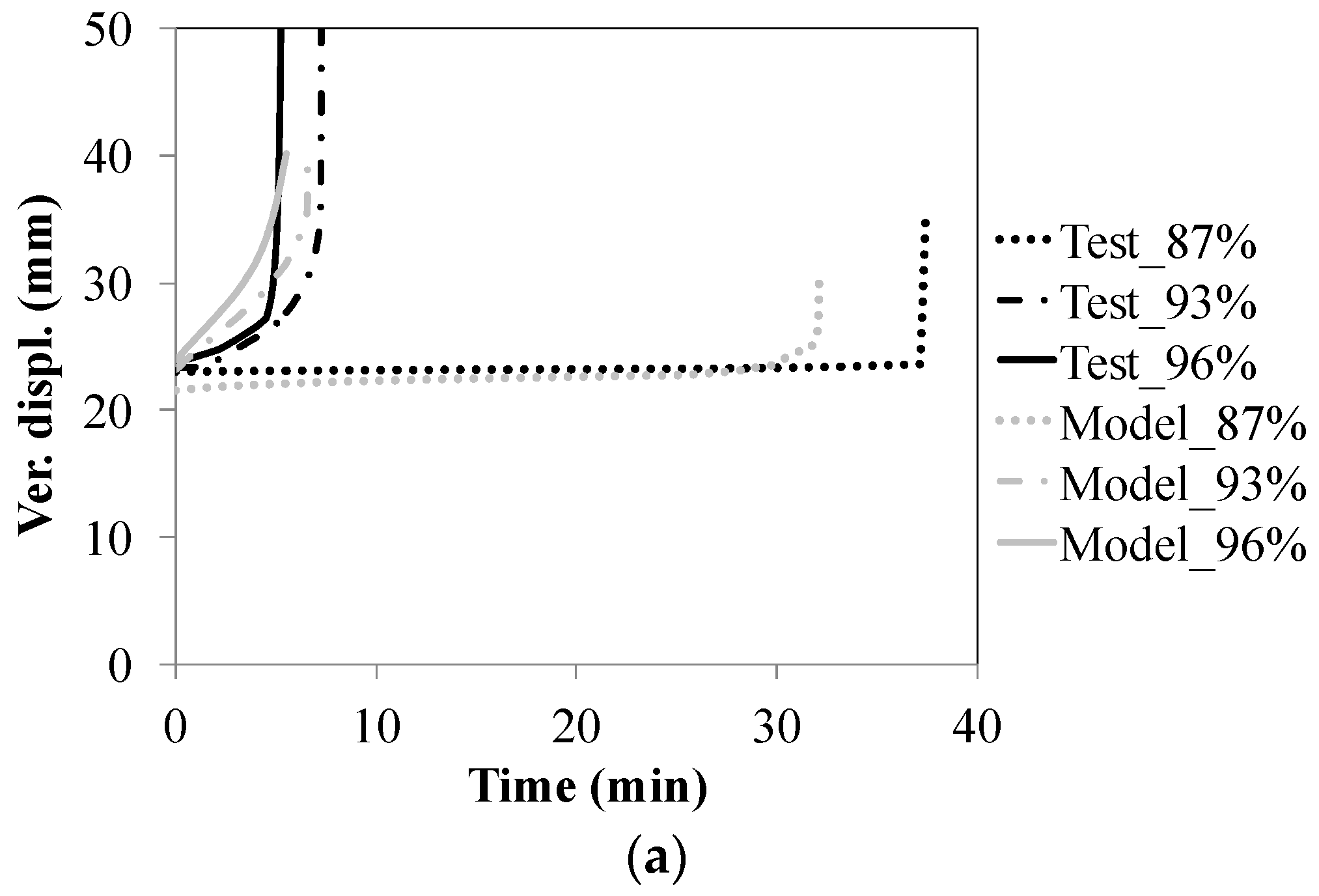

2.3. Constant-Temperature Creep Tests

3. Modelling of the Fire Tests

3.1. The Numerical Model

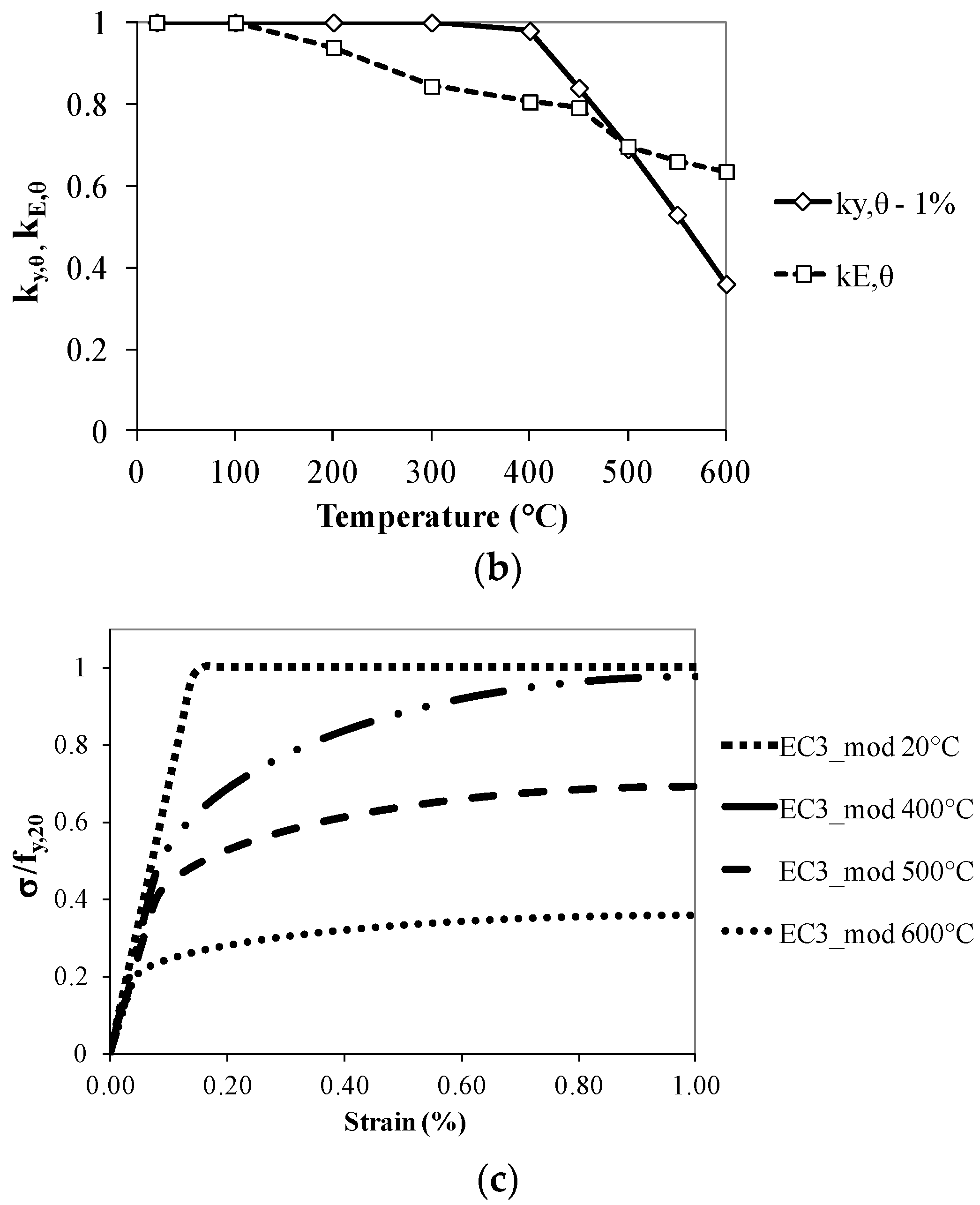

3.2. Stress-Related and Creep Strain Model

3.3. The Friction Model

3.4. Comparison of the Results

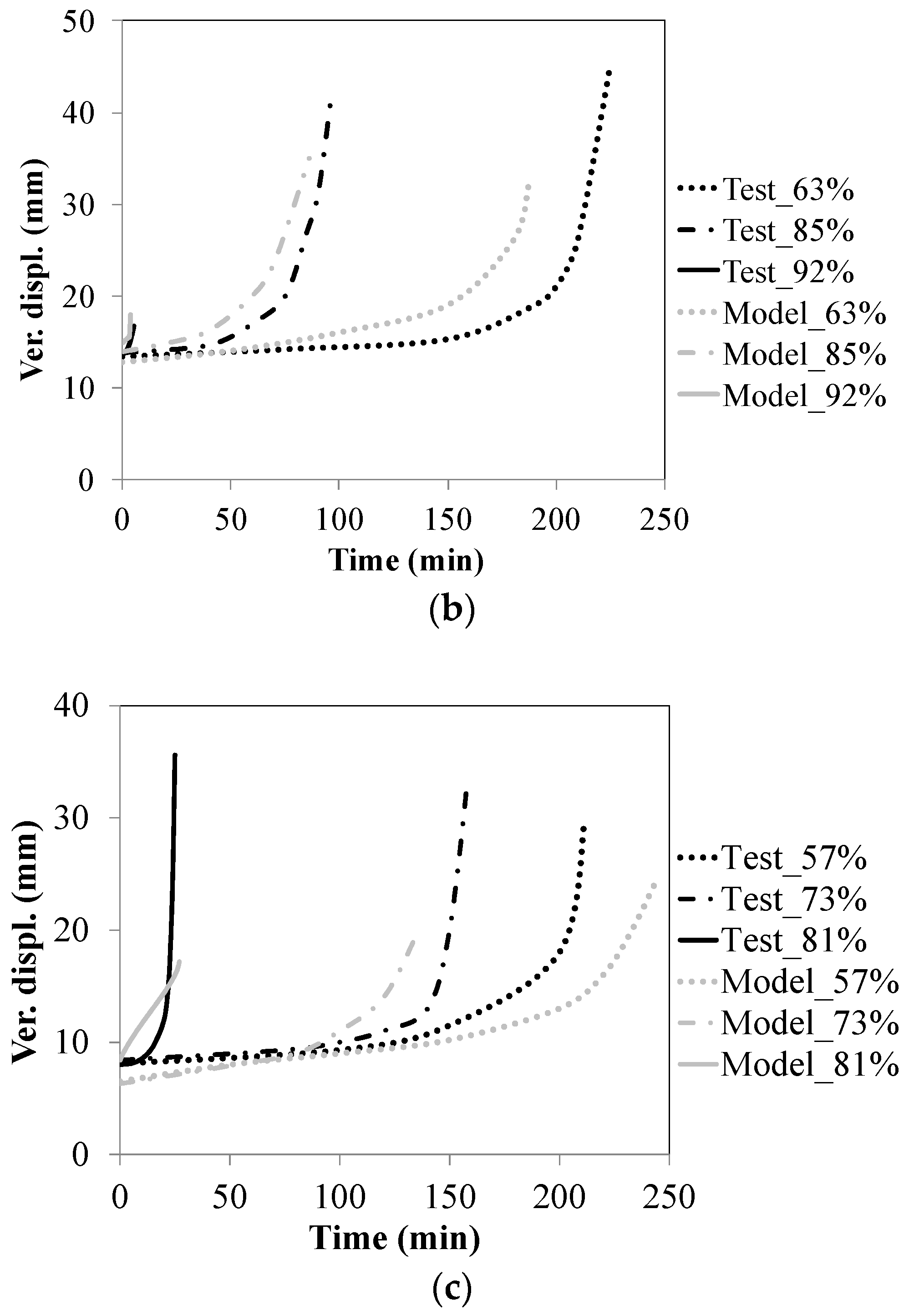

4. Discussion of Results

4.1. Accuracy of the Column Model

4.2. The Influence of Load Ratio

4.3. Failure Times of Columns

4.4. The Influence of Support Friction

4.5. Applied Material Models

5. Conclusions

- High-temperature creep can induce column failure at temperatures from 400 °C at high load levels (87% and above).

- The short-term creep resistance of S275JR columns can be considered as low at load levels above 90% of their axial load capacity within the temperature region 400–600 °C.

- The effect of support friction on the column response during creep tests cannot be neglected, and needs to be taken into account in numerical analysis.

- The previously developed analytical creep model used in the numerical study has proven sufficiently accurate to model creep behaviour in high-temperature column tests.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| fy,20 | yield strength at normal temperature |

| fy,θ | yield strength at temperature θ |

| f0.2,θ | stress at 0.2% strain at temperature θ |

| Ey,20 | modulus of elasticity at normal temperature |

| Ey,θ | modulus of elasticity at temperature θ |

| kE,θ | reduction factor for modulus of elasticity at temperature θ |

| ky,θ | reduction factor for yield strength at temperature θ |

References

- ASTM Standard E119-05: ASTM, Standard Methods of Fire Tests of Building Construction and Materials; American Society for Testing and Materials: West Conshohocken, PA, USA, 2005.

- ISO 834: Fire Resistance Tests—Elements of Building Construction; International Organization for Standardization: Geneva, Switzerland, 1975.

- EN 1993-1-2:2005: Eurocode 3—Design of Steel Structures—Part 1-2: General Rules—Structural Fire Design; European Committee for Standardization: Brussels, Belgium, 2005.

- Wainman, D.E.; Kirby, B.R. Compendium of UK Standard Fire Test Data: Unprotected Structural Steel—1; Report RS/RSC/S10328/1/87/B; British Steel Corporation: London, UK, 1988; p. 88. [Google Scholar]

- Torić, N.; Brnić, J.; Boko, I.; Brčić, M.; Burgess, I.W.; Uzelac Glavinić, I. Development of a high temperature material model for grade S275JR steel. J. Constr. Steel Res. 2017, 137, 161–168. [Google Scholar] [CrossRef]

- Torić, N.; Brnić, J.; Boko, I.; Brčić, M.; Burgess, I.W.; Uzelac Glavinić, I. Experimental analysis of the behaviour of aluminium alloy EN6082 AW T6 at high temperature. Metals 2017, 7, 126. [Google Scholar] [CrossRef]

- Boko, I.; Torić, N.; Peroš, B. Structural fire design parameters and procedures—Analysis of the potential of eurocode 3. Materialwiss. Werkstofftech. 2012, 43, 1036–1052. [Google Scholar] [CrossRef]

- Torić, N.; Harapin, A.; Boko, I. Experimental verification of a newly developed implicit creep model for steel structures exposed to fire. Eng. Struct. 2013, 57, 116–124. [Google Scholar] [CrossRef]

- Torić, N.; Harapin, A.; Boko, I. Modelling of the influence of creep strains on the fire response of stationary heated steel members. J. Struct. Fire Eng. 2015, 6, 155–176. [Google Scholar] [CrossRef]

- Kodur, V.K.R.; Dwaikat, M.M.S. Effect of high temperature creep on the fire response of restrained steel beams. Mater. Struct. 2010, 43, 1327–1341. [Google Scholar] [CrossRef]

- Li, G.-Q.; Guo, S.-X. Experiment on restrained steel beams subjected to heating and cooling. J. Constr. Steel Res. 2008, 64, 268–274. [Google Scholar] [CrossRef]

- Huang, Z.-F.; Tan, K.-H.; Ting, S.-K. Heating rate and boundary restraint effects on fire resistance of steel columns with creep. Eng. Struct. 2006, 28, 805–817. [Google Scholar] [CrossRef]

- Li, G.-Q.; Zhang, C. Creep effect on buckling of axially restrained steel columns in real fires. J. Constr. Steel Res. 2012, 71, 182–188. [Google Scholar] [CrossRef]

- Morovat, M.A.; Engelhardt, M.D.; Helwig, T.A.; Taleff, E.M. High-temperature creep buckling phenomenon of steel columns subjected to fire. J. Constr. Steel Res. 2014, 5, 189–202. [Google Scholar] [CrossRef]

- Tan, K.-H.; Toh, W.-S.; Huang, Z.-F.; Phng, G.-H. Structural responses of restrained steel columns at elevated temperatures part 1: Experiments. Eng. Struct. 2007, 29, 1641–1652. [Google Scholar] [CrossRef]

- Huang, Z.-F.; Tan, K.-H. Structural response of restrained steel columns at elevated temperatures part 2: FE simulation with focus on experimental secondary effects. Eng. Struct. 2007, 29, 2036–2047. [Google Scholar] [CrossRef]

- Moura Correia, A.J.P.; Rodrigues, J.P.C. Fire resistance of steel columns with restrained thermal elongation. Fire Saf. J. 2012, 50, 1–11. [Google Scholar] [CrossRef]

- Yang, K.-C.; Hsu, R. Structural behavior of centrally loaded steel columns at elevated temperature. J. Constr. Steel Res. 2009, 65, 2062–2068. [Google Scholar] [CrossRef]

- Li, G.-Q.; Wang, P.; Wang, Y. Behaviour and design of restrained steel column in fire, part1: Fire test. J. Constr. Steel Res. 2010, 66, 1138–1147. [Google Scholar] [CrossRef]

- Cai, J.; Burgess, I.W.; Plank, R.J. A generalised steel/reinforced concrete beam-column element model for fire conditions. Eng. Struct. 2003, 25, 817–833. [Google Scholar] [CrossRef]

- Torić, N.; Sun, R.R.; Burgess, I.W. Creep-free fire analysis of steel structures with Eurocode 3 material model. J. Struct. Fire Eng. 2016, 7, 234–248. [Google Scholar] [CrossRef]

- Anderberg, Y. Modelling steel behaviour. Fire Saf. J. 1988, 13, 17–26. [Google Scholar] [CrossRef]

- Torić, N.; Sun, R.-R.; Burgess, I.W. Development of a creep-free stress-strain law for fire analysis of steel structures. Fire Mater. 2016, 40, 896–912. [Google Scholar] [CrossRef]

- Influence of Creep Strain on the Load Capacity of Steel and Aluminium Columns Exposed to Fire. Croatian Science Foundation Installation Research Project UIP-2014-09-5711. Available online: https://metalcreepsite.wordpress.com/ (accessed on 10 October 2018).

| Testing Method | Steady-State | |||||

|---|---|---|---|---|---|---|

| Load Type | Bending + Axial Compression | |||||

| Target Temperature (°C) | 20 | 400 | 500 | 600 | ||

| Max. force (kN) | Test 1 | Axial | 478.0 | 560.0 | 530.0 | 376.0 |

| Mean vert. | 46.0 | 37.0 | 30.0 | 16.0 | ||

| Dev.int. | ±0.5 | ±0.8 | ±1.0 | ±0.6 | ||

| Test 2 | Axial | 505.0 | - | 409.0 | 226.0 | |

| Mean vert. | 46.0 | - | 46.0 | 24.0 | ||

| Dev.int. | ±0.7 | - | ±0.6 | ±0.8 | ||

| Test 3 | Axial | 878.0 | - | - | - | |

| Mean vert. | 50.0 | - | - | - | ||

| Dev.int. | ±0.8 | - | - | - | ||

| Testing Method | Steady-State | ||||

|---|---|---|---|---|---|

| Load Type | Bending + Axial Compression | ||||

| Target Temperature (°C) | 400 | 500 | 600 | ||

| Max. force (kN) | Test 1 | H (mean/dev.) | 488.0/±7.5 | 335.0/±9.7 | 214.0/±8.1 |

| V (mean/dev.) | 37.0/±0.4 | 30.0/±0.5 | 16.0/±0.6 | ||

| Load ratio (%) | 87 | 63 | 57 | ||

| Failure time (min) | 37.8 | 233.4 | 212.2 | ||

| Model pred. (min) | 32.1 | 187.1 | 243.1 | ||

| Test 2 | H (mean/dev.) | 518.0/±11.3 | 450.0/±8.7 | 274.0/±9.2 | |

| V (mean/dev.) | 37.0/±0.3 | 30.0/±0.9 | 16.0/±0.7 | ||

| Load ratio (%) | 93 | 85 | 73 | ||

| Failure time (min) | 7.5 | 95.8 | 159.9 | ||

| Model pred. (min) | 6.6 | 86.1 | 136.2 | ||

| Test 3 | H (mean/dev.) | 535.0/±4.5 | 486.0/±7.1 | 305.0/±8.8 | |

| V (mean/dev.) | 37.0/±1.2 | 30.0/±0.9 | 16.0/±0.6 | ||

| Load ratio (%) | 96 | 92 | 81 | ||

| Failure time (min) | 6.1 | 5.7 | 25.6 | ||

| Model pred. (min) | 6.0 | 3.5 | 27.1 | ||

| Test Results/Vulcan Analysis | |||||

|---|---|---|---|---|---|

| Temperature (°C) | 20 | 400 | 500 | 600 | |

| Test 1 | Axial Resistance (kN) | 478.0/495.0 | 560.0/560.0 | 530.0/470.0 | 370.0/310.0 |

| Spring stiffness (Nmm/rad) | 4.00E + 06 | 7.50E + 07 | 1.00E + 10 | 1.00E + 10 | |

| Test 2 | Axial Resistance (kN) | 505.0/495.0 | - | 409.0/370.0 | 226.0/205.0 |

| Spring stiffness (Nmm/rad) | 4.00E + 06 | - | 1.00E + 10 | 1.00E + 10 | |

| Test 3 | Axial Resistance (kN) | 878.0/800.0 | - | - | - |

| Spring stiffness (Nmm/rad) | 1.00E + 10 | - | - | - | |

| Temperature (°C) | Reduction Factors | |

|---|---|---|

| fy,θ/fy,20 − 1% | Ey,θ/Ey,20 | |

| 100 | 1.0 | 1.0 |

| 200 | 1.0 | 0.94 |

| 300 | 1.0 | 0.84 |

| 400 | 0.98 | 0.81 |

| 500 | 0.69 | 0.70 |

| 600 | 0.36 | 0.64 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torić, N.; Boko, I.; Divić, V.; Burgess, I.W. Behaviour of Steel Grade S275JR Columns under the Influence of High-Temperature Creep. Metals 2018, 8, 874. https://doi.org/10.3390/met8110874

Torić N, Boko I, Divić V, Burgess IW. Behaviour of Steel Grade S275JR Columns under the Influence of High-Temperature Creep. Metals. 2018; 8(11):874. https://doi.org/10.3390/met8110874

Chicago/Turabian StyleTorić, Neno, Ivica Boko, Vladimir Divić, and Ian W. Burgess. 2018. "Behaviour of Steel Grade S275JR Columns under the Influence of High-Temperature Creep" Metals 8, no. 11: 874. https://doi.org/10.3390/met8110874

APA StyleTorić, N., Boko, I., Divić, V., & Burgess, I. W. (2018). Behaviour of Steel Grade S275JR Columns under the Influence of High-Temperature Creep. Metals, 8(11), 874. https://doi.org/10.3390/met8110874