The Edge Crack, Texture Evolution, and Mechanical Properties of Mg-1Al-1Sn-Mn Alloy Sheets Prepared Using On-Line Heating Rolling

Abstract

1. Introduction

2. Materials and Methods

3. Results

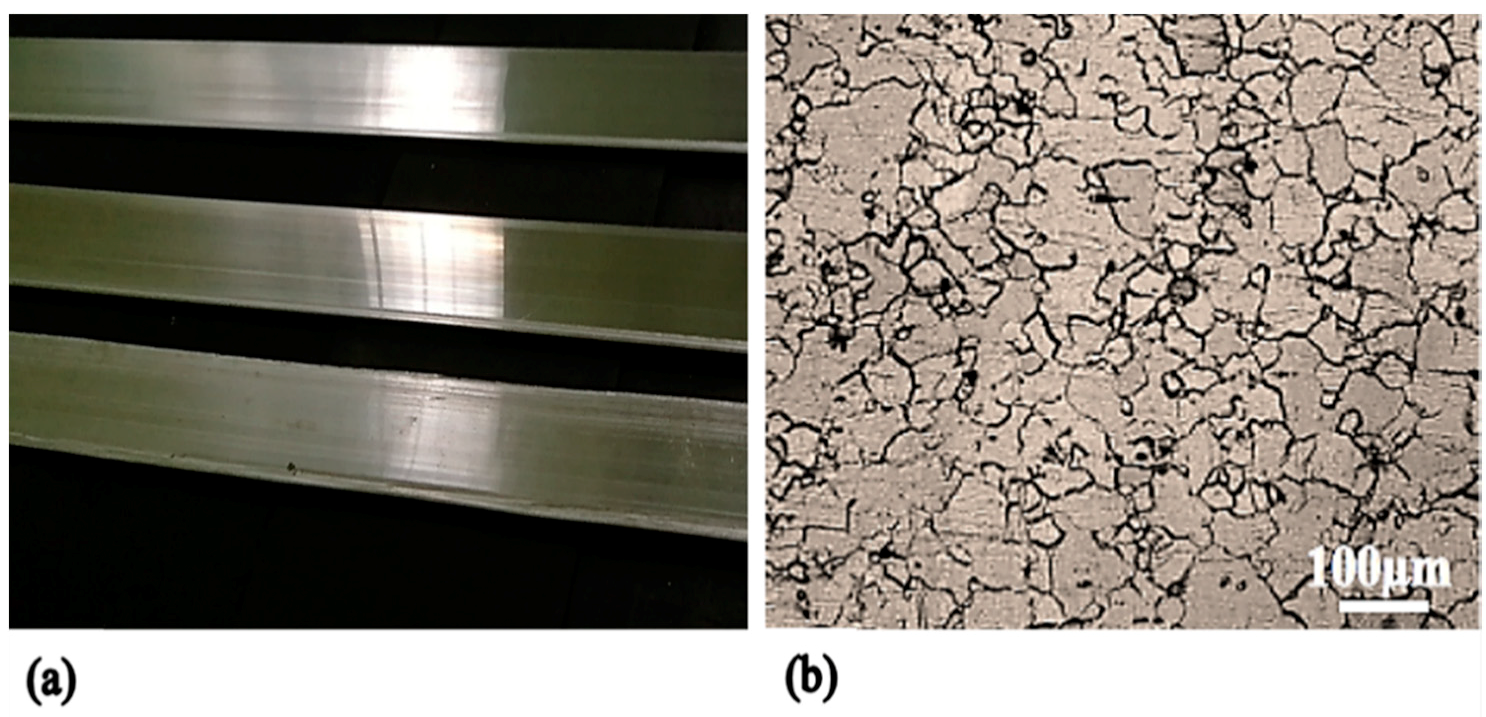

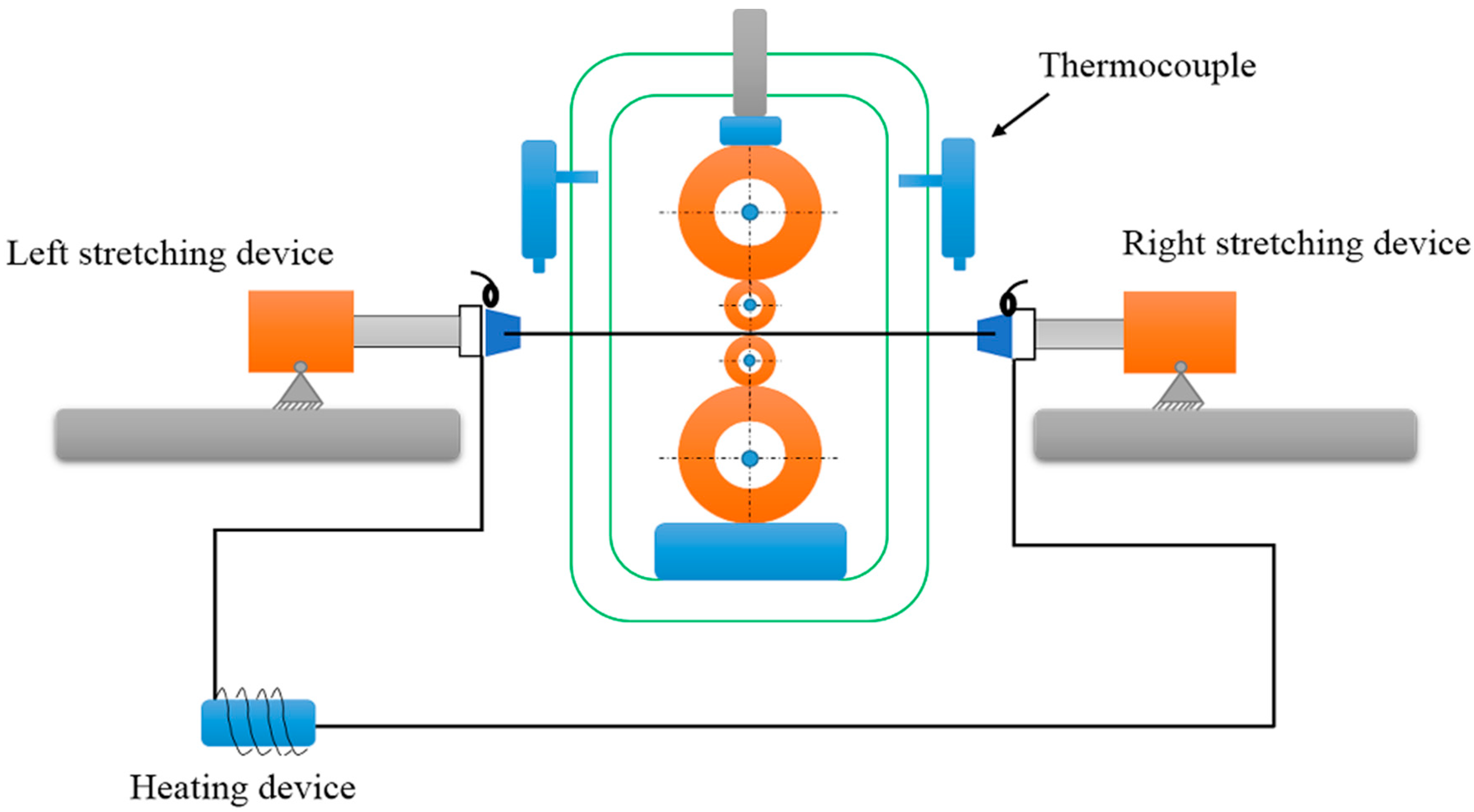

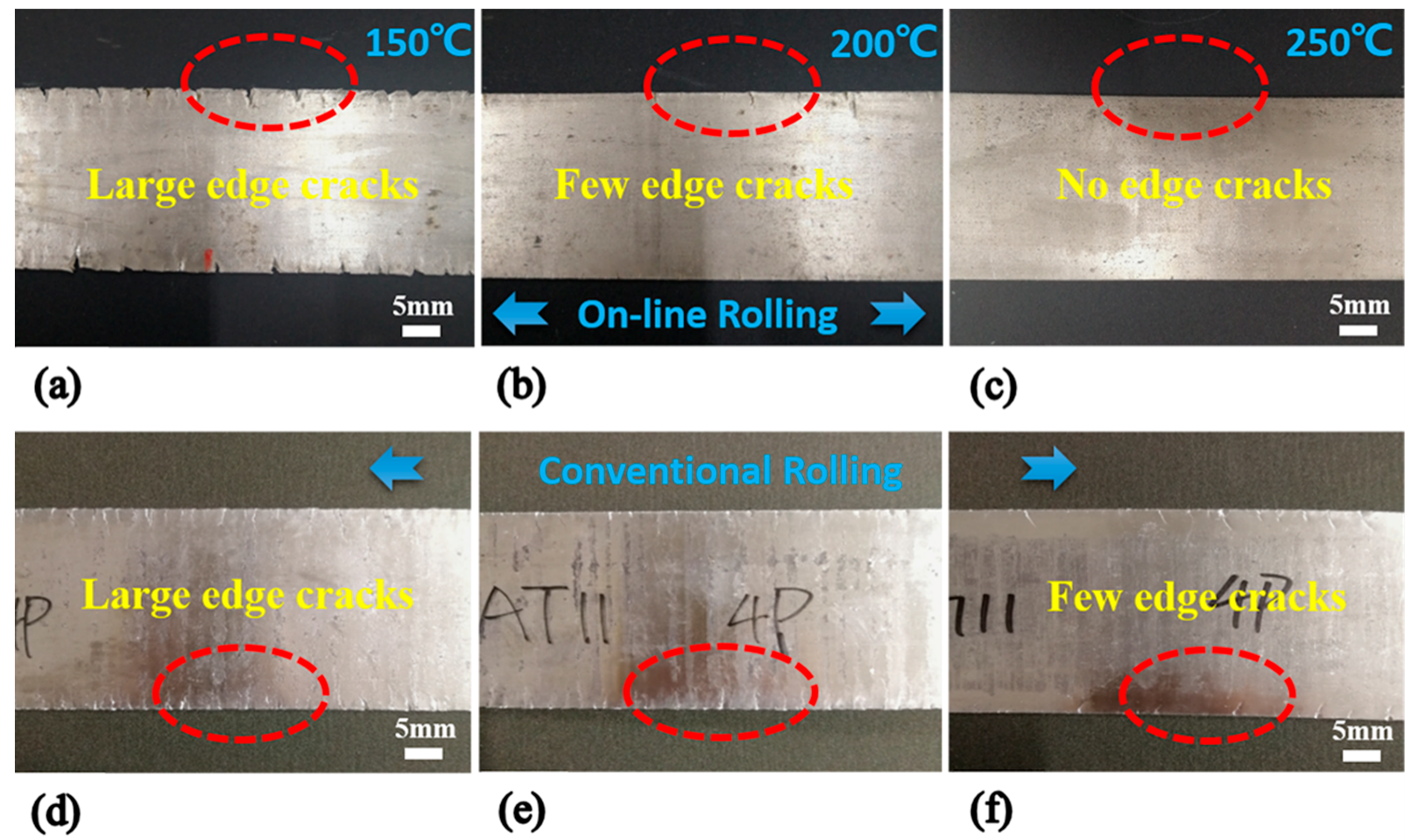

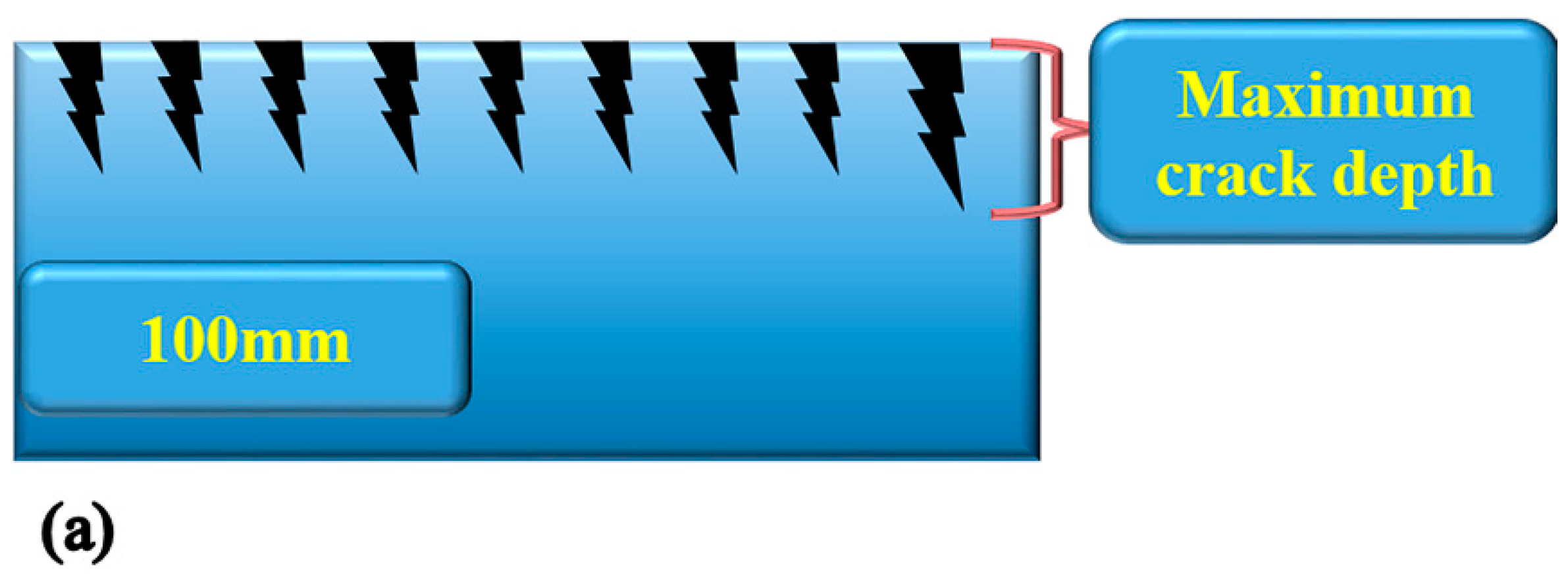

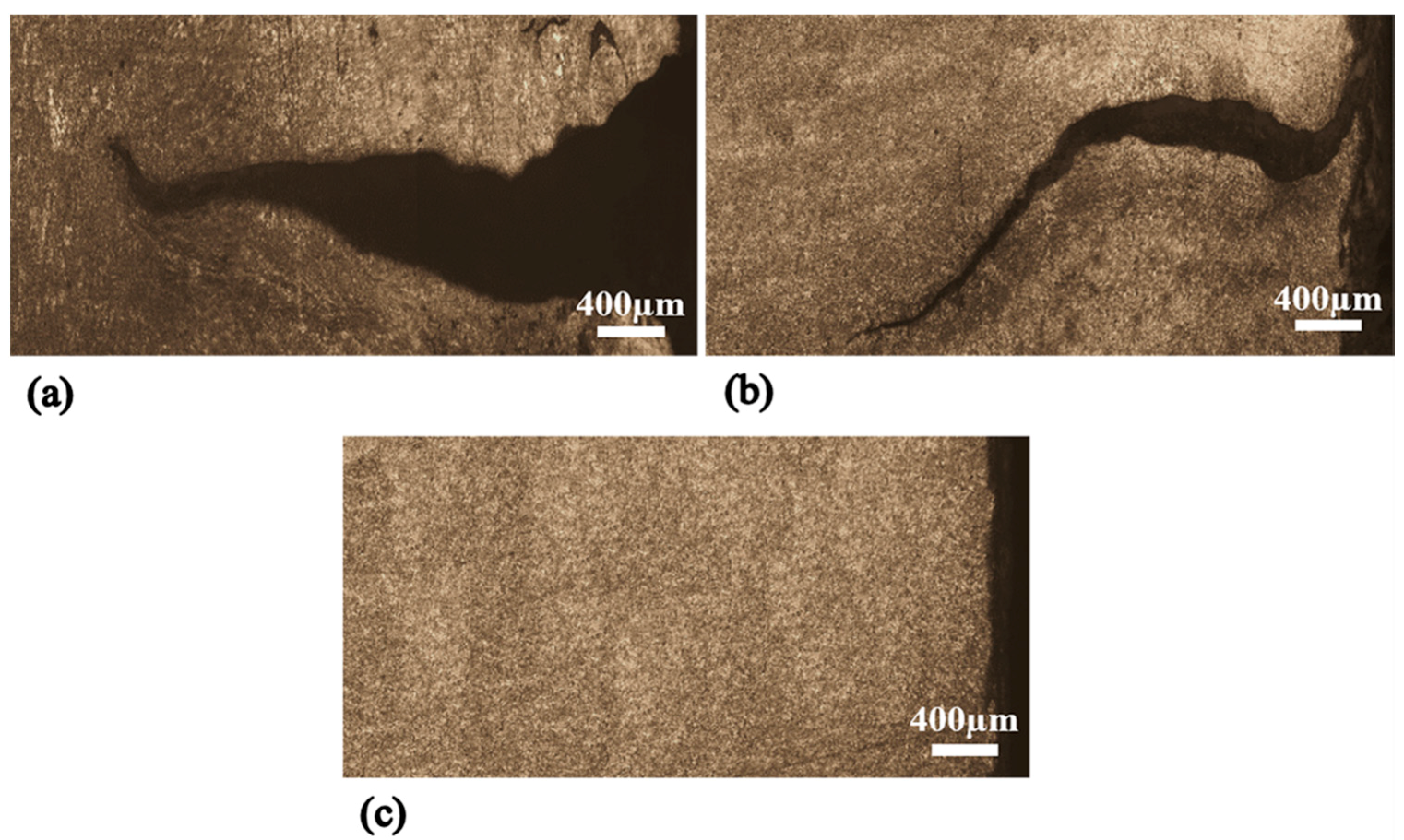

3.1. Rolling Feasibility

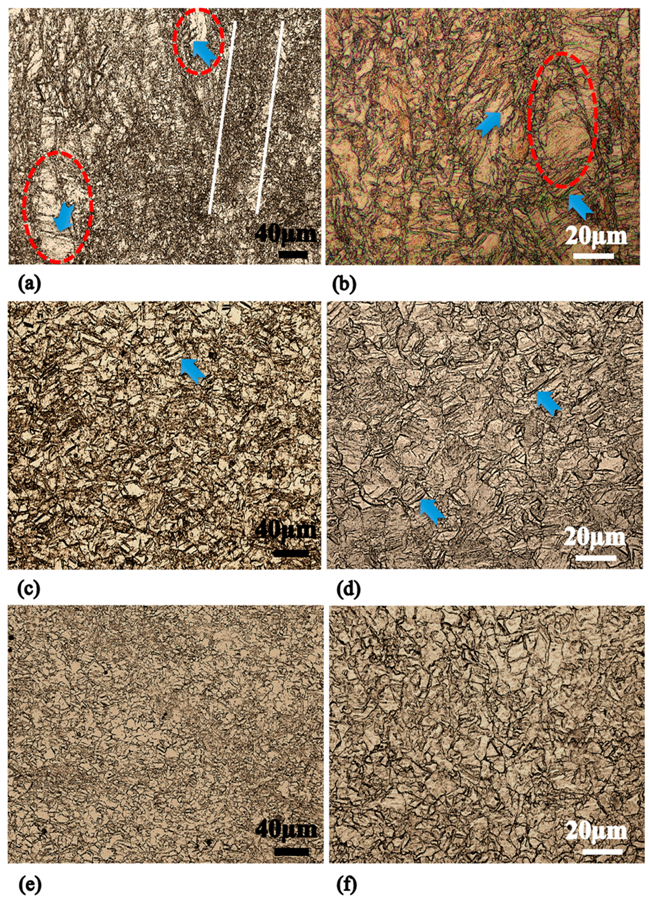

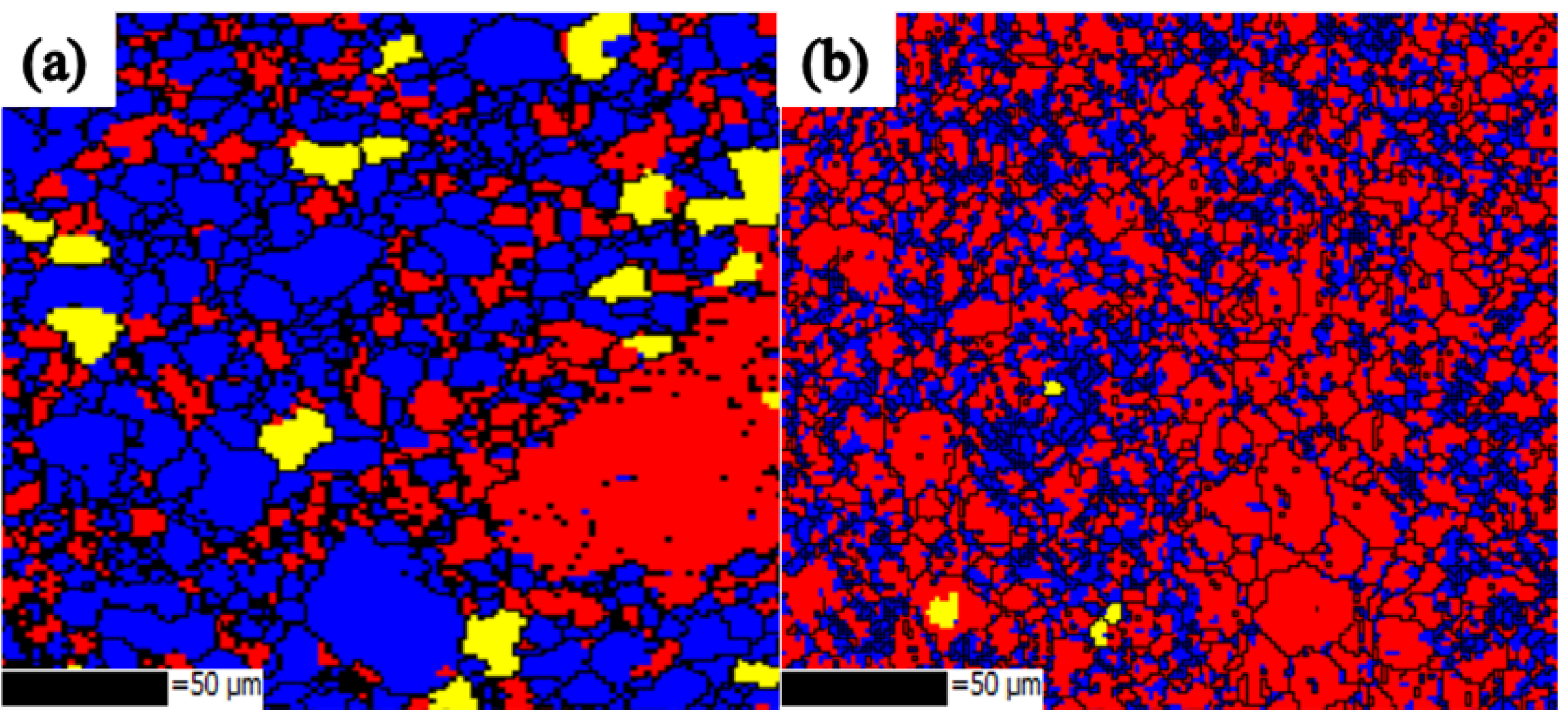

3.2. Microstructures

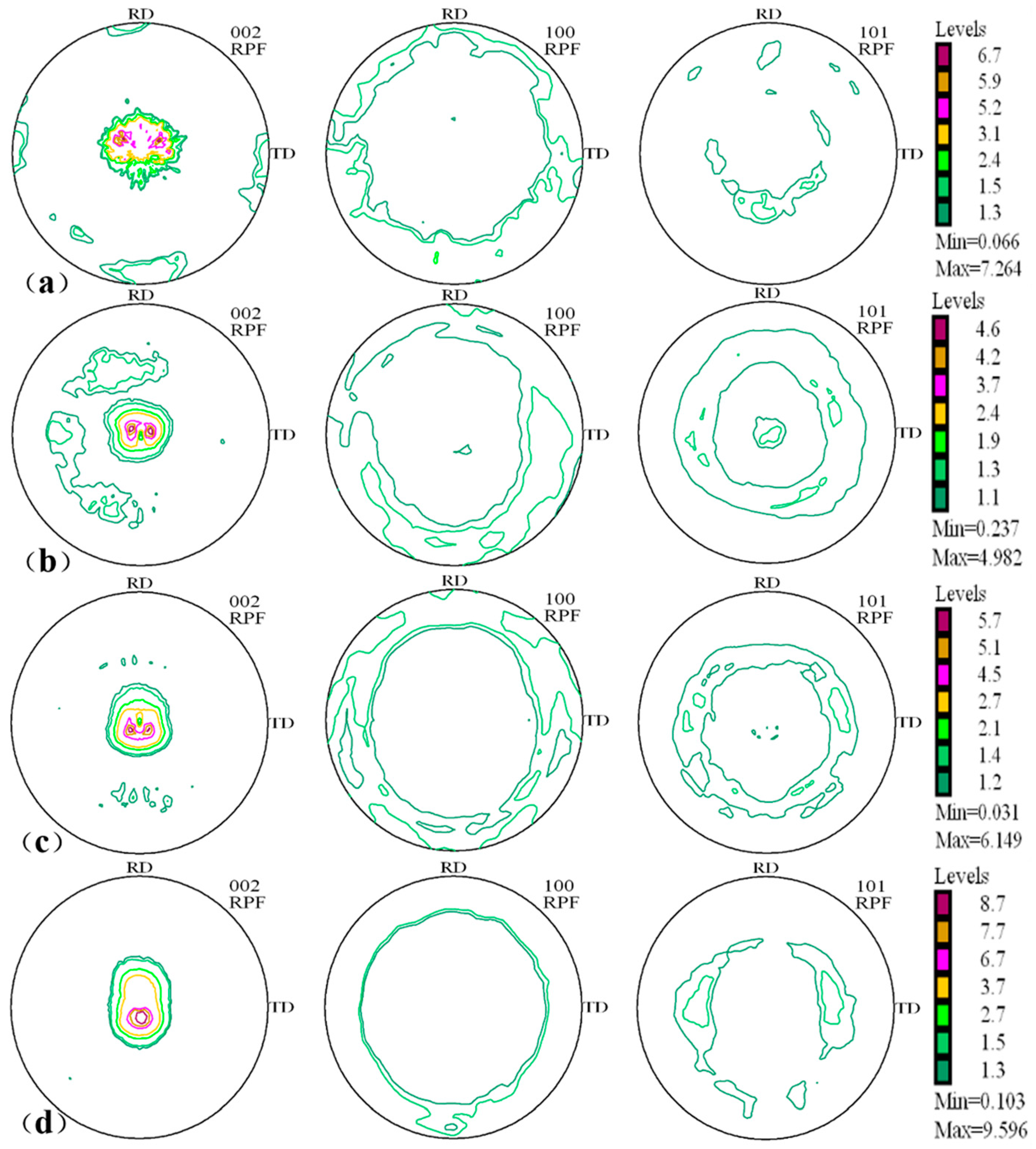

3.3. Texture Evolution

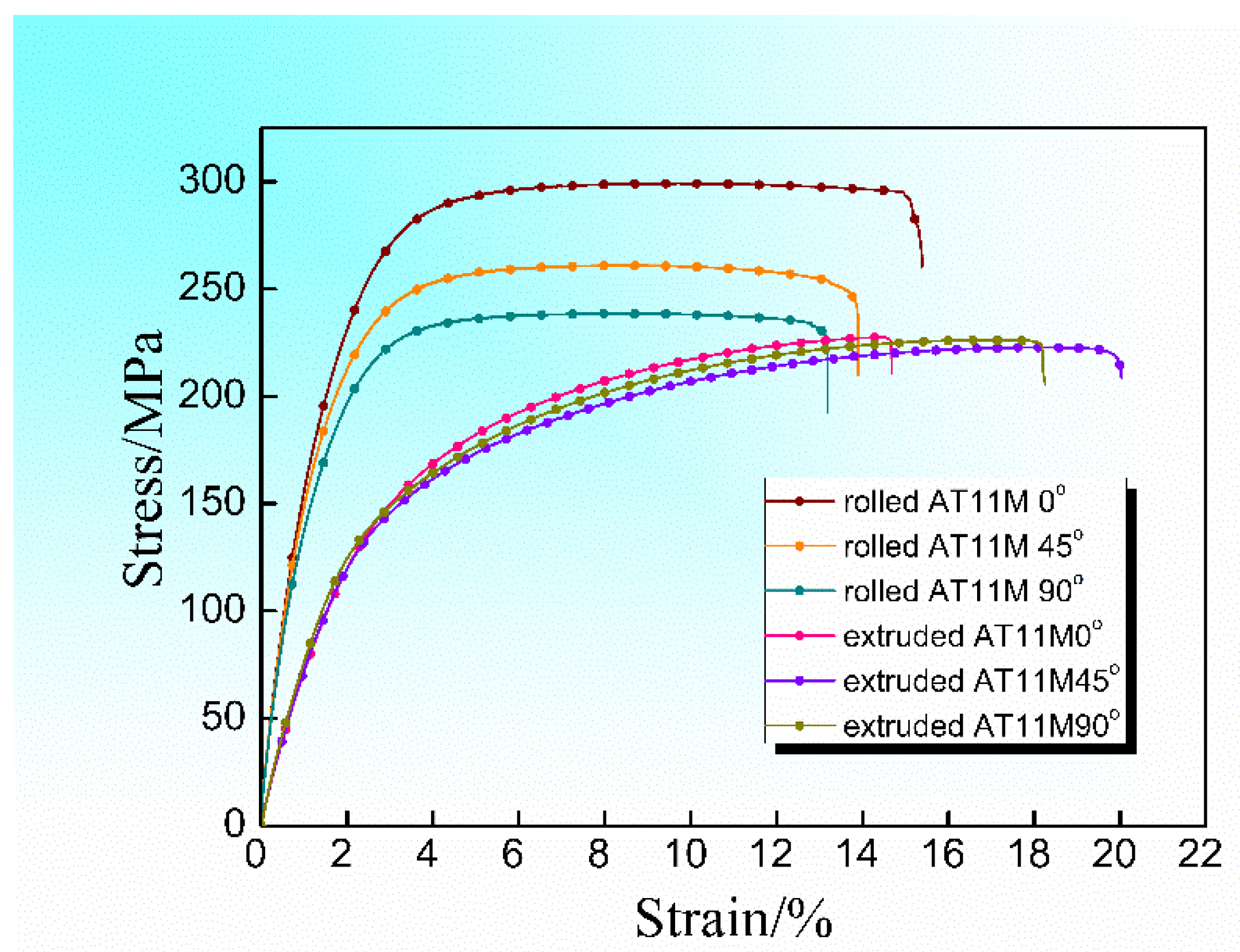

3.4. Mechanical Properties

4. Discussion

4.1. Microstructure Evolution

4.2. Edge Crack Formation

5. Conclusions

- (1)

- Mg-1Al-1Sn-Mn alloy thin sheets were successfully prepared with large strain rolling (pass reduction as high as 25%, with a total reduction of ≈67% by four passes) at a moderate temperature of 250 °C using on-line heating rolling. The rolled sheets showed no obvious edge cracks.

- (2)

- A typical strong basal texture was formed during the rolling process leading to the mechanical anisotropy at a rolling temperature of 250 °C. In addition, the activation of <c + a> pyramidal slips may be mainly responsible for the splitting of the basal poles of texture towards the rolling direction.

- (3)

- Mg-1Al-1Sn-Mn alloy sheets rolled using the on-line heating exhibited good comprehensive mechanical properties: the yield strength (YS), ultimate tensile strength (UTS), and elongation along rolling direction were 148 MPa, 298 Mpa, and 14.6%, respectively. Furthermore, it has potential to be commercialized.

- (4)

- The reason for no obvious edge cracks could be attributed to the homogeneous microstructure caused by grain refinement and the activation of non-basal slips at edge region in a larger extent at edge section. Furthermore, the decline of the stacking fault energy accompanying the addition of Sn element, as well as the softening behavior due to deformation adiabatic heating and dynamic recrystallization, may also be important factors for no edge cracks forming.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mordike, B.L.; Ebert, T. Magnesium: Properties applications—Potential. Mater. Sci. Eng. A 2001, 302, 37–45. [Google Scholar] [CrossRef]

- You, S.; Huang, Y.; Kainer, K.U.; Hort, N. Recent research and developments on wrought magnesium alloys. J. Magnes. Alloys 2017, 5, 239–253. [Google Scholar] [CrossRef]

- Polmear, I.J. Magnesium alloys and applications. Met. Sci. J. 1994, 10, 1–16. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Okotete, E.A. Enhancing plastic deformability of Mg and its alloys—A review of traditional and nascent developments. J. Magnes. Alloys 2017, 5, 460–475. [Google Scholar] [CrossRef]

- Pekguleryuz, M.O. Current developments in wrought magnesium alloys. Adv. Wrought Magnes. Alloys 2012, 3–62. [Google Scholar] [CrossRef]

- Parks, D.M.; Ahzi, S. Polycrystalline plastic deformation and texture evolution for crystals lacking five independent slip systems. J. Mech. Phys. Solids 1990, 38, 701–724. [Google Scholar] [CrossRef]

- Matsubara, K.; Miyahara, Y.; Horita, Z.; Langdon, T.G. Achieving enhanced ductility in a dilute magnesium alloy through severe plastic deformation. Metall. Mater. Trans. A 2004, 35, 1735–1744. [Google Scholar] [CrossRef]

- Pekguleryuz, M.; Celikin, M.; Hoseini, M.; Becerra, A.; Mackenzie, L. Study on edge cracking and texture evolution during 150 °C rolling of magnesium alloys: The effects of axial ratio and grain size. J. Alloys Compd. 2012, 510, 15–25. [Google Scholar] [CrossRef]

- Emley, E.F. Principles of Magnesium Technology; Pergamon Press: Oxford, UK, 1966. [Google Scholar]

- Yoo, M.H.; Agnew, S.R.; Morris, J.R.; Ho, K.M. Non-basal slip systems in HCP metals and alloys: Source mechanisms. Mater. Sci. Eng. A 2001, 319–321, 87–92. [Google Scholar] [CrossRef]

- Koike, J.; Kobayashi, T.; Mukai, T.; Watanabe, H.; Suzuki, M.; Maruyama, K.; Higashi, K. The activity of non-basal slip systems and dynamic recovery at room temperature in fine-grained AZ31B magnesium alloys. Acta Mater. 2003, 51, 2055–2065. [Google Scholar] [CrossRef]

- Agnew, S.R.; Duygulu, Ö. Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B. Int. J. Plast. 2005, 21, 1161–1193. [Google Scholar] [CrossRef]

- Catorceno, L.L.C.; de Abreu, H.F.G.; Padilha, A.F. Effects of cold and warm cross-rolling on microstructure and texture evolution of AZ31B magnesium alloy sheet. J. Magnes. Alloys 2018, 6, 121–133. [Google Scholar] [CrossRef]

- Wang, H.Y.; Zhang, N.; Wang, C.; Jiang, Q.C. First-principles study of the generalized stacking fault energy in Mg–3Al–3Sn alloy. Scr. Mater. 2011, 65, 723–726. [Google Scholar] [CrossRef]

- Saboori, A.; Dadkhah, M.; Pavese, M.; Manfredi, D.; Biamino, S.; Fino, P. Hot deformation behavior of Zr-1%Nb Alloy: Flow Curve Analysis and Microstructure Observations. Mater. Sci. Eng. A 2017, 696, 366–373. [Google Scholar] [CrossRef]

- Pan, F.; Zeng, B.; Jiang, B.; Zhang, M.; Dong, H. Enhanced mechanical properties of AZ31B magnesium alloy thin sheets processed by on-line heating rolling. J. Alloys Compd. 2017, 693, 414–420. [Google Scholar] [CrossRef]

- She, J.; Pan, F.; Zhang, J.; Tang, A.; Luo, S.; Yu, Z.; Song, K.; Rashad, M. Microstructure and mechanical properties of Mg–Al–Sn extruded alloys. J. Alloys Compd. 2016, 657, 893–905. [Google Scholar] [CrossRef]

- Guan, M.; Hu, Y.; Zheng, T.; Zhao, T.; Pan, F. Composition Optimization and Mechanical Properties of Mg-Al-Sn-Mn Alloys by Orthogonal Design. Materials 2018, 11, 1424. [Google Scholar] [CrossRef] [PubMed]

- Ion, S.E.; Humphreys, F.J.; White, S.H. Dynamic recrystallisation and the development of microstructure during the high temperature deformation of magnesium. Acta Metall. 1982, 30, 1909–1919. [Google Scholar] [CrossRef]

- Kavyani, M.; Ebrahimi, G.R.; Sanjari, M.; Haghshenas, M. Texture evaluation in warm deformation of an extruded Mg–6Al–3Zn alloy. J. Magnes. Alloys 2016, 4, 89–98. [Google Scholar] [CrossRef]

- Zhang, H.; Jin, W.; Fan, J.; Cheng, W.; Roven, H.J.; Xu, B.; Dong, H. Grain refining and improving mechanical properties of a warm rolled AZ31 alloy plate. Mater. Lett. 2014, 135, 31–34. [Google Scholar] [CrossRef]

- Wang, Y.; Xin, Y.; Yu, H.; Lv, L.; Liu, Q. Formation and microstructure of shear bands during hot rolling of a Mg–6Zn–0.5Zr alloy plate with a basal texture. J. Alloys Compd. 2015, 644, 147–154. [Google Scholar] [CrossRef]

- Valle, J.A.D.; Pérez-Prado, M.T.; Ruano, O.A. Texture evolution during large-strain hot rolling of the Mg AZ61 alloy. Mater. Sci. Eng. A 2003, 355, 68–78. [Google Scholar] [CrossRef]

- Liu, Q.; Zhou, X.; Zhou, H.; Fan, X.; Liu, K. The effect of extrusion conditions on the properties and textures of AZ31B alloy. J. Magnes. Alloys 2017, 5, 202–209. [Google Scholar] [CrossRef]

- Sun, H.; Liang, S.; Wang, E. Mechanical properties and texture evolution during hot rolling of AZ31 magnesium alloy. Trans. Nonferr. Met. Soc. China 2009, 19, s349–s354. [Google Scholar] [CrossRef]

- Yan, Y.; Luo, J.; Zhang, J.; Zhuang, L. Study on the microstructural evolution and mechanical properties control of a strong textured AZ31 magnesium alloy sheet during cryorolling. Acta Metall. Sin. 2017, 53, 107–113. [Google Scholar]

- Huang, X.; Suzuki, K.; Chino, Y.; Mabuchi, M. Influence of initial texture on rolling and annealing textures of Mg–3Al–1Zn alloy sheets processed by high temperature rolling. J. Alloys Compd. 2012, 537, 80–86. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, X.; Lu, X.; Yang, Y.; Wang, Z. Microstructure, texture and mechanical properties of hot-rolled Mg–4Al–2Sn–0.5Y–0.4Nd alloy. J. Magnes. Alloys 2016, 4, 207–213. [Google Scholar] [CrossRef]

- Li, X.; Qi, W. Effect of initial texture on texture and microstructure evolution of ME20 Mg alloy subjected to hot rolling. Mater. Sci. Eng. A 2013, 560, 321–331. [Google Scholar] [CrossRef]

- Jia, W.P.; Hu, X.D.; Zhao, H.Y.; Ju, D.Y.; Chen, D.L. Texture evolution of AZ31 magnesium alloy sheets during warm rolling. J. Alloys Compd. 2015, 645, 70–77. [Google Scholar] [CrossRef]

- Li, X.; Al-Samman, T.; Gottstein, G. Mechanical properties and anisotropy of ME20 magnesium sheet produced by unidirectional and cross rolling. Mater. Des. 2011, 32, 4385–4393. [Google Scholar] [CrossRef]

- Fu, X.S.; Yang, Q.; Sun, W.; Lu, S.J.; Chen, G.Q.; Zhou, W.L. Multi-pass large strain rolling of as-cast AZ31 magnesium alloy. Met. Sci. J. 2016, 32, 1869–1876. [Google Scholar] [CrossRef]

- Jin, L.; Lin, D.; Mao, D.; Zeng, X.; Chen, B.; Ding, W. Microstructure evolution of AZ31 Mg alloy during equal channel angular extrusion. Mater. Sci. Eng. A 2006, 423, 247–252. [Google Scholar] [CrossRef]

- Tripathi, A.; Murty, S.V.S.N.; Narayanan, P.R. Microstructure and texture evolution in AZ31 magnesium alloy during caliber rolling at different temperatures. J. Magnes. Alloys 2017, 5, 340–347. [Google Scholar] [CrossRef]

- Ammouri, A.H.; Kridli, G.; Ayoub, G.; Hamade, R.F. Relating grain size to the Zener–Hollomon parameter for twin-roll-cast AZ31B alloy refined by friction stir processing. J. Mater. Process. Technol. 2015, 222, 301–306. [Google Scholar] [CrossRef]

- Fatemi-Varzaneh, S.M.; Zarei-Hanzaki, A.; Beladi, H. Dynamic recrystallization in AZ31 magnesium alloy. Mater. Sci. Eng. A 2007, 456, 52–57. [Google Scholar] [CrossRef]

- Barnett, M.R. Twinning and the ductility of magnesium alloys: Part I: “Tension” twins. Mater. Sci. Eng. A 2007, 464, 1–7. [Google Scholar] [CrossRef]

- Jones, A.R. Annealing twinning and the nucleation of recrystallization at grain boundaries. J. Mater. Sci. 1981, 16, 1374–1380. [Google Scholar] [CrossRef]

- Rodriguez, A.K.; Ayoub, G.A.; Mansoor, B.; Benzerga, A.A. Effect of strain rate and temperature on fracture of magnesium alloy AZ31B. Acta Mater. 2016, 112, 194–208. [Google Scholar] [CrossRef]

| AT11M | Al | Sn | Mn | Si | Fe | Zn | Mg |

|---|---|---|---|---|---|---|---|

| Sample | 0.87 | 0.86 | 0.49 | 0.04 | 0.01 | 0.01 | Bal. |

| Temperature (°C) | Reduction (per Pass/%) | Initial Thickness (mm) | Final Thickness (mm) | Roll Speed (mm/s) | Tension (kN) |

|---|---|---|---|---|---|

| 150 | 25 | 3.02 | 0.99 | 0.05 | 1.5 |

| 200 | 25 | 2.97 | 0.95 | 0.05 | 1.5 |

| 250 | 25 | 2.94 | 0.93 | 0.05 | 1.5 |

| AT11M | YS (MPa) | UTS (MPa) | EL (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0° | 45° | 90° | 0° | 45° | 90° | 0° | 45° | 90° | |

| Extruded | 84 ± 4 | 80 ± 5 | 70 ± 1 | 226 ± 2 | 223 ± 1 | 225 ± 1 | 14.8 ± 0.5 | 19.4 ± 0.5 | 17.9 ± 1.2 |

| As-Rolled | 148 ± 6 | 147 ± 5 | 136 ± 9 | 298 ± 2 | 261 ± 2 | 236 ± 3 | 14.6 ± 0.7 | 13.7 ± 0.5 | 13.6 ± 2.2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Q.; Song, J.; Pan, F.; She, J.; Zhang, S.; Peng, P. The Edge Crack, Texture Evolution, and Mechanical Properties of Mg-1Al-1Sn-Mn Alloy Sheets Prepared Using On-Line Heating Rolling. Metals 2018, 8, 860. https://doi.org/10.3390/met8100860

Liu Q, Song J, Pan F, She J, Zhang S, Peng P. The Edge Crack, Texture Evolution, and Mechanical Properties of Mg-1Al-1Sn-Mn Alloy Sheets Prepared Using On-Line Heating Rolling. Metals. 2018; 8(10):860. https://doi.org/10.3390/met8100860

Chicago/Turabian StyleLiu, Qiang, Jiangfeng Song, Fusheng Pan, Jia She, Shuo Zhang, and Peng Peng. 2018. "The Edge Crack, Texture Evolution, and Mechanical Properties of Mg-1Al-1Sn-Mn Alloy Sheets Prepared Using On-Line Heating Rolling" Metals 8, no. 10: 860. https://doi.org/10.3390/met8100860

APA StyleLiu, Q., Song, J., Pan, F., She, J., Zhang, S., & Peng, P. (2018). The Edge Crack, Texture Evolution, and Mechanical Properties of Mg-1Al-1Sn-Mn Alloy Sheets Prepared Using On-Line Heating Rolling. Metals, 8(10), 860. https://doi.org/10.3390/met8100860