Surface Morphology and Its Influence on Cyclic Deformation Behavior of High-Mn TWIP Steel

Abstract

1. Introduction

2. Experimental Setup and Investigated Material

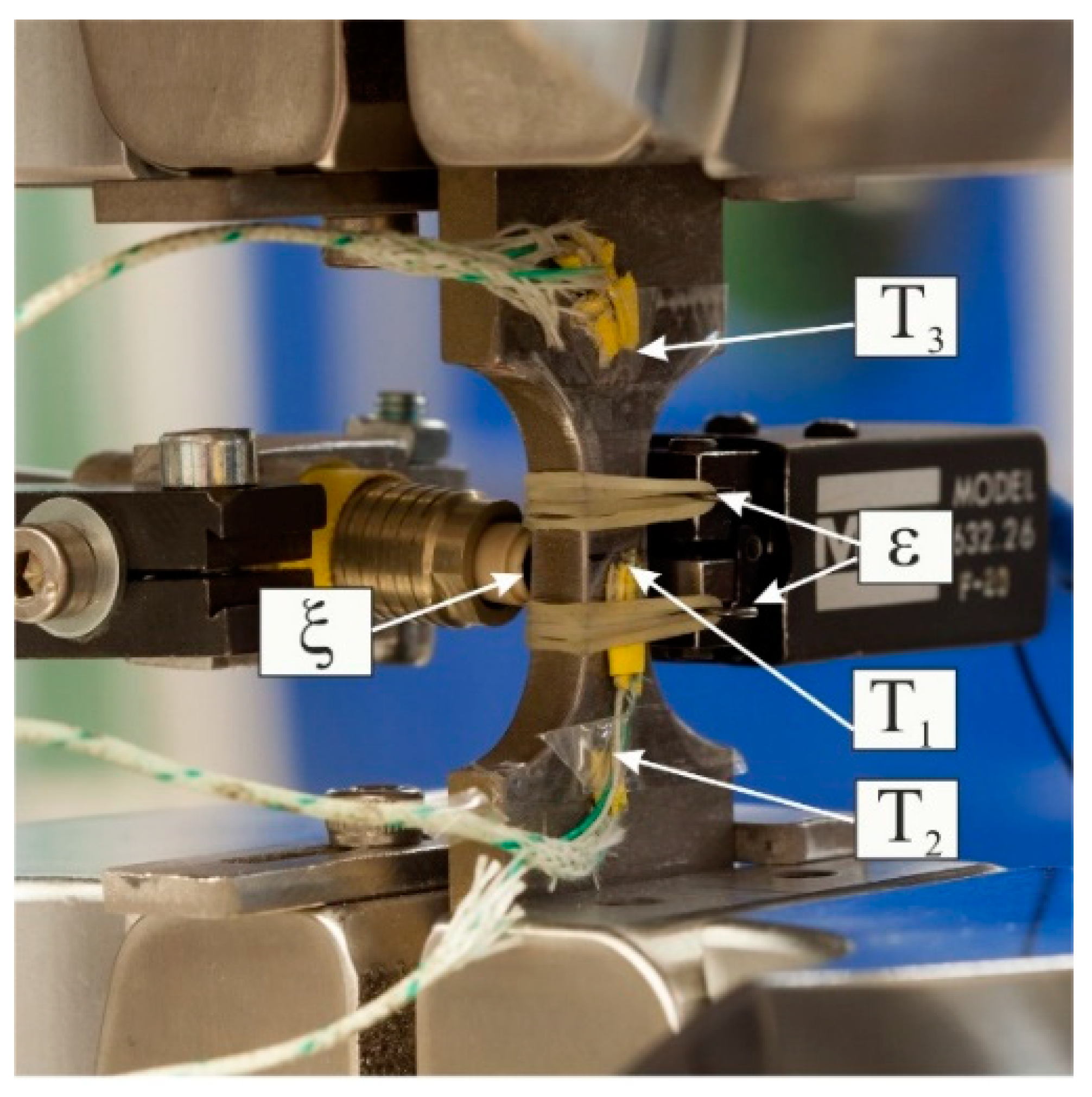

2.1. Experimental Setup

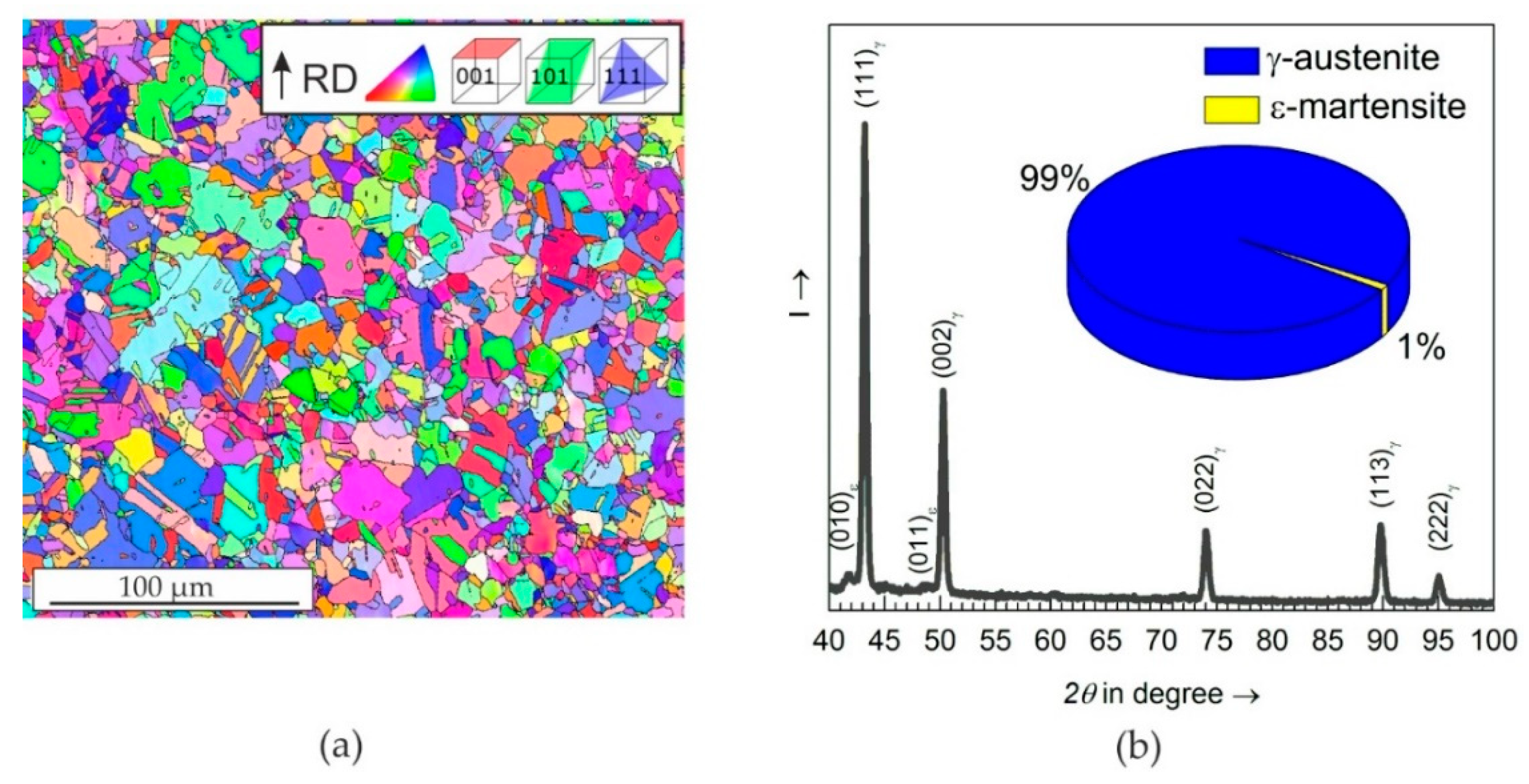

2.2. Investigated Material

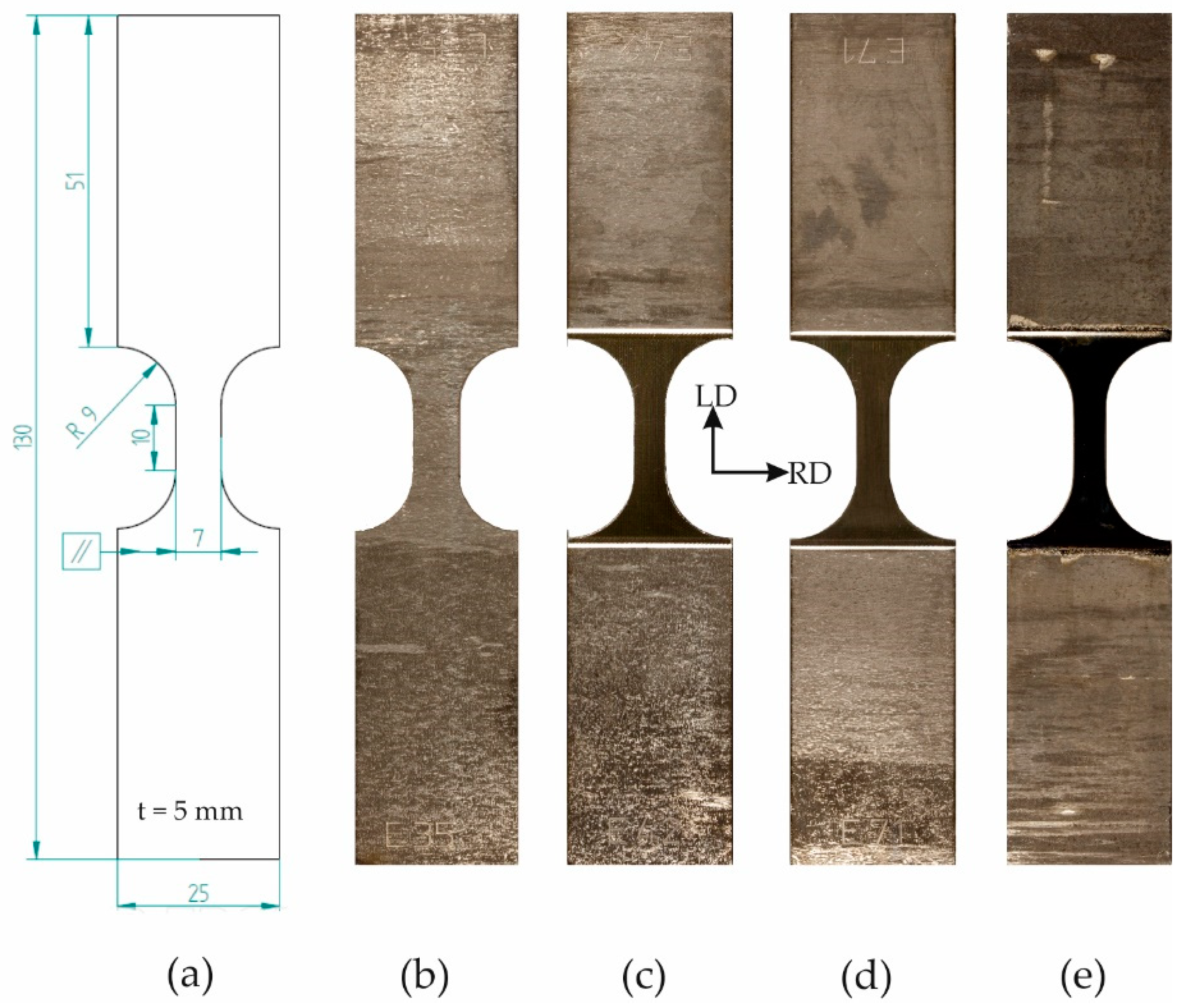

2.3. Specimen Manufacturing with Different Surface Morphologies

3. Results and Discussion

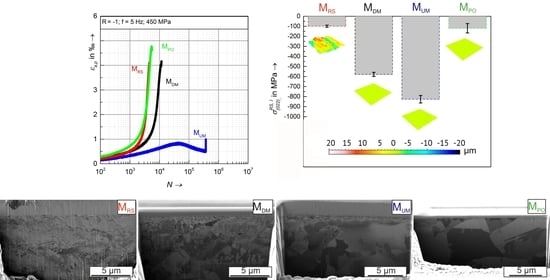

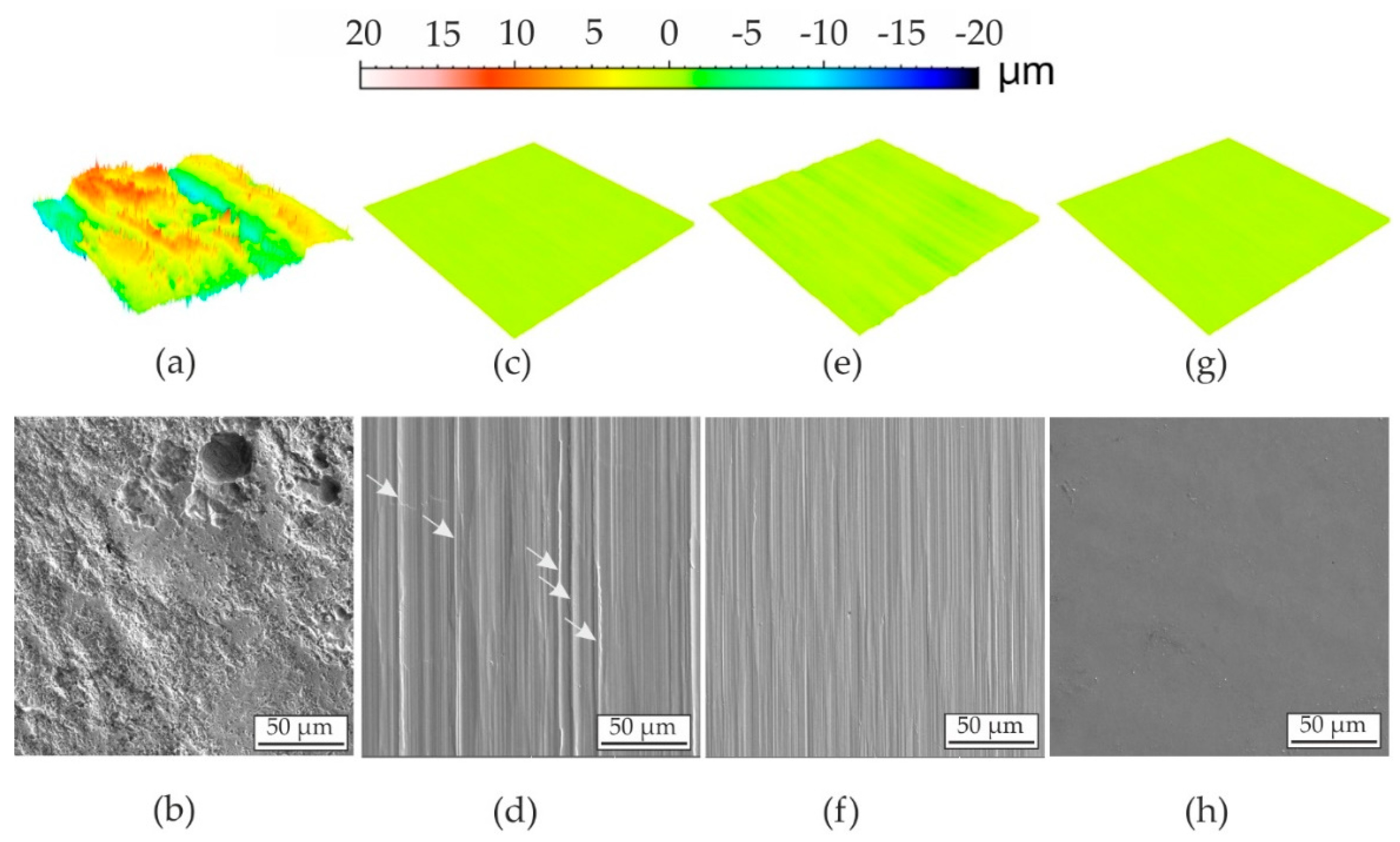

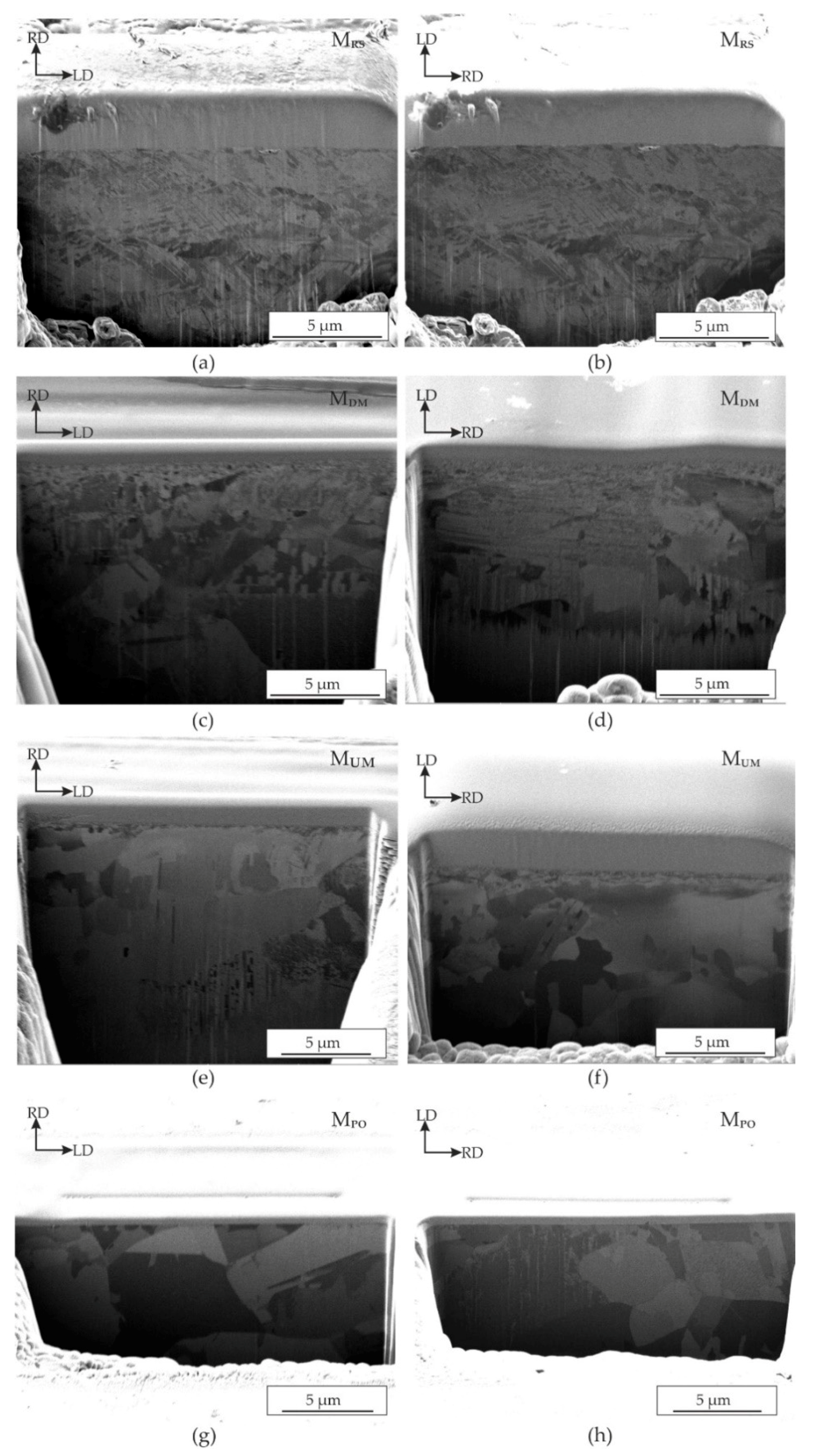

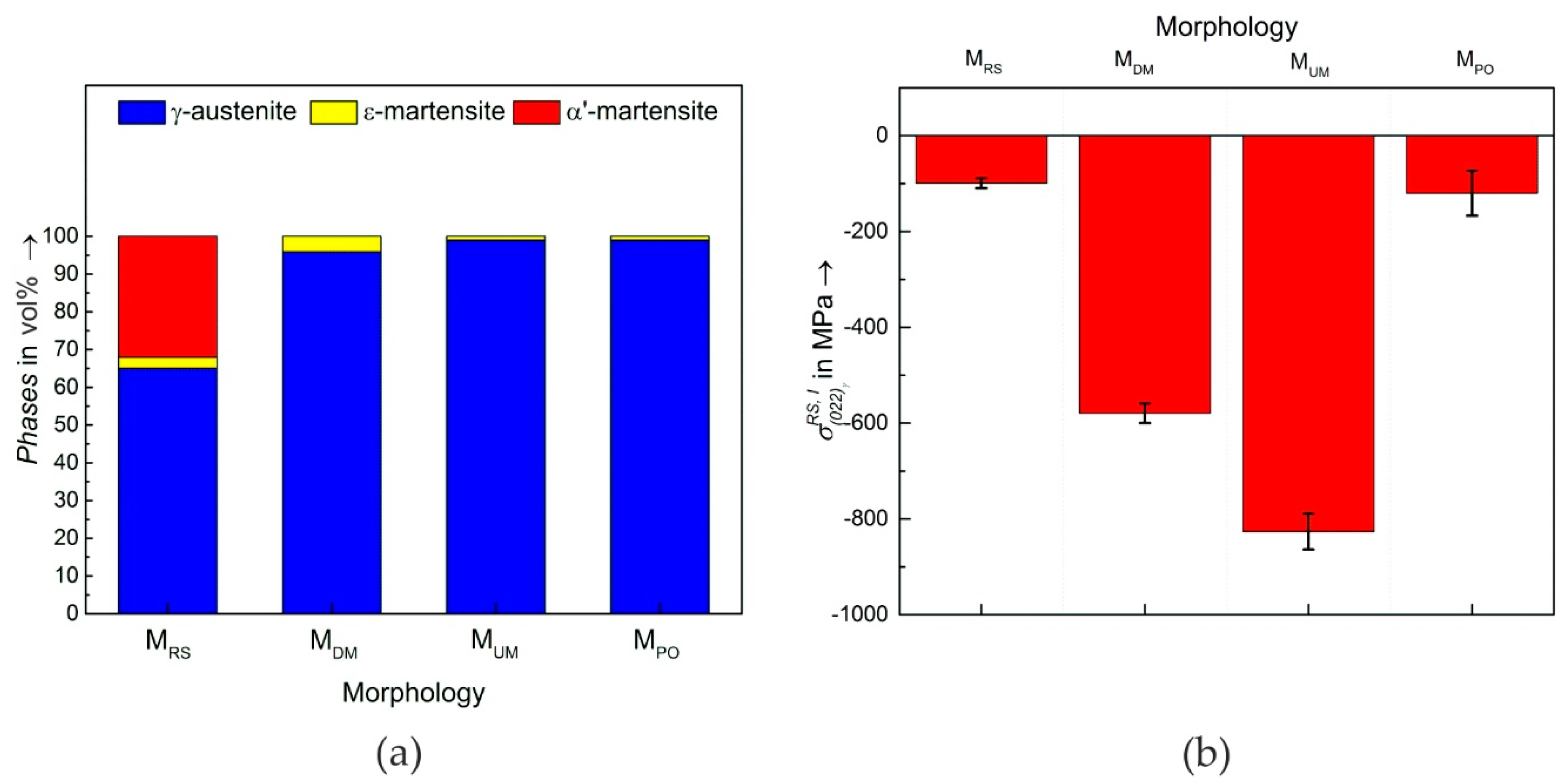

3.1. Investigated Surface Morphologies

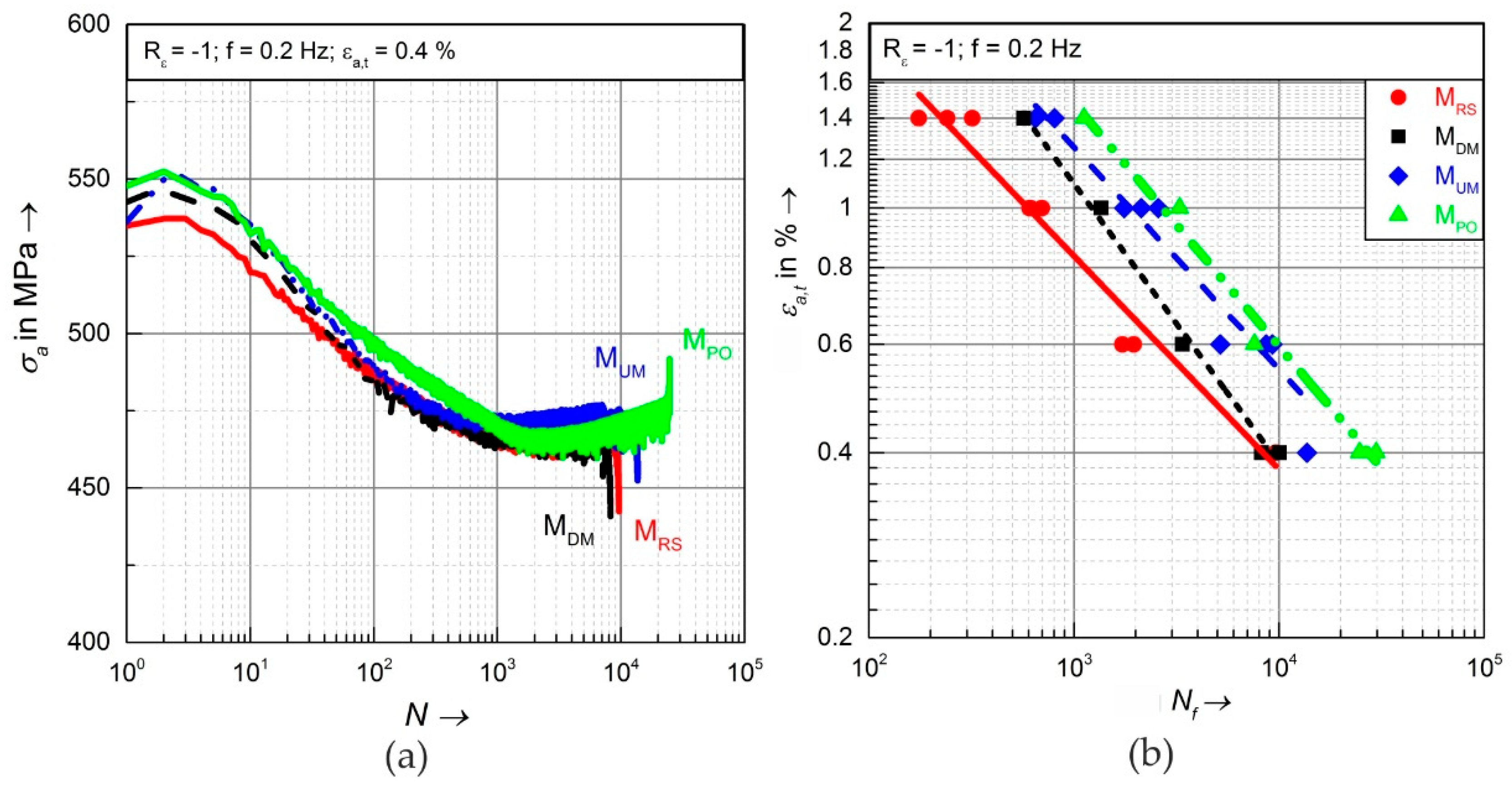

3.2. Cyclic Deformation Behavior

4. Summary and Conclusions

- The morphology MRS was by far the roughest and showed an uneven surface. Both of the milled morphologies MDM and MUM had significantly smoother surfaces, but showed periodic traces of the milling tool, which were more pronounced on the morphology MDM. The morphology MPO showed the smoothest surface. A fraction of 32 vol. % of α’-martensite was present in MRS while the other morphologies MDM, MUM and MPO were mostly austenitic with a small fraction of ε-martensite. In the milled morphologies compressive residual stresses of −600 MPa (MUM) and −800 MPa (MDM) were measured while the morphologies MRS and MPO showed significantly smaller residual stresses of −100 MPa and −120 MPa, respectively. FIB cuts revealed a machining induced nanocrystalline sub-surface layer in the milled morphologies MUM and MDM.

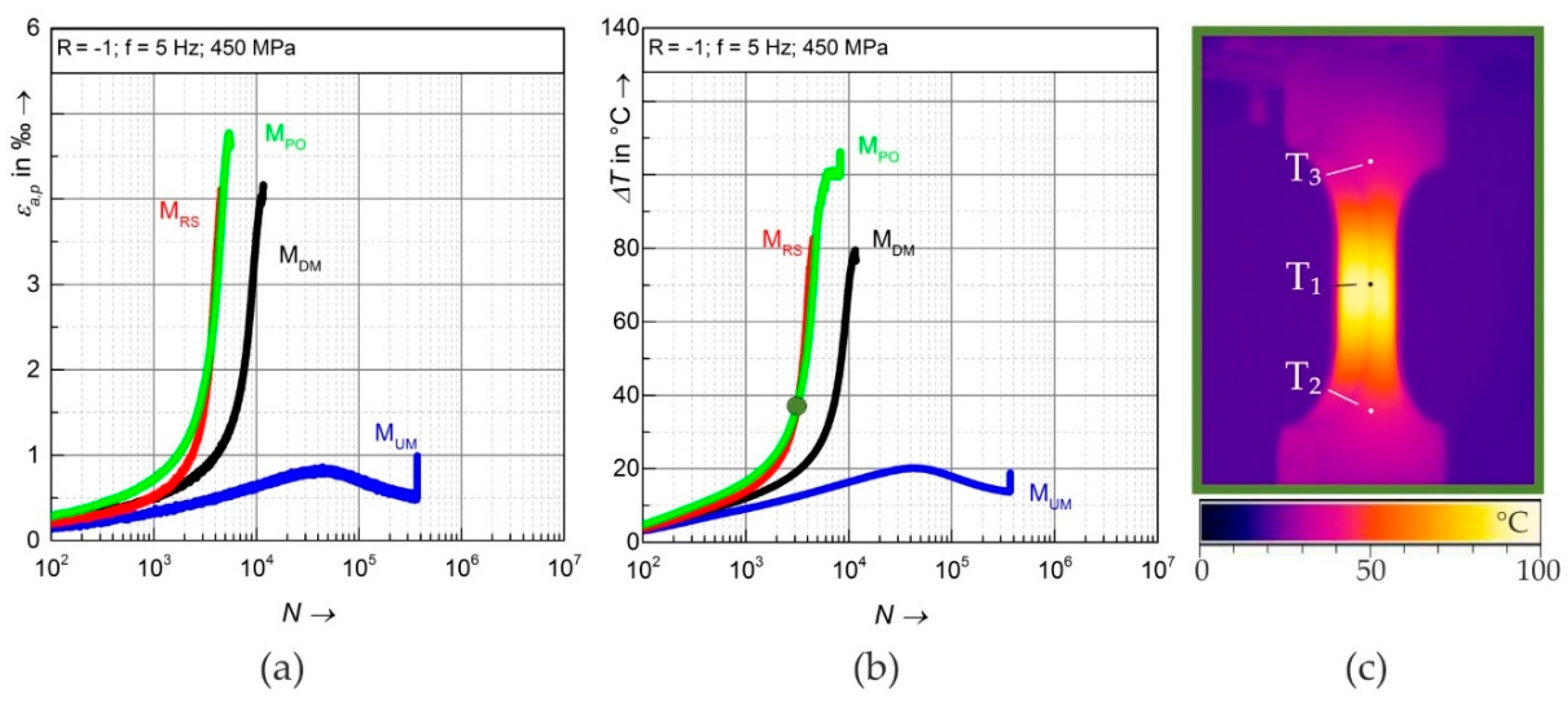

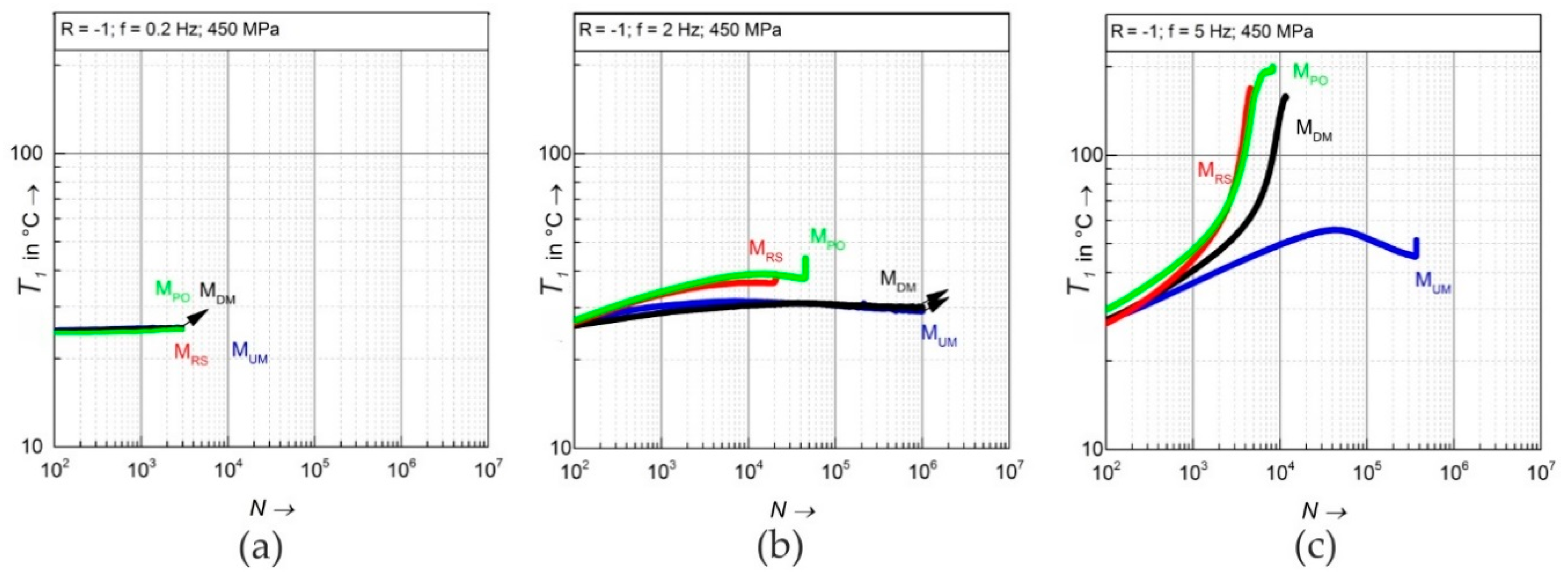

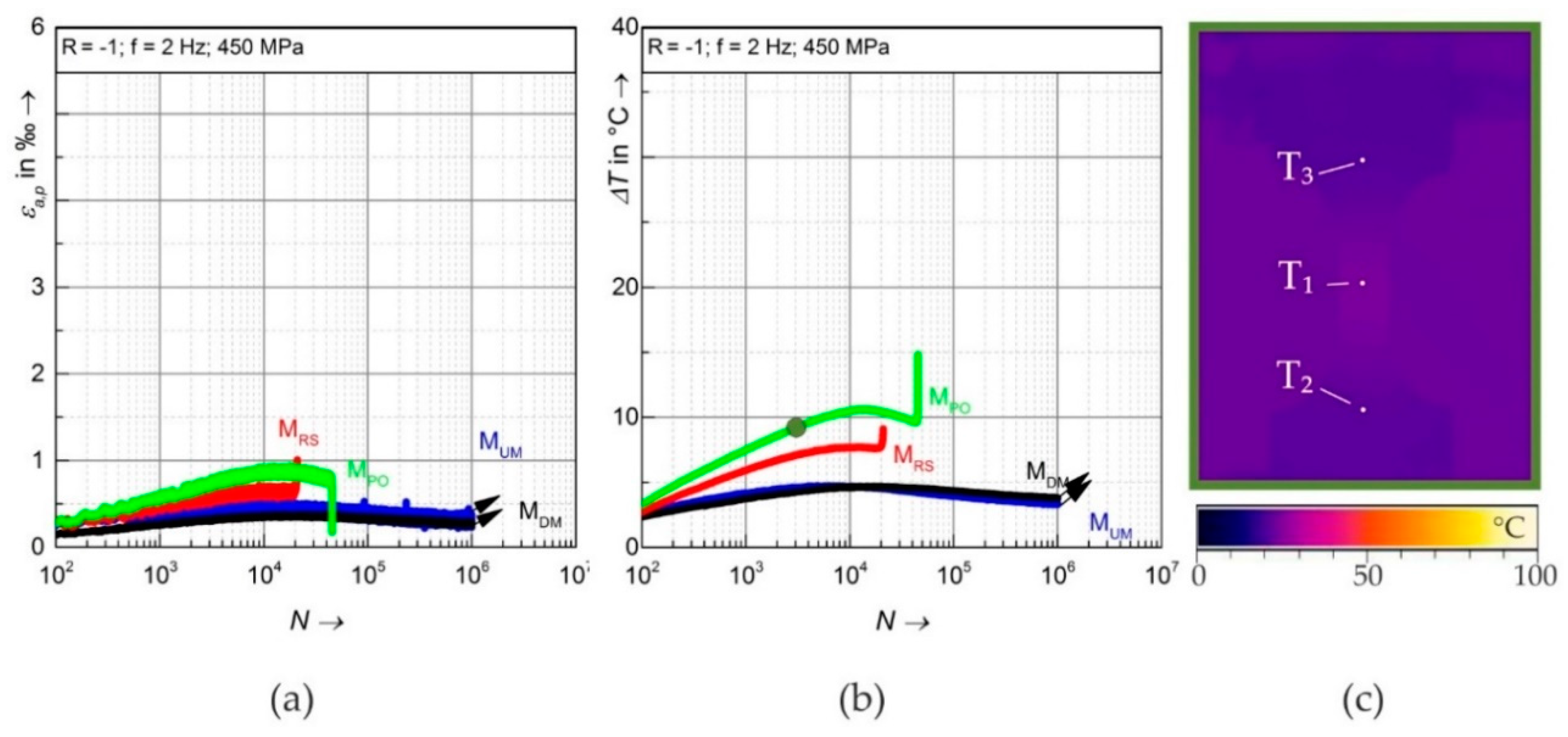

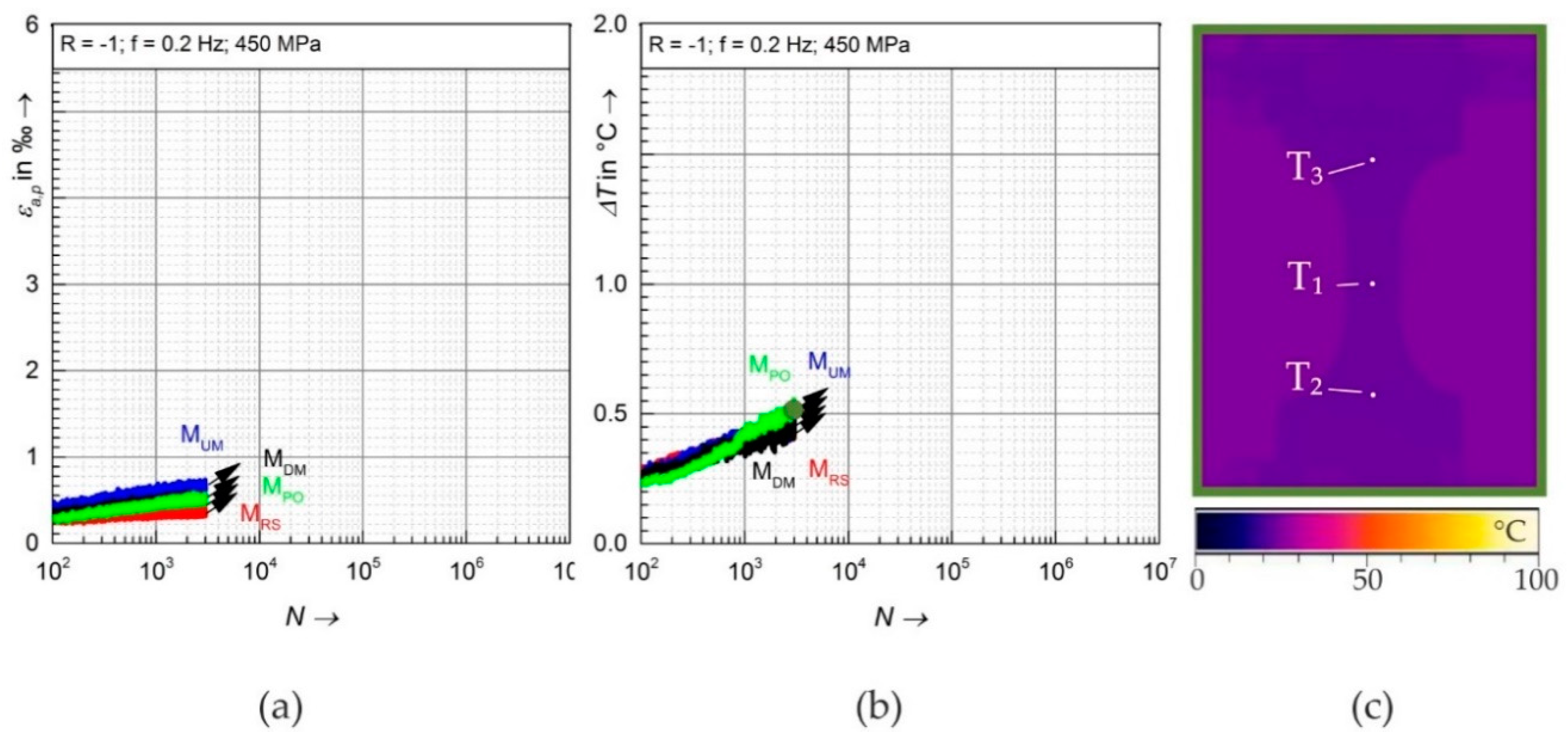

- In the LCF regime mainly the surface topography influenced fatigue lifetime. In the HCF regime, the influence of the other surface morphology features, i.e., residual stress and nanocrystalline sub-surface layers became significant. At f = 5 Hz, specimens with the morphology MUM showed initial cyclic softening followed cyclic hardening while for all other morphologies progressive cyclic softening and early failure was observed. For f = 2 Hz, only specimens with the milled surfaces reached the fatigue limit of 106 cycles due to their nanocrystalline surface layer and high compressive residual stresses.

- When applying a testing frequency of f = 5 Hz in HCF tests, the specimen temperature increased up to 200 °C due to plasticity induced self-heating. This promoted progressive cyclic softening as well as early failure of the specimens with the morphologies MRS, MUM and MPO. For f = 2 Hz, the self-heating of the specimens was significantly less pronounced and the specimen temperatures remained below 50 °C for all investigated surface morphologies. The temperature change ΔT in the gage length with respect to the clamping sections was significantly lower than the absolute temperatures and hence not suitable to explain the temperature influence on cyclic deformation, but to be an efficient means to characterize the cyclic deformation behavior, i.e., softening, hardening or saturation.

- To achieve comparable results for different loading amplitudes and surface morphologies, it is hence essential to choose appropriate test frequencies at which specimen self-heating does not influence the cyclic deformation behavior.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Raabe, D. Multistage strain hardening through dislocation substructure and twinning in a high strength and ductile weight-reduced Fe–Mn–Al–C steel. Acta Mater. 2012, 60, 5791–5802. [Google Scholar] [CrossRef]

- Saeed-Akbari, A.; Schwedt, A.; Bleck, W. Low stacking fault energy steels in the context of manganese-rich iron-based alloys. Scr. Mater. 2012, 66, 1024–1029. [Google Scholar] [CrossRef]

- Frommeyer, G.; Brüx, U.; Neumann, P. Supra-Ductile and High-Strength Manganese-TRIP/TWIP Steels for High Energy Absorption Purposes. ISIJ Int. 2003, 43, 438–446. [Google Scholar] [CrossRef]

- Saeed-Akbari, A.; Mosecker, L.; Schwedt, A.; Bleck, W. Characterization and Prediction of Flow Behavior in High-Manganese Twinning Induced Plasticity Steels. Metall. Mater. Trans. A 2012, 43, 1688–1704. [Google Scholar] [CrossRef]

- Grässel, O.; Krüger, L.; Frommeyer, G.; Meyer, L. High strength Fe–Mn–(Al, Si) TRIP/TWIP steels development–properties–application. Int. J. Plast. 2000, 16, 1391–1409. [Google Scholar] [CrossRef]

- Torganchuk, V.; Glezer, A.M.; Belyakov, A.; Kaibyshev, R. Deformation Behavior of High-Mn TWIP Steels Processed by Warm-to-Hot Working. Metals 2018, 8, 415. [Google Scholar] [CrossRef]

- Klein, M.W.; Skorupski, R.; Smaga, M.; Beck, T. Phase Transformation and Deformation Behavior of Steels with Different Content of Metastable Austenite. Eng. Trans. 2016, 64, 69–75. [Google Scholar]

- Gutierrez-Urrutia, I.; Raabe, D. Grain size effect on strain hardening in twinning-induced plasticity steels. Scr. Mater. 2012, 66, 992–996. [Google Scholar] [CrossRef]

- Linderov, M.; Segel, C.; Weidner, A.; Biermann, H.; Vinogradov, A. Deformation mechanisms in austenitic TRIP/TWIP steels at room and elevated temperature investigated by acoustic emission and scanning electron microscopy. Mater. Sci. Eng. A 2014, 597, 183–193. [Google Scholar] [CrossRef]

- Martin, S.; Fabrichnaya, O.; Rafaja, D. Prediction of the local deformation mechanisms in metastable austenitic steels from the local concentration of the main alloying elements. Mater. Lett. 2015, 159, 484–488. [Google Scholar] [CrossRef]

- Bouaziz, O.; Allain, S.; Scott, C.P.; Cugy, P.; Barbier, D. High manganese austenitic twinning induced plasticity steels. Curr. Opin. Solid State Mater. Sci. 2011, 15, 141–168. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Rivera-Díaz-del-Castillo, P. Understanding martensite and twin formation in austenitic steels. Acta Mater. 2017, 128, 120–134. [Google Scholar] [CrossRef]

- Herrera, C.; Ponge, D.; Raabe, D. Design of a novel Mn-based 1GPa duplex stainless TRIP steel with 60% ductility by a reduction of austenite stability. Acta Mater. 2011, 59, 4653–4664. [Google Scholar] [CrossRef]

- Dumay, A.; Chateau, J.-P.; Allain, S.; Migot, S.; Bouaziz, O. Influence of addition elements on the stacking-fault energy and mechanical properties of an austenitic Fe–Mn–C steel. Mater. Sci. Eng. A 2008, 483–484, 184–187. [Google Scholar] [CrossRef]

- Saeed-Akbari, A.; Imlau, J.; Prahl, U.; Bleck, W. Derivation and Variation in Composition-Dependent Stacking Fault Energy Maps Based on Subregular Solution Model in High-Manganese Steels. Metall. Mater. Trans. A 2009, 40, 3076–3090. [Google Scholar] [CrossRef]

- Lu, S.; Hu, Q.-M.; Johansson, B.; Vitos, L. Stacking fault energies of Mn, Co and Nb alloyed austenitic stainless steels. Acta Mater. 2011, 59, 5728–5734. [Google Scholar] [CrossRef]

- Abbasi, A.; Dick, A.; Hickel, T.; Neugebauer, J. First-principles investigation of the effect of carbon on the stacking fault energy of Fe–C alloys. Acta Mater. 2011, 59, 3041–3048. [Google Scholar] [CrossRef]

- Pierce, D.T.; Jiménez, J.A.; Bentley, J.; Raabe, D.; Oskay, C.; Wittig, J.E. The influence of manganese content on the stacking fault and austenite/ε-martensite interfacial energies in Fe–Mn–(Al–Si) steels investigated by experiment and theory. Acta Mater. 2014, 68, 238–253. [Google Scholar] [CrossRef]

- Martin, S.; Wolf, S.; Martin, U.; Krüger, L.; Rafaja, D. Deformation Mechanisms in Austenitic TRIP/TWIP Steel as a Function of Temperature. Metall. Mater. Trans. A 2016, 47, 49–58. [Google Scholar] [CrossRef]

- Baeumer, A.; Antonio Jimenez, J.; Bleck, W. Effect of temperature and strain rate on strain hardening and deformation mechanisms of high manganese austenitic steels. Int. J. Mater. Res. 2010, 101, 705–714. [Google Scholar] [CrossRef]

- Kim, J.-K.; Chen, L.; Kim, H.-S.; Kim, S.-K.; Estrin, Y.; de Cooman, B.C. On the Tensile Behavior of High-Manganese Twinning-Induced Plasticity Steel. Metall. Mater. Trans. A 2009, 40, 3147–3158. [Google Scholar] [CrossRef]

- Bintu, A.; Vincze, G.; Picu, C.R.; Lopes, A.B.; Grácio, J.J.; Barlat, F. Strain hardening rate sensitivity and strain rate sensitivity in TWIP steels. Mater. Sci. Eng. A 2015, 629, 54–59. [Google Scholar] [CrossRef]

- Wu, Y.-X.; Tang, D.; Jiang, H.-T.; Mi, Z.-L.; Xue, Y.; Wu, H.-P. Low Cycle Fatigue Behavior and Deformation Mechanism of TWIP Steel. J. Iron Steel Res. Int. 2014, 21, 352–358. [Google Scholar] [CrossRef]

- Schilke, M.; Ahlström, J.; Karlsson, B. Low cycle fatigue and deformation behaviour of austenitic manganese steel in rolled and in as-cast conditions. Procedia Eng. 2010, 2, 623–628. [Google Scholar] [CrossRef]

- Shao, C.W.; Zhang, P.; Liu, R.; Zhang, Z.J.; Pang, J.C.; Zhang, Z.F. Low-cycle and extremely-low-cycle fatigue behaviors of high-Mn austenitic TRIP/TWIP alloys. Acta Mater. 2016, 103, 781–795. [Google Scholar] [CrossRef]

- Shao, C.W.; Zhang, P.; Zhu, Y.K.; Zhang, Z.J.; Pang, J.C.; Zhang, Z.F. Improvement of low-cycle fatigue resistance in TWIP steel by regulating the grain size and distribution. Acta Mater. 2017, 134, 128–142. [Google Scholar] [CrossRef]

- Nikulin, I.; Sawaguchi, T.; Tsuzaki, K. Effect of alloying composition on low-cycle fatigue properties and microstructure of Fe–30Mn–(6−x)Si–xAl TRIP/TWIP alloys. Mater. Sci. Eng. A 2013, 587, 192–200. [Google Scholar] [CrossRef]

- Nikulin, I.; Sawaguchi, T.; Ogawa, K.; Tsuzaki, K. Effect of γ to ε martensitic transformation on low-cycle fatigue behaviour and fatigue microstructure of Fe–15Mn–10Cr–8Ni–xSi austenitic alloys. Acta Mater. 2016, 105, 207–218. [Google Scholar] [CrossRef]

- Ju, Y.-B.; Koyama, M.; Sawaguchi, T.; Tsuzaki, K.; Noguchi, H. Effects of ε-martensitic transformation on crack tip deformation, plastic damage accumulation, and slip plane cracking associated with low-cycle fatigue crack growth. Int. J. Fatigue 2017, 103, 533–545. [Google Scholar] [CrossRef]

- Song, S.W.; Lee, J.H.; Lee, H.J.; Bae, C.M.; Lee, C.S. Enhancing high-cycle fatigue properties of cold-drawn Fe–Mn–C TWIP steels. Int. J. Fatigue 2016, 85, 57–64. [Google Scholar] [CrossRef]

- Hamada, A.S.; Karjalainen, L.P.; Puustinen, J. Fatigue behavior of high-Mn TWIP steels. Mater. Sci. Eng. A 2009, 517, 68–77. [Google Scholar] [CrossRef]

- Hamada, A.S.; Karjalainen, L.P.; Ferraiuolo, A.; Gil Sevillano, J.; de las Cuevas, F.; Pratolongo, G.; Reis, M. Fatigue Behavior of Four High-Mn Twinning Induced Plasticity Effect Steels. Metall. Mater. Trans. A 2010, 41, 1102–1108. [Google Scholar] [CrossRef]

- Hamada, A.S.; Karjalainen, L.P. High-cycle fatigue behavior of ultrafine-grained austenitic stainless and TWIP steels. Mater. Sci. Eng. A 2010, 527, 5715–5722. [Google Scholar] [CrossRef]

- Niendorf, T.; Lotze, C.; Canadinc, D.; Frehn, A.; Maier, H.J. The role of monotonic pre-deformation on the fatigue performance of a high-manganese austenitic TWIP steel. Mater. Sci. Eng. A 2009, 499, 518–524. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, P.; Duan, Q.Q.; Zhang, Z.J.; Yang, H.J.; Pang, J.C.; Tian, Y.Z.; Li, X.W.; Zhang, Z.F. High-cycle fatigue properties and damage mechanisms of pre-strained Fe-30Mn-09C twinning-induced plasticity steel. Mater. Sci. Eng. A 2017, 679, 258–271. [Google Scholar] [CrossRef]

- Rüsing, C.J.; Lambers, H.-G.; Lackmann, J.; Frehn, A.; Nagel, M.; Schaper, M.; Maier, H.J.; Niendorf, T. Property Optimization for TWIP Steels—Effect of Pre-deformation Temperature on Fatigue Properties. Mater. Today Proc. 2014, 2, 681–685. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, P.; Duan, Q.Q.; Zhang, Z.J.; Yang, H.J.; Pang, J.C.; Tian, Y.Z.; Li, X.W.; Zhang, Z.F. Synchronously improved fatigue strength and fatigue crack growth resistance in twinning-induced plasticity steels. Mater. Sci. Eng. A 2018, 711, 533–542. [Google Scholar] [CrossRef]

- Skorupski, R.; Smaga, M.; Eifler, D. Influence of Surface Morphology on the Fatigue Behavior of Metastable Austenitic Steel. Adv. Mater. Res. 2014, 891–892, 464–469. [Google Scholar] [CrossRef]

- Mughrabi, H. Cyclic Slip Irreversibilities and the Evolution of Fatigue Damage. Metall. Mater. Trans. B 2009, 40, 431–453. [Google Scholar] [CrossRef]

- Zhang, H.; Hei, Z.; Liu, G.; Lu, J.; Lu, K. Formation of nanostructured surface layer on AISI 304 stainless steel by means of surface mechanical attrition treatment. Acta Mater. 2003, 51, 1871–1881. [Google Scholar] [CrossRef]

- Boemke, A.; Smaga, M.; Beck, T. Influence of surface morphology on the very high cycle fatigue behavior of metastable and stable austenitic Cr-Ni steels. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2018; Volume 165. [Google Scholar] [CrossRef]

- Roland, T.; Retraint, D.; Lu, K.; Lu, J. Fatigue life improvement through surface nanostructuring of stainless steel by means of surface mechanical attrition treatment. Scr. Mater. 2006, 54, 1949–1954. [Google Scholar] [CrossRef]

- Altenberger, I.; Scholtes, B.; Martin, U.; Oettel, H. Cyclic deformation and near surface microstructures of shot peened or deep rolled austenitic stainless steel AISI 304. Mater. Sci. Eng. A 1999, 264, 1–16. [Google Scholar] [CrossRef]

- Smaga, M.; Skorupski, R.; Eifler, D.; Beck, T. Microstructural characterization of cyclic deformation behavior of metastable austenitic stainless steel AISI 347 with different surface morphology. J. Mater. Res. 2017, 32, 4452–4460. [Google Scholar] [CrossRef]

- Kalsar, R.; Suwas, S. A novel way to enhance the strength of twinning induced plasticity (TWIP) steels. Scr. Mater. 2018, 154, 207–211. [Google Scholar] [CrossRef]

- Nikitin, B.; Besel, M. Effect of low-frequency on fatigue behaviour of austenitic steel AISI 304 at room temperature and 25 °C. Int. J. Fatigue 2008, 30, 2044–2049. [Google Scholar] [CrossRef]

- Pessoa, D.F.; Kirchhoff, G.; Zimmermann, M. Influence of loading frequency and role of surface micro-defects on fatigue behavior of metastable austenitic stainless steel AISI 304. Int. J. Fatigue 2017, 103, 48–59. [Google Scholar] [CrossRef]

- Smaga, M.; Boemke, A.; Daniel, T.; Klein, M.W. Metastability and fatigue behavior of austenitic stainless steels. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2018; Volume 165, p. 4010. [Google Scholar] [CrossRef]

- Bish, D.L.; Howard, S.A. Quantitative phase analysis using the Rietveld method. J. Appl. Crystallogr. 1988, 21, 86–91. [Google Scholar] [CrossRef]

- Biallas, G.; Piotrowski, A.; Eifler, D. Cyclic Stress-Strain, Stress-Temperature and Stress-Electrical Resistance Response of NiCuMo alloyed sintered steel. Fatigue Fract. Eng. Mat. Struct. 1995, 18, 605–615. [Google Scholar] [CrossRef]

- Piotrowski, A.; Eifler, D. Characterization of cyclic deformation behaviour by mechanical, thermometrical and electrical methods. Materialwiss. Werkstofftech. 1995, 26, 121–127. [Google Scholar]

- Klein, M.W.; Smaga, M.; Beck, T. Influence of the surface morphology on the cyclic deformation behavior of HSD® 600 steel. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2018; Volume 165, p. 6010. [Google Scholar] [CrossRef]

| Element | C | Mn | Al | Si |

|---|---|---|---|---|

| wt. % | 0.36 | 15.30 | 1.80 | 2.30 |

| Direction | Young’s Modulus in GPa | Yield Strength in MPa | Tensile Strength in MPa | Elongation at the Fracture in % | Hardness HV10 |

|---|---|---|---|---|---|

| Longitudinal to RD | 169 ± 7 | 607 ± 21 | 1028 ± 10 | 53 ± 2 | 301 ± 13 |

| Transverse to RD | 180 ± 1 | 621 ± 5 | 1044 ± 4 | 50 ± 2 | 301 ± 13 |

| Tool Coating | fz/mm | n | nz |

|---|---|---|---|

| AlTiN | 0.025 | 5091 | 4 |

| Morphology | MRS | MDM | MUM | MPO |

|---|---|---|---|---|

| Rz in µm (confocal) | 6.17 | 0.75 | 1.18 | 0.20 |

| Rz in µm (tactile) | 5.80 | 0.55 | 1.96 | 0.45 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klein, M.W.; Smaga, M.; Beck, T. Surface Morphology and Its Influence on Cyclic Deformation Behavior of High-Mn TWIP Steel. Metals 2018, 8, 832. https://doi.org/10.3390/met8100832

Klein MW, Smaga M, Beck T. Surface Morphology and Its Influence on Cyclic Deformation Behavior of High-Mn TWIP Steel. Metals. 2018; 8(10):832. https://doi.org/10.3390/met8100832

Chicago/Turabian StyleKlein, Matthias W., Marek Smaga, and Tilmann Beck. 2018. "Surface Morphology and Its Influence on Cyclic Deformation Behavior of High-Mn TWIP Steel" Metals 8, no. 10: 832. https://doi.org/10.3390/met8100832

APA StyleKlein, M. W., Smaga, M., & Beck, T. (2018). Surface Morphology and Its Influence on Cyclic Deformation Behavior of High-Mn TWIP Steel. Metals, 8(10), 832. https://doi.org/10.3390/met8100832