Crystallization Kinetics and Consolidation of Al82La10Fe4Ni4 Glassy Alloy Powder by Spark Plasma Sintering

Abstract

1. Introduction

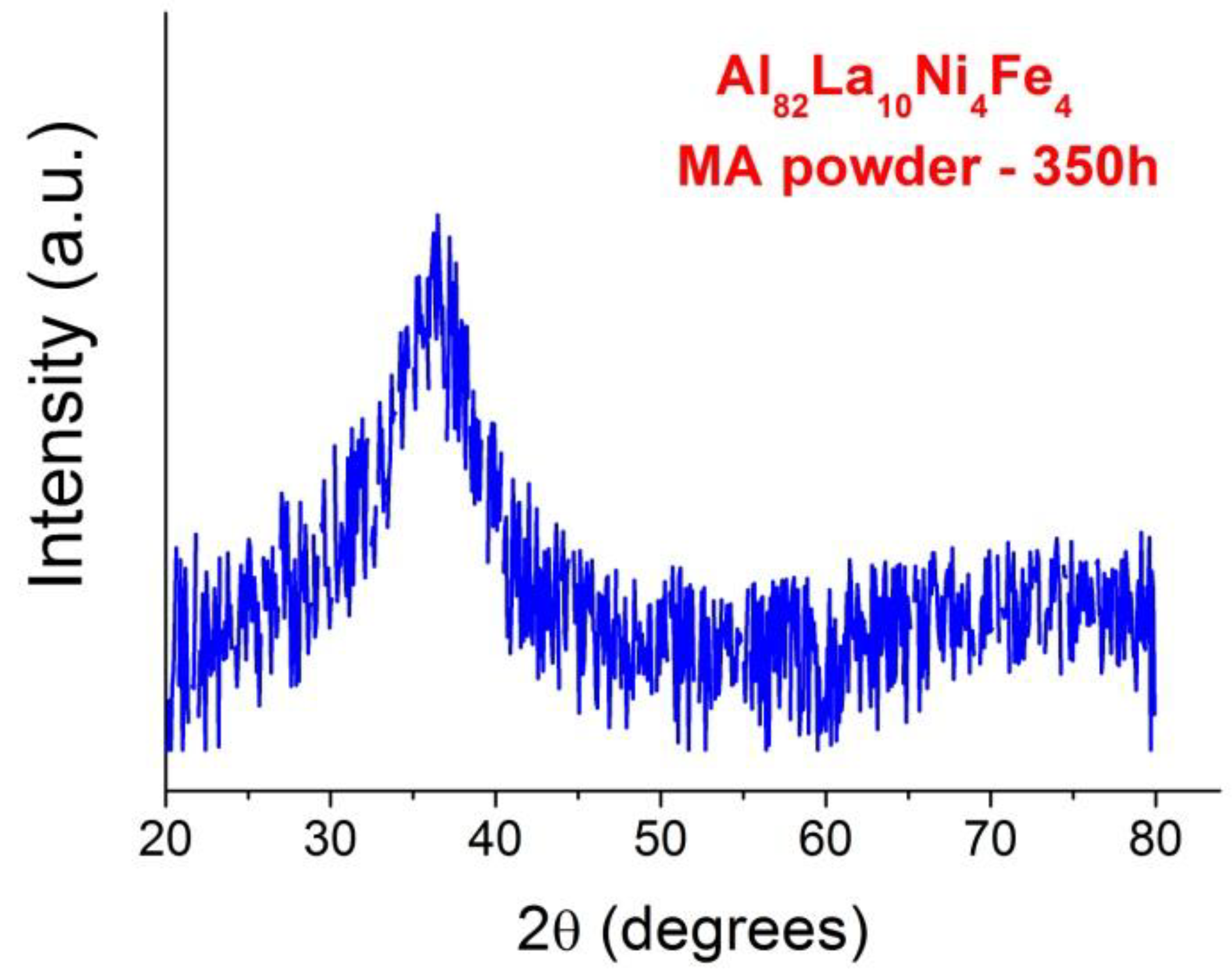

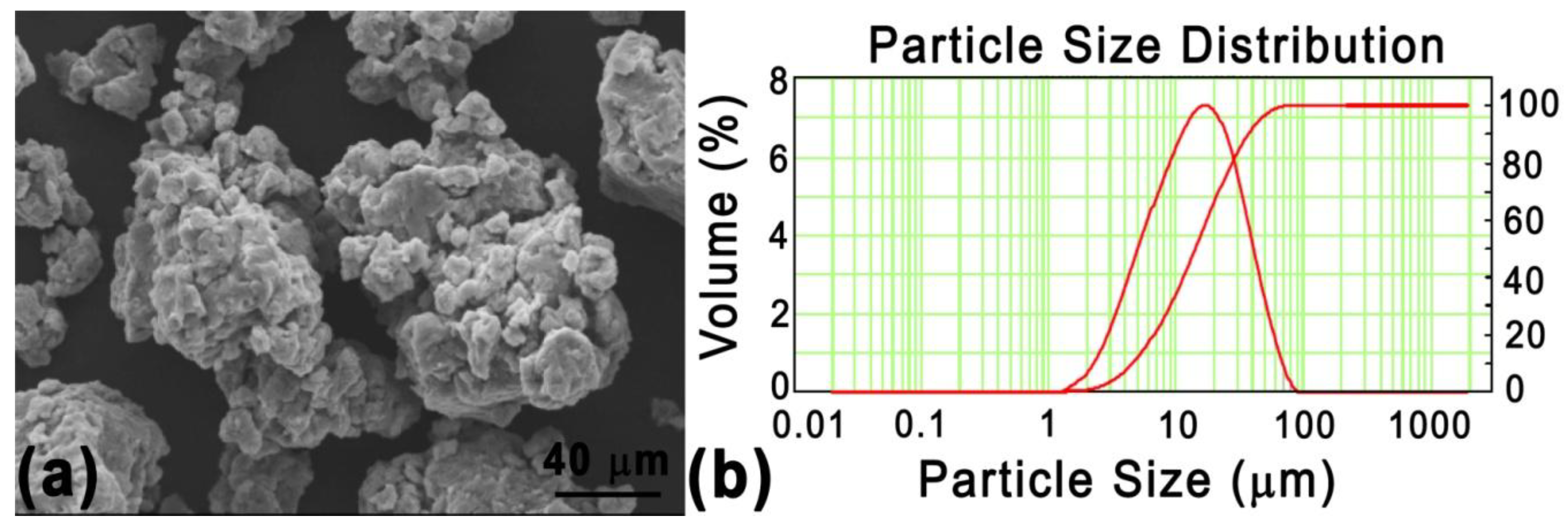

2. Materials and Methods

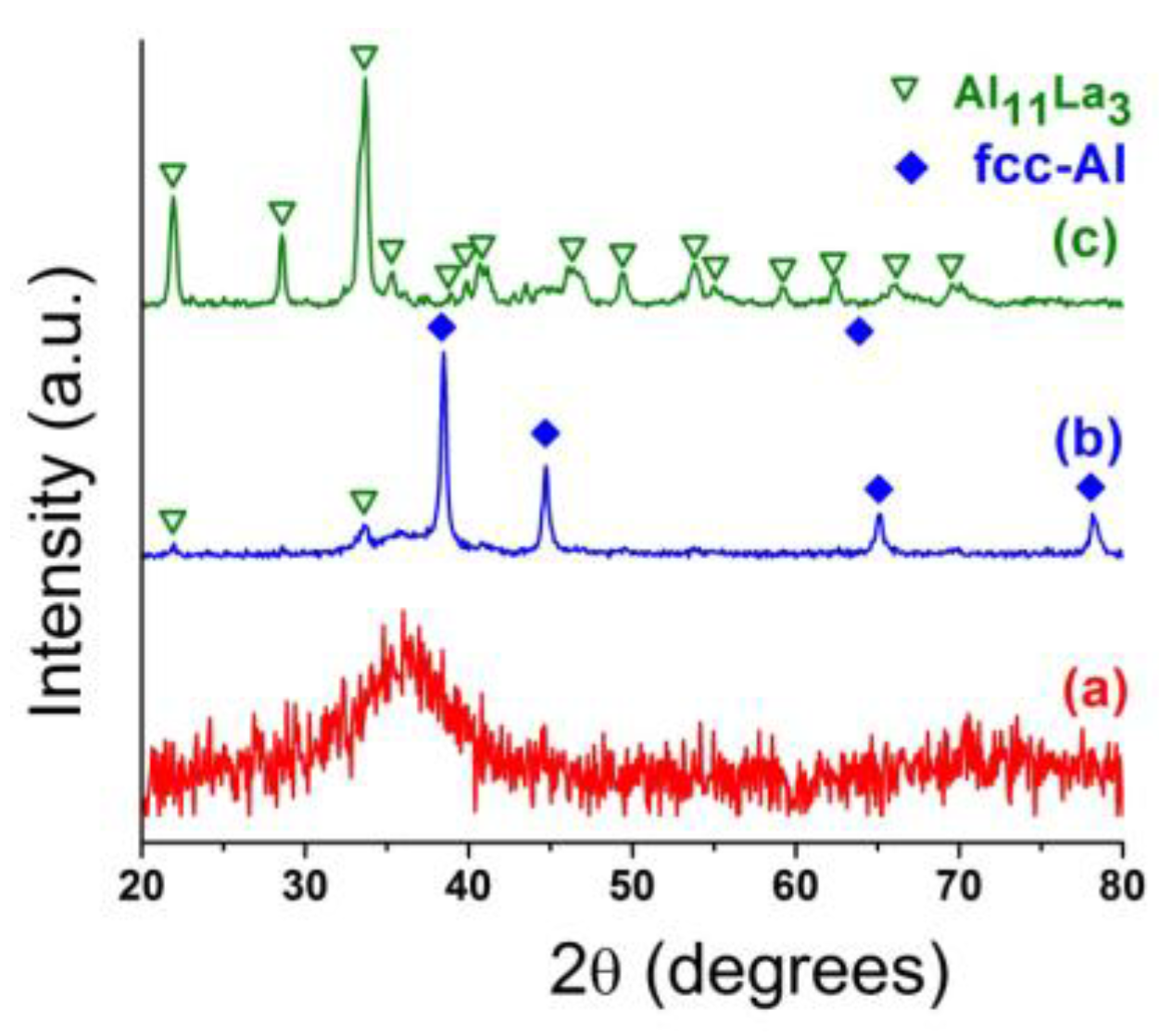

3. Results and Discussion

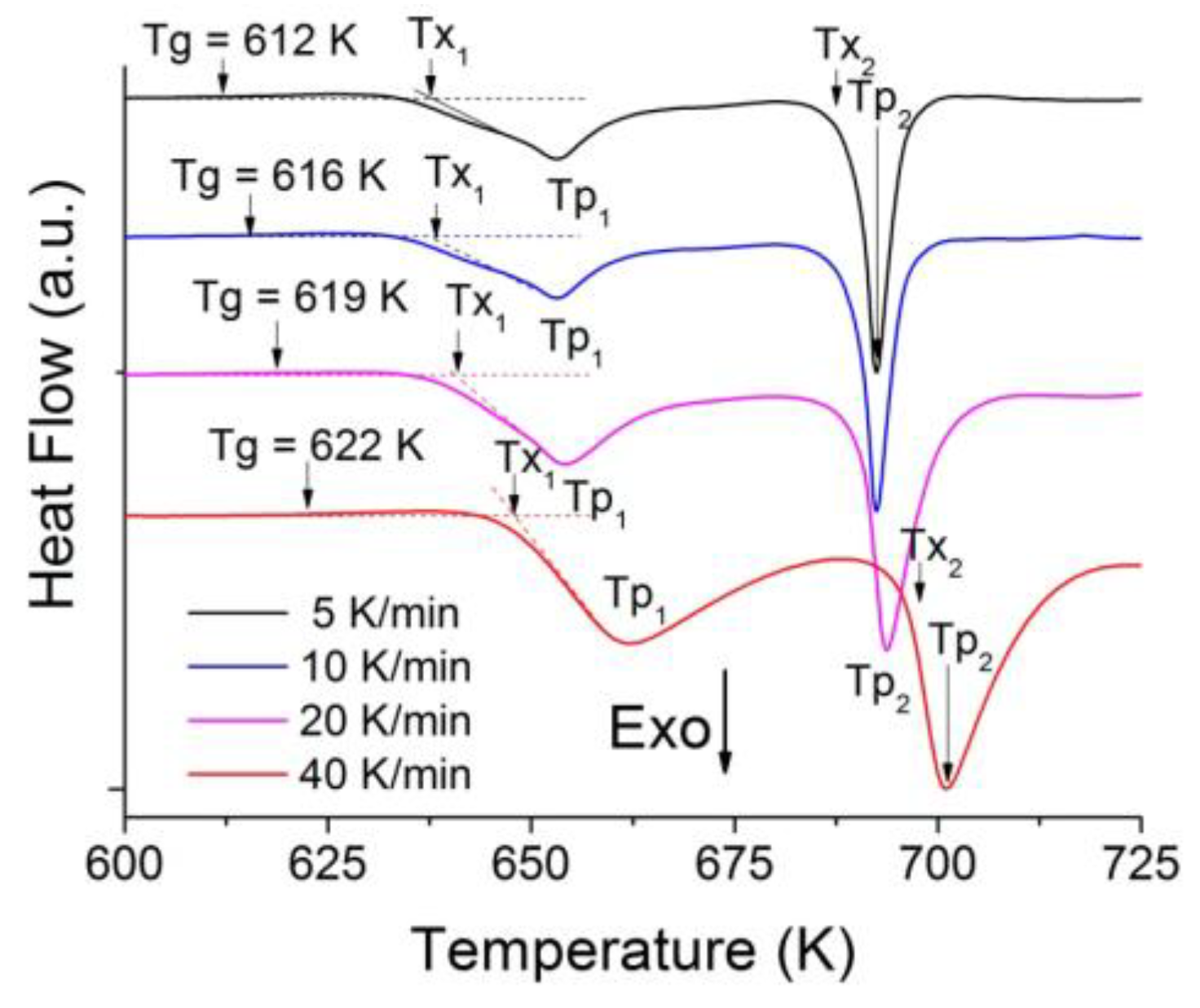

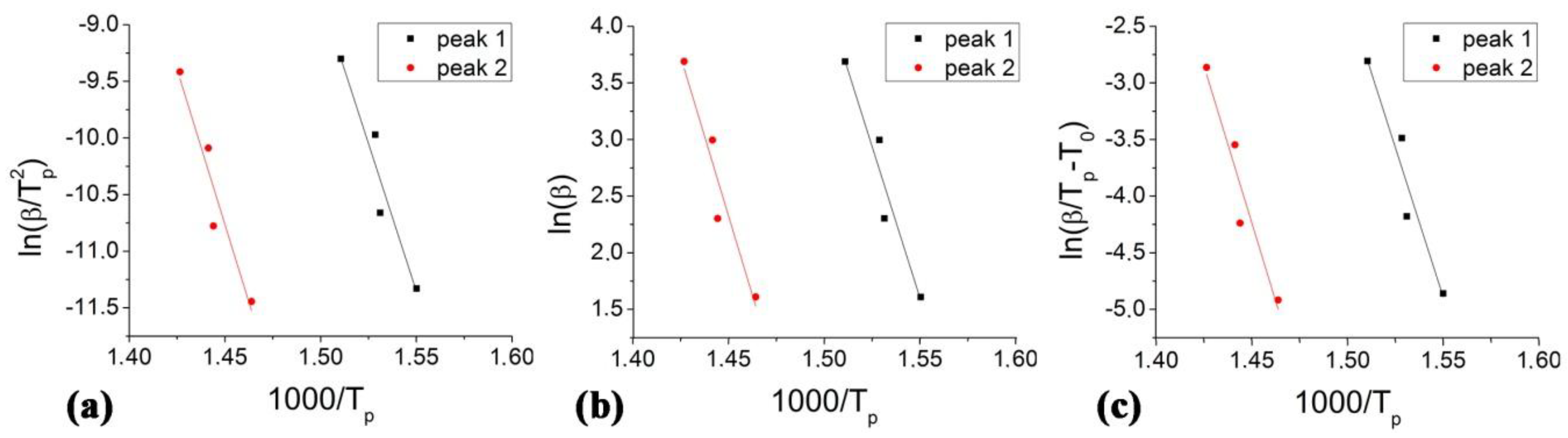

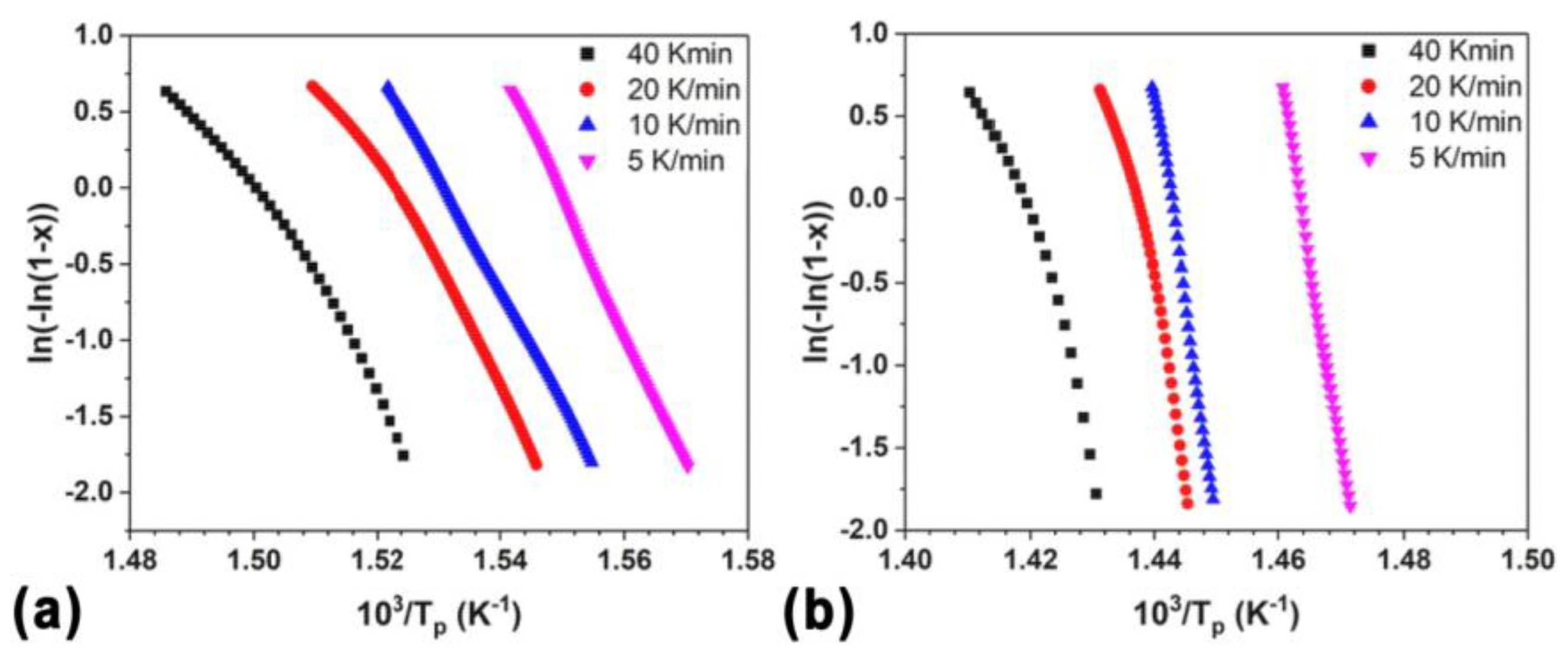

3.1. Crystallization Kinetics

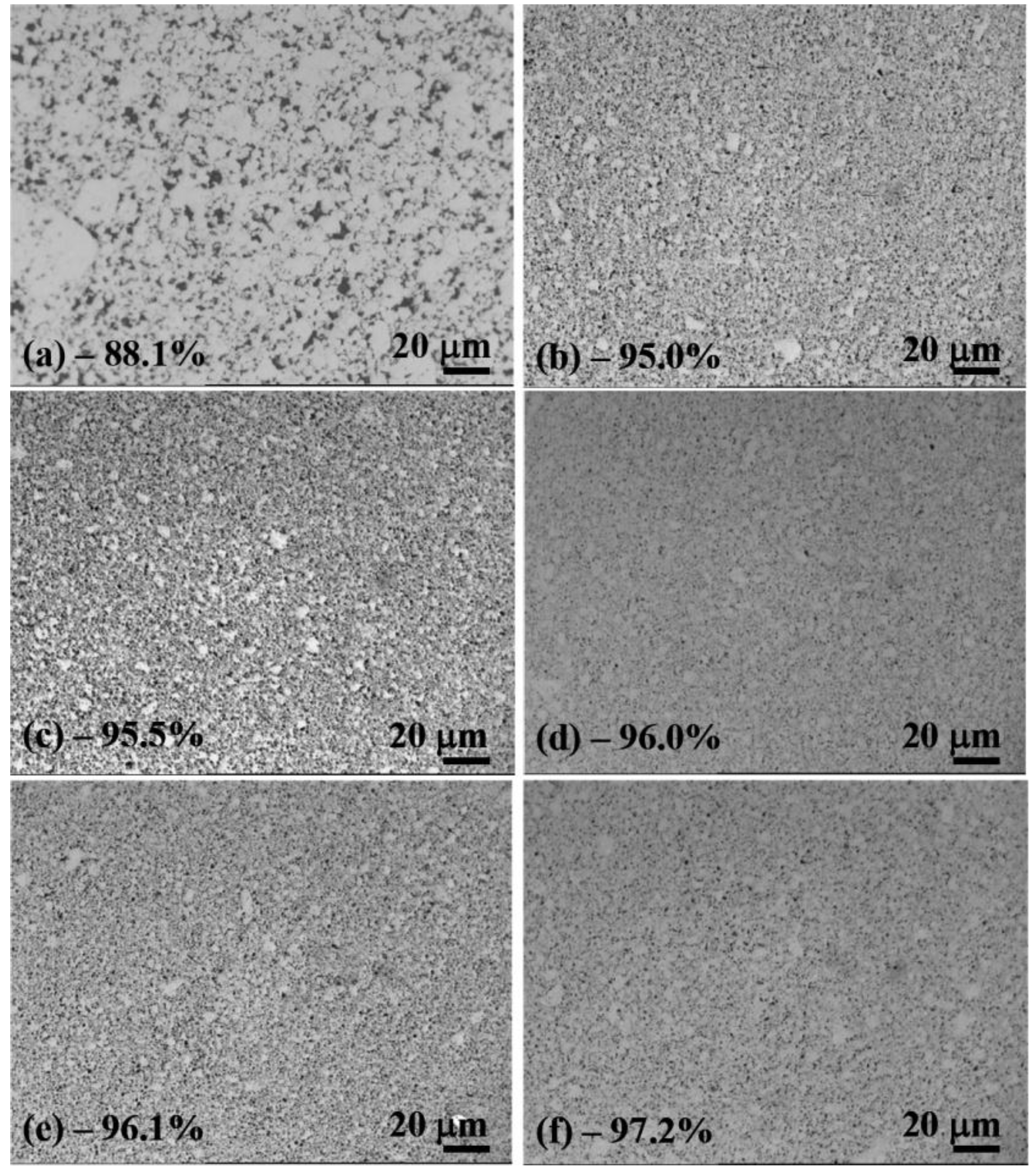

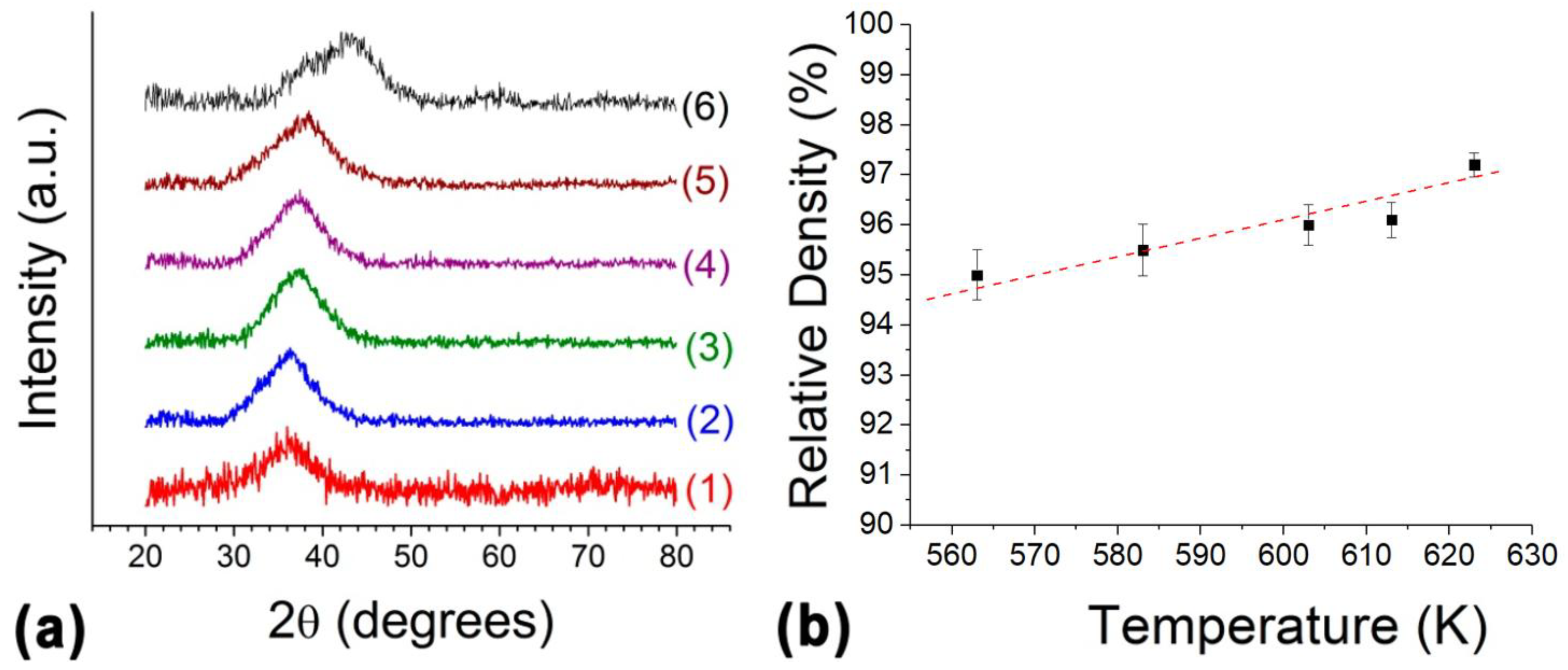

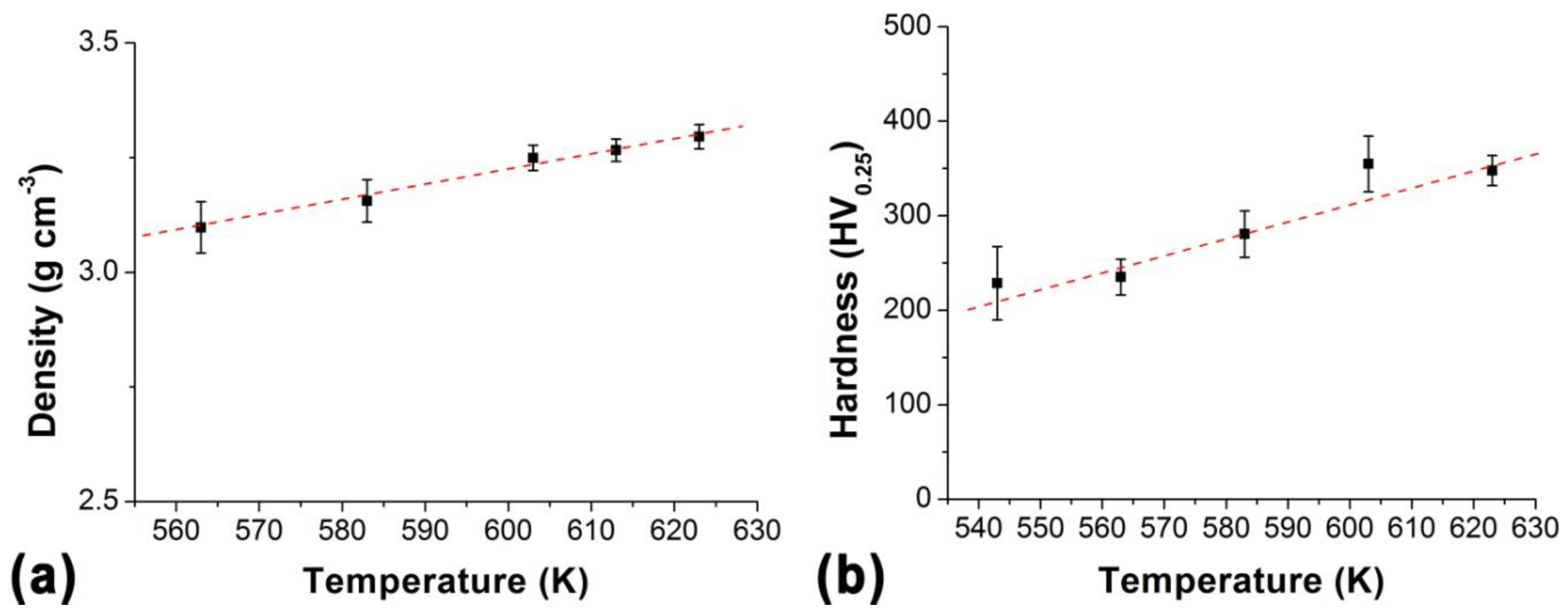

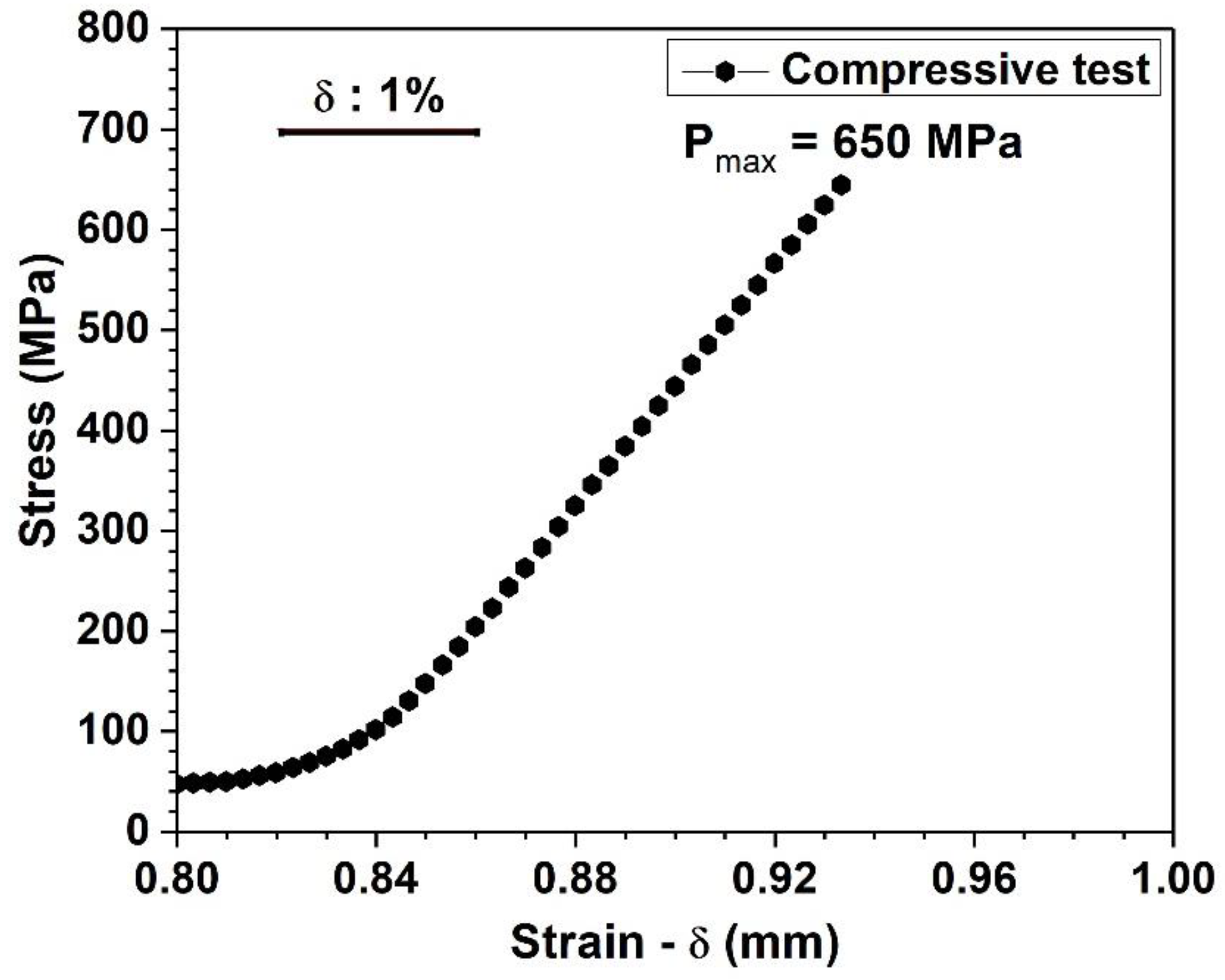

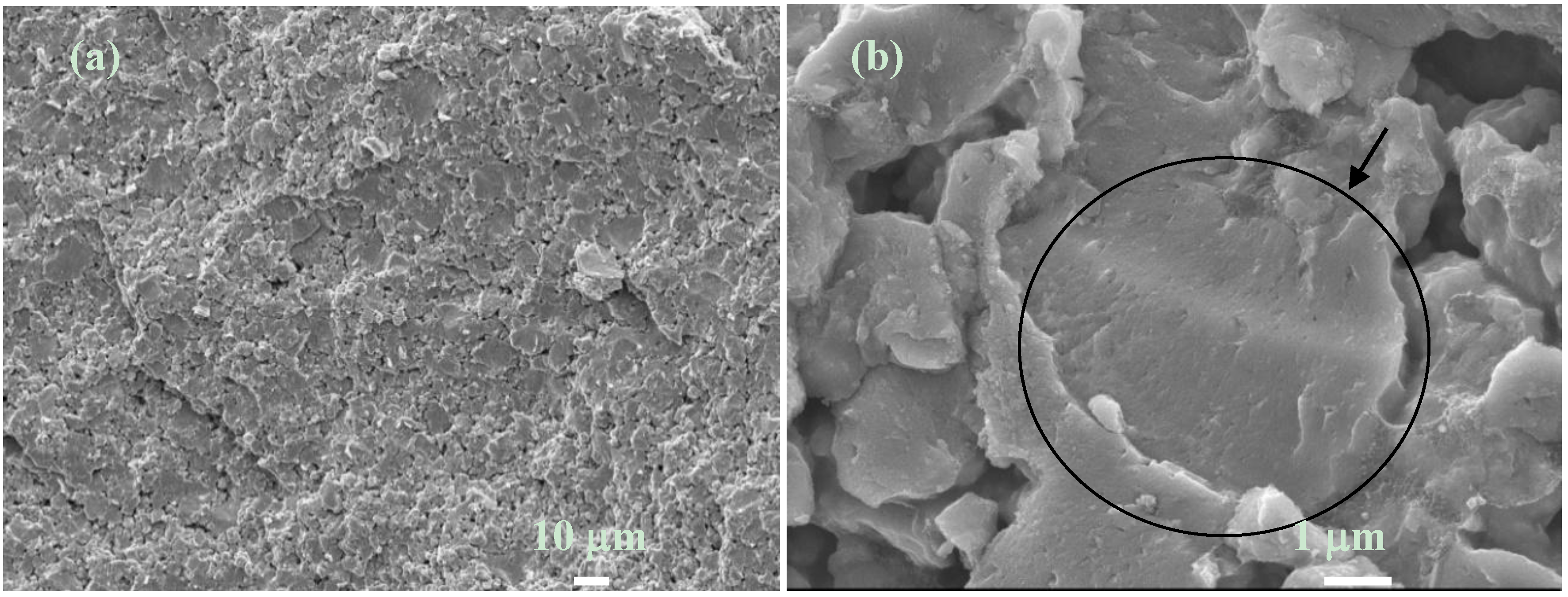

3.2. Consolidation and Mechanical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Inoue, A.; Kita, K.; Ohtera, K.; Kimura, H.; Masumoto, T. Al-Y-Ni amorphous powders prepared by high-pressure gas atomization. J. Mater. Sci. Lett. 1988, 7, 1287–1290. [Google Scholar] [CrossRef]

- Ye, F.; Lu, K. Crystallization kinetics of Al–La–Ni amorphous alloy. J. Non Cryst. Solids 2000, 262, 228–235. [Google Scholar] [CrossRef]

- Zhang, Z.; Witkin, D.; Lavernia, E.J. Crystallization behavior of a gas atomized Al85Ni10La5 amorphous alloy. J. Non Cryst. Solids 2005, 351, 1646–1652. [Google Scholar] [CrossRef]

- Scudino, S.; Surreddi, K.B.; Nguyen, H.V.; Liu, G.; Gemming, T.; Sakaliyska, M.; Kim, J.S.; Vierke, J.; Wollgarten, M.; Eckert, J. High-strength Al87Ni8La5 bulk alloy produced by spark plasma sintering of gas atomized powders. J. Mater. Res. 2011, 24, 2909–2916. [Google Scholar] [CrossRef]

- Zhuo, L.-C.; Pang, S.-J.; Wang, H.; Zhang, T. Ductile Bulk Aluminum-Based Alloy with Good Glass-Forming Ability and High Strength. Chin. Phys. Lett. 2009, 26, 066402. [Google Scholar]

- Inoue, A.; Matsumoto, N.; Masumoto, T. Al-Ni-Y-Co Amorphous Alloys with High Mechanical Strengths, Wide Supercooled Liquid Region and Large Glass-Forming Capacity. Mater. Trans. JIM 1990, 31, 493–500. [Google Scholar] [CrossRef]

- Kim, Y.-H.; Inoue, A.; Masumoto, T. Mechanical properties of Al88(Y1−xCex)2Ni9Fe1(x = 0, 0.5, 1) amorphous alloys containing nanoscale fcc-Al particles. J. Jpn. Inst. Met. 1992, 42, 217–223. [Google Scholar] [CrossRef]

- Zhong, Z.C.; Jiang, X.Y.; Greer, A.L. Nanocrystallization in Al-based amorphous alloys. Philos. Mag. B 1997, 76, 505–510. [Google Scholar] [CrossRef]

- Tsai, A.P.; Kamiyama, T.; Kawamura, Y.; Inoue, A.; Masumoto, T. Formation and precipitation mechanism of nanoscale Al particles in Al-Ni base amorphous alloys. Acta Mater. 1997, 45, 1477–1487. [Google Scholar] [CrossRef]

- Gloriant, T.; Greer, A.L. Al-based nanocrystalline composites by rapid solidification of Al-Ni-Sm alloys. Nanostruct. Mater. 1998, 10, 389–396. [Google Scholar] [CrossRef]

- Johnson, W.L. Bulk Glass-Forming Metallic Alloys: Science and Technology. MRS Bull. 2013, 24, 42–56. [Google Scholar] [CrossRef]

- Wang, W.H. Bulk Metallic Glasses with Functional Physical Properties. Adv. Mater. 2009, 21, 4524–4544. [Google Scholar] [CrossRef]

- Eckert, J.; Das, J.; Pauly, S.; Duhamel, C. Mechanical properties of bulk metallic glasses and composites. J. Mater. Res. 2011, 22, 285–301. [Google Scholar] [CrossRef]

- Xu, J.; Ramamurty, U.; Ma, E. The fracture toughness of bulk metallic glasses. JOM 2010, 62, 10–18. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Inoue, A. Bulk Metallic Glasses; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Masumoto, T. Recent progress in amorphous metallic materials in Japan. Mater. Sci. Eng. A 1994, 179–180, 8–16. [Google Scholar] [CrossRef]

- Peker, A.; Johnson, W.L. A highly processable metallic glass: Zr41.2Ti13.8Cu12.5Ni10.0Be22.5. Appl. Phys. Lett. 1993, 63, 2342–2344. [Google Scholar] [CrossRef]

- Schroers, J.; Johnson, W.L. Highly processable bulk metallic glass-forming alloys in the Pt–Co–Ni–Cu–P system. Appl. Phys. Lett. 2004, 84, 3666–3668. [Google Scholar] [CrossRef]

- Inoue, A.; Zhang, T.; Nishiyama, N.; Ohba, K.; Masumoto, T. Preparation of 16 mm Diameter Rod of Amorphous Zr65Al7.5Ni10Cu17.5 Alloy. Mater. Trans. JIM 1993, 34, 1234–1237. [Google Scholar] [CrossRef]

- Perepezko, J.H.; Smith, J.S. Glass formation and crystallization in highly undercooled Te-Cu alloys. J. Non Cryst. Solids 1981, 44, 65–83. [Google Scholar] [CrossRef]

- Si, P.; Bian, X.; Li, W.; Zhang, J.; Yang, Z. Relationship between intermetallic compound formation and glass forming ability of Al–Ni–La alloy. Phys. Lett. A 2003, 319, 424–428. [Google Scholar] [CrossRef]

- Tavoosi, M.; Karimzadeh, F.; Enayati, M.H.; Kim, H.S. Consolidation of amorphous Al80Fe10Ti5Ni5 powders by hot pressing. J. Nanomater. 2012, 2012. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Johnson, W.L. Thermodynamic and kinetic aspects of the crystal to glass transformation in metallic materials. Prog. Mater. Sci. 1986, 30, 81–134. [Google Scholar] [CrossRef]

- Choi, P.P.; Kim, J.S.; Nguyen, O.T.H.; Kwon, D.H.; Kwon, Y.S.; Kim, J.C. Al-La-Ni-Fe bulk metallic glasses produced by mechanical alloying and spark-plasma sintering. Mater. Sci. Eng. A 2007, 449–451, 1119–1122. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Nguyen, O.T.H.; Dudina, D.V.; Le, V.V.; Kim, J.-S. Crystallization Kinetics of Al-Fe and Al-Fe-Y Amorphous Alloys Produced by Mechanical Milling. J. Nanomater. 2016, 2016. [Google Scholar] [CrossRef]

- Schultz, L. Formation of amorphous metals by mechanical alloying. Mater. Sci. Eng. 1988, 97, 15–23. [Google Scholar] [CrossRef]

- Dudina, D.V.; Mukherjee, A.K. Reactive Spark Plasma Sintering: Successes and Challenges of Nanomaterial Synthesis. J. Nanomater. 2013, 2013. [Google Scholar] [CrossRef]

- Yurlova, M.S.; Demenyuk, V.D.; Lebedeva, L.Y.; Dudina, D.V.; Grigoryev, E.G.; Olevsky, E.A. Electric pulse consolidation: An alternative to spark plasma sintering. J. Mater. Sci. 2014, 49, 952–985. [Google Scholar] [CrossRef]

- Kim, S.-Y.; Lee, G.-Y.; Park, G.-H.; Kim, H.-A.; Lee, A.Y.; Scudino, S.; Prashanth, K.G.; Kim, D.-H.; Eckert, J.; Lee, M.-H. High strength nanostructured Al-based alloys through optimized processing of rapidly quenched amorphous precursors. Sci. Rep. 2018, 8, 1090. [Google Scholar] [CrossRef] [PubMed]

- Li, X.P.; Yan, M.; Ji, G.; Qian, M. Applied pressure on altering the nano-crystallization behavior of Al86Ni6Y4.5Co2La1.5 metallic glass powder during spark plasma sintering and its effect on powder consolidation. J. Nanomater. 2013, 2013. [Google Scholar] [CrossRef]

- Vidyasagar, C.S.; Karunakar, D.B. Development of 2024 AA-Yttrium composites by Spark Plasma Sintering. IOP Conf. Ser. Mater. Sci. Eng. 2018, 346, 012050. [Google Scholar] [CrossRef]

- Surreddi, K.B.; Srivastava, V.C.; Scudino, S.; Sakaliyska, M.; Uhlenwinkel, V.; Kim, J.S.; Eckert, J. Production of high-strength Al85Y8Ni5Co2 bulk alloy by spark plasma sintering. J. Phys. Conf. Ser. 2010, 240, 012155. [Google Scholar] [CrossRef]

- Surreddi, K.B.; Scudino, S.; Sakaliyska, M.; Prashanth, K.G.; Sordelet, D.J.; Eckert, J. Crystallization behavior and consolidation of gas-atomized Al84Gd6Ni7Co3 glassy powder. J. Alloys Compd. 2010, 491, 137–142. [Google Scholar] [CrossRef]

- Heireche, L.; Belhadji, M. The methods Matusita, Kissinger and Ozawa in the study of the crystallization of glasses. The case of Ge-Sb-Te alloys. Chalcogenide Lett. 2007, 4, 23–33. [Google Scholar]

- Mehta, N.; Agarwal, P.; Kumar, A. A study of the crystallization kinetics in Se68Ge22Pb10 chalcogenide glass. Indian J. Eng. Mater. Sci. 2004, 11, 511–515. [Google Scholar]

- Roy, D.; Raghuvanshi, H. Study on crystallization kinetics of Al65Cu20Ti15 amorphous alloy. J. Non Cryst. Solids 2011, 357, 1701–1704. [Google Scholar] [CrossRef]

- Sahoo, K.L.; Rao, V.; Mitra, A. Crystallization Kinetics in an Amorphous Al-Ni-Mm-Fe Alloy. Mater. Trans. 2003, 44, 1075–1080. [Google Scholar] [CrossRef]

- Wang, X.; Wang, D.; Zhu, B.; Li, Y.; Han, F. Crystallization kinetics and thermal stability of mechanically alloyed Al76Ni8Ti8Zr4Y4 glassy powder. J. Non Cryst. Solids 2014, 385, 111–116. [Google Scholar] [CrossRef]

- Basu, J.; Ranganathan, S. Crystallisation in Al–ETM–LTM–La metallic glasses. Intermetallics 2004, 12, 1045–1050. [Google Scholar] [CrossRef]

- Mohammadi Rahvard, M.; Tamizifar, M.; Boutorabi, S.M.A. Non-isothermal crystallization kinetics and fragility of Zr56Co28Al16 and Zr56Co22Cu6Al16 bulk metallic glasses. J. Therm. Anal. Calorim. 2018. [Google Scholar] [CrossRef]

- Petersen, A.S.; Cheung, A.M.; Neilson, H.J.; Poon, S.J.; Shiflet, G.J.; Lewandowski, J.J. Processing and Properties of Ni-Based Bulk Metallic Glass via Spark Plasma Sintering of Pulverized Amorphous Ribbons. MRS Adv. 2017, 2, 3815–3820. [Google Scholar] [CrossRef]

- Rometsch, P.A.; Zhang, Y.; Knight, S. Heat treatment of 7xxx series aluminium alloys—Some recent developments. Trans. Nonferrous Met. Soc. China 2014, 24, 2003–2017. [Google Scholar] [CrossRef]

- Sheng, X.; Lei, Q.; Xiao, Z.; Wang, M. Hot Deformation Behavior of a Spray-Deposited Al-8.31Zn-2.07Mg-2.46Cu-0.12Zr Alloy. Metals 2017, 7, 299. [Google Scholar] [CrossRef]

| Heating Rate β, K/min | ΔTx (K) | Tx1 (K) | Tp1 (K) | Tx2 (K) | Tp2 (K) |

|---|---|---|---|---|---|

| 5 | 24.3 | 636.6 | 651.6 | 686.2 | 689.3 |

| 10 | 23.5 | 638.9 | 652.6 | 690.5 | 693.0 |

| 20 | 23.1 | 641.1 | 653.7 | 690.8 | 694.3 |

| 40 | 24.1 | 648.2 | 662 | 695.6 | 701.0 |

| Peak | Methods | ||

|---|---|---|---|

| Kissinger | Ozawa | Augis-Bennett | |

| 1 | 432.33 | 443.20 | 437.76 |

| 2 | 456.75 | 468.25 | 462.50 |

| Peak | n | 40 K/min | 20 K/min | 10 K/min | 5 K/min |

|---|---|---|---|---|---|

| 1 | 1.41 | 1.16 | 1.33 | 1.42 | 1.71 |

| 2 | 3.61 | 2.07 | 3.12 | 4.84 | 4.41 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Viet, N.H.; Oanh, N.T.H.; Kim, J.-S.; Jorge, A.M., Jr. Crystallization Kinetics and Consolidation of Al82La10Fe4Ni4 Glassy Alloy Powder by Spark Plasma Sintering. Metals 2018, 8, 812. https://doi.org/10.3390/met8100812

Viet NH, Oanh NTH, Kim J-S, Jorge AM Jr. Crystallization Kinetics and Consolidation of Al82La10Fe4Ni4 Glassy Alloy Powder by Spark Plasma Sintering. Metals. 2018; 8(10):812. https://doi.org/10.3390/met8100812

Chicago/Turabian StyleViet, Nguyen Hoang, Nguyen Thi Hoang Oanh, Ji-Soon Kim, and Alberto Moreira Jorge, Jr. 2018. "Crystallization Kinetics and Consolidation of Al82La10Fe4Ni4 Glassy Alloy Powder by Spark Plasma Sintering" Metals 8, no. 10: 812. https://doi.org/10.3390/met8100812

APA StyleViet, N. H., Oanh, N. T. H., Kim, J.-S., & Jorge, A. M., Jr. (2018). Crystallization Kinetics and Consolidation of Al82La10Fe4Ni4 Glassy Alloy Powder by Spark Plasma Sintering. Metals, 8(10), 812. https://doi.org/10.3390/met8100812