The Influence of Laser Welding on the Mechanical Properties of Dual Phase and Trip Steels

Abstract

:1. Introduction

- Conversion efficiency of electric energy to the energy of the laser beam being higher by 30% compared to the CO2 lasers,

- Higher focusability that expands the field of industrial applicability,

- Improved flexibility and stability of output parameters,

- Increased dynamics of beam parameters with the possibility of shaping the rise and decay, and the tip of the laser pulse.

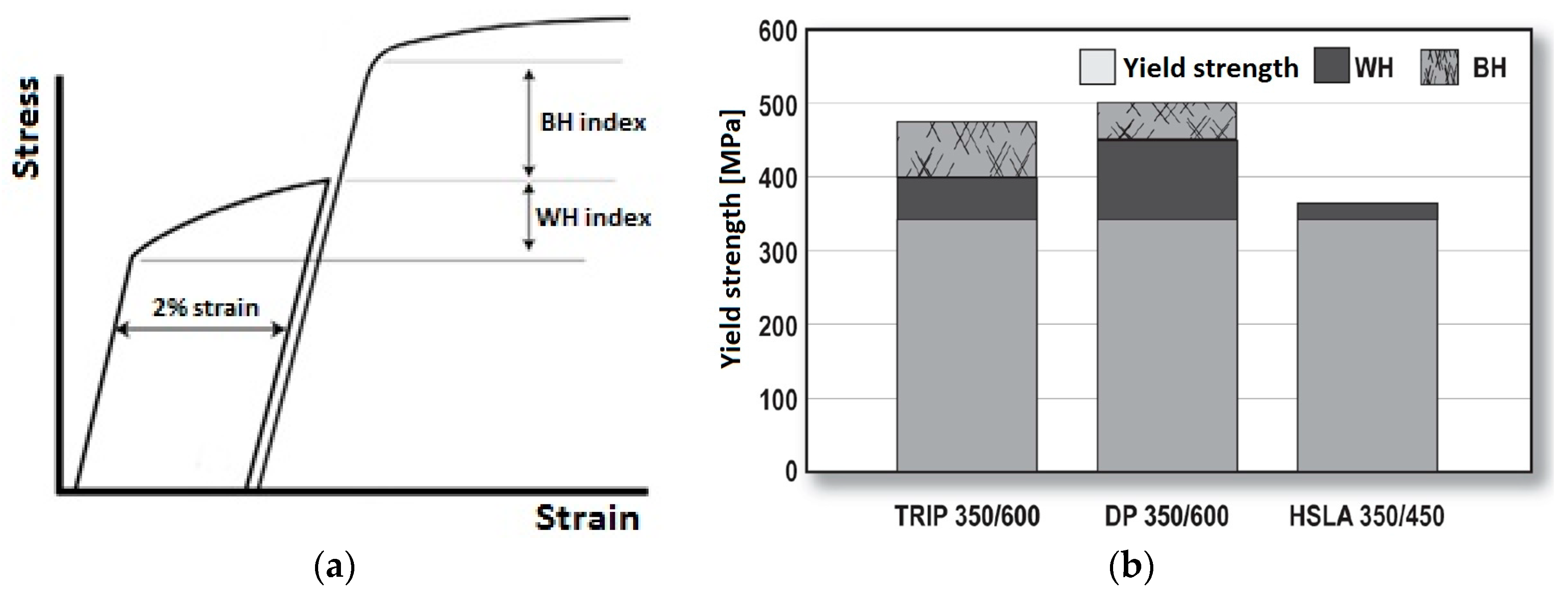

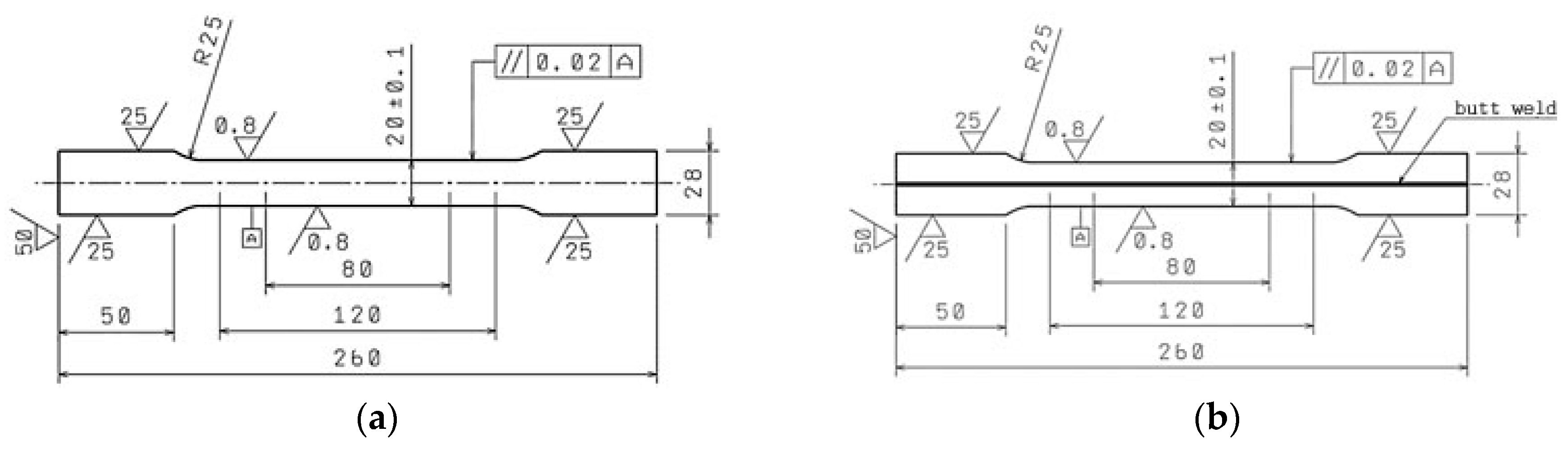

2. Materials and Methods

3. Results and Discussion

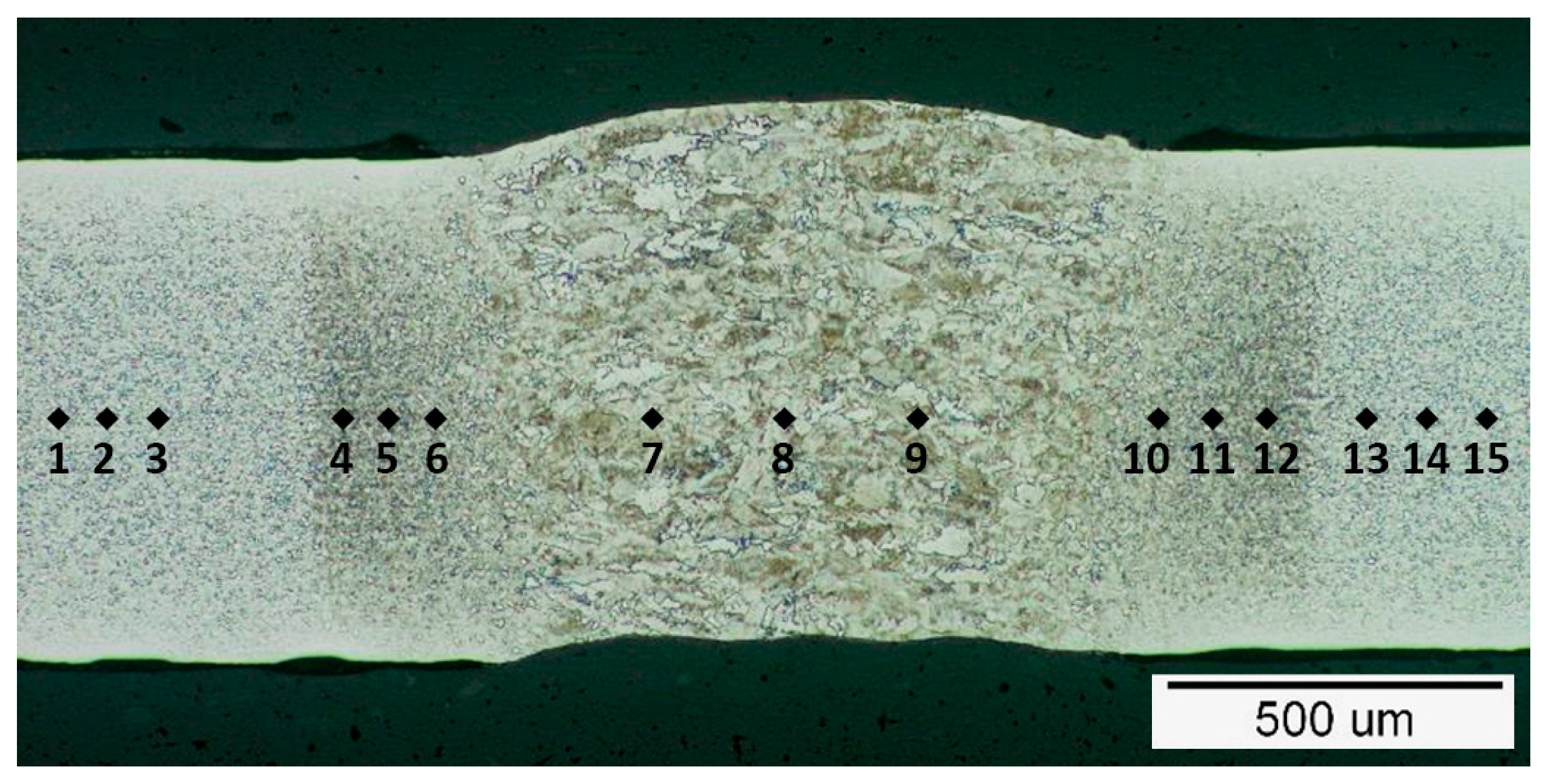

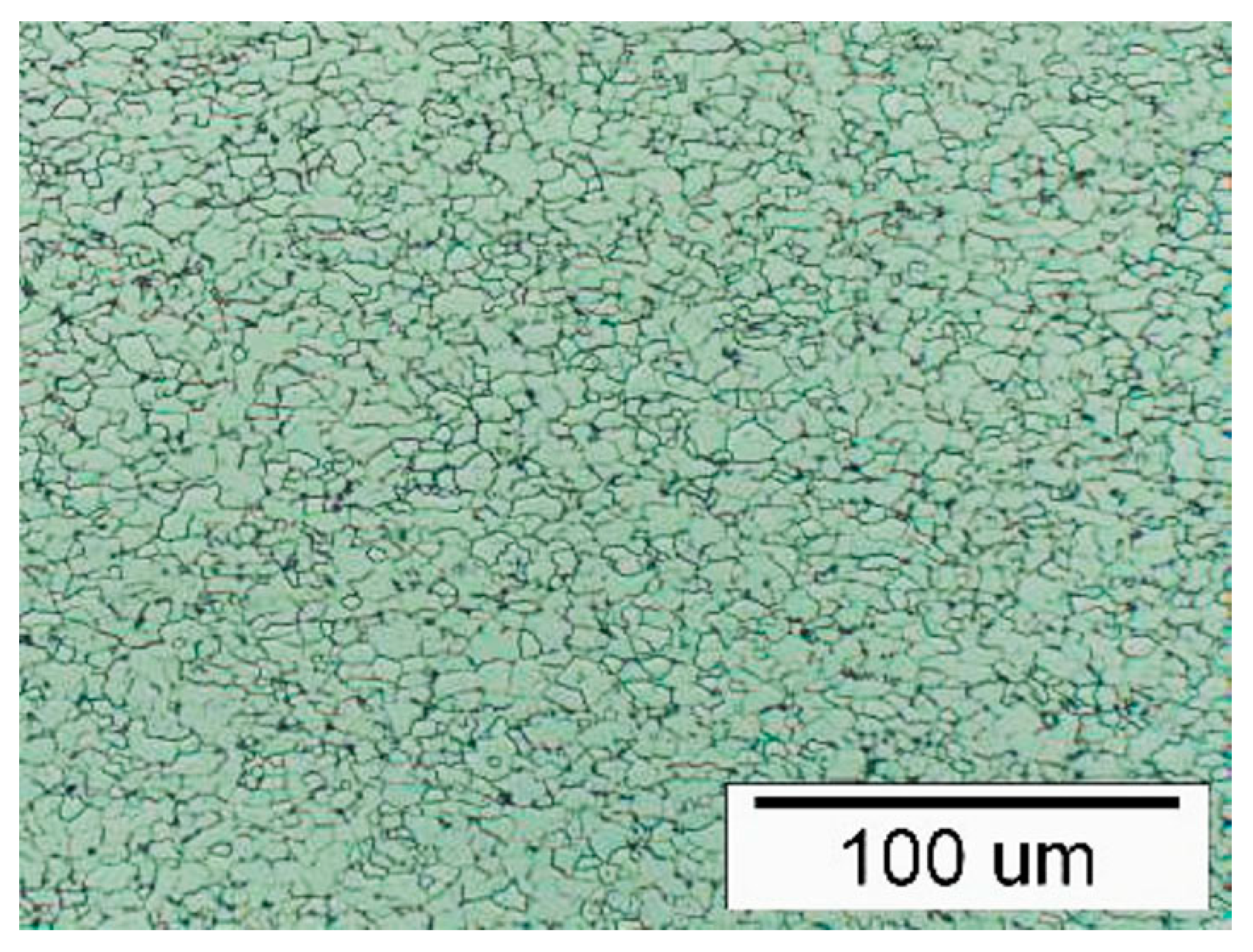

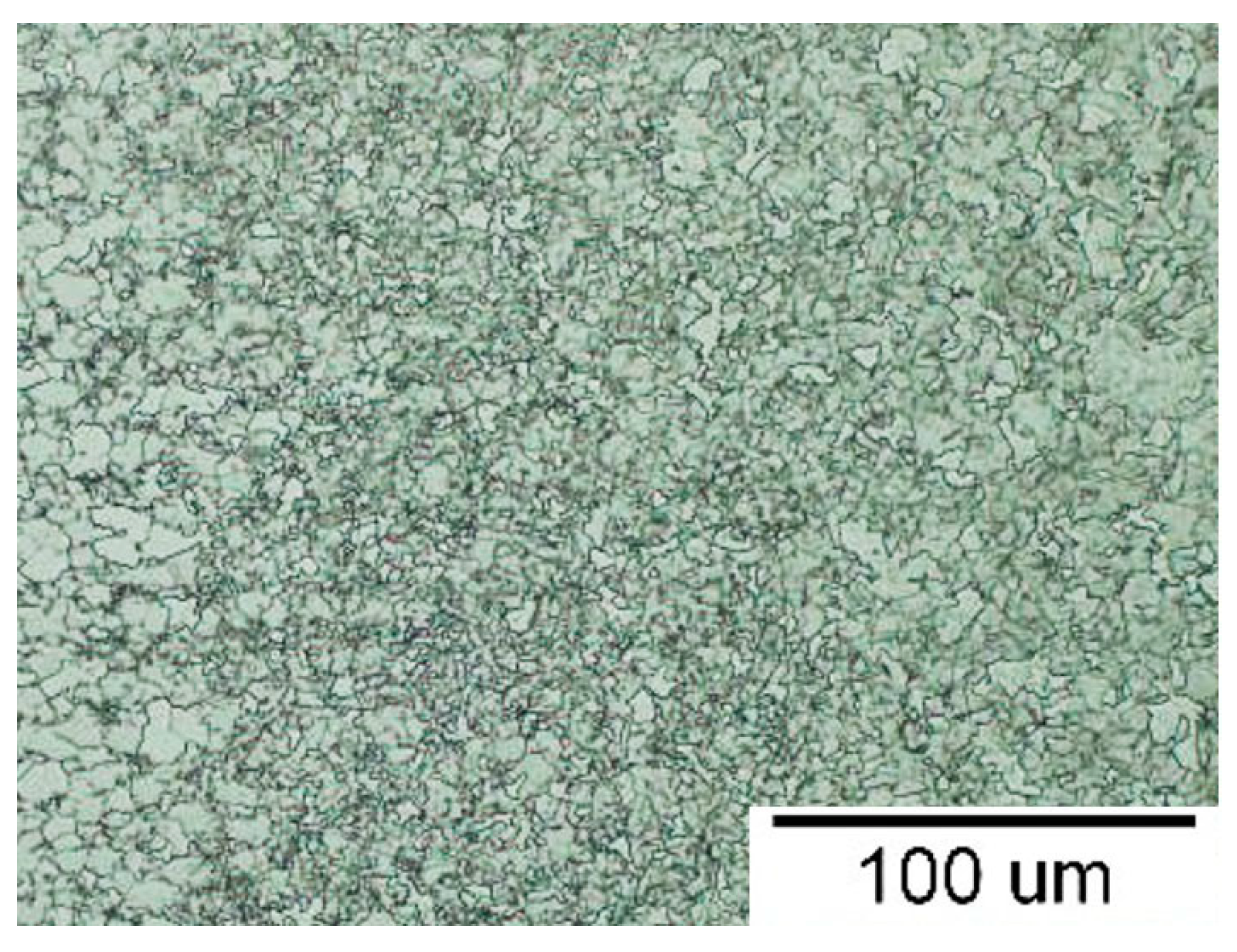

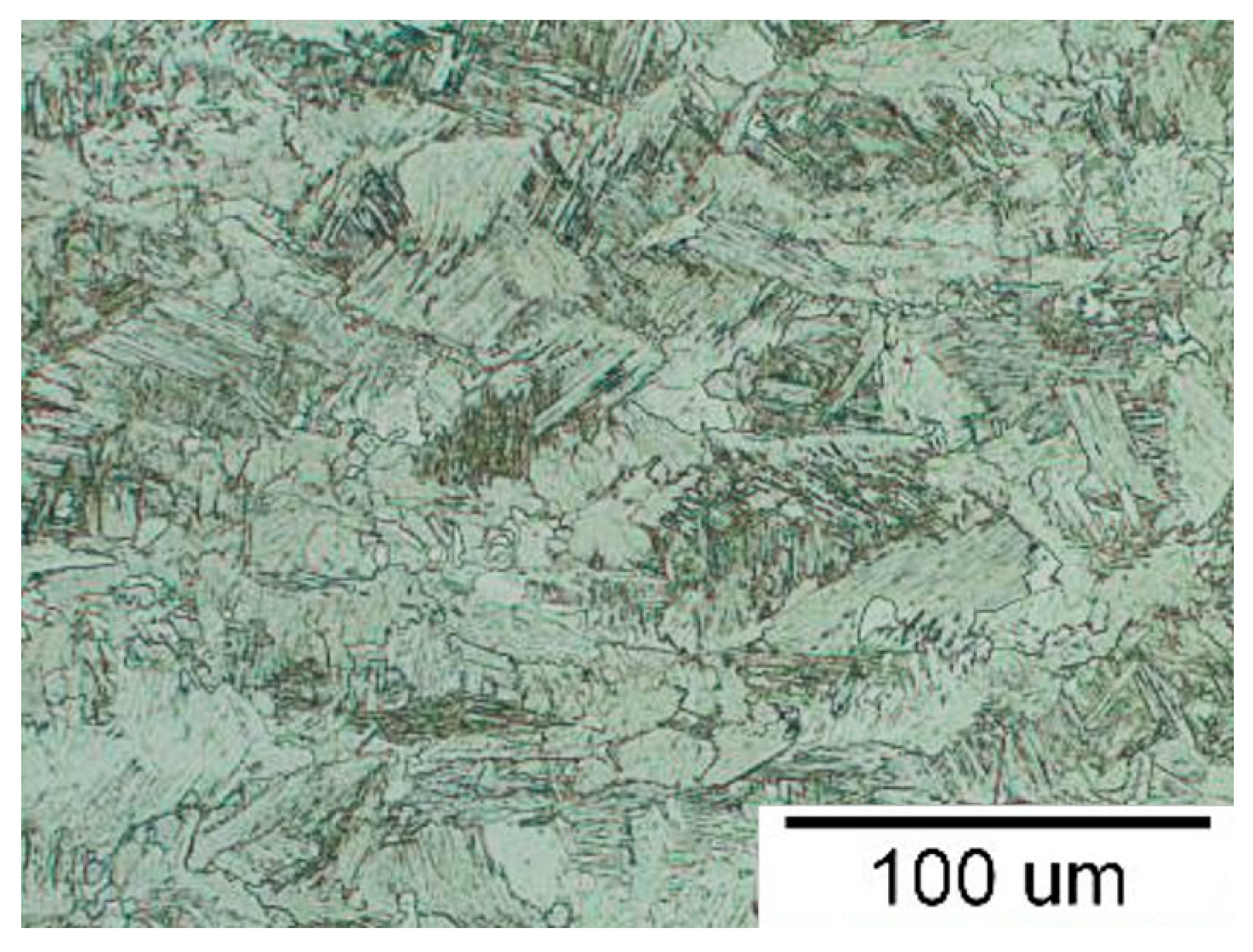

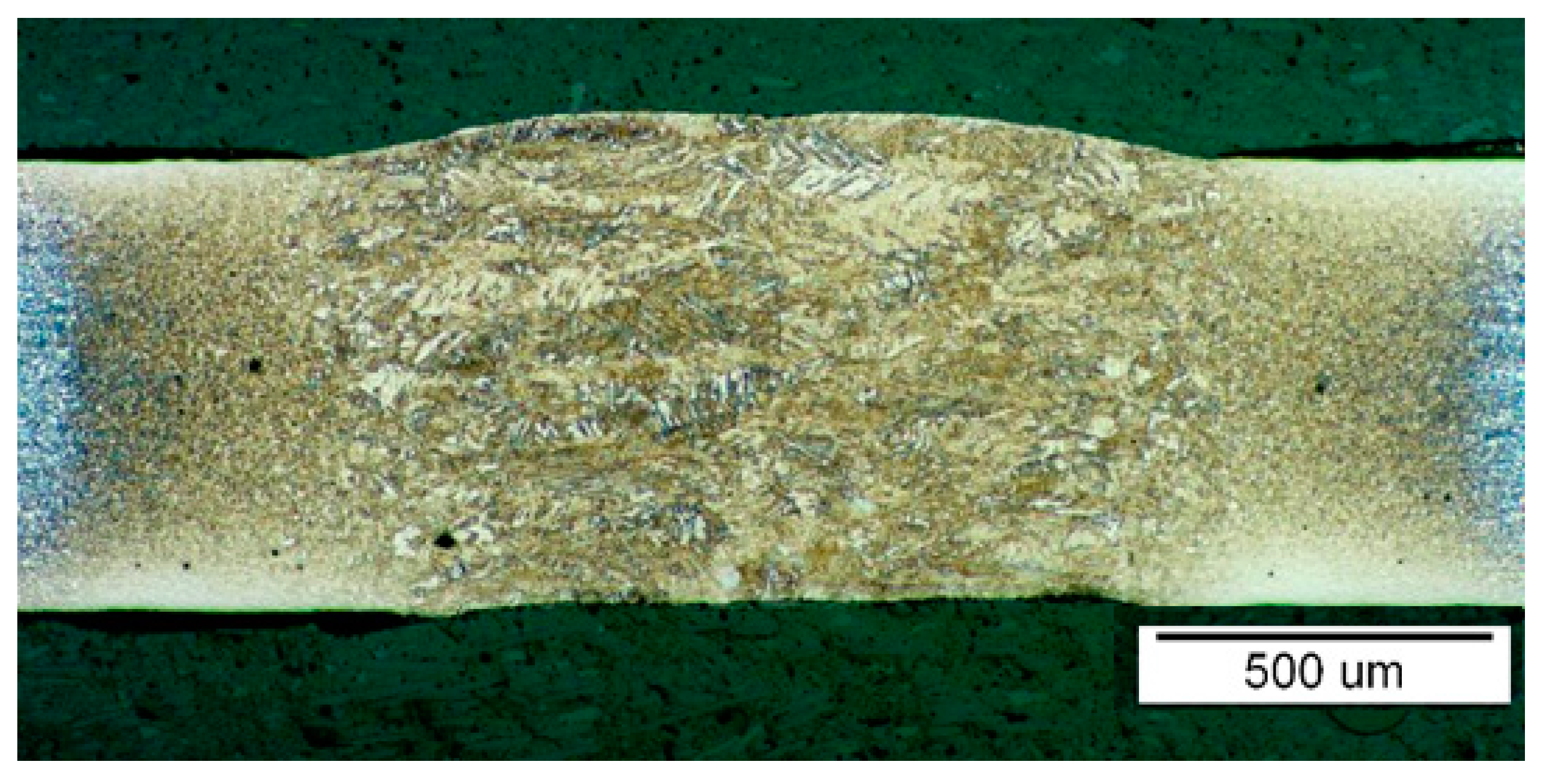

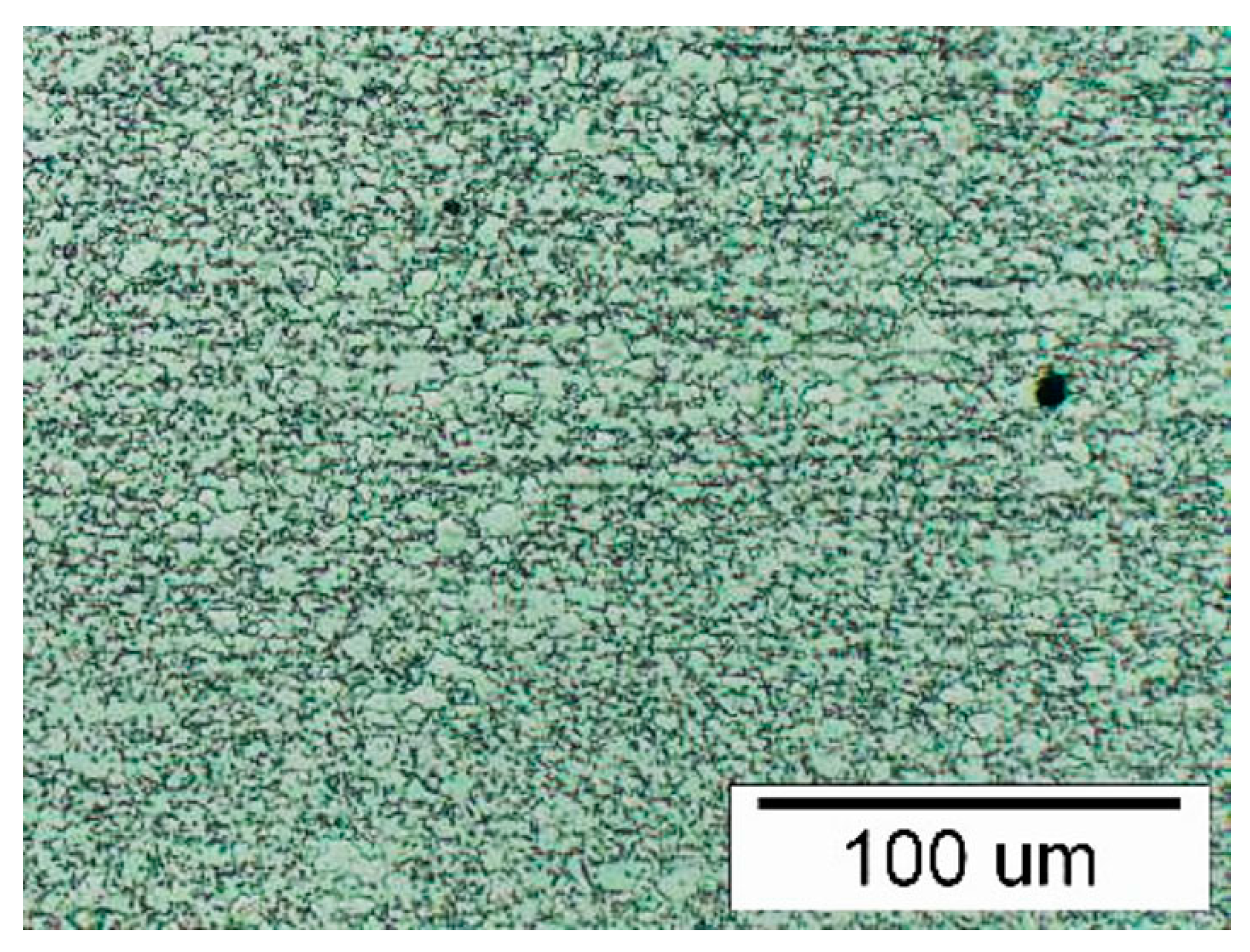

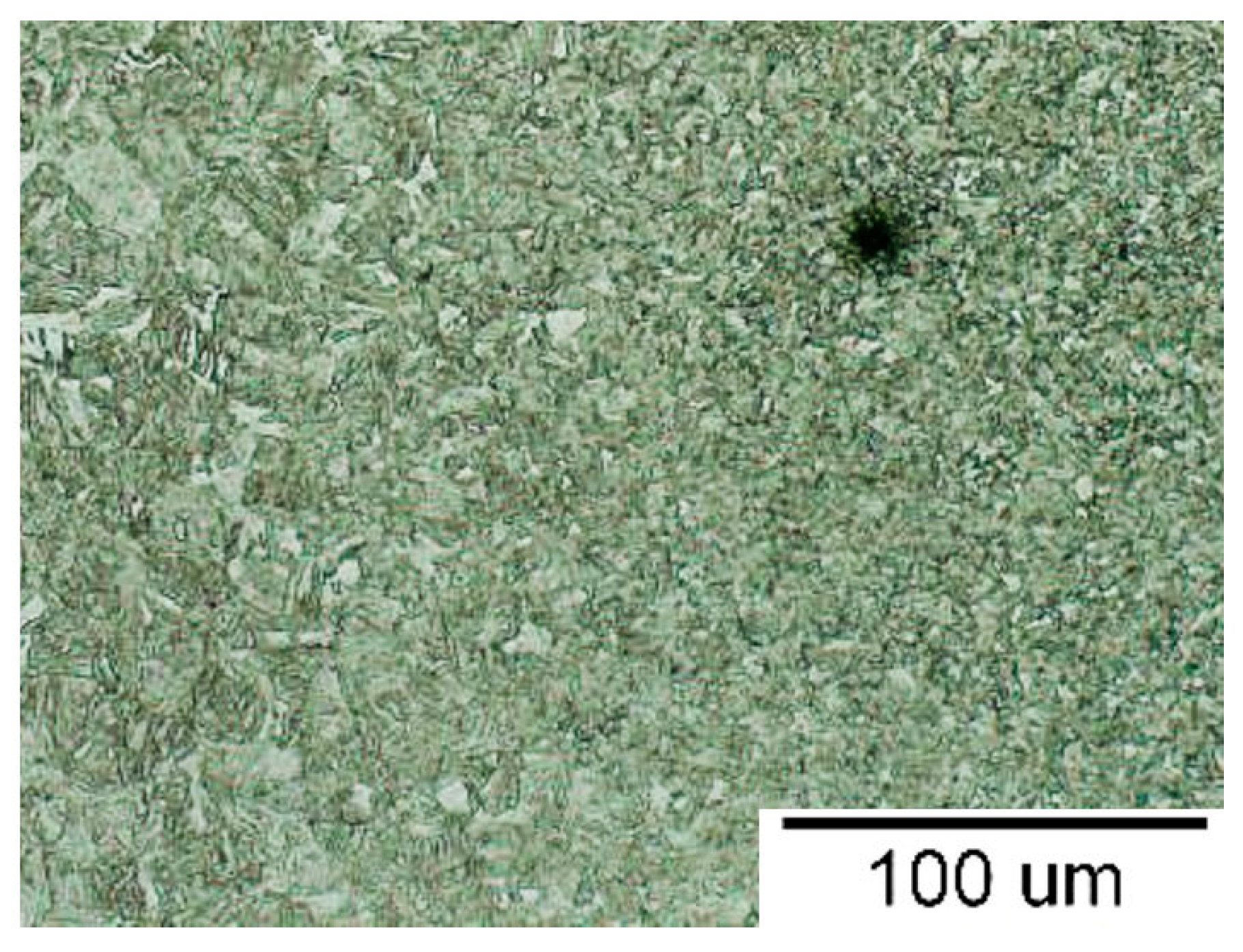

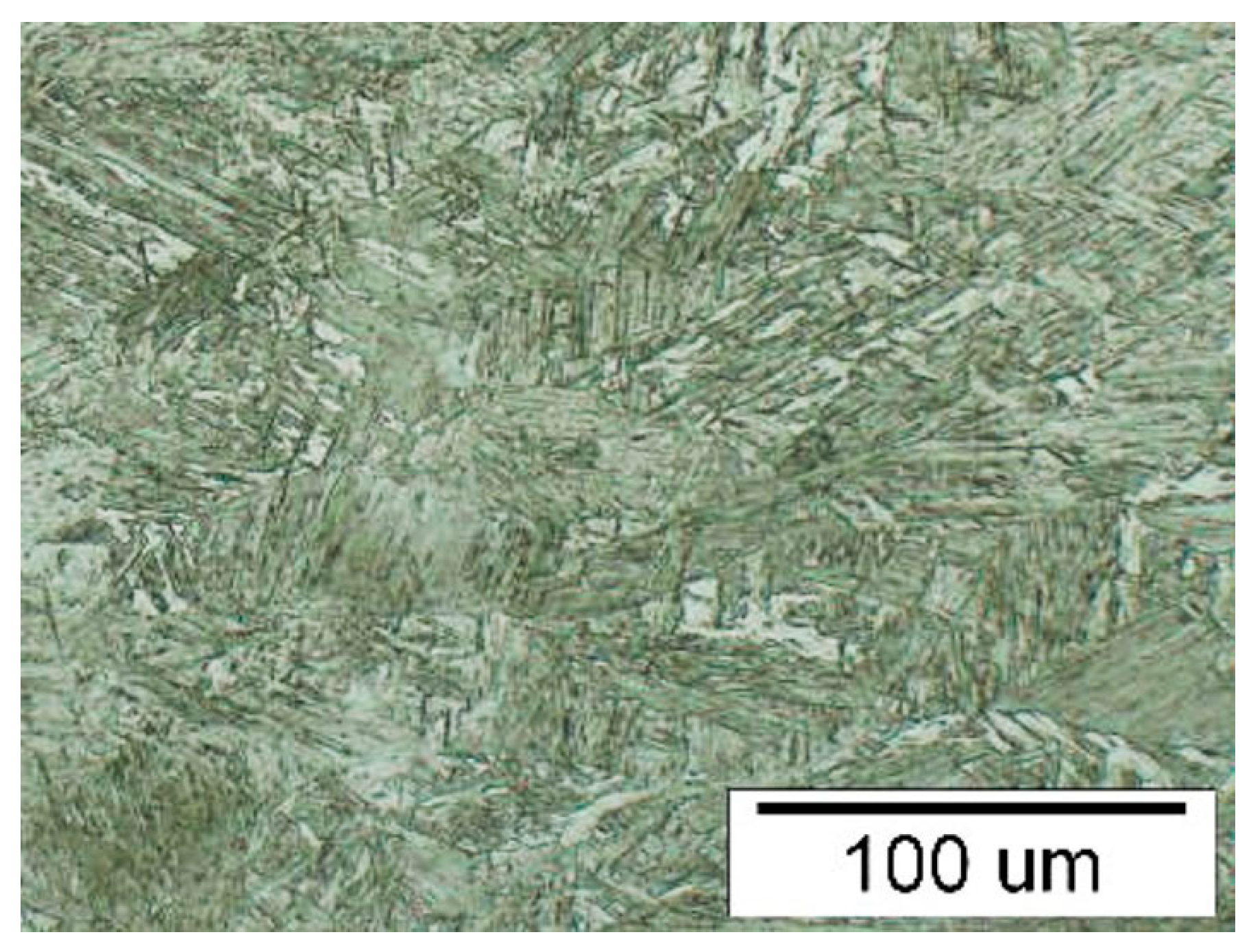

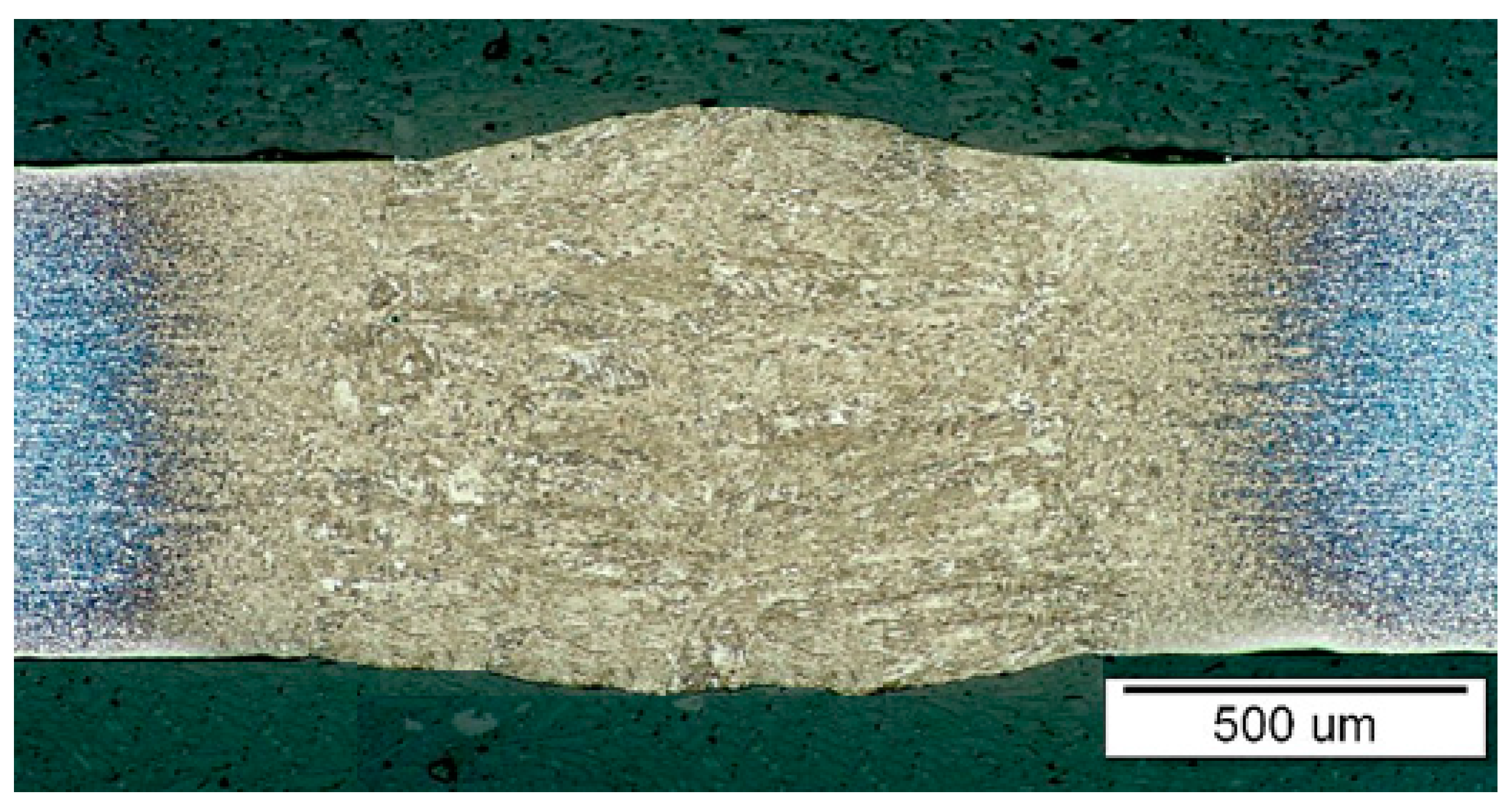

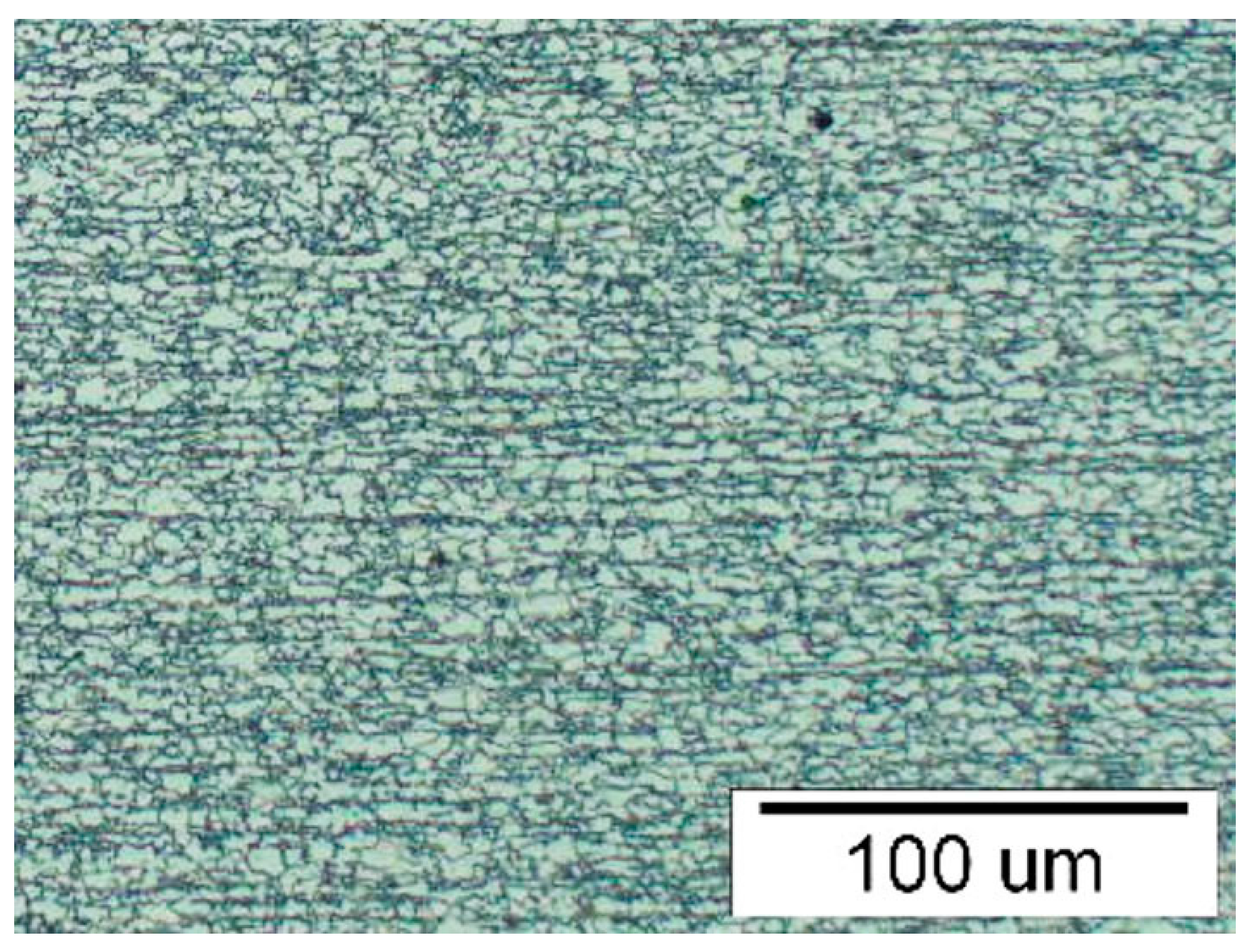

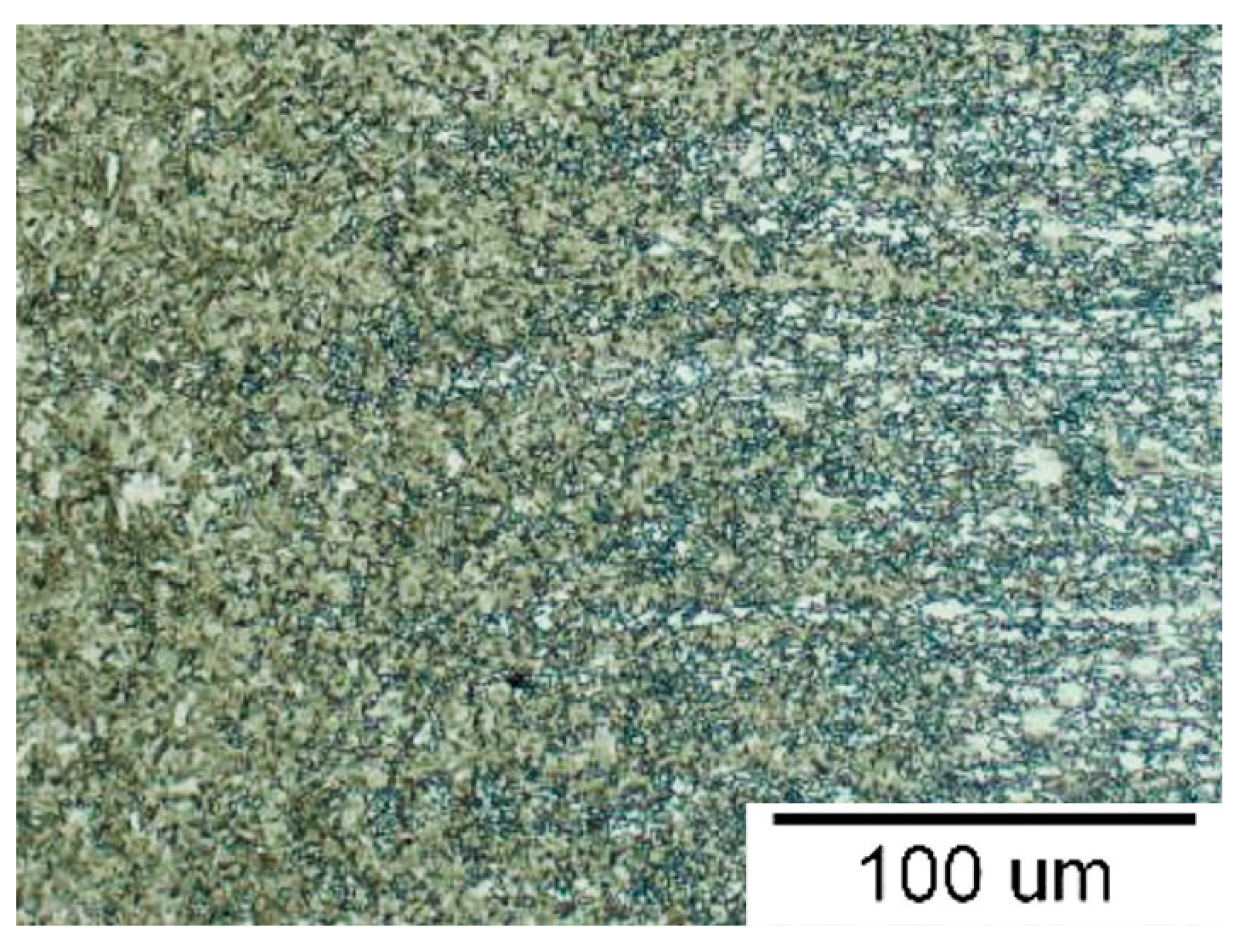

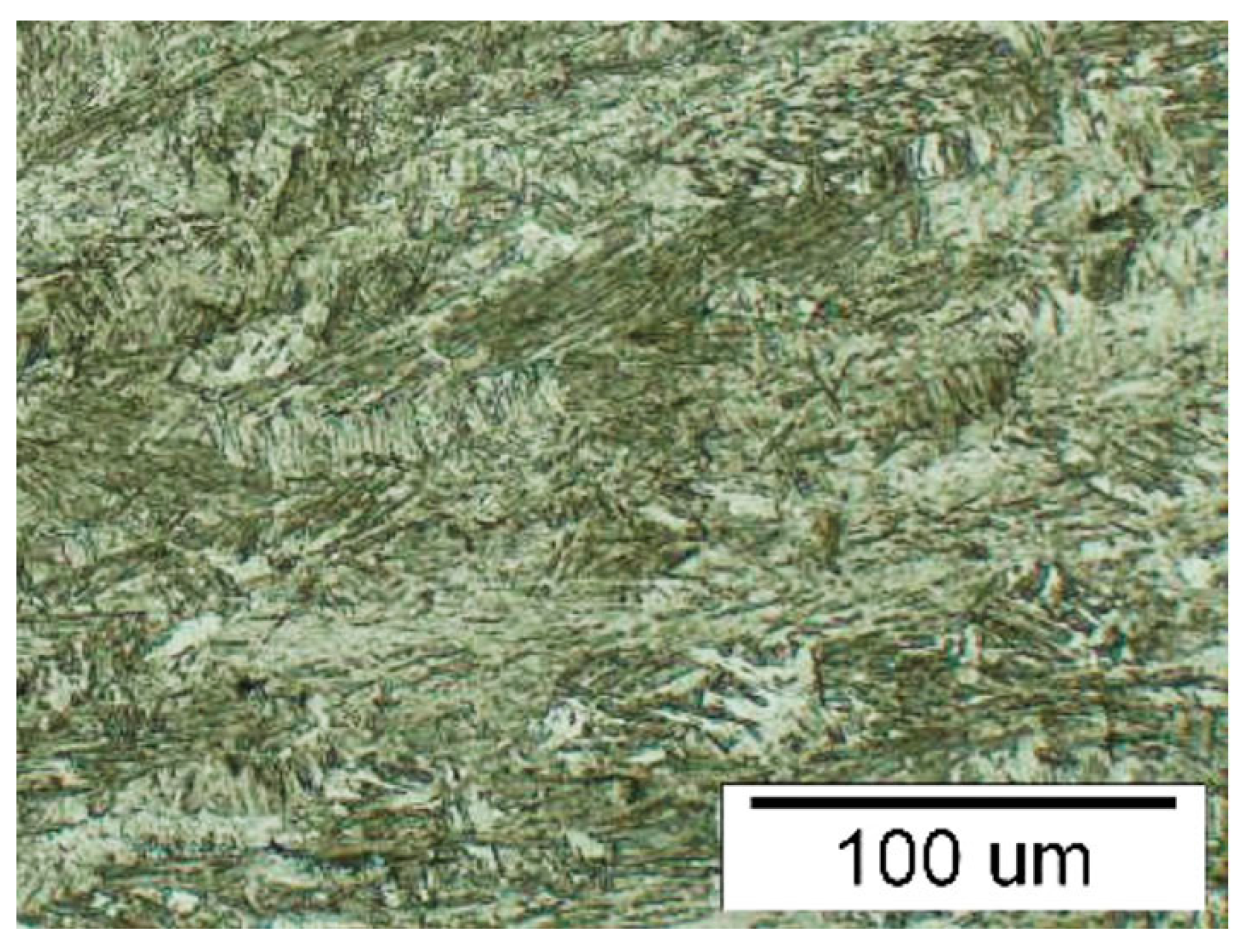

3.1. Analysis of Microstructure

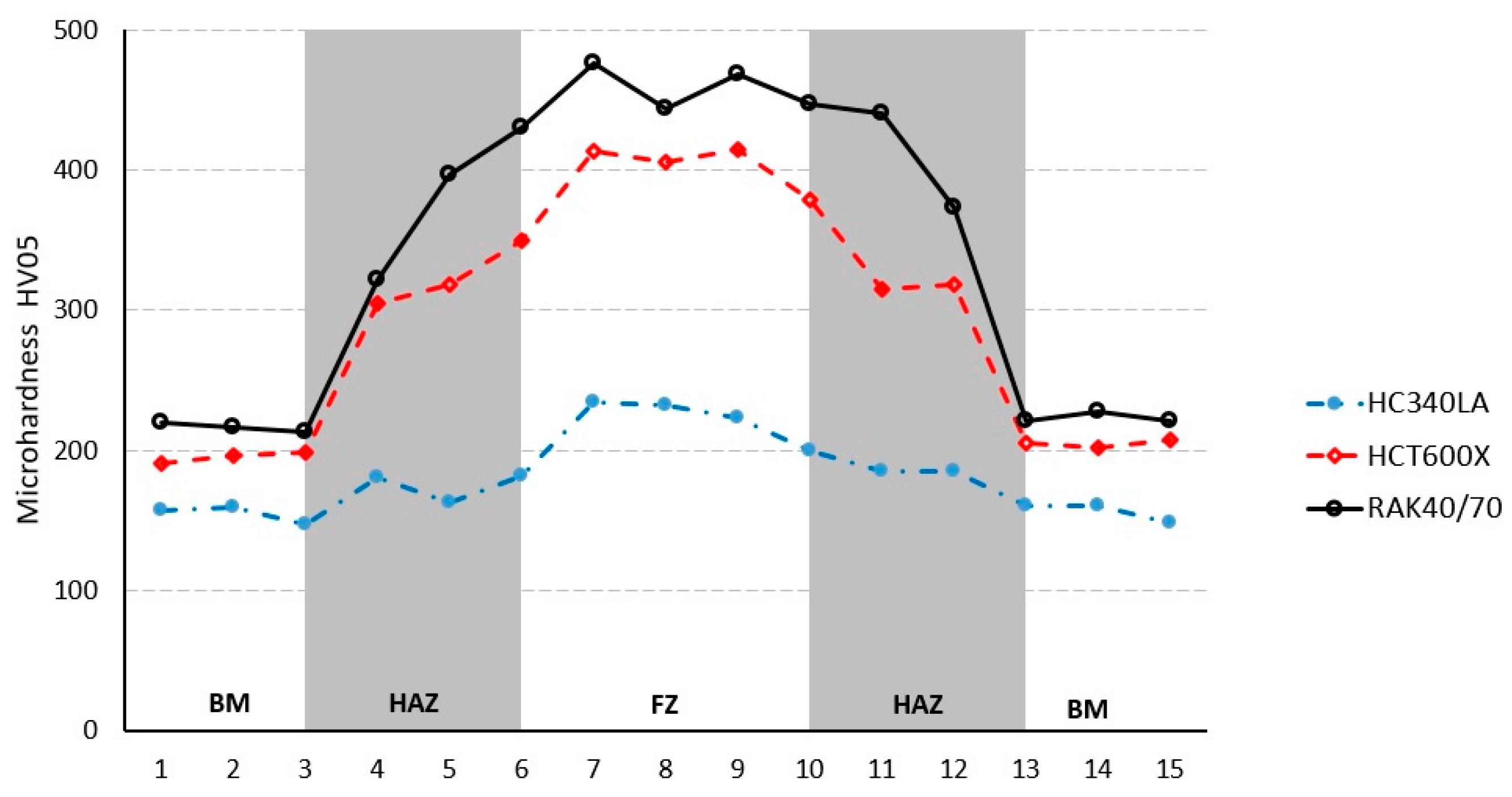

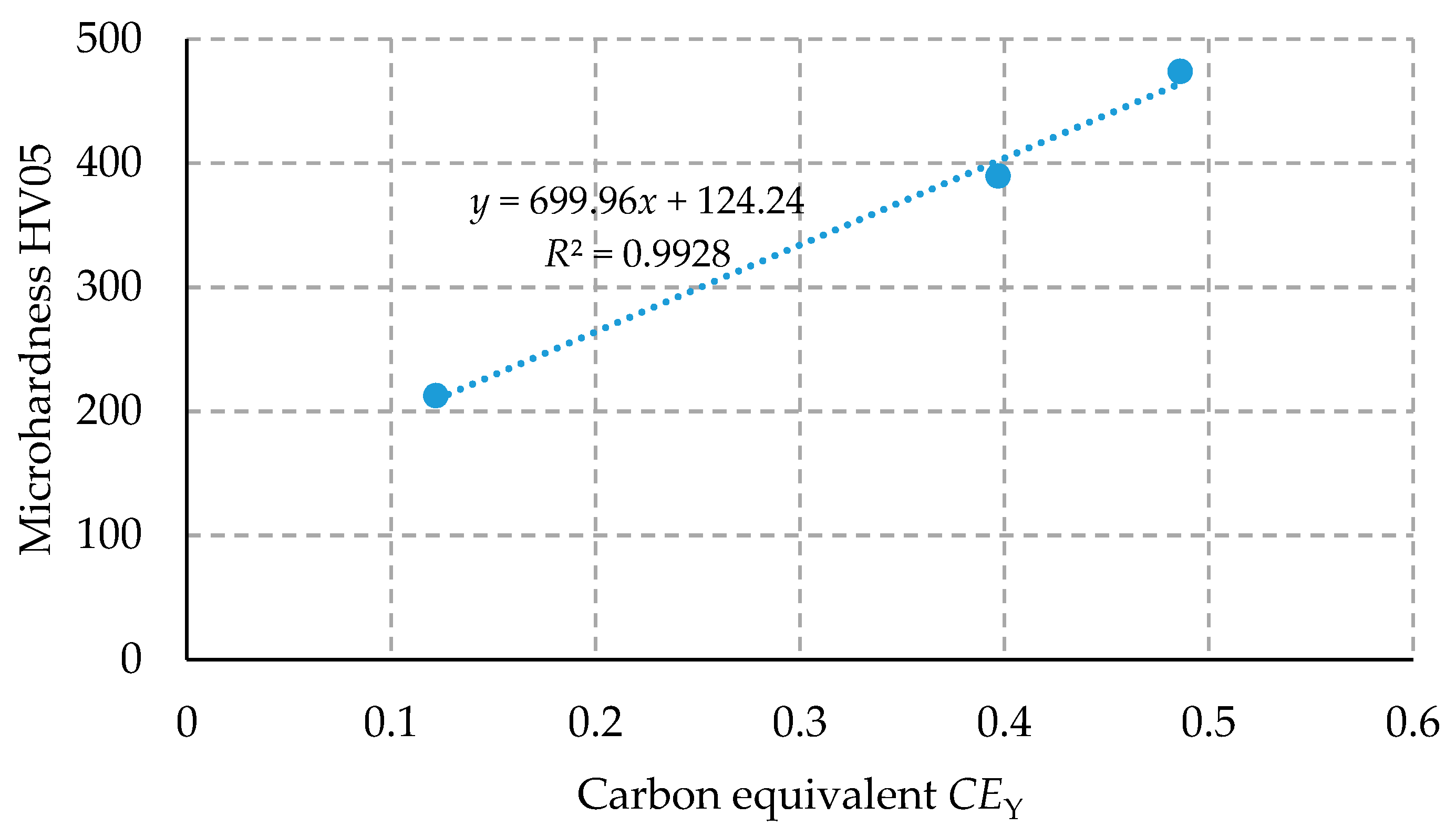

3.2. Analysis of Microhardness and Its Distribution

3.3. Analysis of Mechanical Properties

4. Conclusions

- The proper quality of laser-welded joints has been reached for lower welding speed and power: 50 mm·s−1 and 1700 W for low alloyed steel HC340LA-HC340LA; 50 mm·s−1 and 2000 W for dual phase steel HTC600X-HTC600X; and 50 mm·s−1 and 2000 W for multi-phase steel RAK40/70-RAK40/70. This is well correlated with results presented in [18,19,28,29].

- Laser-welded joints of experimental materials have shown proper quality of weld root and no porosity, and the good quality of joints has also been proven by tensile test, where fracture occurs in the base metal for each material.

- Microhardness HV05 measured in samples for microstructural analysis has shown the highest values in the fusion zone for each material, and these gradually declined in heat affected zones towards the base material. Any substantial soft zone has not been found for each material. Microhardness of the fusion zone is well correlated to the carbon equivalent calculated by Yoriuki. Higher scattering of microhardness has been found for dual phase and multi-phase steel as a result of microstructure in the fusion zone and heat affected zone.

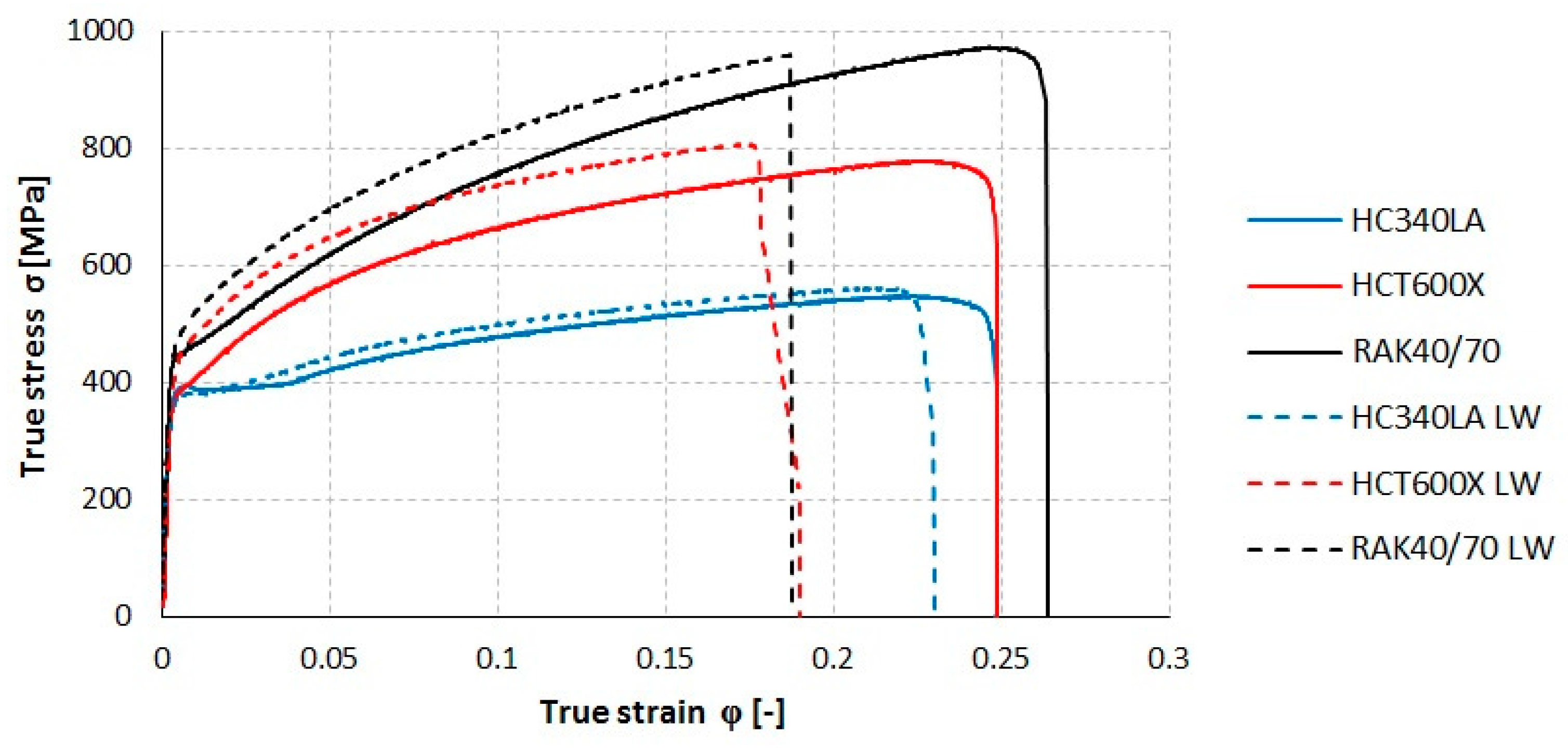

- Stress strain curves for base material and laser-welded ones show the same tendency for each material. The highest work hardening has been found for multi-phase steel RAK40/70 due to phase transformation of austenite to martensite when plastically deformed.

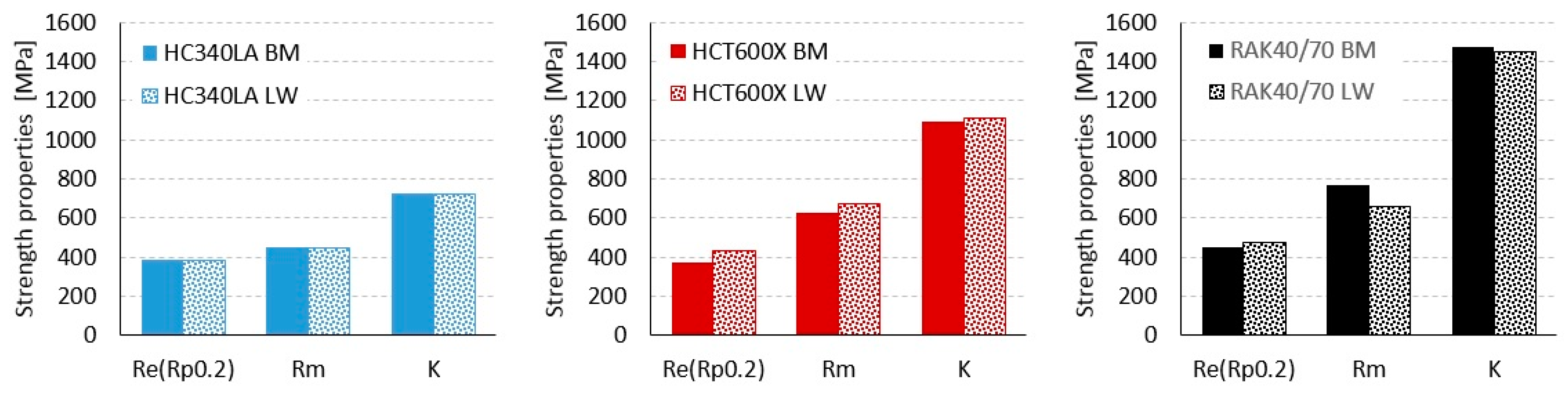

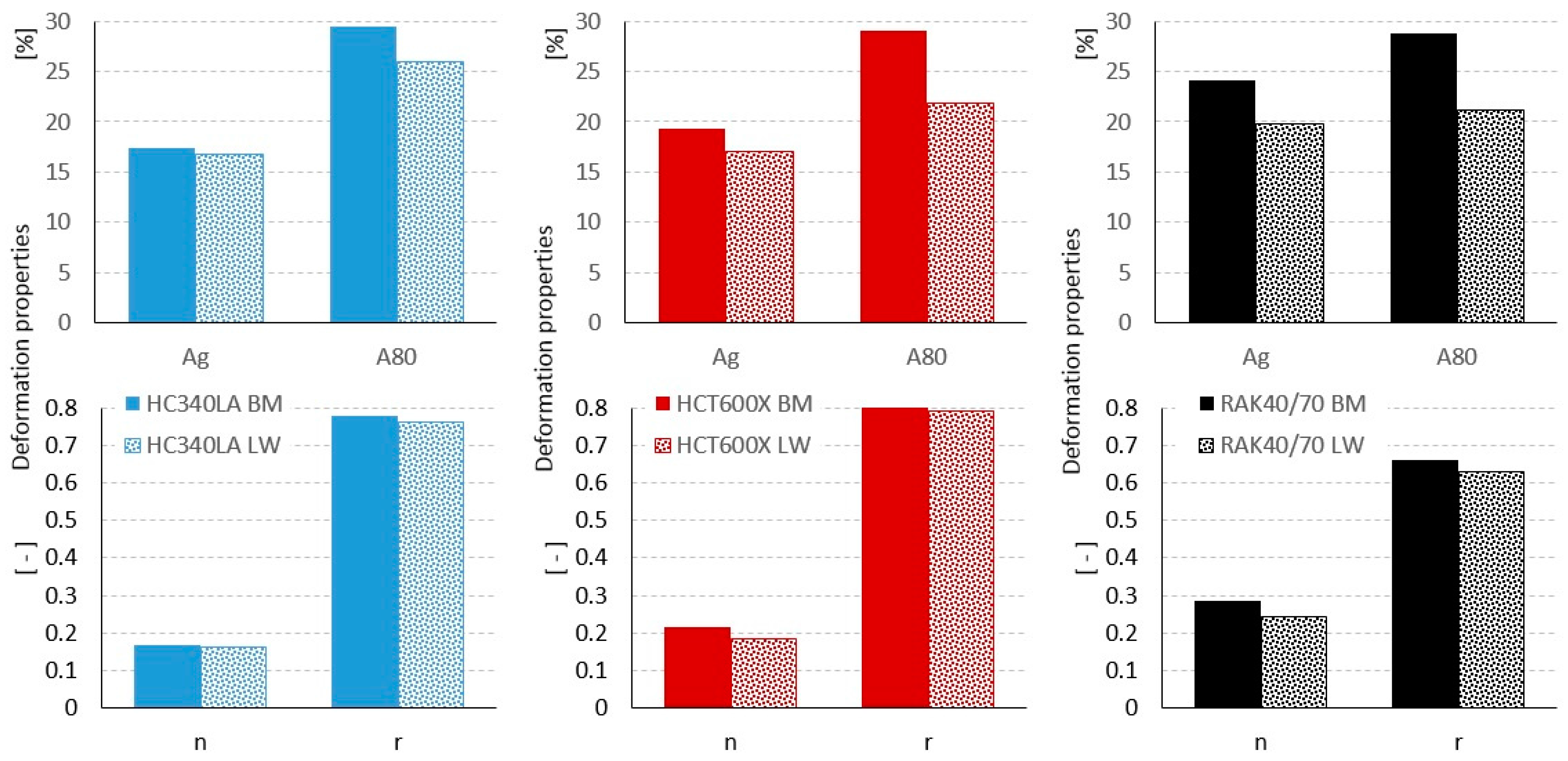

- Deformation properties are more sensitive than strength properties to the change of microstructure in the fusion zone. A greater change of uniform extension Ag and total extension A as well as a lower change of normal anisotropy ratio r and strain hardening exponent n—has been found for dual phase steel HTC600X-HTC600X and multi-phase steel RAK40/70-RAK40/70 when compared to low alloyed steel HC340LA-HC340LA. This is related to martensitic structure, its morphology and distribution in the fusion zone for dual and multi-phase steels, and ferrite, bainite (or martensite) structure in the fusion zone for high strength low-alloyed steel.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Drewes, E.J.; Prange, W. Innovative Halbzeuge für den Leichtbau mit Stahl. In 16th Steel Colloquium Aachen, “Umformtechnik, Stahl und NE-Werkstoffe-Innovative Halbzeuge—Basis für Hochleistungsprodukte”; Verlag Mainz: Aachen, Germany, 2001; pp. 207–221. [Google Scholar]

- Evin, E.; Tkáčová, J.; Tkáč, J. Aspects of steel sheets selection for car body components. AI Mag. No. 2 2012, 5, 88–91. [Google Scholar]

- Evin, E.; Tkáčová, J.; Tkáč, J. Aspects of steel sheets selection for car body components. AI Mag. No. 3 2012, 5, 96–98. [Google Scholar]

- Kvačkaj, T. Development of steels for automotive industry. In MAT/TECH for Automotive Industry; Technical University of Košice: Košice, Slovakia, 2015; pp. 58–67. [Google Scholar]

- Yuce, C.; Tutar, M.; Karpat, F.; Yavuz, N. The optimization of process parameters and microstructural characterization of fiber laser welded dissimilar HSLA and MART steel joints. Metals 2016, 6, 245. [Google Scholar] [CrossRef]

- Farabi, N.; Chen, D.L.; Zhou, Y. Microstructure and mechanical properties of laser welded dissimilar DP600/DP980 dual-phase steel joints. J. Alloys Compd. 2011, 509, 982–989. [Google Scholar] [CrossRef]

- Mujica, L.; Weber, S.; Pinto, H.; Thomy, C.; Vollertsen, F. Microstructure and mechanical properties of laser-welded joints of TWIP and TRIP steels. Mater. Sci. Eng. A 2010, 527, 2071–2078. [Google Scholar] [CrossRef]

- Chena, W.; Linb, G.S.; Hub, S.J. Comparison study on the effectiveness of stepped binder and weld line clamping pins on formability improvement for tailor-welded blanks. J. Mater. Process. Technol. 2008, 207, 204–210. [Google Scholar] [CrossRef]

- Meyer, A.; Wietbrock, B.; Hirt, G. Increasing of the drawing depth using tailor rolled blanks—numerical and experimental analysis. Int. J. Mach. Tools Manuf. 2008, 48, 522–531. [Google Scholar] [CrossRef]

- Chan, S.M.; Chan, L.C.; Lee, T.C. Tailored welded blanks of different thickness ratios effects on forming limiting diagrams. J. Mater. Process. Technol. 2003, 132, 95–101. [Google Scholar] [CrossRef]

- Merklein, M.; Lechner, M. Manufacturing flexibilisation of metal forming components by tailored blanks. In Proceedings of the COMA 13th International Conference on Competitive Manufacturing, Stellenbosch, South Africa, 30 January–1 February 2013; pp. 1–6. [Google Scholar]

- Monaco, A.; Sinke, J.; Benedictus, R. Experimental and numerical analysis of a beam made of adhesively bonded tailor-made blanks. Int. J. Adv. Manuf. Technol. 2009, 44, 766–780. [Google Scholar] [CrossRef]

- Reisgen, U.; Schleser, M.; Mokrov, O.; Ahmed, E. Statistical modeling of laser welding of DP/TRIP steel sheets. Opt. Laser Technol. 2012, 44, 92–101. [Google Scholar] [CrossRef]

- Sennaroglu, A. Solid-State Lasers and Applications, 1st ed.; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Koechner, W.; Bass, M. Solid-State Lasers: A Graduate Text, 1st ed.; Springer: New York, NY, USA, 2003. [Google Scholar]

- Hyrcza-Michalska, M.; Grosman, F. The evaluate of laser welded tailor and tubular blanks formability for automotive vehicle elements stamping. Arch. Civ. Mech. Eng. 2009, 9, 69–81. [Google Scholar] [CrossRef]

- Piela, A.; Lisok, J.; Rojek, J. Experimental study and numerical simulation of tailor welded blanks. In Proceedings of the International Conference on Advanced Materials & Processing Technologies AMPT 2003, Dublin, Ireland, 8–11 July 2003. [Google Scholar]

- Esquivel, A.S.; Nayak, S.S.; Xia, M.S.; Zhou, Y. Microstructure, hardness and tensile properties of fusion zone in laser welding of advanced high strength steels. Can. Metall. Q. 2012, 51, 328–335. [Google Scholar] [CrossRef]

- Švec, P.; Schrek, A.; Hrnčiar, V.; Csicsó, T. Fibre laser welding of dual phase steels. Acta. Metall. Slovaca 2015, 21, 311–320. [Google Scholar] [CrossRef]

- Saha, D.C.; Westerbaan, D.; Nayak, S.S.; Biro, E.; Gerlich, A.P.; Zhou, Y. Microstructure-properties correlation in fiber laser welding of dual-phase and HSLA steels. Mater. Sci. Eng. A 2014, 607, 445–453. [Google Scholar] [CrossRef]

- Yurioka, N.; Okumura, M.; Kasuya, T.; Cotton, H. Prediction of HAZ hardness of transformable steels. Met. Constr. 1987, 4, 217R–223R. [Google Scholar]

- Yurioka, N.; Kasuya, T. A chart method to determine necessary preheat temperature in steel welding. Q. J. Jpn. Weld. Soc. 1995, 13, 347–357. [Google Scholar]

- ESI Group. PAM-STAMP 2G 2011: Users’s Guide, 1st ed.; ESI Group: Paris, France, 2010. [Google Scholar]

- Banabic, D. Sheet Metal Forming Processes: Constitutive Modelling and Numerical Simulation, 1st ed.; Springer: Berlin, Germany, 2010. [Google Scholar]

- Evin, E.; Tomáš, M. Annual Report of the Project APVV-0273-12; Technical University of Kosice: Kosice, Slovakia, 2014. [Google Scholar]

- Evin, E.; Tomáš, M. Annual Report of the Project APVV-0273-12; Technical University of Kosice: Kosice, Slovakia, 2015. [Google Scholar]

- Evin, E.; Tomáš, M. Annual Report of the Project APVV-0273-12; Technical University of Kosice: Kosice, Slovakia, 2016. [Google Scholar]

- Zhang, C.H.; Song, X.; Lu, P.; Hu, X. Effect of microstructure on mechanical properties in weld-repaired high strength low alloy steel. Mater. Des. 2012, 36, 233–242. [Google Scholar] [CrossRef]

- Singh, S.; Nanda, T.; Ravi Kumar, B.; Singh, V. Controlled phase transformation simulations to design microstructure for tailored mechanical properties in steel. Mater. Manuf. Process. 2016, 31, 2064–2075. [Google Scholar] [CrossRef]

| Material | Chemical Composition wt % | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| HC340LA | C | Si | Mn | P | S | Cu | Al | Cr | Mo |

| 0.083 | 0.039 | 0.181 | 0.038 | <0.002 | 0.081 | 0.062 | 0.044 | 0.034 | |

| Ni | V | Ti | Nb | Co | W | CEY acc. to (1) | |||

| 0.048 | 0.018 | <0.002 | 0.071 | 0.155 | - | 0.122 | |||

| HCT600X | C | Si | Mn | P | S | Cu | Al | Cr | Mo |

| 0.111 | 0.279 | 1.963 | 0.026 | <0.002 | 0.019 | 0.031 | 0.206 | <0.002 | |

| Ni | V | Ti | Nb | Co | W | CEY acc. to (1) | |||

| <0.002 | 0.012 | <0.002 | 0.02 | 0.017 | <0.005 | 0.397 | |||

| RAK40/70 | C | Si | Mn | P | S | Cu | Al | Cr | Mo |

| 0.197 | 0.165 | 1.576 | 0.015 | <0.002 | 0.022 | 1.352 | 0.0455 | 0.022 | |

| Ni | V | Ti | Nb | Co | W | CEY acc. to (1) | |||

| 0.016 | 0.011 | - | 0.002 | - | - | 0.486 | |||

| Material | Sheet Thickness [mm] | Laser Power [W] | Focal Point [mm] | Welding Speed [mm·s−1] | Width of FZ 1 [mm] | Width of HAZ 2 [mm] | Note |

|---|---|---|---|---|---|---|---|

| HC340LA | 0.78 | 1700 | 10 | 50 | 0.9 | 0.35 | Optimal |

| 2100 | 70 | 0.92 | 0.36 | - | |||

| 2300 | 70 | 0.96 | 0.38 | - | |||

| HCT600X | 0.77 | 2000 | 10 | 50 | 2.15 | 0.45 | Optimal |

| 2700 | 70 | 2.21 | 0.47 | - | |||

| RAK40/70 | 0.77 | 2000 | 10 | 50 | 1.05 | 0.40 | Optimal |

| 2700 | 70 | 1.17 | 0.48 | - |

| Material | Base Metal | Heat Affected Zone | Fusion Zone | ||

|---|---|---|---|---|---|

| HV05 | HV05 | HVHAZ/HVBM | HV05 | HVFZ/HVBM | |

| HC340LA | 152 ± 2 | 183 ± 7 | 1.2 | 213 ± 3 | 1.4 |

| HCT600X | 205 ± 3 | 314 ± 49 | 1.5 | 390 ± 3 | 1.9 |

| RAK40/70 | 219 ± 3 | 314 ± 56 | 1.4 | 474 ± 3 | 2.2 |

| Material | Dir. | Re (Rp0.2) [MPa] | Rm [MPa] | Ag [%] | A [%] | K | n | r |

|---|---|---|---|---|---|---|---|---|

| HC340LA * | 0° | 378 | 449 | 17.4 | 28.5 | 728 | 0.178 | 0.66 |

| 45° | 383 | 455 | 16.8 | 30.4 | 722 | 0.161 | 0.85 | |

| 90° | 389 | 446 | 18.1 | 29.5 | 724 | 0.169 | 0.76 | |

| Average | 383 | 450 | 17.4 | 29.5 | 725 | 0.169 | 0.78 | |

| Stdev | 5.5 | 4.6 | 0.7 | 1 | 3 | 0.009 | 0.09 | |

| HC340LA ** | 0° | 375 | 447 | 17 | 29 | 726 | 0.175 | 0.65 |

| 45° | 380 | 451 | 16.4 | 30.4 | 718 | 0.157 | 0.84 | |

| 90° | 386 | 440 | 17.3 | 26.5 | 717 | 0.163 | 0.71 | |

| Average | 380 | 444 | 16.7 | 26 | 718 | 0.163 | 0.76 | |

| Stdev | 5.5 | 5.6 | 0.5 | 2 | 5 | 0.009 | 0.09 |

| Material | Dir. | Re (Rp0.2) [MPa] | Rm [MPa] | Ag [%] | A [%] | K | n | r |

|---|---|---|---|---|---|---|---|---|

| HCT600X * | 0° | 376 | 632 | 19 | 28.4 | 1096 | 0.217 | 0.77 |

| 45° | 378 | 626 | 19.5 | 28 | 1084 | 0.215 | 0.84 | |

| 90° | 371 | 627 | 19.3 | 30.7 | 1095 | 0.220 | 0.81 | |

| Average | 375 | 628 | 19.3 | 29 | 1092 | 0.217 | 0.81 | |

| Stdev | 4 | 3 | 0.3 | 1 | 7 | 0.003 | 0.04 | |

| HCT600X ** | 0° | 435 | 677 | 17 | 20 | 1109 | 0.182 | 0.76 |

| 45° | 430 | 672 | 17.3 | 22.3 | 1117 | 0.185 | 0.81 | |

| 90° | 427 | 674 | 17.1 | 23.3 | 1112 | 0.187 | 0.78 | |

| Average | 431 | 674 | 17.1 | 21.9 | 1112 | 0.185 | 0.79 | |

| Stdev | 4 | 3 | 0.2 | 2 | 4 | 0.003 | 0.02 |

| Material | Dir. | Re (Rp0.2) [MPa] | Rm [MPa] | Ag [%] | A [%] | K | n | r |

|---|---|---|---|---|---|---|---|---|

| RAK40/70 * | 0° | 440 | 764 | 25.3 | 30.3 | 1497 | 0.295 | 0.658 |

| 45° | 462 | 761 | 22.8 | 26.6 | 1452 | 0.275 | 0.689 | |

| 90° | 457 | 766 | 24.3 | 29.4 | 1474 | 0.281 | 0.623 | |

| Average | 453 | 764 | 24.1 | 28.8 | 1474 | 0.284 | 0.66 | |

| Stdev | 5 | 3 | 0.8 | 1.5 | 13 | 0.004 | 0.03 | |

| RAK40/70 ** | 0° | 466 | 657 | 20 | 21 | 1459 | 0.249 | 0.66 |

| 45° | 483 | 659 | 19 | 20.1 | 1436 | 0.235 | 0.63 | |

| 90° | 474 | 662 | 20.3 | 22.3 | 1458 | 0.244 | 0.60 | |

| Average | 474 | 659 | 19.8 | 21.1 | 1451 | 0.243 | 0.63 | |

| Stdev | 9 | 2 | 1 | 1 | 13 | 0.007 | 0.03 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Evin, E.; Tomáš, M. The Influence of Laser Welding on the Mechanical Properties of Dual Phase and Trip Steels. Metals 2017, 7, 239. https://doi.org/10.3390/met7070239

Evin E, Tomáš M. The Influence of Laser Welding on the Mechanical Properties of Dual Phase and Trip Steels. Metals. 2017; 7(7):239. https://doi.org/10.3390/met7070239

Chicago/Turabian StyleEvin, Emil, and Miroslav Tomáš. 2017. "The Influence of Laser Welding on the Mechanical Properties of Dual Phase and Trip Steels" Metals 7, no. 7: 239. https://doi.org/10.3390/met7070239

APA StyleEvin, E., & Tomáš, M. (2017). The Influence of Laser Welding on the Mechanical Properties of Dual Phase and Trip Steels. Metals, 7(7), 239. https://doi.org/10.3390/met7070239