An Investigation on the Softening Mechanism of 5754 Aluminum Alloy during Multistage Hot Deformation

Abstract

:1. Introduction

2. Materials and Material Testing

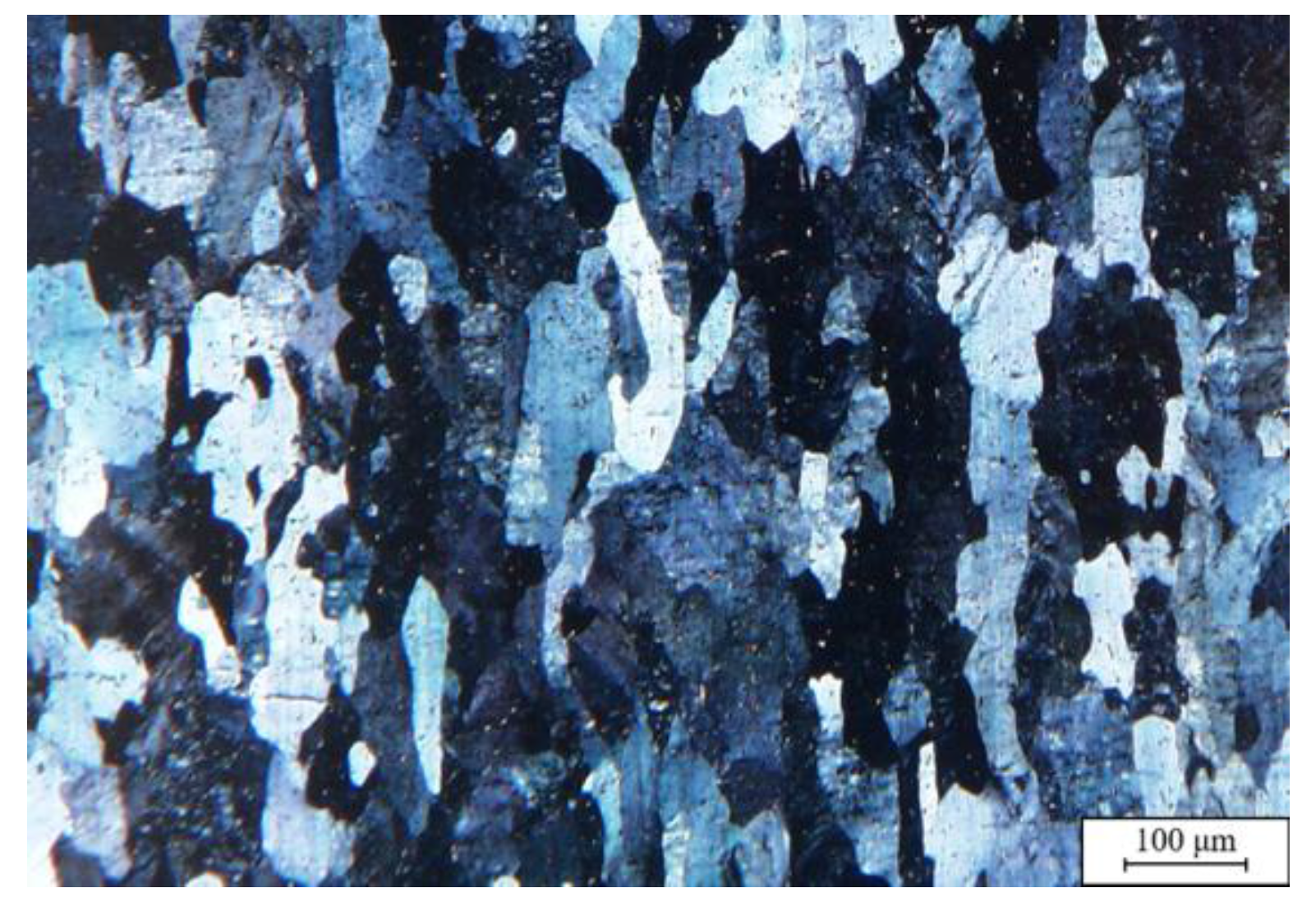

2.1. Materials

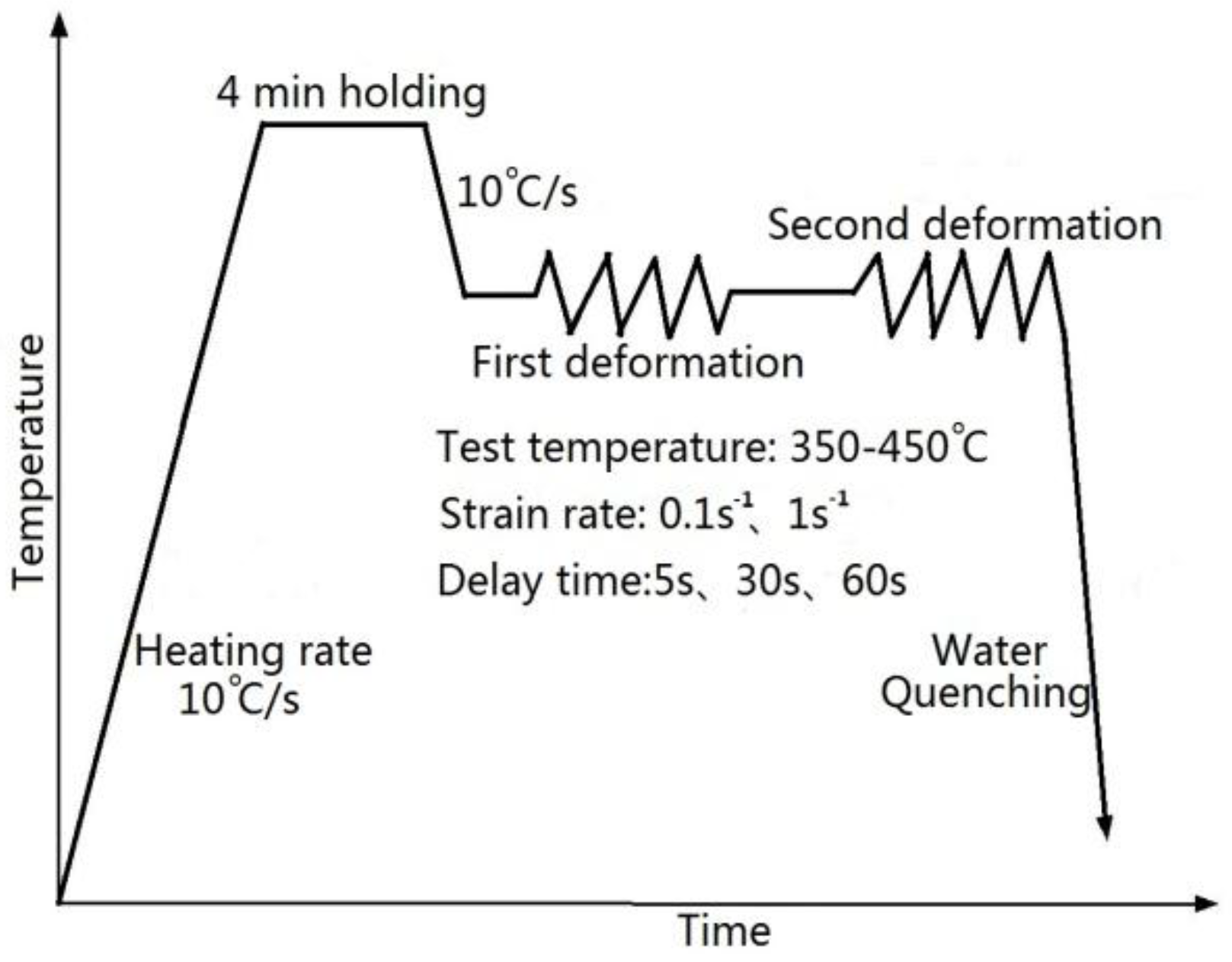

2.2. Material Testing

3. Results and Discussion

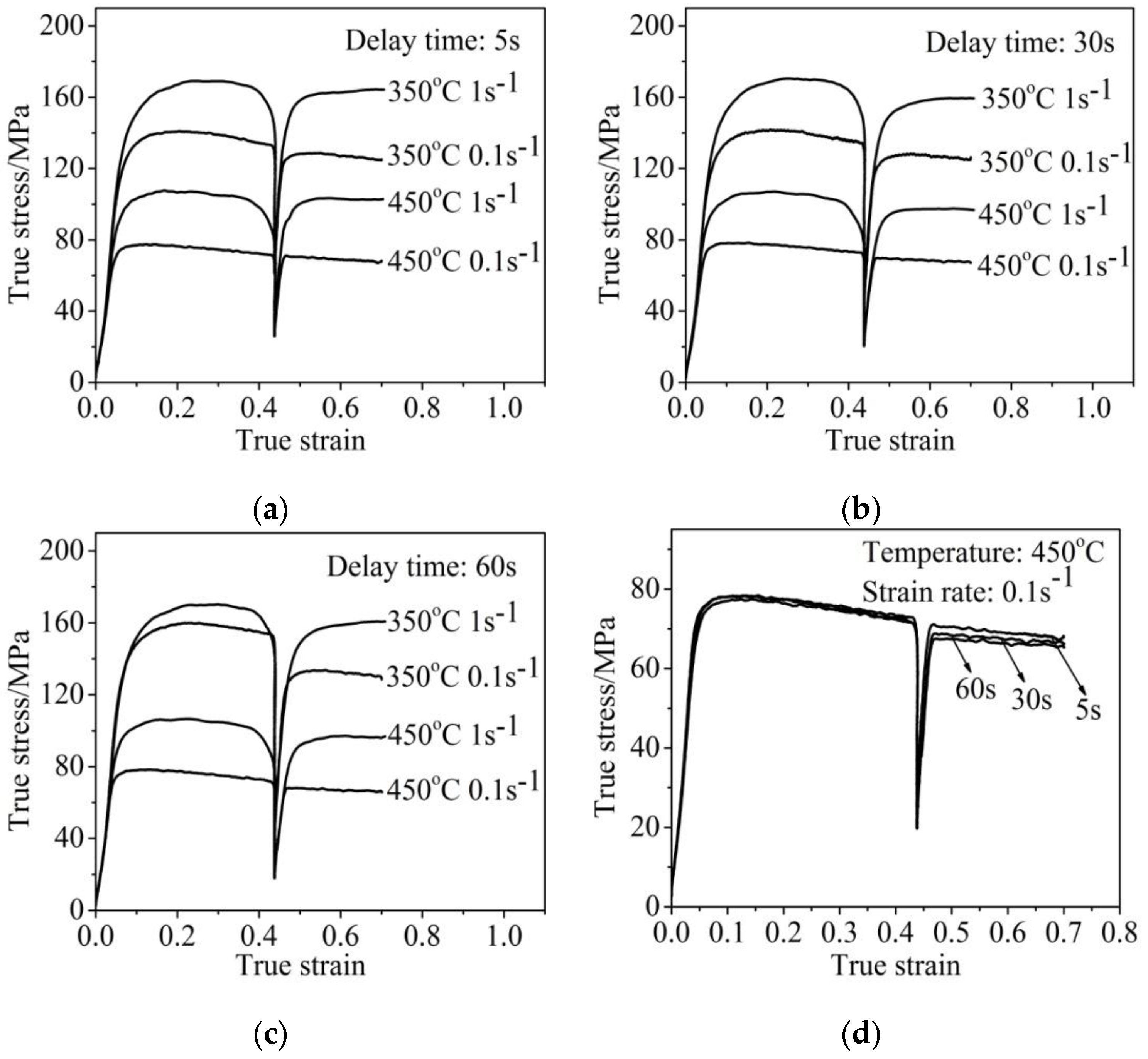

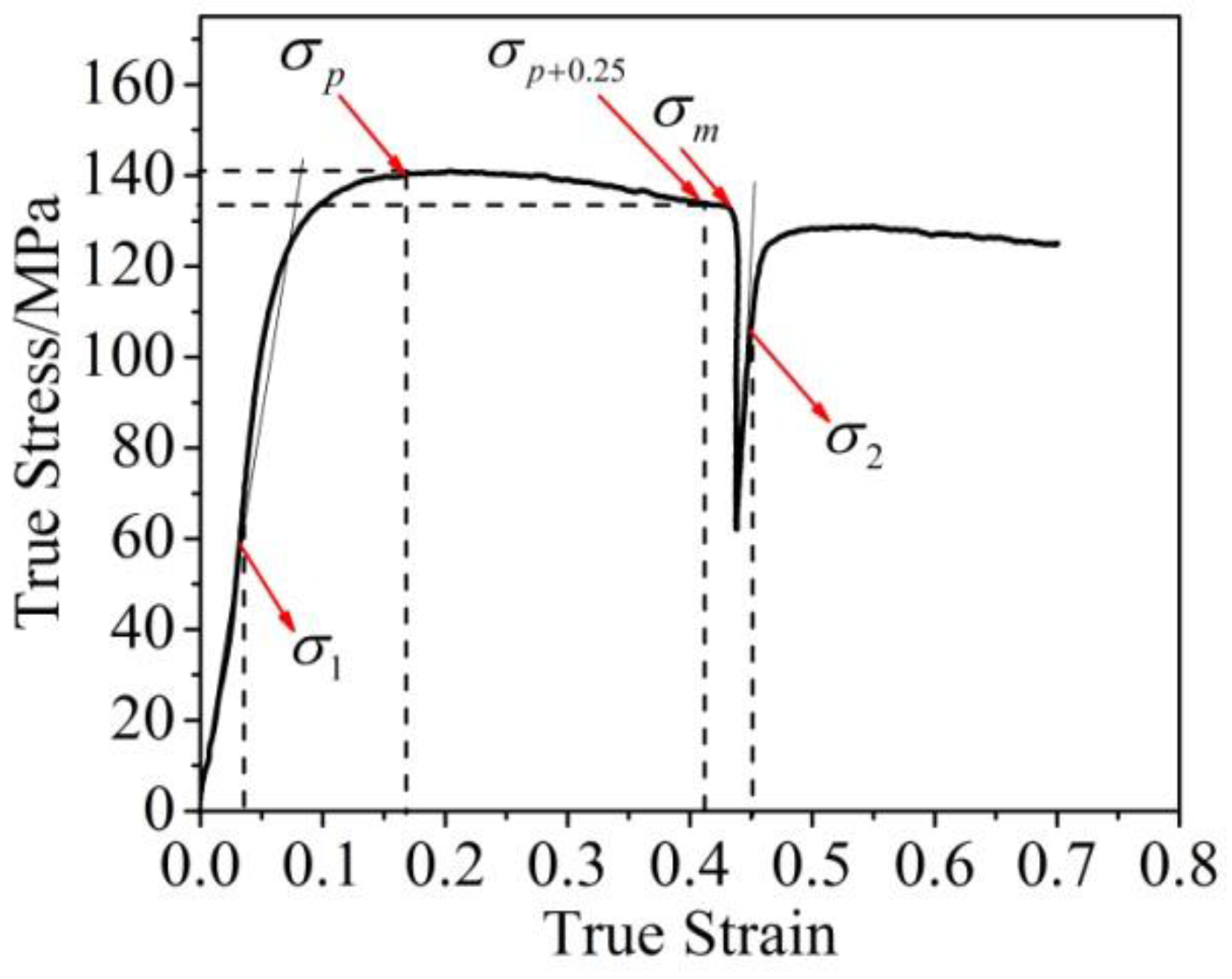

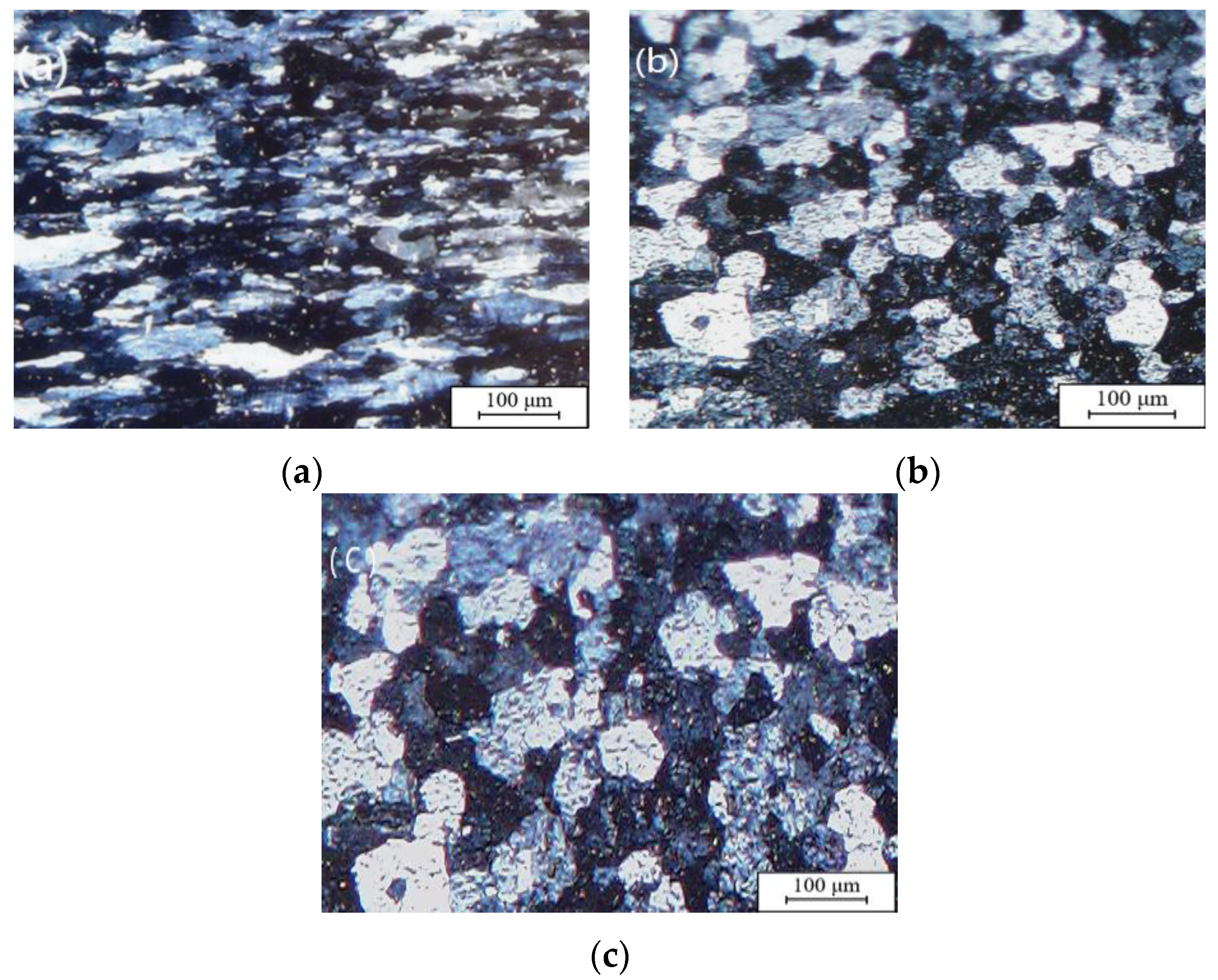

3.1. Dynamic Softening Behavior

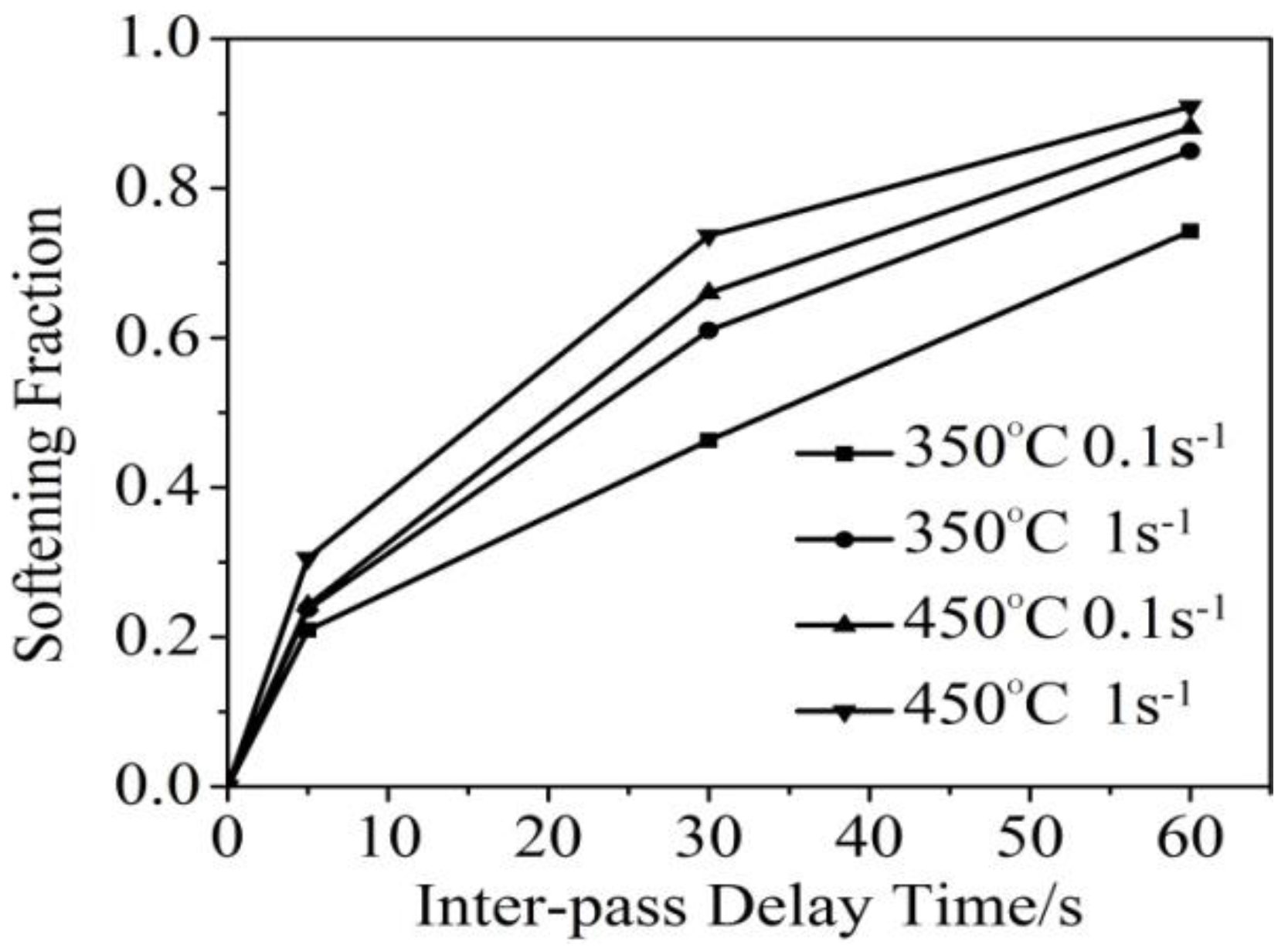

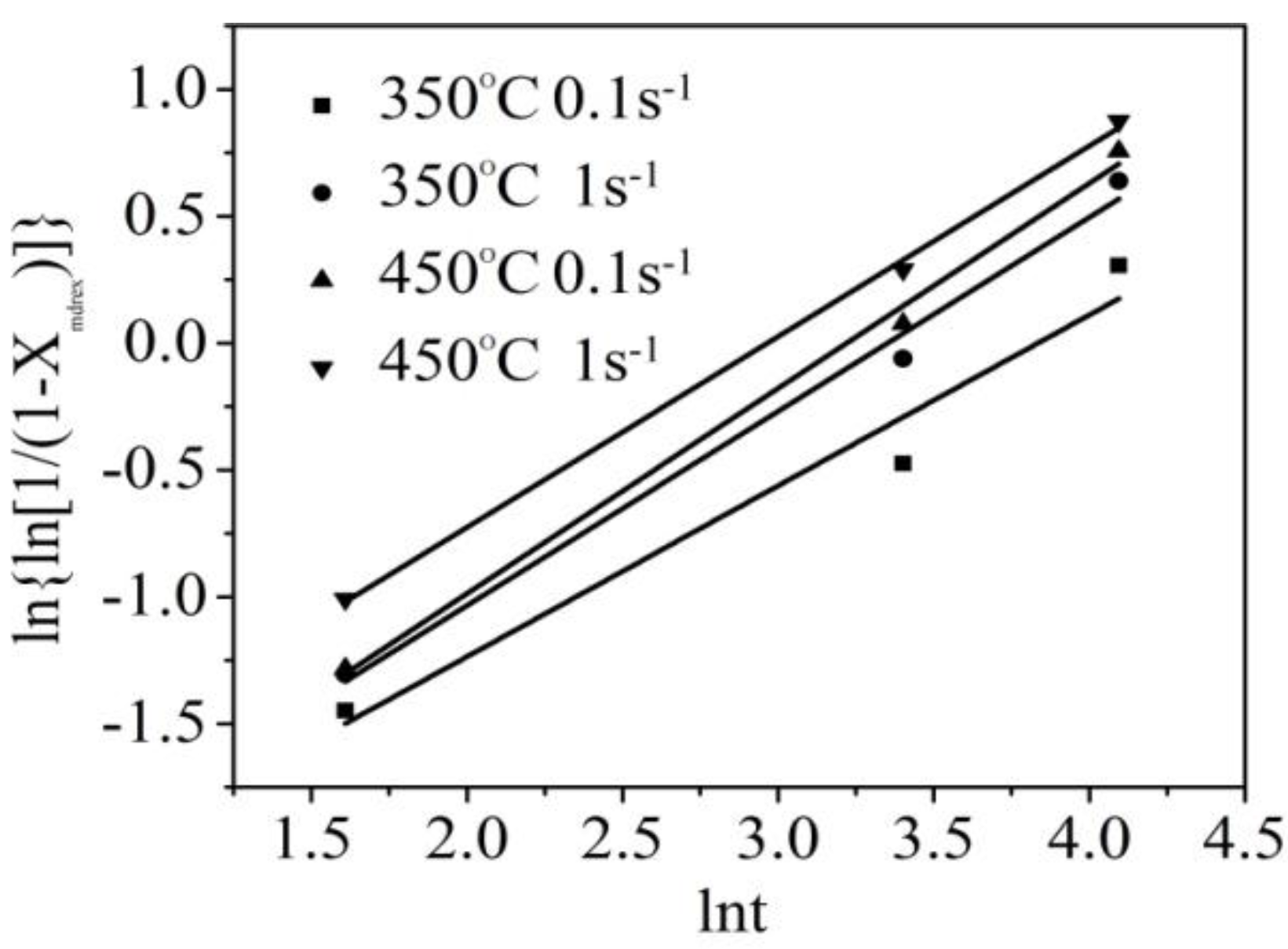

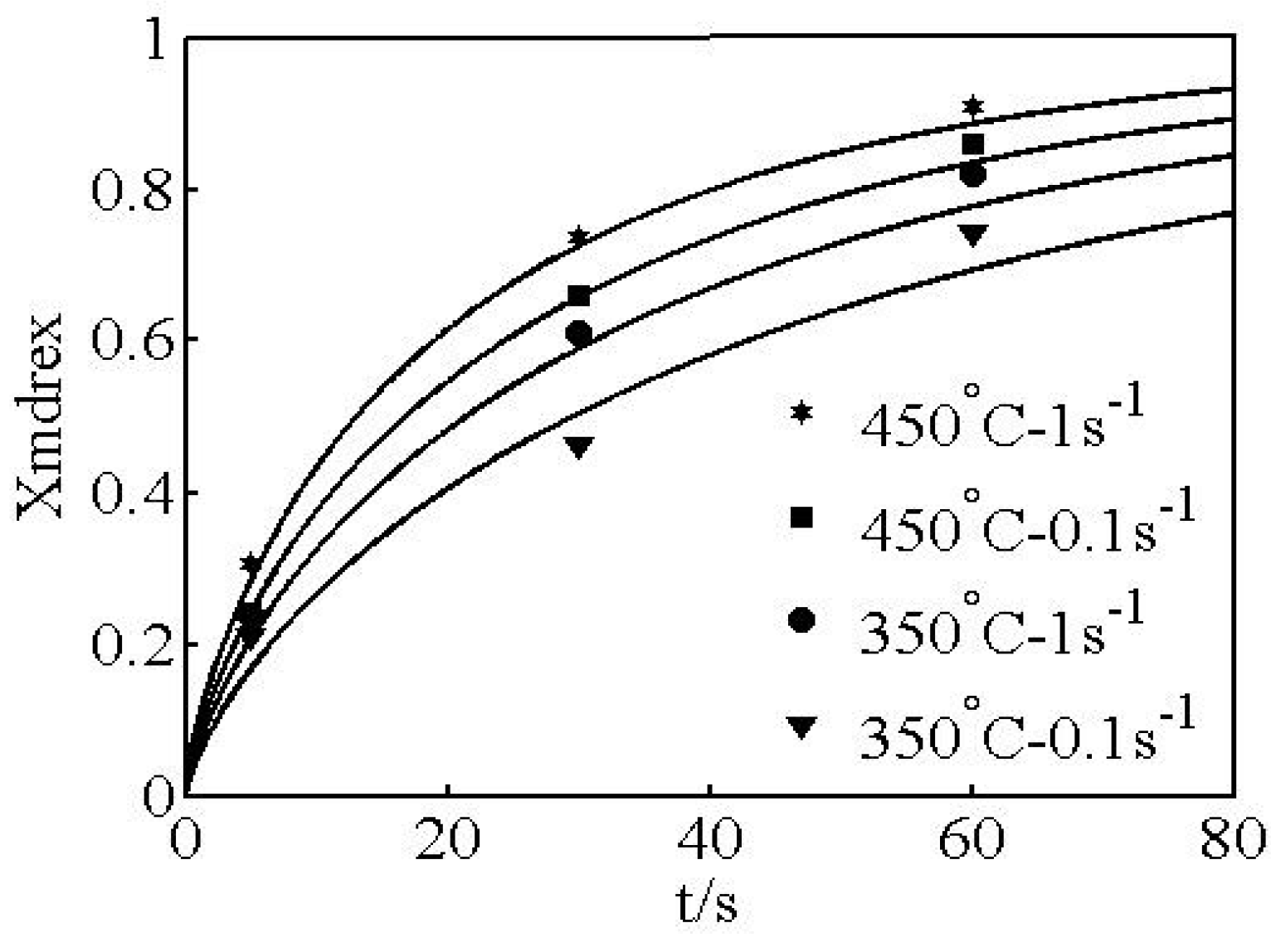

3.2. Modeling the Kinetics of Metadynamic Recrystallization

3.2.1. Determination of n

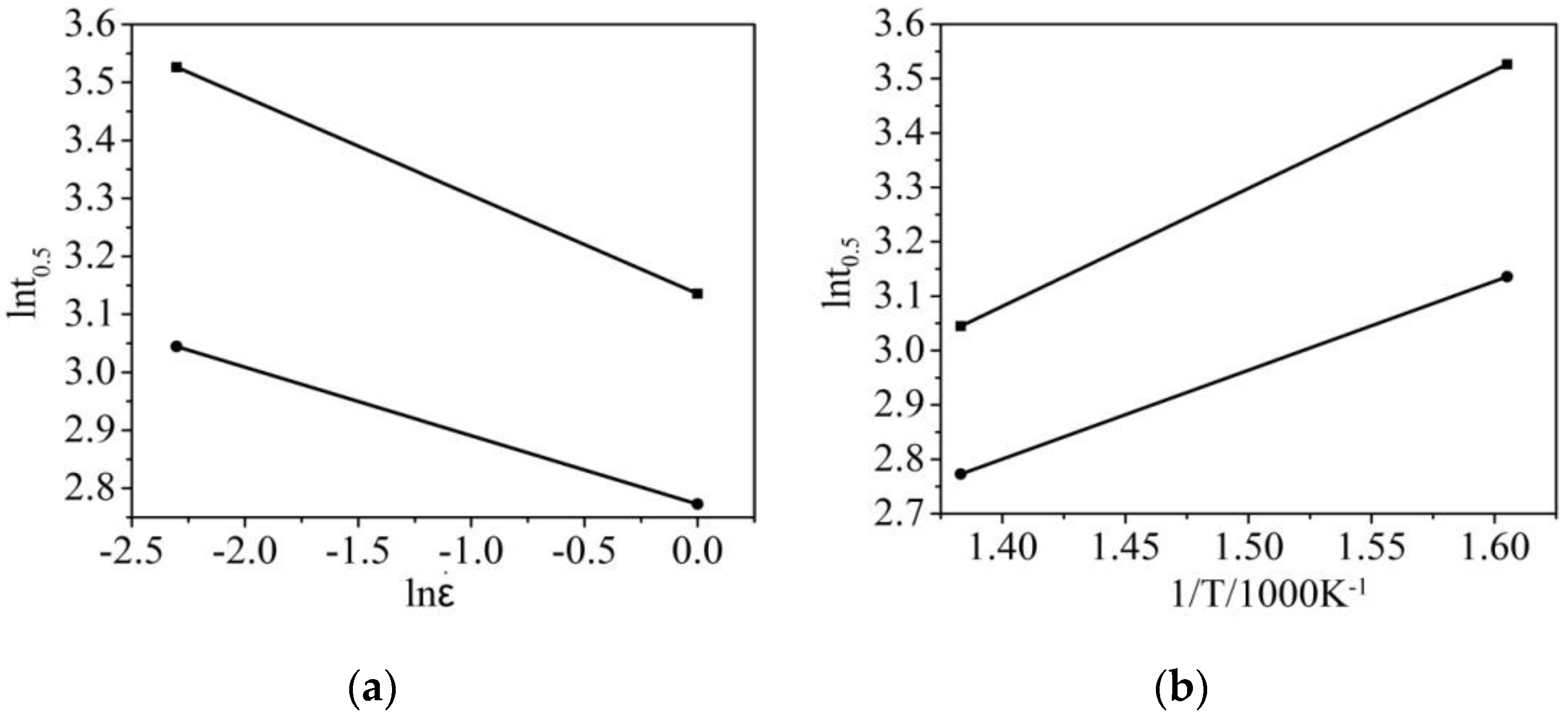

3.2.2. Determination of the Dependence of t0.5 on Deformation Parameters

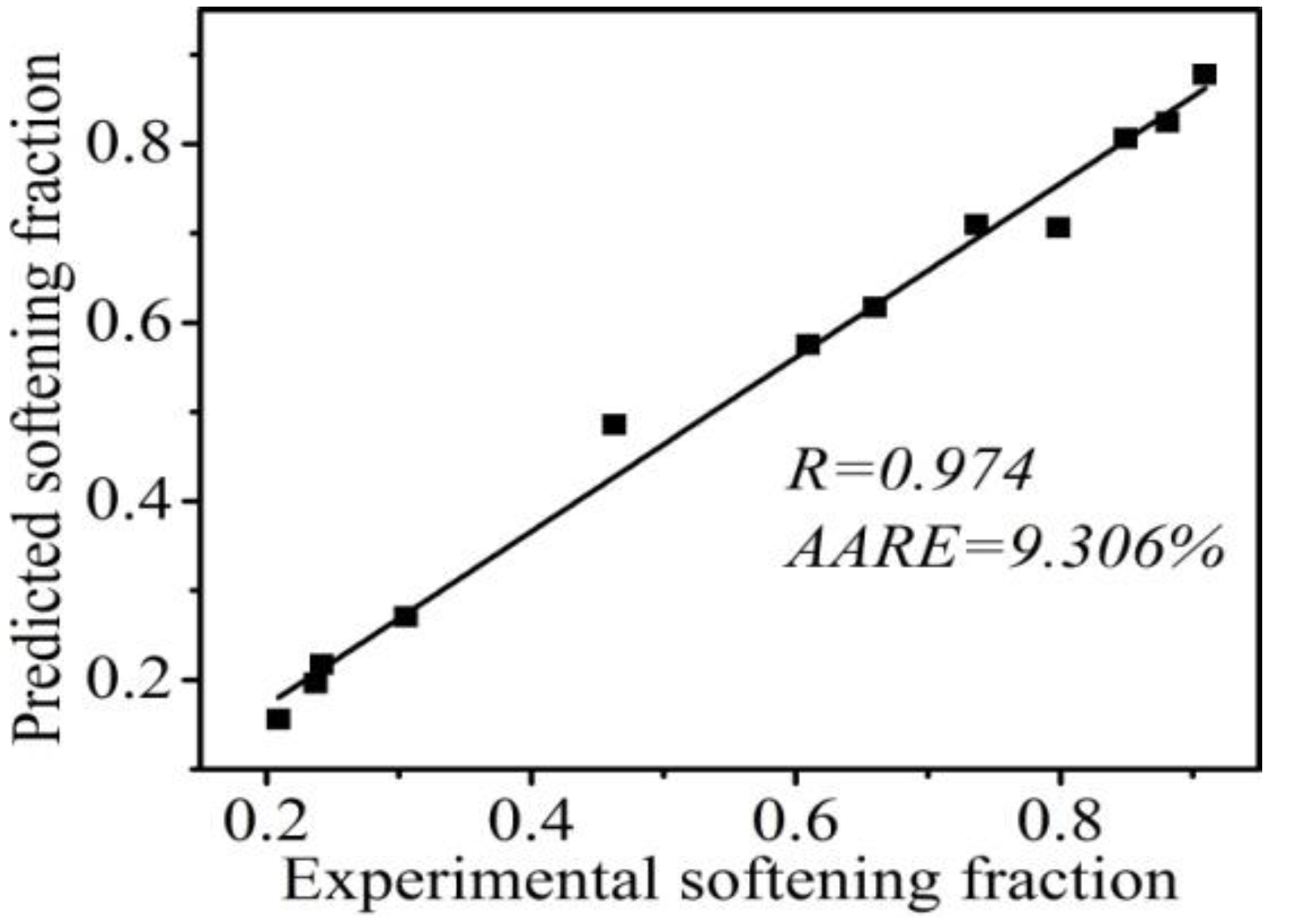

3.3. Verification of the Developed Kinetic Equation

4. Conclusions

- (1)

- The relative softening values under different test conditions signify the occurrence of dynamic softening at each stage, and the softening fraction may approach zero with further straining at the second deformation stage.

- (2)

- For the two-pass hot compressed 5754 aluminum alloy, the restoration mechanism is governed by metadynamic recrystallization. The softening fraction attributed to metadynamic recrystallization increases with increasing deformation temperature, delay time, and strain rate.

- (3)

- The predicted results were highly consistent with the experimental ones, which indicates that the developed kinetics equation can accurately describe the metadynamic recrystallization behaviors of 5754 aluminum alloy.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sang, D.; Li, Y. The Hot Deformation Activation Energy of 7050 Aluminum Alloy under Three Different Deformation Modes. Metals 2016, 49, 1–8. [Google Scholar] [CrossRef]

- Lin, Y.C.; Li, L.T.; Xia, Y.C. A new method to predict the metadynamic recrystallization behavior in 2124 aluminum alloy. Comput. Mater. Sci. 2011, 50, 2038–2043. [Google Scholar] [CrossRef]

- Zhou, M.; Clode, M.P. Constitutive equations for modeling flow softening due to dynamic recovery and heat generation during plastic deformation. Mech. Mater. 1988, 27, 63–76. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, L.B.; Peng, D.S.; Meng, L.P. Flow stress equation for multipass hot-rolling of aluminum alloys. Cent. South Technol. 2011, 8, 13–17. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, L.B.; Peng, D.S.; Meng, L.P. Recrystallization model for hot-rolling of 5182 aluminum alloy. Trans. Nonferr. Met. Soc. China 2011, 11, 382–386. [Google Scholar]

- Sang, H.C.; Kim, S.I.; Yoo, Y.C. Determination of ‘no-recrystallization’ temperature of Invar alloy by fractional softening measurement during the multistage deformation. Mater. Sci. Lett. 1997, 16, 1836–1837. [Google Scholar]

- Zheng, B.; Lin, Y.; Zhou, Y.; Lavernia, E.J. Gas Atomization of Amorphous Aluminum Powder: Part II. Experimental Investigation. Metall. Mater. Trans. B 2009, 40, 995–1004. [Google Scholar] [CrossRef]

- Ding, H.L.; Wang, T.Y.; Yang, L.; Kamado, S. FEM modeling of dynamical recrystallization during multi-pass hot rolling of AM50 alloy and experimental verification. Trans. Nonferr. Met. Soc. China 2013, 23, 2678–2685. [Google Scholar] [CrossRef]

- Xiang, S.; Liu, D.Y.; Zhu, R.H.; Jin-Feng, L.I.; Chen, Y.L.; Zhang, X.H. Hot deformation behavior and microstructure evolution of 1460 Al–Li alloy. Trans. Nonferr. Met. Soc. China 2015, 25, 3855–3864. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.S.; Zhong, J. Study of metadynamic recrystallization behaviors in a low alloy steel. J. Mater. Process. Technol. 2009, 29, 2477–2482. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.S.; Zhong, J. Study of static recrystallization kinetics in a low alloy steel. Comput. Mater. Sci. 2008, 44, 316–321. [Google Scholar] [CrossRef]

- Shi, C.; Lai, J.; Chen, X.G. Microstructural Evolution and Dynamic Softening Mechanisms of Al-Zn-Mg-Cu Alloy during Hot Compressive Deformation. Materials 2014, 7, 244–264. [Google Scholar] [CrossRef]

- Liu, Y.; Shao, Y.; Liu, C.; Chen, Y.; Zhang, D. Microstructure Evolution of HSLA Pipeline Steels after Hot Uniaxial Compression Microstructure Evolution of HSLA Pipeline Steels after Hot Uniaxial Compression. Materials 2016, 9, 721. [Google Scholar] [CrossRef]

- Jiang, F.; Zhang, H.; Li, L.; Chen, J. The kinetics of dynamic and static softening during multistage hot deformation of 7150 aluminum alloy. Mater. Sci. Eng. A Struct. 2012, 552, 269–275. [Google Scholar] [CrossRef]

- Maghsoudi, M.H.; Zarei-Hanzaki, A.; Changizian, P.; Marandi, A. Metadynamic recrystallization behavior of AZ61 magnesium alloy. Mater. Des. 2014, 57, 487–493. [Google Scholar] [CrossRef]

- Zhang, P.; Yi, C.; Chen, G.; Qin, H.; Wang, C. Constitutive model based on dynamic recrystallization behavior during thermal deformation of a nickel-based superalloy. Metals 2016, 6, 1–19. [Google Scholar] [CrossRef]

- Sun, Z.C.; Liu, L.; Yang, H. Microstructure evolution of different loading zones during TA15 alloy multi-cycle isothermal local forging. Mater. Sci. Eng. A Struct. 2011, 528, 5112–5121. [Google Scholar] [CrossRef]

- Mandal, S.; Bhaduri, A.K.; Sarma, V.S. A study on microstructural evolution and dynamic recrystallization during isothermal deformation of a Ti-modified austenitic stainless steel. Metall. Mater. Trans. A 2011, 42, 1062–1072. [Google Scholar] [CrossRef]

- Zhang, D.X.; Yang, X.Y.; Sun, H.; Li, Y.; Wang, J.; Zhang, Z.R.; Ye, Y.X.; Sakai, T. Dynamic recrystallization behaviors and the resultant mechanical properties of a Mg-Y-Nd-Zr alloy during hot compression after aging. Mater. Sci. Eng. A Struct. 2015, 640, 51–60. [Google Scholar] [CrossRef]

- Agnoli, A.; Bernacki, M.; Logé, R.; Franchet, J.M.; Laigo, J.; Bozzolo, N. Selective Growth of Low Stored Energy Grains During δ Sub-solvus Annealing in the Inconel 718 Nickel-Based Superalloy. Met. Mater. Trans. A 2015, 46, 4405–4421. [Google Scholar] [CrossRef]

- Verlinden, B.; Wouters, P.; McQueen, H.J.; Aernoudt, E.; Delaey, L.; Cauwenberg, S. Effect of homogenization and precipitation treatments on the hot workability of aluminum alloy AA2024. Mater. Sci. Eng. A Struct. 1900, 123, 239–245. [Google Scholar]

- Verlinden, B.; Wouters, P.; McQueen, H.J.; Aernoudt, E.; Delaey, L.; Cauwenberg, S. Effect of different homogenization treatments on the hot workability of aluminum alloy AA2024. Mater. Sci. Eng. A Struct. 1900, 123, 229–237. [Google Scholar] [CrossRef]

- Haghdadi, N.; Cizek, P.; Beladi, H.; Hodgson, P.D. A novel high-strain-rate ferrite dynamic softening mechanism facilitated by the interphase in the austenite/ferrite microstructure. Acta Mater. 2017, 126, 44–57. [Google Scholar] [CrossRef]

- Liu, C.M.; Jiang, S.N.; Zhang, X.M. Continuous dynamic recrystallization and discontinuous dynamic recrystallization in 99.99% polycrystalline aluminum during hot compression. Trans. Nonferr. Met. Soc. China 2005, 15, 82–86. [Google Scholar]

- Zhang, H.; Lin, G.Y.; Peng, D.S.; Yang, L.B.; Lin, Q.Q. Dynamic and static softening behaviors of aluminum alloys during multistage hot deformation. J. Mater. Process. Technol. 2004, 148, 245–249. [Google Scholar] [CrossRef]

- Jung, K.H.; Lee, H.W.; Im, Y.T. A microstructure evolution model for numerical prediction of austenite grain size distribution. Int. J. Mech. Sci. 2010, 52, 1136–1144. [Google Scholar] [CrossRef]

- Yue, C.X.; Zhang, L.W.; Liao, S.L.; Gao, H.J. Mathematical models for predicting the austenite grain size in hot working of GCr15 steel. Comput. Mater. Sci. 2009, 45, 462–466. [Google Scholar] [CrossRef]

- Toloui, M.; Serajzadeh, S. Modelling recrystallization kinetics during hot rolling of AA5083. J. Mater. Process. Technol. 2007, 184, 345–353. [Google Scholar] [CrossRef]

- Raghunathan, N.; Zaidi, M.A.; Sheppard, T. Recrystallization kinetics of Al-Mg alloys AA 5056 and AA 5083 after hot deformation. Mater. Sci. Technol. 1986, 9, 938–945. [Google Scholar] [CrossRef]

- McQueen, H.J.; Ryum, N. Hot working and subsequent static recrystallization of Al and Al-Mg alloys. Scand. J. Metall. 1985, 14, 183–194. [Google Scholar]

- Haghdadi, N.; Martin, D.; Hodgson, P. Physically-based constitutive modelling of hot deformation behavior in a LDX 2101 duplex stainless steel. Mater. Des. 2016, 106, 420–427. [Google Scholar] [CrossRef]

- Haghdadi, N.; Zarei-Hanzaki, A.; Abedi, H.R. The flow behavior modeling of cast A356 aluminum alloy at elevated temperatures considering the effect of strain. Mater. Sci. Eng. A Struct. 2012, 535, 252–257. [Google Scholar] [CrossRef]

| Composition | Si | Cu | Mg | Zn | Mn | Gr | Al |

| Content (wt %) | 0.40 | 0.10 | 2.6~3.6 | 0.20 | 0.50 | 0.30 | Bal |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, C.-Q.; Deng, J.; Wang, S.-X.; Liu, L.-l. An Investigation on the Softening Mechanism of 5754 Aluminum Alloy during Multistage Hot Deformation. Metals 2017, 7, 107. https://doi.org/10.3390/met7040107

Huang C-Q, Deng J, Wang S-X, Liu L-l. An Investigation on the Softening Mechanism of 5754 Aluminum Alloy during Multistage Hot Deformation. Metals. 2017; 7(4):107. https://doi.org/10.3390/met7040107

Chicago/Turabian StyleHuang, Chang-Qing, Jie Deng, Si-Xu Wang, and Lei-lei Liu. 2017. "An Investigation on the Softening Mechanism of 5754 Aluminum Alloy during Multistage Hot Deformation" Metals 7, no. 4: 107. https://doi.org/10.3390/met7040107

APA StyleHuang, C.-Q., Deng, J., Wang, S.-X., & Liu, L.-l. (2017). An Investigation on the Softening Mechanism of 5754 Aluminum Alloy during Multistage Hot Deformation. Metals, 7(4), 107. https://doi.org/10.3390/met7040107