Microstructural, Mechanical, and Electrochemical Analysis of Duplex and Superduplex Stainless Steels Welded with the Autogenous TIG Process Using Different Heat Input

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

- Duplex Stainless Steel UNS S31803, designated in this work as SAF 2205;

- Lean Duplex Stainless Steel UNS S32304, designated in this work as SAF 2304;

- Superduplex Stainless Steel UNS S32750, designated in this work as SAF 2507.

2.2. Methods

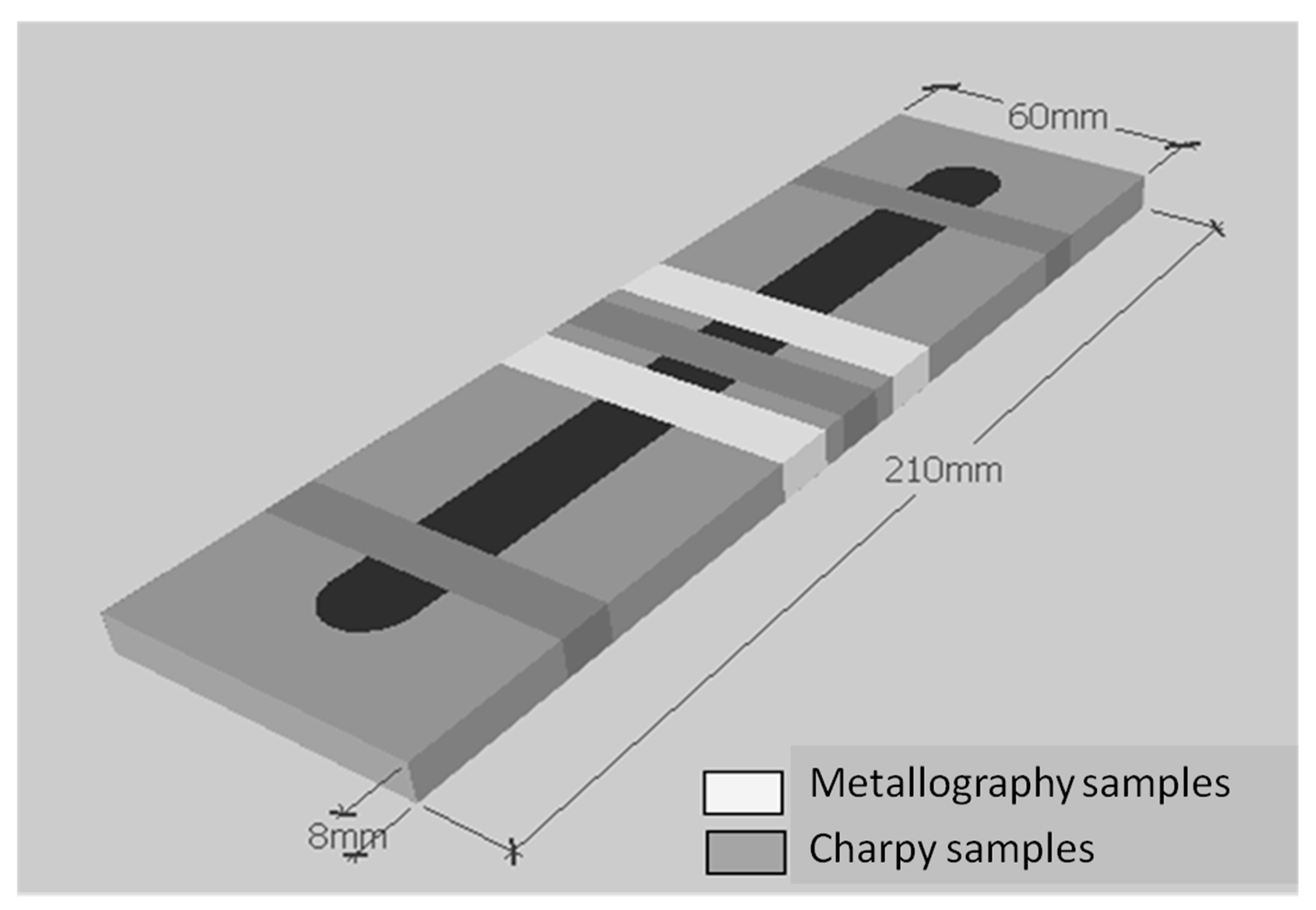

2.2.1. Welding

2.2.2. Temperature Evolution and Cooling Rates

2.2.3. Volume Fraction, Vickers Hardness, Charpy Test

2.2.4. Electrochemical Tests, Scanning Electron Microscopy (SEM)

3. Results and Discussion

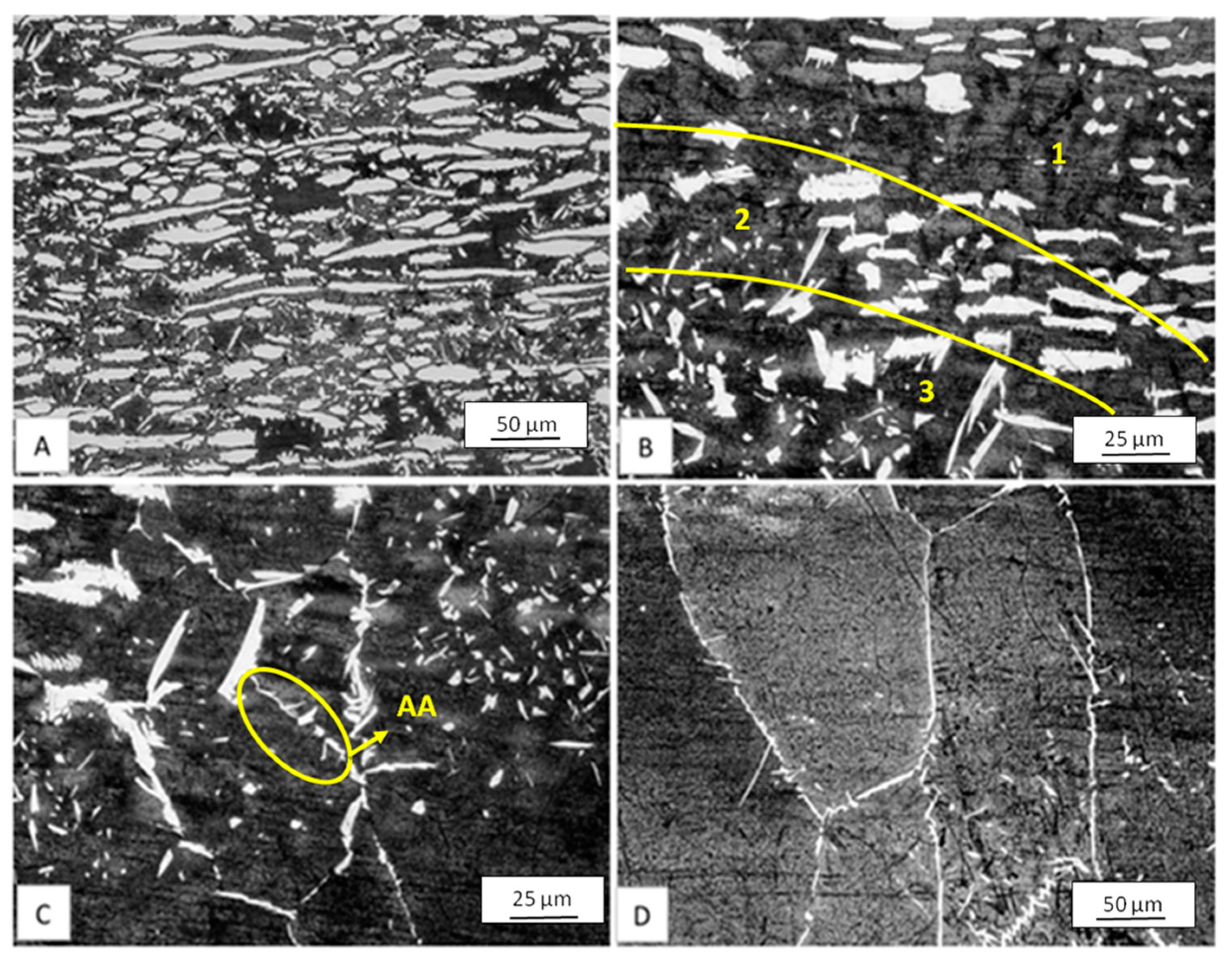

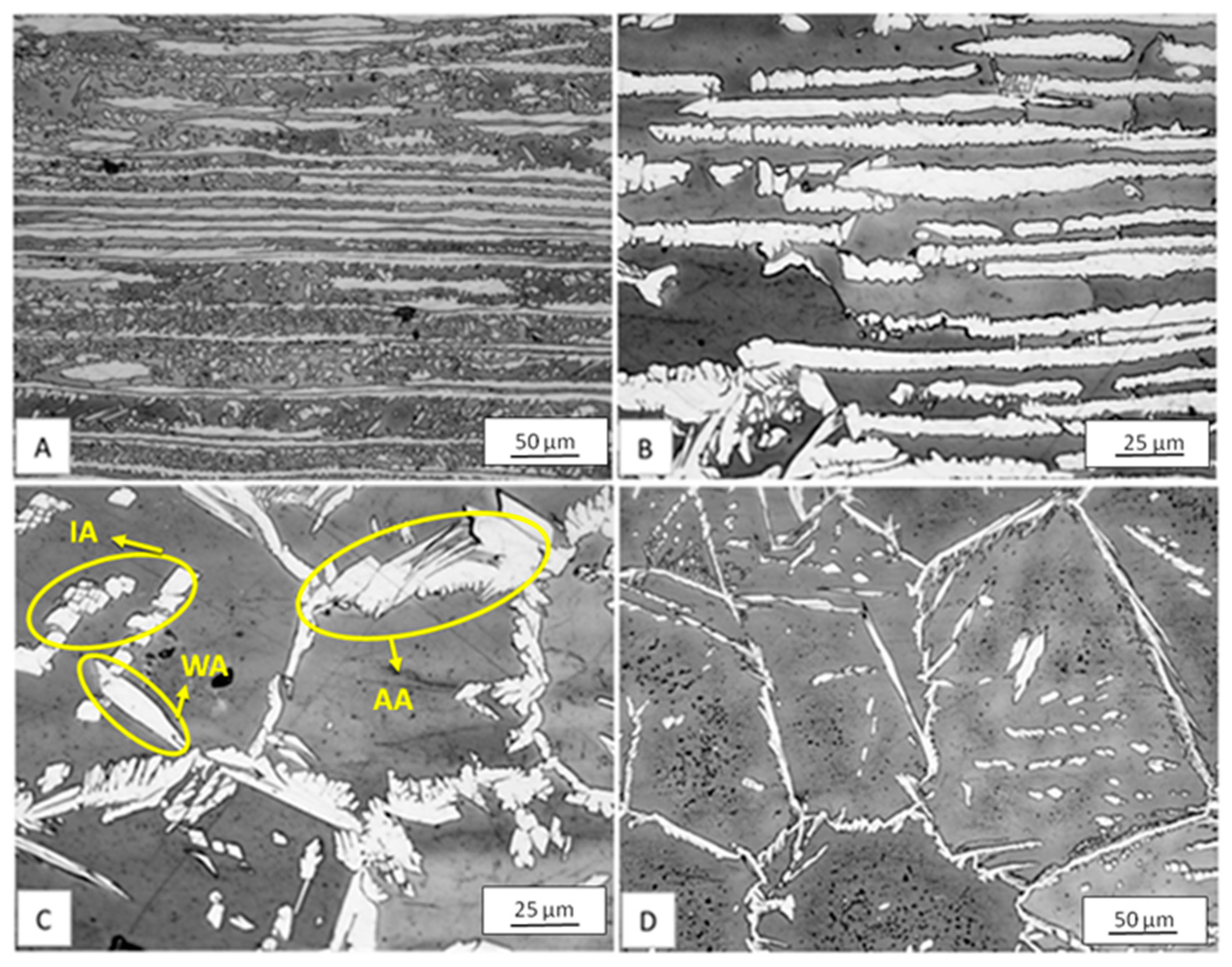

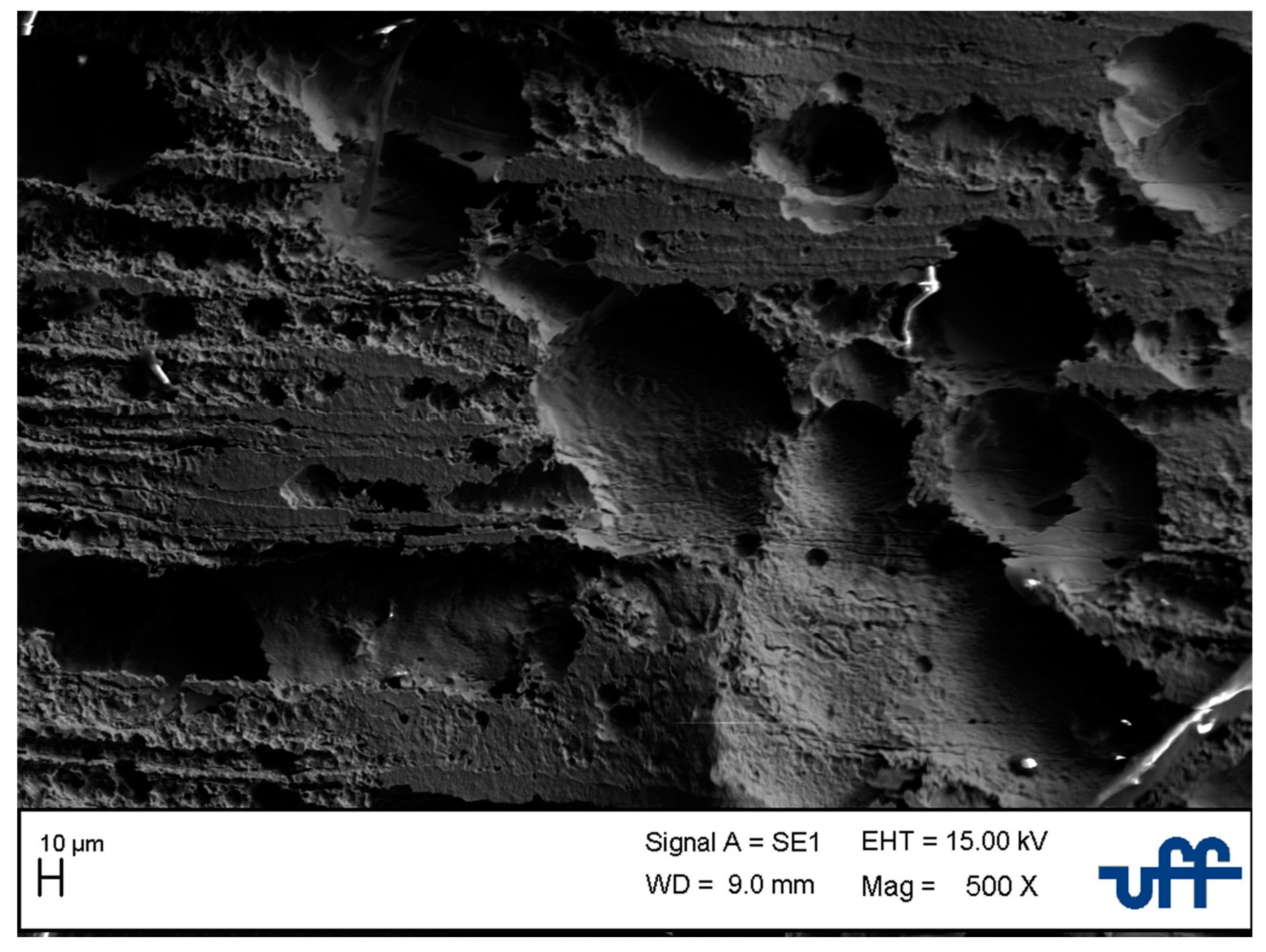

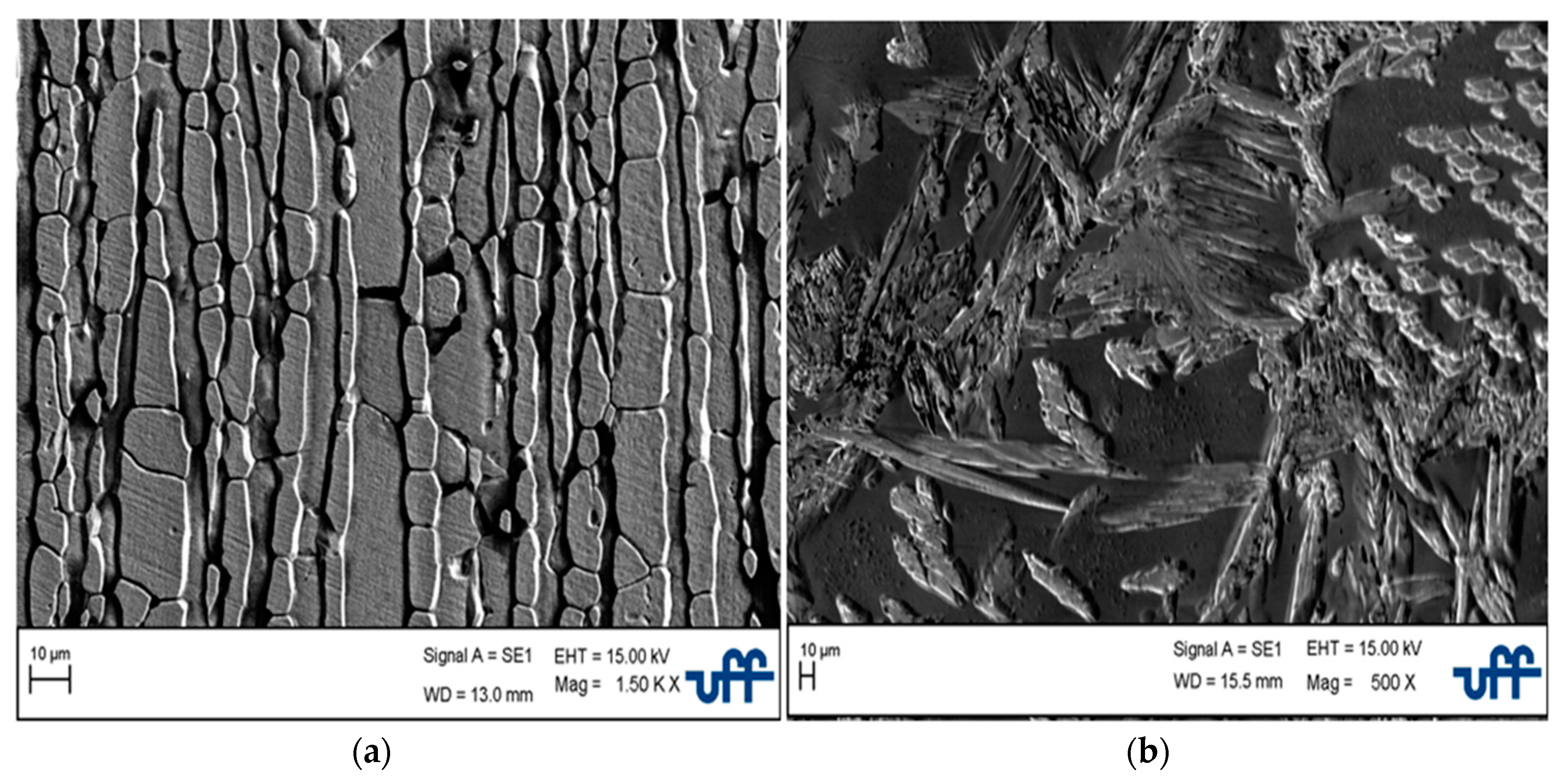

3.1. Microstructural Characterization

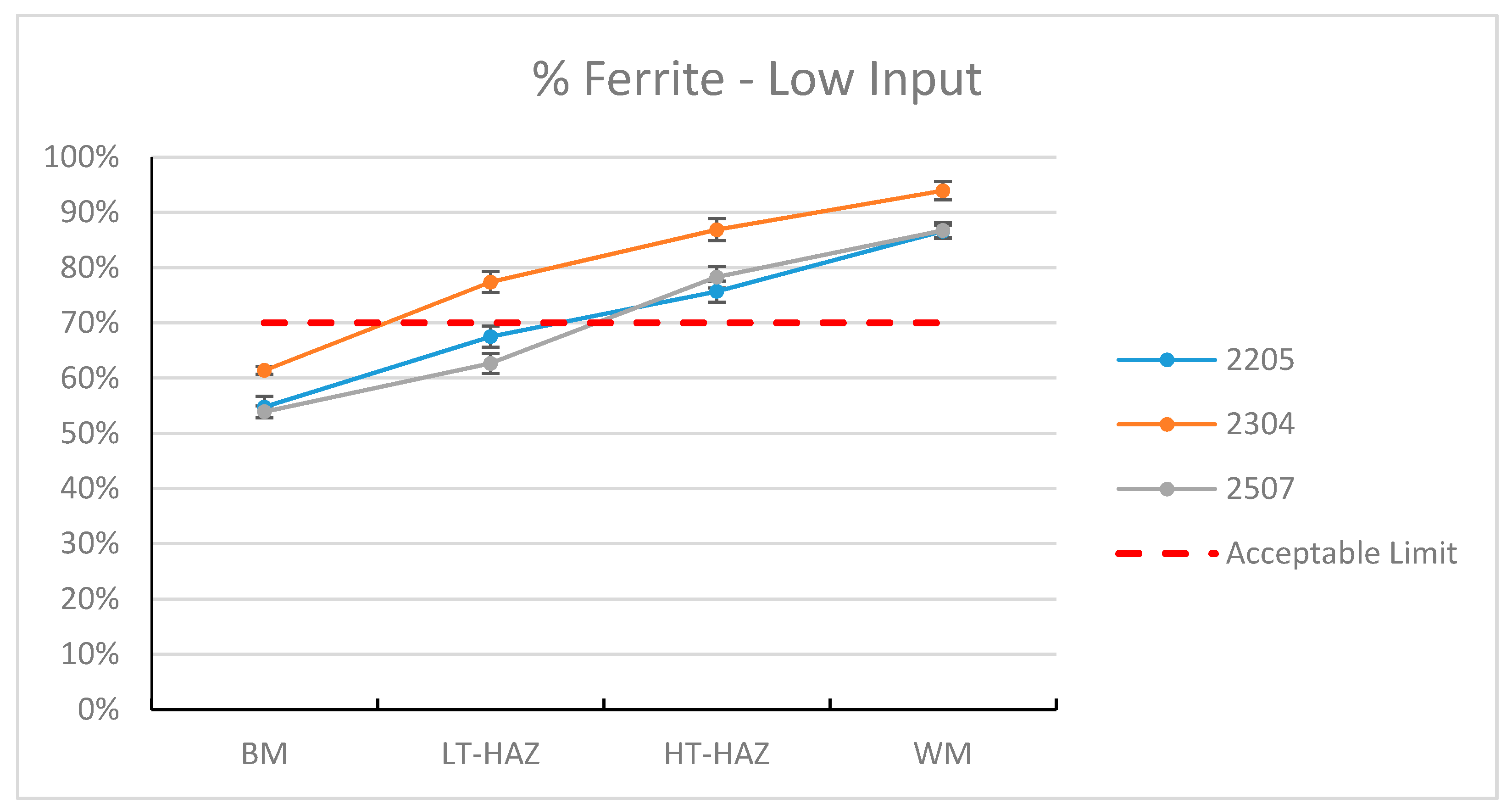

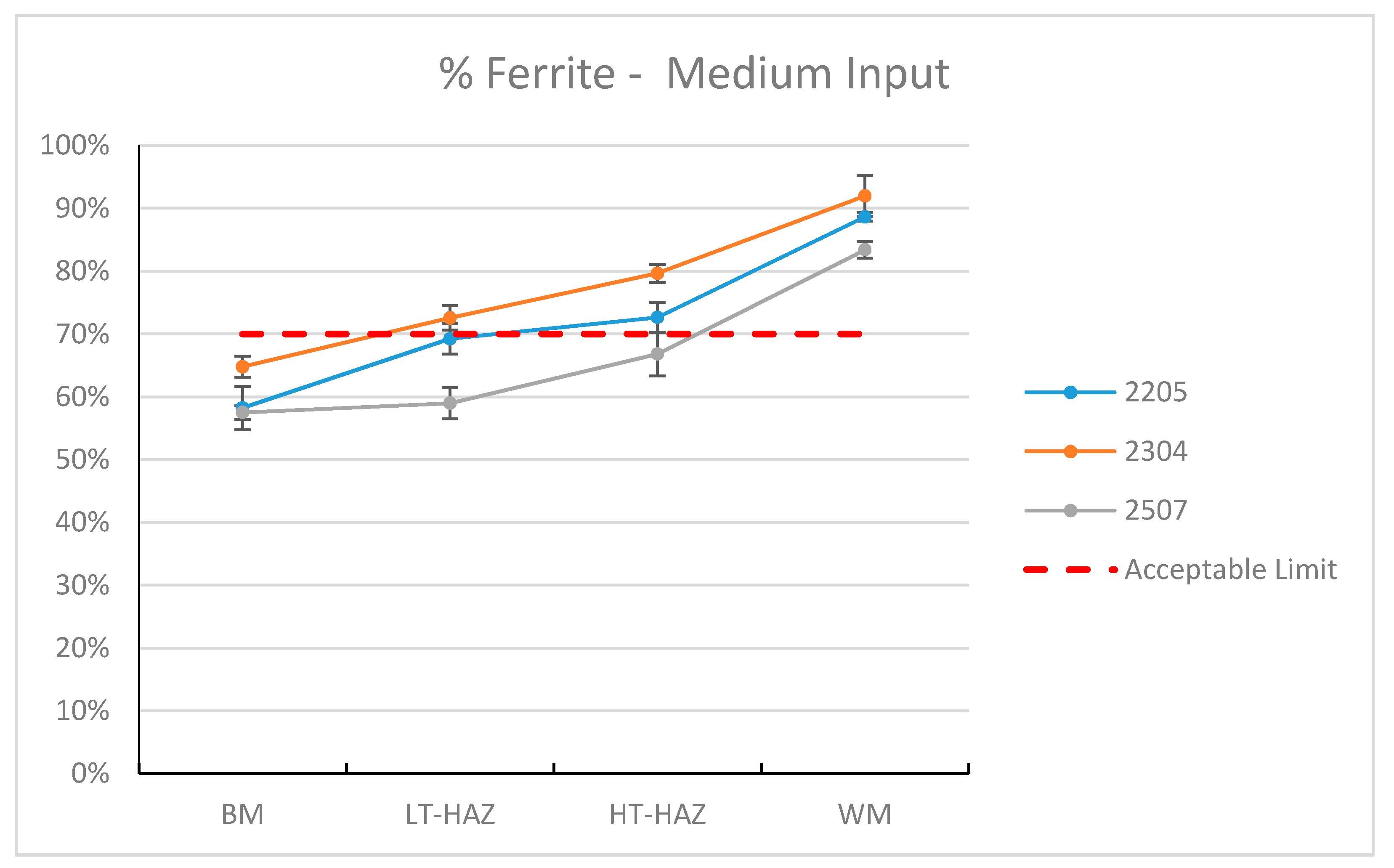

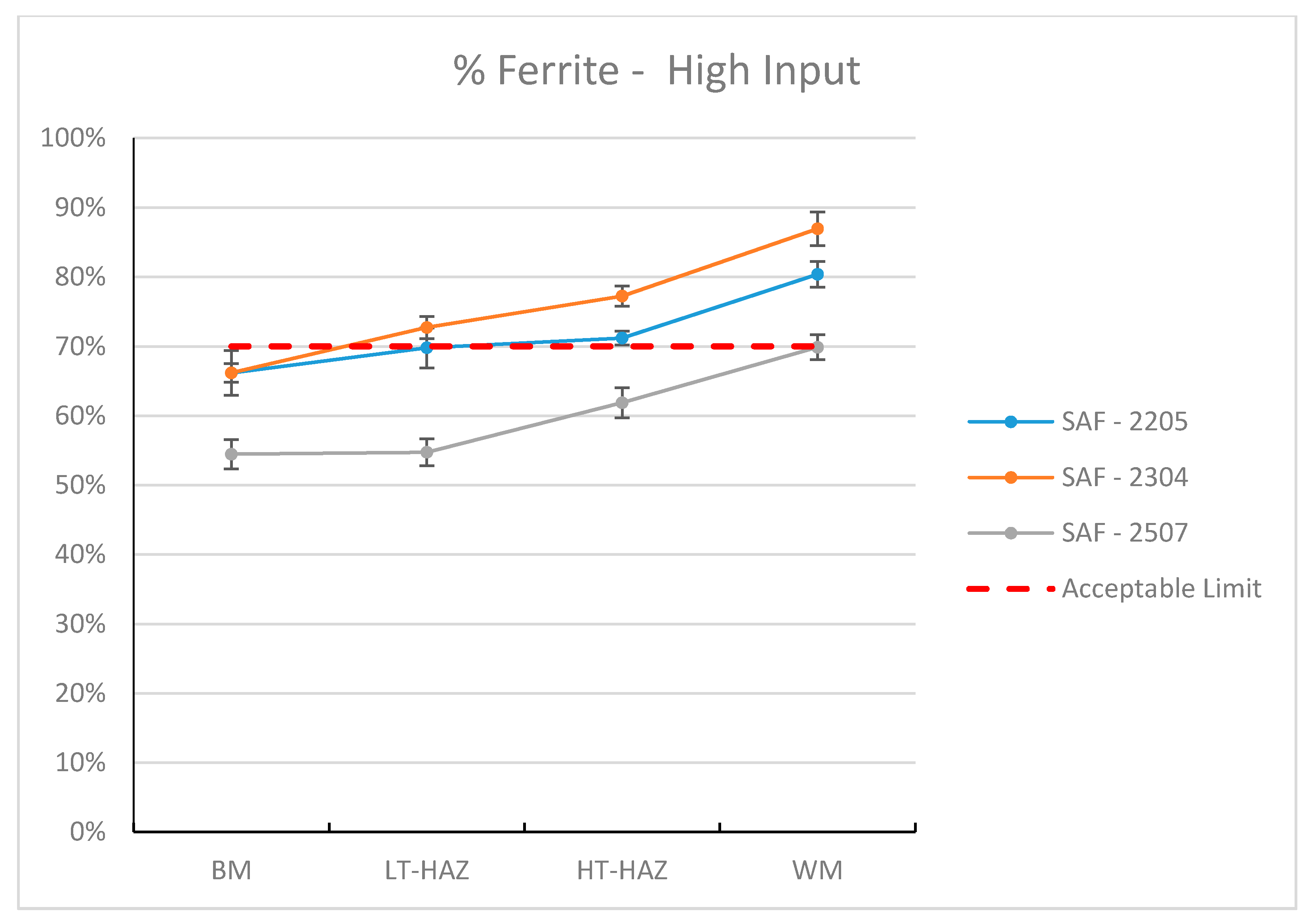

3.2. Volumetric Fraction of Ferrite

3.3. Mechanical Properties

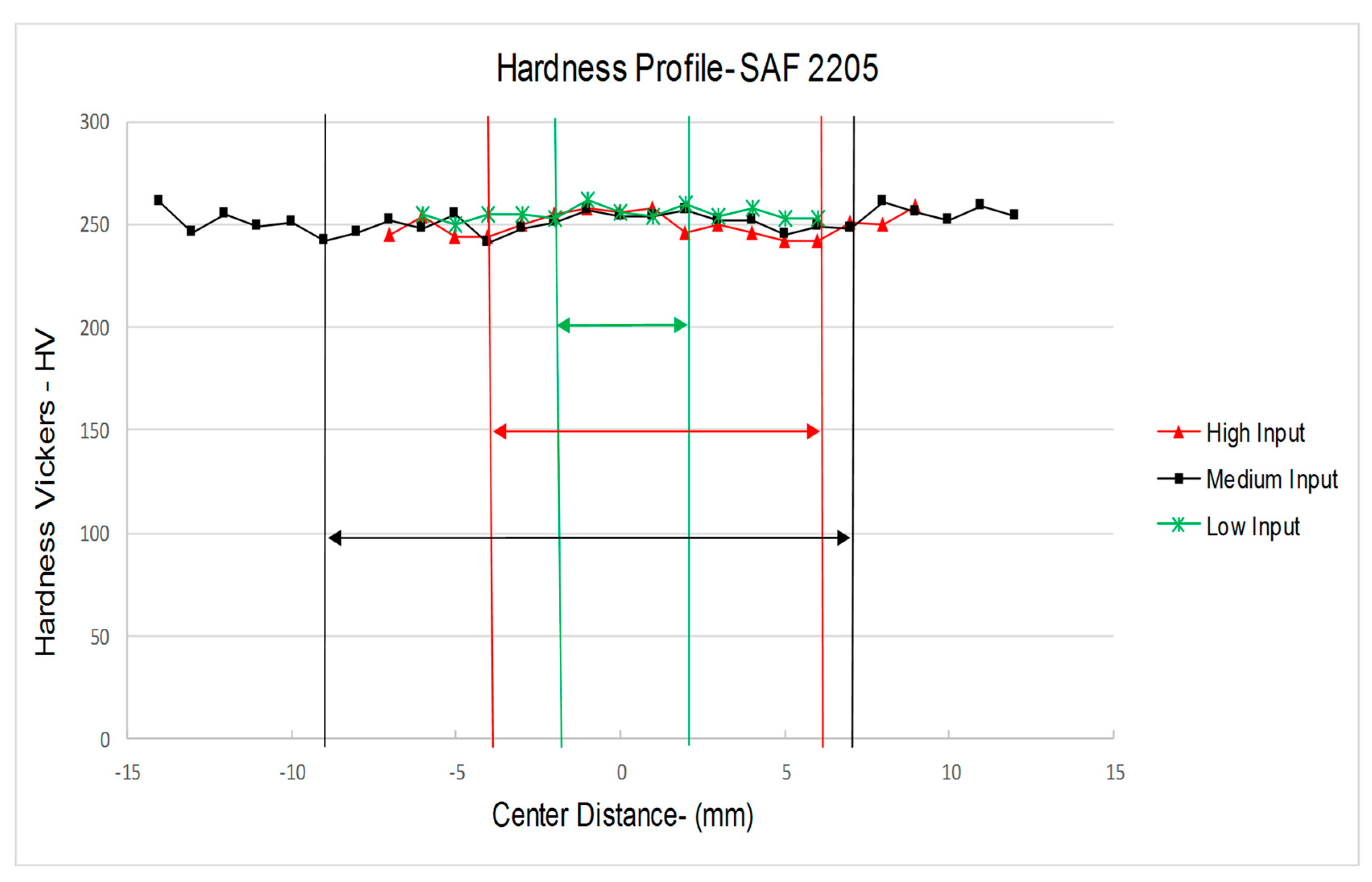

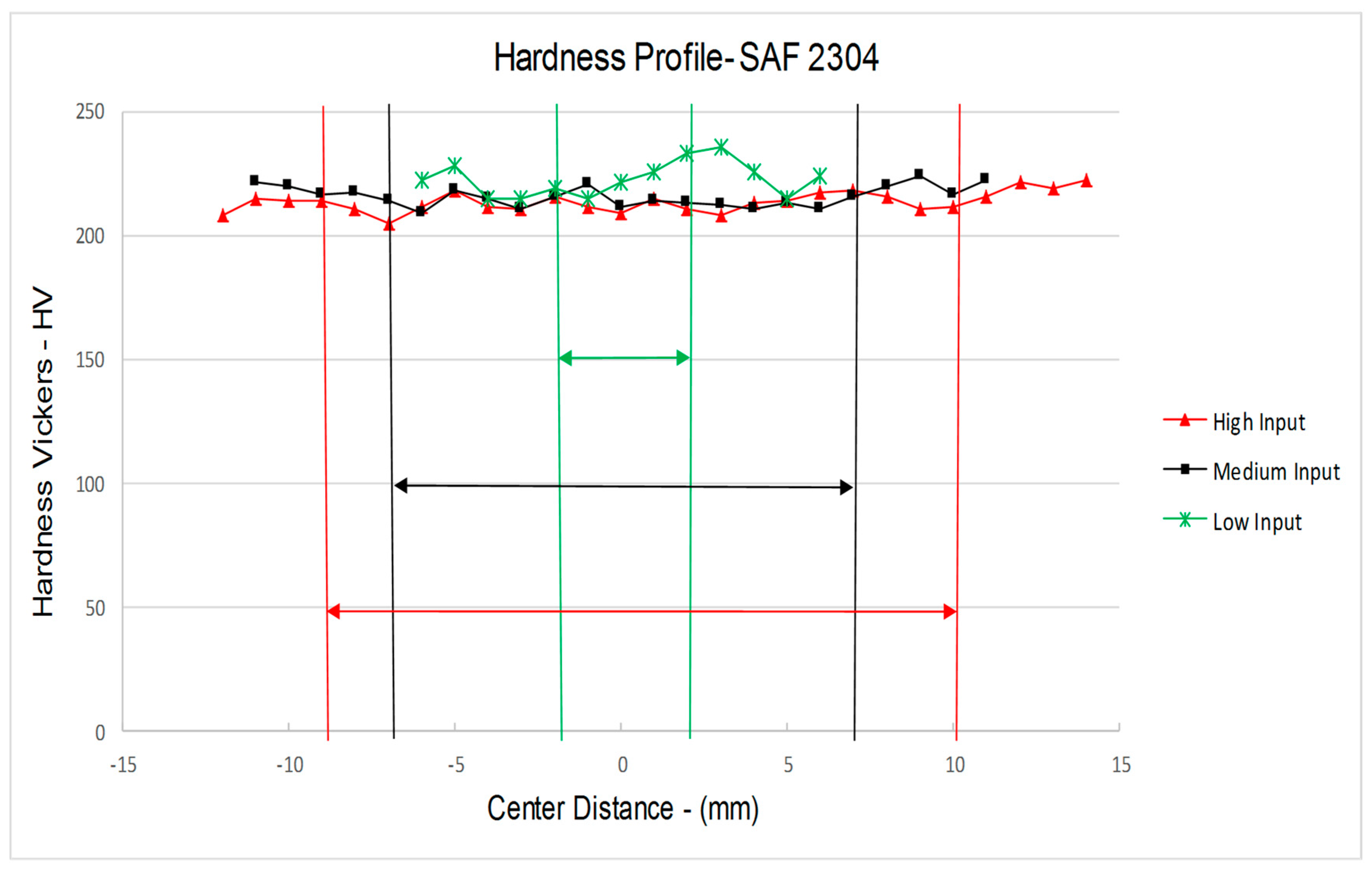

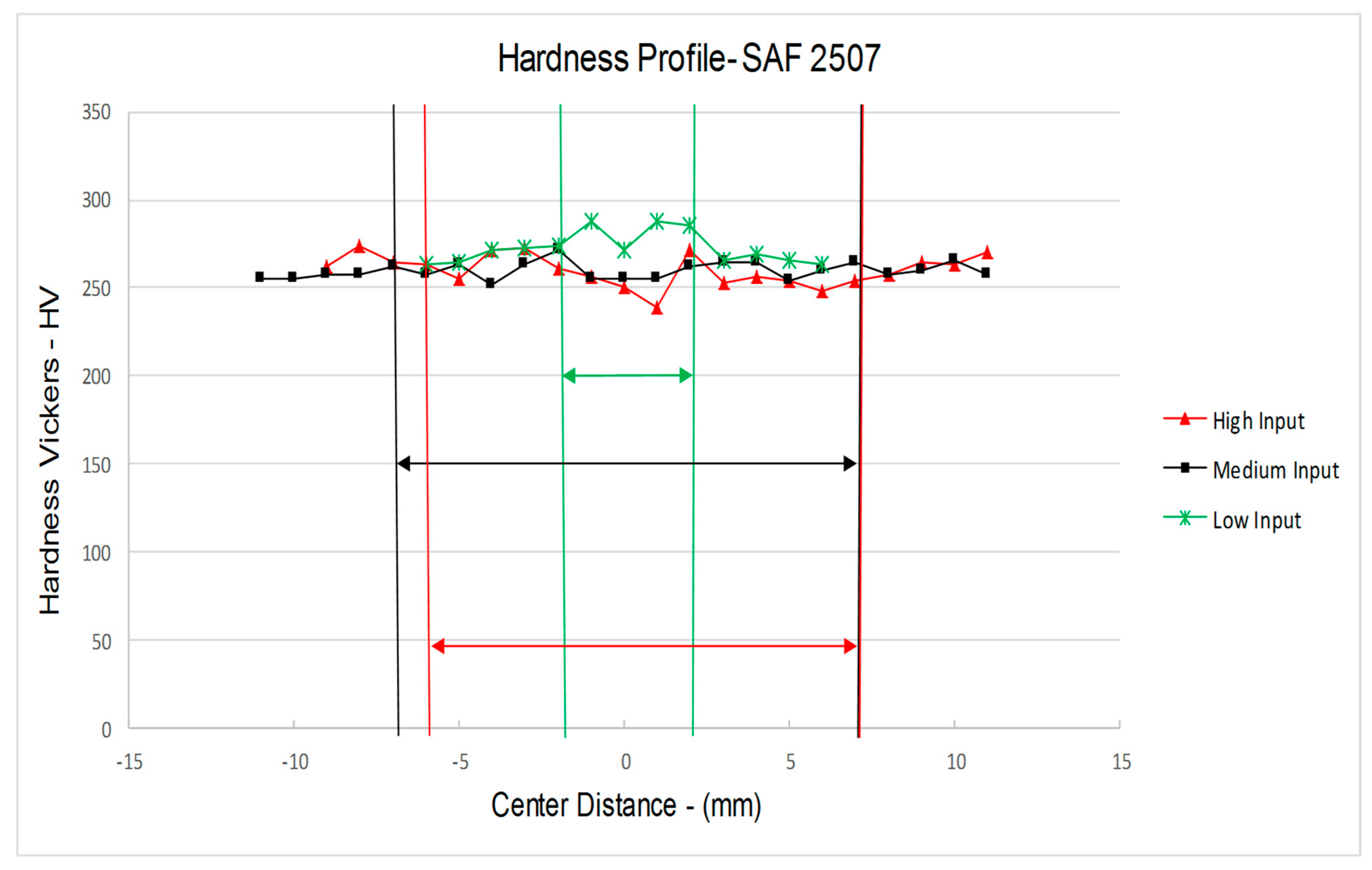

3.3.1. Vickers Hardness

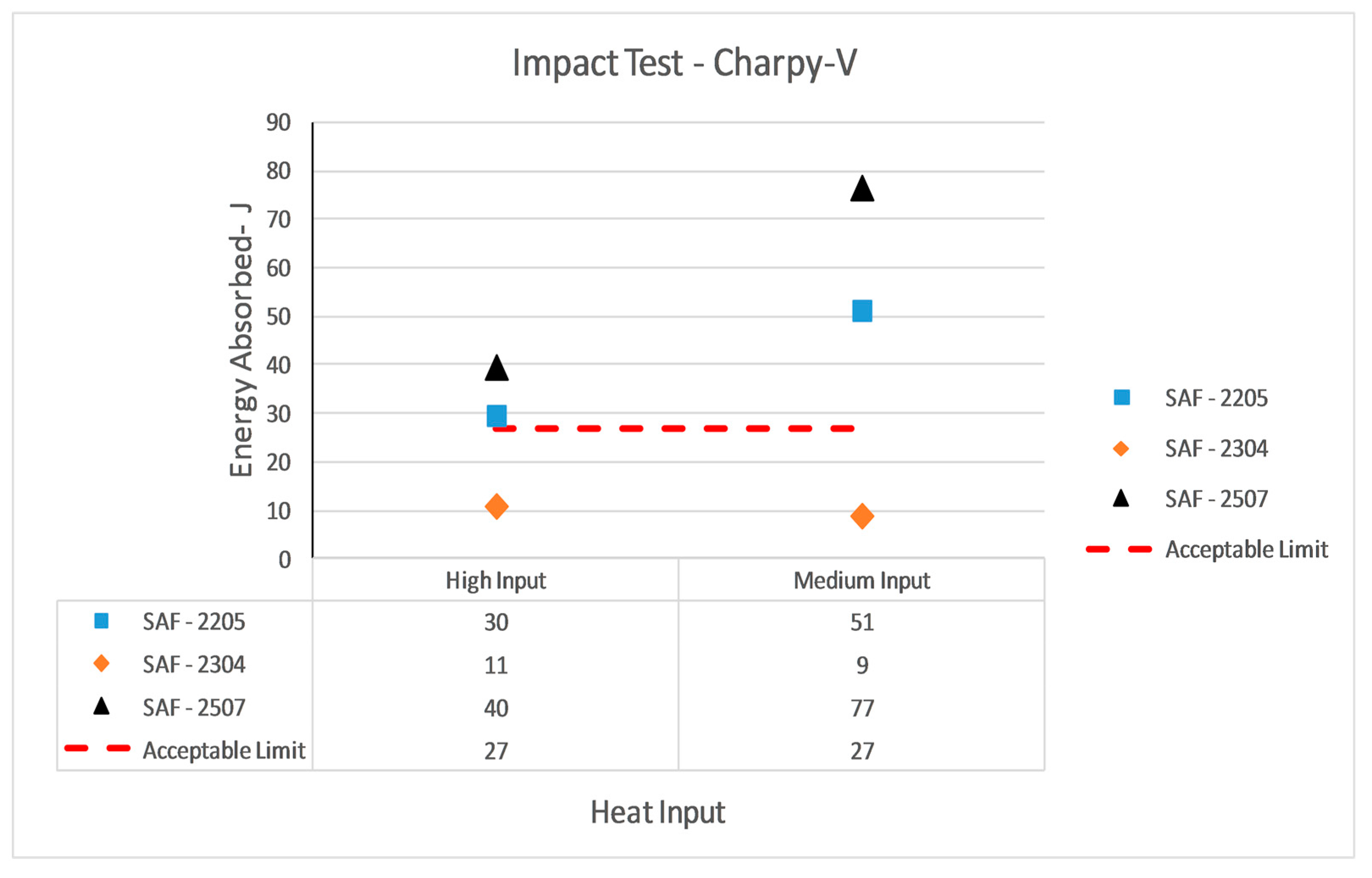

3.3.2. Charpy Impact Test

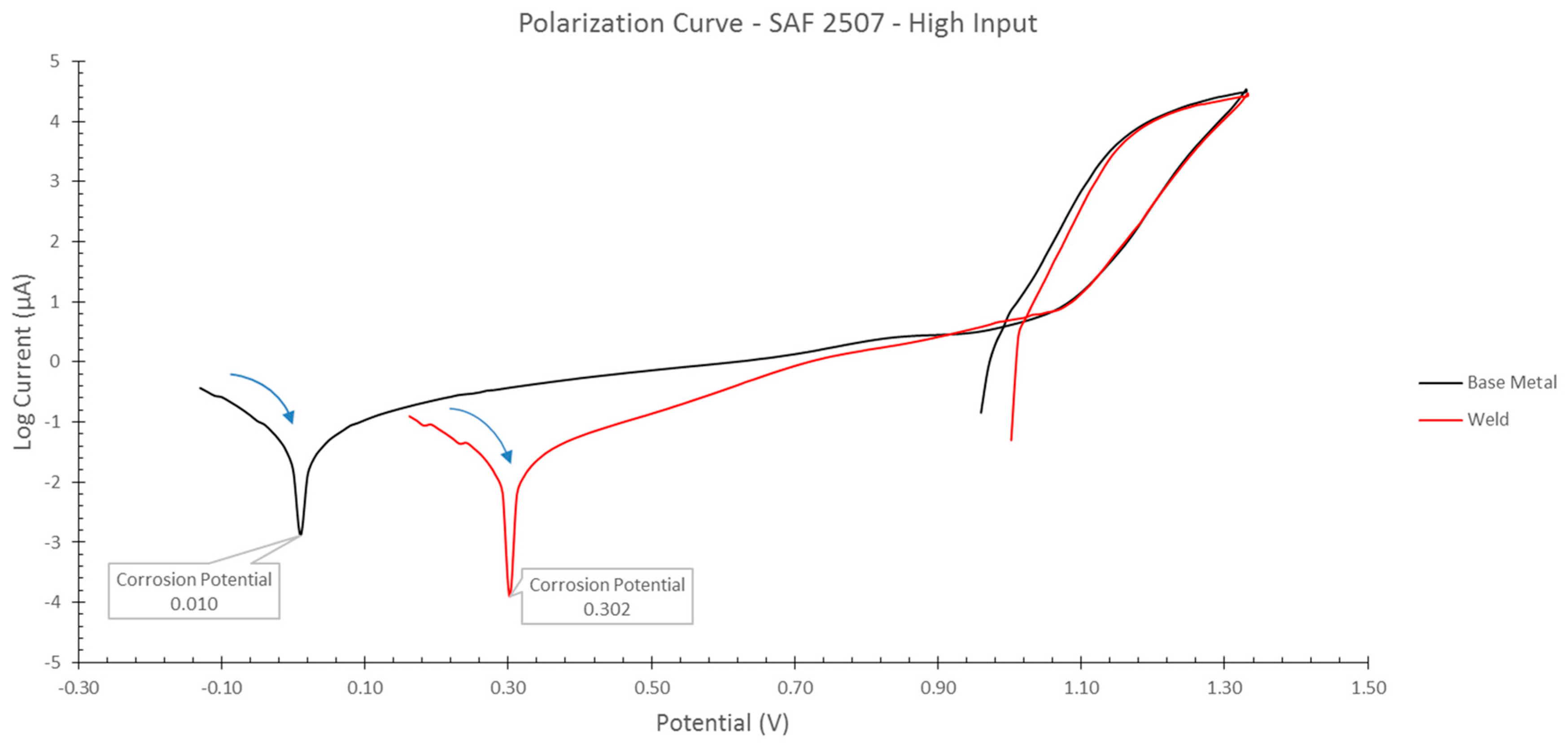

3.4. Electrochemical Tests

4. Conclusions

- In the HAZ and WM, besides the ferrite, there is austenite in three morphologies: allotriomorphic, intragranular, and Widmanstätten. The volumetric fraction of ferrite measured in each region (BM, LT-HAZ, HT-HAZ, WM) for each steel as a function of the heat input shows that SDSS 2507 welded with high input is within the values of the standard in all regions measures. An honorable mention must be made of the behavior of SAF 2205 and SAF 2507 welded with medium heat input, since, with the exception of the amount of ferrite in WM (greater than 70%), all other regions are within the value stipulated by the standard. SAF 2304 presents values higher than 70% of ferrite in the HAZ and WM for all heat inputs used.

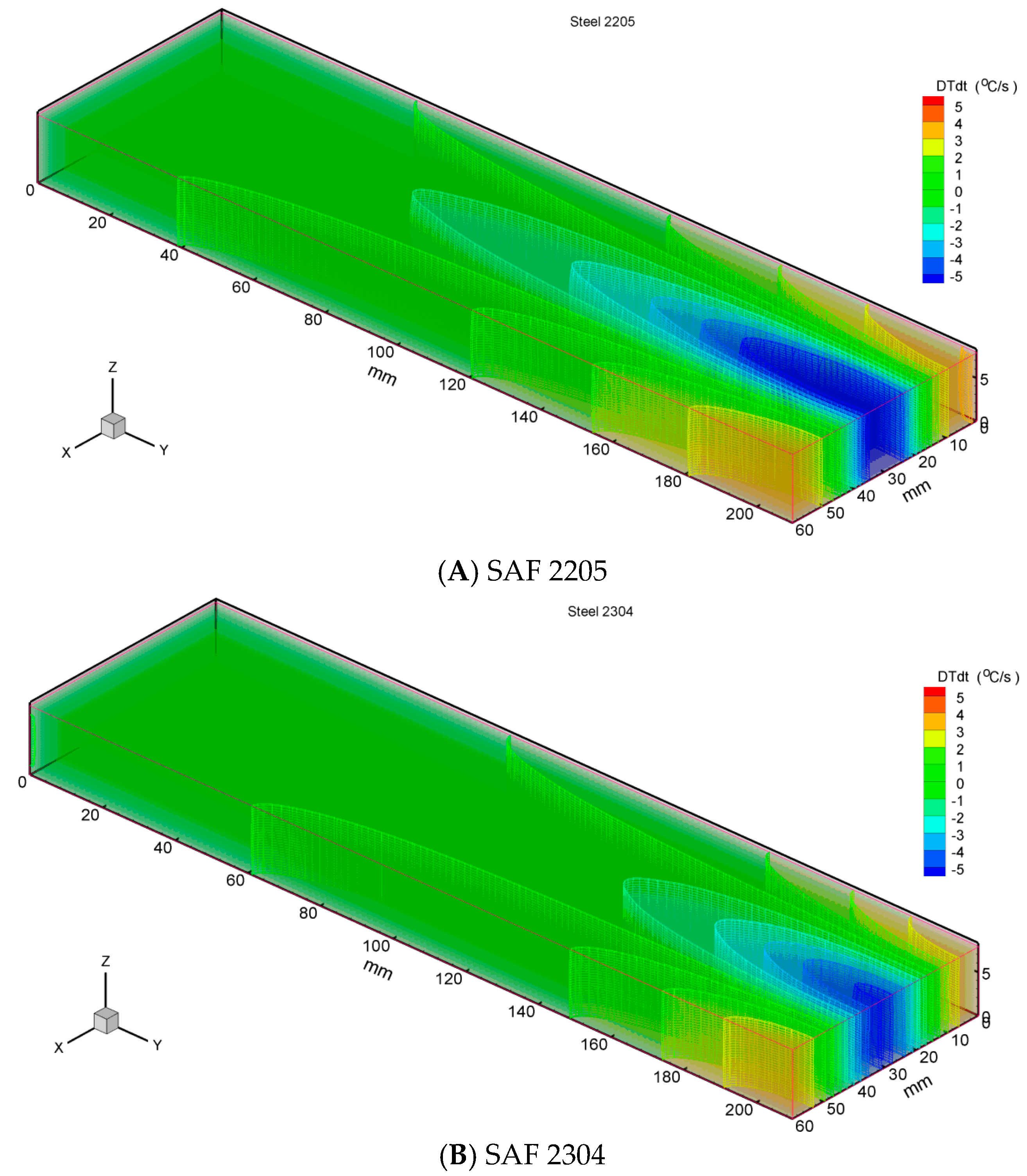

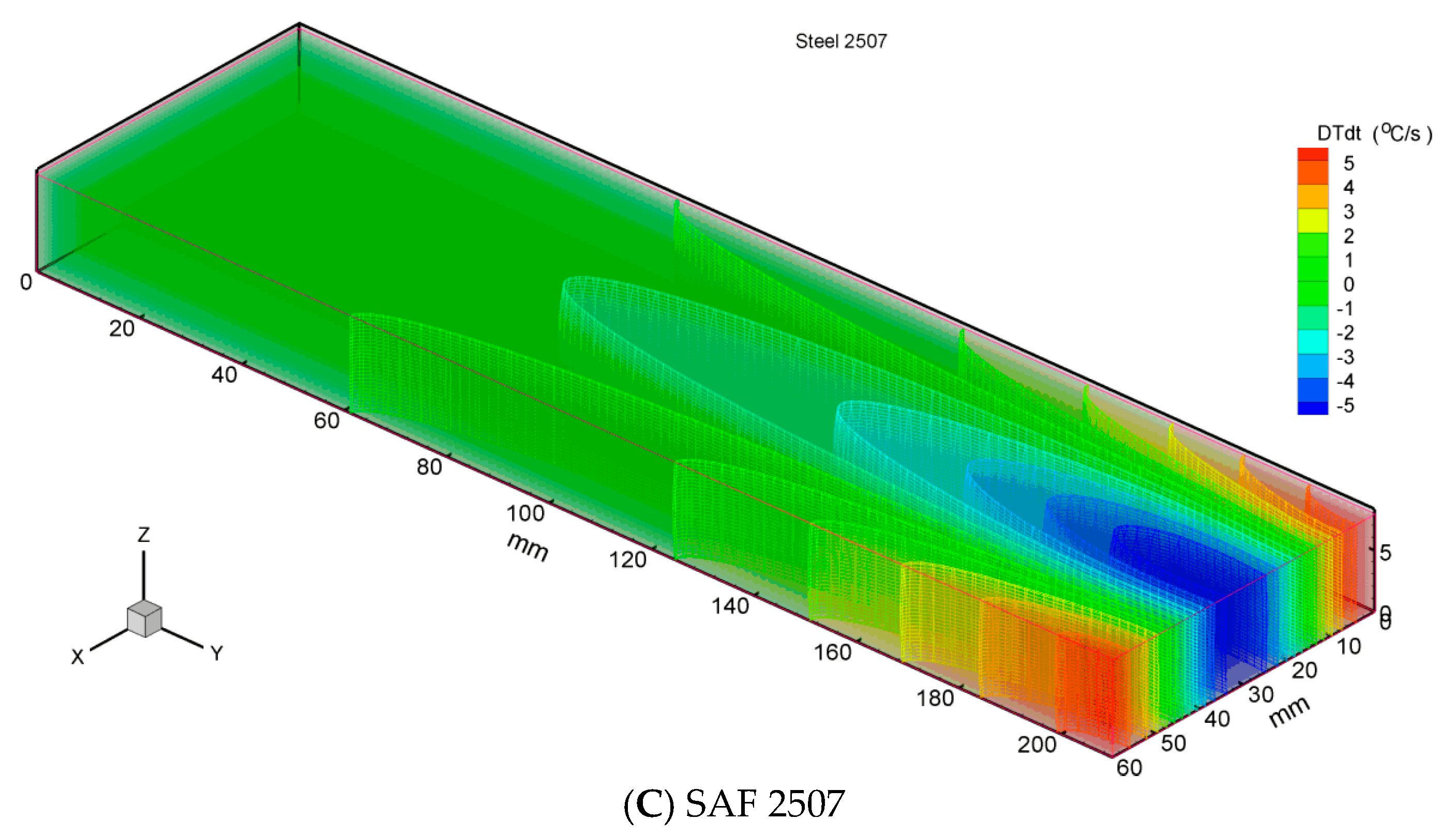

- The measured hardness value remained relatively constant and together with the micrographs shown and heating/cooling rates distribution simulation, shows that there is no precipitation of deleterious phases.

- The values obtained by Chapy impact test at −46 °C show that SAF 2205 and SDSS 2507 remained above the value of 27 J (acceptance limit). The higher absorbed energy obtained for samples welded with medium heat input compared to high heat input is related to the higher amount of AW formed in WM for high input, which would decrease the toughness. The energy absorbed by the SAF 2304 was below that required by the standard.

- SAF 2507 welded with high heat input has the highest corrosion potential value, indicating a higher corrosion resistance than the others.

- After all the results presented, the welding parameters presented in this work with high heat input would be adequate for SDSS 2507 because it maintains the ferrite—austenite balance, does not form deleterious phases that would weaken the steel, and it maintains with high corrosion resistance.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Fonseca, G.S.; Oliveira, P.M.; Diniz, M.G.; Bubnoff, D.M.; Castro, J.A. Sigma Phase in Superduplex Stainless Steel: Formation, Kinetics and Microstructural Path. Mater. Res. 2017, 20, 249–255. [Google Scholar] [CrossRef]

- Escriba, D.M.; Materna-Morris, E.; Plaut, R.L.; Padilha, A.F. Chi-phase precipitation in a duplex stainless steel. Mater. Charact. 2009, 60, 1214–1219. [Google Scholar] [CrossRef]

- Magnabosco, R. Kinetics of sigma phase formation in a Duplex Stainless Steel. Mater. Res. 2009, 12. [Google Scholar] [CrossRef]

- Calliari, I.; Zanesco, M.; Ramous, E. Influence of isothermal aging on secondary phases precipitation and toughness of a duplex stainless steel SAF 2205. J. Mater. Sci. 2006, 41, 7643–7649. [Google Scholar] [CrossRef]

- Karlsson, L. Welding duplex stainless steels—A review of current recommendations. Weld World 2012, 56, 65–76. [Google Scholar] [CrossRef]

- Brytan, Z.; Niagaj, J. Corrosion resistance and mechanical properties of TIG and A-TIG welded joints of lean duplex stainless steel S82441/1.4662. Arch. Metall. Mater. 2016, 61, 771–784. [Google Scholar] [CrossRef]

- Mohammed, G.R.; Ishak, E.; Aqida, S.N.; Abdulhadi, H.A. Effects of Heat Input on Microstructure, Corrosion and Mechanical Characteristics of Welded Austenitic and Duplex Stainless Steels: A Review. Metals 2017, 7, 39. [Google Scholar] [CrossRef]

- Dobranszky, J.; Szabo, P.J.; Berecz, T.; Hrotko, V.; Portko, M. Energy dispersive spectroscopy and electron backscatter diffraction analysis of isothermally aged SAF 2507 type superduplex stainless steel. Spectrochim. Acta Part B 2004, 59, 1781–1788. [Google Scholar] [CrossRef]

- Hsieh, C.C.; Wu, W. Overview of Intermetallic Sigma (σ) Phase Precipitation in Stainless Steels. ISRN Metall. 2012, 2012, 732471. [Google Scholar] [CrossRef]

- Kobayashi, D.Y.; Wolynec, S. Evaluation of the low corrosion resistant phase formed during the sigma phase precipitation in duplex stainless steels. Mater. Res. 1999, 2, 239–247. [Google Scholar] [CrossRef]

- Villanueva, D.M.E.; Junior, F.C.P.; Plaut, R.L.; Padilha, A.F. Comparative study on sigma phase precipitation of three types of stainless steels: Austenitic, superferritic and duplex. Mater. Sci. Technol. 2006, 22, 1098–1104. [Google Scholar] [CrossRef]

- Elmer, J.W.; Palmer, T.A.; Specht, E.D. Direct Observations of Sigma Phase Formation in Duplex Stainless Steels Using In-Situ Synchrotron X-ray Diffraction. Metall. Mater. Trans. A 2007, 38, 464–475. [Google Scholar] [CrossRef]

- Badji, R.; Bouabdallah, M.; Bacroix, B.; Kahloun, C.; Belkessa, B.; Maza, H. Phase transformation and mechanical behavior in annealed 2205 duplex stainless steel welds. Mater. Charact. 2008, 59, 447–453. [Google Scholar] [CrossRef]

- Fan, K.; Liu, F.; Ma, Y.Z.; Yang, G.C.; Zhou, Y.H. Modeling of σ-phase precipitation in a 2205 duplex stainless steel using an analytical soft impingement treatment. Mater. Sci. Eng. A 2010, 527, 4450–4553. [Google Scholar] [CrossRef]

- Xavier, C.R.; Delgado, J.H.G.; Castro, J.A. An experimental and numerical approach for the welding effects on the duplex stainless steel microstructure. Mater. Res. 2015, 18, 489–502. [Google Scholar] [CrossRef]

- Xavier, C.R.; Delgado, J.H.G.; Castro, J.A.; Ferreira, A.F. Numerical predictions for the thermal history, microstructure and hardness distributions at the HAZ during welding of low alloy steels. Mater. Res. 2016, 19, 520–533. [Google Scholar] [CrossRef]

- Xavier, C.R.; Campos, M.F.; Castro, J.A. Numerical method applied to duplex stainless steel. Ironmak. Steelmak. 2013, 40, 420–429. [Google Scholar] [CrossRef]

- Russ, J.C.; Dehoff, R.T. Practical Stereology, 2nd ed.; Kluwer Academic/Plenum Publishers: New York, NY, USA, 2000; pp. 45–78. ISBN 0-306-46476-4. [Google Scholar]

- ASTM Standard E23-16b. Standard Test Methods for Notched Bar Impact Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar] [CrossRef]

- Norsok Standard M-601. Welding and Inspection of Piping; Standards Norway: Lysaker, Norway, 2008. [Google Scholar]

- Deng, B.; Jiang, Y.; Gong, J.; Zhong, C.; Gao, J.; Li, J. Critical pitting and repassivation temperatures for duplex stainless steel in chloride solutions. Electrochim. Acta 2008, 53, 5220–5225. [Google Scholar] [CrossRef]

- IMOA International Molybdenum Association. Available online: http://www.imoa.info/download_files/stainless-steel/Duplex-Stainless-Steel_3rd_Edition.pdf (accessed on 10 January 2017).

- Porter, D.A.; Easterling, K.E. Phase Transformations in Metals and Alloys, 2nd ed.; Chapman & Hall: London, UK, 1992; pp. 185–260. ISBN 0-412-45030-5. [Google Scholar]

- Sieurin, H.; Sandström, R. Sigma phase precipitation in duplex stainless steel 2205. Mater. Sci. Eng. A 2007, 444, 271–276. [Google Scholar] [CrossRef]

- Callister, W.D., Jr. Materials Science and Engineering: An Introduction, 7th ed.; John Wiley & Sons: New York, NY, USA, 2007; pp. 207–251. ISBN 978-0-471-73696-7. [Google Scholar]

- Muthupandi, V.; Srinivasan, P.B.; Seshadri, S.K.; Sundaresan, S. Chi Effect of weld metal chemistry and heat input on the structure and properties of duplex stainless steel welds. Mater. Sci. Eng. A 2003, 358, 9–16. [Google Scholar] [CrossRef]

| SAF | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

|---|---|---|---|---|---|---|---|---|---|---|

| 2205 | 0.023 | 0.320 | 1.85 | 0.030 | 0.001 | 22.50 | 5.30 | 2.90 | 0.166 | 0.030 |

| 2304 | 0.016 | 0.410 | 1.49 | 0.025 | 0.0001 | 22.62 | 3.58 | 0.24 | 0.112 | 0.450 |

| 2507 | 0.020 | 0.328 | 0.85 | 0.027 | 0.0009 | 24.89 | 6.82 | 3.72 | 0.278 | 0.156 |

| SAF | I (A) | E (V) | Arc (mm) | Heat Input (kJ/mm) |

|---|---|---|---|---|

| 2205 | 76 | 9 | 2 | 0.5 |

| 2304 | 76 | 9 | 2 | 0.5 |

| 2507 | 76 | 9 | 2 | 0.5 |

| 2205 | 211 | 13 | 2 | 2.2 |

| 2304 | 211 | 15 | 2 | 2.5 |

| 2507 | 211 | 14 | 2 | 2.4 |

| 2205 | 232 | 15 | 2.5 | 2.8 |

| 2304 | 285 | 15 | 2 | 3.4 |

| 2507 | 249 | 16 | 2.5 | 3.2 |

| Region | 2205 | 2304 | 2507 | Heat Input |

|---|---|---|---|---|

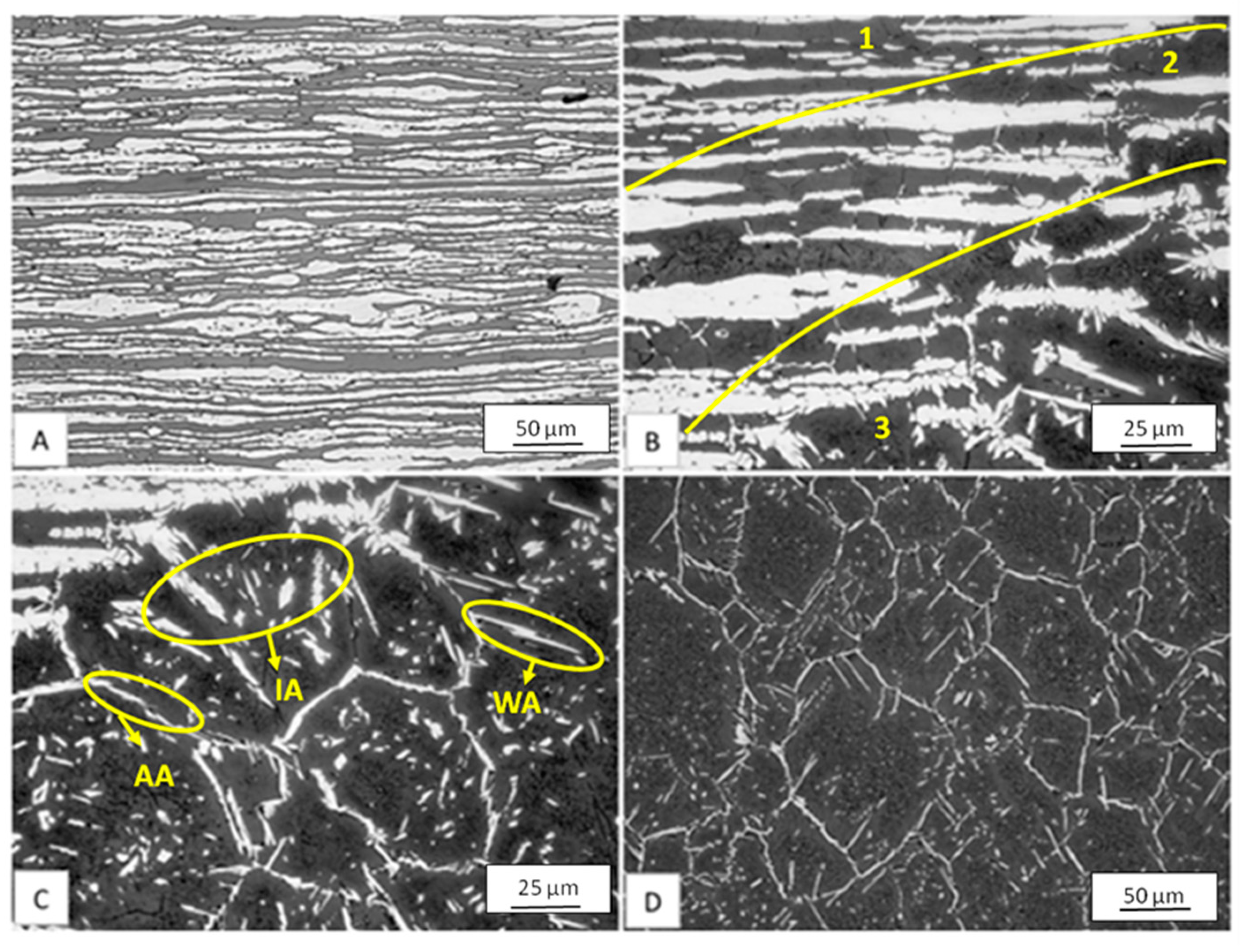

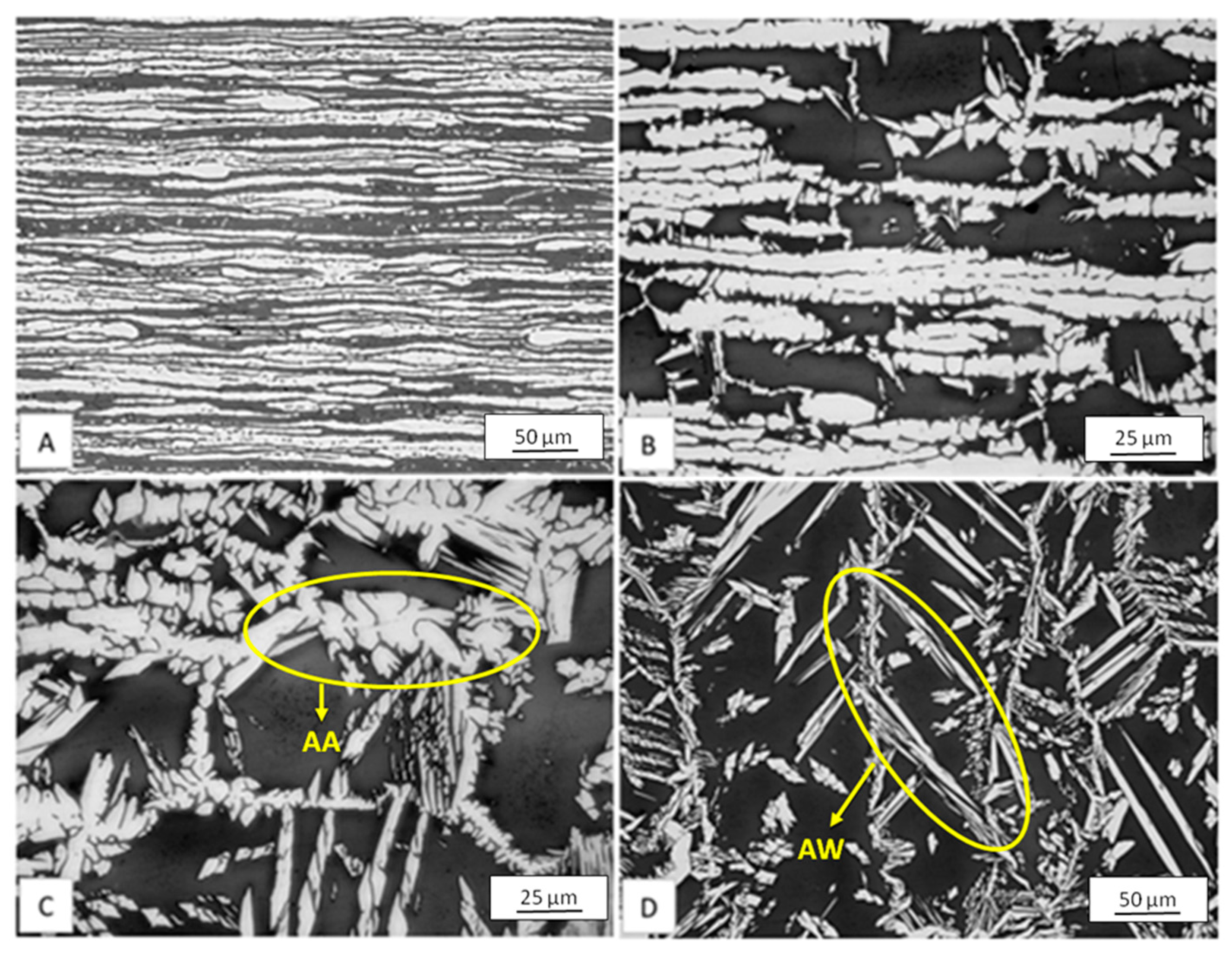

| BM | F and A lamellar | F and A lamellar | F and A lamellar | Low |

| F and A lamellar | F and A lamellar. F thicker | F and A lamellar | High | |

| LT-HAZ | F and A lamellar. very narrow range | F matrix. A islands. very narrow range | F and A thicker than BM. very narrow range | Low |

| F and A lamellar. F thicker | F and A thicker | F and A thicker than BM | High | |

| HT-HAZ | F thickening. Tendency to change in grain morphology (“pancakes” for equiaxial) compared to BM and LT-HAZ. A Morphology: AA, WA, IA | F grain defined by a low amount of AA. Presence of IA | F grains slightly defined by AA. Reasonable amount of IA and WA. Similar 2205. | Low |

| F defined by AA with thicker agglomerates (AA, WA, IA) | Well-defined F grains and a larger agglomerate of AA. IA and WA growing. | F grains and large A agglomerates. AA and IA | High | |

| WM | Equiaxial F defined by AA. Presence of WA and IA | F grain almost columnar. Lowest amount of A | Similar SAF 2205 | Low |

| Larger F grains. Presence of AA, WA and IA | F and A thicker compared to low heat input. Presence of AA, WA, IA | Columnar F grains and a large amount of WA | High |

| SAF | Low Input | Medium Input | High Input | |

|---|---|---|---|---|

| 2205 | BM | 0.244 | 0.284 | 0.004 |

| Weld | 0.256 | 0.282 | 0.178 | |

| 2304 | BM | 0.024 | −0.182 | −0.274 |

| Weld | −0.267 | −0.036 | −0.051 | |

| 2507 | BM | 0.269 | 0.258 | 0.010 |

| Weld | 0.096 | 0.073 | 0.302 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Da Fonseca, G.S.; Barbosa, L.O.R.; Ferreira, E.A.; Xavier, C.R.; De Castro, J.A. Microstructural, Mechanical, and Electrochemical Analysis of Duplex and Superduplex Stainless Steels Welded with the Autogenous TIG Process Using Different Heat Input. Metals 2017, 7, 538. https://doi.org/10.3390/met7120538

Da Fonseca GS, Barbosa LOR, Ferreira EA, Xavier CR, De Castro JA. Microstructural, Mechanical, and Electrochemical Analysis of Duplex and Superduplex Stainless Steels Welded with the Autogenous TIG Process Using Different Heat Input. Metals. 2017; 7(12):538. https://doi.org/10.3390/met7120538

Chicago/Turabian StyleDa Fonseca, Gláucio Soares, Luis Otavio Rodrigues Barbosa, Elivelton Alves Ferreira, Carlos Roberto Xavier, and José Adilson De Castro. 2017. "Microstructural, Mechanical, and Electrochemical Analysis of Duplex and Superduplex Stainless Steels Welded with the Autogenous TIG Process Using Different Heat Input" Metals 7, no. 12: 538. https://doi.org/10.3390/met7120538

APA StyleDa Fonseca, G. S., Barbosa, L. O. R., Ferreira, E. A., Xavier, C. R., & De Castro, J. A. (2017). Microstructural, Mechanical, and Electrochemical Analysis of Duplex and Superduplex Stainless Steels Welded with the Autogenous TIG Process Using Different Heat Input. Metals, 7(12), 538. https://doi.org/10.3390/met7120538