Effects of Welding Parameters on Strength and Corrosion Behavior of Dissimilar Galvanized Q&P and TRIP Spot Welds

Abstract

:1. Introduction

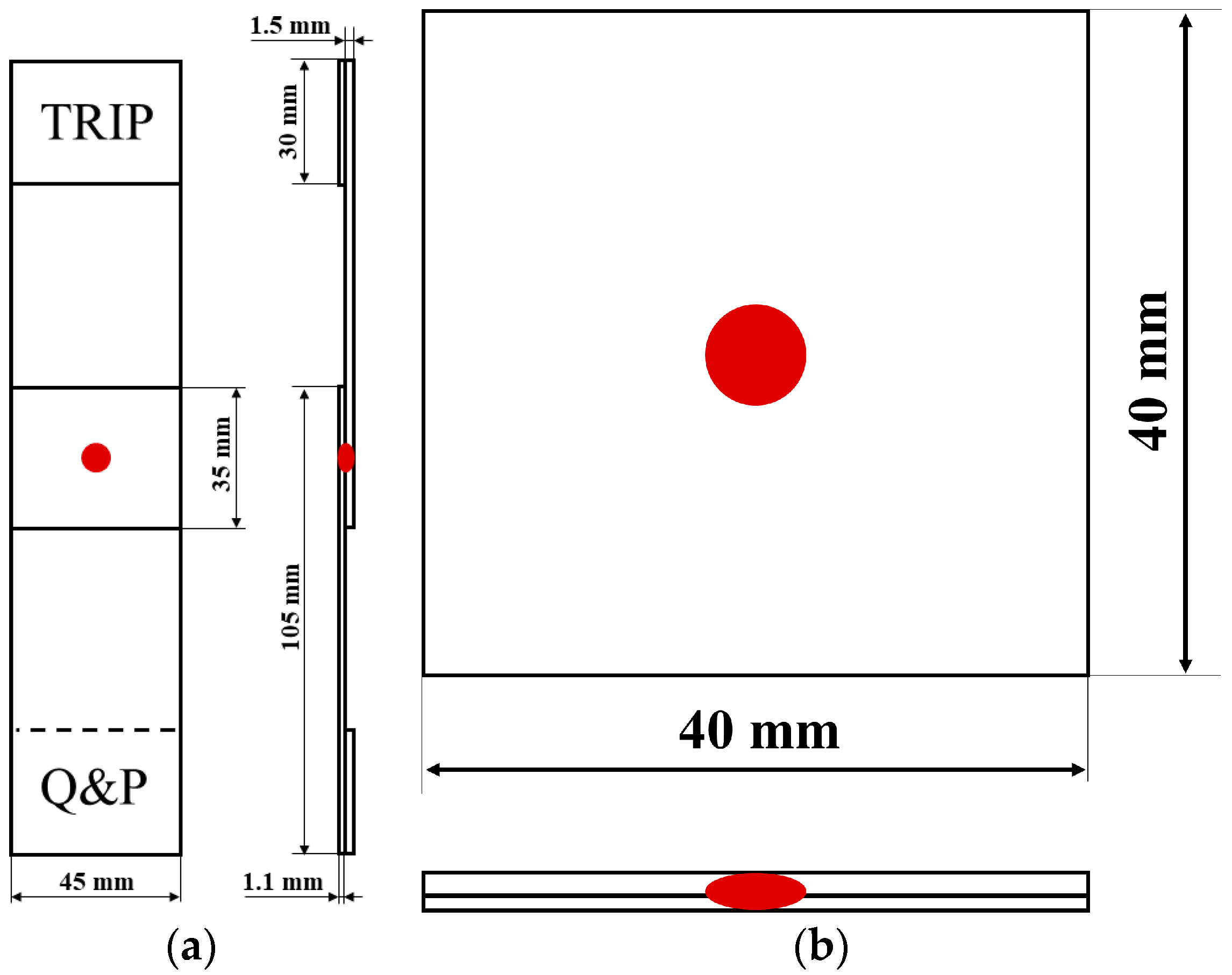

2. Materials and Methods

3. Results and Discussion

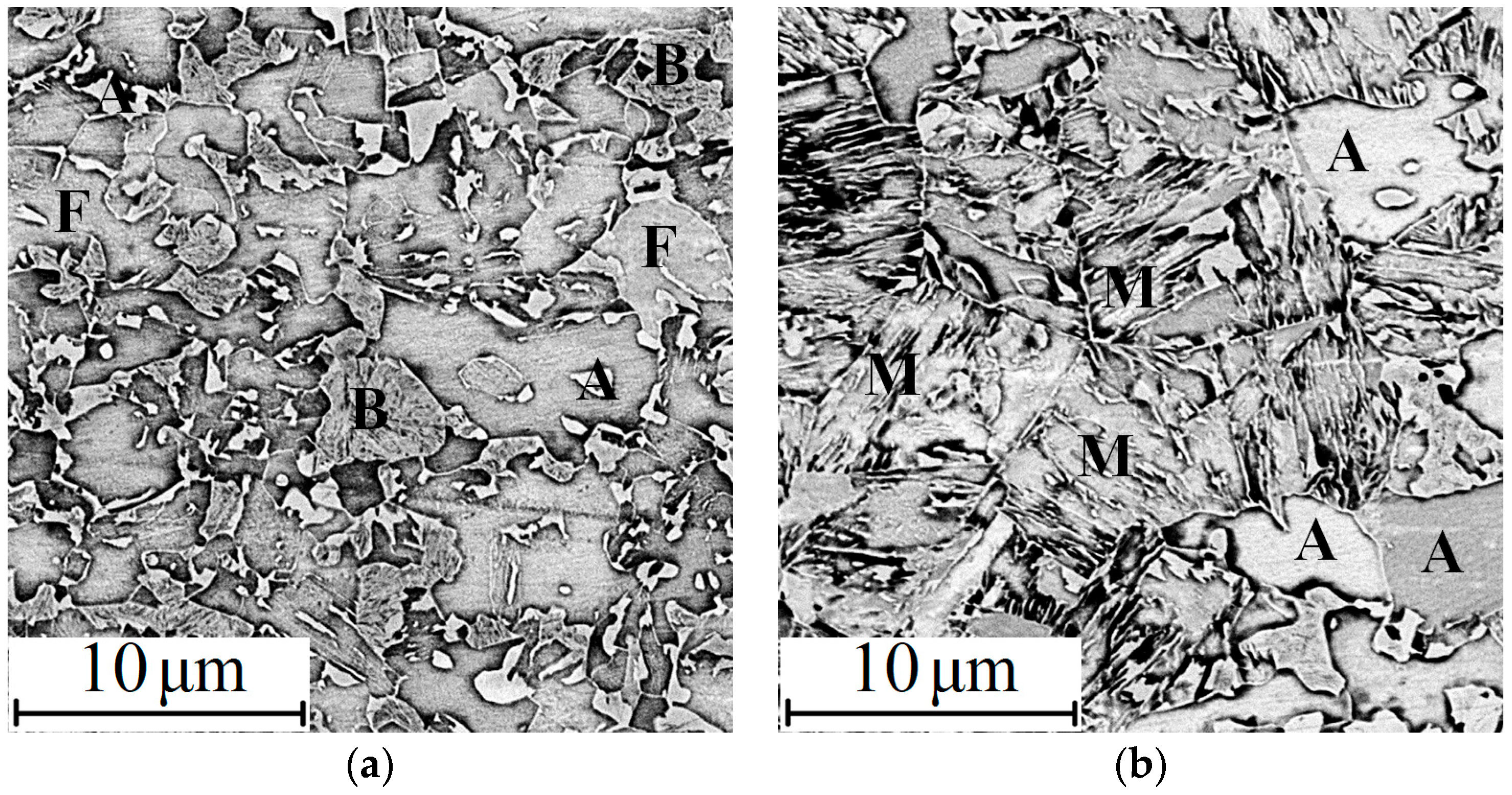

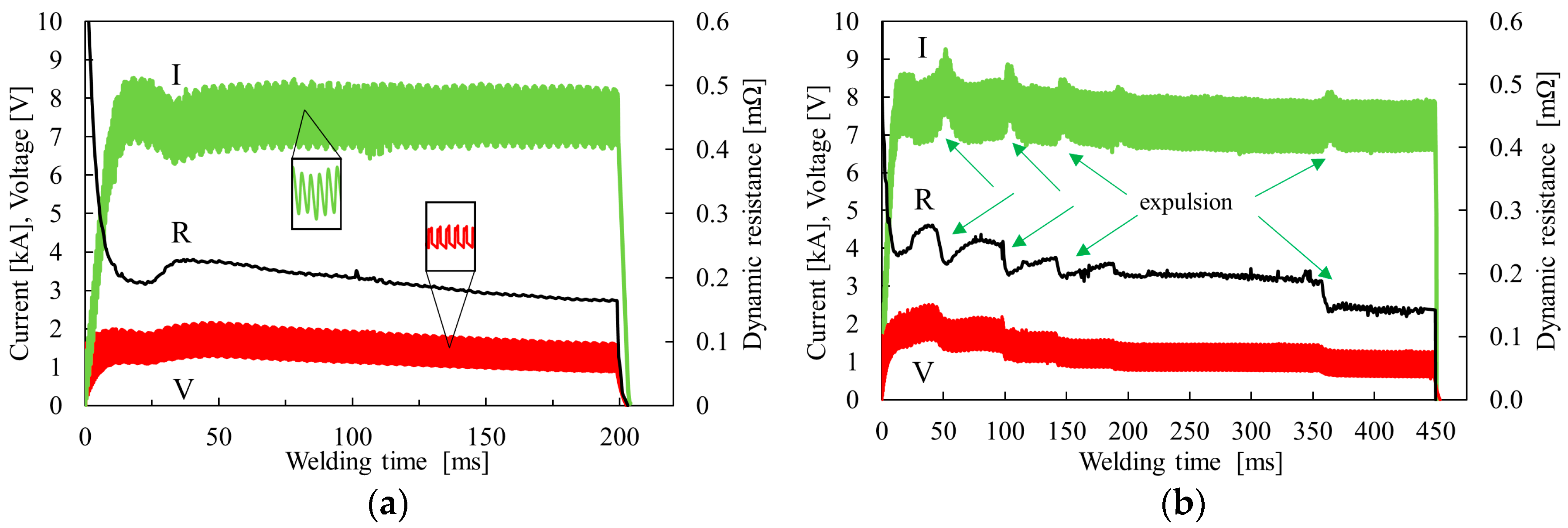

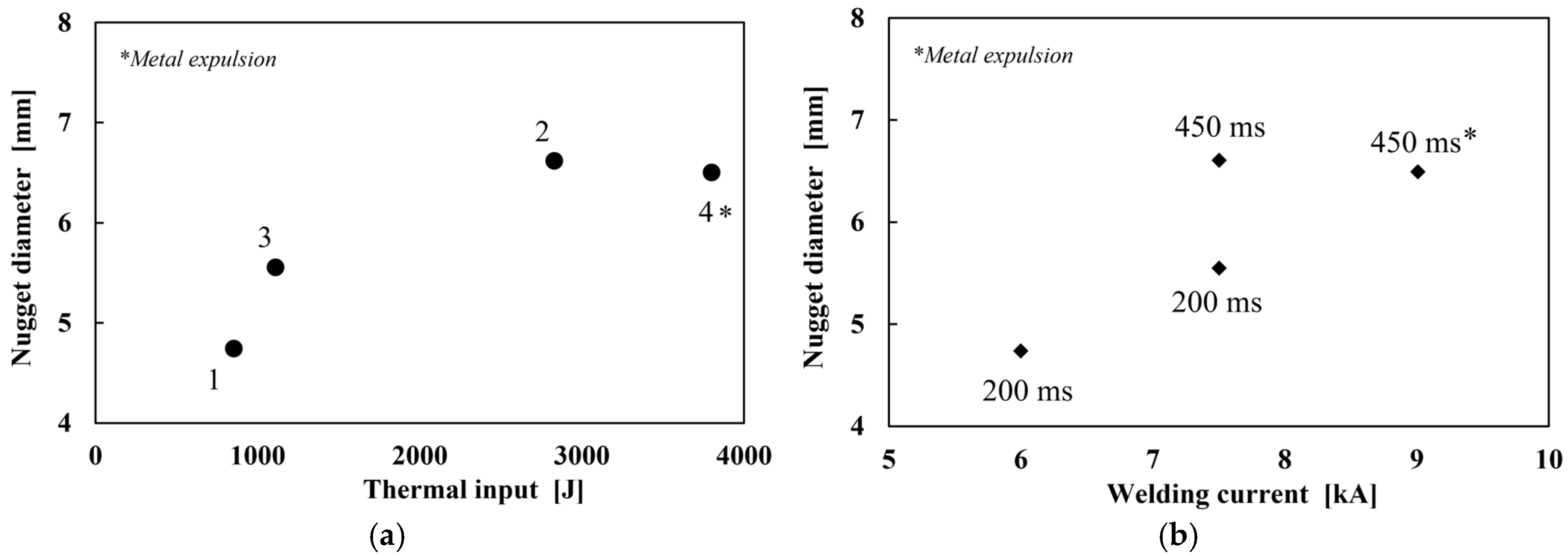

3.1. Spot Welding and Joint Features

3.2. Mechanical Properties of Spot Welds

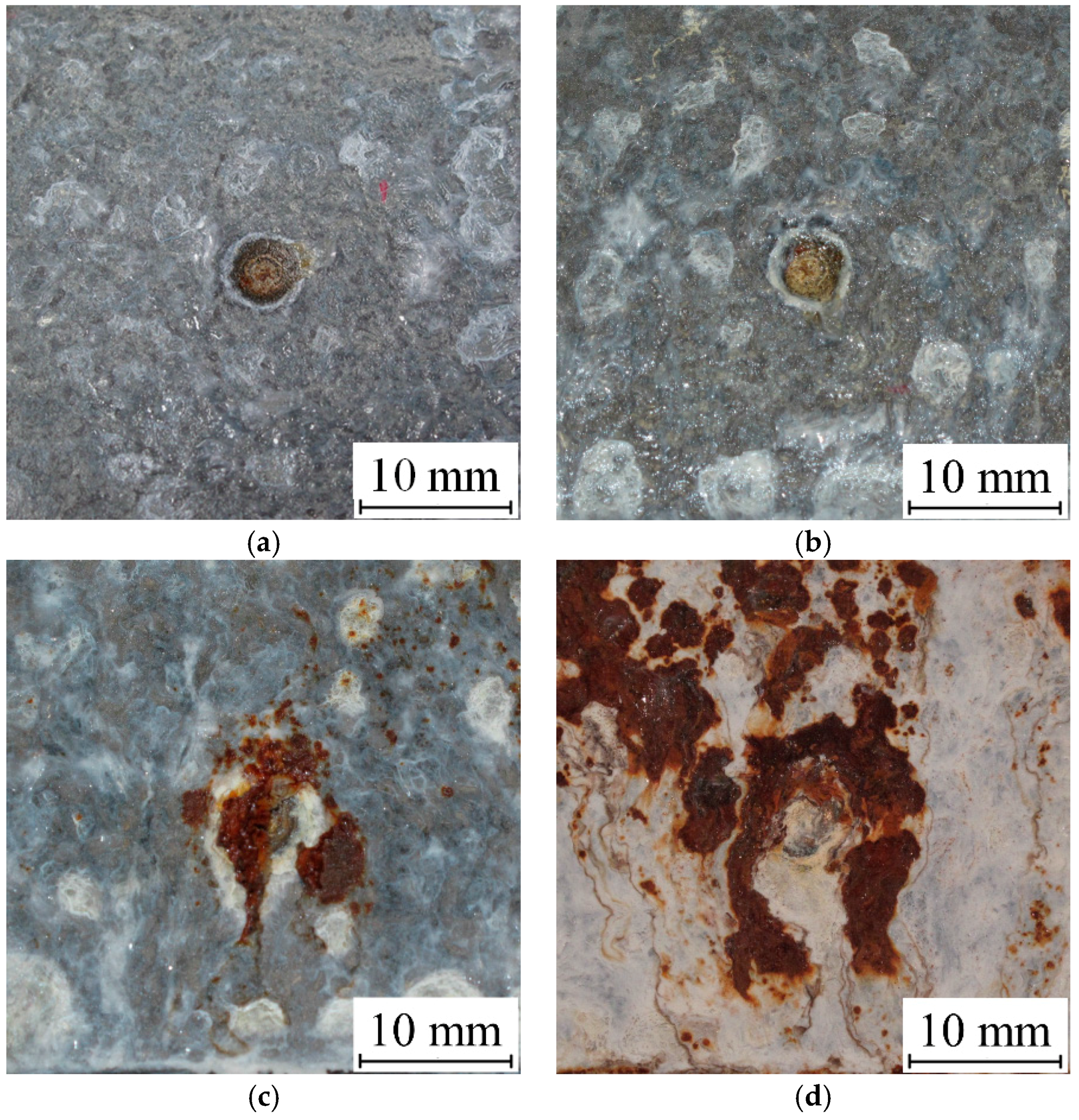

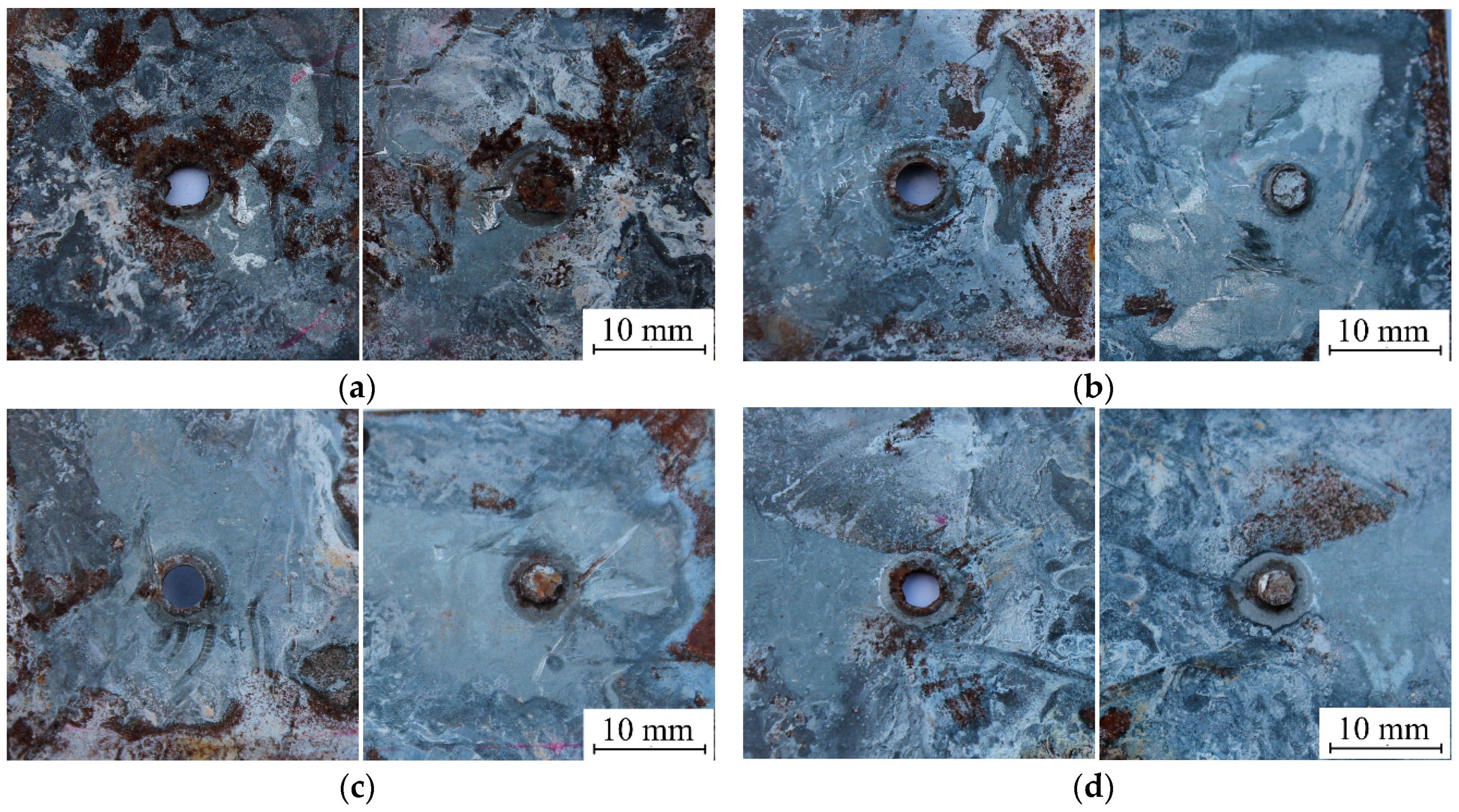

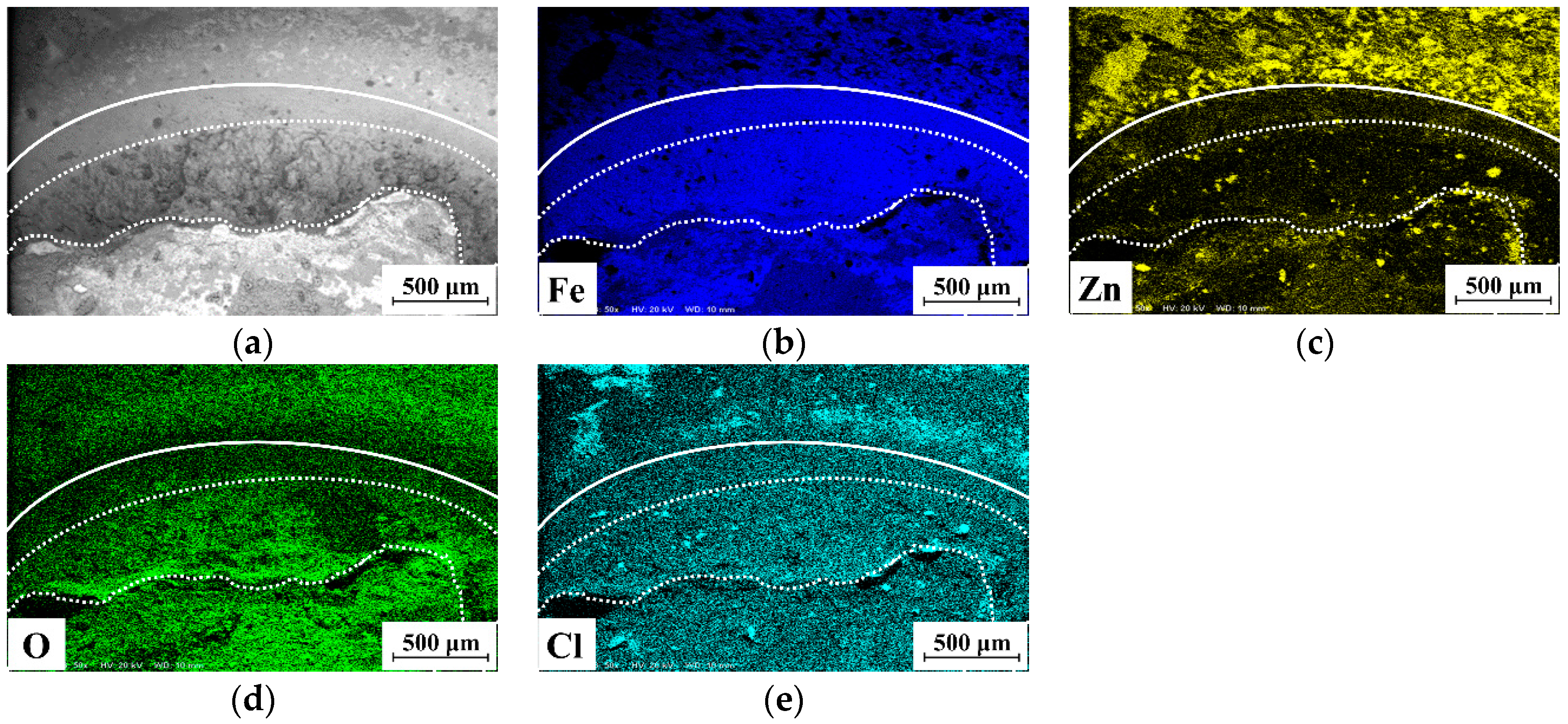

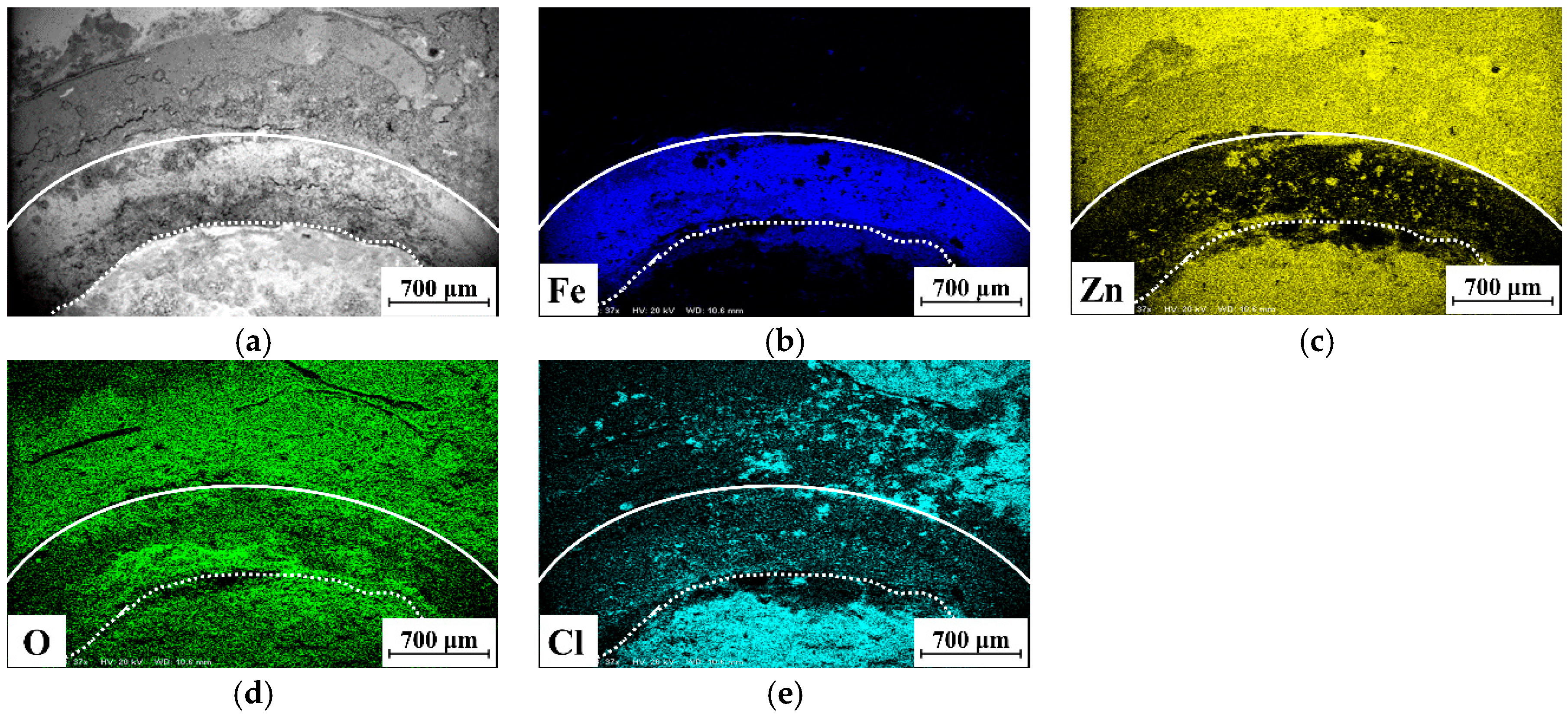

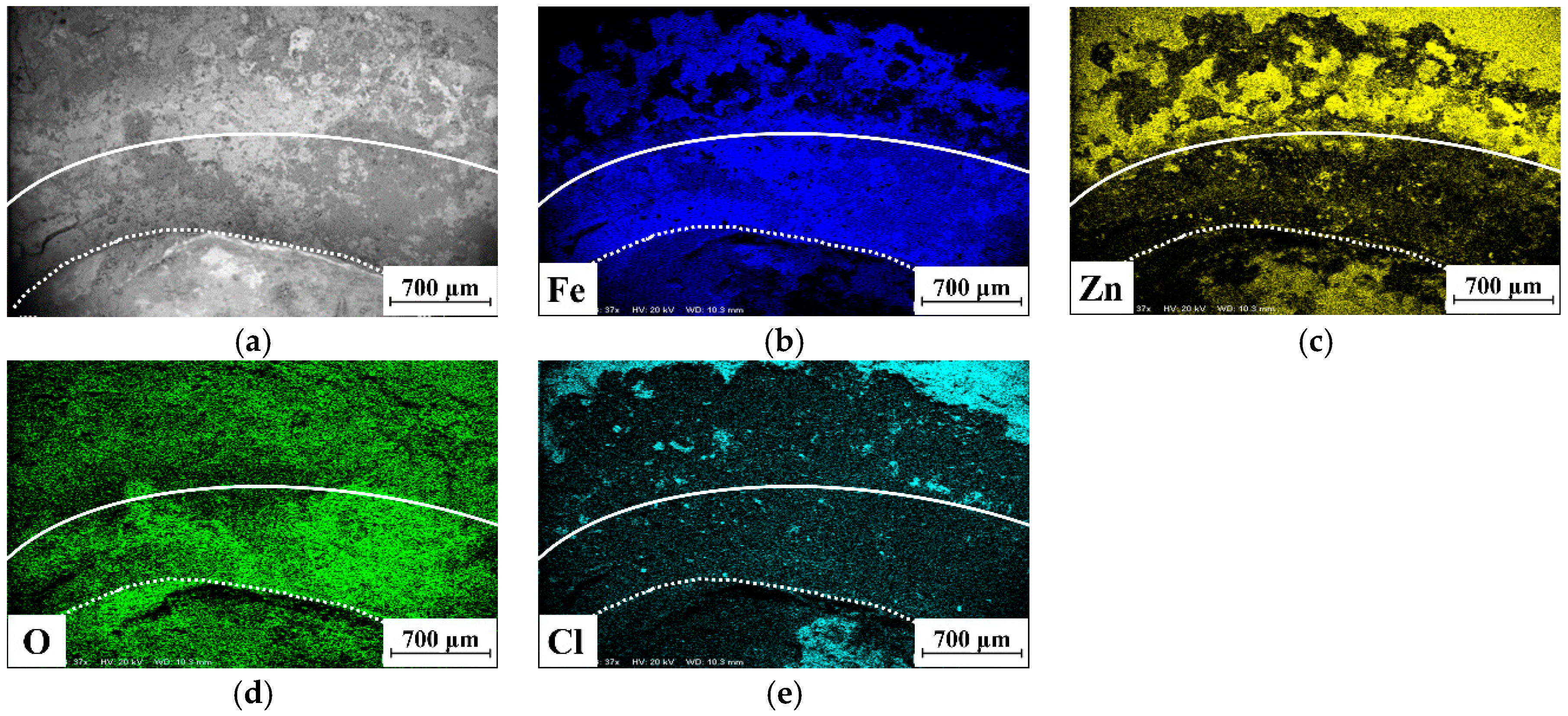

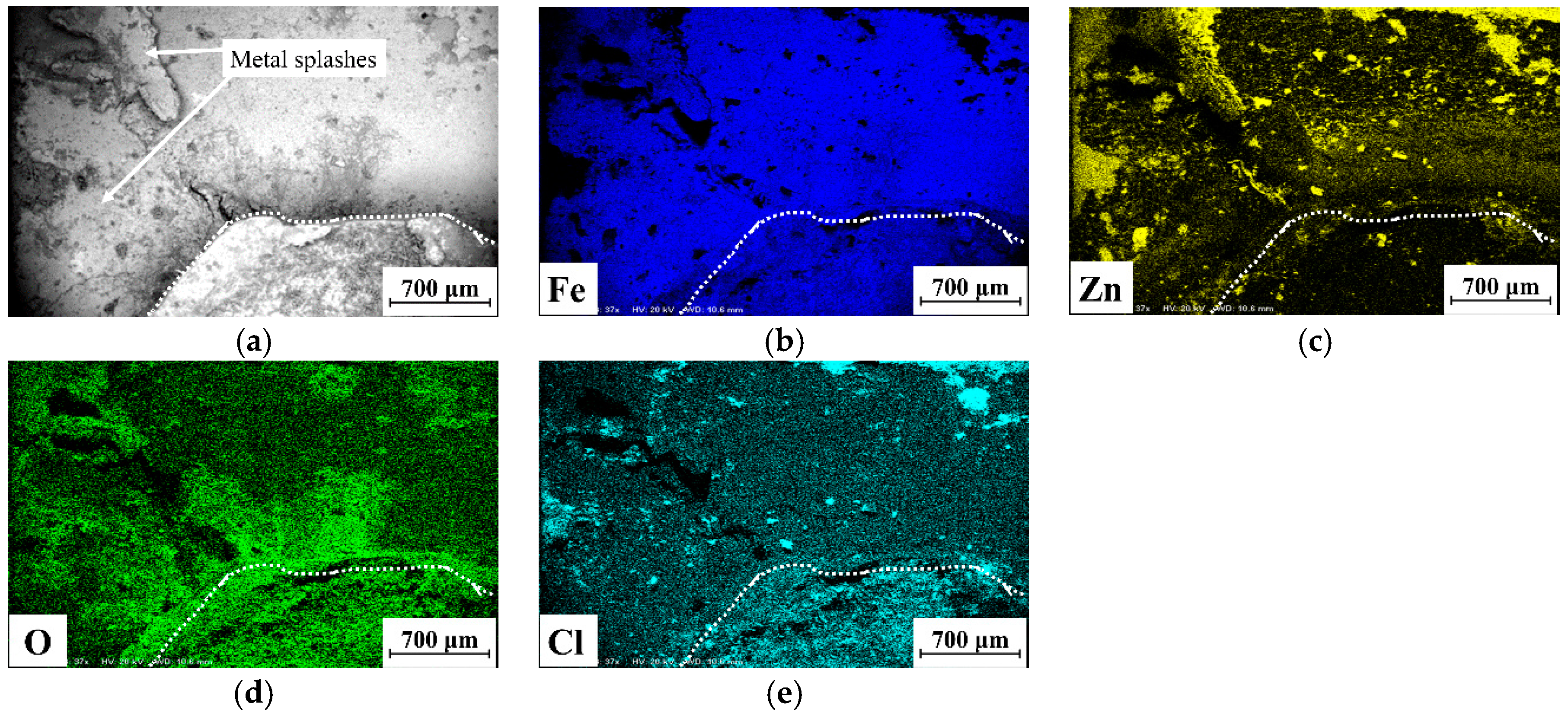

3.3. Corrosion Behavior

4. Conclusions

- (1)

- Welding current and time are the main factor affecting shear strength of Q&P/TRIP spot welds, clamping force has a minor influence.

- (2)

- Clamping force has a beneficial effect on corrosion resistance of the internal side of the spot welds because it is more tightly sheltered from the corrosive environment by the surrounding sheets, being they squeezed together by the indentation of the electrode tips.

- (3)

- The local distribution of zinc coating and corrosion products near the spot welds is highly dependent on the specific setting of the welding parameters: welding current and time seem to have the main effect on the damage of the Zn coating close to the weld spots, whereas clamping force primarily drives the corrosion resistance on the sheet surfaces farther from the joints.

- (4)

- Metal expulsion limits that maximum achievable shear strength of the spot welds. Moreover, it leads to a stronger vaporization of the zinc coating around the spot welds, thereby exposing more steel substrate to a corrosive attack.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- De Moor, E.; Speer, J.G.; Matlock, D.K.; Kwak, J.H.; Lee, S.B. Effect of carbon and manganese on the quenching and partitioning response of CMnSi steels. ISIJ Int. 2011, 51, 137–144. [Google Scholar] [CrossRef]

- Sun, J.; Yu, H. Microstructure development and mechanical properties of quenching and partitioning (Q&P) steel and an incorporation of hot-dipping galvanization during Q&P process. Mater. Sci. Eng. A 2013, 586, 100–107. [Google Scholar]

- Yan, S.; Liu, X.; Liu, W.J.; Liang, T.; Zhang, B.; Liu, L.; Zhao, Y. Comparative study on microstructure and mechanical properties of a C-Mn-Si steel treated by quenching and partitioning (Q&P) processes after a full and intercritical austenitization. Mater. Sci. Eng. A 2017, 684, 261–269. [Google Scholar]

- Seo, E.J.; Cho, L.; Estrin, Y.; De Cooman, B.C. Microstructure-mechanical properties relationships for quenching and partitioning (Q&P) processed steel. Acta Mater. 2016, 113, 124–139. [Google Scholar]

- Zhang, H.; Senkara, J. Resistance Welding: Fundamentals and Applications, 2nd ed.; CRC Press: London, UK, 2011. [Google Scholar]

- Akkaş, N.; Ilhan, E.; Aslanlar, S.; Varol, F. The effect of nugget sizes on mechanical properties in resistance spot welding of SPA-C atmospheric corrosion resistant steel sheets used in rail vehicles. Mater. Test. 2014, 56, 879–883. [Google Scholar] [CrossRef]

- Wang, B.; Duan, Q.Q.; Yao, G.; Pang, J.C.; Li, X.W.; Wang, L.; Zhan, Z.F. Investigation on fatigue fracture behaviors of spot welded Q&P980 steel. Int. J. Fract. 2014, 66, 20–28. [Google Scholar]

- Russo Spena, P.; De Maddis, M.; Lombardi, F.; Rossini, M. Dissimilar resistance spot welding of Q&P and TWIP steel sheets. Mater. Manuf. Proc. 2016, 31, 291–299. [Google Scholar]

- Russo Spena, P.; De Maddis, M.; D’Antonio, G.; Lombardi, F. Weldability and Monitoring of Resistance Spot Welding of Q&P and TRIP Steels. Metals 2016, 6, 270. [Google Scholar]

- Wloka, J.; Laukant, H.; Glatzel, U.; Virtanen, S. Corrosion properties of laser beam joints of aluminium with zinc-coated steel. Corros. Sci. 2007, 49, 4243–4258. [Google Scholar] [CrossRef]

- Almeida, E.; Morcillo, M. Lap-joint corrosion of automotive coated materials in chloride media. Part 2—Galvannealed steel. Surf. Coat. Technol. 2000, 124, 180–189. [Google Scholar] [CrossRef]

- Tzeng, Y.F. Effects of process parameters on the corrosion rate of pulsed Nd:YAG laser-welded zinc-coated steel. J. Mater. Proc. Technol. 2002, 124, 1–7. [Google Scholar] [CrossRef]

- Lukin, V.I.; Kovalchuk, V.G.; Kondrashov, E.K.; Malova, N.E.; Golev, E.V. Resistance spot welding of high-strength steels through new corrosion-resisting coatings. Weld. Int. 2010, 24, 963–968. [Google Scholar] [CrossRef]

- Mei, L.; Yan, D.; Chen, G.; Xie, D.; Zhang, M.; Ge, X. Comparative study on CO2 laser overlap welding and resistance spot welding for automotive body in white. Mater. Des. 2015, 78, 107–117. [Google Scholar] [CrossRef]

- Mei, L.; Yi, J.; Yan, D.; Liu, J.; Chen, G. Comparative study on CO2 laser overlap welding and resistance spot welding for galvanized steel. Mater. Des. 2012, 40, 433–442. [Google Scholar]

- Banerjee, G.; Pal, T.K.; Bandyopadhyay, N.; Bhattacharjee, D. Effect of welding conditions on corrosion behaviour of spot welded coated steel sheets. Corros. Eng. Sci. Technol. 2011, 46, 64–69. [Google Scholar]

- Davoodi, A.; Esfahani, Z.; Sarvghad, M. Microstructure and corrosion characterization of the interfacial region in dissimilar friction stir welded AA5083 to AA7023. Corros. Sci. 2016, 107, 133–144. [Google Scholar] [CrossRef]

- Vincent Proton, V.; Alexis, J.; Andrieu, E.; Delfosse, J.; Lafont, M.C.; Blanc, B. Characterisation and understanding of the corrosion behaviour of the nugget in a 2050 aluminium alloy friction stir welding joint. Corros. Sci. 2013, 73, 130–142. [Google Scholar] [CrossRef]

- Sabbaghzadeh, B.; Parvizi, R.; Davoodi, A.; Moayed, M.H. Corrosion evaluation of multi-pass welded nickel-aluminum bronze alloy in 3.5% sodium chloride solution: A restorative application of gas tungsten arc welding process. Mater. Des. 2014, 58, 346–356. [Google Scholar] [CrossRef]

- Gharavi, F.; Matori, K.A.; Yunus, R.; Othman, N.K.; Fadaeifard, F. Corrosion behavior of Al6061 alloy weldment produced by friction stir welding process. J. Mater. Res. Technol. 2015, 4, 314–322. [Google Scholar] [CrossRef]

- Huang, C.A.; Wang, T.H.; Han, W.C.; Lee, C.H. A study of the galvanic corrosion behavior of Inconel 718 after electron beam welding. Mater. Chem. Phys. 2007, 104, 293–300. [Google Scholar] [CrossRef]

- Wu, W.; Hu, S.; Shen, J. Microstructure, mechanical properties and corrosion behavior of laser welded dissimilar joints between ferritic stainless steel and carbon steel. Mater. Des. 2015, 65, 855–861. [Google Scholar] [CrossRef]

- Rossi, S.; Fedel, M.; Deflorian, F.; Vadillo, M.C. Localized electrochemical techniques: Theory and practical examples in corrosion studies. C. R. Chim. 2008, 11, 984–994. [Google Scholar] [CrossRef]

- Deng, Y.; Peng, B.; Xu, G.; Pan, Q.; Ye, R.; Wang, Y.; Lu, L.; Yin, Z. Stress corrosion cracking of a high-strength friction-stir-welded joint of an Al-Zn-Mg-Zr alloy containing 0.25 wt. % Sc. Corros. Sci. 2015, 100, 57–72. [Google Scholar] [CrossRef]

- Thomä, M.; Wagner, G.; Straß, B.; Wolter, B.; Benfer, S.; Fürbeth, W. Ultrasound enhanced friction stir welding of aluminum and steel: Process and properties of EN AW 6061/DC04-Joints. Mater. Sci. Technol. 2017, in press. [Google Scholar]

- Gharavi, F.; MAtori, K.; Yunus, R.; Othman, N.K.; Fadaeifard, F. Corrosion evaluation of friction stir welded lap joints of AA6061-T6 aluminum alloy. Trans. Nonferr. Met. Soc. China 2016, 26, 684–696. [Google Scholar] [CrossRef]

- Liu, C.; Chen, D.L.; Bhole, S.; Cao, X.; Jahazi, M. Polishing-assisted galvanic corrosion in the dissimilar friction stir welded joint of AZ31 magnesium alloy to 2024 aluminum alloy. Mater. Charact. 2009, 60, 370–376. [Google Scholar] [CrossRef]

- AWS D8.9M. Test Methods for Evaluating the Resistance Spot Welding Behavior of Automotive Sheet Steel Materials; American Welding Society (AWS): Miami, FL, USA, 2012. [Google Scholar]

- ISO 9227:2017. Corrosion Tests in Artificial Atmospheres—Salt Spray Tests; International Organization for Standardization (ISO): Geneva, Switzerland, 2017. [Google Scholar]

- Pouranvari, M.; Marashi, S.P.H. Critical review of automotive steels spot welding: Process, structure and properties. Sci. Technol. Weld. Join. 2013, 18, 361–403. [Google Scholar] [CrossRef]

- Pouranvari, M.; Asgari, H.T.; Mosavizadch, S.M.; Marashi, P.H.; Goodarzi, M. Effect of weld nugget size on overload failure mode of resistance spot welds. Sci. Technol. Weld. Join. 2007, 12, 217–225. [Google Scholar] [CrossRef]

- Huin, T.; Dancette, S.; Fabrègue, D.; Dupuy, T. Investigation of the failure of advanced high strength steels heterogeneous spot welds. Metals 2016, 6, 111. [Google Scholar] [CrossRef]

- Liang, J.; Zhang, H.; Qiu, X.; Shi, Y. Characteristics of the resistance spot welding joints in dissimilar thickness dual-phase steels. ISIJ Int. 2015, 55, 2002–2007. [Google Scholar] [CrossRef]

- Chao, Y.J. Failure modes of spot welds: Interfacial versus pullout. Sci. Technol. Weld. Join. 2013, 8, 133–137. [Google Scholar]

| Steel | % C | % Mn | % Si | % P + S | % Al | % Ti | % Nb | % Fe |

|---|---|---|---|---|---|---|---|---|

| Q&P | 0.22 | 1.88 | 1.41 | <0.02 | 0.04 | - | <0.001 | Bal. |

| TRIP | 0.20 | 2.23 | 0.31 | <0.02 | 1.05 | 0.01 | 0.022 | Bal. |

| Steel | Hardness (HV30) | YS (MPa) | UTS (MPa) | ef (%) | n |

|---|---|---|---|---|---|

| Q&P | 260 | 655 | 1000 | 22 | 0.10 |

| TRIP | 225 | 525 | 890 | 27 | 0.20 |

| Run No. | Current (kA) | Clamping Force (kN) | Welding Time (ms) |

|---|---|---|---|

| 1 | 6 | 2 | 200 |

| 2 | 7.5 | 3 | 450 |

| 3 | 7.5 | 4 | 200 |

| 4 | 9 | 2 | 450 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Russo Spena, P.; Rossi, S.; Wurzer, R. Effects of Welding Parameters on Strength and Corrosion Behavior of Dissimilar Galvanized Q&P and TRIP Spot Welds. Metals 2017, 7, 534. https://doi.org/10.3390/met7120534

Russo Spena P, Rossi S, Wurzer R. Effects of Welding Parameters on Strength and Corrosion Behavior of Dissimilar Galvanized Q&P and TRIP Spot Welds. Metals. 2017; 7(12):534. https://doi.org/10.3390/met7120534

Chicago/Turabian StyleRusso Spena, Pasquale, Stefano Rossi, and Rudi Wurzer. 2017. "Effects of Welding Parameters on Strength and Corrosion Behavior of Dissimilar Galvanized Q&P and TRIP Spot Welds" Metals 7, no. 12: 534. https://doi.org/10.3390/met7120534

APA StyleRusso Spena, P., Rossi, S., & Wurzer, R. (2017). Effects of Welding Parameters on Strength and Corrosion Behavior of Dissimilar Galvanized Q&P and TRIP Spot Welds. Metals, 7(12), 534. https://doi.org/10.3390/met7120534