Effect of the Ultrasonic Nanocrystalline Surface Modification (UNSM) on Bulk and 3D-Printed AISI H13 Tool Steels

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Direct Metal Tooling and Specimen Preparation

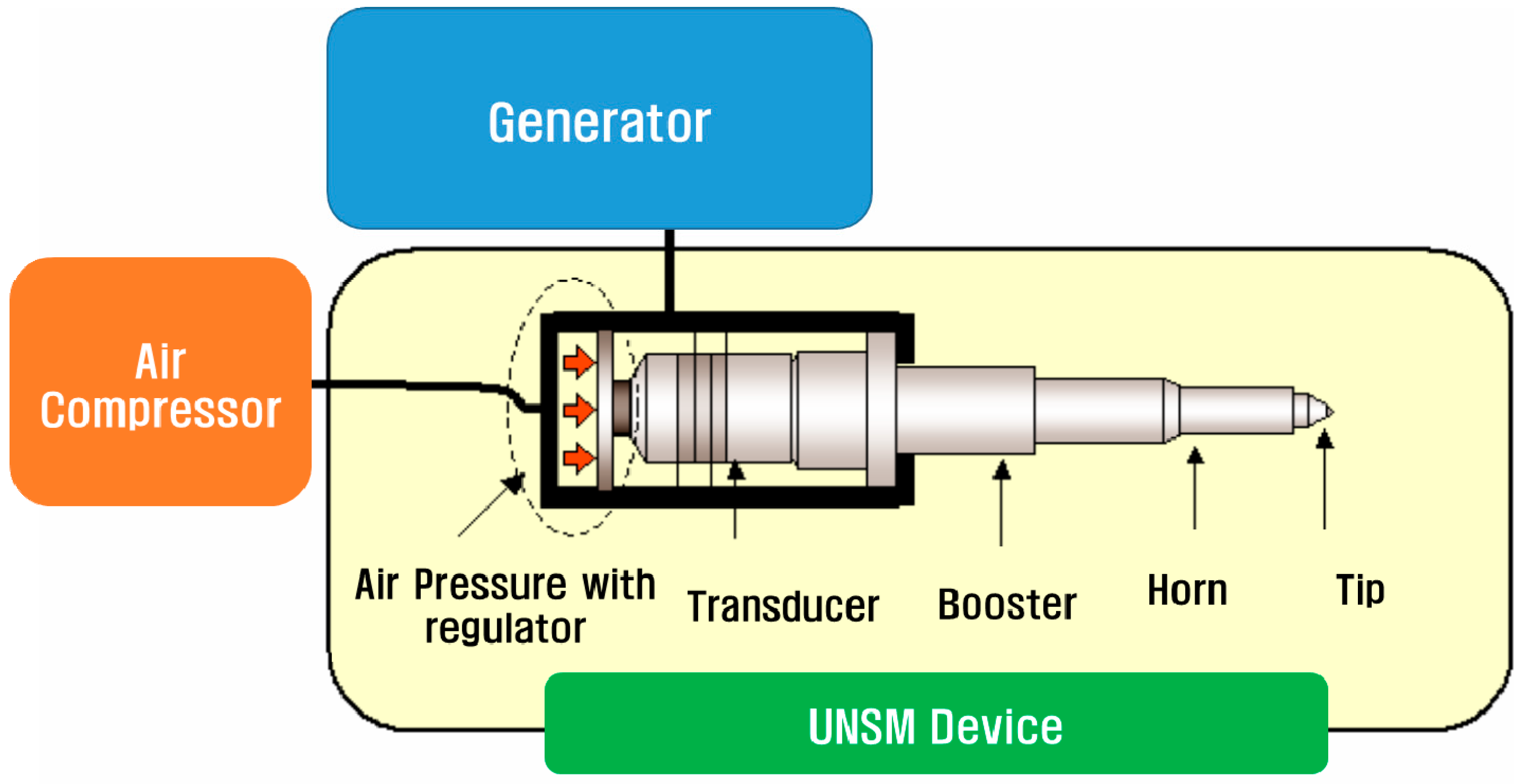

2.2. UNSM Technique

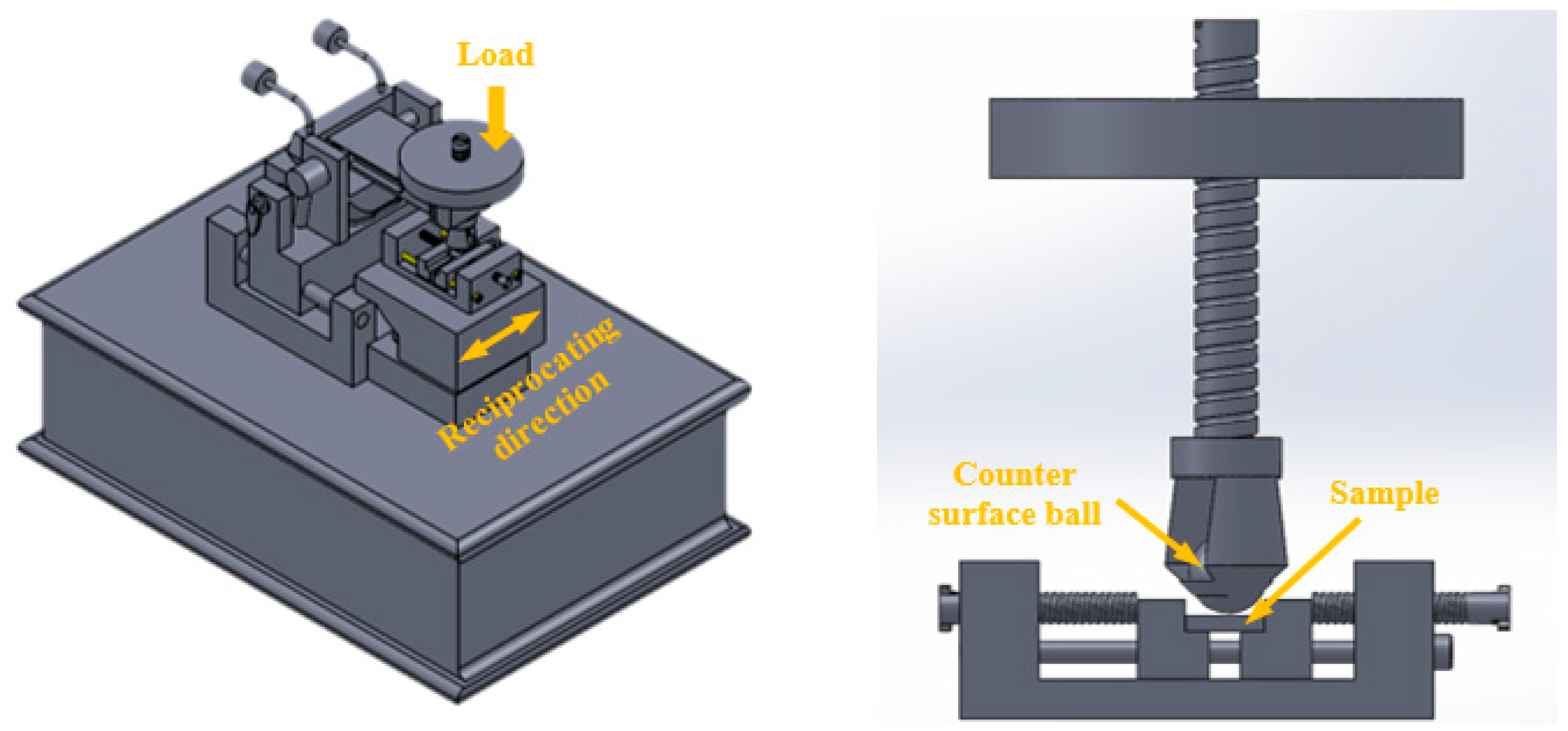

2.3. Friction and Wear Test

2.4. Scratch Test

2.5. Characterization Tools

3. Results

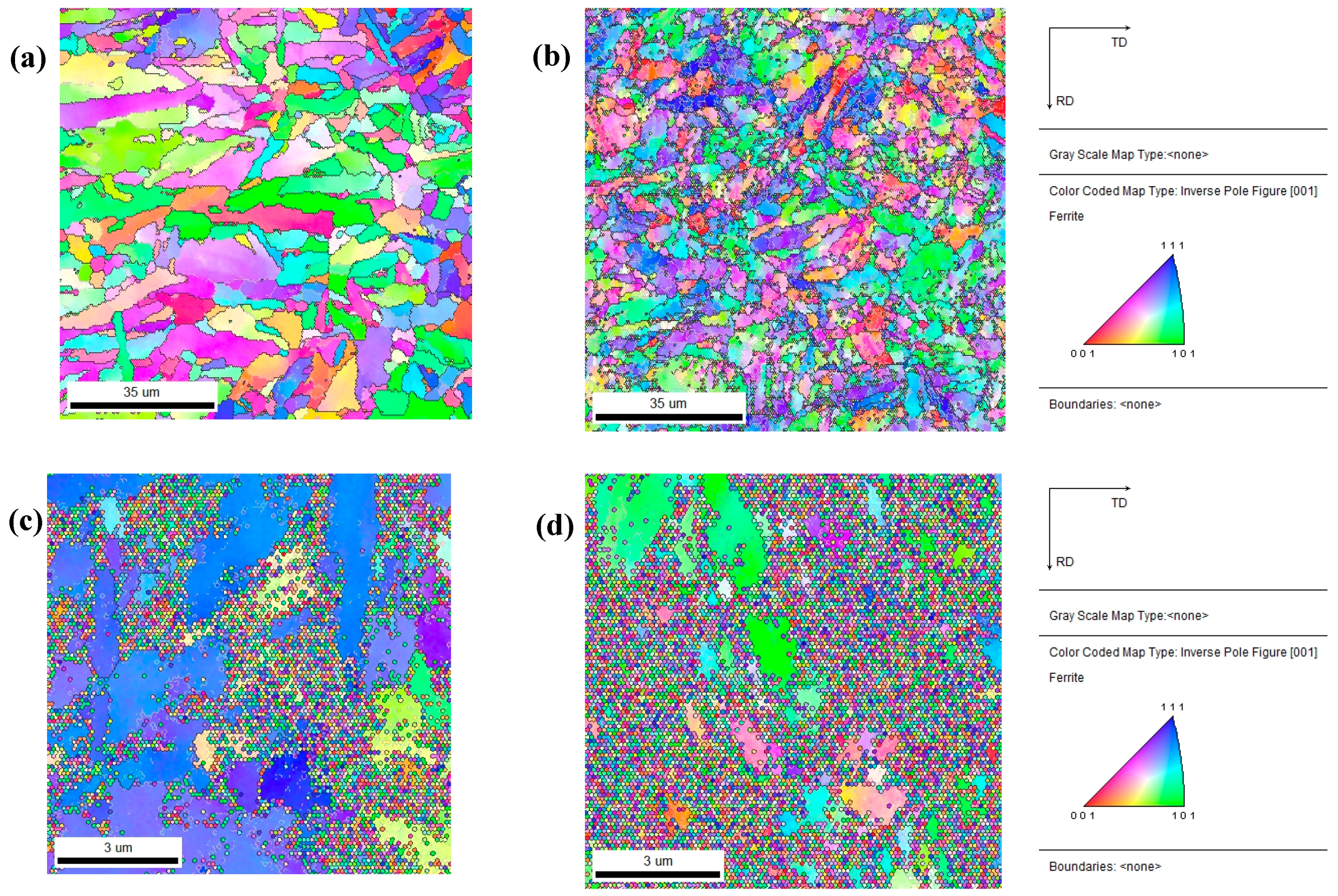

3.1. Microstructural Evolution

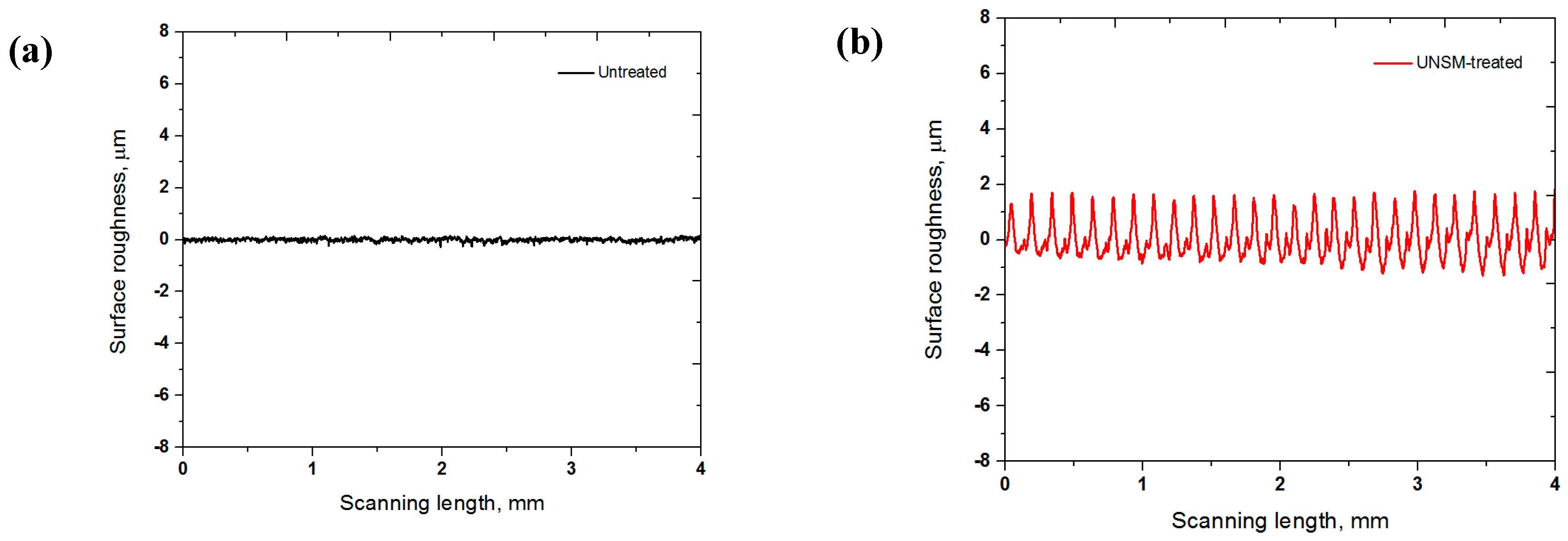

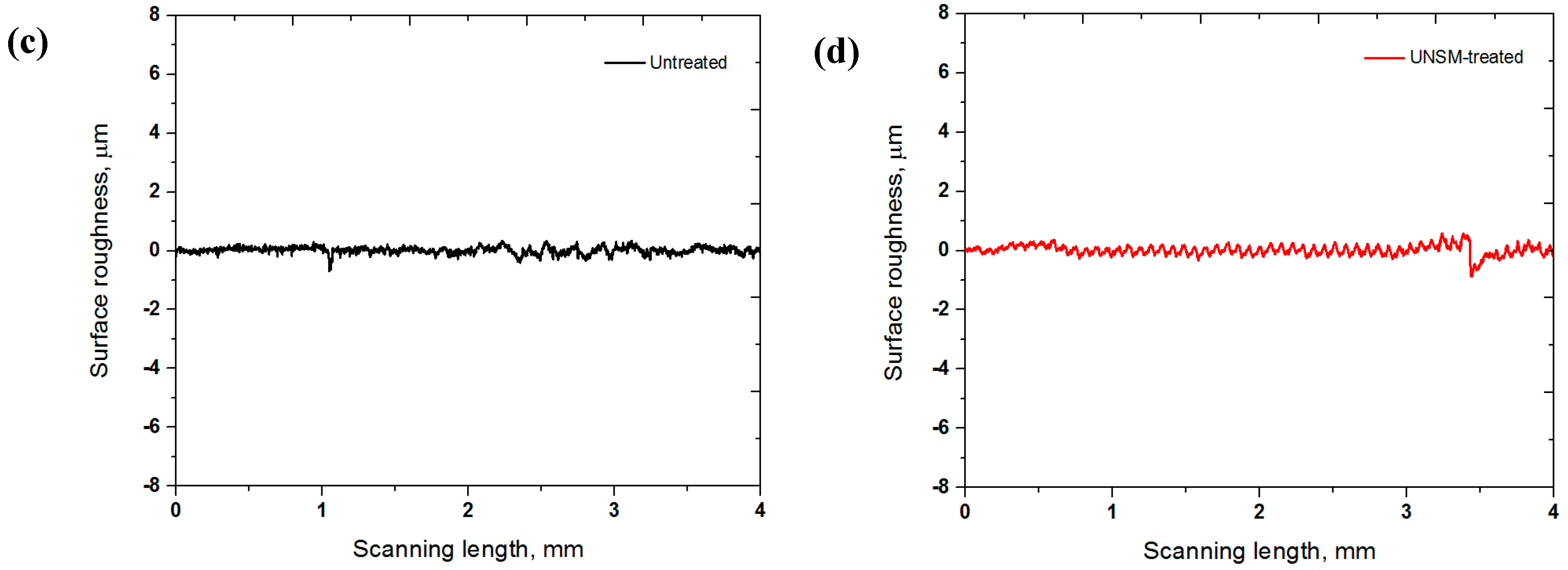

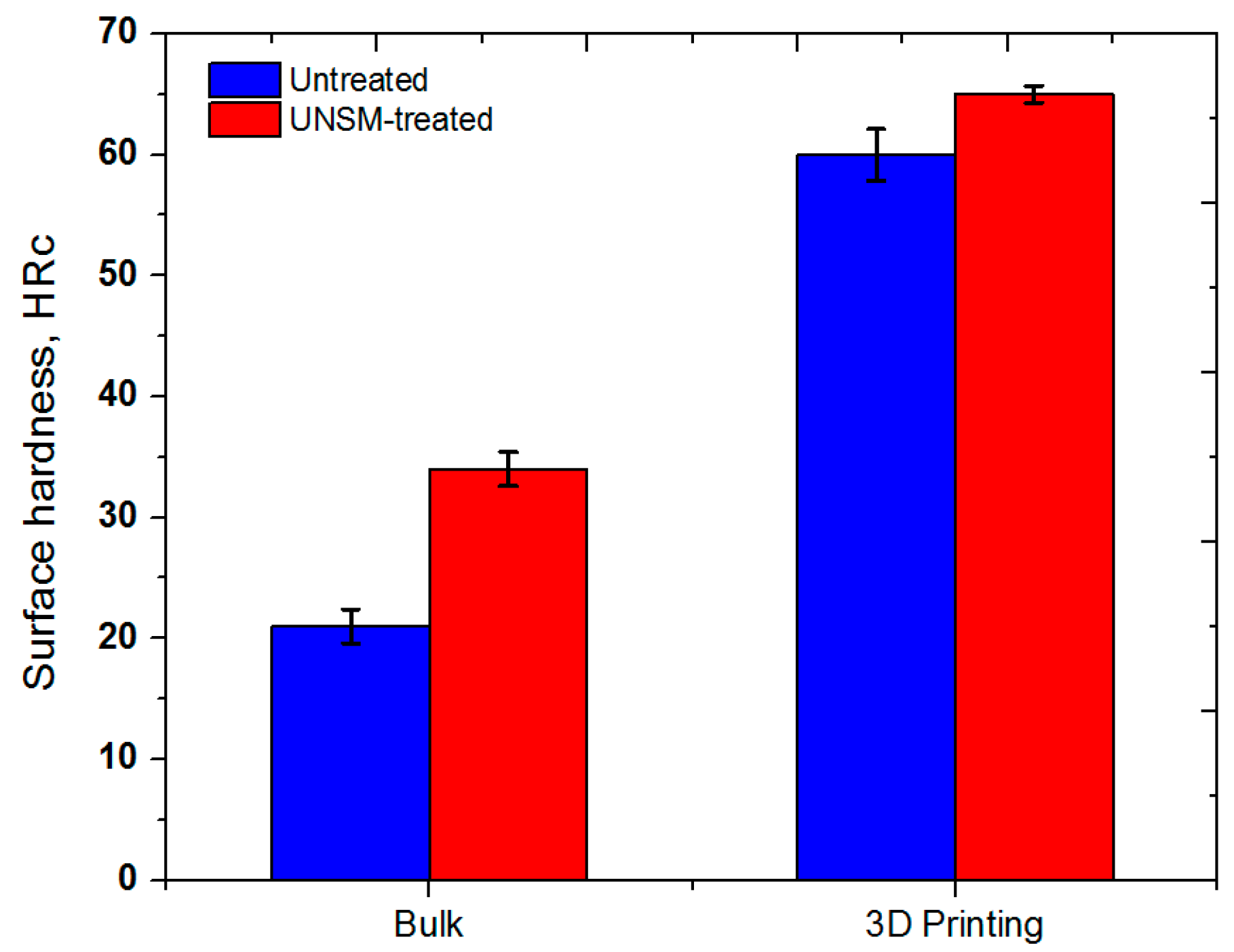

3.2. Surface Roughness and Surface Hardness

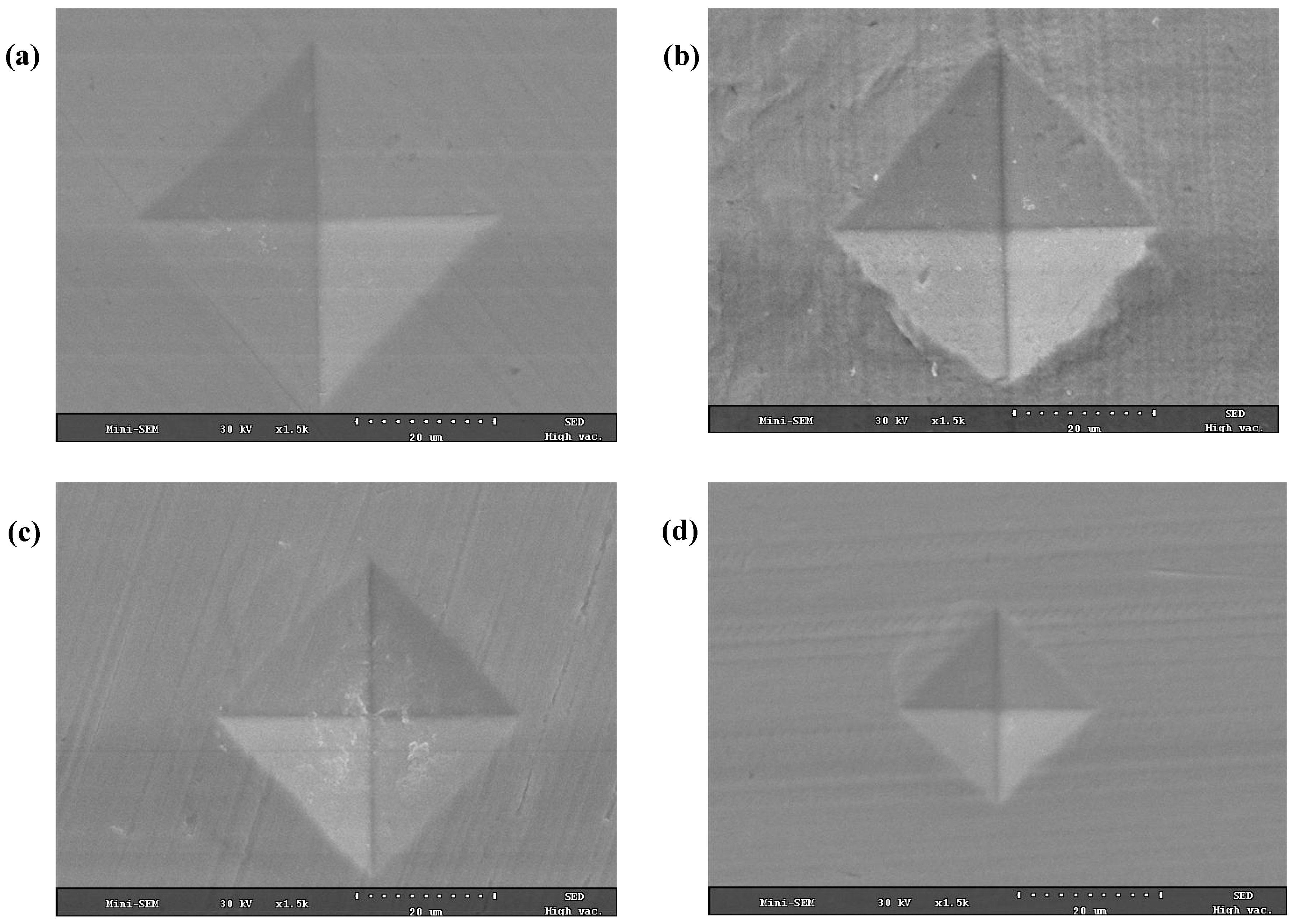

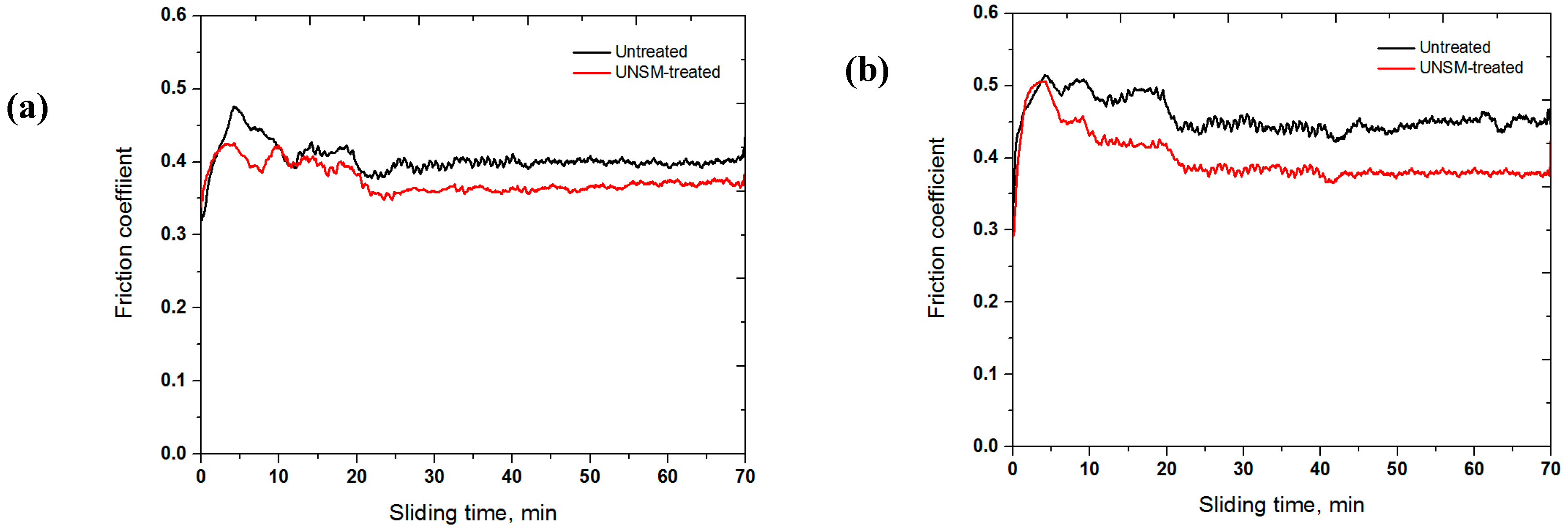

3.3. Friction and Wear Behavior

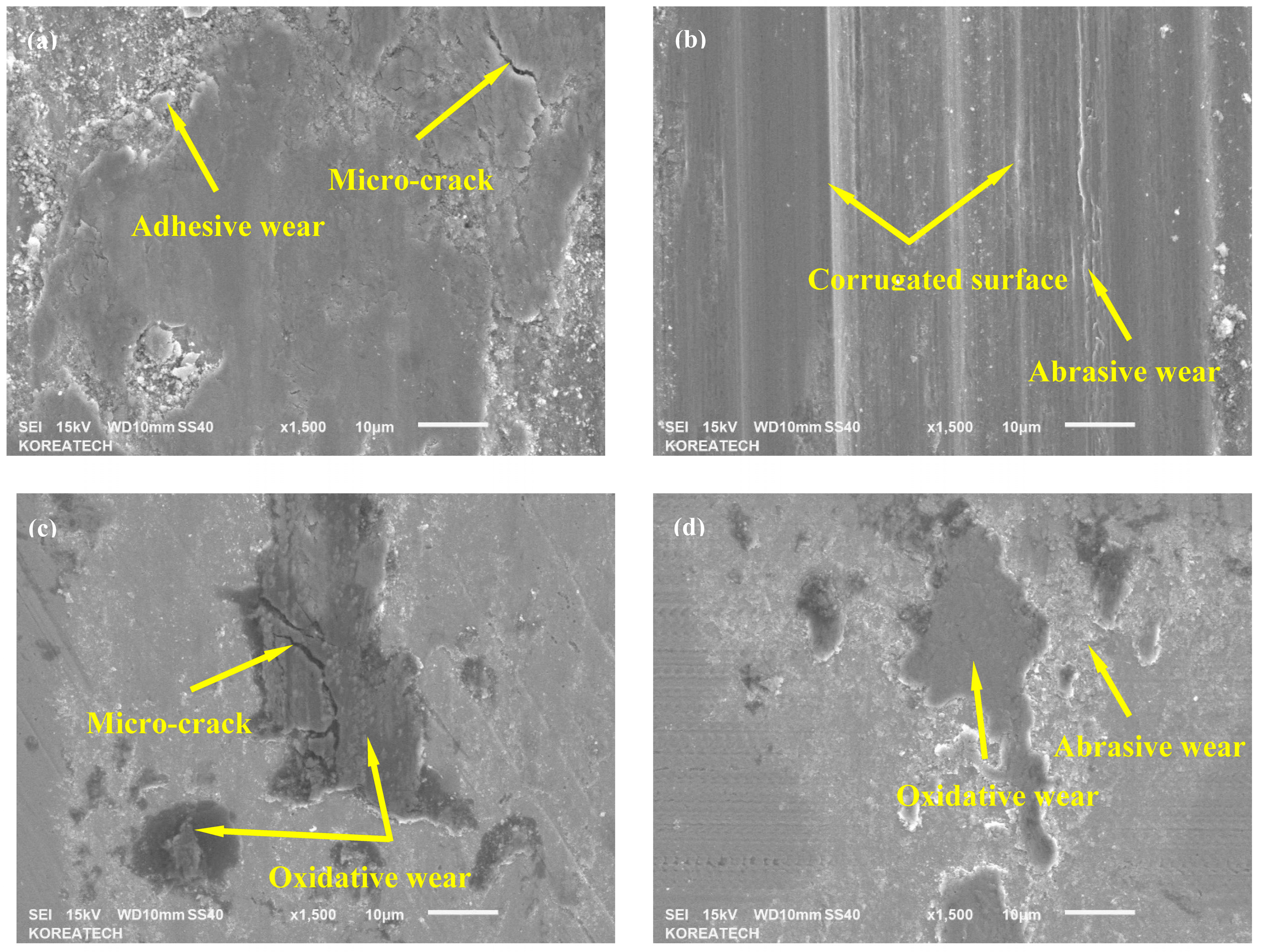

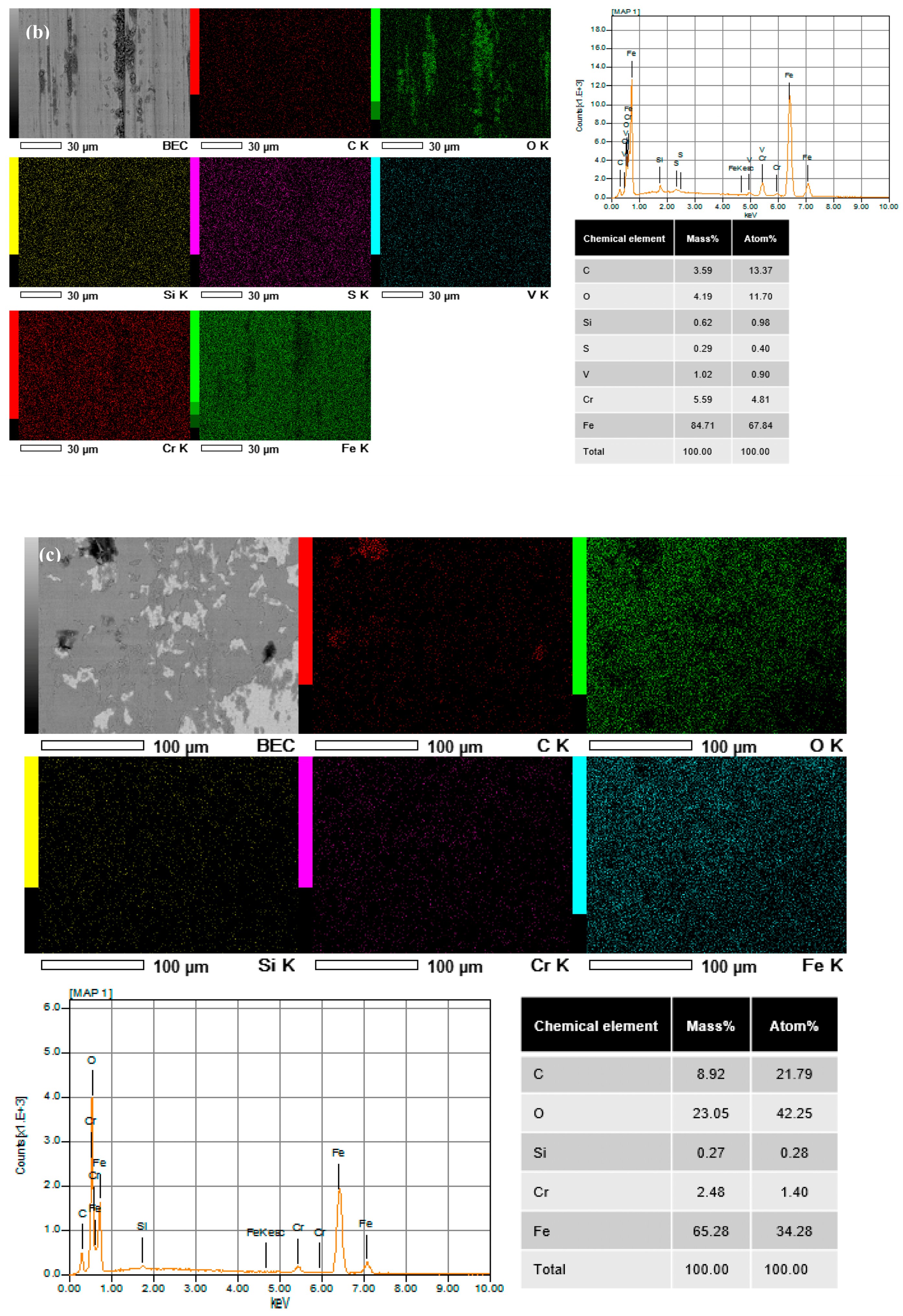

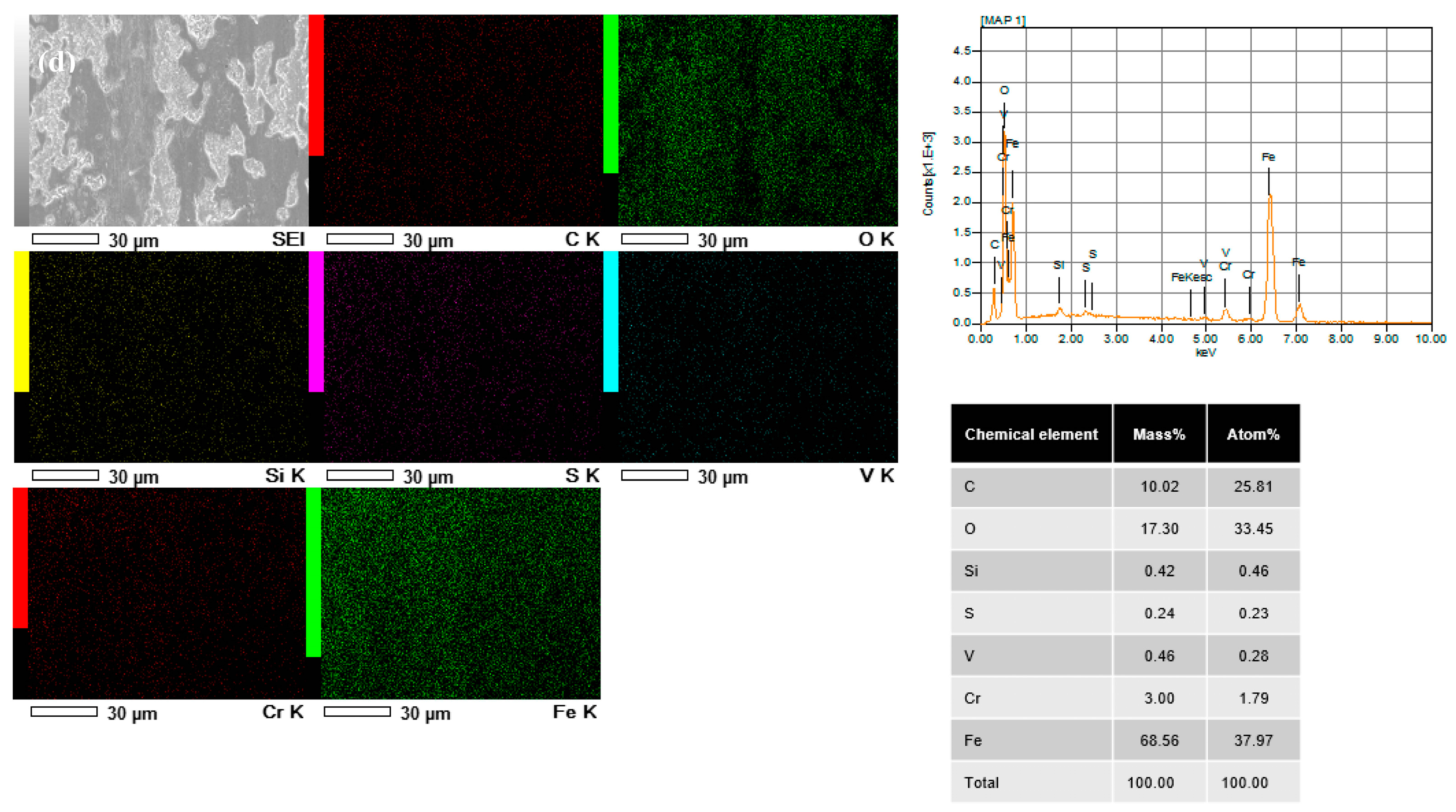

4. Conclusions

- (1)

- The average grain size of the as-received specimen was in the range of 5–30 μm in the longitudinal direction, which was refined to very fine grains with sizes in the range of 1–10 μm in the longitudinal direction after UNSM treatment. LAGB and HAGB of the bulk specimens were about 21% and 79%, and those of the 3D-printed specimens were about 8% and 92%, respectively.

- (2)

- The average surface roughness of the bulk specimen increased after UNSM treatment from 0.445 to 0.563 μm, while no significant difference was observed for the average surface roughness of the 3D-printed untreated and UNSM-treated specimens, with observed values of 0.451 and 0.454 μm, respectively. The surface hardness of the as-received and UNSM-treated bulk and 3D-printed specimens increased from 21 to 34 HRC and 60 to 65 HRC, respectively.

- (3)

- The friction coefficient of the untreated specimen in the running-in and steady-state periods was found to be higher than that of the UNSM-treated specimen by about 14%. For the 3D-printed specimens, the friction coefficient increased rapidly at the onset of sliding, where the UNSM-treated specimen showed a higher decrease rate than the untreated one by about 20%. The specific wear rates of the untreated and UNSM-treated bulk and 3D-printed specimens were 5.6 × 10−6 mm3/Nm, 3.4 × 10−6 mm3/Nm, 2.4 × 10−6 mm3/Nm, and 1.3 × 10−6 mm3/Nm, respectively.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, S.; Wu, X.; Chen, S.; Li, J. Wear resistance of H13 and a new hot-work die steel at high temperature. J. Mater. Eng. Perform. 2016, 25, 2993–3006. [Google Scholar] [CrossRef]

- Marashi, J.; Yakushina, E.; Xirouchakis, P.; Zante, R.; Foster, J. An evaluation of H13 tool steel deformation in hot forging conditions. J. Mater. Process. Technol. 2017, 246, 276–284. [Google Scholar] [CrossRef]

- Lee, J.Y.; An, J.; Chul, C.K. Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Baletti, C.; Ballarin, M.; Guerra, F. 3D printing: State of the art and future perspectives. J. Cult. Herit. 2017, 26, 172–182. [Google Scholar] [CrossRef]

- Chen, L.Y.; Huang, J.C.; Lin, C.H.; Pan, C.T.; Chen, S.Y.; Yang, T.L.; Lin, D.Y.; Lin, H.K.; Jang, J.S.C. Anisotropic response of Ti-6Al-4V alloy fabricated by 3D printing selective laser melting. Mater. Sci. Eng. A 2017, 682, 389–395. [Google Scholar] [CrossRef]

- Geissbauer, R.; Wunderlin, J.; Lehr, J. The Future of Spare Parts of 3D: A look at the challenges and opportunities of 3D printing. Strategy, 30 January 2017. [Google Scholar]

- Wong, K.V.; Hernandez, A. A review of additive manufacturing. ISRN Mech. Eng. 2012, 2012. [Google Scholar] [CrossRef]

- Lipson, H.; Kurman, M. Fabricated: The New World of 3D Printing: The Promise and Peril of a Machine That Can Make (Almost) Anything; John Wiley & Sons, Inc.: Lebanon, IN, USA, 2013. [Google Scholar]

- Bremen, S.; Meiners, W.; Diatlov, A. Selective laser melting. Laser Technol. J. 2012, 9, 33–38. [Google Scholar] [CrossRef]

- Slotwinski, J.A.; Garboczi, E.J.; Hebenstreit, K.M. Porosity measurement and analysis for metal additive manufacturing process control. J. Res. Natl. Inst. Stand. Technol. 2014, 119, 494–506. [Google Scholar] [CrossRef] [PubMed]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1931. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Yang, J.M. Selective laser melting of TiB2/H13 steel nanocomposites: Influence of hot isostatic pressing post-treatment. J. Mater. Process. Technol. 2017, 244, 344–353. [Google Scholar] [CrossRef]

- Yang, H.; Wu, X.; Cao, G.; Yang, Z. Enhanced boronizing kinetics and high temperature wear resistance of H13 steel with boriding treatment assisted by air blast shot peening. Surf. Coat. Technol. 2016, 307, 506–516. [Google Scholar] [CrossRef]

- Yeh, S.H.; Chiu, L.H.; Chuang, T.L.; Wu, C.Y. Thermal fatigue behavior evaluation of shot-peened JIS SKD61 hot-work mold steel. Mater. Trans. 2013, 54, 1053–1056. [Google Scholar] [CrossRef]

- Sabirov, I.; Enikeev, N.A.; Murashkin, M.Y.; Valiev, R.Z. Bulk Nanostructured Materials with Multifunction Properties; SpringerBriefs Materials; Springer: New York, NY, USA, 2015. [Google Scholar]

- Cho, K.T.; Song, K.; Oh, S.H.; Lee, Y.K.; Lee, W.B. Surface hardening of shot peened H13 steel by enhanced nitrogen diffusion. Surf. Coat. Technol. 2013, 232, 912–919. [Google Scholar] [CrossRef]

- Pinkerton, A.J.; Wang, W.; Li, L. Component repair using laser direct metal deposition. Part B J. Eng. Manuf. 2008, 222, 827–836. [Google Scholar] [CrossRef]

- Chen, J.; Xue, L. Laser cladding of CPM tool steels on hardened H13 hot-work steel for low-cost high-performance automotive tooling. J. Mater. Sci. 2012, 64, 688–693. [Google Scholar] [CrossRef]

- Amanov, A.; Cho, I.S.; Pyoun, Y.S.; Lee, C.S.; Park, I.G. Micro-dimples surface by ultrasonic nanocrystal surface modification and its tribological effects. Wear 2012, 286–287, 136–144. [Google Scholar] [CrossRef]

- Amanov, A.; Cho, I.S.; Kim, D.E.; Pyun, Y.S. Fretting wear and friction reduction of CP titanium and Ti-6Al-4V alloy by ultrasonic nanocrystalline surface modification. Surf. Coat. Technol. 2012, 207, 135–142. [Google Scholar] [CrossRef]

- Amanov, A.; Pyun, Y.S.; Sasaki, S. Effects of ultrasonic nanocrystalline surface modification (UNSM) technique on the tribological behavior of sintered Cu-based alloy. Tribol. Int. 2014, 74, 187–197. [Google Scholar] [CrossRef]

- Amanov, A.; Lee, S.W.; Pyun, Y.S. Low friction and high strength of 316L stainless steel tubing for biomedical application. Mater. Sci. Eng. C 2017, 71, 176–185. [Google Scholar] [CrossRef] [PubMed]

- Amanov, A.; Cho, I.S.; Park, I.G.; Pyun, Y.S. The migration of spheroidal cementite towards the surface in nanostructured AISI 52100 steel. Mater. Lett. 2016, 174, 142–145. [Google Scholar] [CrossRef]

- Shackelford, J. Introduction to Materials Science for Engineers; Pearson: San Francisco, CA, USA, 2015. [Google Scholar]

- Valiev, R.Z.; Zhilyaev, A.P.; Langdon, T.G. Bulk Nanostructured Materials: Fundamentals and Applications; John Wiley & Sons: New York, NY, USA, 2013. [Google Scholar]

- Amanov, A.; Cho, I.S.; Pyun, Y.S. Microstructural evolution and surface properties of nanostructured Cu-based alloy by ultrasonic nanocrystalline surface modification. Appl. Surf. Sci. 2016, 388, 185–195. [Google Scholar] [CrossRef]

- Greiner, C.; Merz, T.; Braun, D.; Codrignani, A.; Magagnato, F. Optimum dimple diameter for friction reduction with laser surface texturing: The effect of viscosity gradient. Surf. Topogr. Metrol. Prop. 2015, 3, 044001. [Google Scholar] [CrossRef]

- Amanov, A.; Pyun, Y.S.; Zhang, B.; Park, J.H.; Nohava, J. Preliminary study of the effect of micro-scale dimple size on friction and wear under oil-lubricated sliding conditions. Tribol. Int. 2011, 6, 284–290. [Google Scholar]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Hanamura, T.; Qui, H. Analysis of Fracture Toughness Mechanism in Ultra-Fine Grained Steels; NIMS Monographs; Springer: Ibaraki, Japan, 2014. [Google Scholar]

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering: An Introduction; John Wiley & Sons: New York, NY, USA, 2013. [Google Scholar]

- Amanov, A.; Sasaki, S.; Pyun, Y.S. Frictional behavior of duplex nano-corrugated and nanostructured Cu alloy produced by UNSM. Procedia Eng. 2013, 68, 491–496. [Google Scholar] [CrossRef]

- Johnson, K.K. Contact Mechanics, 9th ed.; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Pereira, D.; Gandra, J.; Pamies-Teixeira, J.; Miranda, R.M.; Vilaca, P. Wear behaviour of steel coatings produced by friction surfacing. J. Mater. Process. Technol. 2014, 214, 2858–2868. [Google Scholar] [CrossRef]

- Amanov, A.; Penkov, O.V.; Pyun, Y.S.; Kim, D.E. Effects of ultrasonic nanocrystalline surface modification on the tribological properties of AZ91D magnesium alloy. Tribol. Int. 2012, 54, 106–113. [Google Scholar] [CrossRef]

- Fontavlo, G.A.; Hummer, R.; Mitterer, C.; Sammt, K.; Schemmel, I. Microstructural aspects determining the adhesive wear of tool steels. Wear 2006, 260, 1028–1034. [Google Scholar]

- Mesquita, R.A. Tool Steels: Properties and Performance; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Stachowiak, G.W.; Batchelor, A.W. Engineering Tribology, 3rd ed.; Elsevier: Oxford, UK, 2005. [Google Scholar]

- Ulutan, M.; Celik, O.N.; Gasan, H.; Er, U. Effect of different surface treatment methods on the friction and wear behavior of AISI 4140 steel. J. Mater. Sci. Technol. 2010, 26, 251–257. [Google Scholar] [CrossRef]

| Material | C | V | Si | Mo | Mn | Cr | Fe |

|---|---|---|---|---|---|---|---|

| Bulk | 0.32 | 1.00 | 1.00 | 1.33 | 0.25 | 5.13 | balance |

| 3D-printed | 0.41 | 0.90 | 1.00 | 1.40 | 0.35 | 5.35 | balance |

| Material | Yield Strength, MPa | Elastic Modulus, GPa | UTS, GPa | Elongation, % |

|---|---|---|---|---|

| Bulk | 1650 ± 24.64 | 210 ± 3.44 | 1990 ± 28.34 | 9 ± 0.63 |

| 3D-printed | 1720 ± 24.99 | 218 ± 3.35 | 2010 ± 29.67 | 12 ± 0.66 |

| Material | Frequency, kHz | Amplitude, μm | Static Load, N | Speed, mm/min | Feed Rate, μm | Ball Diameter, mm | Ball Material |

|---|---|---|---|---|---|---|---|

| Bulk | 20 | 30 | 30 | 2000 | 70 | 2.38 | WC |

| 3D-printed | 70 |

| Material | Applied Load, N | Contact Stress, GPa | Reciprocating Speed, cm/s | Reciprocating Time, min | Stroke, mm |

|---|---|---|---|---|---|

| Bulk | 10 | 0.6 | 2.51 | 60.0 | 2.0 |

| 3D-printed |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, I.-S.; Lee, C.-S.; Choi, C.-H.; Lee, H.-G.; Lee, M.G.; Jeon, Y. Effect of the Ultrasonic Nanocrystalline Surface Modification (UNSM) on Bulk and 3D-Printed AISI H13 Tool Steels. Metals 2017, 7, 510. https://doi.org/10.3390/met7110510

Cho I-S, Lee C-S, Choi C-H, Lee H-G, Lee MG, Jeon Y. Effect of the Ultrasonic Nanocrystalline Surface Modification (UNSM) on Bulk and 3D-Printed AISI H13 Tool Steels. Metals. 2017; 7(11):510. https://doi.org/10.3390/met7110510

Chicago/Turabian StyleCho, In-Sik, Chang-Soon Lee, Chang-Ha Choi, Hyung-Gyu Lee, Moon Gu Lee, and Yongho Jeon. 2017. "Effect of the Ultrasonic Nanocrystalline Surface Modification (UNSM) on Bulk and 3D-Printed AISI H13 Tool Steels" Metals 7, no. 11: 510. https://doi.org/10.3390/met7110510

APA StyleCho, I.-S., Lee, C.-S., Choi, C.-H., Lee, H.-G., Lee, M. G., & Jeon, Y. (2017). Effect of the Ultrasonic Nanocrystalline Surface Modification (UNSM) on Bulk and 3D-Printed AISI H13 Tool Steels. Metals, 7(11), 510. https://doi.org/10.3390/met7110510