CO2 Laser Cutting of Hot Stamping Boron Steel Sheets

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. ANOVA

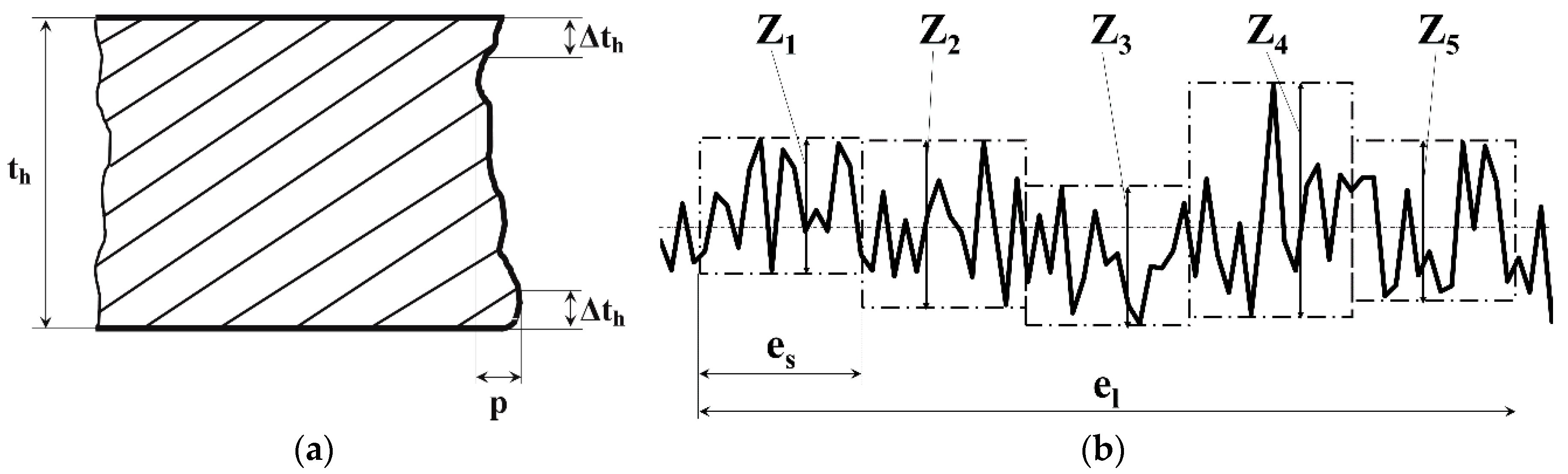

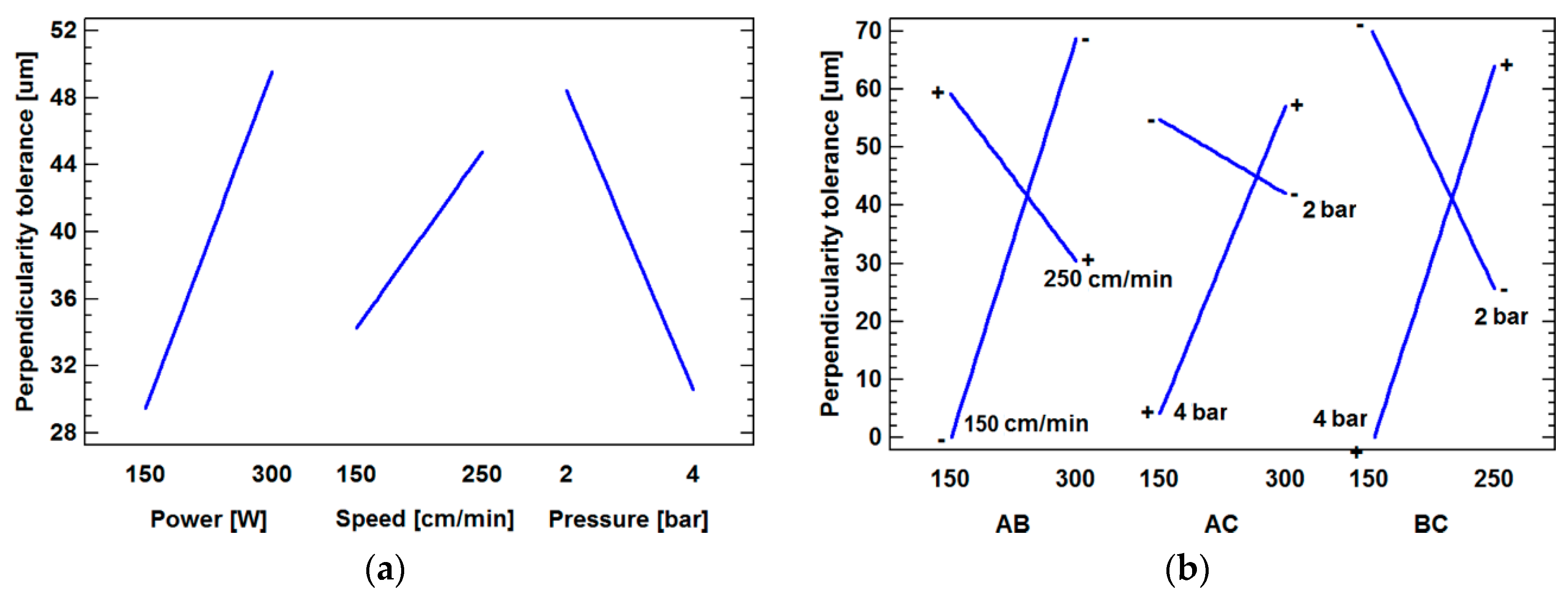

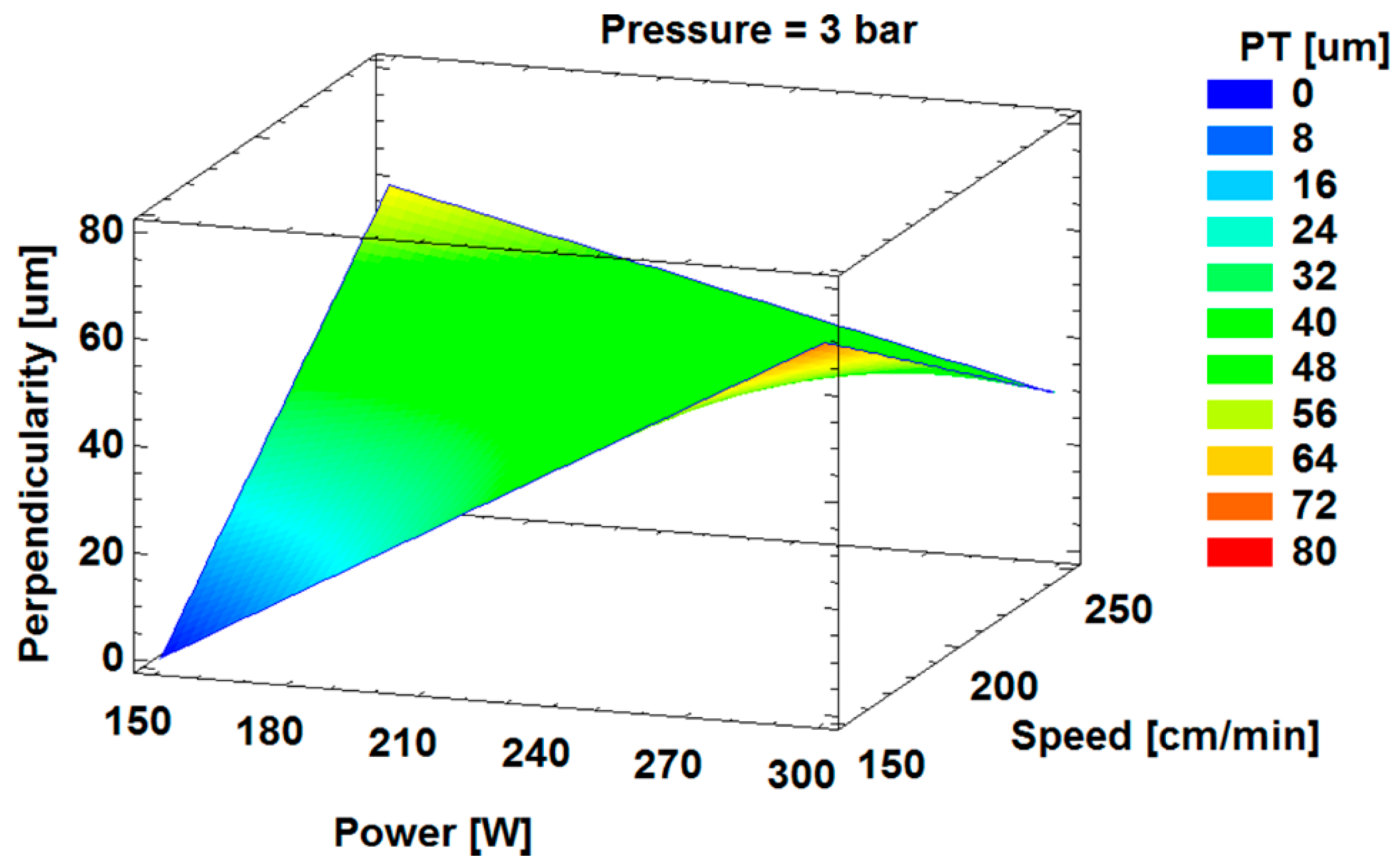

3.2. Perpendicularity Tolerance

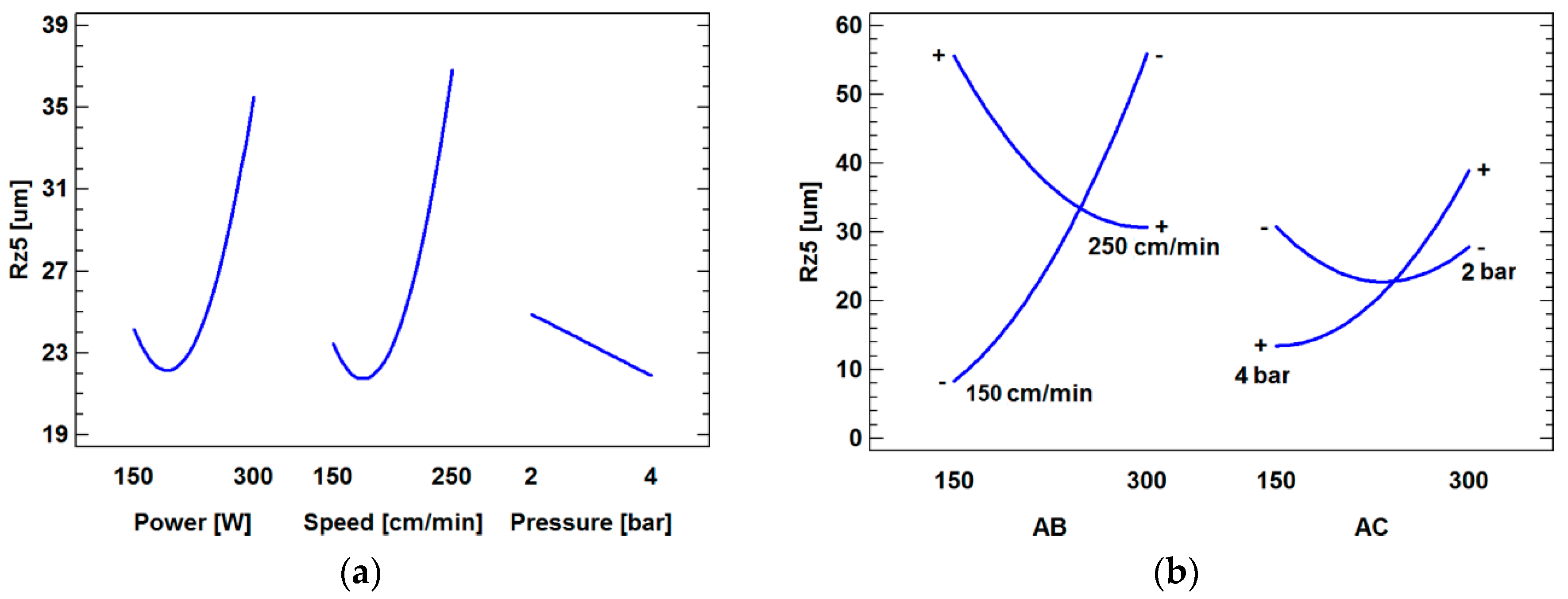

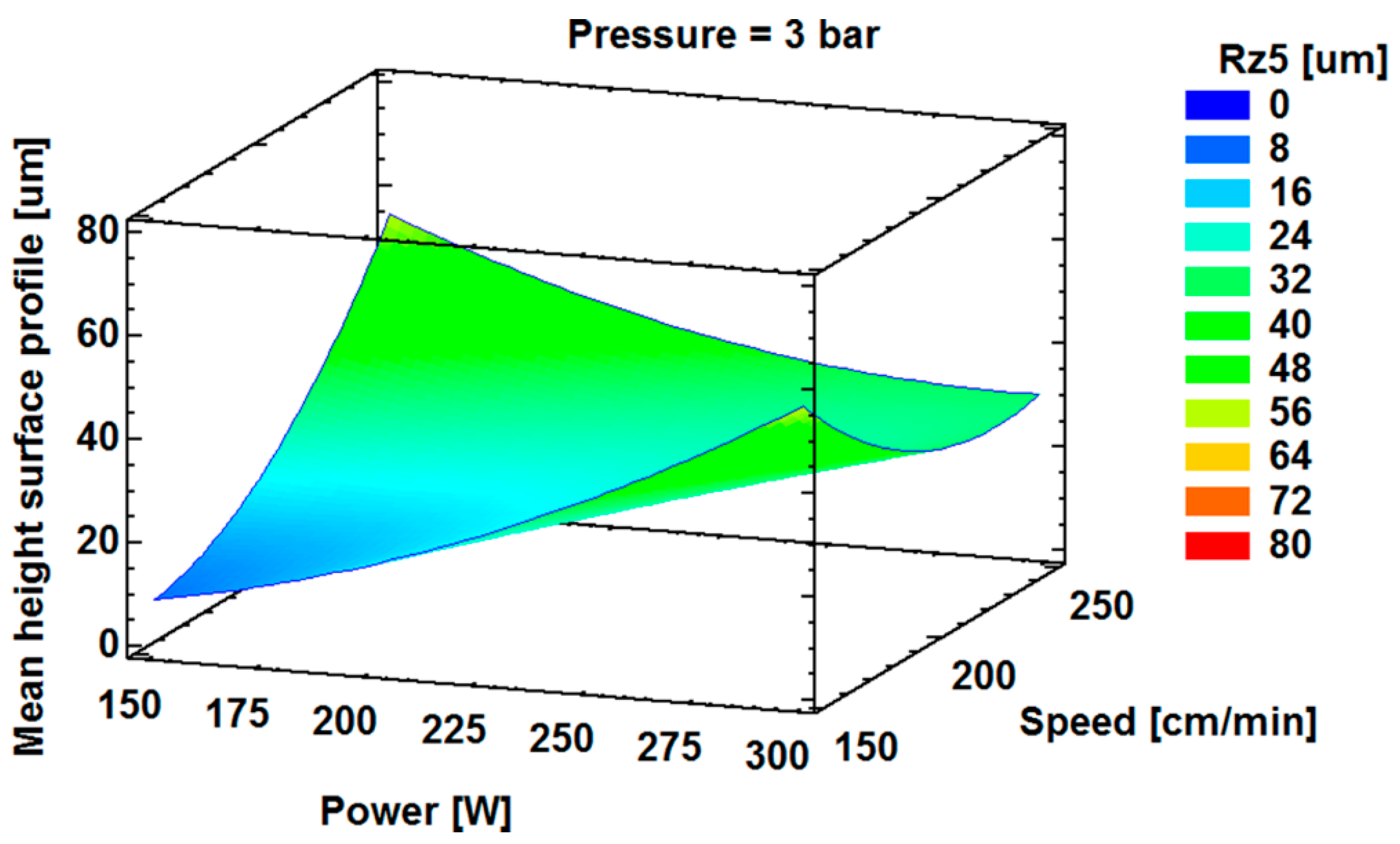

3.3. Mean Height of the Surface Profile (RZ5)

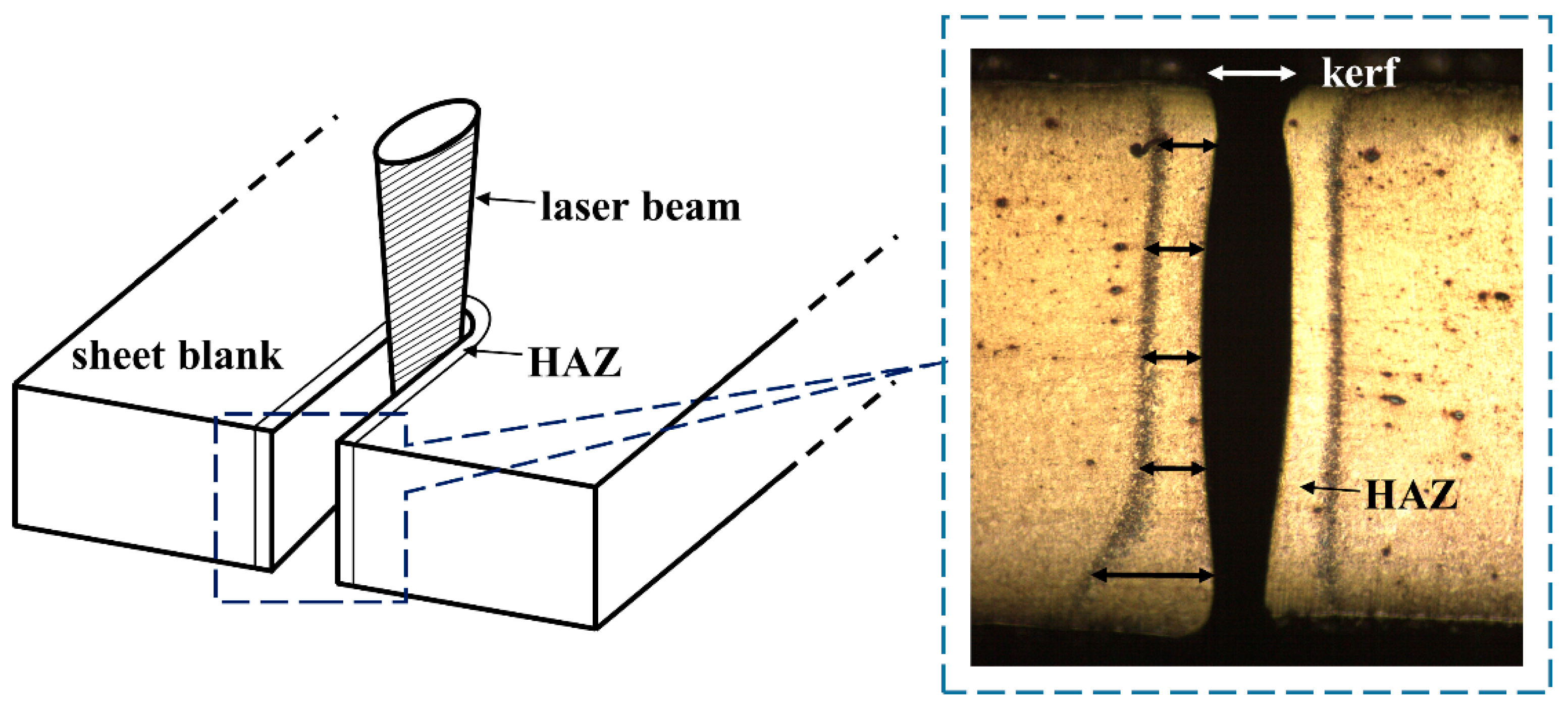

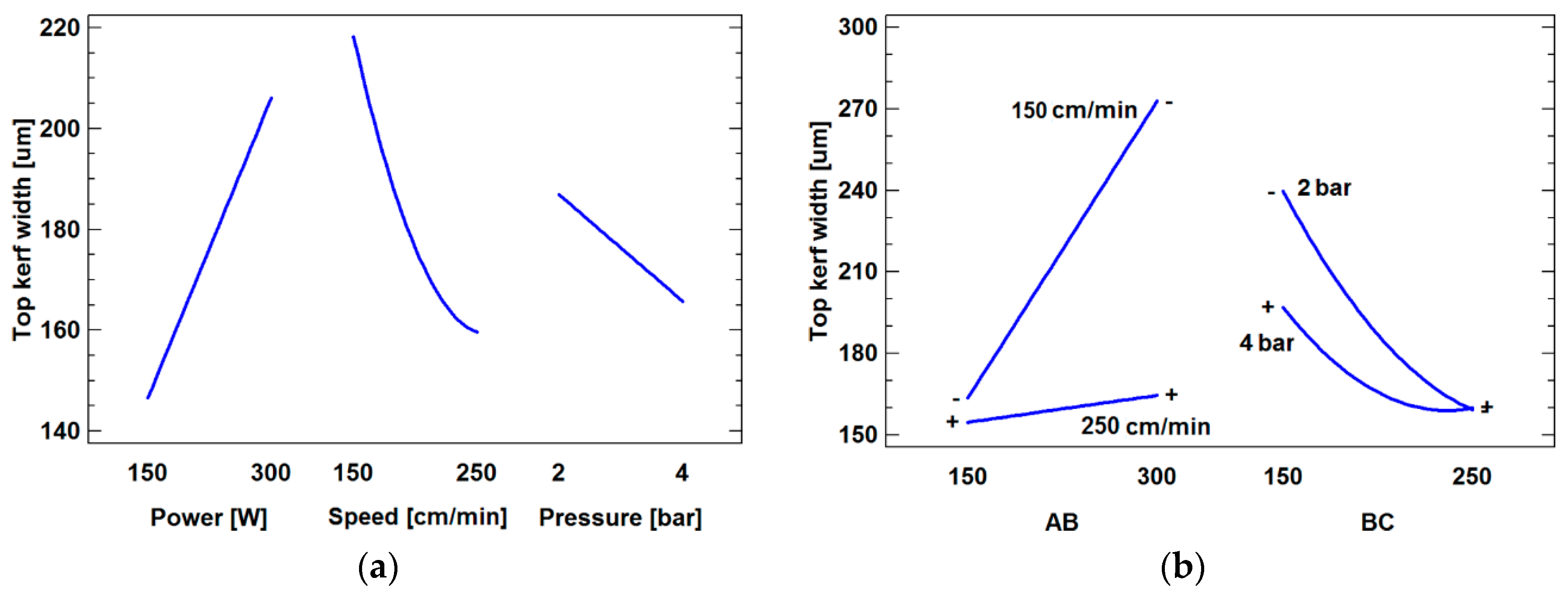

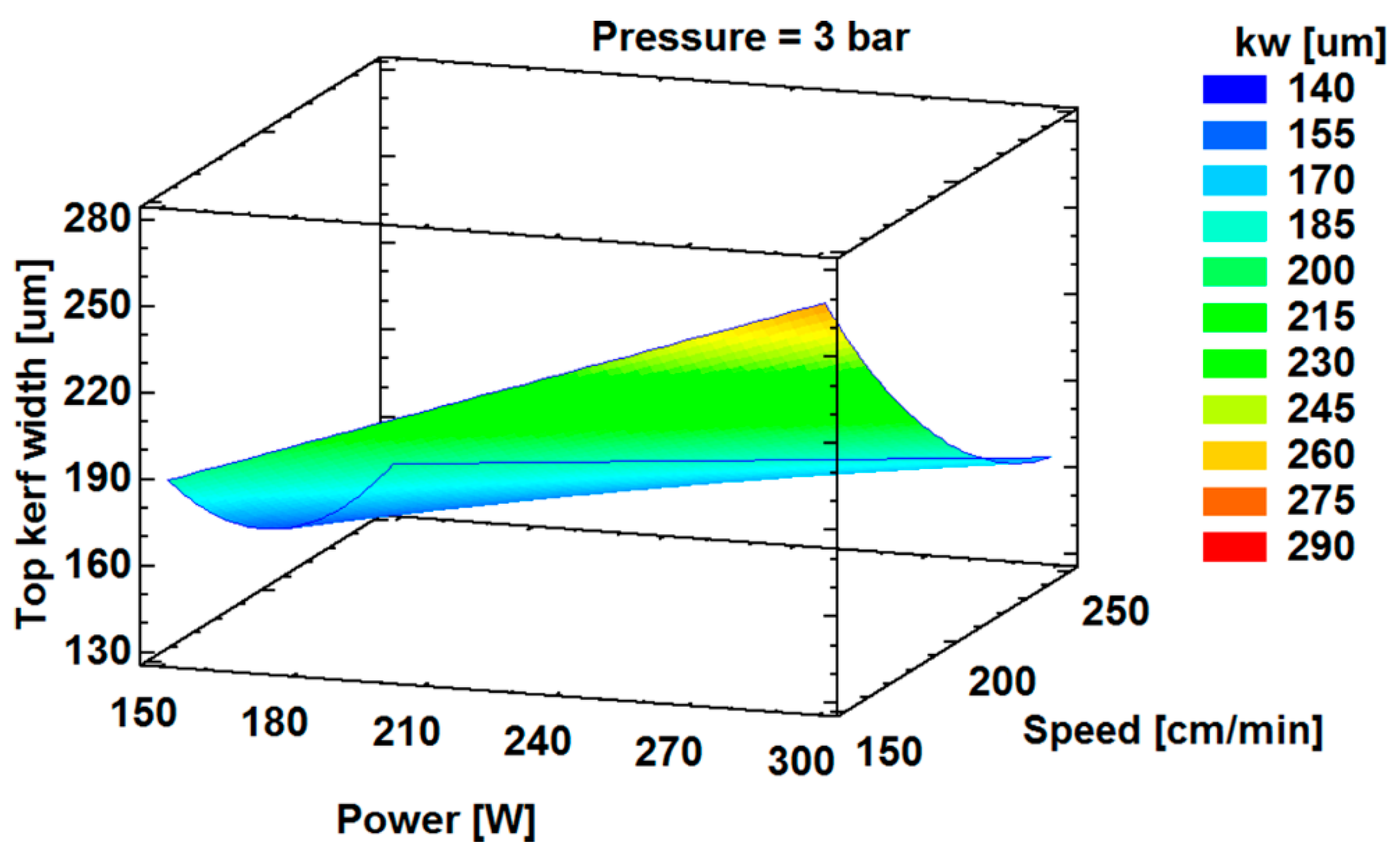

3.4. Top Kerf Width

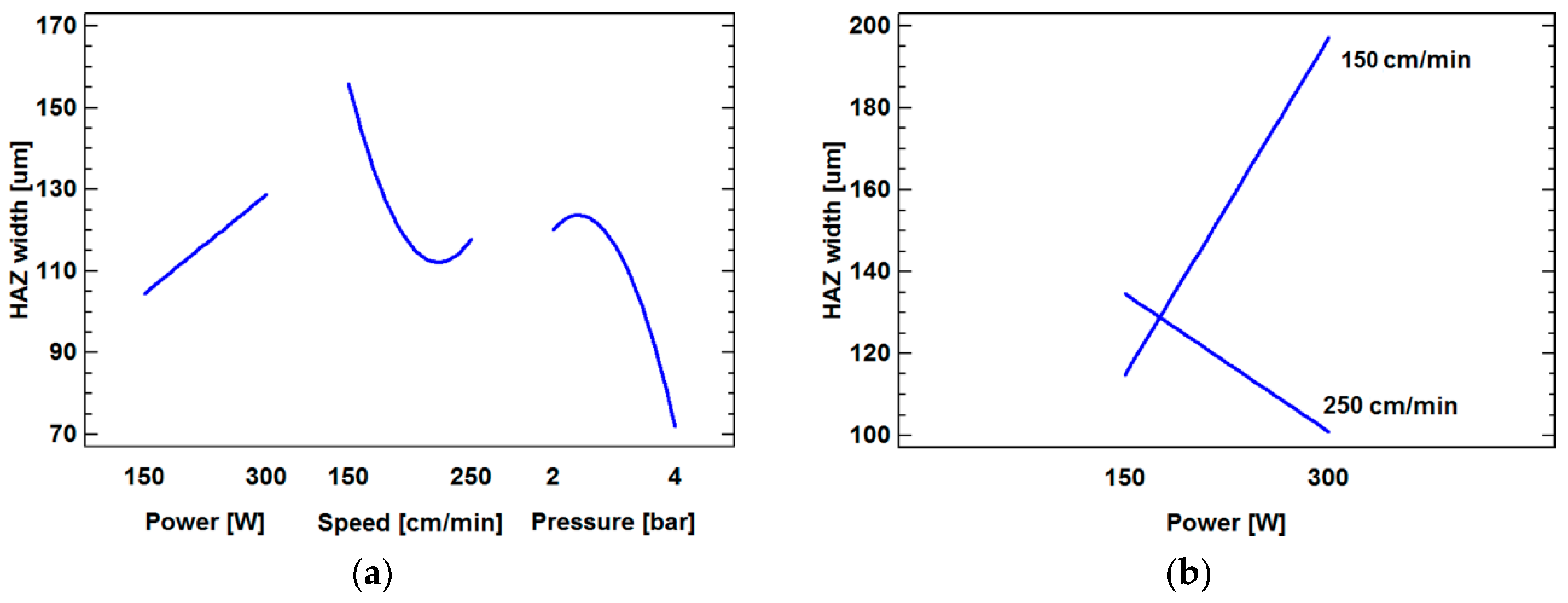

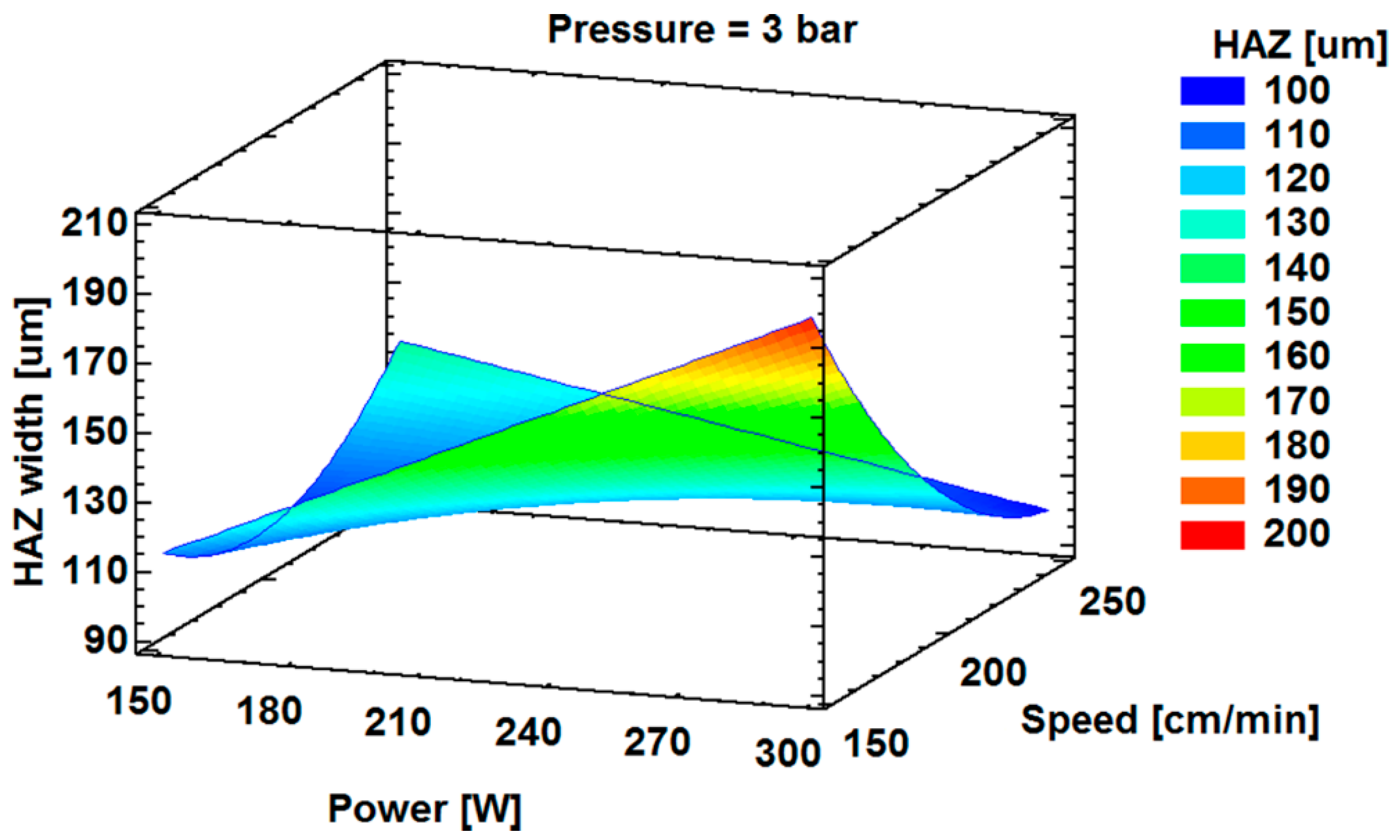

3.5. HAZ Width

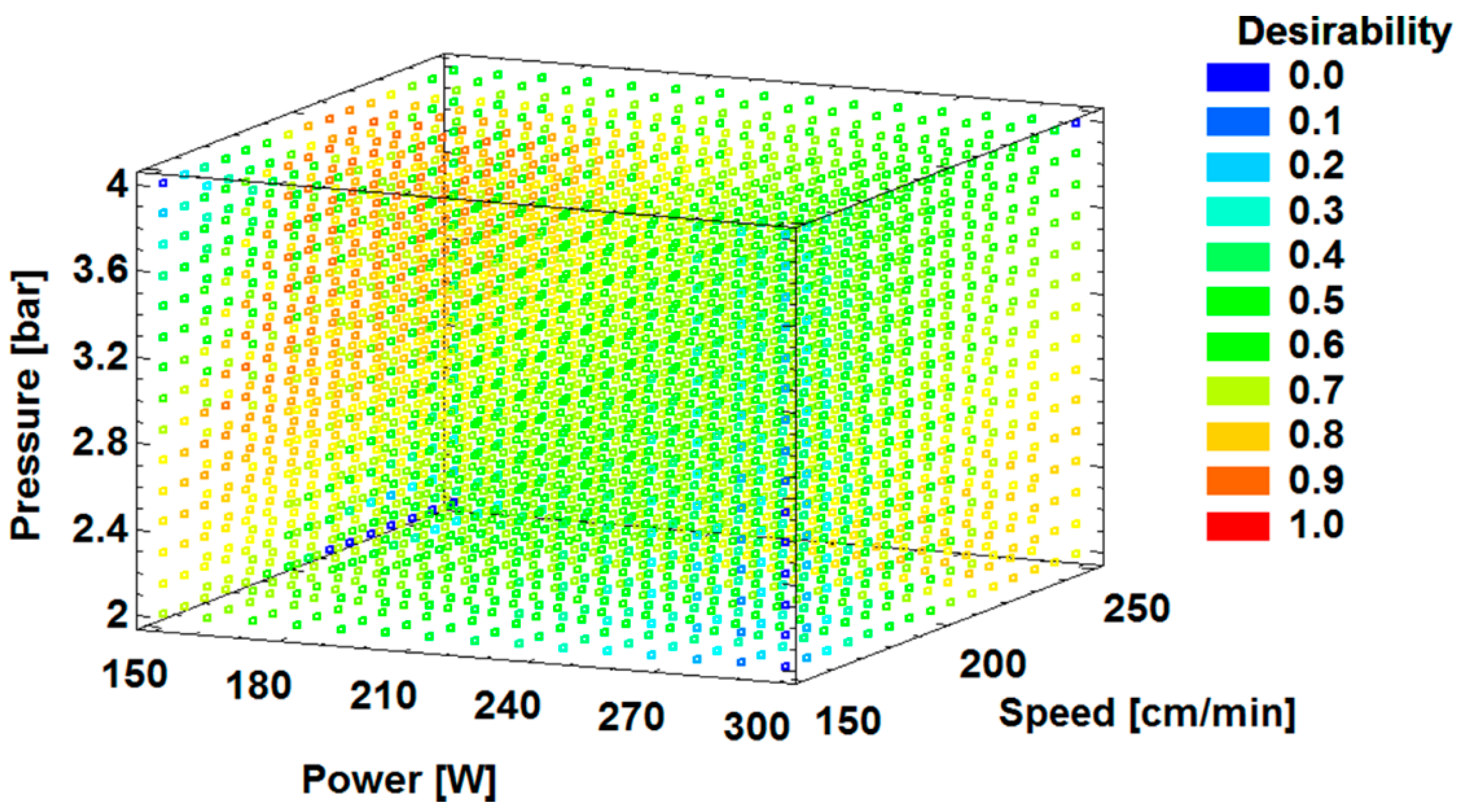

3.6. Desirability Approach in Optimizing Cut Surface Quality and Confirmation Experiment

4. Conclusions

- ANOVA highlights that some examined process parameters and interactions have a key role in affecting cut quality. Particularly, cutting speed has the most important influence on top kerf and HAZ width, whereas its interactions with laser power and assist gas pressure primarily affect mean height of the surface profile and perpendicularity tolerance, respectively;

- Under the examined ranges of process parameters, the difficulty to blow out the molten material, also probably due to the presence of oxides from the melting of the Fe/Al/Si layer, is considered the main factor responsible for a widening of kerf in the middle of the sheet thickness, which badly affects perpendicularity tolerance;

- Laser power and cutting speed have the strongest influence on mean height of the surface profile. They drive the formation of sideways burnings and turbulence within the molten metal, which increase the peak-to-valley distance of striations on cut surfaces;

- Kerf width is predominantly affected by cutting speed and laser power, the interaction factors instead have a much more limited influence. This outcome confirms the utmost importance of these parameters regardless the nature of sheets, as already claimed by previous studies on different metal alloys;

- HAZ width is mainly affected by cutting speed and oxygen pressure, and its size is directly related to the thermal heat and cooling occurring during the cutting process. Other minor mechanisms ascribable to the pulsed nature of the laser source might be involved in HAZ widening;

- Small amounts of resolidified material (dross) are always present on sheet surfaces cut with the lowest cutting speed (150 cm/min). In the other cases, a low oxygen pressure can favor dross formation;

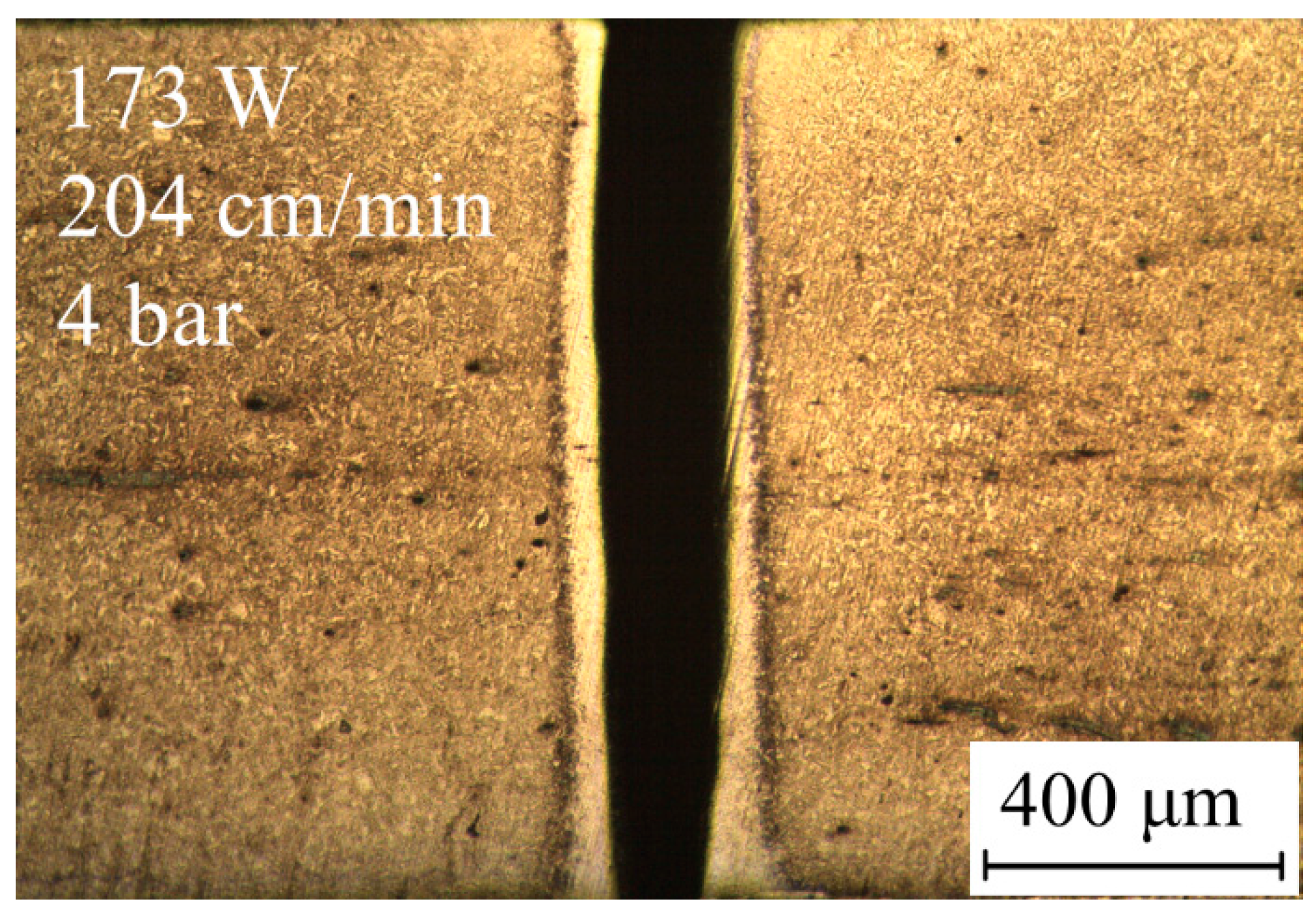

- A laser power of 173 W, a cutting speed of 204 cm/min and an assist gas pressure of 4 bar is the optimal combination with a desirability over 90%. A confirmation experiment has demonstrated the appropriateness of the quadratic models and optimization criterion used to predict quality responses, with a little underestimation of the actual values.

- CO2 laser processing can be a suitable alternative to the mechanical cutting of automotive stamped part made of 22MnB5 steel grades. However, proper attention must be paid because cut quality depends strongly on laser settings. Particularly, interactions among cutting parameters can have opposite effects for different factor levels. This is because different physical, mechanical, and chemical phenomena, also due to the presence of a Fe/Al/Si coating, can be involved and/or have different effects at varying cutting conditions.

Acknowledgments

Conflicts of Interest

References

- Karbasian, H.; Tekkaya, A.E. A review on hot stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Russo Spena, P.; De Maddis, M.; Lombardi, F. Cut quality assessment of CO2 laser cutting of twinning-induced plasticity steel sheets. J. Eng. Manuf. 2015, 229, 3–19. [Google Scholar] [CrossRef]

- Tahir, A.F.M.; Aqida, S. An investigation of laser cut quality of 22MnB5 ultra high strength steel using response surface methodology. Opt. Laser Technol. 2017, 92, 142–149. [Google Scholar] [CrossRef]

- Nagasaka, A.; Kubota, Y.; Sugimoto, K.; Mio, A.; Hojo, T.; Makii, K.; Kawajiri, M.; Kitayama, M. Effect of YAG laser cutting on stretch-flangeability of ultra high strength TRIP sheet steel with bainitic ferrite matrix. ISIJ Int. 2010, 50, 1441–1446. [Google Scholar] [CrossRef]

- Radovanovic, M. Experimental investigations of CO2 laser cut quality: A review. Nonconv. Technol. Rev. 2011, 4, 35–42. [Google Scholar]

- Sharma, A.; Yadava, V. Modelling and optimization of cut quality during pulsed Nd:YAG laser cutting of thin Al-alloy sheet for curved profile. Opt. Lasers Eng. 2013, 51, 77–88. [Google Scholar] [CrossRef]

- Pandey, A.K.; Dubey, A.K. Taguchi based fuzzy logic optimization of multiple quality characteristics in laser cutting of Duralumin sheet. Opt. Lasers Eng. 2012, 50, 328–335. [Google Scholar] [CrossRef]

- Eltawahni, H.A.; Hagino, M.; Benyounis, K.Y.; Inoue, T.; Olabi, A.G. Effect of CO2 laser cutting process parameters on edge quality and operating cost of AISI316L. Opt. Laser Technol. 2012, 44, 1068–1082. [Google Scholar] [CrossRef]

- Yilbas, B. Experimental investigation into laser cutting parameters. J. Mater. Process. Technol. 1996, 58, 323–330. [Google Scholar] [CrossRef]

- Yilbas, B.; Karatas, C.; Uslan, I.; Keles, O.; Usta, Y.; Yilbas, Z.; Ahsan, M. Wedge cutting of mild steel by CO2 laser and cut-quality assessment in relation to normal cutting. Opt. Lasers Eng. 2008, 46, 777–784. [Google Scholar] [CrossRef]

- Hao, H.J.; Xu, J.Y.; Li, J. Prediction of laser cut quality based on an improved Pareto genetic algorithm. Lasers Eng. 2014, 27, 43–56. [Google Scholar]

- Dubey, A.K.; Yadava, V. Multi-objective optimization of Nd:YAG laser cutting of nickel-based superalloy sheet using orthogonal array with principal component analysis. Opt. Lasers Eng. 2008, 46, 124–132. [Google Scholar] [CrossRef]

- Mullick, S.; Madhukar, Y.K.; Roy, S.; Nath, A.K. Performance optimization of water-jet assisted underwater laser cutting of AISI 304 stainless steel sheet. Opt. Lasers Eng. 2016, 83, 32–47. [Google Scholar] [CrossRef]

- Sanchez, J.A.; López de Lacalle, L.N.; Lamikiz, A. A computer-aided system for the optimization of the accuracy of the wire electro-discharge machining process. Int. J. Comp. Integr. Manuf. 2004, 17, 413–420. [Google Scholar] [CrossRef]

- EN ISO 9013 Standard. Thermal Cutting—Classification of Thermal Cuts—Geometrical Product Specification and Quality Tolerances; ISO Copyright Office: Geneva, Switzerland, 2017. [Google Scholar]

- Powell, J. Laser cutting steels. In CO2 Laser Cutting, 1st ed.; Powell, J., Ed.; Springer: London, UK, 1993; pp. 23–70. ISBN 978-1-4471-3386-5. [Google Scholar]

- Ghany, K.A.; Newishy, M. Cutting of 1.2 mm thick austenitic stainless steel sheet using pulsed and CW Nd:YAG laser. J. Mater. Proc. Technol. 2005, 168, 438–447. [Google Scholar] [CrossRef]

- Yilbas, B.S. Effect of process parameters on the kerf width during the laser cutting process. J. Eng. Manuf. 2001, 215, 1357–1365. [Google Scholar] [CrossRef]

- Yilbas, B.S. Laser cut quality and thermal efficiency analysis. J. Mater. Proc. Technol. 2004, 155–156, 2106–2115. [Google Scholar] [CrossRef]

- Dilthey, U.; Faerber, M.; Weick, J. Laser cutting of steel-cut quality depending on cutting parameters. Weld. World 1992, 30, 275–278. [Google Scholar]

- Radovanovic, M.; Dasic, P. Research on surface roughness by laser cut. In The Annals of University “Dunarea De Jos” of Galati; Fascicle VII Tribology; Dunarea De Jos of Galati: Galati, Romania, 2006; pp. 84–88. [Google Scholar]

- Yilbas, B.S.; Rashid, M. CO2 laser cutting of Incoloy 800 HT alloy and its quality assessment. J. Laser Eng. 2002, 12, 135–145. [Google Scholar] [CrossRef]

- Neimeyer, R.; Smith, R.N.; Kaminski, D.A. Effects of operating parameters on surface quality for laser cutting of mild steel. J. Eng. Ind. 1993, 115, 359–362. [Google Scholar] [CrossRef]

- Jarosz, K.; Löschner, P.; Niesłony, P. Effect of cutting speed on surface quality and heat-affected zone in laser cutting of 316L stainless steel. Procedia Eng. 2016, 149, 155–162. [Google Scholar] [CrossRef]

- Sharma, A.; Yadava, V. Modelling and optimization of cut quality during pulsed Nd:YAG laser cutting of thin Al-alloy sheet for straight profile. Opt. Laser Technol. 2012, 44, 159–168. [Google Scholar] [CrossRef]

- Lamikiz, A.; López de Lacalle, L.N.; Sanchez, J.A.; Del Pozo, D.; Etayo, J.M.; Lopez, J.M. CO2 laser cutting of advanced high strength steels (AHSS). Appl. Surf. Sci. 2005, 242, 362–368. [Google Scholar] [CrossRef]

- Rajaram, N.; Sheikh-Ahmad, J.; Cheraghi, H. CO2 laser cut quality of 4130 steel. Int. J. Mach. Tools Manuf. 2003, 43, 351–358. [Google Scholar] [CrossRef]

- Powell, J.; Al-Mashikhi, S.O.; Kaplan, A.F.H.; Voisey, K.T. Fibre laser cutting of thin section mild steel: An explanation of the “striation free” effect. Opt. Laser Eng. 2011, 49, 1069–1075. [Google Scholar] [CrossRef]

- Wandera, C.; Kujanpää, V.; Salminen, A. Laser power requirement for cutting thick-section steel and effects of processing parameters on mild steel cut quality. J. Eng. Manuf. 2011, 225, 651–661. [Google Scholar] [CrossRef]

- Riveiro, A.; Quintero, F.; Lusquiños, F.; Comesaña, R.; Pou, J. Influence of assist gas nature on the surfaces obtained by laser cutting of Al-Cu alloys. Surf. Coat. Technol. 2010, 5, 1878–1885. [Google Scholar] [CrossRef]

- Ali, H.M.; Iqbal, A.; Hashemipour, M. Cut quality and strength evaluation of hole making in glass fibre reinforced polymer (GFRP) composite using laser beam cutting technology. Lasers Eng. 2015, 31, 71–95. [Google Scholar]

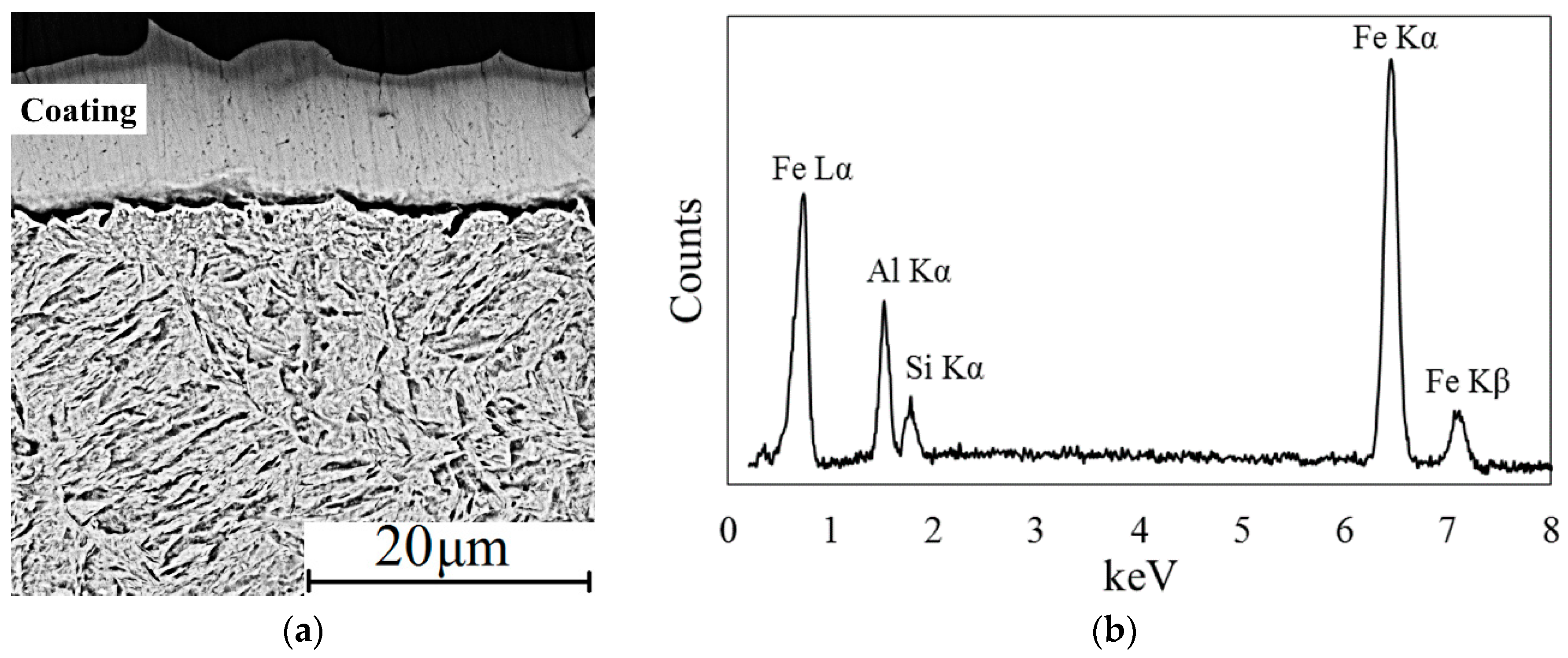

| Element | Fe | C | Si | Mn | Cr | Al | Ti | B | P + S |

|---|---|---|---|---|---|---|---|---|---|

| 22MnB5 | bal. | 0.25 | 0.23 | 1.30 | 0.13 | 0.036 | 0.039 | 0.047 | <0.03 |

| Coating | 87.9 | - | 3.5 | - | - | 8.6 | - | - | - |

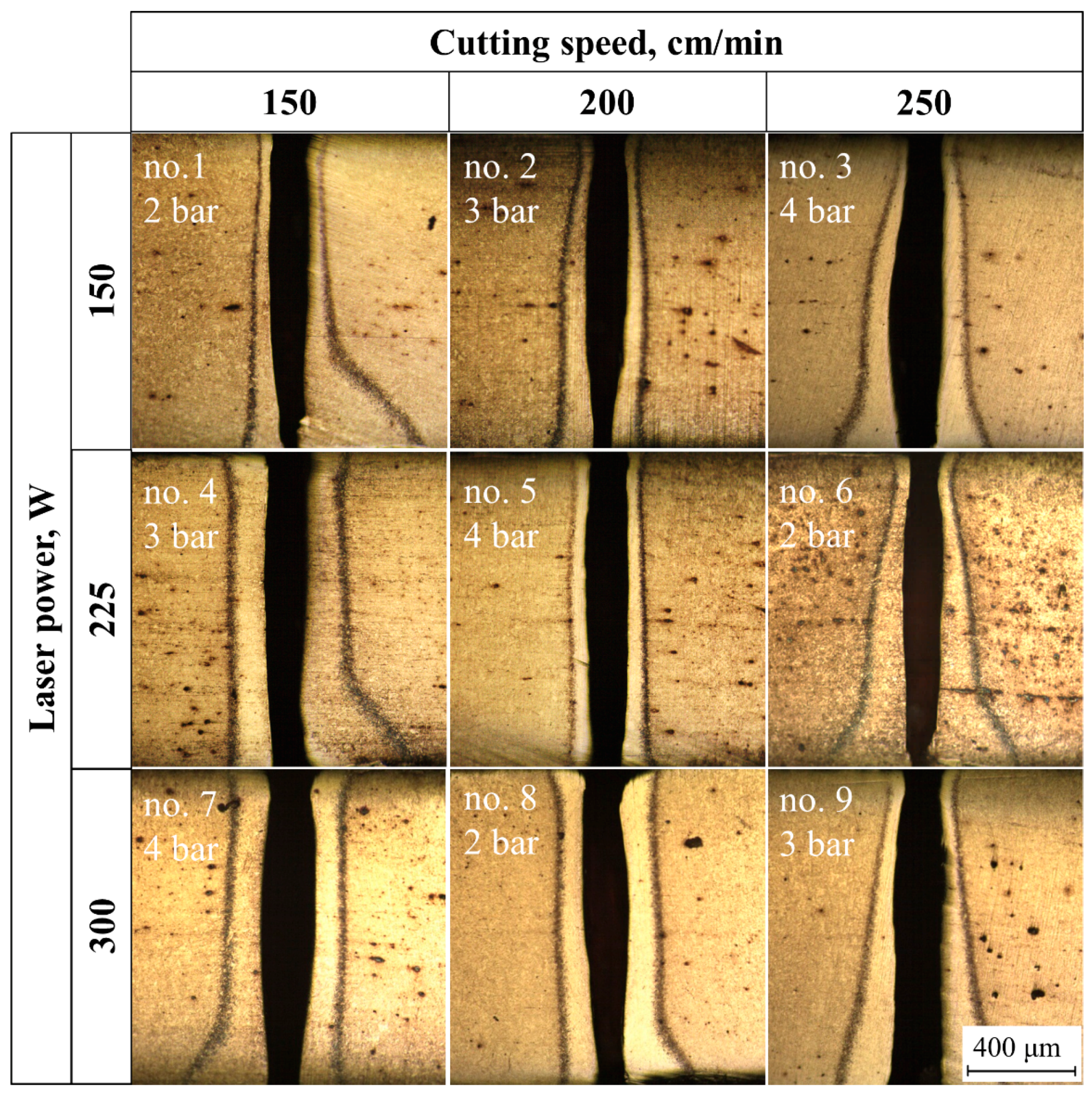

| Run No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| Laser power [W] | 150 | 150 | 150 | 225 | 225 | 225 | 300 | 300 | 300 |

| Cutting speed [cm/min] | 150 | 200 | 250 | 150 | 200 | 250 | 150 | 200 | 250 |

| Oxygen pressure [bar] | 2.0 | 3.0 | 4.0 | 3.0 | 4.0 | 2.0 | 4.0 | 2.0 | 3.0 |

| Run | Process Parameters | Quality Responses | ||||||

|---|---|---|---|---|---|---|---|---|

| No. | Laser Power [W] | Cutting Speed [cm/min] | Oxygen Pressure [bar] | PT [μm] | RZ5 [μm] | kw [μm] | HAZ [μm] | Class of Cut |

| 1 | 150 | 150 | 2 | 53 ± 2 | 15 ± 3 * | 160 ± 9 | 115 ± 38 | II |

| 2 | 150 | 200 | 3 | 31 ± 3 | 24 ± 2 | 151 ± 5 | 96 ± 11 | I * |

| 3 | 150 | 250 | 4 | 62 ± 3 | 47 ± 12 | 175 ± 8 | 91 ± 5 | I * |

| 4 | 225 | 150 | 3 | 34 ± 4 | 23 ± 2 | 226 ± 13 | 168 ± 26 | II |

| 5 | 225 | 200 | 4 | 29 ± 10 | 22 ± 2 | 182 ± 10 | 79 ± 1 * | I * |

| 6 | 225 | 250 | 2 | 25 ± 2 * | 38 ± 5 | 137 ± 5 * | 123 ± 5 | II |

| 7 | 300 | 150 | 4 | 49 ± 2 | 60 ± 9 | 269 ± 9 | 144 ± 21 | II |

| 8 | 300 | 200 | 2 | 42 ± 3 | 30 ± 2 | 197 ± 20 | 134 ± 16 | II |

| 9 | 300 | 250 | 3 | 31 ± 7 | 31 ± 3 | 167 ± 10 | 97 ± 4 | I * |

| Factor | Sum of Squares | df | Mean Square | F | p-Value |

|---|---|---|---|---|---|

| A: Laser power | 795.018 | 1 | 795.018 | 38.82 | 0.0000 |

| B: Cutting speed | 218.698 | 1 | 218.698 | 10.68 | 0.0043 |

| C: Oxygen pressure | 624.446 | 1 | 624.446 | 30.49 | 0.0000 |

| AB | 2096.79 | 1 | 2096.79 | 102.38 | 0.0000 |

| AC | 944.643 | 1 | 944.643 | 46.12 | 0.0000 |

| BC | 2762.7 | 1 | 2762.7 | 134.89 * | 0.0000 |

| Lack-of-fit | 28.6138 | 2 | 14.3069 | 0.70 | 0.5103 |

| Pure error | 368.667 | 18 | 20.4815 | - | - |

| Total (corr.) | 4170.74 | 26 | - | - | - |

| Factor | Sum of Squares | df | Mean Square | F | p-Value |

|---|---|---|---|---|---|

| A: Laser power | 578.0 | 1 | 578.0 | 18.40 | 0.0004 |

| B: Cutting speed | 416.351 | 1 | 416.351 | 13.26 | 0.0019 |

| C: Oxygen pressure | 23.1429 | 1 | 23.1429 | 0.74 | 0.4020 |

| AA | 249.185 | 1 | 249.185 | 7.93 | 0.0114 |

| AB | 1992.3 | 1 | 1992.3 | 63.43 * | 0.0000 |

| AC | 262.059 | 1 | 262.059 | 8.34 | 0.0098 |

| BB | 208.286 | 1 | 208.286 | 6.63 | 0.0191 |

| Lack-of-fit | 0.222222 | 1 | 0.222222 | 0.01 | 0.9339 |

| Pure error | 565.333 | 18 | 31.4074 | - | - |

| Total (corr.) | 5262.07 | 26 | - | - | - |

| Factor | Sum of Squares | df | Mean Square | F | p-Value |

|---|---|---|---|---|---|

| A: Laser power | 10,658.0 | 1 | 10,658.0 | 95.57 | 0.0000 |

| B: Cutting speed | 12,278.3 | 1 | 12,278.3 | 110.10 * | 0.0000 |

| C: Oxygen pressure | 2141.91 | 1 | 2141.91 | 19.21 | 0.0004 |

| AB | 1315.23 | 1 | 1315.23 | 11.79 | 0.0030 |

| AC | 961.445 | 1 | 961.445 | 8.62 | 0.0088 |

| BB | 1771.87 | 1 | 1771.87 | 15.89 | 0.0009 |

| Lack-of-fit | 162.644 | 2 | 81.3218 | 0.73 | 0.4960 |

| Pure error | 2007.33 | 18 | 111.519 | - | - |

| Total (corr.) | 41,895.2 | 26 | - | - | - |

| Factor | Sum of Squares | df | Mean Square | F | p-Value |

|---|---|---|---|---|---|

| A:Laser power | 2664.5 | 1 | 2664.5 | 8.16 | 0.0105 |

| B:Cutting speed | 6574.22 | 1 | 6574.22 | 20.13 * | 0.0003 |

| C:Oxygen pressure | 5965.79 | 1 | 5965.79 | 18.27 | 0.0005 |

| AB | 5065.35 | 1 | 5065.35 | 15.51 | 0.0010 |

| BB | 2453.63 | 1 | 2453.63 | 7.51 | 0.0134 |

| CC | 2044.63 | 1 | 2044.63 | 6.26 | 0.0222 |

| Lack-of-fit | 1115.63 | 2 | 557.815 | 1.71 | 0.2093 |

| Pure error | 5877.33 | 18 | 326.519 | - | - |

| Total (corr.) | 25618.3 | 26 | - | - | - |

| Factor | Objective | Impact |

|---|---|---|

| Laser power | in the range (150–300 W) | - |

| Cutting speed | in the range (150–250 cm/min) | - |

| Oxygen pressure | in the range (2–4 bar) | - |

| Perpendicularity tolerance | minimize | 5 |

| Mean height of the surface profile | minimize | 5 |

| Kerf width | minimize | 3 |

| HAZ width | minimize | 3 |

| Setting at Optimum: 173 W, 204 cm/min, 4 bar | |||

|---|---|---|---|

| Quality responses | Prediction | Desirability | Actual |

| Perpendicularity tolerance | 17.0 μm | 0.99 | 18.7 μm |

| Mean height of the surface profile | 17.8 μm | 0.91 | 20.8 μm |

| Top kerf width | 165 μm | 0.69 | 179 μm |

| HAZ width | 63.8 μm | 0.98 | 69.2 μm |

© 2017 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Russo Spena, P. CO2 Laser Cutting of Hot Stamping Boron Steel Sheets. Metals 2017, 7, 456. https://doi.org/10.3390/met7110456

Russo Spena P. CO2 Laser Cutting of Hot Stamping Boron Steel Sheets. Metals. 2017; 7(11):456. https://doi.org/10.3390/met7110456

Chicago/Turabian StyleRusso Spena, Pasquale. 2017. "CO2 Laser Cutting of Hot Stamping Boron Steel Sheets" Metals 7, no. 11: 456. https://doi.org/10.3390/met7110456

APA StyleRusso Spena, P. (2017). CO2 Laser Cutting of Hot Stamping Boron Steel Sheets. Metals, 7(11), 456. https://doi.org/10.3390/met7110456