Abstract

Recently, an increasing amount of research has focused on the biological and mechanical behavior of highly porous structures of metallic biomaterials, as implant materials for dental implants. Particularly, pure titanium and its alloys are typically used due to their outstanding mechanical and biological properties. However, these materials have high stiffness (Young’s modulus) in comparison to that of the host bone, which necessitates careful implant design to ensure appropriate distribution of stresses to the adjoining bone, to avoid stress-shielding or overloading, both of which lead to bone resorption. Additionally, many coating and roughening techniques are used to improve cell and bone-bonding to the implant surface. To date, several studies have revealed that porous geometry may be a promising alternative to bulk structures for dental implant applications. This review aims to summarize the evidence in the literature for the importance of porosity in the integration of dental implants with bone tissue and the different fabrication methods currently being investigated. In particular, additive manufacturing shows promise as a technique to control pore size and shape for optimum biological properties.

1. Introduction

Dental implants are an effective treatment to replace the root part of the naturally missing tooth [1], in order to restore patients’ appearance, speech and health [2]. They are completely placed into the jaw bone and give support to a dental prosthesis [3]. They are categorized according to their shape, surface roughness, surface treatment and the connection type with the prosthetic part. The length and diameter of commercially available dental implants vary according to the clinical treatment requirements. For example, the dimensions of cylindrical thread dental implants range from 3.25–6.0 mm in diameter and 5–18 mm in length [1]. Over the last decade, there has been a universal growing interest in dental implants, which are used to treat about one million people per year around the world [4]. The increasing demand for dental implants can be mostly attributed to their ability to completely restore dentition, the significant increase in the mean age of the world population, the higher number of elderly people in the population and higher public awareness [4]. Additionally, there are complications associated with conventional removable dentures, fixed crowns and bridges; for example, the reduced bearing area that supports the removable prosthesis due to the gradual bone resorption of the residual ridge following tooth extraction. Thus, using endosseous titanium implants is more convenient with better functionality than conventional dentures [5].

Nevertheless, dental implants, along with orthopedic implants face certain limitations, especially when used in smokers, diabetics, elderly osteoporotic patients and people with low bone density, such as a lack of biological interaction and interfacial stability with bone tissue [3,6]. Fundamentally, implants need to be constructed from biomaterials compatible with the human body environment. Titanium and its alloys have been reported as the materials of choice for most orthopedic and dental implants due to their outstanding mechanical properties and biocompatibility [7]. However, the Young’s modulus of these materials is higher than that of mineralized tissue. Furthermore, the traditional structure of titanium for medical and dental implants is non-porous; this dense structure of implants can cause a mismatch between the Young’s modulus of the titanium implant (110 GPa) and natural cortical (17–20 GPa) and cancellous bone (around 4 GPa) [8,9].

The high Young’s modulus of titanium implants leads to stress shielding and inadequate loading of the underlying bone tissue [10]. Since bone is a living tissue which is continuously modified by the bone cells in response to external signals, reduced mechanical loading leads to resorption of bone, implant loosening and ultimately failure, which has particularly been a problem for orthopaedic implants in the past [9]. Alternatively, overloading also creates high stresses in local regions of bone which can also initiate resorption [11]. Accordingly, many attempts have been undertaken to develop biomaterials with mechanical properties well-suited to the bone tissue. Most of these studies have aimed at optimising the important features of interactions between the implant surface and bone tissue. Advances in orthopaedic and dental implant design, as well as scaffolds for bone tissue engineering, have all contributed to the fabrication of novel porous titanium structures, and these fields draw on each other’s technologies.

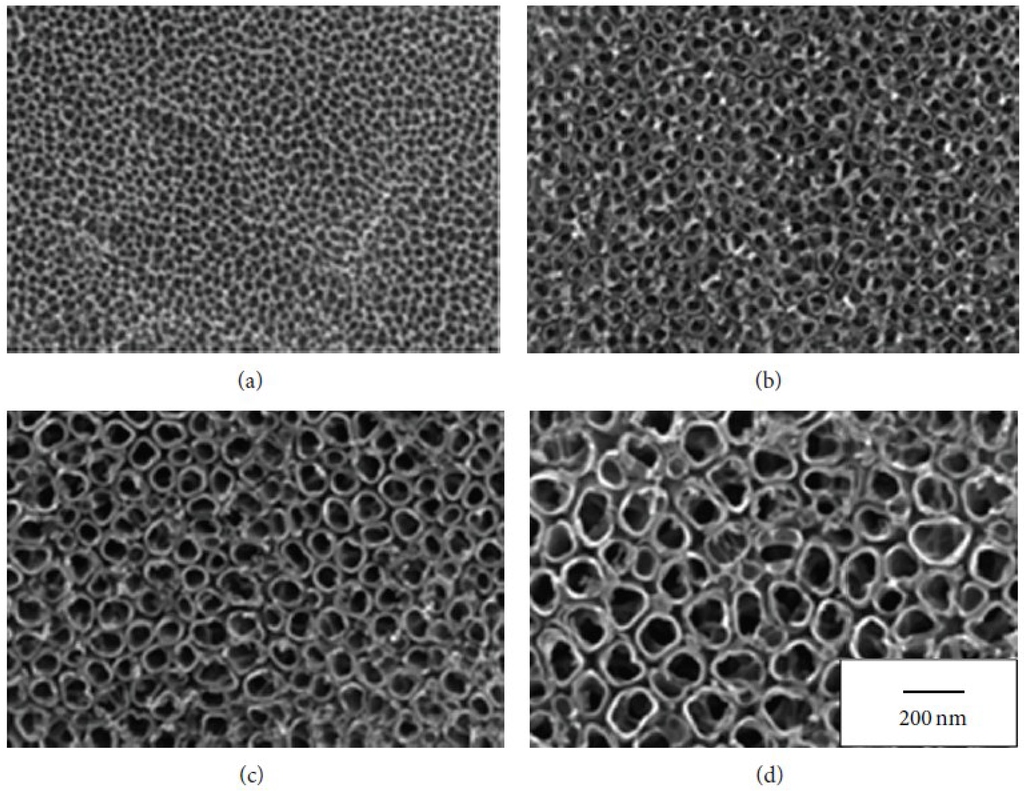

Implant morphology has a crucial role in bone-implant contact and can enhance the osseointegration process. To improve dental implant stability different surface modifications have been proposed to adapt the properties of titanium dental implants [12]. Modifying the implant surface can improve the implant to bone interaction, however, there is not always a clear explanation for the mechanism of improvement. For example, a morphological or a chemical mechanism, such as roughening the implant surface can also create modifications in the chemistry of the dental implant surface [13]. Plasma spraying with different powder particles such as titanium oxide, calcium phosphate and hydroxyapatite has been used to coat dental implants [14]. Sand blasting with stiff particles such as alumina, TiO2 and ceramic has also been suggested to roughen the dental implant surface [4]. Çelen & Özden in 2012 advocated another more controllable technique of laser micro-machining of commercially pure titanium dental implant [15]. Materials with nanometer-scale porosity such as TiO2 nanotubes have also been used recently as implant surface-treatments. These materials can be generated on the titanium dental implant by controlling the anodizing process (Figure 1) [16].

Figure 1.

SEM images of different diameter sizes of TiO2 nanotubes, (a) 30; (b) 50; (c) 70 and (d) 100 nm using 200 nm scale bar. Adapted from Ref. [16].

Despite being very successful, there are some shortcomings associated with these procedures; the bulk structure is still high-density titanium, the coating materials can dissolve over a long period of time. Moreover, coating particles that break away from the surface could have a negative biological effect on the adjacent tissue such as peri-implantitis [14]. Therefore, several alternative approaches have been proposed to overcome these drawbacks of coating materials by creating porous biomaterials as a substitute for the classical solid structure. Cellular structures can provide a suitable biological environment for the host tissue to grow into the pores [6], providing improved early implant stability, as demonstrated by commercially available dental implants from Zimmer with a porous tantalum central region. To our knowledge, the Zimmer implant is the only porous dental implant on the market and animal and short-term clinical studies indicate excellent bone integration and implant stability [17]. However, tantalum is an expensive material which may not be affordable to many seeking dental implant treatments, and, therefore, methods of providing a porous structure in titanium or a titanium alloy is of strong interest to the dental implant community [18].

To date, numerous studies have been undertaken to manipulate the mechanical and topographical properties of titanium implants. In many studies, micro- and nanoporous titanium has been proposed as a promising alternative to solid structures for biomedical and dental implant applications. Many fabrication methods have been used to fabricate porous titanium for medical purposes. However, the size, shape, percentage and distribution of pores were variable and need further optimization [19]. This review article aims to summarize the evidence in the literature of the benefits of using porous structures to improve integration of titanium dental implants with bone tissue. Furthermore, the most widely used fabrication methods for porous titanium are discussed as well as their potential to be used for dental implants.

2. Titanium and Its Alloys as Implant Materials

Ever since the 1960s, commercially pure titanium and its alloys have been shown to be versatile biomaterials that can be used to produce a variety of medical devices including those used in dentistry [7]. This is mostly related to their unique properties such as excellent mechanical behavior, superior corrosion [20], as well as high ratio of strength to weight [21]. Titanium is biocompatible because it is biologically nearly inert and well tolerated by the environment of the human body. According to the British Standards for surgical implants, the oxygen percentage should not exceed 0.5% [22]. Furthermore, the properties of titanium are influenced by its structure which is made up of two allotropic structures: a close packed hexagonal (α phase) and body-centered cubic crystal (β phase). These phases enable titanium to undergo a reversible transformation; at room temperature it tends to be categorized as α phase and transfer to β phase as the temperature exceeds 883 °C [23].

The strength properties of commercially pure titanium are weaker than that required for medical implants [23]. Thus, to improve these properties, titanium alloys have been proposed via incorporation of variable types and quantities of elements such as Al, Mo, V, Nb, Ta, Mn, Fe, Cr, Co, Ni and Cu. Each of these elements has a different impact on the transition temperature of titanium alloys. Those that increase the transition temperature, such as aluminium, are identified as α stabilizing element, whereas those that decrease it, such as vanadium, are referred to as β stabilizing elements. Accordingly, alloys are classified into three main types (α, β, and α + β alloys) depending on their transition temperature [23].

Through the years, several types of titanium alloys have been developed as implant biomaterials such as Ti–6Al–4V, Ti–Nb–Ta–Zr [24], Ti–Ni–Ta [25], Ti–15Mo–5Zr–3A [8], Ni–Ti [26] and Ti–Sn–Nb [27]. Among the aforementioned alloys, Ti–6Al–4V [28] and Ni–Ti [29] have been reported as the most widely used biomedical materials for bone replacement devices, also in comparison to other medical grade alloys such as stainless steel and Co–29Cr–6Mo. This is due to the better mechanical performance of these titanium alloys [28], and their significant corrosion resistance, especially for the interconnected porous titanium structures due to the free flow fluid inside the pores [30]. This allows them to be used as load-bearing implants for tissue engineering scaffolds [31]. Nevertheless, Andani et al. stated that despite the flexible modulus of elasticity of NiTi, it was not straightforward to design interconnected porous structured scaffolds with this alloy because of its high melting point [32]. Even with the popularity of Ti–6Al–4V and NiTi the potentially adverse biological reaction to their elements by the living tissue still remains a matter of concern. This has directed researchers to keep developing alloys aimed at improving biocompatibility such as Ti–6Al–7Nb, Ti–13Nb–13Zr. These are more likely to mimic the biological and mechanical properties of Ti–6Al–4V [33].

The elastic modulus of pure titanium and its alloy (Ti–6Al–4V) is half that of Co–Cr, thus stress shielding is lower [34]. In order to produce titanium alloy with reduced Young’s modulus and adequate strength for orthopaedic implants, various attempts have been reported in the literature. For instance, in 1998, Kuroda et al. introduced Ti–Nb–Ta–Zr, Ti–Nb–Ta–Mo and Ti–Nb–Ta–Sn [35]. Matsumoto et al. (2005) introduced B-type titanium alloys (Ti–29Nb–13Ta–4.6Zr) and (Ti–Nb–Sn) which showed a remarkably lower Young’s modulus [36]. Attempts have also been made to produce porous Ti alloy compacts (Ti–15Mo–5Zr–3Al) using a hot-pressing technique, which could reduce the Young’s modulus to within the range of cortical bone [8]. Another possibility is to incorporate hydroxyapatite particles with titanium powder using an infiltration method and sintering [37]. The addition of hydroxyapatite has the additional aim of improving bone fixation because bone cells attach well to hydroxyapatite surfaces [38]. The Young’s modulus of porous titanium-hydroxyapatite composites can be controlled by changing the percentage of hydroxyapatite particles [37].

3. Characteristic Features of Porous Metal

Due to their morphology, physical and mechanical properties, porous metal structures have many possible applications in several different industries [39], including medicine [40]. Several classification systems have been used in the literature for porous metals of different types; these can, for example, be based on the structure, applications, properties or fabrication processes used. For bone applications, porous metal is typically classified into three main forms, which describe the nature of the whole component: completely porous across the whole metal parts, an entirely or partially porous layer coating a dense core or structure composed of a fully solid and a porous metal part joined together [34]. Considering the porous part on its own, Goodall et al. classified porous metals according to their structure, producing five groups: materials containing isolated porosity, true metal foams, particle packing to form a porous body, precursor based metal foams and lattices [41]. Additionally, for any of these types, porosity can be designed in a graduated manner, for example, by increasing in quantity from the core to the superficial layer [42,43]. Nevertheless, due to the reduction in mechanical properties that the incorporation of porosity brings, an entirely porous metal structure is unlikely to be suitable for an implant with a load bearing requirement. Therefore, a porous cover on a solid substrate is often preferentially chosen for dental implants to ensure sufficient strength to tolerate the physiological loads [34].

Porous metals exist in both closed (fully isolated pores) and open cell forms (connected with each other and the external environment). Although both types are widely used, the open type is evidently better for medical implant applications, because a degree of ingrowth into the structure is desired [44]. As well as providing a suitable environment for the bone cells such that they infiltrate into the porosity, an interconnected foam with sufficiently large pores allows the formation of the vascular system required for bone maintenance [28,45].

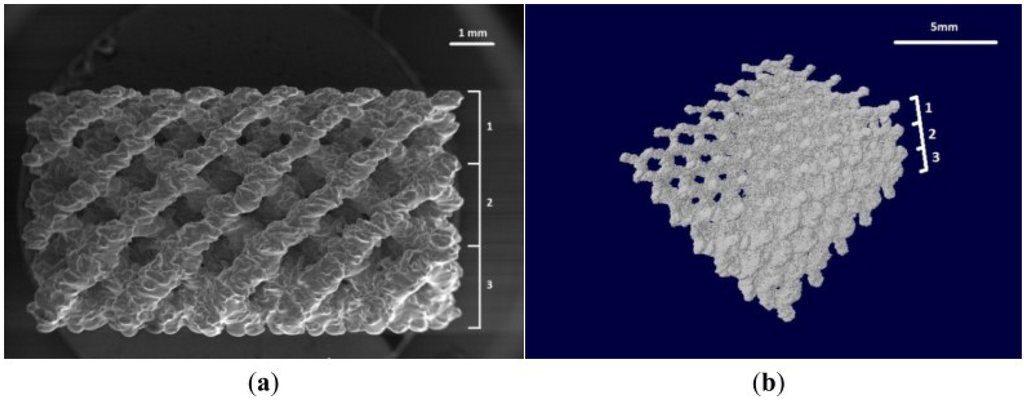

Within the porous metals and the classification system used by Goodall et al. [41], lattices are those structures made up of a regular repeating array of simple structural elements. These have certain attractive features, such as the fact that the properties can in principle be predicted to greater accuracy than when the pores are randomly located, though they have formerly been difficult to produce in anything other than elementary forms and small sizes, barring certain structures such as honeycombs. However, this is changing with the growth in, and further development of, additive manufacturing technologies, which deposit or fuse material, building up a 3D structure (as detailed in Section 4). Within the lattices, the regular repeating unit cell structure has a dominant role in determining the mechanical properties of the structure overall [40]. An almost infinite array of designs is possible, and many have been produced, two dimensional honeycombs [46], simple cubic lattices [47], rhombic dodecahedron [48] and diamond lattice (a cubic unit cell where the struts are positioned in the same way as the atomic structure of diamond) [49,50]. Graded lattices are also possible; recently, van Grunsven et al. used different strut thicknesses to produce a diamond lattice structure with graded porosity (Figure 2). In this study, it was found that the mechanical properties that could be achieved could be relevant for orthopedic implants [51]. Analytical and numerical solutions for the mechanical properties of a diamond lattice structure of Ti–6Al–4V were reported by Ahmadi et al. The results were compared with experimental observations. According to their findings, there was a good agreement between the analytical solutions and experimental observations, whereas the prediction of the finite element models was less likely to be accurate when compared with the experimental observations [40]. This is somewhat unexpected as finite element methods should allow more complex behavior to be captured, but may indicate imperfect input parameters for the base alloy. It has been pointed out that the mechanical properties of the porous Ti–6Al–4V alloy with the diamond unit cell are similar to those of trabecular bone [52]. A similar approach, but for random porous structures, has been used by Cheng et al., in which they used human trabecular bone as a template to define a structure allowing an interconnected porous Ti–6Al–4V structure to be created using different levels of porosity (15%–70%). By increasing the porosity, a structure was created which closely mimics that of trabecular bone [3].

Figure 2.

(a) SEM image of graded diamond lattice structure; (b) Micro CT scan of 3D image shows different strut thicknesses. Adapted from Ref. [51].

Typically, a porosity of 75%–85% and a pore size of more than 100 μm are considered to be preferable for rapid bone ingrowth [19]. Wen et al. revealed that porous titanium with pore size ranging from 200–500 μm was sufficient for adequate bone formation and fluid transport [53]. Otsuki et al. have examined sintered porous titanium implants with different levels of porosity (50% and 70%) and pore sizes (250–500 μm) and (500–1500 μm). The results indicated 500–1500 μm was the optimal pore size for bone tissue ingrowth for both levels of porosity [54], whereas Murphy et al. stated that the ideal pore size for bone ingrowth was around 325 μm [55]. A graded structure as a coating with macro and nanoporosity (at a level of more than 70%) on titanium substrates was another approach developed by Fu et al. Three different materials (hydroxyapatite, calcium carbonate and titanium) and a combination of a modified plasma spray method and anodic oxidation process were used to produce porous scaffolds with macro-, micro- and nanopores (100–350 µm, 0.2–90 µm and 100 nm, respectively). The result showed that the mechanical properties were close to those of bone [56]. Chen et al. created titanium scaffolds with a uniform and highly porous structure. The porous specimens were produced by stack sintering of micro porous Ti spheres using centrifuge granulation technique. Based on the properties of the original titanium powders specimens should have micro- and macroporosity of 6.1–11.8 μm and 180.0–341.8 μm, respectively, and the mechanical properties were reported as being suitable for implant applications in load-bearing areas [57].

As can be seen, there is no clear identification of the optimum pore size for bone ingrowth. In general, the mechanical and biological performance of the porous metal structure is governed by the combined effects of characteristic features of the porosity such as pore shape, size, distribution and their interconnectivity, as well as the base metal from which the porous structure is made [58]. Thus, with the current level of understanding the pore geometry needs to be optimized for each specific case to achieve a suitable environment for the surrounding bone tissue. Furthermore, it should be noted that not only the properties of the coating, but also those of the underlying base material will have an effect on the mechanical properties of the final product.

4. Fabrication Methods and Mechanical Evaluation of Porous Titanium Dental Implants

Titanium is well known as a relatively high cost engineering material due to the difficulties in the extraction, forming and machining processes [59]. Traditionally, a titanium alloy dental root implant is manufactured via a casting or powder metallurgy route [60]. With the casting method, in particular, machining and other finishing steps are required with a large amount of waste material [23]. Furthermore, the high melting temperature of the titanium base alloy and the high reactivity of titanium with atmospheric gasses at elevated temperatures make it difficult to adapt many existing techniques which were developed for lower melting point metals, such as aluminium [34]. Powder metallurgy has more recently been promoted for titanium implant production. It is less expensive and has reduced amounts of waste compared to the other production methods available [23]. Relatively simple techniques for the production of porous materials include sintering hollow spheres or the use of thermal decomposition of, for example, TiH2. Fairly homogenous foam structures have been made from high melting temperature metals such as titanium and its alloys [19] and this method is also suitable for the production of titanium foams with pore sizes meeting the standard requirements considered to be suitable for bone ingrowth [6]. Improving the compaction process of alloy powder also has an influence on the accuracy and degree of porosity of the final part [61].

For porous materials as a whole, there are certain potential disadvantages for use as implants. For example, the fatigue strength is unlikely to satisfy the requirements of implant devices. Nevertheless, this can be improved. It has, for example, been shown that, for cases where a foaming agent is combined with metal powder, the fatigue life can be increased by having a more uniform foam structure through reduced stress concentrations. This is achieved by adjustments to the mixing strategy for the powder of foaming agent, metal and binder as reviewed by Ryan et al. [34]. Other methods have shown their suitability for the production of medical grade titanium alloy for medical applications, including sintering of powders, compressing and sintering of titanium beads or fibers to create interconnected porous structures [62].

For more regular titanium pore geometry, a controlled mix of removable space holder and titanium metal powder particles has been suggested and explored by a considerable number of studies. The range of materials used as a space holder include saccharose crystals [63], NaF [64], NaCl [65,66] and polymer granules [67]. Magnesium has also been used as a space holder to produce porous dental and orthopedic implants [68]. Jurczyk et al. recommended ammonium hydrogen carbonate to produce a porous nanocomposite scaffold using titanium containing 10 wt. % SiO2 appropriate for dental applications [69]. Caution is recommended though as a strong reaction has been reported between titanium and some space holders with both high and low melting temperatures, leading to the formation of impurities within the foam [70].

With all the aforementioned approaches, titanium implants can be made with an entirely porous or solid structure though it is not straightforward to produce a porous shell on a solid core. A variety of methods have been developed over the last few decades to create dental root implants which mimic the morphology and mechanical properties of natural dental roots [60]. One method involving an electron-discharge compaction has also been reported to produce porous surface on the commercially dental implant, porosity on a compact core was created using input energy 1–2.5 kJ/g to atomized the Ti–6Al–4V powder [71]. A one-step microwave processing method has also been suggested to sinter titanium powders in order to produce dental implants, with gradient porosity, microwave power energy of 1–1.5 kW and a 30 min soaking period used. The pore size was about 30–100 µm and thickness was ranging from 100–200 µm, as determined by the level of microwave power [62].

Among these methods, additive manufacturing technology has been developed considerably [72] including selective laser sintering (SLS) [73], selective laser melting (SLM) and electron beam melting (EBM) [74]. The additive manufacturing approach is based on building up a three-dimensional structure from a computer aided design (CAD) model [34]. Each fabrication method will have many variables; for example, for SLS, parameters would include laser power, scanning speed, laser beam diameter and layer thickness [72]. Additive processes are in general less time consuming overall [72] and allow the creation of porous structures with different unit cells [40] and high resolution (i.e., small cell sizes) [3].

Additive manufacturing technology has more specifically been applied to produce non-porous parts with complex geometry for use in implants, such as dental, craniofacial, maxillofacial and orthopedic implants [75]. In 2002, Tolochko et al. demonstrated the possibility of producing dental root implants from Ti powders with two different zones, comprising a compact core and irregular porous shell by incorporating (SLS) for the porous surface and (SLM) for the solid core (Figure 2). The thickness of both layers was determined by the laser power. Microscopical examination showed that the average pore size was 100–200 µm and the porosity 40%–45% [60]. Dental implant models with a dense core and porous layer consisting of a series of channels which are 1 mm in depth and 1 mm in diameter have been considered. Laser-forming techniques with continuous wave and pulsed lasers were used. The channel diameters of the products were lower than those of the CAD model. The fatigue and tensile strength of the titanium samples produced were influenced by the different processing parameters utilized in this study. These variables include the scanning speed of the laser, the laser peak power and the hatching pitch, all of which combine to alter the amount of energy input into the material, and thus influence the solidification and cooling. The effect is to alter the microstructure of the material, and as the flow of thermal energy is also affected by part shape and location in the part. This can occur in complex ways. The processing parameters were found to be optimal at a scan speed of 6 mm/s, a laser peak power of 1 kW, and a hatching pitch of 0.4 mm [76]. Traini et al. have also produced titanium dental implants incorporating graduated porosity from the inner core of the structure to the outer surface using titanium alloy (Ti–6Al–4V) powders with a laser sintering procedure. The average porosity was 28.7% and the modulus value of the dense core was similar to that of a machined titanium implant whereas the porous part was comparable to that of bone tissue [73]. The study of Mangano et al. did not go quite as far as producing a fully porous structure, rather stating that direct laser fabrication is an economical technique that has potential to produce dental implants with irregular and narrow intercommunicating crevices and shallow depressions using titanium alloy powder. The surfaces were analyzed under stereo scanning electron microscopy. However, there was a residue of metal particles on the implant surface. Thus, they suggested acid etching as treatment to eliminate the adherent particles [77].

Schiefer et al. examined the long term stability and mechanical properties of two types of porous dental implants under static and dynamic conditions. Implants were surrounded by porous layers that were made using ammonium hydrogen-carbonate (NH4)HCO3 as space holder particles. Samples were tested in fatigue according to modified ISO 14801 and finite element analysis (FEA) was used to predict the fatigue behavior of these implants. This suggested that implants will struggle to perform well against forces in a range similar to that produced by human jaw. Moreover, pore alignment can affect the mechanical properties of porous titanium [10]. Murr et al. in 2010 used electron beam melting (EBM) to produce Ti–6Al–4V open cellular foams with different cell wall structures (solid and hollow). The elastic moduli were found to decrease with increasing porosity as widely known for porous metals of all types. However, the micro indentation hardness of the solid cell wall structure was lower than that of the hollow cell wall [75]. Li et al. established that the electron beam melting process has the potential to process Ti–6Al–4V implants with versatile pore geometry. The compressive properties of porous implants are variable with pore architecture and can be similar to those of natural bone [46]. To improve the surface wear resistance of the titanium structures, Laoui et al. applied laser gas nitriding using a CW Nd:YAG laser, and the coating layer was able to withstand more cycles without fracturing [76].

One of the essential requirements of dental implants is to have a rough surface with macroscopic grooves and threads or a porous surface to provide primarily mechanical stabilization between implants and bone tissues [60]. Furthermore, sufficient mechanical support should be provided between the root of the dental implant and its superstructure crown. This can be achieved by creating a solid core and porous shell as a substitute to an entirely porous structure [60]. One concern is that stress concentrations could arise at the junction area of the shell and core of the implant where the mechanical properties change rapidly [34]. This weakens the bond between the covering layer of the implant and the core. To reduce the component of this problem that is related to residual stresses, a post-sintering heat treatment has been suggested by Clook and co-workers, which showed an improvement in the fatigue strength of titanium alloy by about 15% [78]. Nevertheless, the idea of creating functionally graded structures can be helpful to avoid the stress concentration between the interface layers where the elastic modulus changes suddenly [79]. The concept of creation of functionally graded structures in porous materials by changing the structure of the lattice has also been investigated [80].

Table 1.

Comparison table of the main fabrication methods used for creating rough and porous implants with potential dental and/or orthopedic applications.

| Fabrication Methods | References |

|---|---|

| Plasma spraying with different powder particles such as: | [14] |

| -titanium oxide | |

| -calcium phosphate | |

| -hydroxyapatite | |

| Sand blasted with stiff particles such as: | [4] |

| -alumina | |

| -TiO2 | |

| -ceramic | |

| Laser micro-machining technique | [15] |

| Anodization TiO2 nanotube | [16] |

| Electron-discharge compaction | [71] |

| One-step microwave processing method | [62] |

| Powder metallurgy | [19,62] |

| -sintering hollow spheres | |

| -thermal decomposition | |

| -sintering of powders, compressing and sintering of titanium beads or fibers | |

| Removable space holder and titanium metal powder particles: | [63,64,65,66,67,68,69] |

| -saccharose crystals | |

| -NaF | |

| -NaCl | |

| -polymer granules | |

| -Magnesium | |

| -ammonium hydrogen carbonate | |

| Additive manufacturing technology: | [60,66,74] |

| -selective laser sintering | |

| -selective laser melting | |

| -electron beam melting |

Bandyopadhyay and colleagues suggested laser engineered net shaping (LENS™) to construct porous structures from Ti–6Al–4V alloy across the range 23%–32% porosity with low modulus (7–60 GPa) which can be tailored to match human cortical bone [81]. Nomura et al. in 2010 recommended the infiltration technique in a vacuum with sintering to create porous titanium/hydroxyapatite composites. The Young’s modulus was estimated using the percentage of porosity and it was tailored to be in the range of bone tissue (given by 24%–34% porosity). Porosity can be controlled by modifying the temperature and pressure applied in a hot-pressing stage. Furthermore, Hanks’ buffered salt solution was used to reduce the Young’s modulus of the sintered porous titanium/hydroxyapatite composites [37]. Witek et al. measured the bone implant contact and removal torque of dental implants with a porous layer produced by laser sintering and compared them with sandblasted-acid etched implant (i.e., those with a rough, but not porous, surface). They concluded that porous dental implants produced by the sintering process showed better biomechanical properties and biocompatibility [82]. The fabrication methods discussed in this review are listed in Table 1.

5. Biological Interaction and Porous Surface Geometry

Most dental implant materials aim to support cell attachment by conferring suitable a area for cell adhesion [83]. It has been demonstrated that bone cell interactions are mainly modulated by the chemistry and mechanical properties of the substrate, the structure of the implanted material and the fabrication method. Cell behavior has been stated to be more influenced by the topography of the surface, it encounters than by the chemistry of implant material or processing method [84], although these effects are difficult to separate as they are all interrelated [83]. In vivo and in vitro observations of the micro- and macro-roughness of the surfaces of dental and orthopedic implants have been shown to play an important role in improving the response of bone-forming cells (osteoblasts) [3]. Rough surfaces provide better osteoblast attachment [19], improved cell proliferation and extracellular matrix formation which in turn enhance the osseointegration process and durability of dental implants [85].

A porous implant surface has a high surface area which should enable more cells to attach compared to a planar surface. In vitro observations have demonstrated a good range of bone ingrowth in porous titanium implant using different manufacturing techniques [6]. Teixeira et al. examined the osteoblastic response on porous titanium with different pore sizes (312, 130, 62 µm) using a powder metallurgy technique. The result showed the highest gene expression of bone markers was with 62 µm porosity [6]. Mangano et al. seeded human dental pulp stem cells on direct laser metal sintered titanium scaffolds and acid etched surfaces. They observed that gene expression and protein secretion were faster on laser sintered scaffolds [86]. Another comparative study has been proposed between porous and non-porous titanium alloy Ti–6Al–4V samples. The pore diameters were 500, 700 and 1000 µm. The result showed that the osteoblast cell viability was maintained over 14 days and the cells entirely covered the porous structure [87]. Cheng et al. proposed using a template from human trabecular bone to fabricate porous Ti–6Al–4V materials using additive manufacturing technology, laser sintering in particular. Different porosities (low, medium and high) ranging from 15%–70% with interconnected structure were fabricated to produce structures that mimicked the trabecular bone of the human body. After specific surface treatment with calcium phosphate particles and acid etching, the trabecular bone structure exhibited micro and nanoscale porosity which was able to enhance osteoblast cell differentiation. Thus, the trabecular structure has the potential to produce devices well-suited for dental and orthopedic implants [3]. Another attempt to improve the mechanical and biological properties of porous titanium structures also incorporated a modified sponge replication method and anodization process. Titanium scaffolds with elongated pores were produced by coating a stretched polymeric sponge template with TiH2. The anodization of the titanium can produce a nanoporous surface that can increase osteoblast cell (MC3T3-E1) proliferation and attachment on implant surfaces [10]. Pore geometry is likely to have a strong effect on cell attachment and matrix formation [88] but researchers rarely investigate different pore geometries within a single material and manufacturing process. Recently, such a study was undertaken by Markhoff et al. who evaluated the viability and proliferation of human osteoblast cells in porous Ti–6Al–4V using different scaffold designs and cultivation methods. Additive manufacturing technology was used to produce different pore geometries (cubic, diagonal, pyramidal), and static and dynamic culture methods were used. Interestingly, there were no significant differences between the static and dynamic cultivation methods, but cell activity and migration were best in the pyramidal design with a 400–620 µm pore size and 75% porosity [89].

Although in vitro studies are often an essential step in the discovery of novel implant materials and structures, there are many inherent limitations to the use of cell culture to predict the long-term survival of an implant. These include the absence of a 3D environment that adequately mimics the chemical and mechanical properties of bone, the lack of mechanical forces acting at the bone-implant interface after implantation, the absence of the complex matrix of proteins and different types of bone cells that are present at the bone-implant interface in vivo and the difficulty of maintaining the culture for long time periods. While researchers are attempting to improve in vitro studies using 3D environments and bioreactors, the current information regarding long-term implant stability comes from in vivo studies.

In vivo studies by Mangano and co-workers used a laser sintering process to design titanium dental implants with interconnected pores and irregular crevices. The clinical observation showed 95% success after one year post operation [72]. In histological evaluations, Shibli et al. measured human bone tissue response to three types of dental implants: direct laser fabrication, sand-blasted acid-etched and machined commercially pure titanium under unloaded conditions. The result indicated that after eight weeks of implant insertion, the bone-implant contact produced by the direct laser and the sandblasted acid-etched processes was not significantly different but was higher than that of machined implant, and there were no significant differences between them. The authors attributed their finding to the surface roughness that was produced by the laser and sandblasting techniques, which enhanced the osseointegration process [90]. Another study using male Sprague-Dawley rats indicated that the biological fixation was influenced by the percentage of porosity in titanium implants (25%, 11%, 3%). After 16 weeks’ examination, the concentration of calcium ions increased proportionally with the increasing porosity percentage [81]. Laoui et al. inserted a Ti implant into a dog’s lower jaw and revealed clear bone growth into the porous structure within the porous surface layer, and no signs of inflammation at the interface were observed [76]. Tolochko et al. inserted a prototype porous dental implant into the lower jaw of a cadaver and demonstrated that the implant was firmly integrated into the alveolar ridge of the lower jaw with a maximum gap width of 200–300 µm between the implant and the bone [60]. Another attempt was made to reduce the healing period required for the dental implant and bone by coating a titanium dental implant with TiO2 nanotubes, which was tested in a rat femur. Variable diameter sizes were used (30 nm, 50 nm, 70 nm, and 100 nm nanotubes), the highest removal torgue and osseointegration rate were observed in the 30 nm implants after two weeks whereas the 70 nm implants exhibited the highest value after six weeks for both tests [16].

6. Conclusions and Future Perspectives

Recent developments in the fabrication of porous architectures for bone ingrowth into dental implant materials have been reviewed. Novel materials developed for orthopaedic implants and bone tissue engineering could also be applied to dental implants due to their similar design requirements; the materials should be biocompatible, non-toxic, corrosion resistant and load bearing. It is not straightforward to create porous titanium with traditional methods. However, the development of additive manufacturing technology enables a designer to produce more regular porous structures with modulated pore sizes, shapes, percentages and distributions and to mimic the biological and mechanical properties of natural bone.

Porous dental implant prototypes manufactured with the additive manufacturing technique have been evaluated from a mechanical and biological point of view. As can be seen, introducing porosity appears to improve implant stability. The optimal pore size is probably somewhere between 200 and 1000 µm, and roughness and surface chemistry also play an important role in determining the fate of stem cells and osteoblasts. Work in this area is promising and provides a basis for exciting improvements in dental implant design for patients with compromised bone healing. However, the body of research to date has still not clearly identified the optimal pore size, geometry and graduation for the most effective biomechanical and biological properties. Therefore, further studies are necessary to evaluate the potential of advanced manufacturing methods to optimize the porous titanium structure of dental implants.

Acknowledgments

The authors acknowledge funding for ZJW from Iraqi Ministry of Higher Education and Scientific Research and or WvG from Orthopaedic Research UK (ORUK). The views expressed here do not necessarily represent those of ORUK.

Author Contributions

Z.J.W. wrote the bulk of manuscript in consultation with the other authors. W.v.G. provided preliminary data and literature review and edited the manuscript. R.G., G.R. and F.C. wrote small sections, edited and advised on the final version of the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Elias, C.N. Factors Affecting the Success of Dental Implants; Turkyilmaz, I., Ed.; InTech: New York, NY, USA, 2011. [Google Scholar]

- Esposito, M.; Hirsch, J.; Lekholm, U.; Thomsen, P. Differential Diagnosis and Treatment Strategies for Biologic Complications and Failing Oral Implants: A Review of the Literature. Int. J. Oral Maxillofac. Implant. 1999, 14, 473–490. [Google Scholar]

- Cheng, A.; Humayun, A.; Cohen, D.J.; Boyan, B.D.; Schwartz, Z. Additively manufactured 3D porous Ti–6Al–4V constructs mimic trabecular bone structure and regulate osteoblast proliferation, differentiation and local factor production in a porosity and surface roughness dependent manner. Biofabrication 2014. [Google Scholar] [CrossRef] [PubMed]

- Le Guéhennec, L.; Soueidan, A.; Layrolle, P.; Amouriq, Y. Surface treatments of titanium dental implants for rapid osseointegration. Dent. Mater. 2007, 23, 844–854. [Google Scholar] [CrossRef] [PubMed]

- Boerrigter, E.M.; Geertman, M.E.; van Oort, R.P.; Bouma, J.; Raghoebar, G.M.; van Waas, M.A.J.; van’t Hof, M.A.; Boering, G.; Kalk, W. Patient satisfaction with implant-retained mandibular overdentures. A comparison with new complete dentures not retained by implants—A multicentre randomized clinical trial. Br. J. Oral Maxillofac. Surg. 1995, 33, 282–288. [Google Scholar] [CrossRef]

- Teixeira, L.N.; Crippa, G.E.; Lefebvre, L.-P.; de Oliveira, P.T.; Rosa, A.L.; Beloti, M.M. The influence of pore size on osteoblast phenotype expression in cultures grown on porous titanium. Int. J. Oral Maxillofac. Surg. 2012, 41, 1097–1101. [Google Scholar] [CrossRef] [PubMed]

- Özcan, M.; Hämmerle, C. Titanium as a Reconstruction and Implant Material in Dentistry: Advantages and Pitfalls. Materials 2012, 5, 1528–1545. [Google Scholar] [CrossRef]

- Nomura, N.; Kohama, T.; Oh, I.H.; Hanada, S.; Chiba, A.; Kanehira, M.; Sasaki, K. Mechanical properties of porous Ti–15Mo–5Zr–3Al compacts prepared by powder sintering. Mater. Sci. Eng. C 2005, 25, 330–335. [Google Scholar]

- Krishna, B.V.; Bose, S.; Bandyopadhyay, A. Low stiffness porous Ti structures for load-bearing implants. Acta Biomater. 2007, 3, 997–1006. [Google Scholar] [CrossRef] [PubMed]

- Schiefer, H.; Bram, M.; Buchkremer, H.P.; Stöver, D. Mechanical examinations on dental implants with porous titanium coating. J. Mater. Sci. Mater. Med. 2009, 20, 1763–1770. [Google Scholar] [CrossRef] [PubMed]

- Isidor, F. Influence of forces on peri-implant bone. Clin. Oral Implants Res. 2006, 17, 8–18. [Google Scholar] [CrossRef] [PubMed]

- Mangano, F.; Chambrone, L.; van Noort, R.; Miller, C.; Hatton, P.; Mangano, C. Direct Metal Laser Sintering Titanium Dental Implants. Int. J. Biomater. 2014. [Google Scholar] [CrossRef] [PubMed]

- Junker, R.; Dimakis, A.; Thoneick, M.; Jansen, J.A. Effects of implant surface coatings and composition on bone integration: A systematic review. Clin. Oral Implant. Res. 2009, 20, 185–206. [Google Scholar]

- Gaviria, L.; Salcido, J.P.; Guda, T.; Ong, J.L. Current trends in dental implants. J. Korean Assoc. Oral Maxillofac. Surg. 2014, 40, 50–60. [Google Scholar] [PubMed]

- Çelen, S.; Özden, H. Laser-induced novel patterns: As smart strain actuators for new-age dental implant surfaces. Appl. Surf. Sci. 2012, 263, 579–585. [Google Scholar] [CrossRef]

- Yi, Y.; Park, Y.; Choi, H.; Lee, K.; Kim, S.; Kim, K.; Oh, S.; Shim, J. The Evaluation of Osseointegration of Dental Implant Surface with Different Size of TiO2 Nanotube in Rats. J. Nanomater. 2015. [Google Scholar] [CrossRef]

- Bencharit, S.; Byrd, W.C.; Altarawneh, S.; Hosseini, B.; Leong, A.; Reside, G.; Morelli, T.; Offenbacher, S. Development and Applications of Porous Tantalum Trabecular Metal-Enhanced Titanium Dental Implants. Clin. Implant Dent. Relat. Res. 2013, 16, 817–826. [Google Scholar] [CrossRef] [PubMed]

- Mohandas, G.; Oskolkov, N.; McMahon, M.T.; Walczak, P.; Janowski, M. Porous tantalum and tantalum oxide nanoparticles for regenerative medicine. Acta Neurobiol. Exp. 2014, 74, 188–196. [Google Scholar]

- Mour, M.; Das, D.; Winkler, T.; Hoenig, E.; Mielke, G.; Morlock, M.M.; Schilling, A.F. Advances in Porous Biomaterials for Dental and Orthopaedic Applications. Materials 2010, 3, 2947–2974. [Google Scholar] [CrossRef]

- Dabrowski, B.; Swieszkowski, W.; Godlinski, D.; Kurzydlowski, K.J. Highly porous titanium scaffolds for orthopaedic applications. J. Biomed. Mater. Res. B Appl. Biomater. 2010, 95, 53–61. [Google Scholar] [CrossRef] [PubMed]

- Li, J.P.; de Wijn, J.R.; van Blitterswijk, C.A.; de Groot, K. Porous Ti6Al4V scaffolds directly fabricated by 3D fibre deposition technique: Effect of nozzle diameter. J. Mater. Sci. Mater. Med. 2005, 16, 1159–1163. [Google Scholar] [PubMed]

- Van Noort, R. Titanium the implant material of today. Mater. Sci. 1987, 22, 3801–3811. [Google Scholar] [CrossRef]

- Nouri, A.; Hodgson, P.D.; Wen, C. Biomimetic Porous Titanium Scaffolds for Orthopedic and Dental Applications; InTech: New York, NY, USA, 2010; pp. 415–451. [Google Scholar]

- Niinomi, M.; Hattori, T.; Niwa, S. Material characteristics and biocompatibility of low ridgidity titanium alloys for biomedical applications. In Biomaterials in Orthopedics; Yaszemski, M.J., Trantolo, D.J., Lewandrowski, K.-U., Hasirci, V., Altobelli, D.E., Wise, D.L., Eds.; Marcel Dekker Inc.: New York, NY, USA, 2004; pp. 41–62. [Google Scholar]

- Gong, C.W.; Wang, Y.N.; Yang, D.Z. Phase transformation and second phases in ternary Ni–Ti–Ta shape memory alloys. Mater. Chem. Phys. 2006, 96, 183–187. [Google Scholar] [CrossRef]

- Shishkovsky, I.V. Shape Memory Effect in Porous Volume NiTi Articles Fabricated by Selective Laser Sintering. Tech. Phys. Lett. 2005, 31, 186–188. [Google Scholar] [CrossRef]

- Nouri, A.; Hodgson, P.D.; Wen, C.E. Effect of process control agent on the porous structure and mechanical properties of a biomedical Ti–Sn–Nb alloy produced by powder metallurgy. Acta Biomater. 2010, 6, 1630–1639. [Google Scholar] [CrossRef] [PubMed]

- Li, J.P.; Li, S.H.; van Blitterswijk, C.A.; de Groot, K. A novel porous Ti6Al4V: Characterization and cell attachment. J. Biomed. Mater. Res. A 2005, 73, 223–233. [Google Scholar] [CrossRef] [PubMed]

- Bahraminasab, M.; Sahari, B.B. NiTi Shape Memory Alloys, Promising Materials in Orthopedic Applications. In Shape Memory Alloys—Processing, Characterization and Applications; InTech: New York, NY, USA, 2013; pp. 261–278. [Google Scholar]

- Seah, K.H.W.; Thampuran, R.; Teoh, S.H. The influence of pore morphology on corrosion. Corros. Sci. 1998, 40, 547–556. [Google Scholar]

- Arifvianto, B.; Zhou, J. Fabrication of Metallic Biomedical Scaffolds with the Space Holder Method: A Review. Materials 2014, 7, 3588–3622. [Google Scholar]

- Andani, M.T.; Moghaddam, N.S.; Haberland, C.; Dean, D.; Miller, M.J.; Elahinia, M. Metals for bone implants. Part 1. Powder metallurgy and implant rendering. Acta Biomater. 2014, 10, 4058–4070. [Google Scholar] [CrossRef] [PubMed]

- Rack, H.J.; Qazi, J.I. Titanium alloys for biomedical applications. Mater. Sci. Eng. C 2006, 26, 1269–1277. [Google Scholar]

- Ryan, G.; Pandit, A.; Apatsidis, D.P. Fabrication methods of porous metals for use in orthopaedic applications. Biomaterials 2006, 27, 2651–2670. [Google Scholar] [CrossRef] [PubMed]

- Kuroda, D.; Niinomi, M.; Morinaga, M.; Kato, Y.; Yashiro, T. Design and mechanical properties of new β type titanium alloys for implant materials. Mater. Sci. Eng. A 1998, 243, 244–249. [Google Scholar] [CrossRef]

- Matsumoto, H.; Watanabe, S.; Hanada, S. β TiNbSn Alloys with Low Young’s Modulus and High Strength. Mater. Trans. 2005, 46, 1070–1078. [Google Scholar] [CrossRef]

- Nomura, N.; Sakamoto, K.; Takahashi, K.; Kato, S.; Abe, Y.; Doi, H.; Tsutsumi, Y.; Kobayashi, M.; Kobayashi, E.; Kim, W.-J.; et al. Fabrication and Mechanical Properties of Porous Ti/HA Composites for Bone Fixation Devices. Mater. Trans. 2010, 51, 1449–1454. [Google Scholar] [CrossRef]

- Deligianni, D.D.; Katsala, N.D.; Koutsoukos, P.G.; Missirlis, Y.F. Effect of surface roughness of hydroxyapatite on human bone marrow cell adhesion, proliferation, differentiation and detachment strength. Biomaterials 2000, 22, 87–96. [Google Scholar] [CrossRef]

- Thiyagasundaram, P.; Sankar, B.V.; Arakere, N.K. Elastic Properties of Open-Cell Foams with Tetrakaidecahedral Cells Using Finite Element Analysis. AIAA J. 2010, 48, 818–828. [Google Scholar] [CrossRef]

- Ahmadi, S.M.; Campoli, G.; Yavari, S.A.; Sajadi, B.; Wauthle, R.; Schrooten, J.; Weinans, H.; Zadpoor, A.A. Mechanical behavior of regular open-cell porous biomaterials made of diamond lattice unit cells. J. Mech. Behav. Biomed. Mater. 2014, 34, 106–115. [Google Scholar] [CrossRef] [PubMed]

- Goodall, R.; Mortensen, A. Porous Metals. In Physical Metallurgy, 5th ed.; Laughlin, D., Hono, K.E., Eds.; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Li, D.S.; Zhang, Y.P.; Eggeler, G.; Zhang, X.P. High porosity and high-strength porous NiTi shape memory alloys with controllable pore characteristics. J. Alloy. Compd. 2009, 470, L1–L5. [Google Scholar] [CrossRef]

- Kutty, M.G.; Bhaduri, S.; Jokisaari, J.R.; Bhaduri, S.B. Development of gradient porosities in Ti dental implant. In 25th Annual Conference on Composites, Advanced Ceramics, Materials, and Structures: B: Ceramic Engineering and Science Proceedings; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2001; Volume 22, pp. 587–592. [Google Scholar]

- Aly, M.S.; Bleck, W.; Scholz, P.-F. How metal foams behave if the temperature rises. Met. Powder Rep. 2005, 60, 38–45. [Google Scholar] [CrossRef]

- Murray, G.; Semple, J. Transfer of tensile loads from a prosthesis to bone using porous titanium. J. Bone Joint Surg. 1981, 63, 138–141. [Google Scholar]

- Li, X.; Wang, C.; Zhang, W.; Li, Y. Fabrication and compressive properties of Ti6Al4V implant with honeycomb-like structure for biomedical applications. Rapid Prototyp. J. 2010, 16, 44–49. [Google Scholar] [CrossRef]

- Parthasarathy, J.; Starly, B.; Raman, S.; Christensen, A. Mechanical evaluation of porous titanium (Ti6Al4V) structures with electron beam melting (EBM). J. Mech. Behav. Biomed. Mater. 2010, 3, 249–259. [Google Scholar] [CrossRef] [PubMed]

- Harrysson, O.L.; Cansizoglu, O.; Marcellin-Little, D.J.; Cormier, D.R.; West, H. Direct metal fabrication of titanium implants with tailored materials and mechanical properties using electron beam melting technology. Mater. Sci. Eng. C 2008, 28, 366–373. [Google Scholar] [CrossRef]

- Campoli, G.; Borleffs, M.S.; Yavari, S.A.; Wauthle, R.; Weinans, H.; Zadpoor, A.A. Mechanical properties of open-cell metallic biomaterials manufactured using additive manufacturing. Mater. Des. 2013, 49, 957–965. [Google Scholar] [CrossRef]

- Heinl, P.; Körner, C.; Singer, R.F. Selective Electron Beam Melting of Cellular Titanium: Mechanical Properties. Adv. Eng. Mater. 2008, 10, 882–888. [Google Scholar] [CrossRef]

- Van Grunsven, W. Porous Metal Implants for Enhanced Bone Ingrowth and Stability. Ph.D. Thesis, University of Sheffield, Sheffield, UK, September 2014. [Google Scholar]

- Heinl, P.; Müller, L.; Körner, C.; Singer, R.F.; Müller, F.A. Cellular Ti–6Al–4V structures with interconnected macro porosity for bone implants fabricated by selective electron beam melting. Acta Biomater. 2008, 4, 1536–1544. [Google Scholar] [CrossRef] [PubMed]

- Wen, C.; Mabuchi, M.; Yamada, Y.; Shimojima, K.; Chino, Y.; Asahina, T. Processing of biocompatible porous Ti and Mg. Scr. Mater. 2001, 45, 1147–1153. [Google Scholar] [CrossRef]

- Otsuki, B.; Takemoto, M.; Fujibayashi, S.; Neo, M.; Kokubo, T.; Nakamura, T. Pore throat size and connectivity determine bone and tissue ingrowth into porous implants: Three-dimensional micro-CT based structural analyses of porous bioactive titanium implants. Biomaterials 2006, 27, 5892–5900. [Google Scholar] [CrossRef] [PubMed]

- Murphy, C.M.; Haugh, M.G.; O’Brien, F.J. The effect of mean pore size on cell attachment, proliferation and migration in collagen-glycosaminoglycan scaffolds for bone tissue engineering. Biomaterials 2010, 31, 461–466. [Google Scholar] [CrossRef] [PubMed]

- Fu, Q.; Hong, Y.; Liu, X.; Fan, H.; Zhang, X. A hierarchically graded bioactive scaffold bonded to titanium substrates for attachment to bone. Biomaterials 2011, 32, 7333–7346. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Wang, C.; Zhu, X.; Zhang, K.; Fan, Y.; Zhang, X. Fabrication of porous titanium scaffolds by stack sintering of microporous titanium spheres produced with centrifugal granulation technology. Mater. Sci. Eng. C Mater. Biol. Appl. 2014, 43, 182–188. [Google Scholar] [CrossRef] [PubMed]

- Hoffmann, W.; Bormann, T.; Rossi, A.; Müller, B.; Schumacher, R.; Martin, I.; de Wild, M.; Wendt, D. Rapid prototyped porous nickel-titanium scaffolds as bone substitutes. J. Tissue Eng. 2014. [Google Scholar] [CrossRef] [PubMed]

- Sidambe, A. Biocompatibility of Advanced Manufactured Titanium Implants—A Review. Materials 2014, 7, 8168–8188. [Google Scholar] [CrossRef]

- Tolochko, N.K.; Savich, V.V.; Laoui, T.; Froyen, L.; Onofrio, G.; Signorelli, E.; Titov, V.I. Dental root implants produced by the combined selective laser sintering/melting of titanium powders. J. Mater. Des. Appl. 2002, 216, 267–270. [Google Scholar] [CrossRef]

- Laptev, A.; Bram, M.; Buchkremer, H.P.; Stöver, D. Study of production route for titanium parts combining very high porosity and complex shape. Powder Metall. 2004, 47, 85–92. [Google Scholar] [CrossRef]

- Kutty, M.G.; Bhaduri, S.; Bhaduri, S.B. Gradient surface porosity in titanium dental implants: Relation between processing parameters and microstructure. J. Mater. Sci. Mater. Med. 2004, 15, 145–150. [Google Scholar] [CrossRef] [PubMed]

- Jakubowicz, J.; Adamek, G.; Dewidar, M. Titanium foam made with saccharose as a space holder. J. Porous Mater. 2013, 20, 1137–1141. [Google Scholar] [CrossRef]

- Bansiddhi, A.; Dunand, D.C. Shape-memory NiTi foams produced by solid-state replication with NaF. Intermetallics 2007, 15, 1612–1622. [Google Scholar] [CrossRef]

- Bansiddhi, A.; Dunand, D.C. Shape-memory NiTi foams produced by replication of NaCl space-holders. Acta Biomater. 2008, 4, 1996–2007. [Google Scholar] [CrossRef] [PubMed]

- Van Grunsven, W.; Goodall, R.; Reilly, G.C. Highly Porous Titanium Alloy: Fabrication and Mechanical Properties. J. Biomech. 2012, 45, S339. [Google Scholar] [CrossRef]

- Jee, C.S.Y.; Guo, Z.X.; Evans, J.R.G.; Özgüven, N. Preparation of High Porosity Metal Foams. Metall. Mater. Trans. B 2000, 31, 1345–1352. [Google Scholar] [CrossRef]

- Kim, S.W.; Jung, H.-D.; Kang, M.-H.; Kim, H.-E.; Koh, Y.-H.; Estrin, Y. Fabrication of porous titanium scaffold with controlled porous structure and net-shape using magnesium as spacer. Mater. Sci. Eng. C Mater. Biol. Appl. 2013, 33, 2808–2815. [Google Scholar] [CrossRef] [PubMed]

- Jurczyk, M.U.; Jurczyk, K.; Niespodziana, K.; Miklaszewski, A.; Jurczyk, M. Titanium-SiO2 nanocomposites and their scaffolds for dental applications. Mater. Charact. 2013, 77, 99–108. [Google Scholar] [CrossRef]

- Li, Y.; Yang, C.; Zhao, H.; Qu, S.; Li, X.; Li, Y. New Developments of Ti-Based Alloys for Biomedical Applications. Materials 2014, 7, 1709–1800. [Google Scholar] [CrossRef]

- Lifland, M.I.; Kim, D.K.; Okazaki, K. Mechanical properties of a Ti–6A1–4V dental implant produced by electro-discharge compaction. Clin. Mater. 1993, 14, 13–19. [Google Scholar] [CrossRef]

- Mangano, C.; Mangano, F.G.; Shibli, J.A.; Ricci, M.; Perrotti, V.; d’Avila, S.; Piattelli, A. Immediate loading of mandibular overdentures supported by unsplinted direct laser metal-forming implants: Results from a 1-year prospective study. J. Periodontol. 2012, 83, 70–78. [Google Scholar] [CrossRef] [PubMed]

- Traini, T.; Mangano, C.; Sammons, R.L.; Mangano, F.; Macchi, A.; Piattelli, A. Direct laser metal sintering as a new approach to fabrication of an isoelastic functionally graded material for manufacture of porous titanium dental implants. Direct laser metal sintering as a new approach to fabrication of an isoelastic functionally grad. Dent. Mater. 2008, 24, 1525–1533. [Google Scholar] [CrossRef] [PubMed]

- Hrabe, N.W.; Heinl, P.; Flinn, B.; Körner, C.; Bordia, R.K. Compression-compression fatigue of selective electron beam melted cellular titanium (Ti–6Al–4V). J. Biomed. Mater. Res. B Appl. Biomater. 2011, 99, 313–320. [Google Scholar] [CrossRef] [PubMed]

- Murr, L.E.; Gaytan, S.M.; Medina, F.; Lopez, H.; Martinez, E.; Machado, B.I.; Hernandez, D.H.; Martinez, L.; Lopez, M.I.; Wicker, R.B.; et al. Next-generation biomedical implants using additive manufacturing of complex, cellular and functional mesh arrays. Philos. Trans. A Math. Phys. Eng. Sci. 2010, 368, 1999–2032. [Google Scholar] [CrossRef] [PubMed]

- Laoui, T.; Santos, E.; Osakada, K.; Shiomi, M.; Morita, M.; Shaik, S.K.; Tolochko, N.K.; Abe, F.; Takahashi, M. Properties of Titanium Dental Implant Models Made by Laser Processing. J. Mech. Eng. Sci. 2006, 220, 857–863. [Google Scholar] [CrossRef]

- Mangano, C.; Raspanti, M.; Traini, T.; Piattelli, A.; Sammons, R. Stereo imaging and cytocompatibility of a model dental implant surface formed by direct laser fabrication. J. Biomed. Mater. Res. A 2009, 88, 823–831. [Google Scholar] [CrossRef] [PubMed]

- Cook, S.D.; Thongpreda, N.; Anderson, R.C.; Haddad, R.J. The effect of post-sintering heat treatments on the fatigue properties of porous coated Ti–6Al–4V alloy. J. Biomed. Mater. Res. 1988, 22, 287–302. [Google Scholar] [CrossRef] [PubMed]

- Joshi, G.V.; Duan, Y.; Neidigh, J.; Koike, M.; Chahine, G.; Kovacevic, R.; Okabe, T.; Griggs, J.A. Fatigue testing of electron beam-melted Ti–6Al–4V ELI alloy for dental implants. J. Biomed. Mater. Res. B Appl. Biomater. 2013, 101, 124–130. [Google Scholar] [CrossRef] [PubMed]

- Van Grunsven, W.; Hernandez-Nava, E.; Reilly, G.; Goodall, R. Fabrication and Mechanical Characterisation of Titanium Lattices with Graded Porosity. Metals 2014, 4, 401–409. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Espana, F.; Balla, V.K.; Bose, S.; Ohgami, Y.; Davies, N.M. Influence of porosity on mechanical properties and in vivo response of Ti6Al4V implants. Acta Biomater. 2010, 6, 1640–1648. [Google Scholar] [CrossRef] [PubMed]

- Witek, L.; Marin, C.; Granato, R.; Bonfante, E.A.; Campos, F.; Bisinotto, J.; Suzuki, M.; Coelho, P.G. Characterization and in vivo evaluation of laser sintered dental endosseous implants in dogs. J. Biomed. Mater. Res. B. Appl. Biomater. 2012, 100, 1566–1573. [Google Scholar] [CrossRef] [PubMed]

- Bidan, C.M.; Kommareddy, K.P.; Rumpler, M.; Kollmannsberger, P.; Fratzl, P.; Dunlop, J.W.C. Geometry as a factor for tissue growth: Towards shape optimization of tissue engineering scaffolds. Adv. Healthc. Mater. 2013, 2, 186–194. [Google Scholar] [CrossRef] [PubMed]

- Kumar, G.; Tison, C.K.; Chatterjee, K.; Pine, P.S.; McDaniel, J.H.; Salit, M.L.; Young, M.F.; Simon, C.G. The determination of stem cell fate by 3D scaffold structures through the control of cell shape. Biomaterials 2011, 32, 9188–9196. [Google Scholar] [CrossRef] [PubMed]

- De Wild, M.; Schumacher, R.; Mayer, K.; Schkommodau, E.; Thoma, D.; Bredell, M.; Gujer, A.K.; Grätz, K.W.; Weber, F.E. Bone regeneration by the osteoconductivity of porous titanium implants manufactured by selective laser melting: A histological and micro computed tomography study in the rabbit. Tissue Eng. Part A 2013, 19, 2645–2654. [Google Scholar] [CrossRef] [PubMed]

- Mangano, C.; Piattelli, A.; d’Avila, S.; Iezzi, G.; Mangano, F.; Onuma, T.; Shibli, J.A. Early human bone response to laser metal sintering surface topography: A histologic report. J. Oral Implantol. 2010, 36, 91–96. [Google Scholar] [CrossRef] [PubMed]

- Hollander, D.A.; von Walter, M.; Wirtz, T.; Sellei, R.; Schmidt-Rohlfing, B.; Paar, O.; Erli, H.-J. Structural, mechanical and in vitro characterization of individually structured Ti–6Al–4V produced by direct laser forming. Biomaterials 2006, 27, 955–963. [Google Scholar] [CrossRef] [PubMed]

- Rumpler, M.; Woesz, A.; Dunlop, J.W.C.; van Dongen, J.T.; Fratzl, P. The effect of geometry on three-dimensional tissue growth. J. R. Soc. Interface 2008, 5, 1173–1180. [Google Scholar] [CrossRef] [PubMed]

- Markhoff, J.; Wieding, J.; Weissmann, V.; Pasold, J.; Jonitz-Heincke, A.; Bader, R. Influence of Different Three-Dimensional Open Porous Titanium Scaffold Designs on Human Osteoblasts Behavior in Static and Dynamic Cell Investigations. Materials 2015, 8, 5490–5507. [Google Scholar] [CrossRef]

- Shibli, J.A.; Mangano, C.; D’avila, S.; Piattelli, A.; Pecora, G.E.; Mangano, F.; Onuma, T.; Cardoso, L.A.; Ferrari, D.S.; Aguiar, K.C.; et al. Influence of direct laser fabrication implant topography on type IV bone: A histomorphometric study in humans. J. Biomed. Mater. Res. A 2010, 93, 607–614. [Google Scholar] [CrossRef] [PubMed]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).