Numerical Simulation of Bubble Flow in Continuous Casting Mold with Bubble Swarm Correction of Drag Coefficient

Abstract

1. Introduction

2. Model Description

2.1. Governing Equations and Turbulence Model of Continuous Phase

2.2. Discrete Bubble Model

2.2.1. Bubble Dynamics

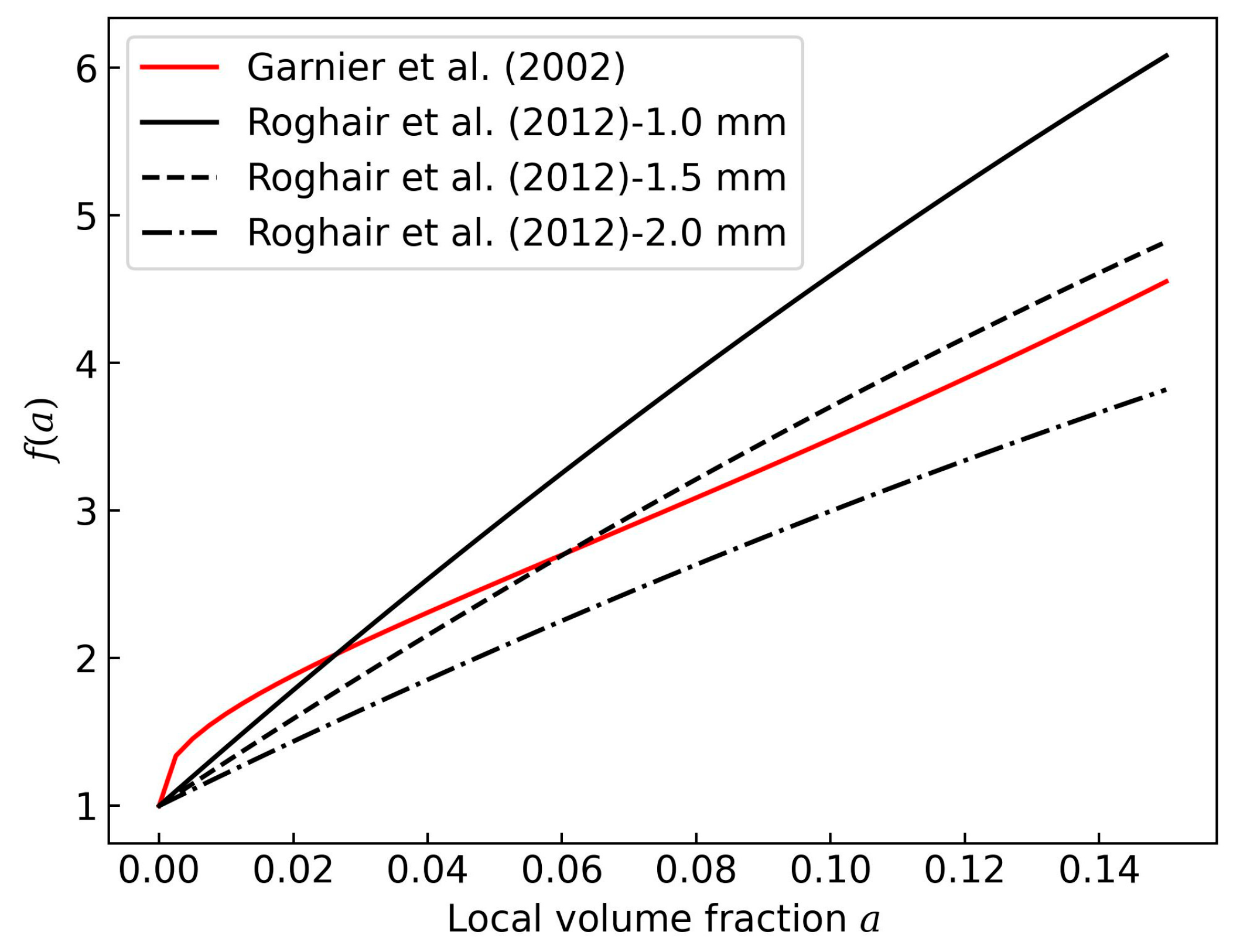

2.2.2. Bubble Swarm Correction of Drag Coefficient

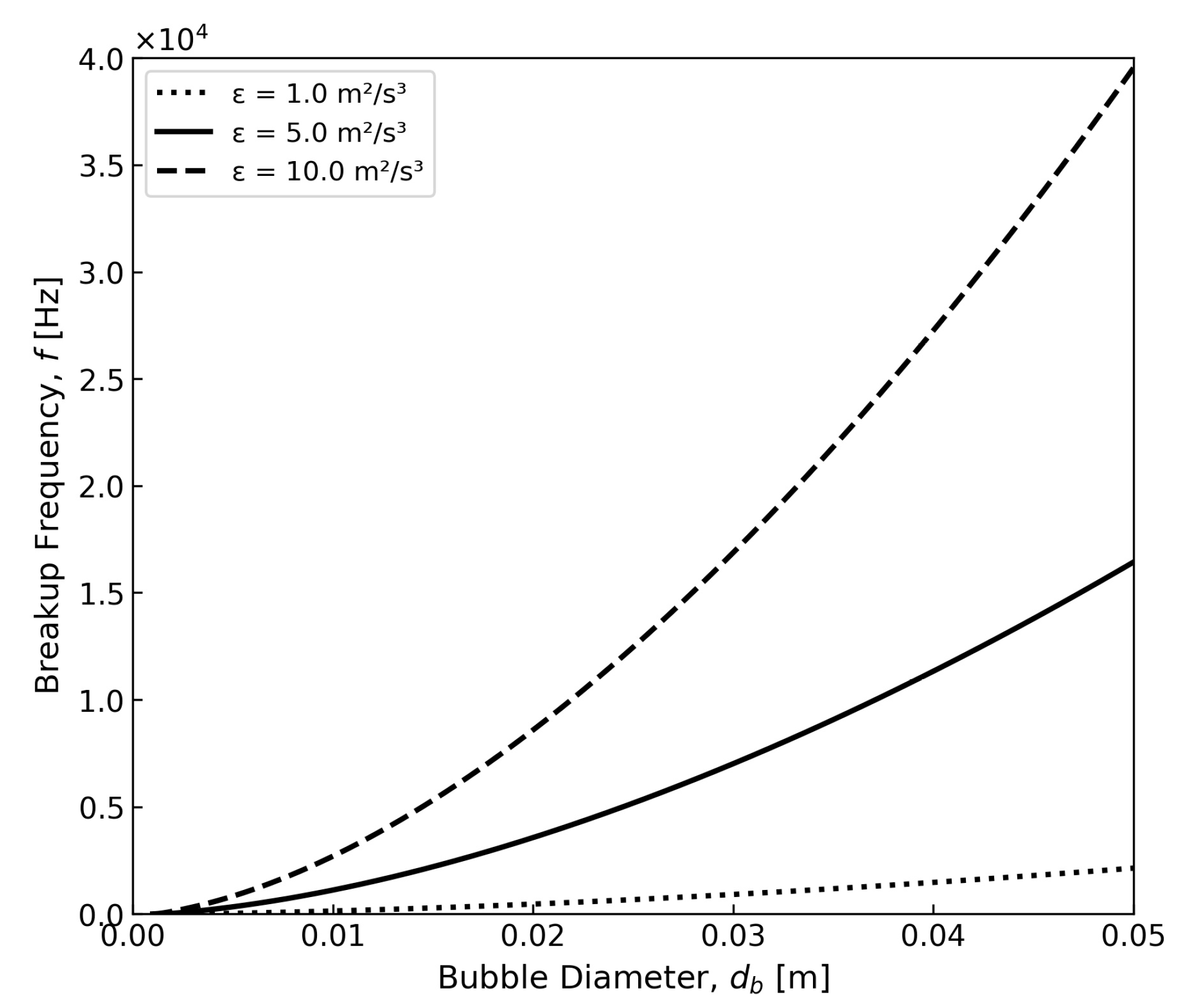

2.2.3. Bubble Coalescence and Breakup

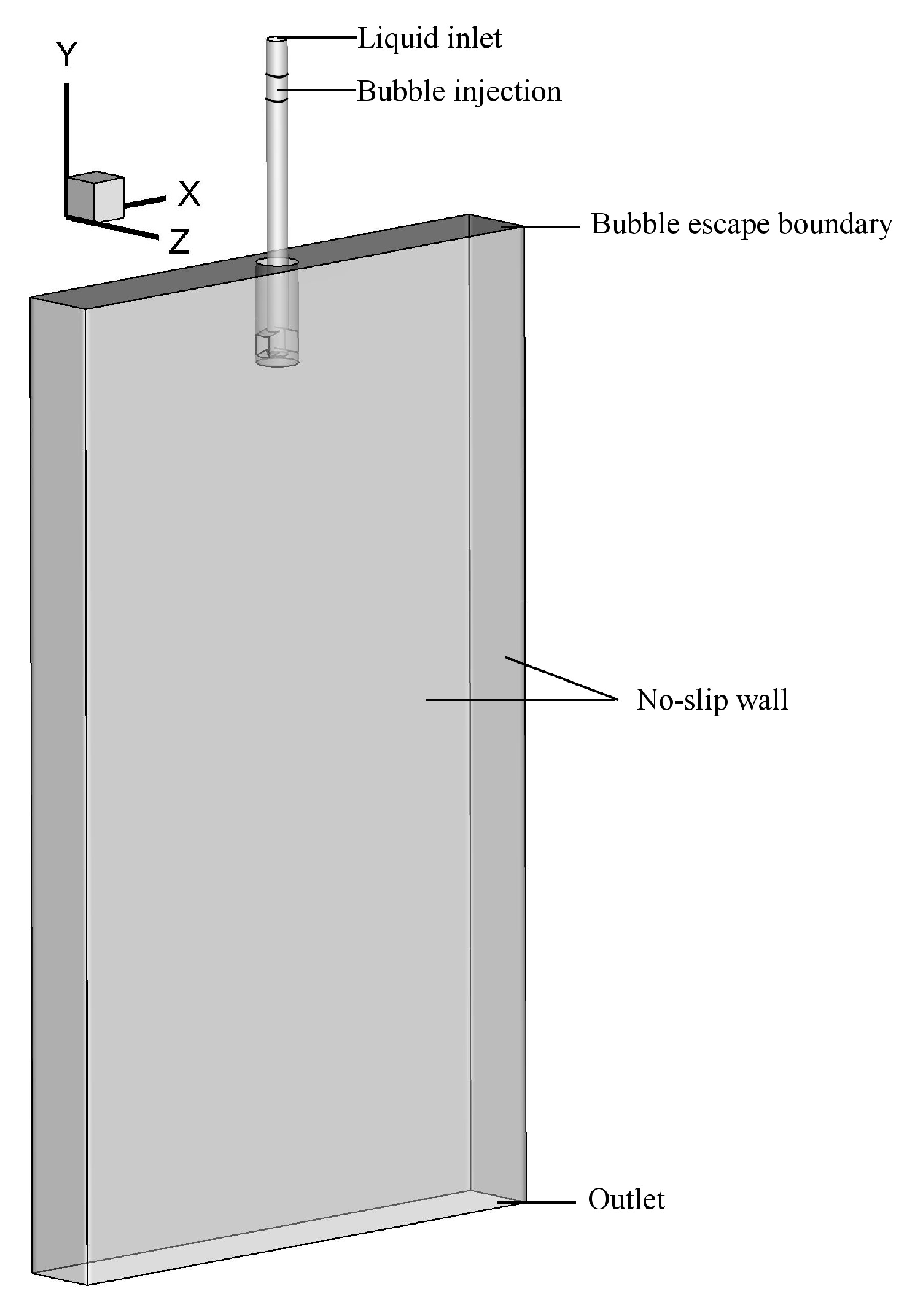

3. Simulation Conditions and Procedure

4. Results and Discussion

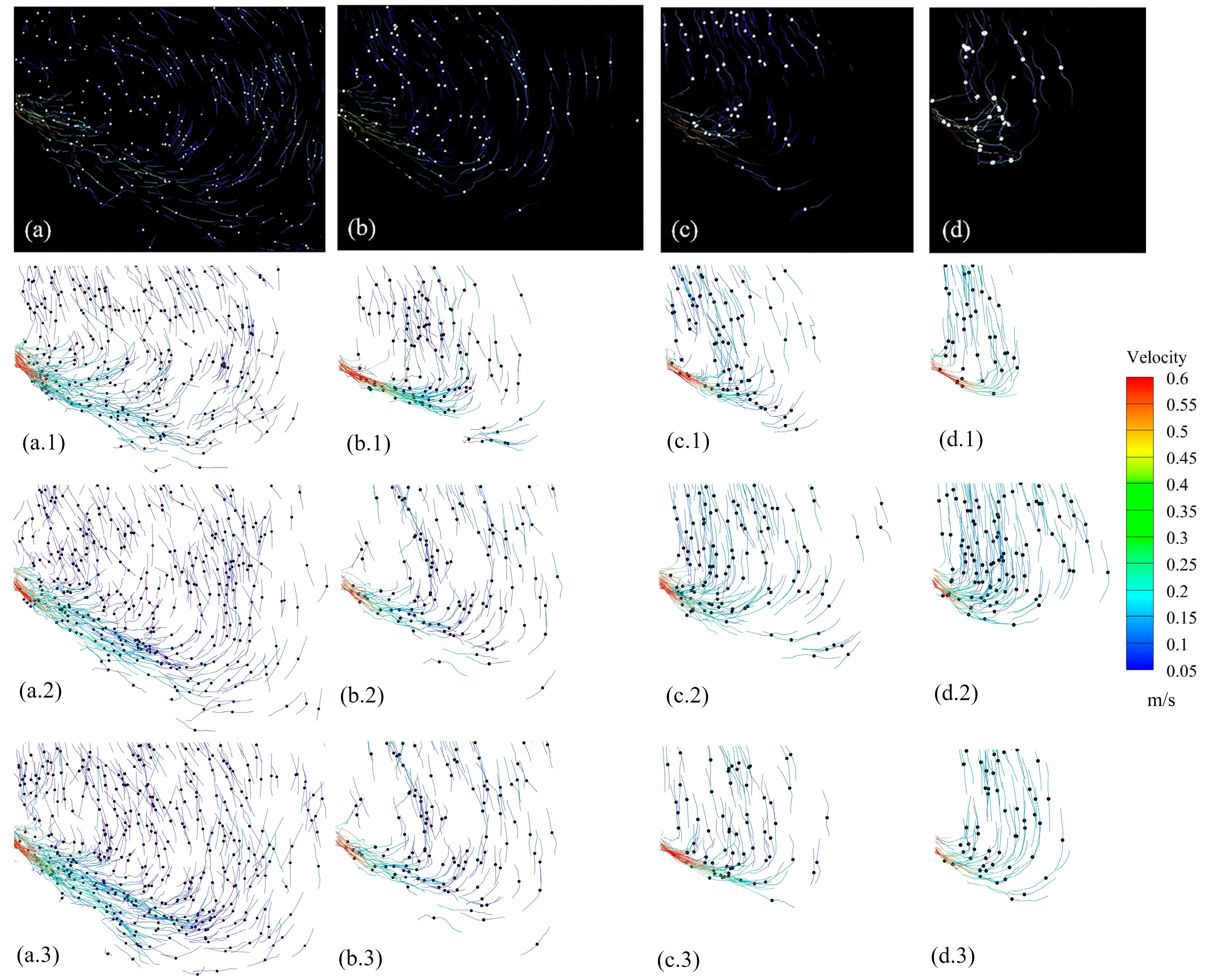

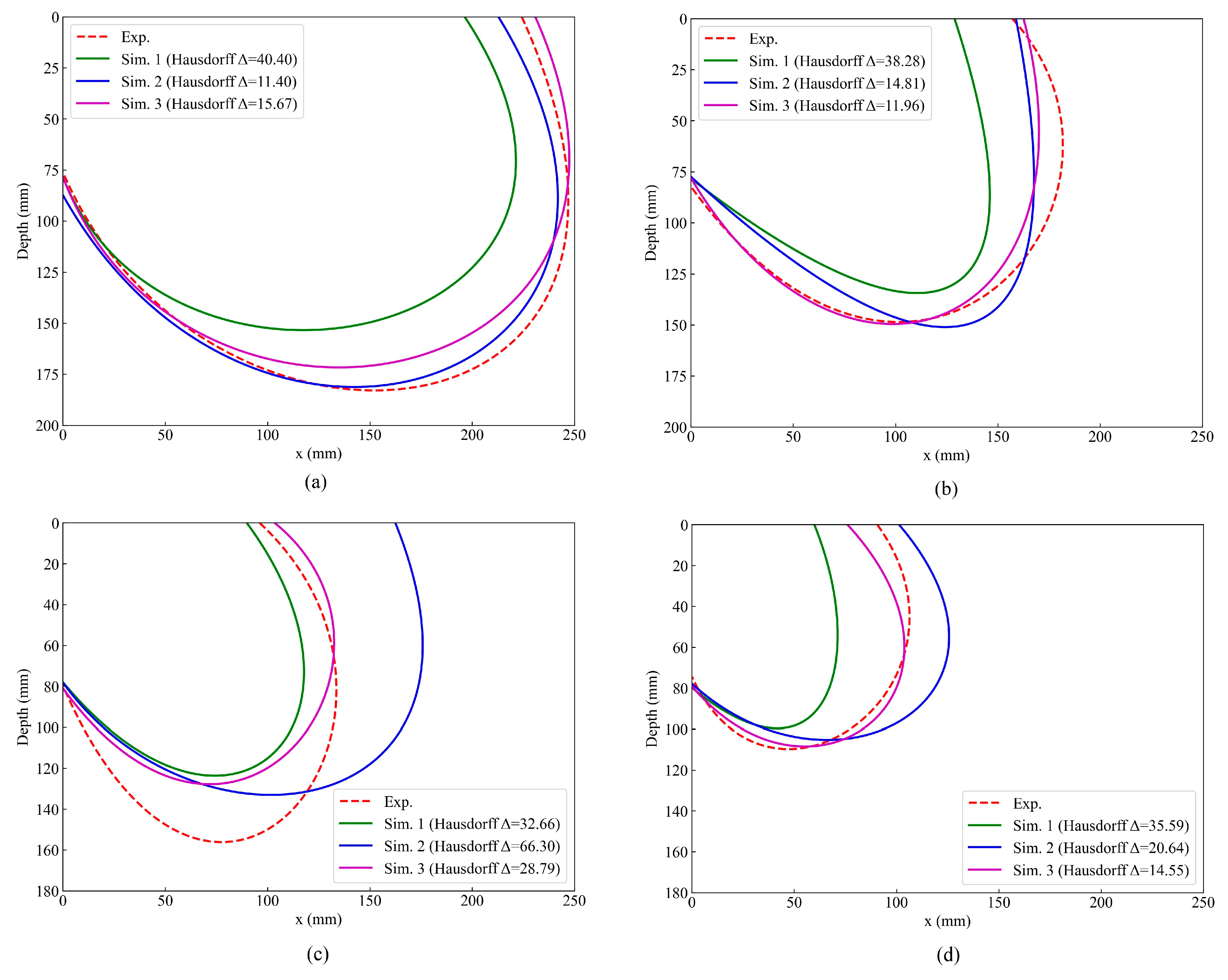

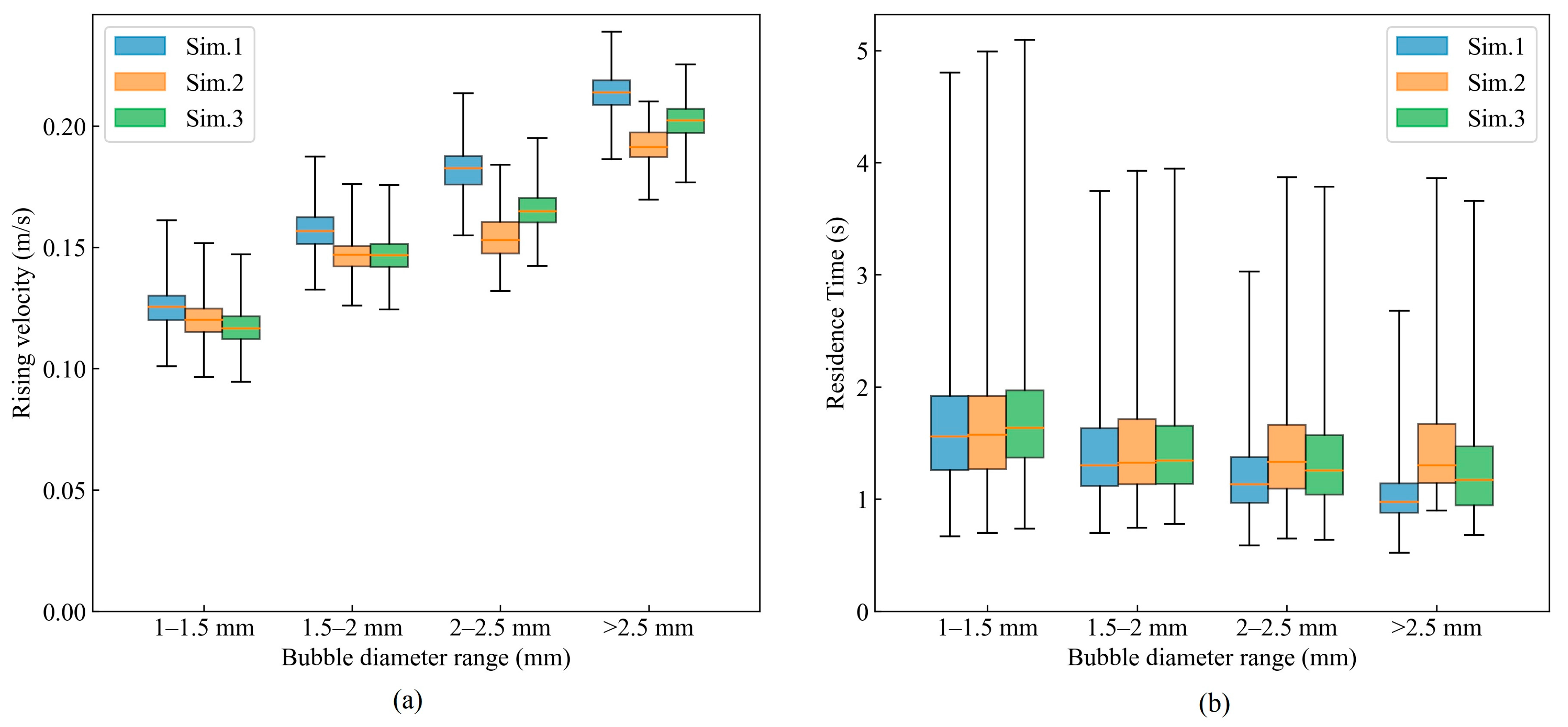

4.1. Bubble Distribution and Trajectory

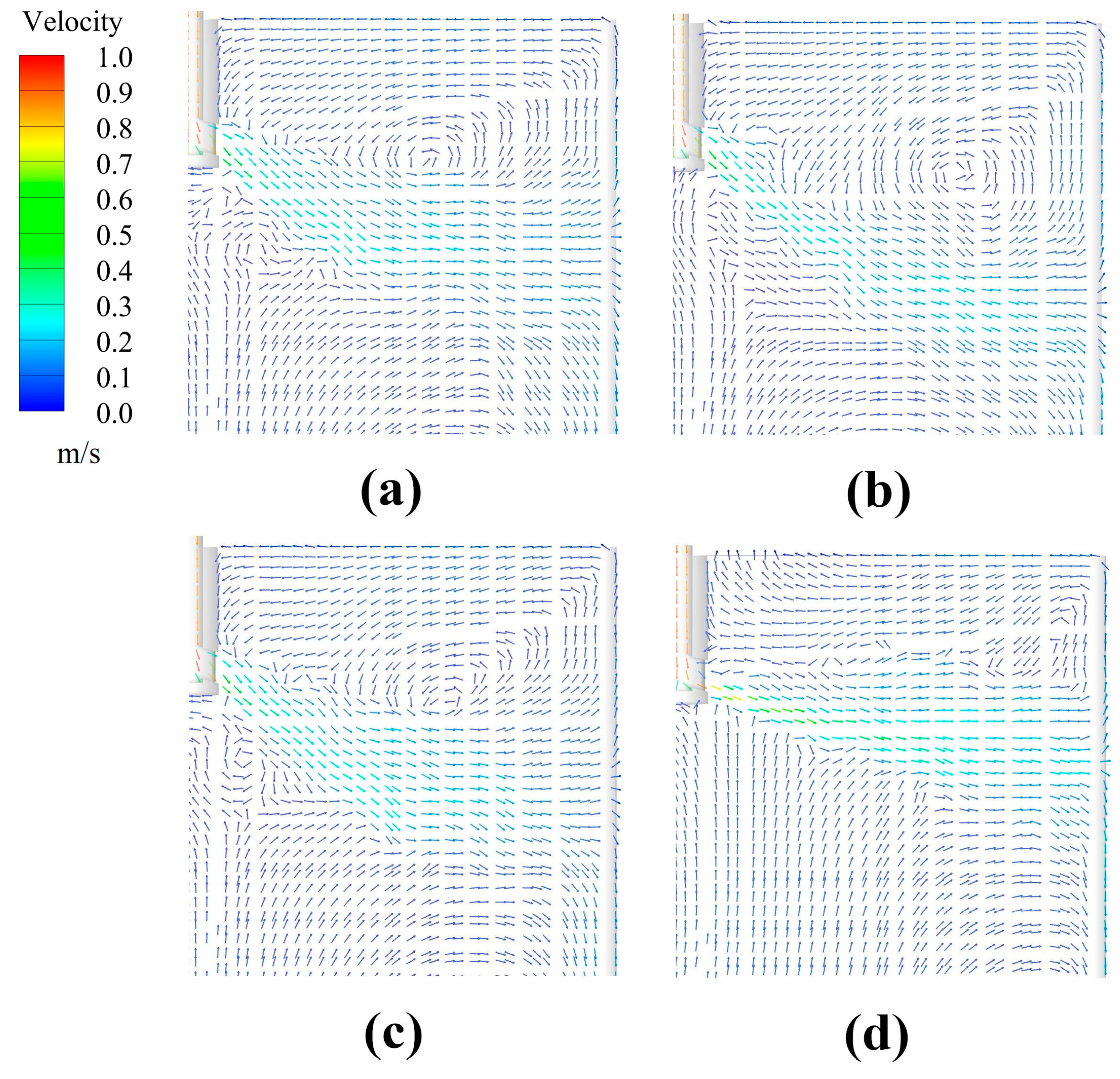

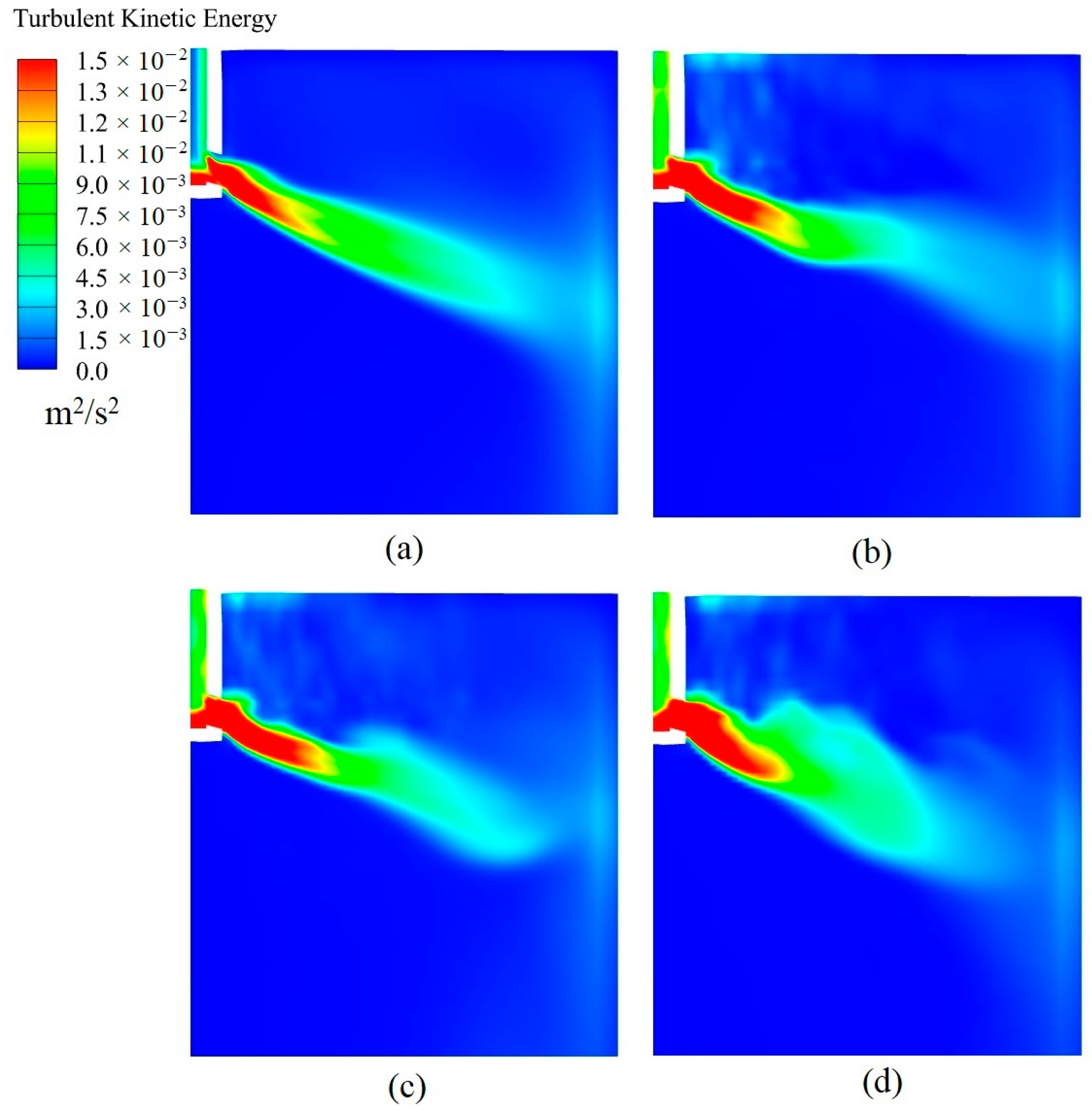

4.2. The Influence of Drag Force on Liquid Phase Flow Field

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| SEN | Submerged Entry Nozzle |

| PBM | Population Balance Model |

| DNS | Direct Numerical Simulation |

References

- Deng, X.; Ji, C.; Zhu, G.; Liu, Q.; Huang, F.; Tian, Z.; Wang, X. Quantitative evaluations of surface cleanliness in IF steel slabs at unsteady casting. Metall. Mater. Trans. B 2019, 50, 1974–1987. [Google Scholar] [CrossRef]

- Miki, Y.; Takeuchi, S. Internal defects of continuous casting slabs caused by asymmetric unbalanced steel flow in mold. ISIJ Int. 2003, 43, 1548–1555. [Google Scholar] [CrossRef]

- Jin, K.; Thomas, B.G.; Ruan, X.M. Modeling and measurements of multiphase flow and bubble entrapment in steel continuous casting. Metall. Mater. Trans. B 2015, 47, 548–565. [Google Scholar] [CrossRef]

- Zhang, T.; Luo, Z.G.; Liu, C.L.; Zhou, H.; Zou, Z.S. A mathematical model considering the interaction of bubbles in continuous casting mold of steel. Powder Technol. 2015, 273, 154–164. [Google Scholar] [CrossRef]

- Yang, W.; Luo, Z.; Gu, Y.; Liu, Z.; Zou, Z. Simulation of bubbles behavior in steel continuous casting mold using an Euler-Lagrange framework with modified bubble coalescence and breakup models. Powder Technol. 2020, 361, 769–781. [Google Scholar] [CrossRef]

- Liu, Z.Q.; Qi, F.S.; Li, B.K.; Cheung, S.C.P. Modeling of bubble behaviors and size distribution in a slab continuous casting mold. Int. J. Multiph. Flow 2016, 79, 190–201. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, Z.; Li, B.; Xiao, L.; Gan, Y. Numerical simulation of multi-size bubbly flow in a continuous casting mold using an inhomogeneous multiple size group model. Powder Technol. 2022, 402, 117368. [Google Scholar] [CrossRef]

- Dijkhuizen, W.; Roghair, I.; Van Sint Annaland, M.; Kuipers, J. Numerical derivation of the drag force coefficient in bubble swarms using a front tracking model. In Proceedings of the 6th International Conference on CFD in the Oil and Gas, Metallurgical and Process Industries, Trondheim, Norway, 10–12 June 2008. [Google Scholar]

- Roghair, I.; Baltussen, M.W.; Van Sint Annaland, M.; Kuipers, J.A.M. Direct Numerical Simulations of the drag force of bi-disperse bubble swarms. Chem. Eng. Sci. 2013, 95, 48–53. [Google Scholar] [CrossRef]

- Simonnet, M.; Gentric, C.; Olmos, E.; Midoux, N. Experimental determination of the drag coefficient in a swarm of bubbles. Chem. Eng. Sci. 2007, 62, 858–866. [Google Scholar] [CrossRef]

- Garnier, C.; Lance, M.; Marié, J.L. Measurement of local flow characteristics in buoyancy-driven bubbly flow at high void fraction. Exp. Therm. Fluid Sci. 2002, 26, 811–815. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, Z.; Wang, F.; Li, B.; Gan, Y. Experimental investigation of trajectories, velocities and size distributions of bubbles in a continuous-casting mold. Powder Technol. 2021, 387, 325–335. [Google Scholar] [CrossRef]

- Yang, G.; Zhang, H.; Luo, J.; Wang, T. Drag force of bubble swarms and numerical simulations of a bubble column with a CFD-PBM coupled model. Chem. Eng. Sci. 2018, 192, 714–724. [Google Scholar] [CrossRef]

- Yan, P.; Jin, H.; He, G.; Guo, X.; Ma, L.; Yang, S.; Zhang, R. CFD simulation of hydrodynamics in a high-pressure bubble column using three optimized drag models of bubble swarm. Chem. Eng. Sci. 2019, 199, 137–155. [Google Scholar] [CrossRef]

- Tomiyama, A. Struggle with Computational Bubble Dynamics. Multiph. Sci. Technol. 1998, 10, 369–405. [Google Scholar] [CrossRef]

- Zhang, D.; Deen, N.G.; Kuipers, J.A.M. Numerical simulation of the dynamic flow behavior in a bubble column: A study of closures for turbulence and interface forces. Chem. Eng. Sci. 2006, 61, 7593–7608. [Google Scholar] [CrossRef]

- Troshko, A.; Hassan, Y. A two-equation turbulence model of turbulent bubbly flows. Int. J. Multiph. Flow 2001, 27, 1965–2000. [Google Scholar] [CrossRef]

- Zenit, R.; Koch, D.L.; Sangani, A.S. Measurements of the average properties of a suspension of bubbles rising in a vertical channel. J. Fluid Mech. 2001, 429, 307–342. [Google Scholar] [CrossRef]

- Roghair, I.; Van Sint Annaland, M.; Kuipers, H.J.A.M. Drag force and clustering in bubble swarms. AlChE J. 2012, 59, 1791–1800. [Google Scholar] [CrossRef]

- Ishii, M.; Zuber, N. Drag coefficient and relative velocity in bubbly, droplet or particulate flows. AlChE J. 1979, 25, 843–855. [Google Scholar] [CrossRef]

- Spelt, P.; Biesheuvel, A. On the motion of gas bubbles in homogeneous isotropic turbulence. J. Fluid Mech. 1997, 336, 221–244. [Google Scholar] [CrossRef]

- Lockett, M.J.; Kirkpatrick, R.D. Ideal bubbly flow and actual flow in bubble columns. Trans. Inst. Chem. Eng. 1975, 53, 267–273. [Google Scholar]

- Bai, H.; Thomas, B.G. Bubble formation during horizontal gas injection into downward-flowing liquid. Metall. Mater. Trans. B 2001, 32, 1143–1159. [Google Scholar] [CrossRef]

- Planquart, P.; Dehaeck, S.; Buchlin, J.M.; Riethmuller, M. Experimental Investigation of Bubbly Flow, Annular Flow and Transition in a Downward Cocurrent Two-Phase Flow. In Proceedings of the Icmf, Yokohama, Japan, 30 May–4 June 2004. [Google Scholar]

- Chen, Y.; Wang, L.; Chang, H.; Zhang, Q. A Review of Drag Coefficient Models in Gas-Liquid Two-Phase Flow. ChemBioEng Rev. 2023, 10, 311–325. [Google Scholar] [CrossRef]

- Chesters, A.K.; Hofman, G. Bubble coalescence in pure liquids. Appl. Sci. Res. 1982, 38, 353–361. [Google Scholar] [CrossRef]

- Duineveld, P. Bouncing and coalescence of bubble pairs rising at high Reynolds number in pure water or aqueous surfactant solutions. Appl. Sci. Res. 1998, 58, 409–439. [Google Scholar] [CrossRef]

- Lehr, F.; Millies, M.; Mewes, D. Bubble-Size distributions and flow fields in bubble columns. AlChE J. 2002, 48, 2426–2443. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, Z.; Li, B.; Gan, Y. Numerical simulation of multi-size bubbly flow in a continuous casting mold using population balance model. Powder Technol. 2022, 396, 224–240. [Google Scholar] [CrossRef]

- ANSYS Inc. ANSYS Fluent Theory Guide, Release 18.1; ANSYS Inc.: Canonsburg, PA, USA, 2017. [Google Scholar]

| Parameters | Garnier et al. [11] | Roghair et al. [19] |

|---|---|---|

| Void fraction | 0–0.3 | 0–0.4 |

| Bubble Reynolds number | 300–500 | No explicit limit |

| Eotvos numbers | No explicit limit | 0.13 to 4.9 |

| Bubble diameter (mm) | 1.0–5.5 | 1.0–6.0 |

| Parameter | Water Model | Prototype |

|---|---|---|

| Mold width × thickness (mm) | 550 × 75 | 2200 × 300 |

| Mold/strand height (mm) | 900 | Open bottom |

| Diameter of SEN (mm) | 20 | 80 |

| Length of SEN (mm) | 305 | 1220 |

| Exit angle of nozzle (degree) | 15 | 15 |

| SEN port height × width (mm) | 20 × 17.5 | 80 × 70 |

| Submergence depth of SEN (mm) | 75 | 300 |

| Density of liquid phase (kg/m3) | 1000 | 7020 |

| Density of gas phase (kg/m3) | 1.138 | 0.56 |

| Viscosity of liquid phase (N·s/m2) | 0.001 | 0.0056 |

| Volume flow rate of liquid phase (L/h) | 700–1100 | 22,400–35,200 |

| Volume flow rate of gas phase (mL/min) | 400–850 | 8000–17,000 |

| Interfacial tension (N/m) | 0.072 | 1.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, Q.; Luo, Z.; Zhang, Y.; Zou, Z.; Li, H. Numerical Simulation of Bubble Flow in Continuous Casting Mold with Bubble Swarm Correction of Drag Coefficient. Metals 2025, 15, 952. https://doi.org/10.3390/met15090952

Lai Q, Luo Z, Zhang Y, Zou Z, Li H. Numerical Simulation of Bubble Flow in Continuous Casting Mold with Bubble Swarm Correction of Drag Coefficient. Metals. 2025; 15(9):952. https://doi.org/10.3390/met15090952

Chicago/Turabian StyleLai, Qingrui, Zhiguo Luo, Yongjie Zhang, Zongshu Zou, and Haifeng Li. 2025. "Numerical Simulation of Bubble Flow in Continuous Casting Mold with Bubble Swarm Correction of Drag Coefficient" Metals 15, no. 9: 952. https://doi.org/10.3390/met15090952

APA StyleLai, Q., Luo, Z., Zhang, Y., Zou, Z., & Li, H. (2025). Numerical Simulation of Bubble Flow in Continuous Casting Mold with Bubble Swarm Correction of Drag Coefficient. Metals, 15(9), 952. https://doi.org/10.3390/met15090952