Research on Hybrid Blue Diode-Fiber Laser Welding Process of T2 Copper

Abstract

1. Introduction

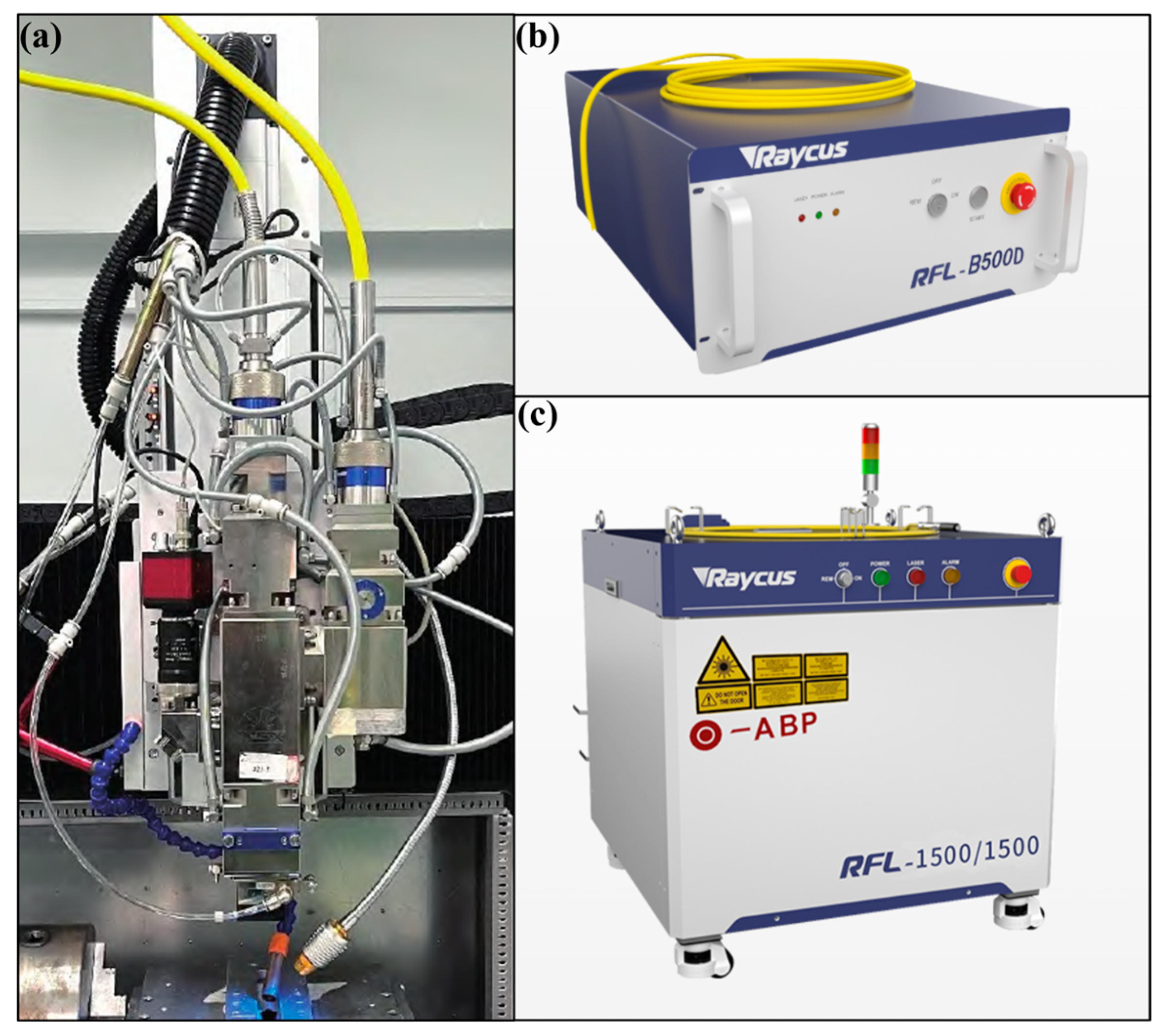

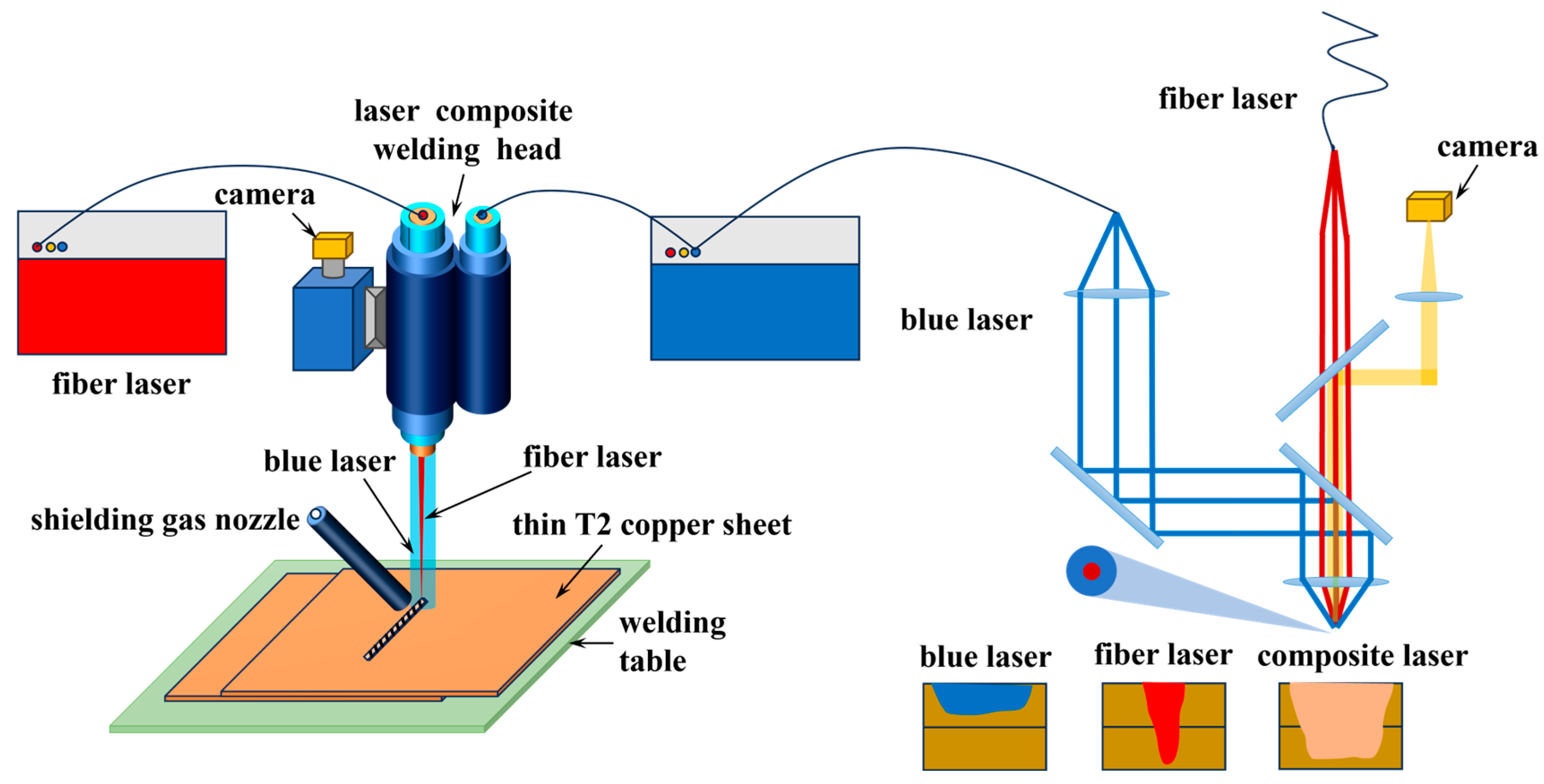

2. Materials and Methods

3. Results and Discussion

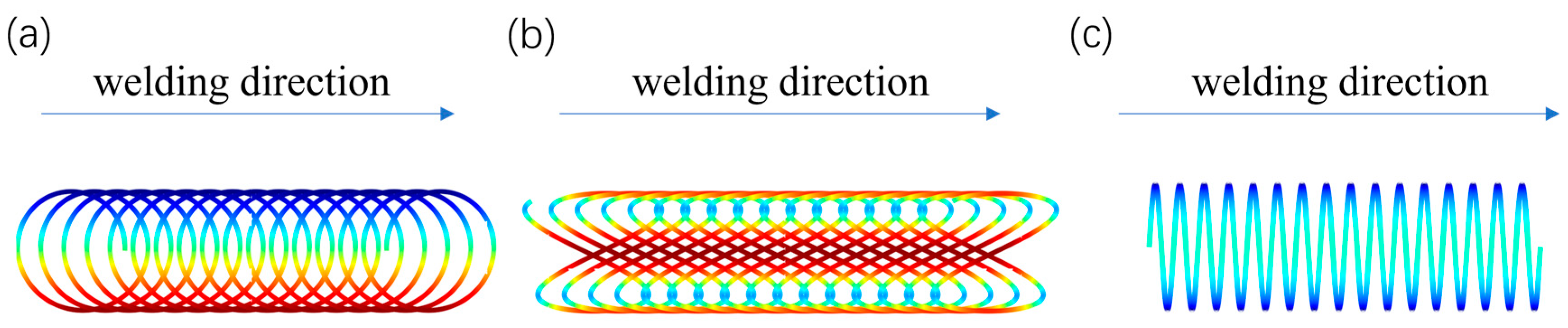

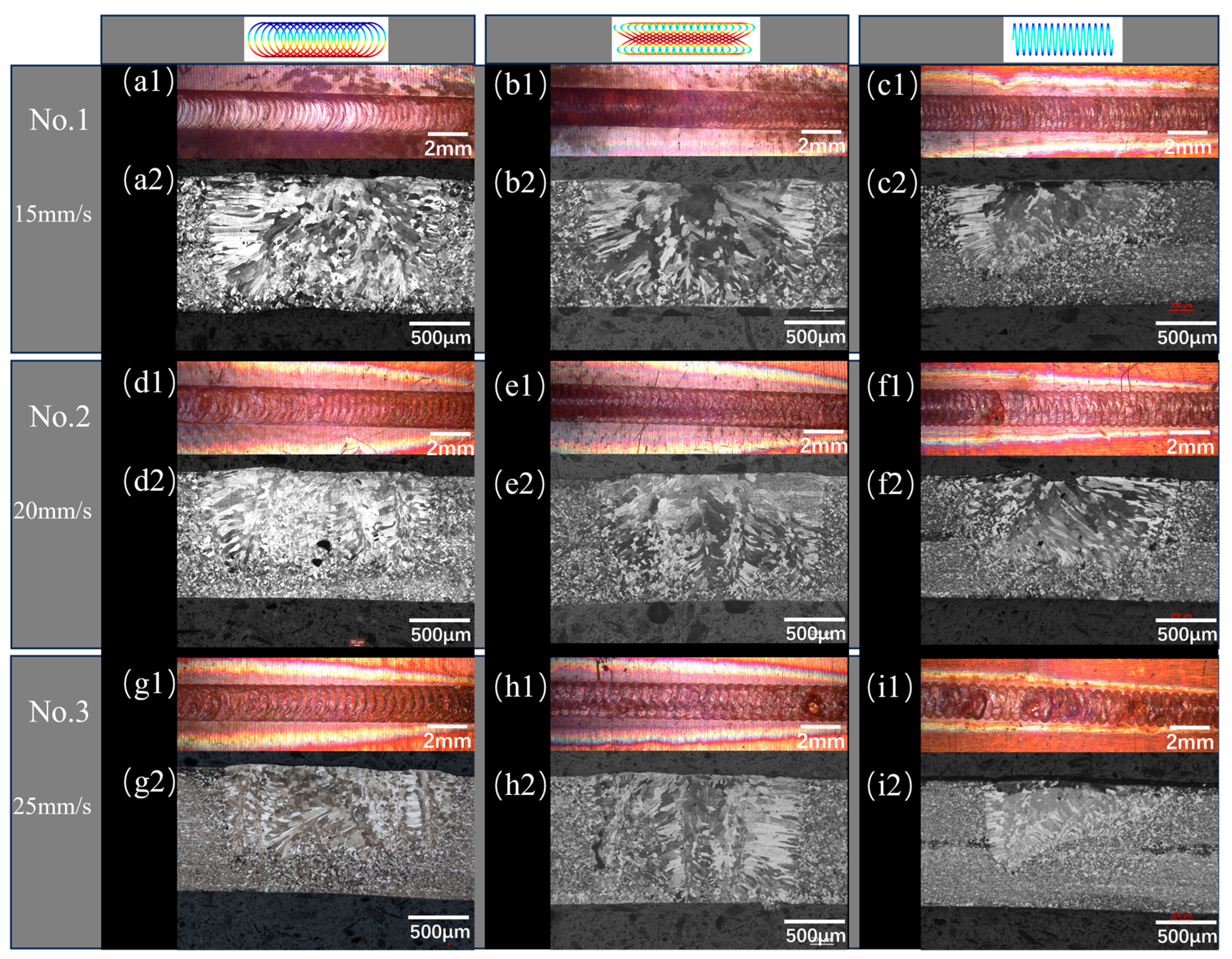

3.1. Effect of Welding Trajectory and Speed on Weld Formation

3.1.1. Weld Appearance Analysis

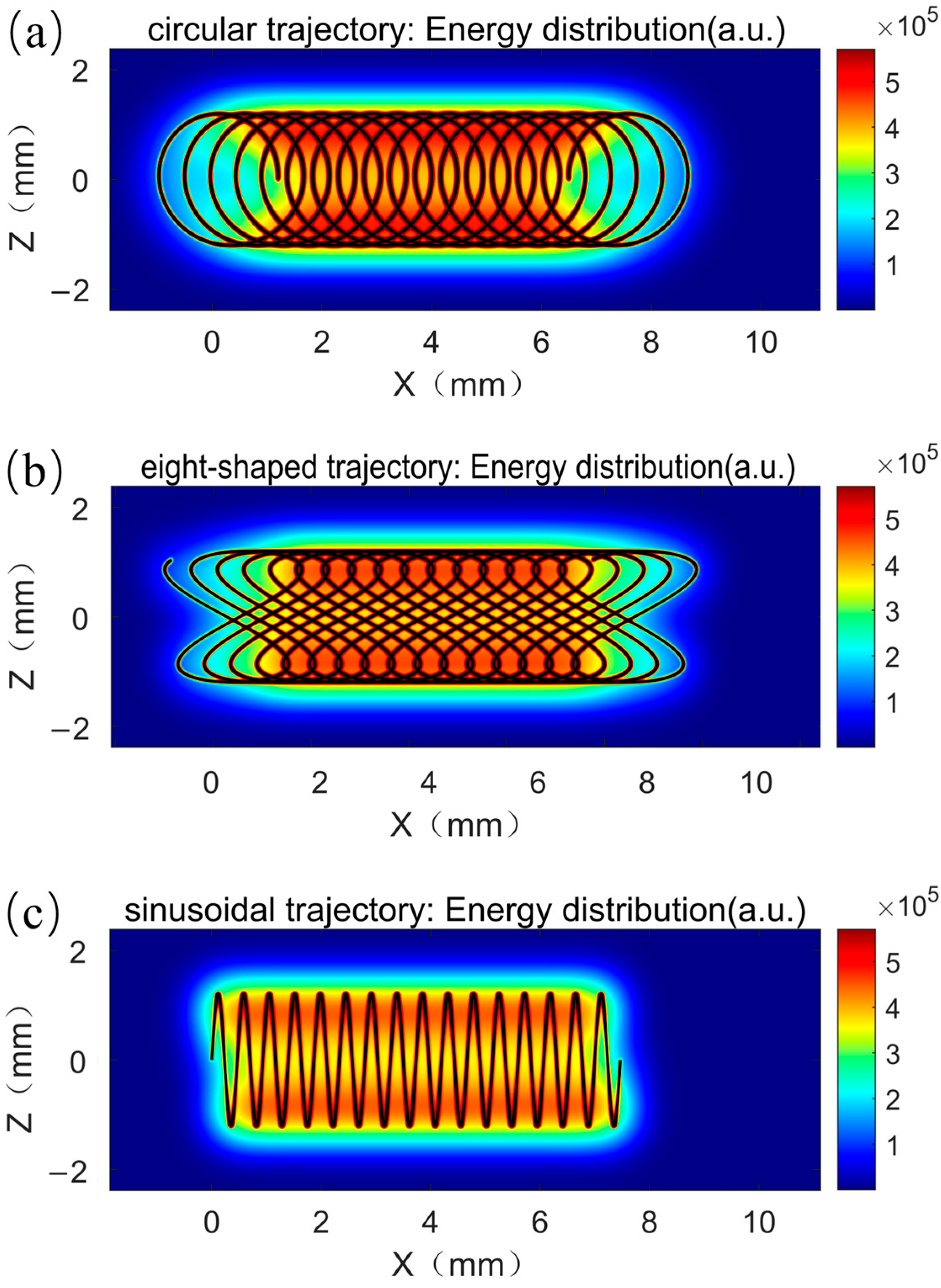

3.1.2. Energy Distribution of Different Welding Trajectories

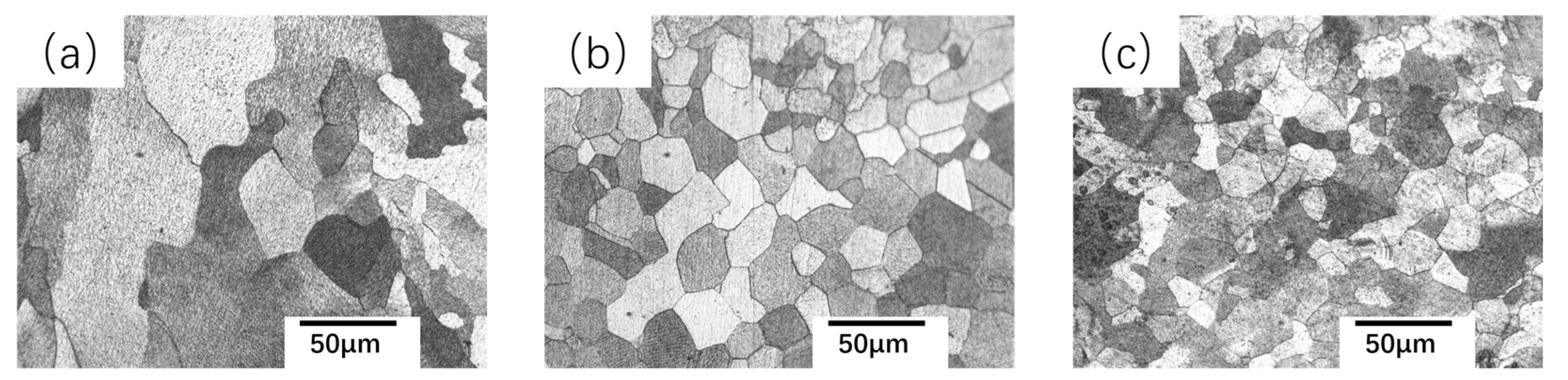

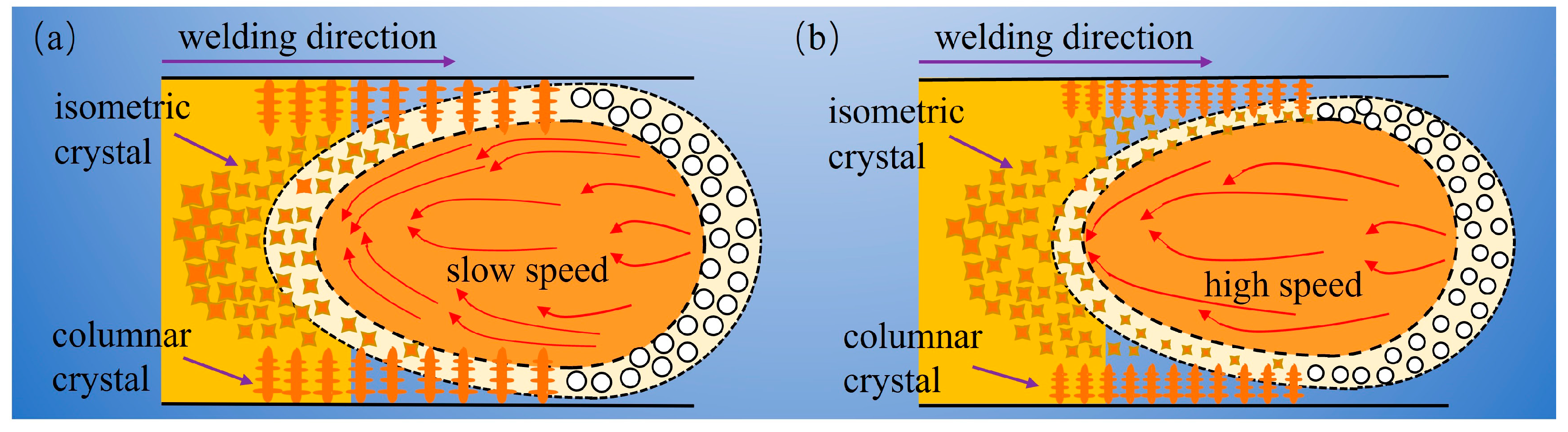

3.2. Microstructural Analysis of Weld Seams

3.3. Mechanical Performance Analysis

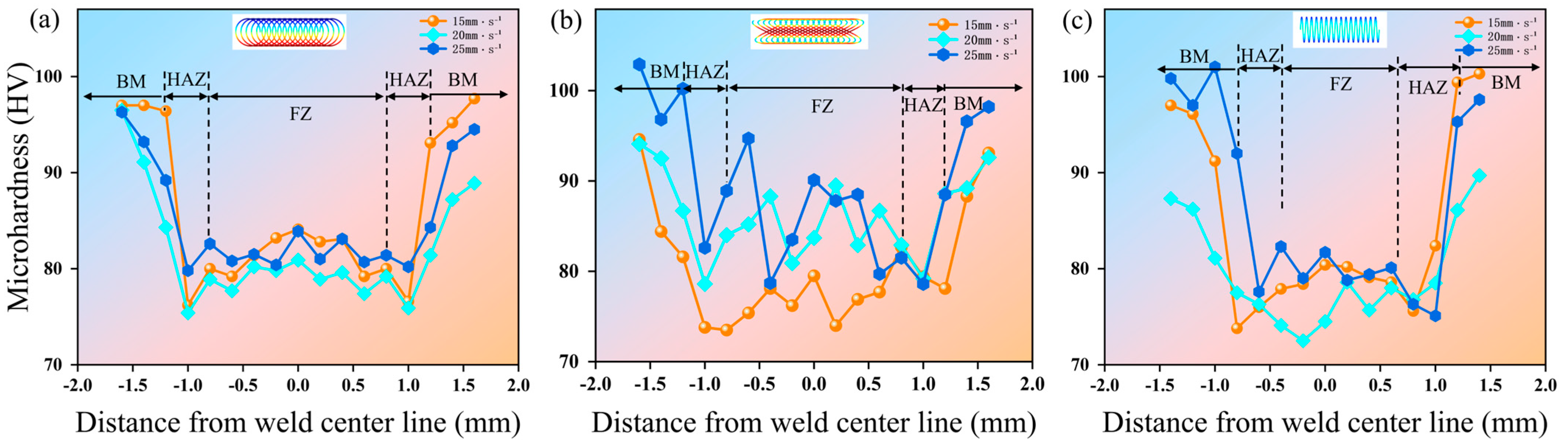

3.3.1. Microhardness Analysis

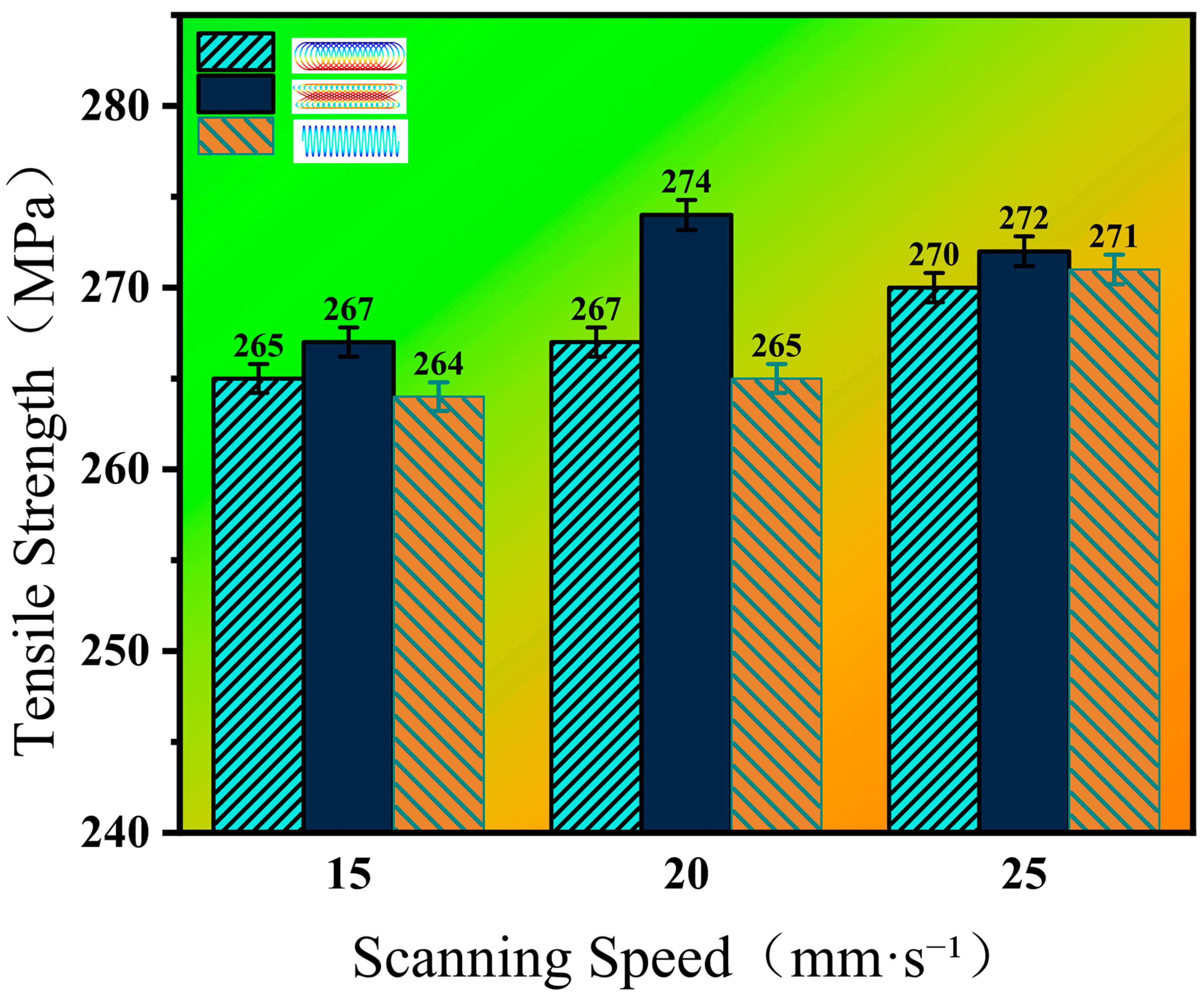

3.3.2. Tensile Property Analysis

4. Conclusions

- All three welding trajectories (circular, 8-shaped, and sinusoidal) effectively improved the weld width. Compared with conventional linear welding, the oscillating trajectories significantly optimized weld formation quality by enhancing molten pool stirring and expanding the heat input area. Among them, the circular and 8-shaped trajectories exhibited more uniform energy distribution, leading to better width-to-depth ratios and higher weld stability than the sinusoidal trajectory.

- Dependency of speed and fusion characteristics: Increasing welding speed reduces linear energy input, which leads to a decrease in both penetration depth and fusion width. At the same time, higher speeds accelerate cooling, promote grain refinement, and improve hardness and tensile strength. Excessive speed, however, may induce porosity due to insufficient time for gas escape.

- Dependency of trajectory and energy distribution: Different oscillation trajectories redistribute laser energy within the molten pool. The circular and 8-shaped paths produce more uniform energy diffusion, resulting in stable molten pool dynamics, suppression of porosity, and balanced width-to-depth ratios. Compared with the other trajectories, the sinusoidal path is more sensitive to changes in welding speed and is more likely to generate localized defects.

- Dependency of microstructure and mechanical performance: Microstructural evolution is directly linked to the interplay of speed and trajectory. Faster cooling and stronger oscillation-induced stirring increase nucleation density, suppress columnar growth, and promote equiaxed grain formation. These refined and homogenized microstructures correlate with higher hardness and superior tensile strength, consistent with the Hall–Petch relationship.

- Overall assessment: For low-power hybrid blue–fiber laser welding of thin T2 copper terminals, the circular trajectory provides the most consistent weld geometry and hardness distribution, while the 8-shaped trajectory achieves the highest tensile strength due to its favorable balance of energy input and molten pool stability. The sinusoidal trajectory may still be useful for narrow-gap applications, though with reduced robustness.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Haubold, M.; Ganser, A.; Eder, T.; Zäh, M.F. Laser Welding of Copper Using a High Power Disc Laser at Green Wavelength. Procedia CIRP 2018, 74, 446–449. [Google Scholar] [CrossRef]

- Kaufmann, F.; Forster, C.; Hummel, M.; Olowinsky, A.; Beckmann, F.; Moosmann, J.; Roth, S.; Schmidt, M. Characterization of Vapor Capillary Geometry in Laser Beam Welding of Copper with 515 Nm and 1030 Nm Laser Beam Sources by Means of In Situ Synchrotron X-Ray Imaging. Metals 2023, 13, 135. [Google Scholar] [CrossRef]

- Pavliček, N.; Mohn, F. Laser bonding of copper ribbons and clips on SiC power MOSFETs with sintered copper bond buffers. In Proceedings of the 2020 IEEE 8th Electronics System-Integration Technology Conference (ESTC), Vestfold, Norway, 15–18 September 2020; pp. 1–4. [Google Scholar]

- Xu, T.; Wang, L.; Ma, X.; Zhu, Z.; Wang, C.; Mi, G. Solidification Sequence and Crystal Growth during Laser Welding Stainless Steel to Copper. Mater. Des. 2023, 225, 111519. [Google Scholar] [CrossRef]

- Chatterjee, S.; Trinh, L.N.; Lee, D. Mechanical and Microstructural Investigation of Dissimilar Joints of Al-Cu and Cu-Al Metals Using Nanosecond Laser. J. Mech. Sci. Technol. 2022, 36, 4205–4211. [Google Scholar] [CrossRef]

- Kim, H.-T.; Yoon, J.-W. Microstructures and Mechanical Properties of Ultrasonic-Welded Cu–Cu Joints for Power Module Terminals in Electric Vehicles. J. Mater. Sci. Mater. Electron. 2023, 34, 1997. [Google Scholar] [CrossRef]

- Biro, E.; Weckman, D.C.; Zhou, Y. Pulsed Nd:YAG Laser Welding of Copper Using Oxygenated Assist Gases. Met. Mater. Trans. A 2002, 33, 2019–2030. [Google Scholar] [CrossRef]

- Wang, L.; Gao, M.; Zhang, C.; Zeng, X. Effect of Beam Oscillating Pattern on Weld Characterization of Laser Welding of AA6061-T6 Aluminum Alloy. Mater. Des. 2016, 108, 707–717. [Google Scholar] [CrossRef]

- Dimatteo, V.; Ascari, A.; Faverzani, P.; Poggio, L.; Fortunato, A. The Effect of Process Parameters on the Morphology, Mechanical Strength and Electrical Resistance of CW Laser-Welded Pure Copper Hairpins. J. Manuf. Process. 2021, 62, 450–457. [Google Scholar] [CrossRef]

- Arjmand, E.; Spann, T.; Madloch, S. Development of Cu-Cu Joining Technology by Laser Welding for Terminal Attach within Power Semiconductor Package. In Proceedings of the PCIM Europe 2023; International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 9–11 May 2023; VDE: Berlin, Germany, 2023; pp. 1–7. [Google Scholar]

- Alter, L.; Heider, A.; Bergmann, J.-P. Investigations on Copper Welding Using a Frequency-Doubled Disk Laser and High Welding Speeds. Procedia CIRP 2018, 74, 12–16. [Google Scholar] [CrossRef]

- Chung, W.-S.; Olowinsky, A.; Gillner, A. Process Studies on Copper Laser Beam Welding over Gap by Using Disc Laser at Green Wavelength. J. Adv. Join. Process. 2020, 1, 100009. [Google Scholar] [CrossRef]

- Cai, H.; Zhou, J.; Zhang, S.; Jia, P. Effect of Red-Blue Composite Laser Welding Joint on Microstructure and Properties of Copper Alloy. Int. Core J. Eng. 2024, 10, 182–190. [Google Scholar]

- Yang, H.; Tang, X.; Hu, C.; Liu, S.; Fan, Y.; Xiao, Y.; Lu, G.; Wang, Q.; Chen, G.; Xing, P.; et al. Study on Laser Welding of Copper Material by Hybrid Light Source of Blue Diode Laser and Fiber Laser. J. Laser Appl. 2021, 33, 032018. [Google Scholar] [CrossRef]

- Fujio, S.; Sato, Y.; Takenaka, K.; Ito, R.; Ito, M.; Harada, M.; Nishikawa, T.; Suga, T.; Tsukamoto, M. Welding of Pure Copper Wires Using a Hybrid Laser System with a Blue Diode Laser and a Single-Mode Fiber Laser. J. Laser Appl. 2021, 33, 042056. [Google Scholar] [CrossRef]

- Wu, D.; Sun, J.; Li, Z.; Huang, J.; Feng, K. Molten Pool Behaviors and Energy Absorption in Coaxial Hybrid Blue-IR Lasers Welding of a Copper Material. Int. J. Therm. Sci. 2023, 184, 107945. [Google Scholar] [CrossRef]

- Fujio, S.; Sato, Y.; Sudo, M.; Takenaka, K.; Tojo, K.; Pasang, T.; Tsukamoto, M. Spatter Reduction in Deep Penetration Welding of Pure Copper Using Blue-IR Hybrid Laser. Weld. World 2024, 68, 1515–1524. [Google Scholar] [CrossRef]

- Jiang, N.; Jiang, M.; Chen, X.; Han, T.; Ma, S.; Chen, Y.; Wang, Z.; Jiang, Y.; Yang, L.; Lei, Z.; et al. Effect of Beam Oscillation on Weld Formation, Microstructure and Mechanical Properties in Vacuum Laser Beam Welding of Thick Section 5083 Aluminum Alloy. Opt. Laser Technol. 2024, 171, 110408. [Google Scholar] [CrossRef]

- Mahrle, A.; Beyer, E. Modeling and Simulation of the Energy Deposition in Laser Beam Welding with Oscillatory Beam Deflection. In Proceedings of the International Congress on Applications of Lasers & Electro-Optics, Orlando, FL, USA, 29 October–1 November 2007; Laser Institute of America: Orlando, FL, USA; p. 1805. [Google Scholar] [CrossRef]

- Prieto, C.; Vaamonde, E.; Diego-Vallejo, D.; Jimenez, J.; Urbach, B.; Vidne, Y.; Shekel, E. Dynamic laser beam shaping for laser aluminium welding in e-mobility applications. Procedia CIRP 2020, 94, 596–600. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, C.; Mi, G.; Jiang, P.; Zhang, X.; Yan, X. Laser Beam Oscillation Welded SiCp/2xx Al Alloy: Microstructure, Phase Interface and Mechanical Properties. Mater. Sci. Eng. A 2021, 820, 141482. [Google Scholar] [CrossRef]

- Greebmalai, J.; Sadasue, S.; Marumoto, K.; Warinsiriruk, E.; Yamamoto, M. Weld Formation and Characteristics of Hot-Wire Laser Welding in Aluminum Alloy Narrow-Gap Joints. Metals 2025, 15, 809. [Google Scholar] [CrossRef]

- Faye, A.; Balcaen, Y.; Lacroix, L.; Alexis, J. Effects of welding parameters on the microstructure and mechanical properties of the AA6061 aluminium alloy joined by a Yb: YAG laser beam. J. Adv. Join. Process. 2021, 3, 100047. [Google Scholar] [CrossRef]

- Kang, S.G.; Shin, J. The effect of laser beam intensity distribution on weld characteristics in laser welded aluminum alloy (AA5052). Opt. Laser Technol. 2021, 142, 107239. [Google Scholar] [CrossRef]

- Pang, X.; Dai, J.; Chen, S.; Zhang, M. Microstructure and Mechanical Properties of Fiber Laser Welding of Aluminum Alloy with Beam Oscillation. Appl. Sci. 2019, 9, 5096. [Google Scholar] [CrossRef]

| Cu | Fe | S | Pb | As | Sb | Bi |

|---|---|---|---|---|---|---|

| >99.9 | 0.005 | 0.005 | 0.005 | 0.002 | 0.002 | 0.001 |

| Laser | Max. Power P/KW | Core Diameter Dc/μm | Wavelength λ/nm |

|---|---|---|---|

| RFL-1500/1500 RFL-B500D | 1.5 0.5 | 50 400 | 1080 445 |

| Welding Trajectory | Blue Laser Power Pblue/W | Fiber Laser Power Pfiber/W | Welding Speed V/ mm·s−1 | Defocus Δ(mm) |

|---|---|---|---|---|

| Circular 8-shaped Sinusoidal | 300 | 600 | 15, 20, 25 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Qi, N.; Liu, S.; Lv, Q.; Fu, Q.; Kang, Y.; Jin, M.; Yang, M. Research on Hybrid Blue Diode-Fiber Laser Welding Process of T2 Copper. Metals 2025, 15, 1058. https://doi.org/10.3390/met15091058

Wu X, Qi N, Liu S, Lv Q, Fu Q, Kang Y, Jin M, Yang M. Research on Hybrid Blue Diode-Fiber Laser Welding Process of T2 Copper. Metals. 2025; 15(9):1058. https://doi.org/10.3390/met15091058

Chicago/Turabian StyleWu, Xiangkuan, Na Qi, Shengxiang Liu, Qiqi Lv, Qian Fu, Yue Kang, Min Jin, and Miaosen Yang. 2025. "Research on Hybrid Blue Diode-Fiber Laser Welding Process of T2 Copper" Metals 15, no. 9: 1058. https://doi.org/10.3390/met15091058

APA StyleWu, X., Qi, N., Liu, S., Lv, Q., Fu, Q., Kang, Y., Jin, M., & Yang, M. (2025). Research on Hybrid Blue Diode-Fiber Laser Welding Process of T2 Copper. Metals, 15(9), 1058. https://doi.org/10.3390/met15091058