Kinetics of the Reduction of Iron Ore Pellets with Hydrogen: A Parametric Experimental and Modeling Study

Abstract

1. Introduction

- -

- The rate of reduction of a pellet is limited by different “resistances”, namely, the external mass transfer of the reactant gas from the bulk gas to the pellet surface, the diffusion of the reactant gas through the pores of the pellet, and the chemical reaction itself [15]. Oxygen solid-state diffusion in the iron layer is sometimes seen as a supplementary resistance, especially in the late stage of the reaction [16]. High temperatures and large pellet diameters promote gas diffusion control, whereas low temperatures and small pellet diameters lead to chemical control [13]. Likewise, high pressures and high temperatures also promote gas diffusion control [17].

- -

- -

- Suitable properties can greatly enhance the reducibility of the pellet. Smaller pellets are reduced faster because of the shorter diffusion distances [20]. Pellets with high porosity and low tortuosity are reduced faster [14], and the impact of porosity is more pronounced at higher temperatures [6]. In addition, natural hematite is more suitable than natural magnetite for reduction since the former is porous and the latter is dense [21]. The reduction is facilitated in pellets with microstructures that feature small grains and a high density of defects [22,23].

- -

- Models that can simulate the reduction of single pellets for a broad range of operating parameters and pellet properties are crucial for the optimization of the H2-DR process. Tsay applied a three-interface shrinking core model (3SCM) to simulate hydrogen reduction experiments with great success [24]. The three interfaces separate shells of Fe, FexO, Fe3O4, and Fe2O3. This model serves as a basis for most of the integrated models that simulate the behavior of the H2-DRSF [3]. However, SEM observations revealed that the oxides are reduced in a diffuse zone and not at sharp interfaces, as assumed in the 3SCM [1,3]. A more sophisticated model that better reflects the actual pellet structure (a porous pellet made up of small grains) is the grain model (GM) [15,25]. In principle, the GM requires numerical integration over the pellet radius. However, an approximation of the GM, which is based on the law of additive reaction times (LART), was proposed by Sohn [26]. The concept of additive reaction times is similar to the sum of mass transfer resistances in series. With a constant reduction temperature (isothermal conditions) and constant molar fractions of gas (static gas conditions), the GM-LART calculation is analytical, which considerably reduces the computation time when it is incorporated into multiparticle reactor models. Under nonisothermal and dynamic gas conditions, the GM-LART can still be applied in differential form, and the approximation made by applying the LART remains very satisfactory [26,27].

2. Materials and Methods

2.1. Raw Materials

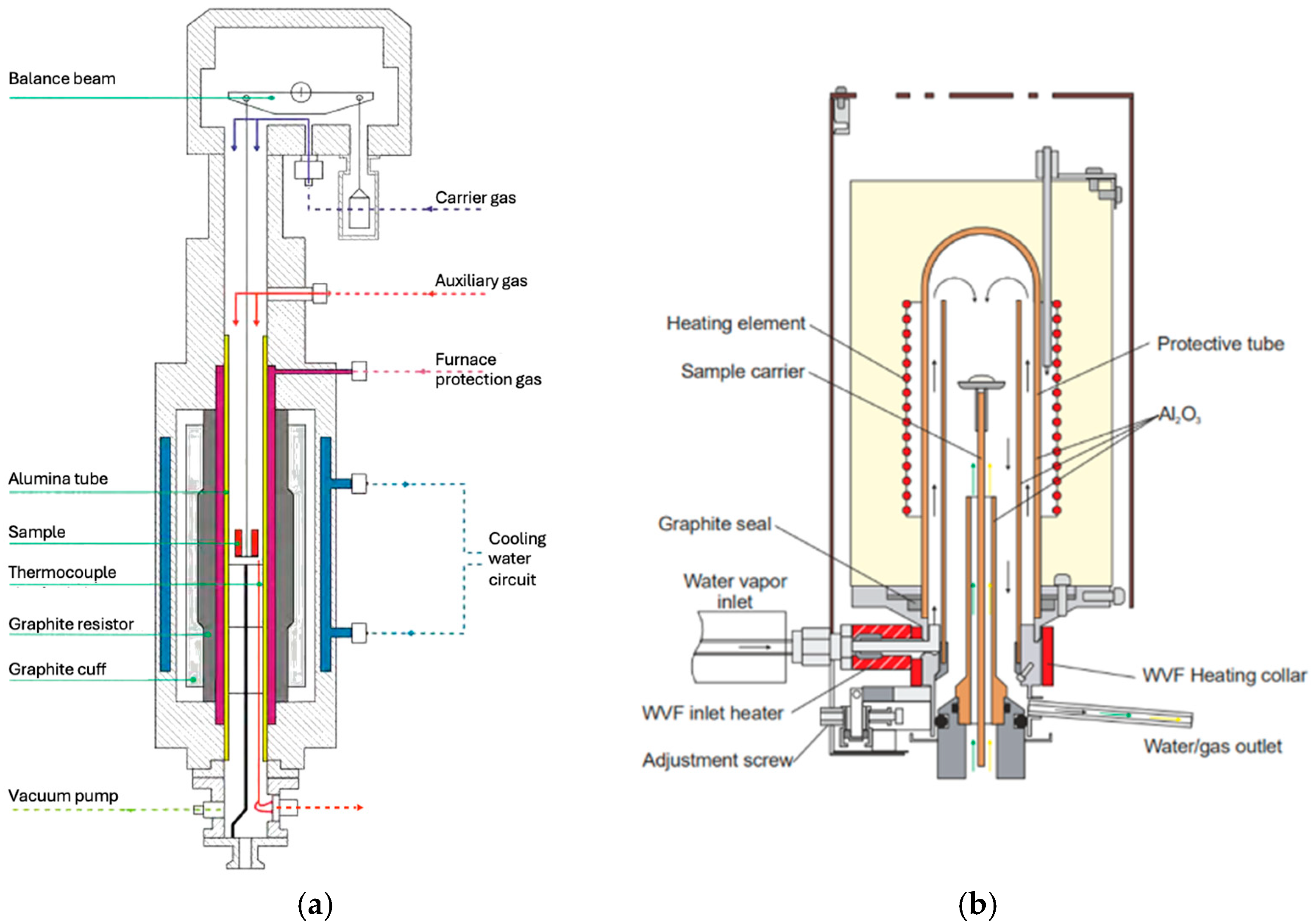

2.2. TGA Devices

2.3. Limits of Isothermal and Static Gas TGA

2.4. Modified Grainy Pellet Model (MGPM)

- -

- The model describes the reduction of a spherical iron ore pellet in a gas mixture (H2, H2O, He, and N2) at T > 570 °C.

- -

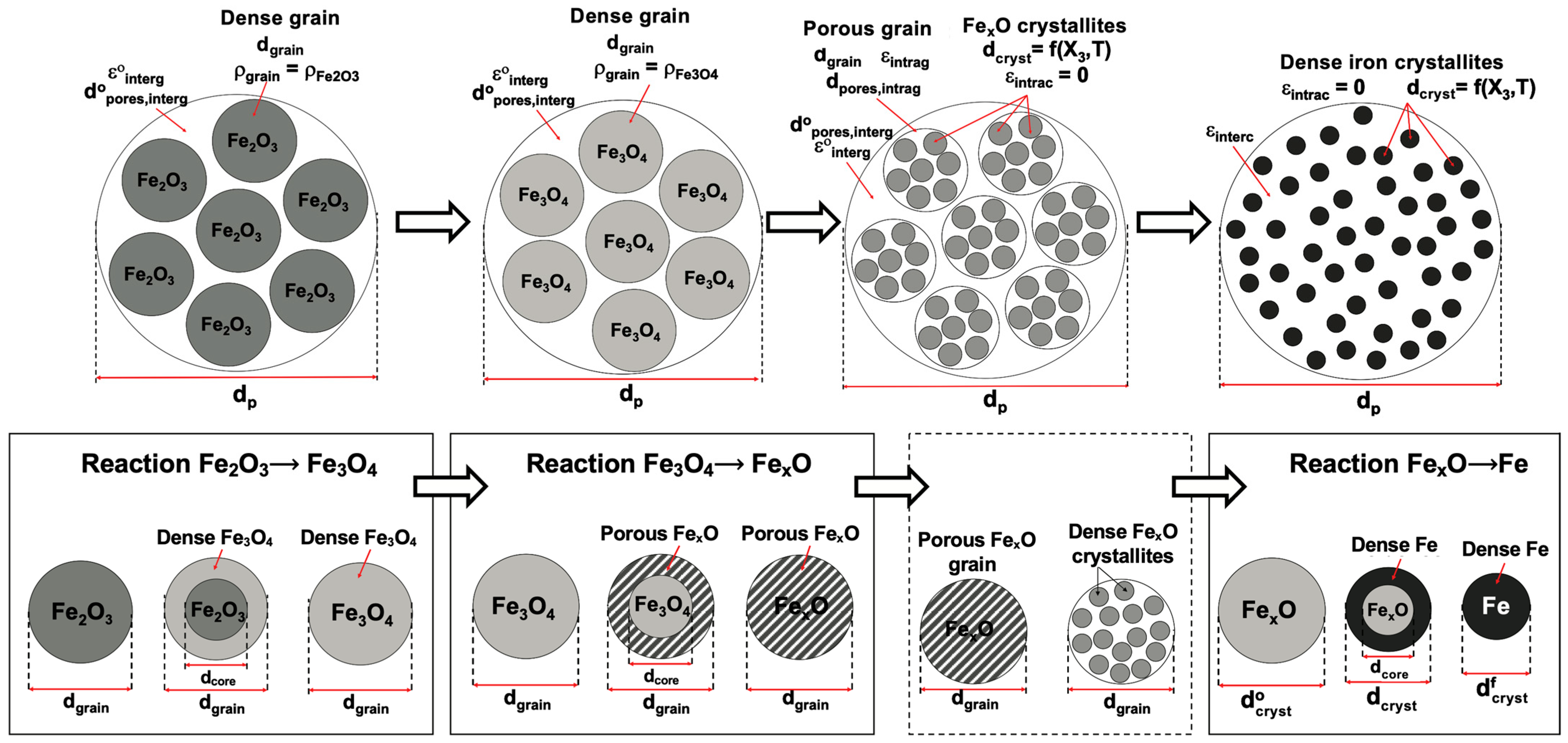

- A pellet of constant size (usually in the range of 10–15 mm) is considered to be made up of monosized grains (Figure 2). The initial hematite grain diameter is derived from the known initial specific area of the pellet.

- -

- As in [32], the dense grains of hematite are converted to dense grains of magnetite, which are then converted to porous grains of wustite. These wustite grains are made of smaller dense particles called crystallites, which are converted to dense iron during the last reduction stage.

- -

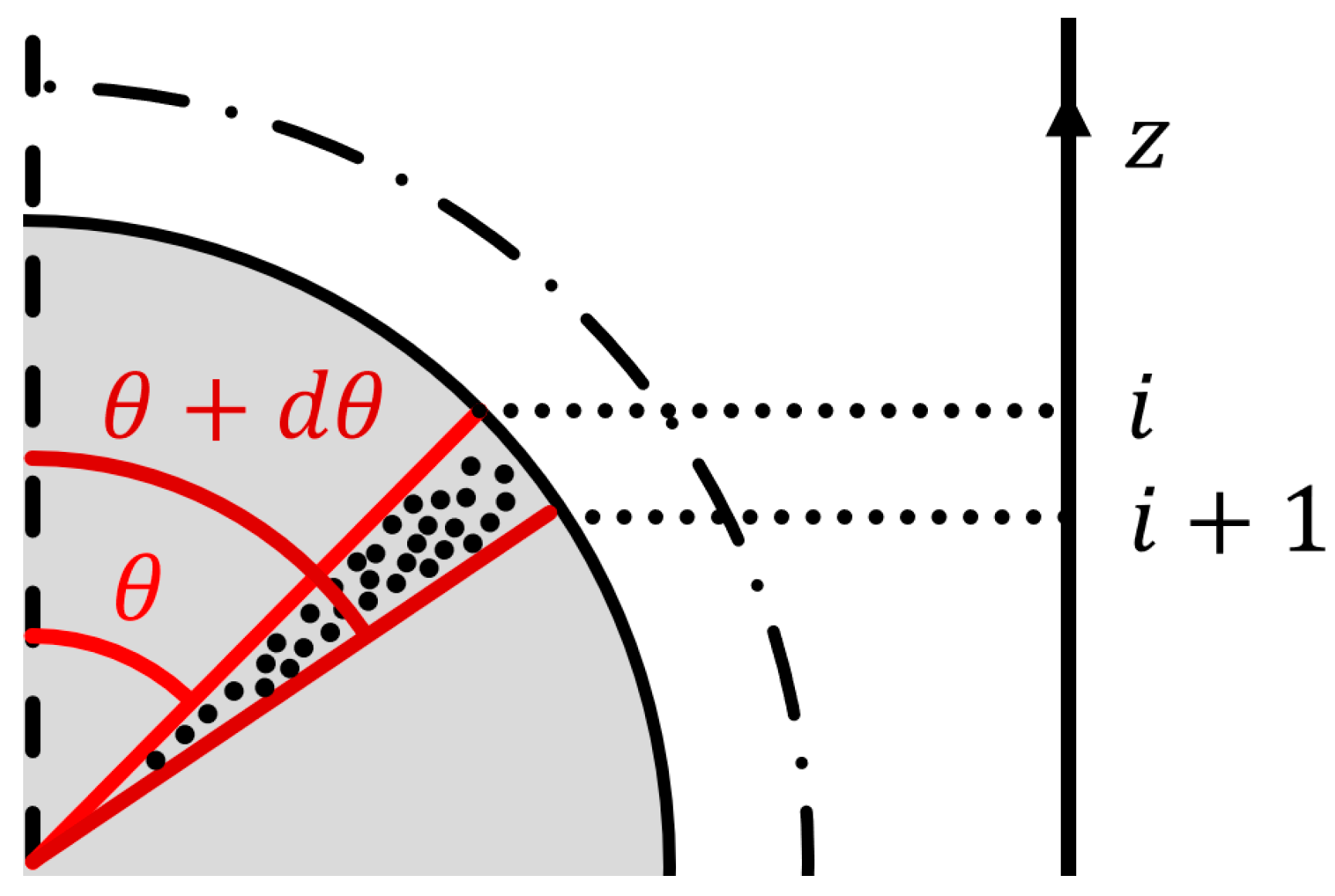

- The TGA furnace is axially discretized. A time-dependent 1-D finite-volume method is implemented, and the numerical resolution is achieved through a Gauss-Seidel algorithm using an upwind scheme. We retained a 1-D model as a simplification able to consider the vertical gradients of gas composition resulting from the reactant gas consumption and product gas production. Horizontally, the average gas composition is considered; the radial gradients, if any, are not described.

- -

- The pellet is discretized into slices, as shown in Figure 3, to match the axial discretization of the furnace. This enables us to relate the local bulk gas composition to the local reaction rate. The gas contained in the volume between the axial indices i and i + 1 is considered to reduce the grains of the pellet located between the polar angles θ and θ + dθ.

- -

- Unlike other models in the literature, e.g., [6], the gas velocity is not calculated inside the pellet: it is assumed—for modeling—that the gas that reacts in a given slice enters and exits in the same slice. This leads to a much simpler calculation.

- -

- At each time step, the grains in the slice (θ, θ + dθ) react according to the GM–LART model [32]. Characteristic time constants are calculated for each solid slice and each subreaction on the basis of the local temperature and gas composition. Each of these time constants accounts for the influence of a potential rate-limiting phenomenon (namely, mass transfer of the reactant gas, pore diffusion, solid-state diffusion and local chemical reactions). All time constants used in the model are given in the Appendix A. The instantaneous rate of each subreaction is obtained from the law of additive reaction times in its differential form [26]:where the functions and are the time derivatives of the conversion functions related to each phenomenon (Table A1). Solid conversion is then readily obtained from first-order Euler integration.

- -

- Additionally, the gas composition is also calculated for each axial slice (i,i + 1) at each time step. is obtained from a simplified mass balance:The gas source term is obtained from the initial apparent molar density of hematite, a geometric factor relating the volume of the solid to the height of the axial slice, and the reaction rate of the global reduction reaction:For clarity, a computation flow chart of the new model is given in Figure 4.

3. Results

3.1. Kinetic Parameter Estimation

3.2. Validation Against Fixed Bed Experimental Results

3.3. Kinetic Regime

3.4. Parametric Study—Both Experimental and Numerical

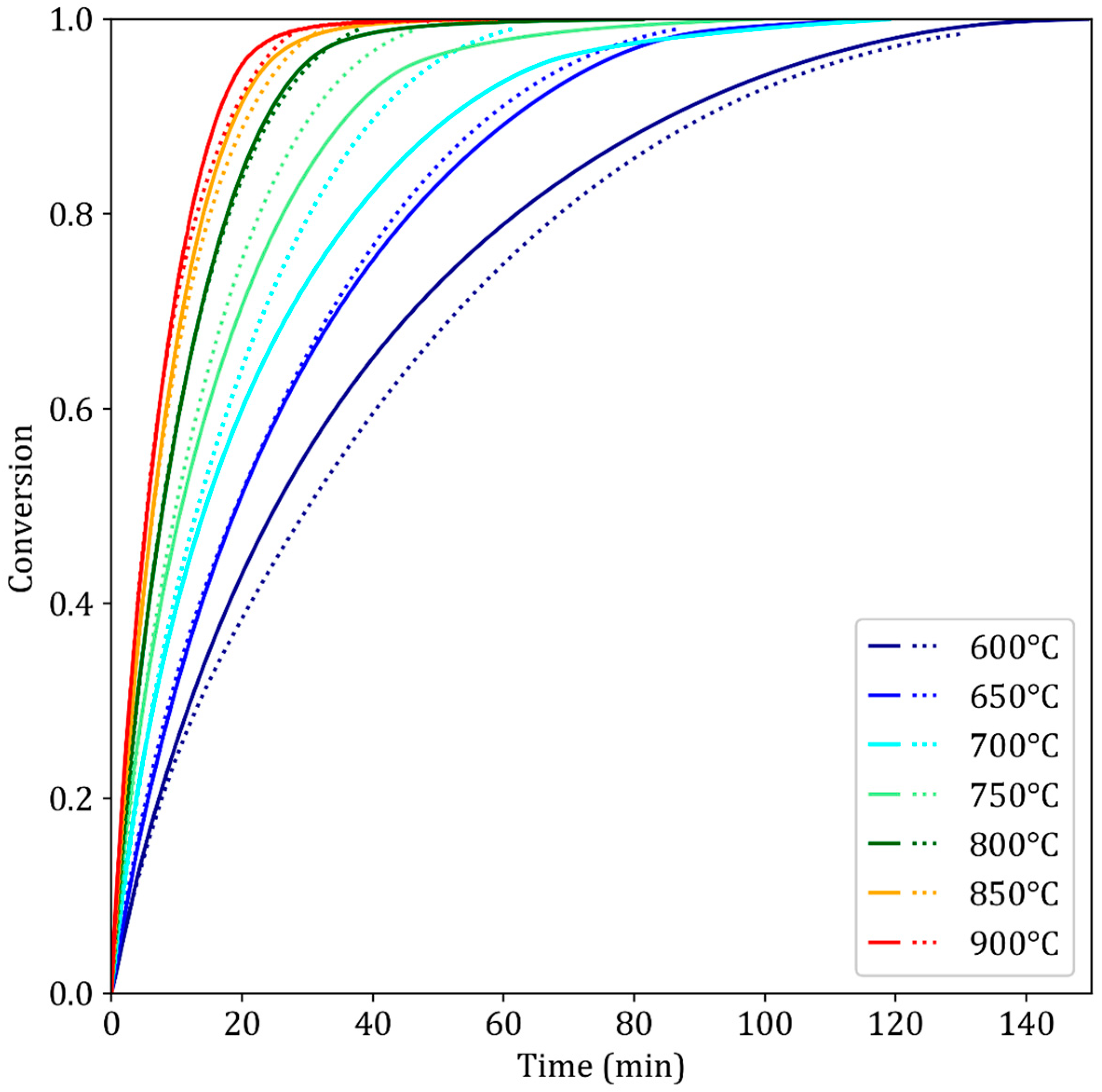

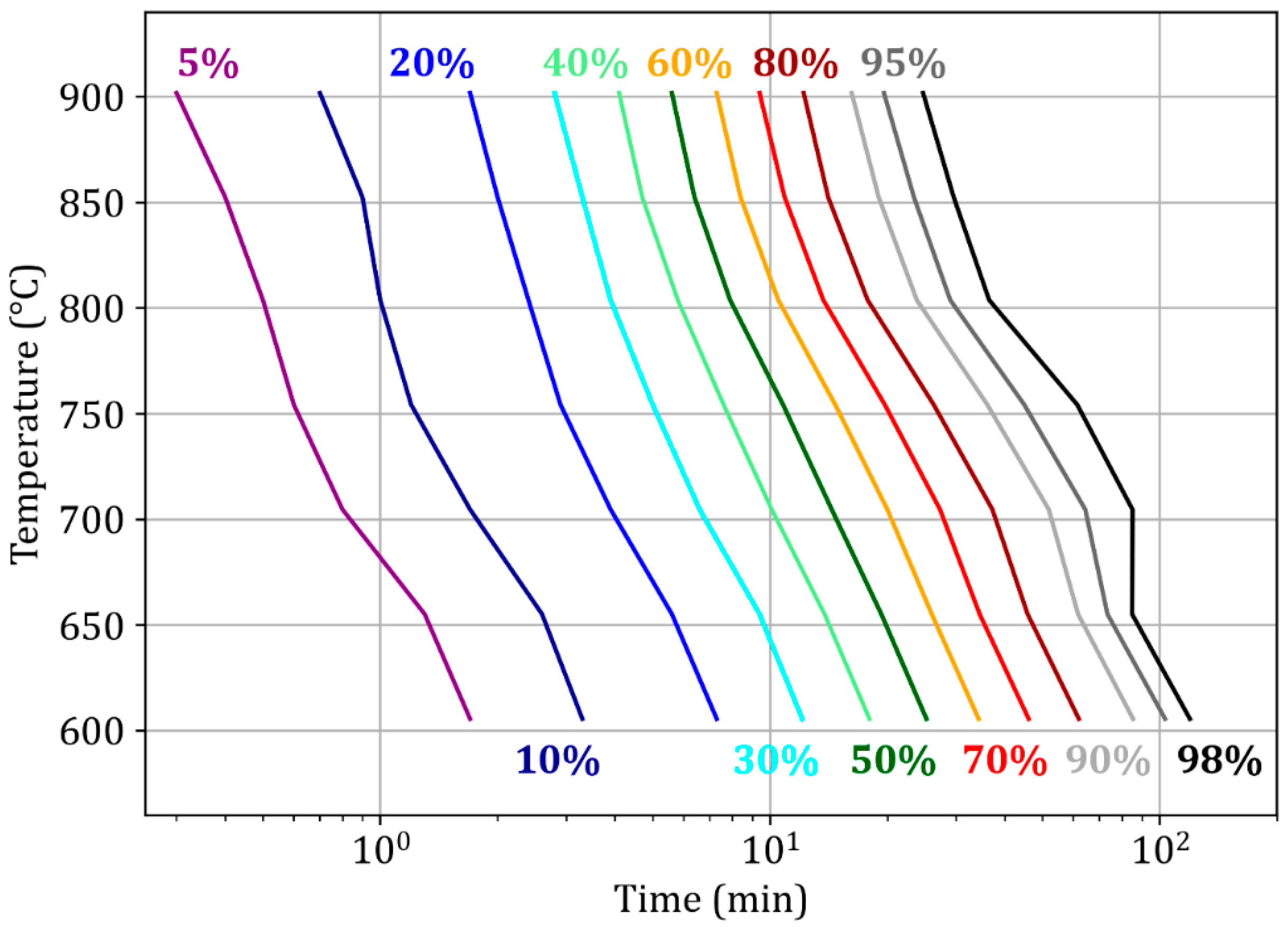

3.4.1. Effect of Temperature

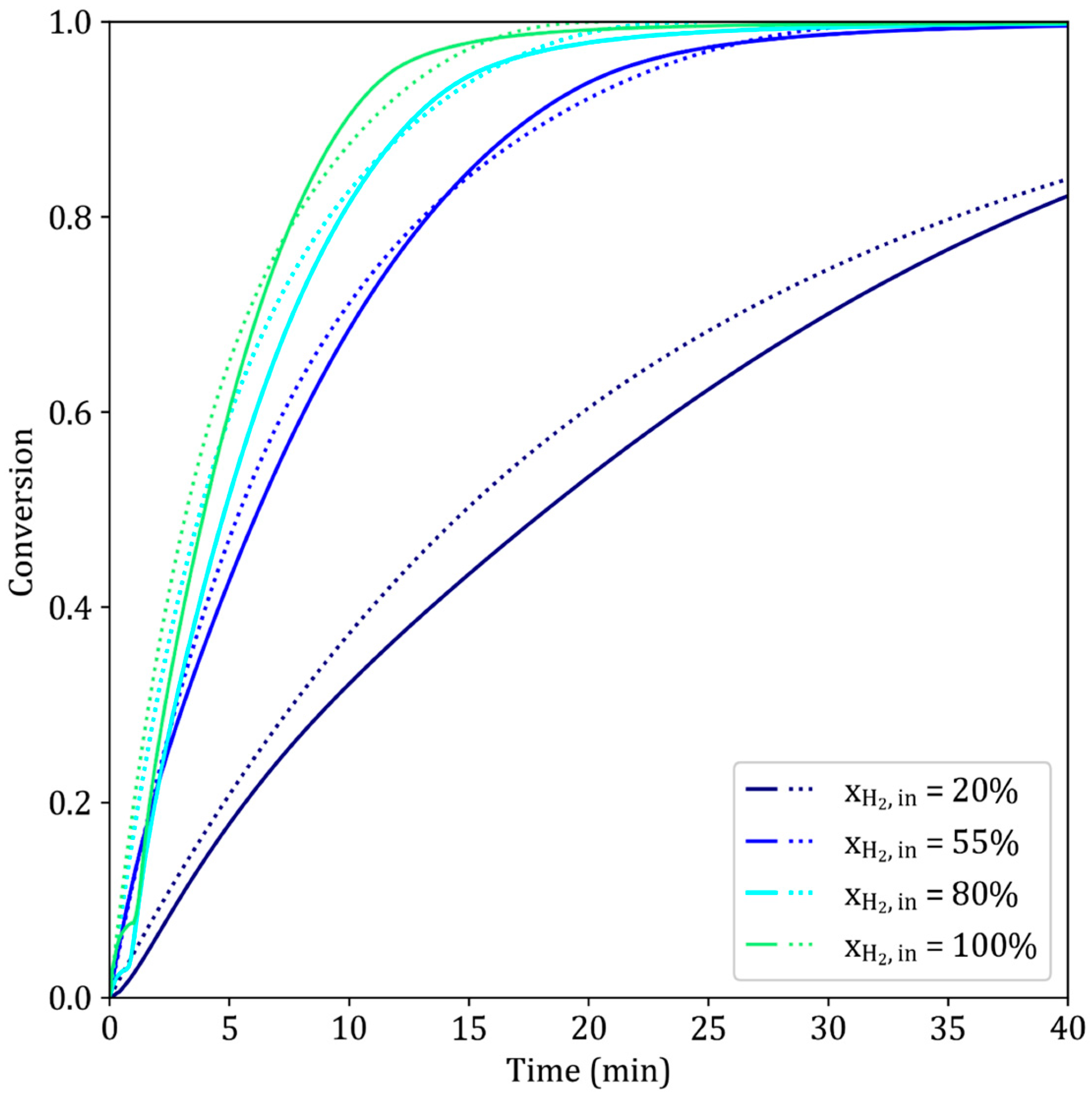

3.4.2. Effect of Dilution in Helium

3.4.3. Effect of the Gas Flow Rate

3.4.4. Effect of the Inlet Water Vapor Content

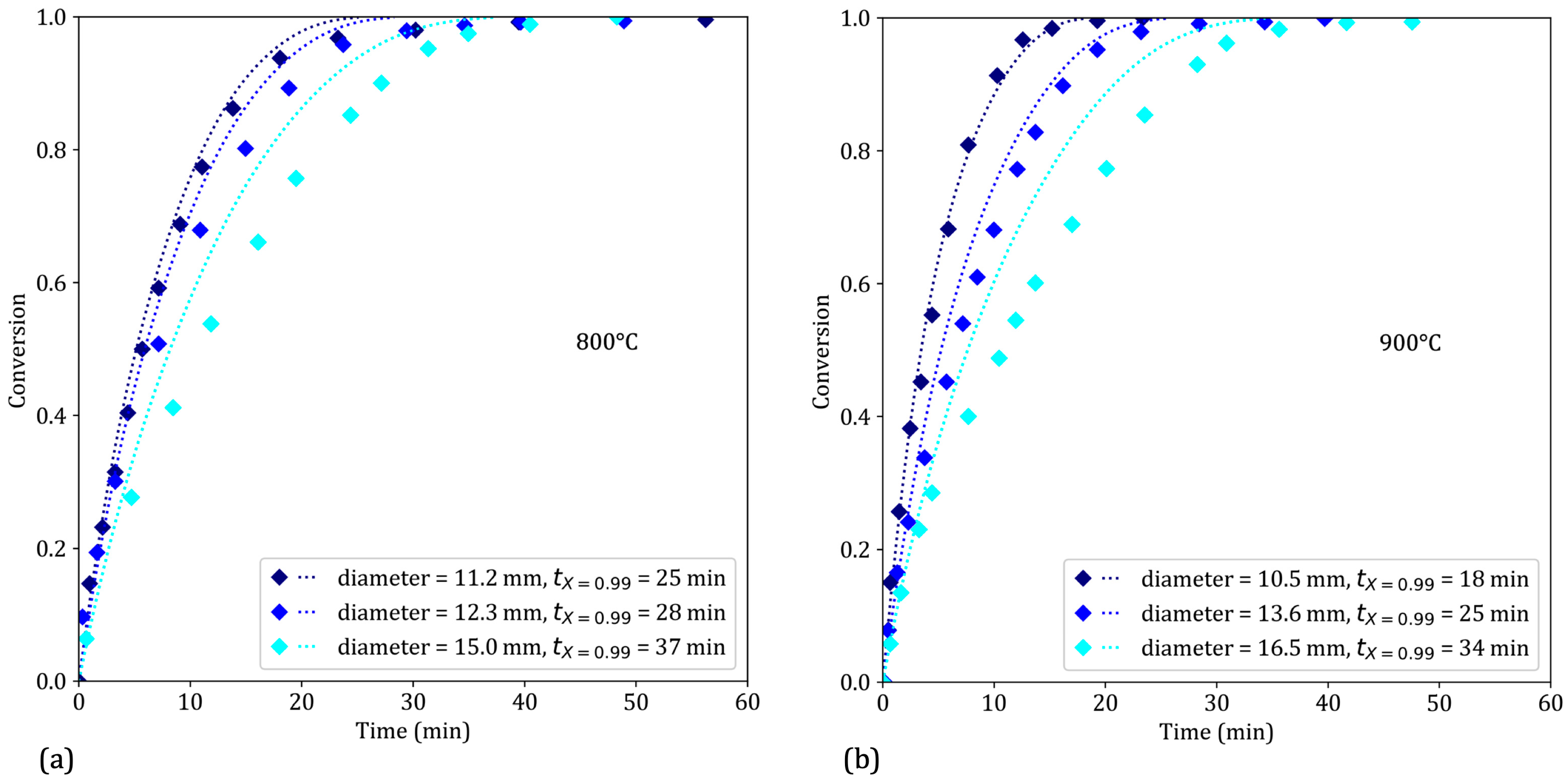

3.4.5. Effect of the Pellet Size

3.5. Parametric Study—Numerical

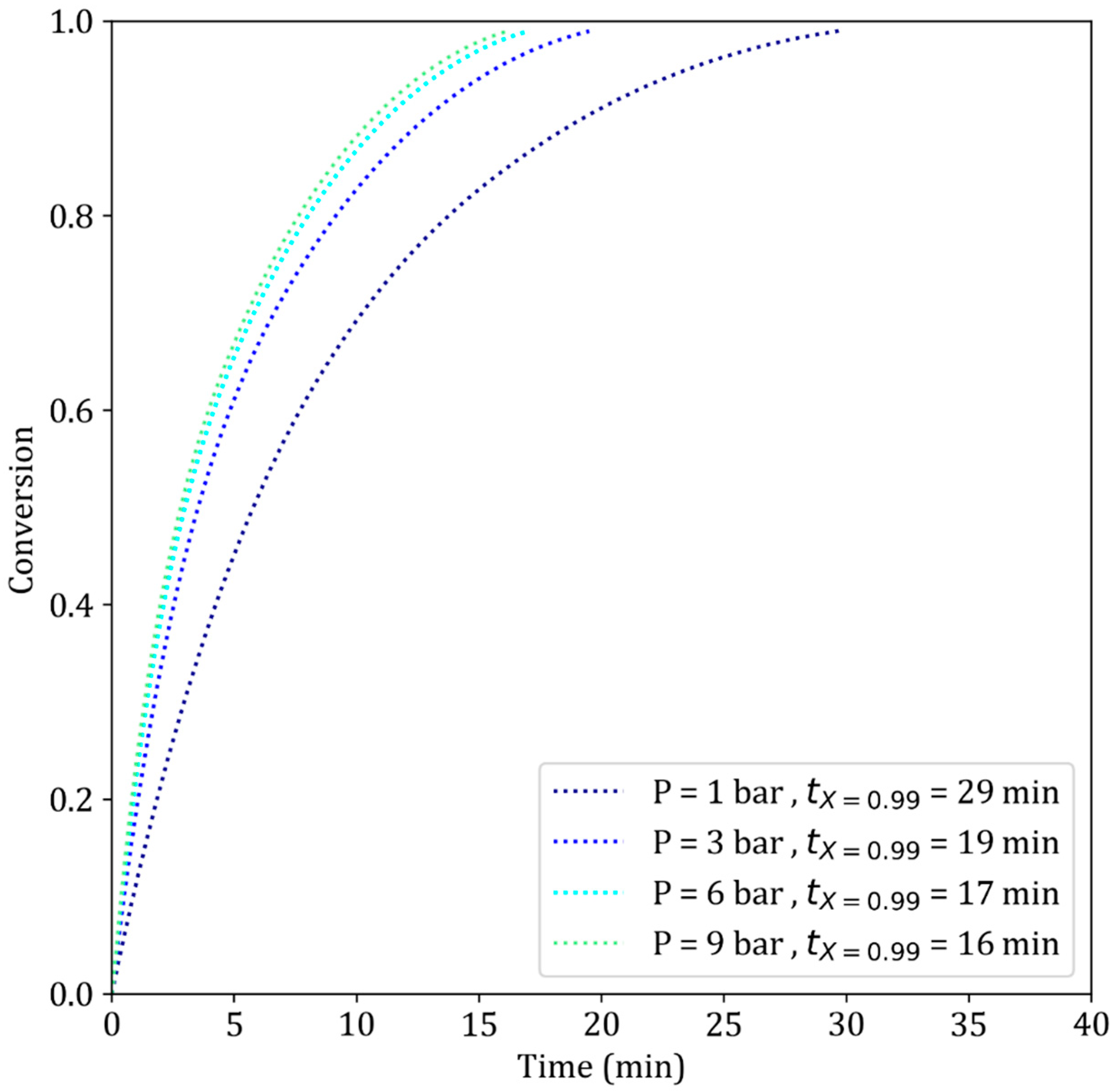

3.5.1. Effect of Pressure

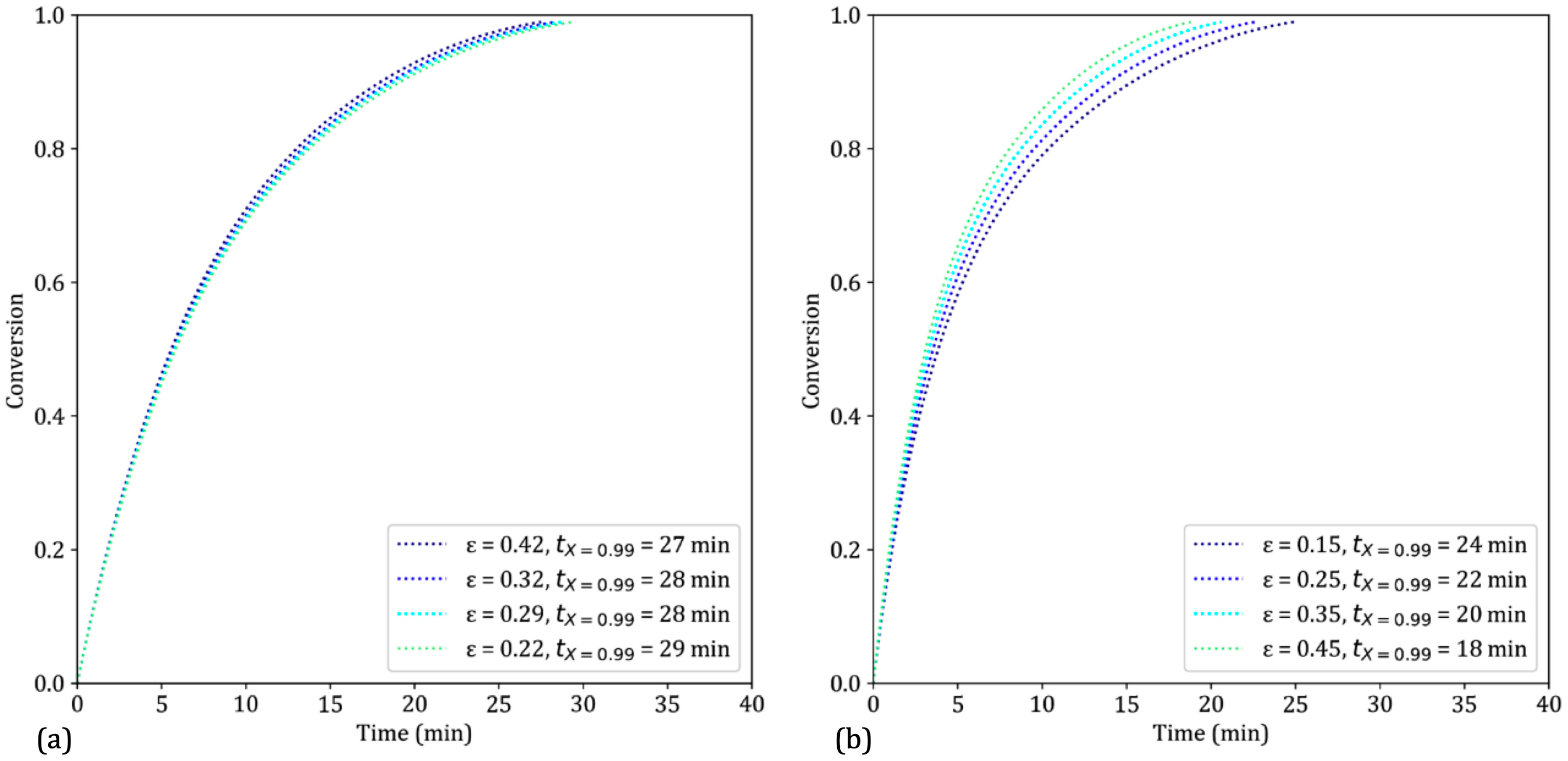

3.5.2. Effect of the Initial Porosity

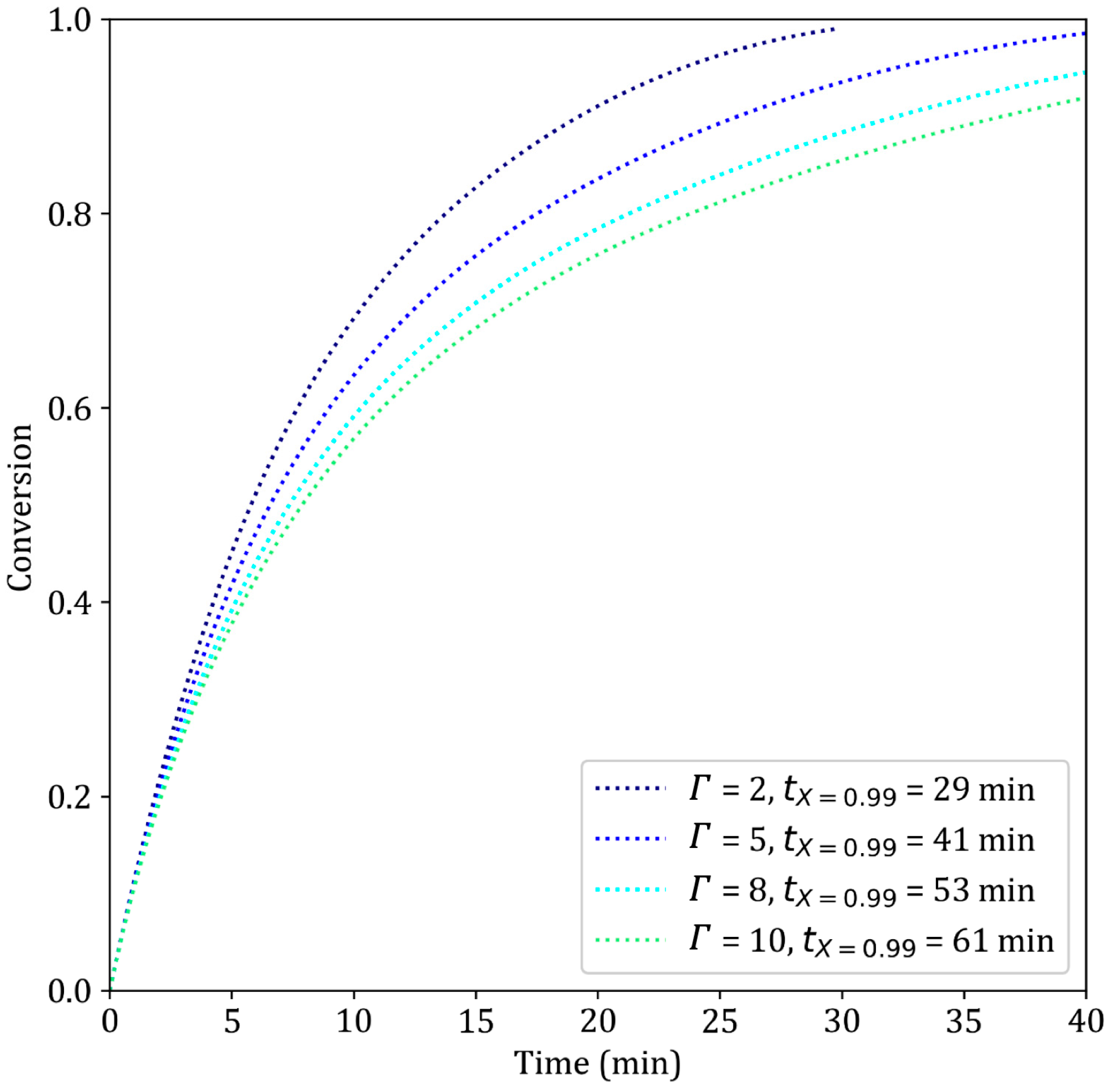

3.5.3. Effect of Tortuosity

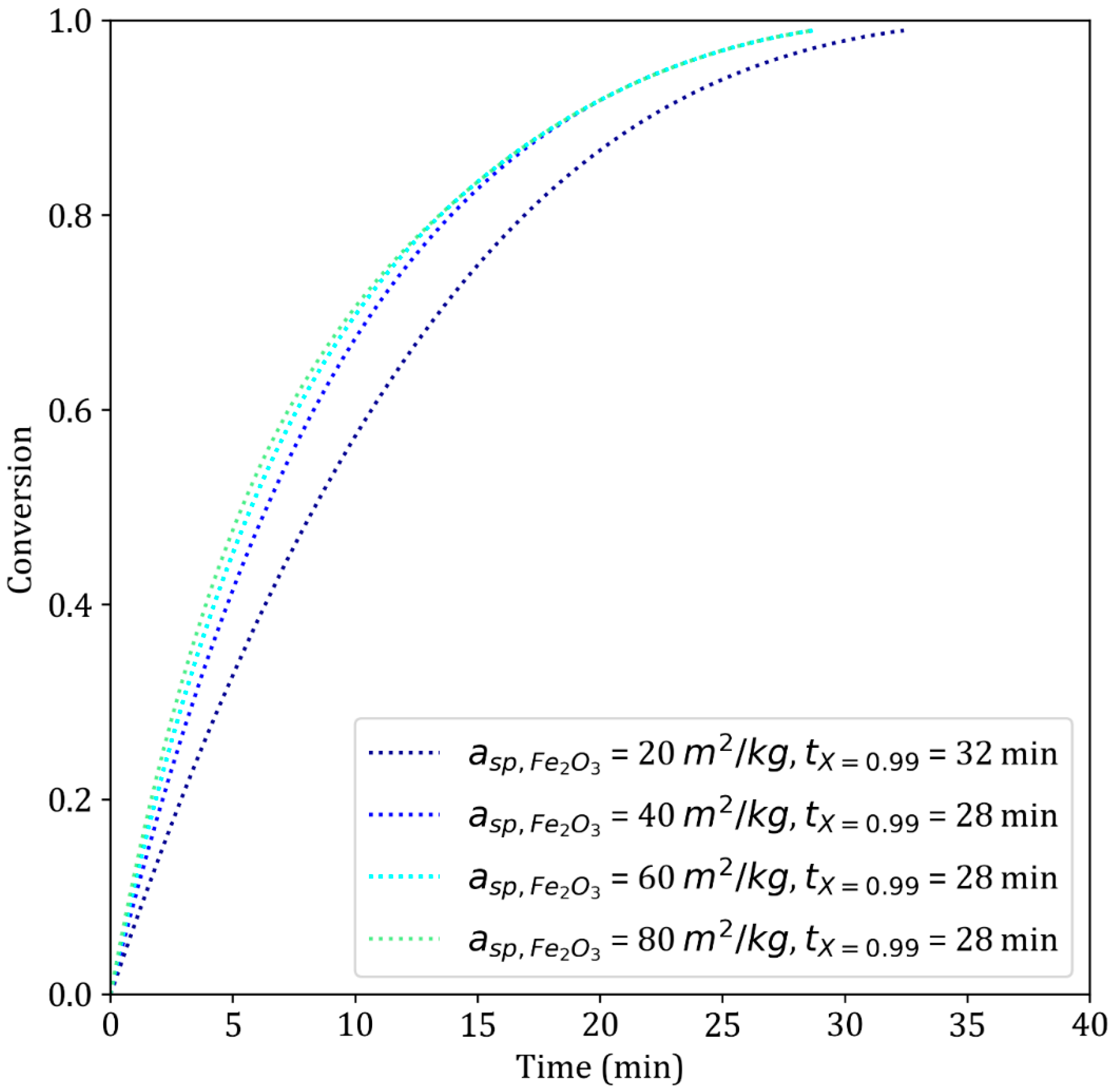

3.5.4. Effect of the Initial Specific Surface Area

3.6. General Discussion

- -

- The reduction of iron oxides with hydrogen is limited mainly by the local chemical reactions, also called phase-boundary control [38]. The numerical parametric study conducted with the model shows that decreasing the diffusion resistance, e.g., increasing the porosity, has quite limited effects on the reduction rate.

- -

- The results indicate that the major parameters to be tuned for the reduction of iron ore pellets are the reduction temperature and the pellet diameter, which agrees with [10]. The molar fraction of hydrogen also plays a great role (if it is diluted or not), as do the molar fraction of water vapor, the initial amount of oxides and the gas flow rate, as corroborated by [19]. Conversely, the initial porosity does not seem to play such an important role in the reduction reaction, as previously observed by [10].

- -

- For moderate flow rates (e.g., 1 Nlpm H2), a high reaction rate leads to substantial hydrogen depletion in the furnace. The atmosphere is partially replaced with water vapor, so assuming a static gas atmosphere is not reasonable. Thus, traditional single pellet reduction models (SCM and GM) cannot correctly describe the reduction reaction at low to medium flow rates in a laboratory furnace. More recent studies [8,9,40] tend to incorporate this evolution of the gas mixture during reduction using more complex models than the present model does. Note that industrial blast or shaft furnaces are not likely concerned by local hydrogen depletion in view of the high gas flow rates used.

- -

- In situations of high water vapor content and hydrogen depletion, discrepancies appear between the simulation and experimental results. This is the case for situations with low flow rates, large pellet diameters and high inlet water vapor contents. According to the literature, this is probably due to the poisoning effect of water vapor, which is adsorbed at reaction sites [38,39]. The decrease in the number of reaction sites available for hydrogen reduction hinders nucleation, which leads to a major slowdown at the start of the third reaction.

- -

- Most operating parameters are directly related to one another in such a way that the analysis is quite intricate. For example, increasing the size of the pellet also increases the amount of oxides to be reduced, which can lead to hydrogen depletion in the furnace and complicate the analysis.

- -

- One possible way to separate the contributions of gas diffusion and local chemical reactions is to study the reduction under specific operating conditions. The high temperature, large diameter and high pressure make the diffusion rate-limiting [13,17]. Conversely, low temperatures, small diameters and low pressures make the local chemical reaction rate-limiting.

4. Conclusions

- -

- The model can qualitatively and quantitatively describe the reduction of an iron ore pellet across a wide range of operating conditions, especially under dynamic gas conditions.

- -

- For the temperature range considered (600–900 °C), there is a direct link between the reduction of a pellet in a TGA system and the reduction of iron ore pellets in a small fixed bed. No particular effect of the bed on the reduction rate was observed.

- -

- The most decisive parameters for increasing the reaction rate are the temperature, pellet diameter, pressure, gas flow rate and gas composition. The initial porosity of a sample does not seem to have a major influence on the reaction rate. The graphical abstract schematically illustrates these results.

- -

- The measured rate of reduction of iron oxides in the presence of a high water vapor content is lower than what is simulated. The same is observed in situations where the pellet is large or the gas flow rate is very low. This is attributed to the poisoning effect of water vapor, which adsorbs on reaction sites instead of hydrogen.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CFD | Computational fluid dynamics |

| GM | Grain model |

| H2-DR | Hydrogen direct reduction of iron ore |

| H2-DRSF | Hydrogen direct reduction shaft furnace |

| LART | Law of additive reaction times |

| MGPM | Modified grainy pellet model |

| SCM | Shrinking core model |

| SEM | Scanning electron microscopy |

| TGA | Thermogravimetry analysis |

| TTT | Time-temperature-transformation |

Nomenclature

| Latin | |

| Initial specific area of the hematite pellets, m2 kg−1 | |

| ct | Molar concentration of the gas mixture, mol m−3 |

| d0,cryst | Diameter of the crystallites at the wustite stage, m |

| dcryst | Diameter of the crystallites at the iron stage, m |

| dfurnace | Furnace diameter, m |

| dgrain | Diameter of the grains of the pellet, m |

| dp | Diameter of the pellet, m |

| ds | Iron oxide characteristic diameter, m |

| Deff | Effective diffusion coefficient of the gas inside the pores, m2 s−1 |

| DKn | Knudsen diffusion coefficient of the gas inside the pores, m2 s−1 |

| Dmix | Molecular diffusion coefficient of hydrogen in the gas, m2 s−1 |

| Ea | Activation energy related to a chemical kinetic constant, J mol−1 |

| f, g, h | Conversion functions (Table A1) |

| Fg | Gas flow rate, m3 s−1 |

| fm | Reaction driving force, mol m−3 |

| k | Kinetic factor associated with a characteristic time, m s−1 |

| k0 | Frequency factor associated with a chemical kinetic constant, m s−1 |

| m | Pellet mass, kg |

| P | Gas pressure, bar |

| R | Ideal gas constant, J mol−1 K−1 |

| rX | Reaction rate, s−1 |

| SH2,i | Source term, mol s−1 m−3 |

| t | Time, s |

| tX | Time to reach a specific conversion degree, s |

| T | Temperature, K |

| uz | Axial superficial velocity of the gas, m s−1 |

| wj | Pellet mass fraction of species j |

| xj | Gas molar fraction of species j |

| X | Conversion degree |

| z | Vertical coordinate, m |

| Zi | Vertical position of slice i |

| Greek | |

| α | Stoichiometric factor associated with a characteristic time |

| Γ | Pellet tortuosity |

| ϵ | Pellet porosity |

| θ | Polar angle |

| Iron oxide molar density, mol m−3 | |

| Initial mass density of the pellet, kg m−3 | |

| τ | Characteristic time, s |

| Subscripts | |

| j | Reduction reaction index, j = 1,2 or 3 |

| z | Axial coordinate |

| X | Iron oxide conversion |

| chem | Local chemical reaction |

| diff | Gas diffusion in the pores |

| ext | Gas external diffusion |

Appendix A. Characteristic Time Constants

| Hematite → Magnetite | Magnetite → Wustite | Wustite → Iron | |

|---|---|---|---|

| External mass transfer | |||

| Intergrain diffusion | / | ||

| Intragrain diffusion | / | / | |

| Intercrystallite diffusion | / | / | |

| Solid–state diffusion | / | / | |

| Local chemical reaction | |||

| The conversion functions below are the same for the three subreactions | |||

| Chemical conversion function | |||

| Diffusion conversion function | |||

| External transfer conversion function | |||

References

- Patisson, F.; Mirgaux, O. Hydrogen Ironmaking: How It Works. Metals 2020, 10, 922. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Brooks, G.; Rhamdhani, M.A. Decarbonisation and Hydrogen Integration of Steel Industries: Recent Development, Challenges and Technoeconomic Analysis. J. Clean. Prod. 2023, 395, 136391. [Google Scholar] [CrossRef]

- Zare Ghadi, A.; Radfar, N.; Valipour, M.S.; Sohn, H.Y. A Review on the Modeling of Direct Reduction of Iron Oxides in Gas-Based Shaft Furnaces. Steel Res. Int. 2023, 94, 2200742. [Google Scholar] [CrossRef]

- MaxH2DR. 2025. Available online: https://www.estep.eu/clean–steel–partnership/maxh2dr (accessed on 8 August 2025).

- Ali, M.L.; Fradet, Q.; Riedel, U. Particle-Resolved Computational Modeling of Hydrogen-Based Direct Reduction of Iron Ore Pellets in a Fixed Bed. Part I: Methodology and Validation. Int. J. Hydrogen Energy 2024, 87, 332–343. [Google Scholar] [CrossRef]

- Elsherbiny, A.A.; Qiu, D.; Wang, K.; Li, M.; Ahmed, M.; Hammam, A.; Zhu, Y.; Song, W.; Galal, A.M.; Chen, H.; et al. Parametric Study on Hematite Pellet Direct Reduction by Hydrogen. Powder Technol. 2024, 435, 119434. [Google Scholar] [CrossRef]

- Hessling, O.; Fogelström, J.B.; Kojola, N.; Martinsson, J. Influence of Water Content on the Kinetics and Mechanisms of Hydrogen Reduction Using Industrial Iron Ore Pellets at 873 K–1173 K. ISIJ Int. 2024, 64, 1493–1502. [Google Scholar] [CrossRef]

- Kazemi, M.; Pour, M.S.; Sichen, D. Experimental and Modeling Study on Reduction of Hematite Pellets by Hydrogen Gas. Met. Mater. Trans. B 2017, 48, 1114–1122. [Google Scholar] [CrossRef]

- Meshram, A.; Govro, J.; OMalley, R.J.; Sridhar, S.; Korobeinikov, Y. Modeling Isothermal Reduction of Iron Ore Pellet Using Finite Element Analysis Method: Experiments & Validation. Metals 2022, 12, 2026. [Google Scholar] [CrossRef]

- Metolina, P.; Ribeiro, T.R.; Guardani, R. Hydrogen-Based Direct Reduction of Industrial Iron Ore Pellets: Statistically Designed Experiments and Computational Simulation. Int. J. Miner. Met. Mater. 2022, 29, 1908–1921. [Google Scholar] [CrossRef]

- Ohmi, M.; Usui, T. Improved Theory on the Rate of Reduction of Single Particles and Fixed Beds of Iron Oxide Pellets with Hydrogen. Trans. Iron Steel Inst. Jpn. 1982, 22, 66–74. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P.; Bayat, M.; Ebrahimzadeh Esfahani, N.; Laska, A.; Koszelow, D. Experimental Study and Numerical Simulation on Porosity Dependent Direct Reducibility of High-Grade Iron Oxide Pellets in Hydrogen. Int. J. Hydrogen Energy 2024, 69, 586–607. [Google Scholar] [CrossRef]

- Turkdogan, E.T.; Vinters, J.V. Gaseous Reduction of Iron Oxides: Part I. Reduction of Hematite in Hydrogen. Met. Trans. 1971, 2, 3175–3188. [Google Scholar] [CrossRef]

- Valipour, M.S.; Motamed Hashemi, M.Y.; Saboohi, Y. Mathematical Modeling of the Reaction in an Iron Ore Pellet Using a Mixture of Hydrogen, Water Vapor, Carbon Monoxide and Carbon Dioxide: An Isothermal Study. Adv. Powder Technol. 2006, 17, 277–295. [Google Scholar] [CrossRef]

- Szekely, J.; Evans, J.W.; Sohn, H.Y. Gas-Solid Reactions; Academic Press: New York, NY, USA, 1976. [Google Scholar]

- El-Geassy, A.A. Gaseous Reduction of Fe2O3 Compacts at 600 to 1050 °C. J. Mater. Sci. 1986, 21, 3889–3900. [Google Scholar] [CrossRef]

- Olsson, R.G.; McKewan, W.M. Diffusion of H2-H2O through Porous Iron Formed by the Reduction of Iron Oxides. Met. Trans. 1970, 1, 1507–1512. [Google Scholar] [CrossRef]

- Özgün, Ö.; Dirba, I.; Gutfleisch, O.; Ma, Y.; Raabe, D. Green Ironmaking at Higher H2 Pressure: Reduction Kinetics and Microstructure Formation During Hydrogen-Based Direct Reduction of Hematite Pellets. J. Sustain. Metall. 2024, 10, 1127–1140. [Google Scholar] [CrossRef]

- Fradet, Q.; Kurnatowska, M.; Riedel, U. Thermochemical Reduction of Iron Oxide Powders with Hydrogen: Review of Selected Thermal Analysis Studies. Thermochim. Acta 2023, 726, 179552. [Google Scholar] [CrossRef]

- Zhang, A.; Monaghan, B.J.; Longbottom, R.J.; Nusheh, M.; Bumby, C.W. Reduction Kinetics of Oxidized New Zealand Ironsand Pellets in H2 at Temperatures up to 1443 K. Met. Mater. Trans. B 2020, 51, 492–504. [Google Scholar] [CrossRef]

- Edström, J.O. The Mechanism of Reduction of Iron Oxides. J. Iron Steel Inst. 1953, 175, 289–304. [Google Scholar]

- Kim, S.-H.; Zhang, X.; Ma, Y.; Souza Filho, I.R.; Schweinar, K.; Angenendt, K.; Vogel, D.; Stephenson, L.T.; El-Zoka, A.A.; Mianroodi, J.R.; et al. Influence of Microstructure and Atomic-Scale Chemistry on the Direct Reduction of Iron Ore with Hydrogen at 700 °C. Acta Mater. 2021, 212, 116933. [Google Scholar] [CrossRef]

- Ma, Y.; Souza Filho, I.R.; Zhang, X.; Nandy, S.; Barriobero-Vila, P.; Requena, G.; Vogel, D.; Rohwerder, M.; Ponge, D.; Springer, H.; et al. Hydrogen-Based Direct Reduction of Iron Oxide at 700 °C: Heterogeneity at Pellet and Microstructure Scales. Int. J. Miner. Met. Mater. 2022, 29, 1901–1907. [Google Scholar] [CrossRef]

- Tsay, Q.T.; Ray, W.H.; Szekely, J. The Modeling of Hematite Reduction with Hydrogen plus Carbon Monoxide Mixtures: Part I. The Behavior of Single Pellets. AIChE J. 1976, 22, 1064–1072. [Google Scholar] [CrossRef]

- Skaf, A.; Tiruta-Barna, L.; Ahmadi, A. Assessing the Potential of Low-Temperature Ironmaking Using Pure Hydrogen in Shaft Reactors. Chem. Eng. Sci. 2025, 304, 121049. [Google Scholar] [CrossRef]

- Sohn, H.Y. The Law of Additive Reaction Times in Fluid-Solid Reactions. Met. Trans. B 1978, 9, 89–96. [Google Scholar] [CrossRef]

- Dussoubs, B.; Jourde, J.; Patisson, F.; Houzelot, J.-L.; Ablitzer, D. Modelling of a Moving Bed Furnace for the Production of Uranium Tetrafluoride. Part 2: Application of the Model. Chem. Eng. Sci. 2003, 58, 2629–2642. [Google Scholar] [CrossRef]

- MaxH2DR. 2025. Available online: https://www.estep.eu/assets/Projects/MaxH2DR/MaxH2DR_D2_D1.2_Procedures–for–the–determination–of–physical–properties–of–DR–raw–materials–intermediate–and–products.pdf (accessed on 8 August 2025).

- Ohmi, M.; Usui, T.; Naito, M.; Minamide, Y. Experimental Study of the Resistance Due to the Rate of Gas Flow on the Hydrogen Reduction of an Iron Oxide Pellet. ISIJ Int. 1983, 23, 81–89. [Google Scholar] [CrossRef]

- Kang, H.; Xu, Q.; Cao, Z.; Lu, X.; Shi, J.; Chen, B.; Guo, L. Influence of Hydrogen Flow Rate on Multistep Kinetics of Hematite Reduction. Int. J. Hydrogen Energy 2024, 49, 1255–1268. [Google Scholar] [CrossRef]

- Hessling, O. Some Aspects of Hydrogen Reduction of Iron Ore; KTH Royal Institute of Technology: Stockholm, Sweden, 2024. [Google Scholar]

- Ranzani Da Costa, A.; Wagner, D.; Patisson, F. Modelling a New, Low CO2 Emissions, Hydrogen Steelmaking Process. J. Clean. Prod. 2013, 46, 27–35. [Google Scholar] [CrossRef]

- Takahashi, R.; Takahashi, Y.; Yagi, J.; Omori, Y. Operation and Simulation of Pressurized Shaft Furnace for Direct Reduction. ISIJ Int. 1986, 26, 765–774. [Google Scholar] [CrossRef]

- Ranzani da Costa, A. La Réduction du Minerai de fer par L’hydrogène: Étude Cinétique, Phénomène de Collage et Modélisation. Ph.D. Dissertation, Institut National Polytechnique de Lorraine, Nancy, France, 2011. [Google Scholar]

- Hara, Y.; Sakawa, M.; Kondo, S. Mathematical Model of the Shaft Furnace for Reduction of Iron-Ore Pellet. Tetsu-to-Hagané 1976, 62, 315–323. [Google Scholar]

- Pineau, A.; Kanari, N.; Gaballah, I. Kinetics of Reduction of Iron Oxides by H2. Thermochim. Acta 2006, 447, 89–100. [Google Scholar] [CrossRef]

- Garg, P.; Hu, X.; Li, Y.; Li, K.; Nag, S.; Zhang, J. Kinetics of Iron Oxide Reduction in H2/H2O Gas Mixture: Global and Stepwise Reduction. Met. Mater. Trans. B 2022, 53, 1759–1774. [Google Scholar] [CrossRef]

- Spreitzer, D.; Schenk, J. Reduction of Iron Oxides with Hydrogen—A Review. Steel Res. int. 2019, 90, 1900108. [Google Scholar] [CrossRef]

- Tokuda, M.; Yoshikoshi, H.; Ohtani, M. Kinetics of the Reduction of Iron Ore. ISIJ Int. 1973, 13, 350–363. [Google Scholar] [CrossRef]

- Fradet, Q.; Ali, M.L.; Riedel, U. Development of a Porous Solid Model for the Direct Reduction of Iron Ore Pellets. Steel Res. Int. 2022, 93, 2200042. [Google Scholar] [CrossRef]

- Brodkey, R.S.; Hershey, H.C. Transport Phenomena: A Unified Aprroach; Brodkey Publishing: New York, NY, USA, 2003. [Google Scholar]

| Pellet | Fe | SiO2 | CaO | Al2O3 | FeO | B2 | MnO | MgO | TiO2 | P2O5 |

|---|---|---|---|---|---|---|---|---|---|---|

| D1 ( < 13 mm) | 66.4 | 2.3 | 1.0 | 0.73 | 0.71 | 0.41 | 0.15 | 0.12 | 0.09 | 0.06 |

| D2 ( > 13 mm) | 67.1 | 2.0 | 0.9 | 0.56 | <0.1 | 0.47 | 0.14 | 0.12 | 0.08 | 0.06 |

| Hematite → Magnetite | Magnetite → Wustite | Wustite → Iron | |

|---|---|---|---|

| Frequency factor | |||

| Activation energy |

| Operating parameters | (Nlpm *) | P (bar) | (m) | ||

| 1.8 | 0.55 | 0.45 | 1 | 0.02 | |

| Pellet properties | (m) | (kg m−3) | (m2 kg−1) | ||

| 0.01282 | 0.963 | 0.037 | 3630 | 60.4 |

| 0.03 | 0.10 | 0.43 | 0.69 | |

| 0.04 | 0.01 | 0.11 | 0.15 | |

| 0.01 | 0.05 | 0.24 | 0.38 | |

| 0.05 | 0.16 | 0.60 | 0.99 | |

| 0.21 | 0.63 | 2.39 | 4.12 | |

| 0.07 | 0.16 | 0.5 | 0.8 | |

| 0.07 | 0.24 | 0.93 | 1.49 | |

| 0.006 | 0.02 | 0.44 | 0.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marsigny, A.; Letz, J.-B.; Mirgaux, O.; Patisson, F. Kinetics of the Reduction of Iron Ore Pellets with Hydrogen: A Parametric Experimental and Modeling Study. Metals 2025, 15, 1034. https://doi.org/10.3390/met15091034

Marsigny A, Letz J-B, Mirgaux O, Patisson F. Kinetics of the Reduction of Iron Ore Pellets with Hydrogen: A Parametric Experimental and Modeling Study. Metals. 2025; 15(9):1034. https://doi.org/10.3390/met15091034

Chicago/Turabian StyleMarsigny, Antoine, Jean-Baptiste Letz, Olivier Mirgaux, and Fabrice Patisson. 2025. "Kinetics of the Reduction of Iron Ore Pellets with Hydrogen: A Parametric Experimental and Modeling Study" Metals 15, no. 9: 1034. https://doi.org/10.3390/met15091034

APA StyleMarsigny, A., Letz, J.-B., Mirgaux, O., & Patisson, F. (2025). Kinetics of the Reduction of Iron Ore Pellets with Hydrogen: A Parametric Experimental and Modeling Study. Metals, 15(9), 1034. https://doi.org/10.3390/met15091034