1. Introduction

The future energy market outlook predicts a consistent increase in renewable energy sources, which are expected to overtake traditional energy sources with the goal of reducing CO2 emissions.

At the same time, the increase in renewable energy production has deeply affected the mix of power production in many countries. Industrial segments such as combined cycle plants (CCPs) have been especially affected by these modifications. With time, these assets have progressively switched from base-load to peak-load production, balancing the intermittent production of wind and solar plants. Consequently, CCPs have been forced to improve their fast start-up capability, making their design more and more challenging for turbomachinery manufacturers.

This scenario comes together with the global demand for an increase in the maximum allowed inlet temperature and pressure for both steam and gas turbines, considering the efficiency boost associated with a higher maximum temperature of the thermodynamic cycle. This temperature increase usually does not come together with the relaxation of the strict flexible operability constraints, such as start-up times, maintenance intervals, and number of cycles at end of life. An application where these trends are particularly stressed is also the implementation of expanders in concentrated solar plants (CSPs).

In this direction, in recent years, several works that aimed to increase the flexible operability of steam and gas turbines operating in CSPs and CCPs have been published [

1]. Another research trend looks at implementing smarter control loops that manage start-up requirements, such as the maximum allowed stress or strain during turbine start-up [

2,

3].

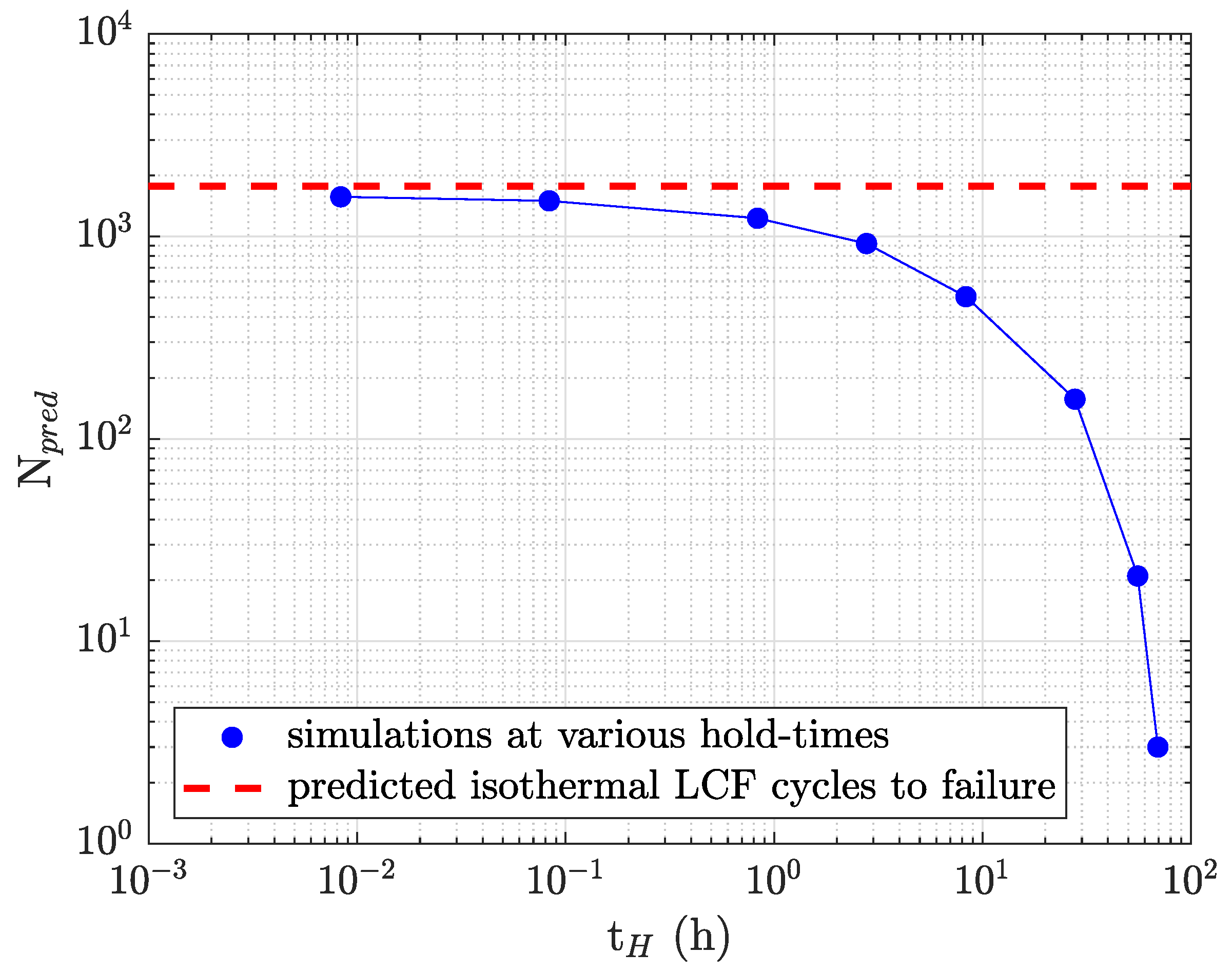

The underlying structural phenomena that have to be taken into account during the design of turbomachinery operating at high temperature under variable loading are creep and low-cycle-fatigue (LCF) induced by thermal loads. While, in the past, these two phenomena and their interaction could be addressed through rather conservative design rules and simple calculations, the market trends described up to now require much more advanced tools capable of capturing many aspects of the life consumption process.

At elevated temperatures, the combination of mechanical and thermal cyclic stresses can initiate and propagate cracks faster than predicted by the sequential analysis of creep and LCF life consumption [

4,

5]. The interaction of creep and fatigue results in complex failure modes [

6], including enhanced crack initiation due to cyclic plastic strain and accelerated crack growth facilitated by creep mechanisms such as grain boundary sliding and void nucleation. Studies have been conducted on the effect of prior creep on fatigue and of prior fatigue on creep, showing that both damage mechanisms exert a reciprocal influence on each other owing to their softening effect on the material [

7].

Looking at turbomachinery components, rotors represent a bottleneck for reductions in start-up time, usually being exposed to the highest temperature in the flow path of rotating equipment while having a higher heat capacity, usually resulting in the worst combination of creep and thermal fatigue damage. In addition, the rotor design usually needs to exclude the nucleation of cracks on their surface, since vibrations might lead to fast crack growth from thermally induced flaws. The application of fracture mechanics approaches, as a consequence, has limited applications in the area of the external surface of the rotor. However, the fracture mechanics methodology can be useful in developing damage-tolerant approaches to assess the criticality of forging defects below the rotor surface.

Common conservative design rules for pressurized components are also extended to the design of turbomachinery components such as casing and rotors. Examples are given by the guidelines outlined in the ASME Boiler and Pressure Vessel Code [

8] and the R5 assessment procedure for the high-temperature response of structures [

9].

The ASME Boiler and Pressure Vessel Code (BPVC), more specifically section III (for nuclear components) and section VIII (for pressure vessels), provides a framework for evaluating high-temperature design through design-by-analysis (DBA) methods. For creep–fatigue, the ASME BPVC incorporates a creep–fatigue damage summation. This approach typically uses a linear or bilinear damage rule, combining cyclic fatigue damage (based on the strain range and fatigue life) with creep damage (based on rupture life fractions) to assess total damage per cycle.

The ASME BPVC is considered conservative and ensures a high safety margin, often simplifying complex interactions to enable practical design evaluations. Just to help grasp the conservative approach followed by ASME, we can observe that after assessing the separate damage due to creep and fatigue, the BPVC prescribes the use of bilinear diagrams to assess the allowable combined damage fraction. Just to give an example, for materials such as the 9Cr-Mo-V class, ASME allows for only a 1% creep damage fraction for a 10% fatigue damage fraction, creating a challenging scenario for designers working in this field.

In contrast, the R5 procedure developed in the United Kingdom for high-temperature plant assessments provides a more mechanistic and comprehensive treatment of creep–fatigue interaction. This methodology incorporates the detailed modeling of cyclic plasticity and creep strain evolution under service conditions, thereby enabling explicit predictions of strain accumulation and stress relaxation.

With respect to creep–fatigue interaction, R5 employs combined interaction diagrams that account for the synergistic effects of creep and fatigue more accurately than linear summation approaches. Compared with the ASME BPVC methodology, the R5 framework is generally less conservative, as it seeks to provide realistic life predictions by explicitly considering the actual material response in service. This feature makes R5 particularly relevant for high-temperature plant life extension and defect tolerance assessments.

Nevertheless, both methodologies inevitably rely on simplifying assumptions to facilitate their application within the context of industrial design. To achieve a more fundamental understanding of the governing degradation mechanisms, alternative approaches should be considered, including those based on continuum damage mechanics (CDM).

In particular, constitutive models based on CDM have enabled the development of “unified” approaches [

10,

11,

12] for creep–fatigue damage assessment, enabling the simultaneous evaluation of different degradation mechanisms within a single theoretical framework. For instance, in the Lemaitre formulation [

10,

11], the damage rate is expressed as directly proportional to the plastic strain rate once a critical threshold of accumulated inelastic strain has been exceeded.

It should be emphasized that although this approach permits the simultaneous evaluation of fatigue and creep damage within a unified computational framework, significant challenges may arise in calibrating the interaction between the two mechanisms, particularly with respect to the evolution of creep curves (see [

12]). In such situations, it becomes necessary to develop separate yet interacting models for low-cycle fatigue (LCF) and creep, followed by the adoption of an appropriate summation rule. To circumvent these limitations, the approach proposed in this study deliberately departs from Lemaitre-type models, instead formulating an innovative relationship for the assessment of LCF damage (see

Section 3.1.1). The analysis presented herein is applied to a representative steel grade commonly employed in turbine rotor forgings, with specific attention to operating conditions where frequent turbine start-ups exacerbate the effects of steady-state service within the creep regime.

Future developments will extend the proposed methodology to additional classes of steels, such as 9Cr-1Mo-V and 12Cr-1Mo-V alloys, which are extensively employed in power generation applications and for which a substantial body of creep–fatigue investigations is available in the literature (e.g., [

13,

14,

15,

16,

17]). Moreover, the predictive capabilities of the model will be evaluated under complex loading scenarios, including service-like thermomechanical fatigue (TMF) conditions [

18,

19].

Within this context, the present study introduces an original approach for the combined assessment of creep–fatigue damage and illustrates its applicability to a representative heat-resistant ferritic–martensitic steel typically employed in rotor forgings. Beyond the development of constitutive models for cyclic plasticity and creep damage, particular emphasis is placed on the definition of innovative relationships for damage evaluation and on a consistent parameter identification strategy. The outcomes are validated against experimental data, thereby highlighting both the predictive accuracy of the approach and its potential relevance for life assessment of components operating under demanding service conditions.