Influence of Different Heat Treatments on Microstructure Evolution and High-Temperature Tensile Properties of LPBF-Fabricated H13 Hot Work Steel

Abstract

1. Introduction

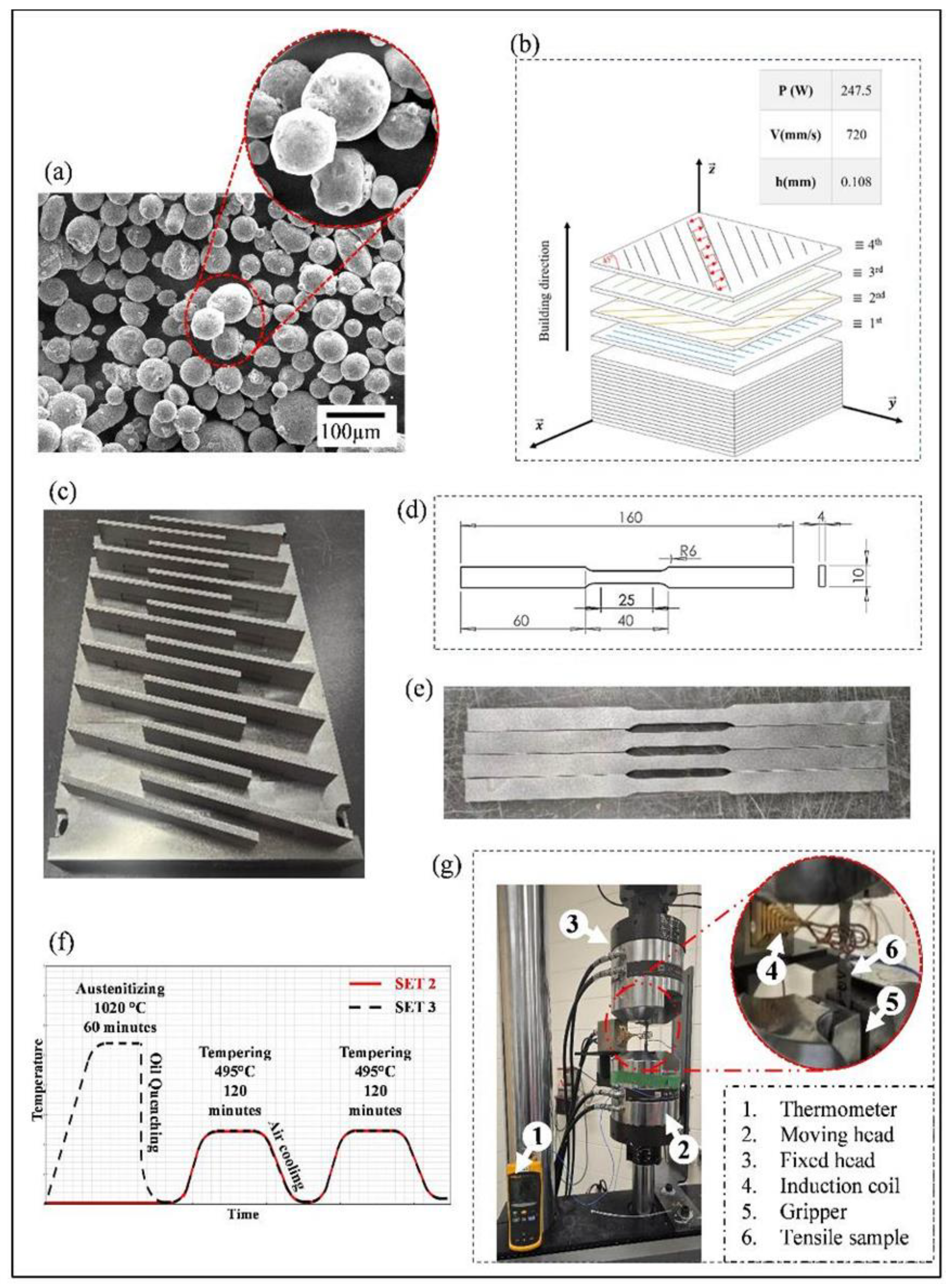

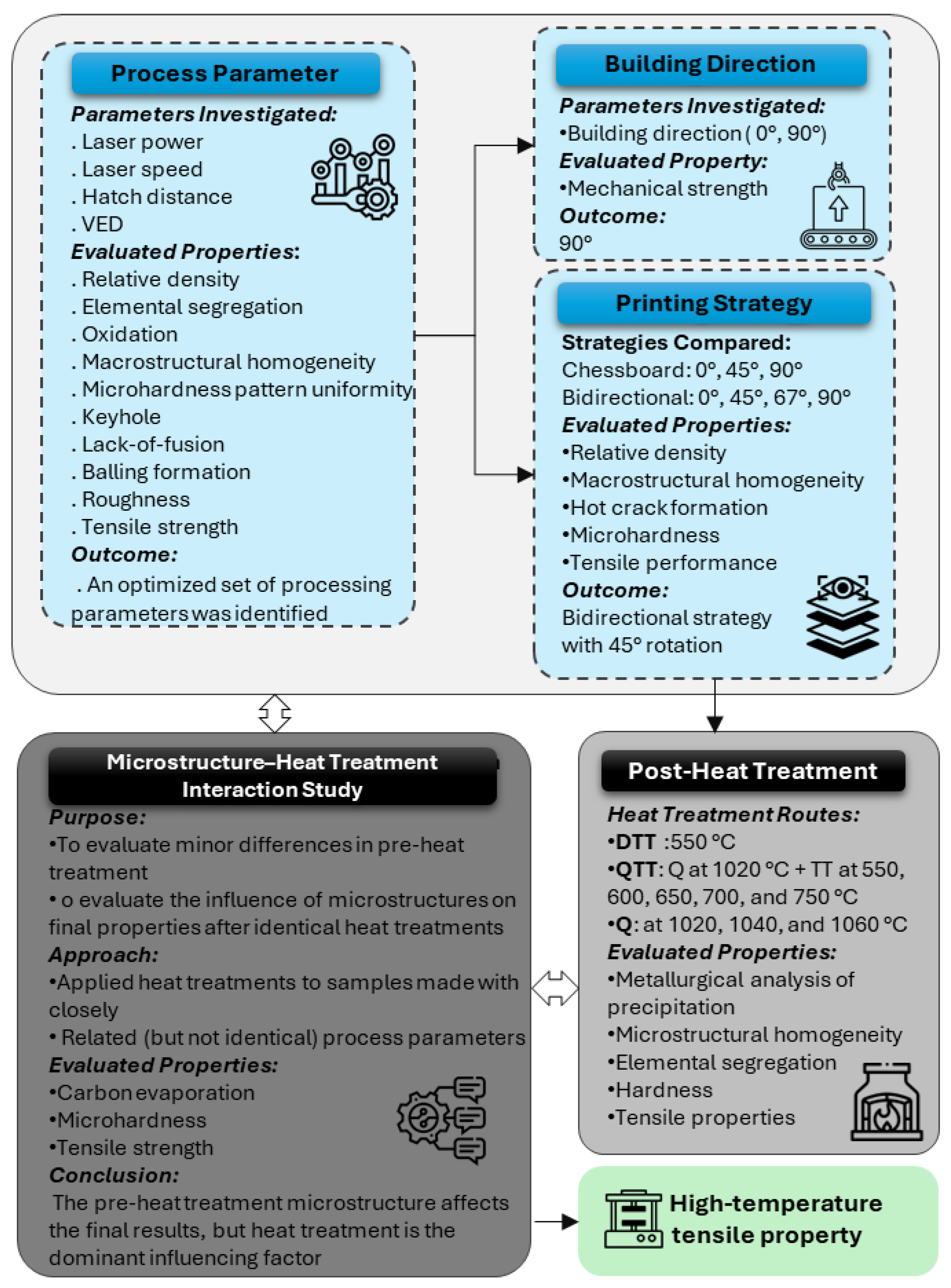

2. Materials and Methods

3. Results and Discussion

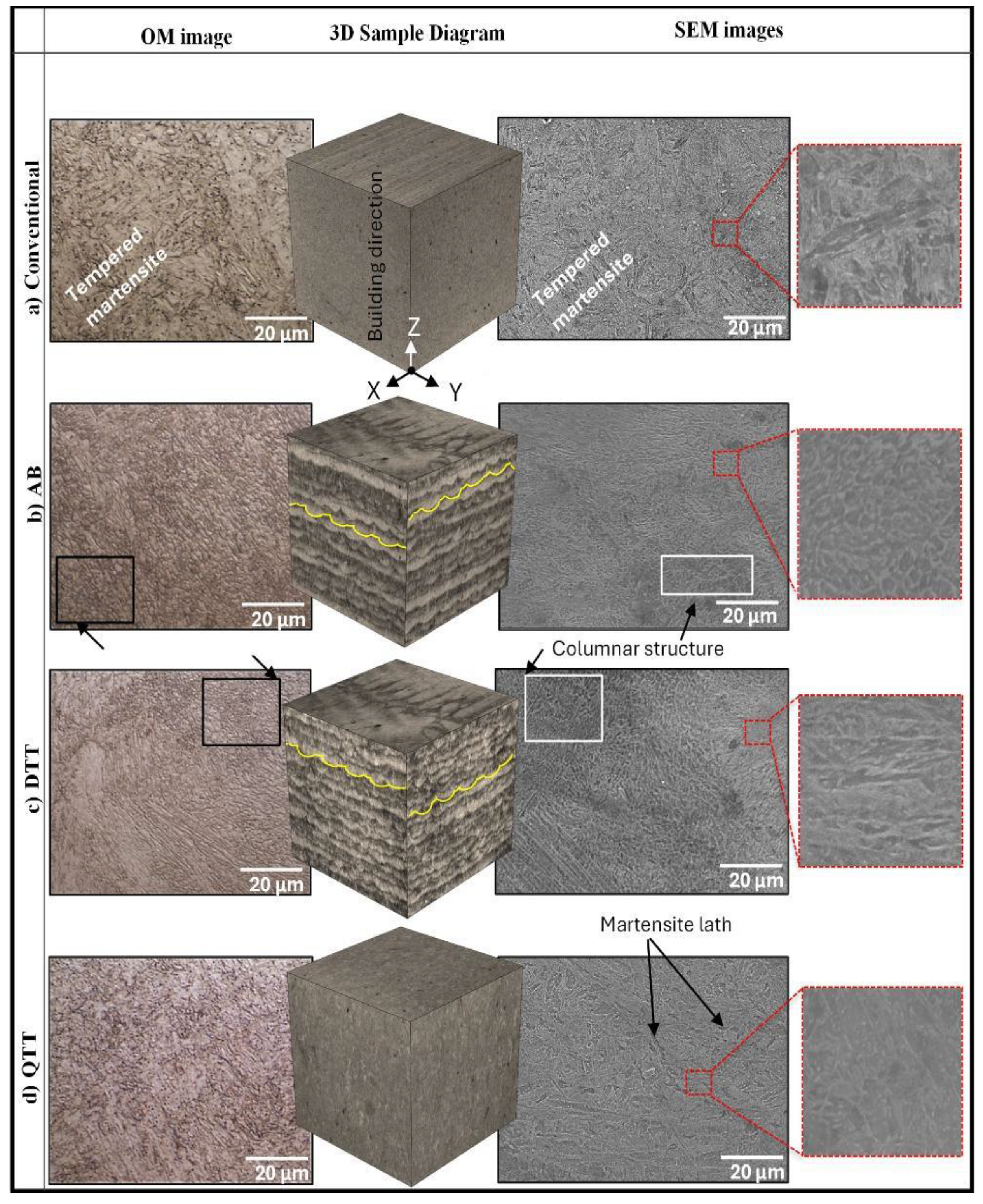

3.1. Microstructure

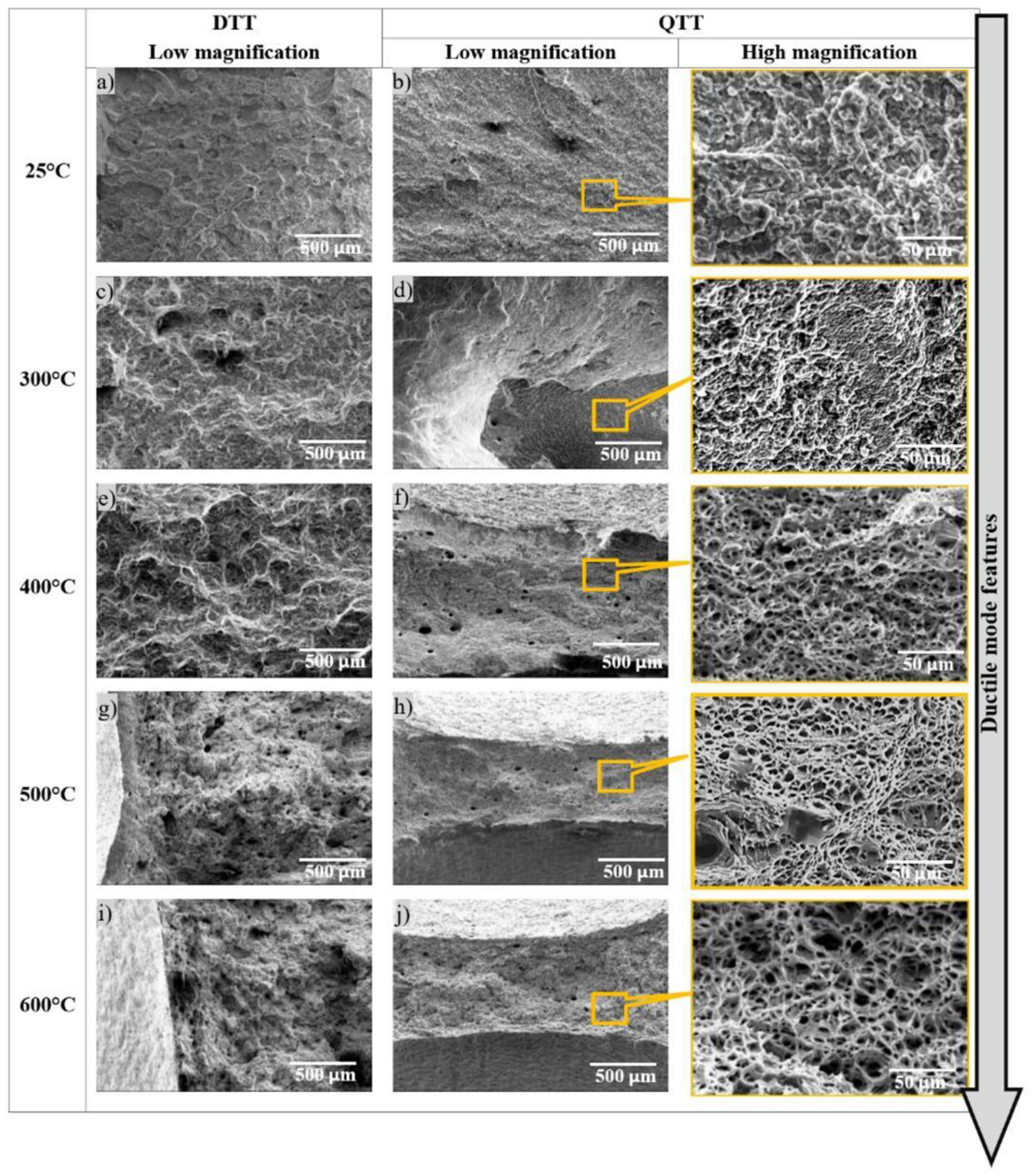

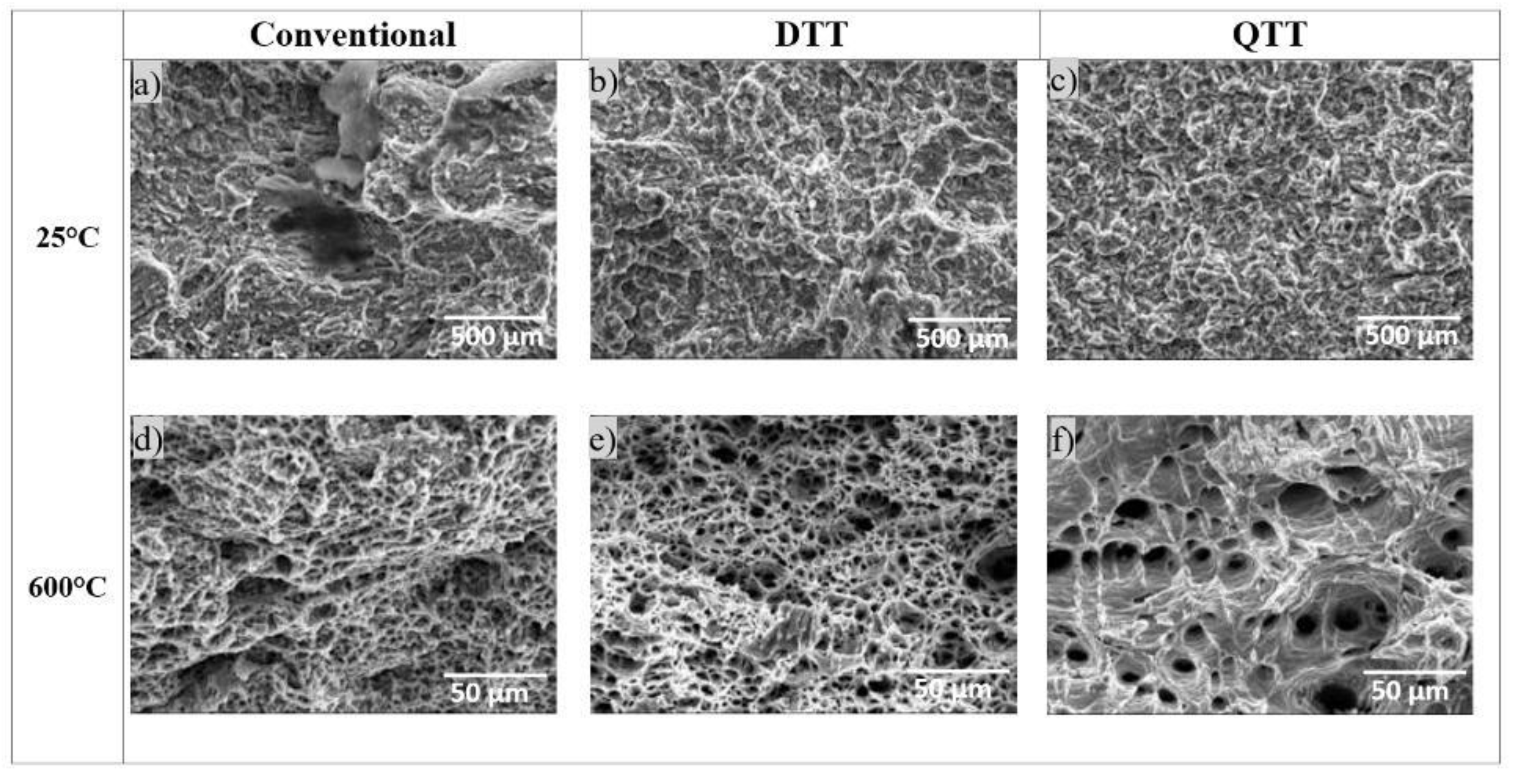

3.2. Fractography

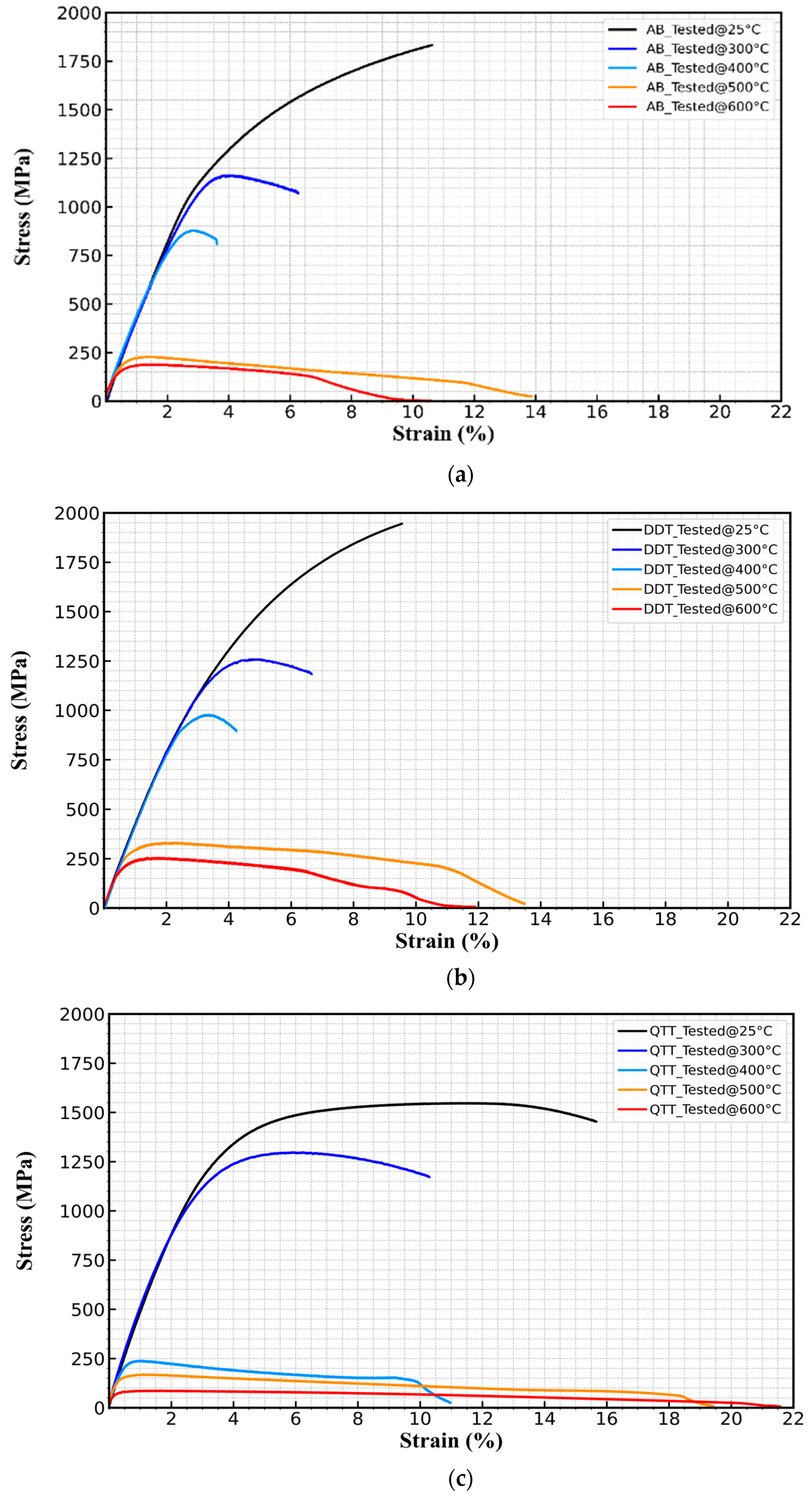

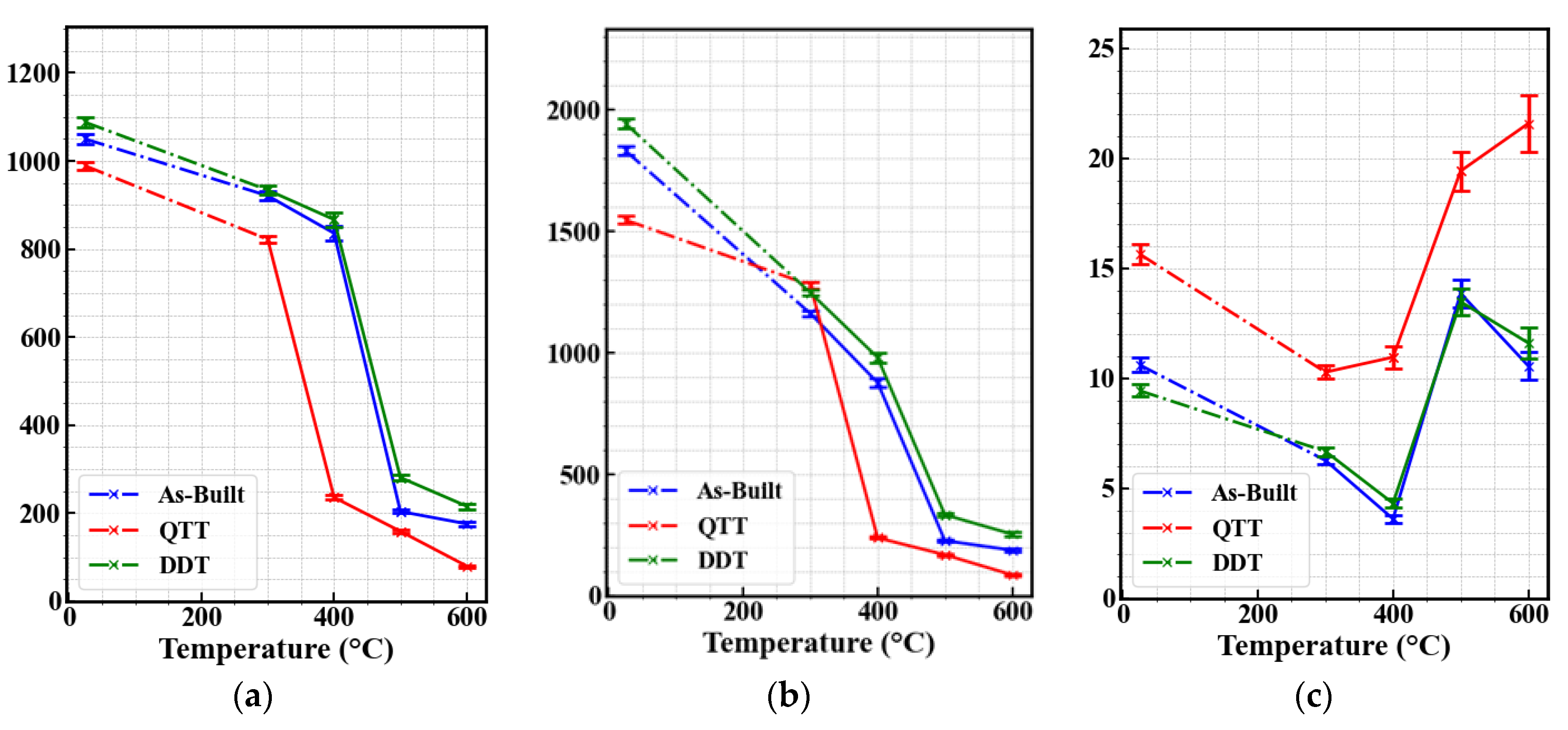

3.3. Mechanical Properties

4. Conclusions

- The DTT configuration exhibited improved mechanical performance compared to the AB condition, particularly at elevated temperatures. At 400 °C, both DTT and AB samples retained approximately 80% of their room-temperature yield strength, demonstrating notable thermal resistance. This enhancement in the DTT sample is attributed to the double tempering process, which promoted microstructural homogeneity and carbide precipitation, thereby mitigating the effects of thermal softening.

- In contrast, the QTT configuration showed a significantly sharper decline in mechanical strength with increasing temperature, retaining only ~24% of its initial yield strength at 400 °C. This unexpected softening behavior suggests that conventional heat treatment protocols may not be directly transferable to LPBF-processed materials without modification, due to their unique microstructural characteristics and thermal history.

- Fractographic analysis revealed a progressive transition from mixed mode to fully ductile fracture in AB and DTT samples as temperature increased, while QTT samples displayed ductile fracture features at all tested temperatures. This indicates that the QTT condition had undergone a higher degree of tempering, leading to a softer microstructure even at lower temperatures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tome, S.; Karpe, B.; Paulin, I.; Godec, M. Effect of Heat Treatment on Thermal Conductivity of Additively Manufactured AISI H13 Tool Steel. Metal 2023, 2024, 146–150. [Google Scholar]

- Li, J.Y.; Chen, Y.L.; Huo, J.H. Mechanism of improvement on strength and toughness of H13 die steel by nitrogen. Mater. Sci. Eng. A 2015, 640, 16–23. [Google Scholar] [CrossRef]

- Prudente, W.R.; Lins, J.F.C.; Siqueira, R.P.; Priscila, S.N. Microstructural evolution under tempering heat treatment in AISI H13 hot-work tool steel. Int. J. Eng. Res. Appl. 2017, 7, 67–71. [Google Scholar] [CrossRef]

- Han, Y.; Li, C.; Ren, J.; Qiu, C.; Zhang, Y.; Wang, J. Dendrite Segregation Changes in High Temperature Homogenization Process of As-cast H13 Steel. ISIJ Int. 2019, 59, 1893–1900. [Google Scholar] [CrossRef]

- Deirmina, F.; Amirabdollahian, S.; Pellizzari, M.; Molinari, A. Effect of Different Post-Processing Thermal Treatments on the Fracture Toughness and Tempering Resistance of Additively Manufactured H13 Hot-Work Tool Steel. Metals 2024, 14, 112. [Google Scholar] [CrossRef]

- Deirmina, F.; Quarzago, L.; Butcher, D.; Bettini, E.; Mehraban, S.; Hann, J.; Pettersson, N.H.; Lavery, N.; Röttger, A. Massimo Pellizzari General investigations on the heat treatment and thermal fatigue behavior of an experimental hot work tool steel tailored for laser powder bed fusion. Mater. Sci. Eng. A 2024, 901, 146554. [Google Scholar] [CrossRef]

- Duan, Z.; Pei, W.; Gong, X.; Chen, H. Superplasticity of annealed H13 steel. Materials 2017, 10, 870. [Google Scholar] [CrossRef]

- Fonseca, E.B.; Gabriel, A.H.G.; Araújo, L.C.; Santos, P.L.; Campo, K.N.; Lopes, E.S. Assessment of laser power and scan speed influence on microstructural features and consolidation of AISI H13 tool steel processed by additive manufacturing. Addit. Manuf. 2020, 34, 101250. [Google Scholar] [CrossRef]

- Kahlert, M.; Brenne, F.; Vollmer, M.; Niendorf, T. Influence of Microstructure and Defects on Mechanical Properties of AISI H13 Manufactured by Electron Beam Powder Bed Fusion. J. Mater. Eng. Perform. 2021, 30, 6895–6904. [Google Scholar] [CrossRef]

- Fonseca, E.B.; Escobar, J.D.; Gabriel, A.H.G.; Ribamar, G.G.; Boll, T.; Lopes, E.S. Tempering of an additively manufactured microsegregated hot-work tool steel: A high-temperature synchrotron X-ray diffraction study. Addit. Manuf. 2022, 55, 102812. [Google Scholar] [CrossRef]

- Narvan, M.; Al-Rubaie, K.S.; Elbestawi, M. Process-structure-property relationships of AISI H13 tool steel processed with selective laser melting. Materials 2019, 12, 2284. [Google Scholar] [CrossRef]

- He, Y.; Zhong, M.; Beuth, J.; Webler, B. A study of microstructure and cracking behavior of H13 tool steel produced by laser powder bed fusion using single-tracks, multi-track pads, and 3D cubes. J. Mater Process Technol. 2020, 286, 116802. [Google Scholar] [CrossRef]

- Katancik, M.; Mirzababaei, S.; Ghayoor, M.; Pasebani, S. Selective laser melting and tempering of H13 tool steel for rapid tooling applications. J. Alloys Compd. 2020, 849, 156319. [Google Scholar] [CrossRef]

- Amirabdollahian, S.; Deirmina, F.; Pellizzari, M.; Bosetti, P.; Molinari, A. Tempering behavior of a direct laser deposited hot work tool steel: Influence of quenching on secondary hardening and microstructure. Mater. Sci. Eng. A 2021, 814, 141126. [Google Scholar] [CrossRef]

- Deirmina, F.; Peghini, N.; AlMangour, B.; Grzesiak, D.; Pellizzari, M. Heat treatment and properties of a hot work tool steel fabricated by additive manufacturing. Mater. Sci. Eng. A 2019, 753, 109–121. [Google Scholar] [CrossRef]

- Omidi, N.; Iltaf, A.; Houria, M.; Jahazi, M.; Barka, N.; Belzile, C. Enhancing Mechanical Properties of Additively Manufactured H13: A Two-Step Approach Integrating Processing Parameters Optimization and a Tailored Heat Treatment. Met. Mater. Int. 2024, 31, 1286–1312. [Google Scholar] [CrossRef]

- Pei, H.X.; Zhang, H.L.; Wang, L.X.; Li, S.L.; Li, D.Z.; Wang, X.T. Tensile behaviour of 316LN stainless steel at elevated temperatures. Mater. High Temp. 2014, 31, 198–203. [Google Scholar] [CrossRef]

- Gardner, L.; Insausti, A.; Ng, K.T.; Ashraf, M. Elevated temperature material properties of stainless steel alloys. J. Constr. Steel Res. 2010, 66, 634–647. [Google Scholar] [CrossRef]

- Chang, K.-H.; Lee, C.-H. Characteristics of High Temperature Tensile Properties and Residual Stresses in Weldments of High Strength Steels. Mater. Trans. 2006, 47, 348–354. [Google Scholar] [CrossRef]

- Wen, D.X.; Wang, J.K.; Wang, K.; Xiong, Y.; Huang, L.; Zheng, Z.; Li, J. Hot tensile deformation and fracture behaviors of a typical ultrahigh strength steel. Vacuum 2019, 169, 108863. [Google Scholar] [CrossRef]

- Xiao, Z.; Huang, Y.; Liu, H.; Wang, S. Hot tensile and fracture behavior of 35CrMo steel at elevated temperature and strain rate. Metals 2016, 6, 210. [Google Scholar] [CrossRef]

- Roy, A.K.; Kukatla, S.R.; Yarlagadda, B.; Potluri, V.N.; Lewis, M.; Jones, M.; O’Toole, B.J. Tensile properties of martensitic stainless steels at elevated temperatures. J. Mater Eng. Perform. 2005, 14, 212–218. [Google Scholar] [CrossRef]

- Ding, H.; Yuan, Z.Z.; Liu, T.; Chen, L.; Zhou, Y.; Cao, Y.; Cao, F.; Luo, R.; Cheng, X. Microstructure and high-temperature tensile behavior of modified H13 steel with the addition of tungsten, molybdenum, and lowering of chromium. Mater. Sci. Eng. A 2023, 866, 144655. [Google Scholar] [CrossRef]

- Ding, H.; Cheng, X.; Liu, T.; Cao, F.; Chen, L.; Luo, R.; Zhang, Y.; Zhang, B. Microstructure and high-temperature tensile behavior of spray-formed modified 2000MPa H13 hot work die steel with 0.5wt % carbon. Mater. Sci. Eng. A 2022, 842, 143102. [Google Scholar] [CrossRef]

- Tanvir, A.N.M.; Ahsan, M.R.U.; Seo, G.; Bates, B.; Lee, C.; Liaw, P.K.; Noakes, M.; Nycz, A.; Ji, C.; Kim, D.B. Phase stability and mechanical properties of wire + arc additively manufactured H13 tool steel at elevated temperatures. J. Mater Sci. Technol. 2021, 67, 80–94. [Google Scholar] [CrossRef]

- Carasi, G.; Yu, B.; Hutten, E.; Zurob, H.; Casati, R.; Vedani, M. Effect of Heat Treatment on Microstructure Evolution of X38CrMoV5-1 Hot-Work Tool Steel Produced by L-PBF. Metall Mater Trans. A Phys. Metall Mater Sci. 2021, 52, 2564–2575. [Google Scholar] [CrossRef]

- Omidi, N.; Houria, M.; Monjez, M.M.; Jahazi, M.; Barka, N.; Ouafi, A.E. Processing parameters optimization for enhanced mechanical strength in PBF-ed H13 tool steel: Minimizing manufacturing defects including microstructural inhomogeneity, sub-surface porosities, and oxide formation. Int. J. Adv. Manuf. Technol. 2025, 136, 2681–2706. [Google Scholar] [CrossRef]

- Kisraoui, C.; Omidi, N.; Dehghan, S.; Belhadj, A.; Slama, S.; Barka, N.; El Ouafi, A. Effect of Printing Strategies on Mechanical Properties of Tool Steel in Laser Powder Bed Fusion Process. Lasers Manuf. Mater. Process. 2025, 12, 147–173. [Google Scholar] [CrossRef]

- ASTM E21-20; Standard Test Methods for Elevated Temperature Tension Tests of Metallic Materials. ASTM: West Conshohocken, PA, USA, 2020. [CrossRef]

- Kwon, G.H.; Choi, B.; Lee, Y.K.; Moon, K.I. Tempering behavior and mechanical properties of tempered AISI H13 steel. Mater Res. Express 2024, 11, 116504. [Google Scholar] [CrossRef]

- Yuan, M.; Cao, Y.; Karamchedu, S.; Hosseini, S.; Yao, Y.; Berglund, J.; Liu, L.; Nyborg, L. Characteristics of a modified H13 hot-work tool steel fabricated by means of laser beam powder bed fusion. Mater. Sci. Eng. A 2022, 831, 142322. [Google Scholar] [CrossRef]

- Fonseca, E.B.; Gabriel, A.H.G.; Ávila, J.A.; Vaz, R.F.; Valim, D.B.; Cano, I.G.; Lopes, É.S. Fracture toughness and wear resistance of heat-treated H13 tool steel processed by laser powder bed fusion. Addit. Manuf. 2023, 78, 103862. [Google Scholar] [CrossRef]

- Han, L.X.; Wang, Y.; Liu, S.F.; Zhang, Z.; Liu, W.; Yang, X.; Ma, D.; Zhou, J.; Wei, Y. Effect of heat treatment on microstructural evolution, mechanical properties and tribological properties of H13 steel prepared using selective laser melting. J. Iron Steel Res. Int. 2024, 31, 1246–1259. [Google Scholar] [CrossRef]

- Chen, C.J.; Yan, K.; Qin, L.; Zhang, M.; Wang, X.; Zou, T.; Hu, Z. Effect of Heat Treatment on Microstructure and Mechanical Properties of Laser Additively Manufactured AISI H13 Tool Steel. J. Mater. Eng. Perform. 2017, 26, 5577–5589. [Google Scholar] [CrossRef]

- Lei, F.; Wen, T.; Yang, F.; Wang, J.; Fu, J.; Yang, H.; Wang, J.; Ruan, J.; Ji, S. Microstructures and Mechanical Properties of H13 Tool Steel Fabricated by Selective Laser Melting. Materials 2022, 15, 2686. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, G.; Xiang, N.; Zheng, Y. Microstructural evolution and high-temperature deformation mechanism of 4Cr5MoSiV1Ti steel. J. Mater. Res. Technol. 2023, 24, 8856–8865. [Google Scholar] [CrossRef]

- Wang, Z.; Jiang, C.; Wei, B.; Wang, Y. Analysis of the High Temperature Plastic Deformation Characteristics of 18CrNi4A Steel and Establishment of a Modified Johnson–Cook Constitutive Model. Coatings 2023, 13, 1697. [Google Scholar] [CrossRef]

- Li, C.; Liu, Y.; Tan, Y.; Zhao, F. Hot deformation behavior and constitutive modeling of H13-mod steel. Metals 2018, 8, 846. [Google Scholar] [CrossRef]

- Hu, X.; Li, L.; Wu, X.; Zhang, M. Coarsening behavior of M23C6 carbides after ageing or thermal fatigue in AISI H13 steel with niobium. Int. J. Fatigue 2006, 28, 175–182. [Google Scholar] [CrossRef]

- Qin, S.; Bo, Y.; Herzog, S.; Hallstedt, B.; Kaletsch, A.; Broeckmann, C. Influence of Process Parameters on Porosity and Hot Cracking of AISI H13 Fabricated by Laser Powder Bed Fusion. Powders 2022, 1, 184–193. [Google Scholar] [CrossRef]

- Godec, M.; Balantič, D.A.S. Coarsening behaviour of M23C6 carbides in creep-resistant steel exposed to high temperatures. Sci. Rep. 2016, 6, 29734. [Google Scholar] [CrossRef]

- Tomiczek, B.; Snopiński, P.; Borek, W.; Król, M.; Gutiérrez, A.R.; Matula, G. Hot Deformation Behaviour of Additively Manufactured 18Ni-300 Maraging Steel. Materials 2023, 16, 2412. [Google Scholar] [CrossRef]

- Wang, M.; Wu, Y.; Wei, Q.; Shi, Y. Thermal fatigue properties of h13 hot-work tool steels processed by selective laser melting. Metals 2020, 10, 116. [Google Scholar] [CrossRef]

| AB | ||||

|---|---|---|---|---|

| Sample Code | (°C) | YS (MPa) | UTS (MPa) | El (%) |

| A0 | 25 | 1052 ± 10.5 | 1832 ± 18.3 | 10.62 ± 0.32 |

| A3 | 300 | 921 ± 9.2 | 1162 ± 11.6 | 6.28 ± 0.19 |

| A4 | 400 | 836 ± 12.5 | 878 ± 13.2 | 3.62 ± 0.16 |

| A5 | 500 | 204 ± 3.1 | 228 ± 3.4 | 13.87 ± 0.62 |

| A6 | 600 | 176 ± 3.5 | 188 ± 3.8 | 10.58 ± 0.63 |

| DTT | ||||

| DTT0 | 25 | 1088 ± 10.9 | 1945 ± 19.4 | 9.45 ± 0.28 |

| DTT3 | 300 | 934 ± 9.3 | 1249 ± 12.5 | 6.69 ± 0.2 |

| DTT4 | 400 | 867 ± 13 | 981 ± 14.7 | 4.33 ± 0.19 |

| DTT5 | 500 | 281 ± 4.2 | 334 ± 5.0 | 13.49 ± 0.61 |

| DTT6 | 600 | 216 ± 4.3 | 254 ± 5.1 | 11.62 ± 0.7 |

| QTT | ||||

| QTT0 | 25 | 989 ± 9.9 | 1547 ± 15.5 | 15.66 ± 0.47 |

| QTT3 | 300 | 822 ± 8.2 | 1279 ± 12.8 | 10.29 ± 0.31 |

| QTT4 | 400 | 236 ± 3.5 | 239 ± 3.6 | 10.97 ± 0.49 |

| QTT5 | 500 | 159 ± 2.4 | 169 ± 2.5 | 19.43 ± 0.87 |

| QTT6 | 600 | 80 ± 1.6 | 87 ± 1.7 | 21.59 ± 1.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Monjez, M.M.; Omidi, N.; Farhadipour, P.; El Ouafi, A.; Barka, N. Influence of Different Heat Treatments on Microstructure Evolution and High-Temperature Tensile Properties of LPBF-Fabricated H13 Hot Work Steel. Metals 2025, 15, 1003. https://doi.org/10.3390/met15091003

Monjez MM, Omidi N, Farhadipour P, El Ouafi A, Barka N. Influence of Different Heat Treatments on Microstructure Evolution and High-Temperature Tensile Properties of LPBF-Fabricated H13 Hot Work Steel. Metals. 2025; 15(9):1003. https://doi.org/10.3390/met15091003

Chicago/Turabian StyleMonjez, Mohamed Meher, Narges Omidi, Pedram Farhadipour, Abderrazak El Ouafi, and Noureddine Barka. 2025. "Influence of Different Heat Treatments on Microstructure Evolution and High-Temperature Tensile Properties of LPBF-Fabricated H13 Hot Work Steel" Metals 15, no. 9: 1003. https://doi.org/10.3390/met15091003

APA StyleMonjez, M. M., Omidi, N., Farhadipour, P., El Ouafi, A., & Barka, N. (2025). Influence of Different Heat Treatments on Microstructure Evolution and High-Temperature Tensile Properties of LPBF-Fabricated H13 Hot Work Steel. Metals, 15(9), 1003. https://doi.org/10.3390/met15091003