Influence of Heat Treatment on the Microstructure and Properties of 2319 Aluminum Alloy Produced by Wire Arc Additive Manufacturing

Abstract

1. Introduction

2. Experiment

3. Results and Discussion

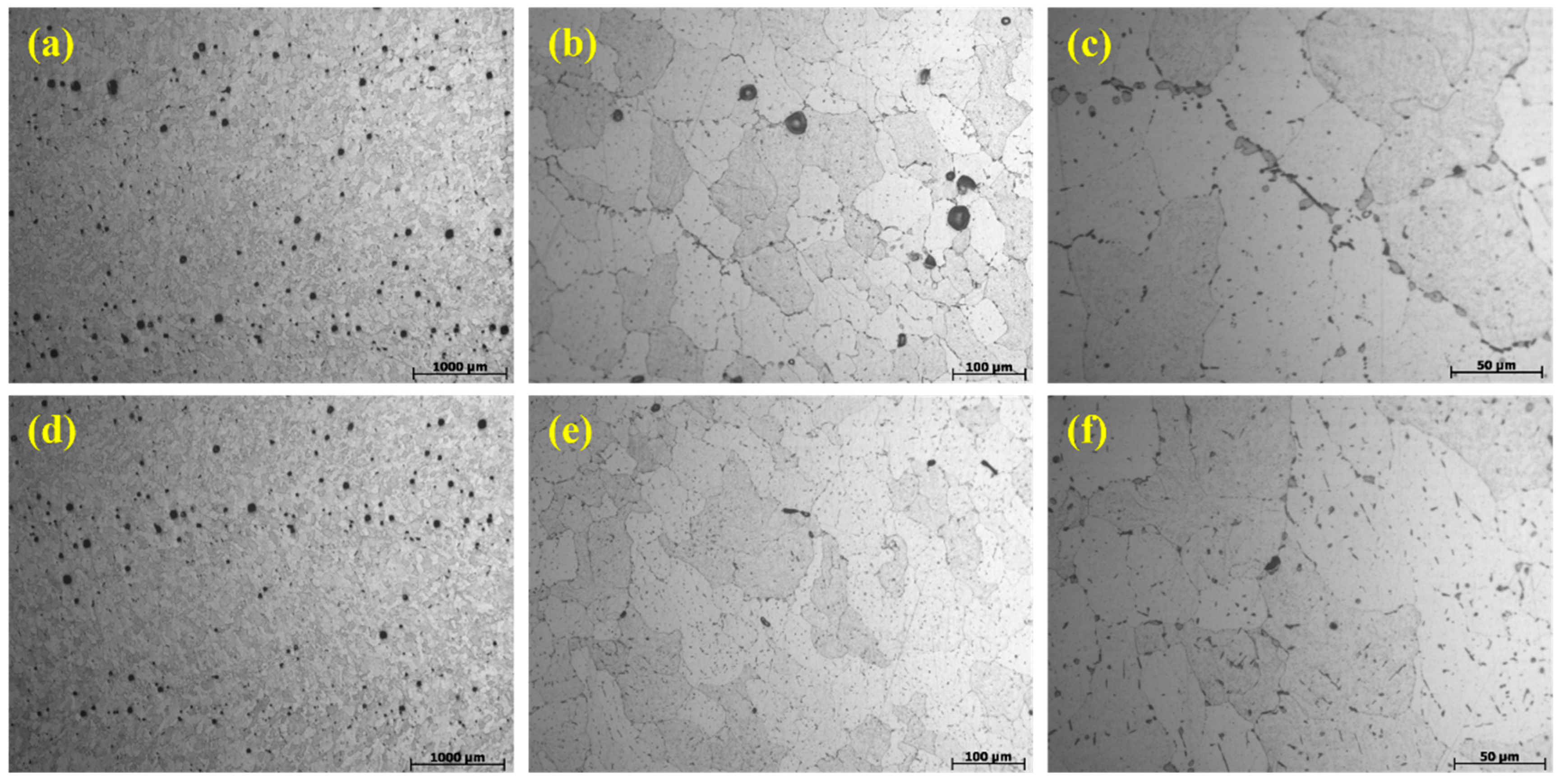

3.1. Microstructure Evolution During Heat Treatment

3.1.1. Microstructure of As-Deposited Specimen

3.1.2. Microstructure of Solid State

3.1.3. Microstructure of Aging State

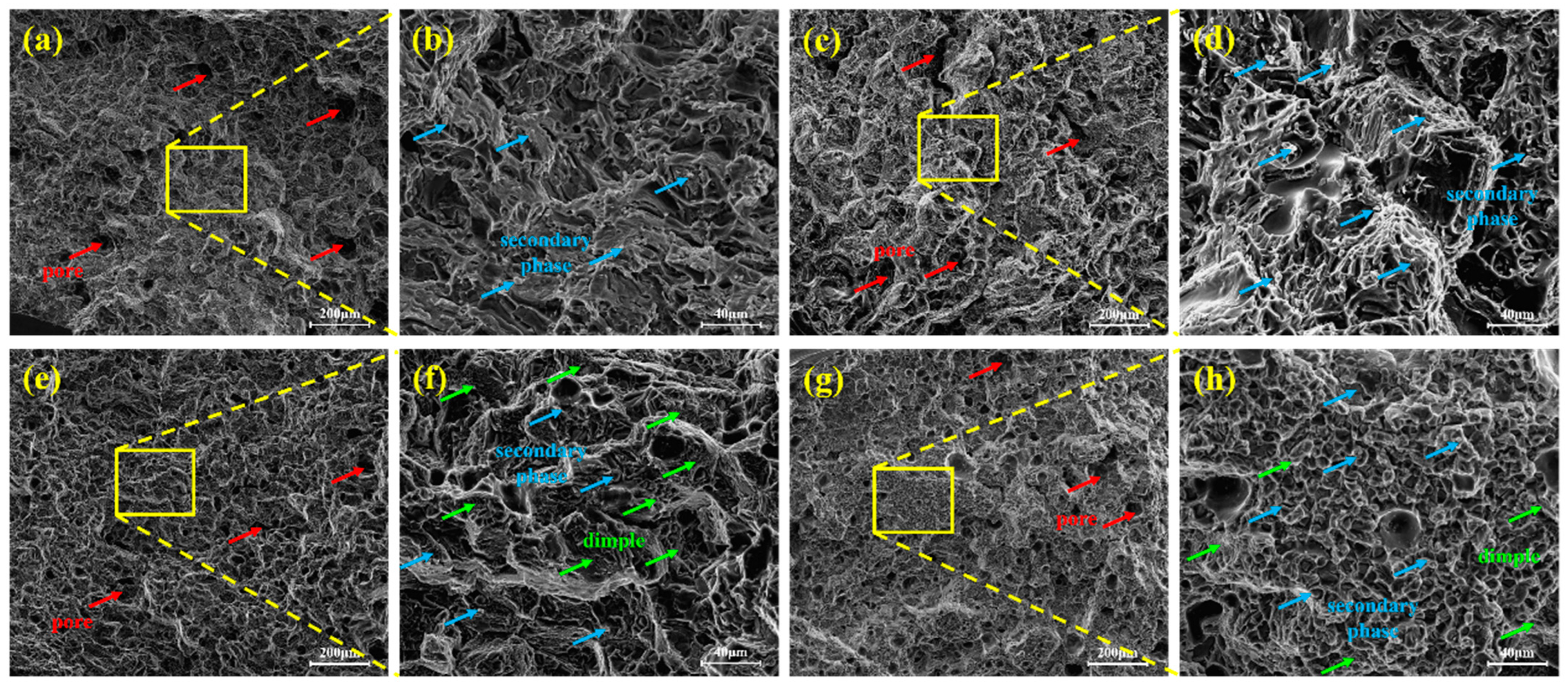

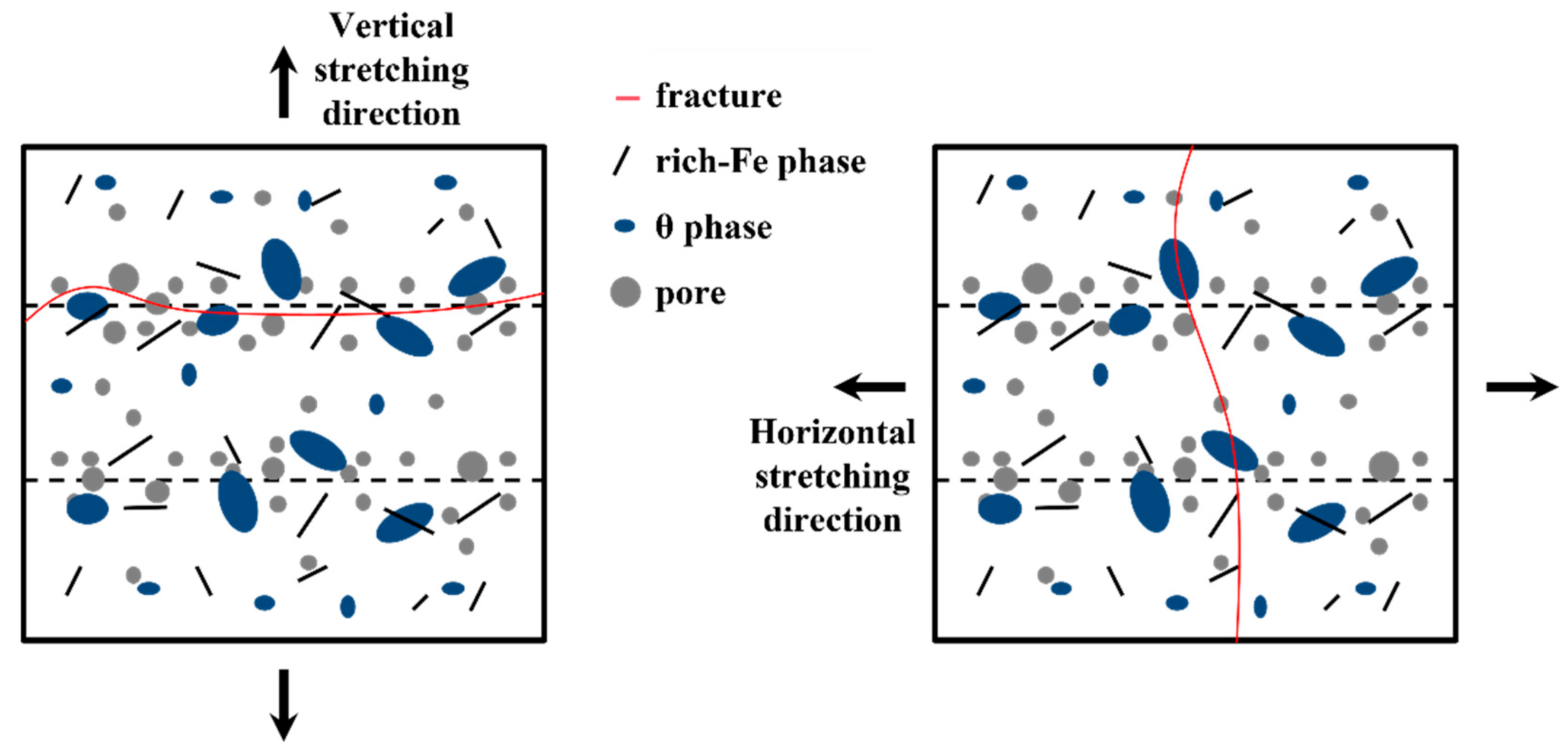

3.2. Mechanical Properties

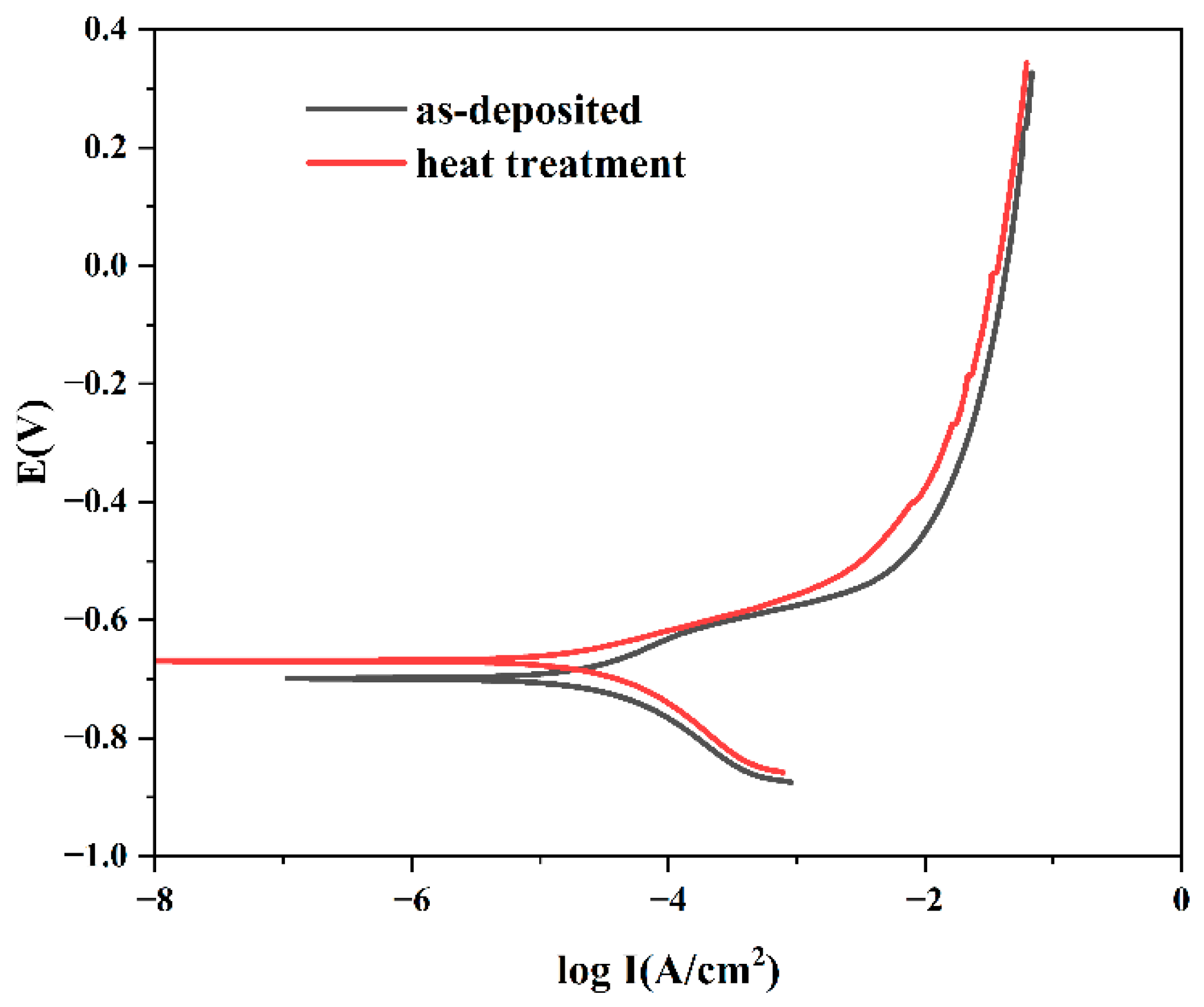

3.3. Corrosion Behavior

4. Conclusions

- (1)

- In the as-deposited microstructure of WAAM 2319 aluminum alloy, the secondary phases form a continuous network, which is numerous and coarse. After solution treatment, most of the secondary phase is dissolved, and the remaining secondary phases mainly consist of the θ phase and other phases. After continuing the aging treatment, a secondary phase with a dispersed distribution and small size is formed within the dendrites.

- (2)

- After heat treatment, the tensile strength of the alloy in the horizontal direction reaches 362 MPa, which is increased by 60.7% compared with the as-deposited state. The vertical-direction tensile strength reaches 339 MPa, which is increased by 63.8% compared with the as-deposited state. However, the plastic deformation ability of the material after aging treatment decreases to a certain extent. This is mainly caused by the micro-porosities and secondary phases being segregated between layers to form weak zones. When the material is stretched in the vertical direction, micro-cracks are likely to form between layers, resulting in poor plasticity and low tensile strength.

- (3)

- The specimens after heat treatment exhibit better corrosion resistance. Based on the analysis of the microstructural changes, the improvement in corrosion resistance is related to the decrease in the quantity, the reduction in size, and the more dispersed distribution of the secondary phases in the specimens after heat treatment.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shi, Y.; Dong, Y.; Ding, H.; Li, T.; Ren, F.; Dai, T.; Bi, Y. Research on the Microstructure and Mechanical Properties of 2319 Aluminum Alloy Fabricated by Wire Arc Additive Manufacturing. J. Mater. Eng. Perform. 2025, 34, 16483–16493. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Kumar Sinha, A.; Pramanik, S.; Yagati, K.P. Research progress in arc based additive manufacturing of aluminium alloys—A review. Measurement 2022, 200, 111672. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Ke, W.C.; Oliveira, J.P.; Cong, B.Q.; Ao, S.S.; Qi, Z.W.; Peng, B.; Zeng, Z. Multi-layer deposition mechanism in ultra high-frequency pulsed wire arc additive manufacturing (WAAM) of NiTi shape memory alloys. Addit. Manuf. 2022, 50, 102513. [Google Scholar] [CrossRef]

- Sarıkaya, M.; Başcıl Önler, D.; Dağlı, S.; Hartomacıoğlu, S.; Günay, M.; Królczyk, G.M. A review on aluminum alloys produced by wire arc additive manufacturing (WAAM): Applications, benefits, challenges and future trends. J. Mater. Res. Technol. 2024, 33, 5643–5670. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Cong, B.; Cai, X.; Qi, Z.; Qi, B.; Zhang, Y.; Zhang, R.; Guo, W.; Zhou, Z.; Yin, Y.; Bu, X. The effects of ultrasonic frequency pulsed arc on wire + arc additively manufactured high strength aluminum alloys. Addit. Manuf. 2022, 51, 102617. [Google Scholar] [CrossRef]

- Cunningham, C.R.; Flynn, J.M.; Shokrani, A.; Dhokia, V.; Newman, S.T. Invited review article: Strategies and processes for high quality wire arc additive manufacturing. Addit. Manuf. 2018, 22, 672–686. [Google Scholar] [CrossRef]

- Marinelli, G.; Martina, F.; Ganguly, S.; Williams, S. Grain refinement in an unalloyed tantalum structure by combining Wire+Arc additive manufacturing and vertical cold rolling. Addit. Manuf. 2020, 32, 101009. [Google Scholar] [CrossRef]

- Wang, F.; Wei, J.; Wu, G.; Qie, M.; He, C. Microstructural modification and enhanced mechanical properties of wire-arc additive manufactured 6061 aluminum alloy via interlayer friction stir processing. Mater. Lett. 2023, 342, 134312. [Google Scholar] [CrossRef]

- Gu, J.; Yang, S.; Gao, M.; Bai, J.; Zhai, Y.; Ding, J. Micropore evolution in additively manufactured aluminum alloys under heat treatment and inter-layer rolling. Mater. Des. 2020, 186, 108288. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H. Effects of heat accumulation on microstructure and mechanical properties of Ti6Al4V alloy deposited by wire arc additive manufacturing. Addit. Manuf. 2018, 23, 151–160. [Google Scholar] [CrossRef]

- Yuan, T.; Yu, Z.; Chen, S.; Xu, M.; Jiang, X. Loss of elemental Mg during wire + arc additive manufacturing of Al-Mg alloy and its effect on mechanical properties. J. Manuf. Process. 2020, 49, 456–462. [Google Scholar] [CrossRef]

- Zhao, Y.; Jia, Y.; Chen, S.; Shi, J.; Li, F. Process planning strategy for wire-arc additive manufacturing: Thermal behavior considerations. Addit. Manuf. 2020, 32, 100935. [Google Scholar] [CrossRef]

- Langelandsvik, G.; Akselsen, O.M.; Furu, T.; Roven, H.J. Review of Aluminum Alloy Development for Wire Arc Additive Manufacturing. Materials 2021, 14, 5370. [Google Scholar] [CrossRef]

- Qi, Z.; Cong, B.; Qi, B.; Sun, H.; Zhao, G.; Ding, J. Microstructure and mechanical properties of double-wire + arc additively manufactured Al-Cu-Mg alloys. J. Mater. Process. Technol. 2018, 255, 347–353. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M. The microstructure and mechanical properties of selectively laser melted AlSi10Mg: The effect of a conventional T6-like heat treatment. Mater. Sci. Eng. A 2016, 667, 139–146. [Google Scholar] [CrossRef]

- Girelli, L.; Tocci, M.; Gelfi, M.; Pola, A. Study of heat treatment parameters for additively manufactured AlSi10Mg in comparison with corresponding cast alloy. Mater. Sci. Eng. A 2019, 739, 317–328. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.-P.; Van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef]

- Yan, Q.; Song, B.; Shi, Y. Comparative study of performance comparison of AlSi10Mg alloy prepared by selective laser melting and casting. J. Mater. Sci. Technol. 2020, 41, 199–208. [Google Scholar] [CrossRef]

- Wang, Z.; Lin, X.; Wang, L.; Cao, Y.; Zhou, Y.; Huang, W. Microstructure evolution and mechanical properties of the wire + arc additive manufacturing Al-Cu alloy. Addit. Manuf. 2021, 47, 102298. [Google Scholar] [CrossRef]

- Liu, G.; Xiong, J.; Tang, L. Microstructure and mechanical properties of 2219 aluminum alloy fabricated by double-electrode gas metal arc additive manufacturing. Addit. Manuf. 2020, 35, 101375. [Google Scholar] [CrossRef]

- Bai, J.Y.; Yang, C.L.; Lin, S.B.; Dong, B.L.; Fan, C.L. Mechanical properties of 2219-Al components produced by additive manufacturing with TIG. Int. J. Adv. Manuf. Technol. 2015, 86, 479–485. [Google Scholar] [CrossRef]

- Sert, E.; Schuch, E.; Öchsner, A.; Hitzler, L.; Werner, E.; Merkel, M. Tensile strength performance with determination of the Poisson‘s ratio of additively manufactured AlSi10Mg samples. Mater. Und Werkst. 2019, 50, 539–545. [Google Scholar] [CrossRef]

- Cai, X.; Yang, M.; Wang, S.; Wang, Z.; Zhou, J.; Xue, F. Experimental investigations on corrosion behavior and antibacterial property of nickel-aluminum bronze fabricated through wire-arc additive manufacturing (WAAM). Corros. Sci. 2023, 214, 111040. [Google Scholar] [CrossRef]

- Tsai, Y.-C.; Chou, C.-Y.; Lee, S.-L.; Lin, C.-K.; Lin, J.-C.; Lim, S.W. Effect of trace La addition on the microstructures and mechanical properties of A356 (Al–7Si–0.35Mg) aluminum alloys. J. Alloys Compd. 2009, 487, 157–162. [Google Scholar] [CrossRef]

- Albu, M.; Krisper, R.; Lammer, J.; Kothleitner, G.; Fiocchi, J.; Bassani, P. Microstructure evolution during in-situ heating of AlSi10Mg alloy powders and additive manufactured parts. Addit. Manuf. 2020, 36, 101605. [Google Scholar] [CrossRef]

- Arana, M.; Ukar, E.; Rodriguez, I.; Aguilar, D.; Álvarez, P. Influence of deposition strategy and heat treatment on mechanical properties and microstructure of 2319 aluminium WAAM components. Mater. Des. 2022, 221, 110974. [Google Scholar] [CrossRef]

- Wang, C.; Jiang, Z.; Ma, X.; Zhang, Y.; He, P.; Han, F. Effect of solid solution time on microstructure and corrosion property of wire arc additively manufactured 2319 aluminum alloy. J. Mater. Res. Technol. 2023, 26, 2749–2758. [Google Scholar] [CrossRef]

- Yuan, T.; Xu, D.; Jiang, X.; Zhao, P.; Chen, S. Enhanced strength-plasticity of 2319 Al-Cu alloy formed by hybrid interlayer friction stir processing and wire-arc additive manufacturing. J. Mater. Process. Technol. 2023, 321, 118146. [Google Scholar] [CrossRef]

| Cu | Mg | Si | Mn | Fe | Zr | Ti | Al |

|---|---|---|---|---|---|---|---|

| 5.92 | 0.04 | 0.08 | 0.32 | 0.09 | 0.15 | 0.14 | Bal. |

| WFS (m/min) | TS (mm/s) | Fw (Hz) | Dw (mm) | EP/EN | T Layer (s) | Layer Height (mm) |

|---|---|---|---|---|---|---|

| 7.5 | 7 | 3 | 3 | 2.0 | 30 | 2.20 |

| C1 | C2 | C3 | C4 | |

|---|---|---|---|---|

| Al | 70.07 | 87.56 | 96.72 | 97.31 |

| Cu | 29.93 | 12.44 | 3.28 | 2.69 |

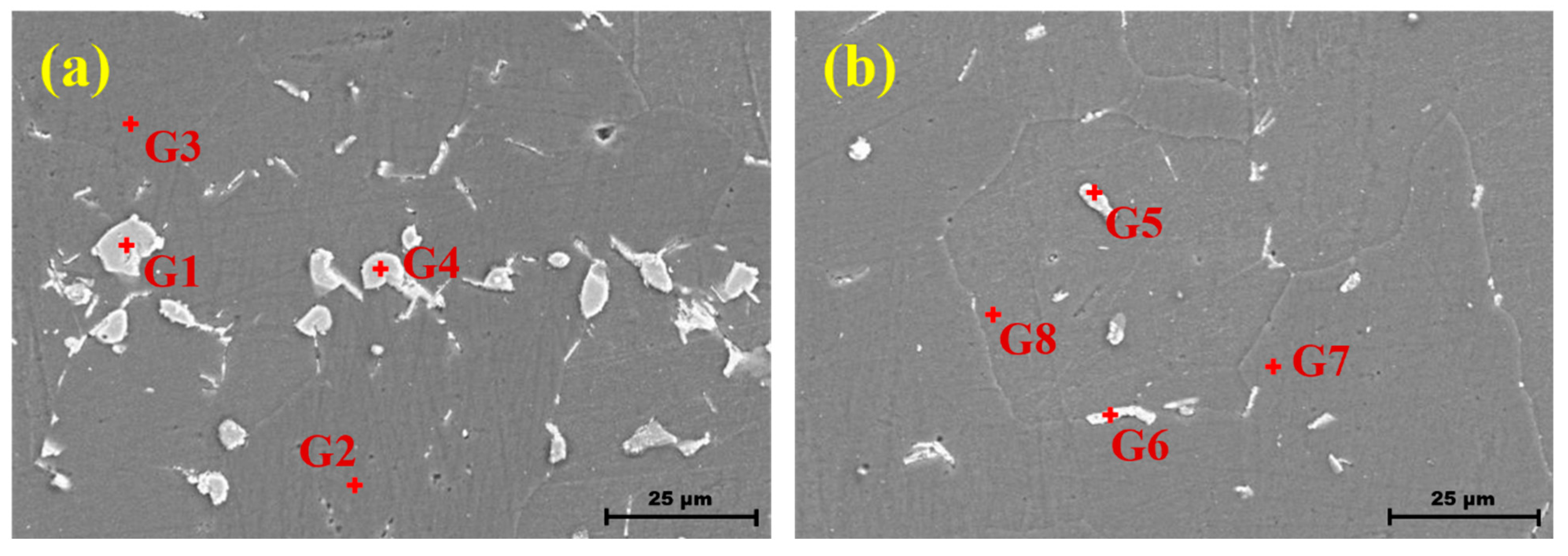

| G1 | G2 | G3 | G4 | G5 | G6 | G7 | G8 | |

|---|---|---|---|---|---|---|---|---|

| Al | 50.65 | 94.46 | 94.41 | 50.75 | 64.38 | 57.07 | 94.13 | 93.97 |

| Cu | 49.35 | 5.54 | 5.59 | 49.25 | 26.53 | 39.27 | 5.87 | 6.03 |

| Fe | - | - | - | - | 7.79 | 3.66 | - | - |

| Mn | - | - | - | - | 1.30 | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, Y.; Guo, Z.; Li, X.; Wen, L. Influence of Heat Treatment on the Microstructure and Properties of 2319 Aluminum Alloy Produced by Wire Arc Additive Manufacturing. Metals 2025, 15, 1002. https://doi.org/10.3390/met15091002

Pan Y, Guo Z, Li X, Wen L. Influence of Heat Treatment on the Microstructure and Properties of 2319 Aluminum Alloy Produced by Wire Arc Additive Manufacturing. Metals. 2025; 15(9):1002. https://doi.org/10.3390/met15091002

Chicago/Turabian StylePan, Yuxin, Zhensen Guo, Xiaoqiang Li, and Lei Wen. 2025. "Influence of Heat Treatment on the Microstructure and Properties of 2319 Aluminum Alloy Produced by Wire Arc Additive Manufacturing" Metals 15, no. 9: 1002. https://doi.org/10.3390/met15091002

APA StylePan, Y., Guo, Z., Li, X., & Wen, L. (2025). Influence of Heat Treatment on the Microstructure and Properties of 2319 Aluminum Alloy Produced by Wire Arc Additive Manufacturing. Metals, 15(9), 1002. https://doi.org/10.3390/met15091002