Effect of Adding TiZr-Based Amorphous Interlayer Through Electron Beam Welding on the Microstructure and Properties of Ti/Al Joints

Abstract

1. Introduction

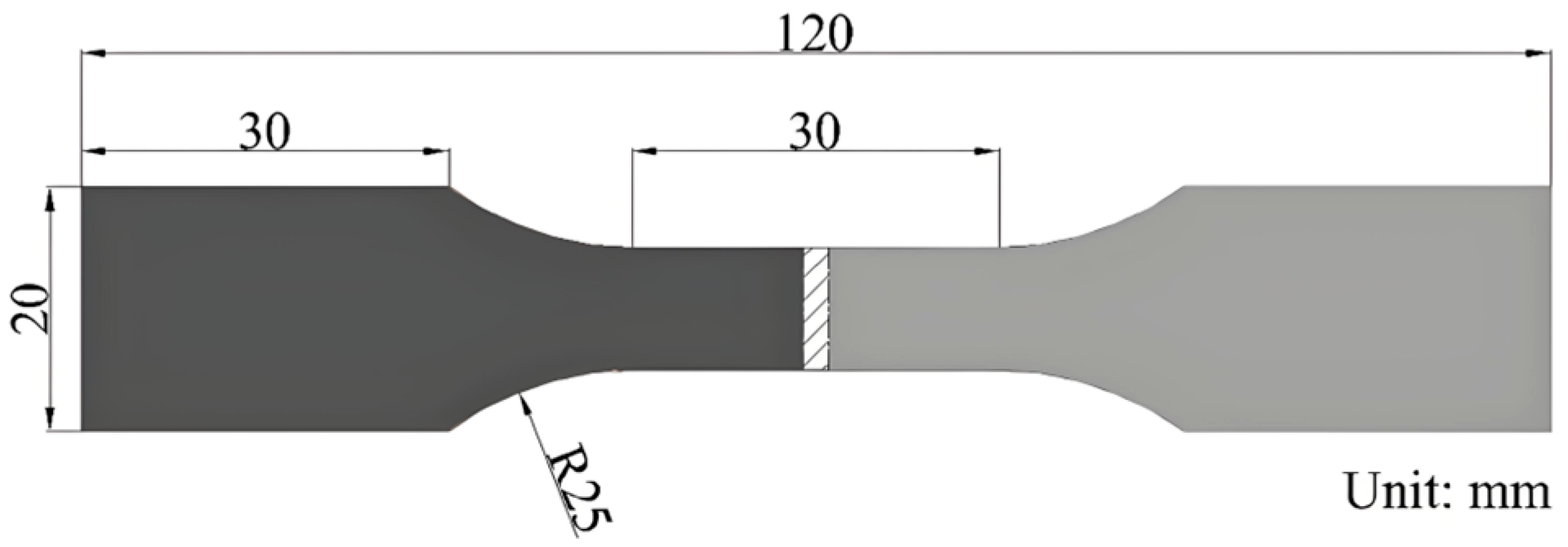

2. Materials and Methods

3. Results

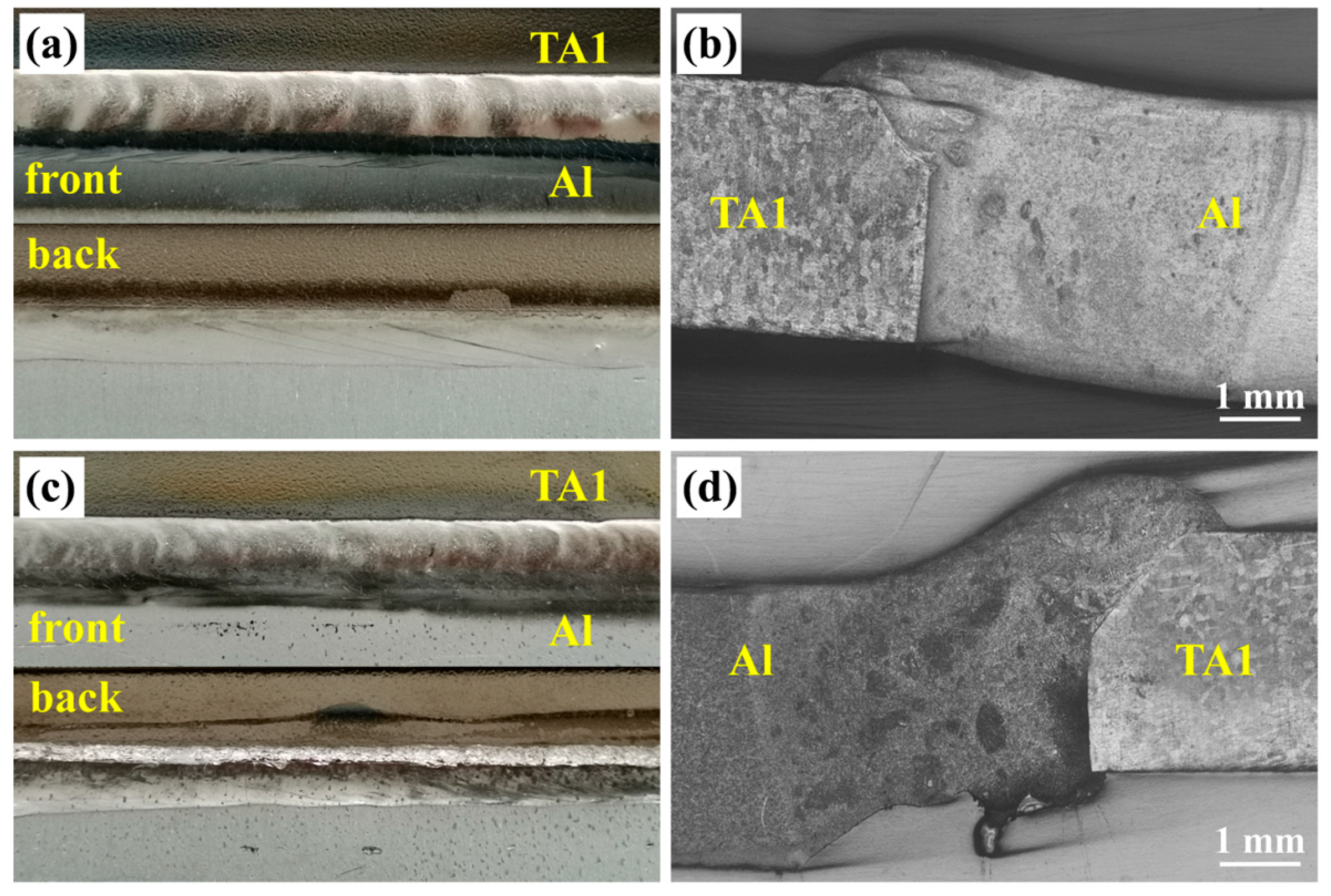

3.1. Macrostructure of Joints

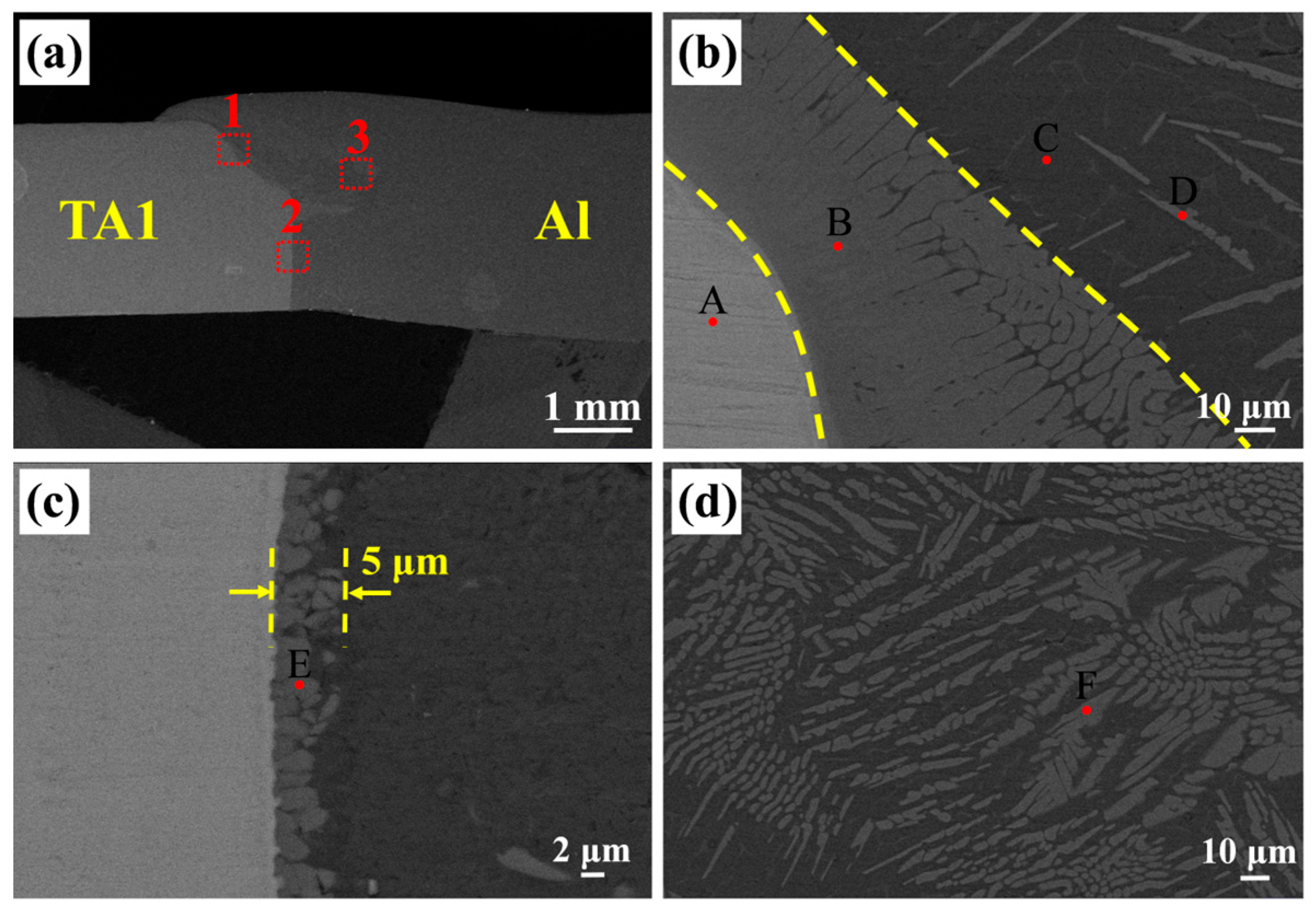

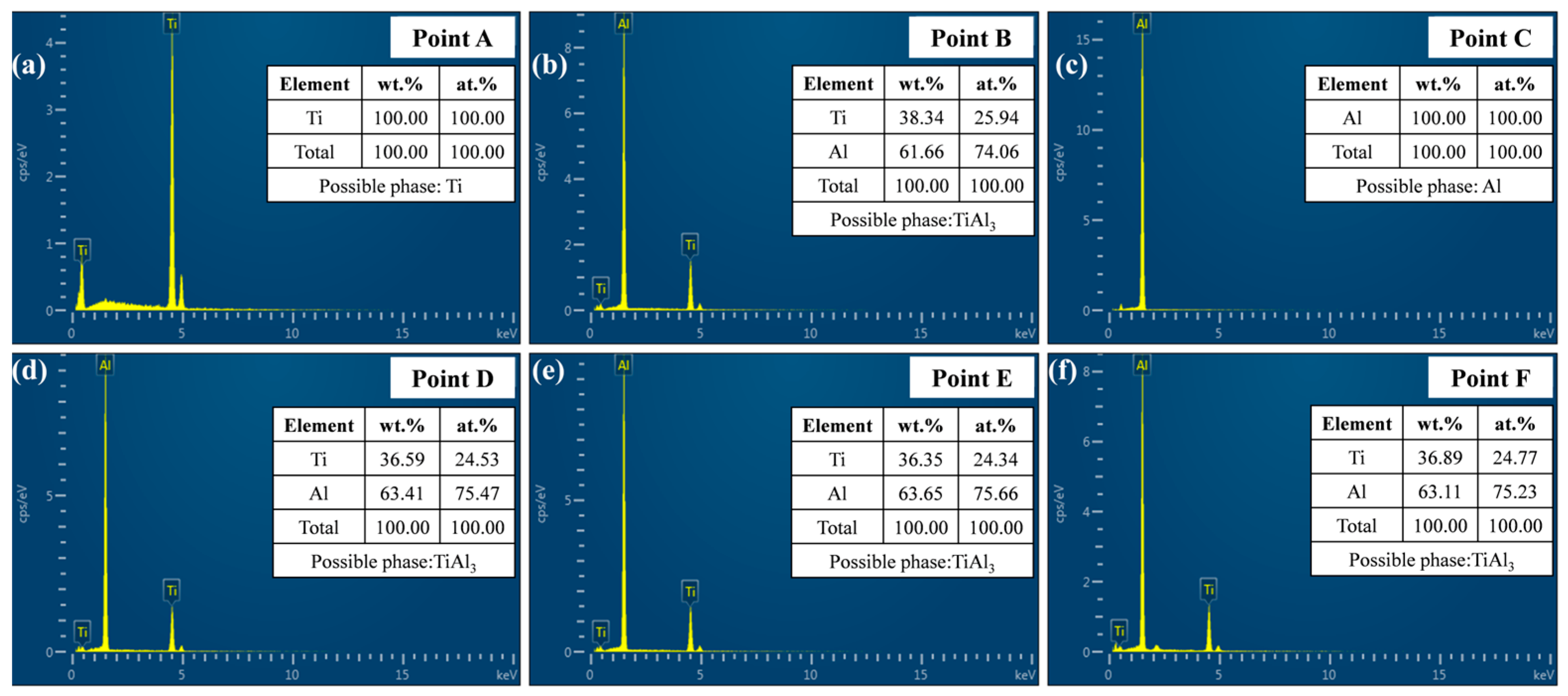

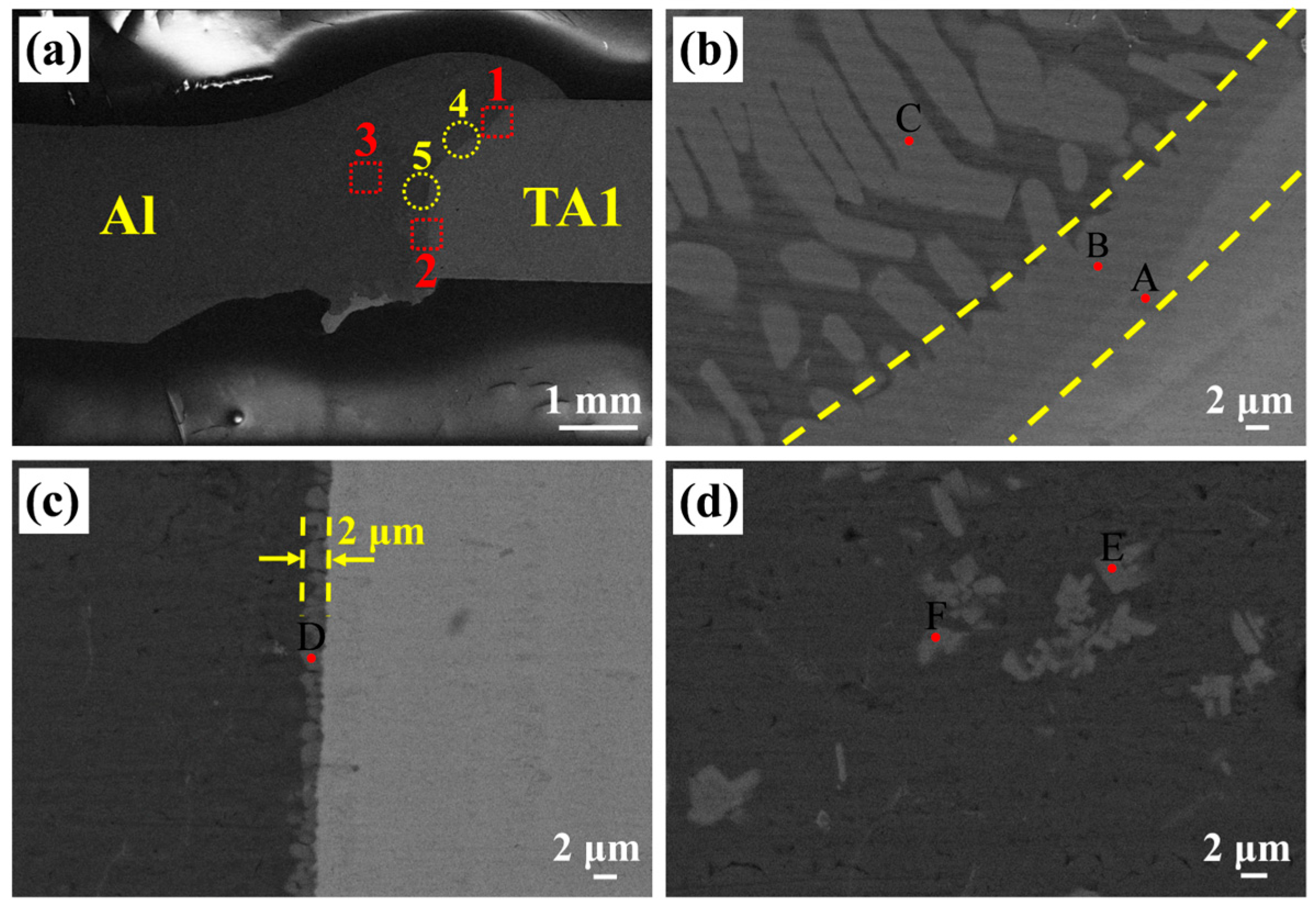

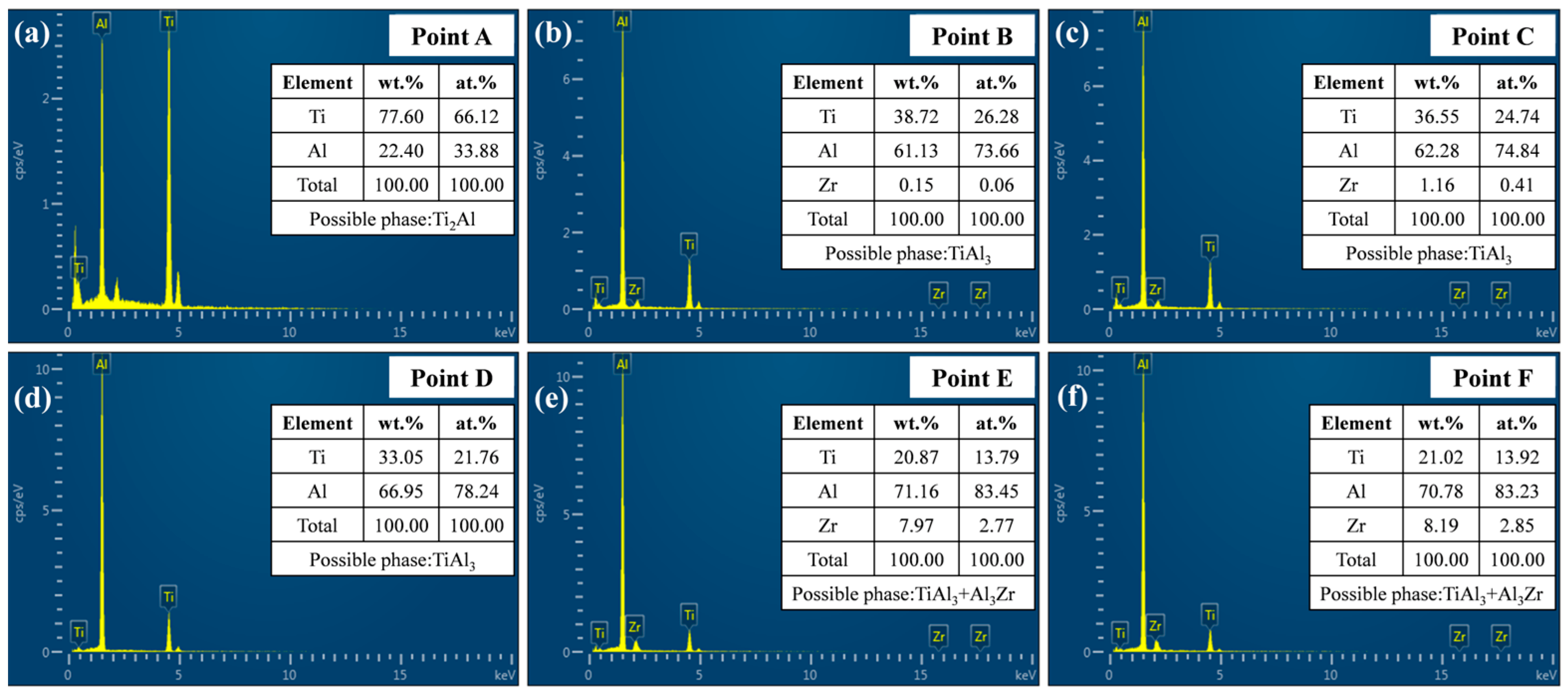

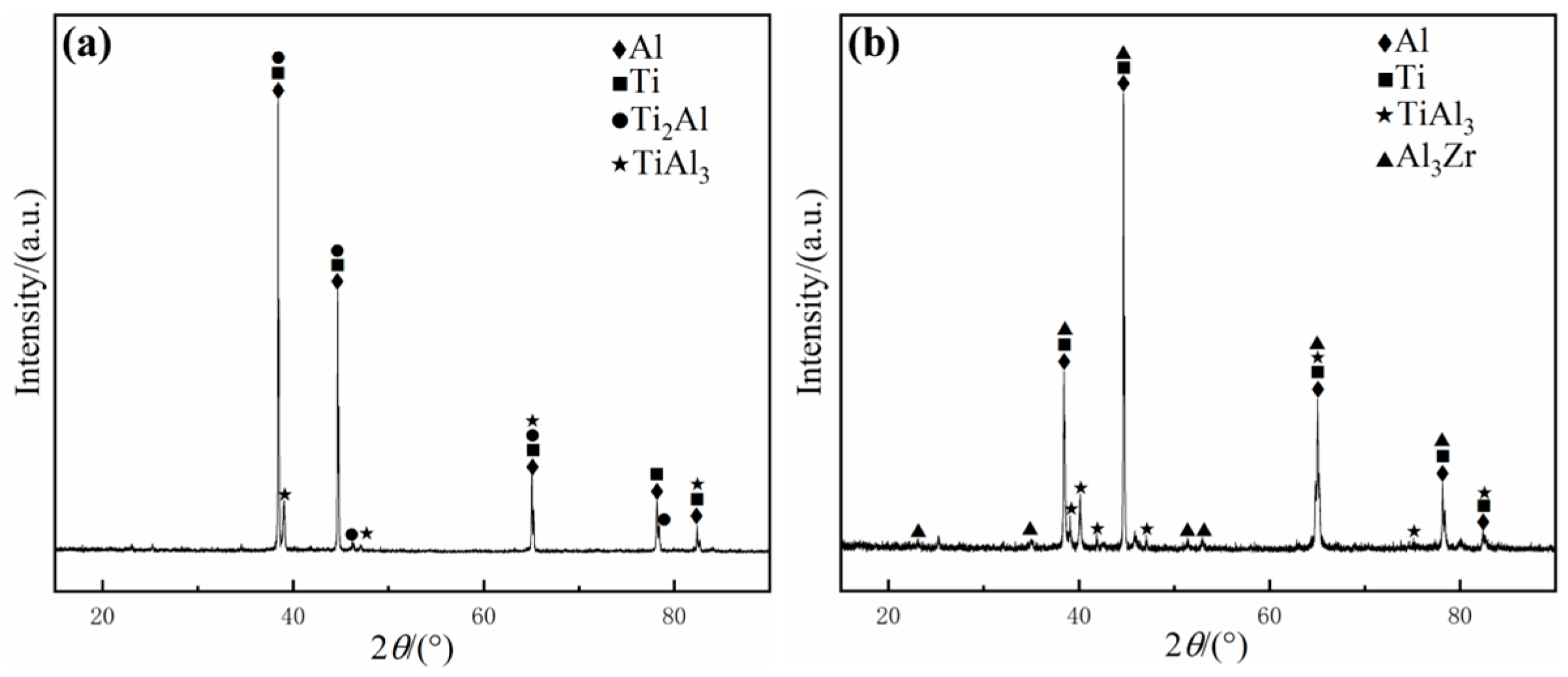

3.2. Microstructure of the Interface

3.3. Tensile Strength and Fracture Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Baqer, Y.M.; Ramesh, S.; Yusof, F.; Manladan, S.M. Challenges and Advances in Laser Welding of Dissimilar Light Alloys: Al/Mg, Al/Ti, and Mg/Ti Alloys. Int. J. Adv. Manuf. Technol. 2018, 95, 4353–4369. [Google Scholar] [CrossRef]

- Kuryntsev, S. A Review: Laser Welding of Dissimilar Materials (Al/Fe, Al/Ti, Al/Cu)—Methods and Techniques, Microstructure and Properties. Materials 2021, 15, 122. [Google Scholar] [CrossRef]

- Xie, J.; Zhang, W.; Chen, Y.; Zhang, L.; Yin, L.; Zhang, T.; Wang, S. Interfacial Microstructure and Mechanical Properties of the Al/Ti Joint by Magnetic Pulse Welding. Mater. Charact. 2022, 194, 112462. [Google Scholar] [CrossRef]

- Li, Z.; Peng, W.; Chen, Y.; Liu, W.; Zhang, H. Simulation and Experimental Analysis of Al/Ti Plate Magnetic Pulse Welding Based on Multi-Seams Coil. J. Manuf. Process. 2022, 83, 290–299. [Google Scholar] [CrossRef]

- Krishna, L.R.; Madhavi, Y.; Sahithi, T.; Rao, D.S.; Ijeri, V.S.; Prakash, O.; Gaydos, S.P. Enhancing the High Cycle Fatigue Life of High Strength Aluminum Alloys for Aerospace Applications. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 698–709. [Google Scholar] [CrossRef]

- Williams, J.C.; Boyer, R.R. Opportunities and Issues in the Application of Titanium Alloys for Aerospace Components. Metals 2020, 10, 705. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Y.; Yang, Y.; Feng, J.; Zhang, L. Properties Study on Ti/Al Butt Joining by GMAW/GTAW Hybrid Welding-Brazing. Mater. Res. Express 2023, 10, 116518. [Google Scholar] [CrossRef]

- Miao, Y.; Ma, Z.; Yang, X.; Liu, J.; Han, D. Experimental Study on Microstructure and Mechanical Properties of AA6061/Ti-6Al-4V Joints Made by Bypass-Current MIG Welding-Brazing. J. Mater. Process Technol. 2018, 260, 104–111. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, J.; Ye, Z.; Cheng, Z.; Yang, J.; Chen, S. Influence of Welding Parameters on the IMCs and the Mechanical Properties of Ti/Al Butt Joints Welded by MIG/TIG Double-Sided Arc Welding-Brazing. J. Alloys Compd. 2018, 747, 764–771. [Google Scholar] [CrossRef]

- Zhao, H.; Yu, M.; Jiang, Z.; Zhou, L.; Song, X. Interfacial Microstructure and Mechanical Properties of Al/Ti Dissimilar Joints Fabricated via Friction Stir Welding. J. Alloys Compd. 2019, 789, 139–149. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Shi, L.; Wu, C.; Li, S.; Gao, S. Double Side Friction Stir Z Shape Butt Lap Welding of Dissimilar Titanium Aluminum Alloys. Int. J. Mech. Sci. 2024, 271, 109135. [Google Scholar] [CrossRef]

- Geyer, M.; Avettand-Fènoël, M.-N.; Vidal, V.; Rezaï-Aria, F.; Boher, C. Multi-Scale Effects of the Tool Shape and Length on the Interfacial Microstructure and the Mechanical Behaviour of Al2024/Ti-6Al-4V Lap Friction Stir Welds. J. Manuf. Process. 2024, 113, 360–372. [Google Scholar] [CrossRef]

- Zhou, J.; Zhou, D. Laser Welding of TC4 Titanium Alloy to 7075 Aluminum Alloy with Infinite-Shape Oscillating Beam. Opt. Laser Technol. 2023, 160, 109044. [Google Scholar] [CrossRef]

- Chen, Z.; Cai, C.; Yu, J.; Huang, J.; Chen, H.; Li, L. Microstructure Evolution and Fracture Behavior of Laser Welded-Brazed Titanium/Aluminum Joints with Various Gap Sizes. J. Mater. Res. Technol. 2024, 29, 714–727. [Google Scholar] [CrossRef]

- Zhou, J.; Zhou, D.; Liu, J. Effect of Oscillating Laser Beam on the Interface and Mechanical Properties of Ti/Al Fusion Welding Joint. J. Mater. Res. Technol. 2022, 19, 1993–2007. [Google Scholar] [CrossRef]

- Wang, T.; Li, X.; Zhang, Y.; Li, H.; Zhang, B.; Feng, J. Regulating the Interfacial Morphology of Electron Beam Welded Pure Ti/2024Al Dissimilar Joint. J. Mater. Process. Technol. 2017, 245, 227–231. [Google Scholar] [CrossRef]

- Basude, A.; Kumar, A.; Rajasingh, G.; Kishore, M.K. Electron Beam Welding of Dissimilar Titanium to Aluminium: Interface Microstructure and Mechanical Properties. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2023, 239, 800–810. [Google Scholar] [CrossRef]

- Anchev, A.; Kaisheva, D.; Kotlarski, G.; Dunchev, V.; Stoyanov, B.; Ormanova, M.; Atanasova, M.; Todorov, V.; Daskalova, P.; Valkov, S. Welding of Ti6Al4V and Al6082-T6 Alloys by a Scanning Electron Beam. Metals 2023, 13, 1252. [Google Scholar] [CrossRef]

- Kalaiselvan, K.; Elango, A.; Nagarajan, N.M.; Sekar, K. Studies on Characteristics of Ti6Al4V/AA2024 Dissimilar Weld Joint Using Laser Beam Focusing from AA2024 Side. Trans. Indian Inst. Met. 2017, 70, 2147–2153. [Google Scholar] [CrossRef]

- Song, Z.; Nakata, K.; Wu, A.; Liao, J. Interfacial Microstructure and Mechanical Property of Ti6Al4V/A6061 Dissimilar Joint by Direct Laser Brazing without Filler Metal and Groove. Mater. Sci. Eng. A 2013, 560, 111–120. [Google Scholar] [CrossRef]

- Iltaf, A.; Dehghan, S.; Barka, N.; Belzile, C. Laser Butt Welding of AA7075 Aluminium Alloy and Ti6Al4V Titanium Alloy Using a Cu Interlayer. Mater. Sci. Technol. 2024, 40, 1015–1020. [Google Scholar] [CrossRef]

- Zhou, J.; Zhou, D.; Li, H. Effect of Adding Nb Foil on Joint Properties of Laser Fusion Welding for TC4 Titanium and 7075 Aluminum Alloy. Chin. J. Aeronaut. 2023, 36, 508–521. [Google Scholar] [CrossRef]

- Gu, X.; Zhang, L. Laser Lap Welding of TC4 Titanium Alloy to 6082 Aluminum Alloy Using a CoNiCuNb0.5 V1.5 High Entropy Alloy Filler. Mater. Lett. 2022, 312, 131562. [Google Scholar] [CrossRef]

- Lv, S.; Cui, Q.; Huang, Y.; Jing, X. Influence of Zr Addition on TIG Welding–Brazing of Ti–6Al–4V toAl5A06. Mater. Sci. Eng. A 2013, 568, 150–154. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, J.; Fu, J.; Nie, P.; Zhang, S. Microstructure and mechanical properties of laser welded-brazed titanium/aluminum joints assisted by titanium mesh interlayer. J. Mater. Process. Technol. 2022, 302, 117502. [Google Scholar] [CrossRef]

- Xia, Y.; Ma, Z.; Du, Q.; Jiu, Y.; Guo, P.; Qin, J.; Li, S.; Zhang, X.; Zhou, P.; Hu, J.; et al. Microstructure and Properties of the TiAl/GH3030 Dissimilar Joints Vacuum-Brazed with a Ti-Based Amorphous Filler Metal. Mater. Charact. 2024, 207, 113520. [Google Scholar] [CrossRef]

- Zhang, L.; Dong, H.; Li, P.; Li, S.; Wu, B.; Ma, Y.; Huang, L.; Li, C.; Li, J.; Yang, Y. Vacuum Brazing TiAl Intermetallic to K4169 Alloy Using Amorphous Filler Metals Ti56.25−xZrxNi25Cu18.75. J. Mater. Sci. Technol. 2023, 154, 217–231. [Google Scholar] [CrossRef]

- Pang, S.; Sun, L.; Xiong, H.; Chen, C.; Liu, Y.; Li, H.; Zhang, T. A Multicomponent TiZr-Based Amorphous Brazing Filler Metal for High-Strength Joining of Titanium Alloy. Scr. Mater. 2016, 117, 55–59. [Google Scholar] [CrossRef]

- Xia, Y.; Dong, H.; Zhang, R.; Wang, Y.; Hao, X.; Li, P.; Dong, C. Interfacial microstructure and shear strength of Ti6Al4V alloy/316L stainless steel joint brazed with Ti33.3Zr16.7Cu50−xNix amorphous filler metals. Mater. Des. 2020, 187, 108380. [Google Scholar] [CrossRef]

- Xia, Y.; Dong, H.; Li, P. Brazing TC4 Titanium Alloy/316L Stainless Steel Joint with Ti50−xZrxCu39Ni11 Amorphous FillerMetals. J. Alloys Compd. 2020, 849, 156650. [Google Scholar] [CrossRef]

- Lazurenko, D.V.; Ivannikov, A.A.; Anisimov, A.G.; Popov, N.S.; Dovzhenko, G.D.; Bataev, I.A.; Emurlaev, K.I.; Ogneva, T.S.; Golovin, E.D. Joining Ti-based metallic glass and crystalline titanium by magnetic pulse welding. J. Non-Cryst. Solids 2022, 597, 121912. [Google Scholar] [CrossRef]

- Liang, H.L.; Luo, N.; Shen, T.; Sun, X.; Fan, X.R.; Cao, Y. Experimental and numerical simulation study of Zr-based BMG/Al composites manufactured by underwater explosive welding. J. Mater. Res. Technol. 2020, 9, 1539–1548. [Google Scholar] [CrossRef]

- GB/T6396-2008; Clad Steel Plates—Mechanical and Technological Test. Standards Press of China: Beijing, China, 2008.

- Padhamnath, P.; Kusmierczyk, F.; Kopyscianski, M.; Gondek, L.; Migas, P.; Karbowniczek, M. Realization of a Novel FeSiAlCuSn Multicomponent Alloy and Characterization of Intermetallic Phases Formed at Different Temperatures During Cooling. Metals 2025, 15, 479. [Google Scholar] [CrossRef]

- Noell, P.J.; Carroll, J.D.; Boyce, B.L. The mechanisms of ductile rupture. Acta Mater. 2018, 161, 83–98. [Google Scholar] [CrossRef]

- Chen, X.; Lei, Z.L.; Chen, Y.B.; Han, Y.; Jiang, M.; Tian, Z.; Bi, J.; Lin, S.B. Microstructure and tensile properties of Ti/Al dissimilar joint by laser welding-brazing at subatmospheric pressure. J. Manuf. Process. 2020, 56, 19–27. [Google Scholar] [CrossRef]

- Lv, S.X.; Jing, X.J.; Huang, Y.X.; Xu, Y.Q.; Zheng, C.Q.; Yang, S.Q. Investigation on TIG Arc Welding–Brazing of Ti/Al Dissimilar Alloys with Al Based Fillers. Sci. Technol. Weld. Join. 2012, 17, 519–524. [Google Scholar] [CrossRef]

- Huang, X.-M.; Cai, G.-M.; Liu, H.-S. Phase Equilibria and Transformation in the Ti–Al–Ta System. J. Mater. Sci. 2022, 57, 2163–2179. [Google Scholar] [CrossRef]

- Zhou, X.; Cao, X.; Zhang, F.; Chen, Z.; Duan, J. Effects of AlSi12 Interlayer on Microstructure and Mechanical Properties of Laser Welded 5A06/Ti6Al4V Joints. Weld. World 2021, 65, 1389–1402. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, J.; Song, B.; Zhang, L.; Han, C.; Cai, C.; Zhou, K.; Shi, Y. A Novel Crack-Free Ti-Modified Al-Cu-Mg Alloy Designed for Selective Laser Melting. Addit. Manuf. 2021, 38, 101829. [Google Scholar] [CrossRef]

- Pozdniakov, A.V.; Barkov, R.Y.; Prosviryakov, A.S.; Churyumov, A.Y.; Golovin, I.S.; Zolotorevskiy, V.S. Effect of Zr on the Microstructure, Recrystallization Behavior, Mechanical Properties and Electrical Conductivity of the Novel Al-Er-Y Alloy. J. Alloys Compd. 2018, 765, 1–6. [Google Scholar] [CrossRef]

- Zhao, Q.; Ueno, T.; Wakabayashi, N. A Review in Titanium-Zirconium Binary Alloy for Use in Dental Implants: Is There an Ideal Ti-Zr Composing Ratio? Jpn. Dent. Sci. Rev. 2023, 59, 28–37. [Google Scholar] [CrossRef] [PubMed]

- Takeuchi, A.; Inoue, A. Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element. Mater. Trans. 2005, 46, 2817–2829. [Google Scholar] [CrossRef]

- Atamanenko, T.V.; Eskin, D.G.; Sluiter, M.; Katgerman, L. On the Mechanism of Grain Refinement in Al–Zr–Ti Alloys. J. Alloys Compd. 2011, 509, 57–60. [Google Scholar] [CrossRef]

| Elements | Fe | Cu | Si | N | C | H | O | Al | Ti |

|---|---|---|---|---|---|---|---|---|---|

| TA1 | 0.2 | - | - | 0.03 | 0.08 | 0.015 | 0.18 | - | Bal. |

| Al | 0.003 | 0.003 | 0.003 | - | - | - | - | Bal. | - |

| Welding Parameters | Value |

|---|---|

| Accelerating voltage, kV | 60 |

| Welding speed, mm/min | 1000 |

| Beam current, mA | 35 |

| Focusing current, mA | 413 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, L.; Zhang, B.; Xu, R.; Zhang, L. Effect of Adding TiZr-Based Amorphous Interlayer Through Electron Beam Welding on the Microstructure and Properties of Ti/Al Joints. Metals 2025, 15, 1001. https://doi.org/10.3390/met15091001

Chen L, Zhang B, Xu R, Zhang L. Effect of Adding TiZr-Based Amorphous Interlayer Through Electron Beam Welding on the Microstructure and Properties of Ti/Al Joints. Metals. 2025; 15(9):1001. https://doi.org/10.3390/met15091001

Chicago/Turabian StyleChen, Lei, Bo Zhang, Rongzheng Xu, and Li Zhang. 2025. "Effect of Adding TiZr-Based Amorphous Interlayer Through Electron Beam Welding on the Microstructure and Properties of Ti/Al Joints" Metals 15, no. 9: 1001. https://doi.org/10.3390/met15091001

APA StyleChen, L., Zhang, B., Xu, R., & Zhang, L. (2025). Effect of Adding TiZr-Based Amorphous Interlayer Through Electron Beam Welding on the Microstructure and Properties of Ti/Al Joints. Metals, 15(9), 1001. https://doi.org/10.3390/met15091001