Effect of Mo on Microstructure and Mechanical Properties of Corrosion-Resistant Tank Steel

Abstract

1. Introduction

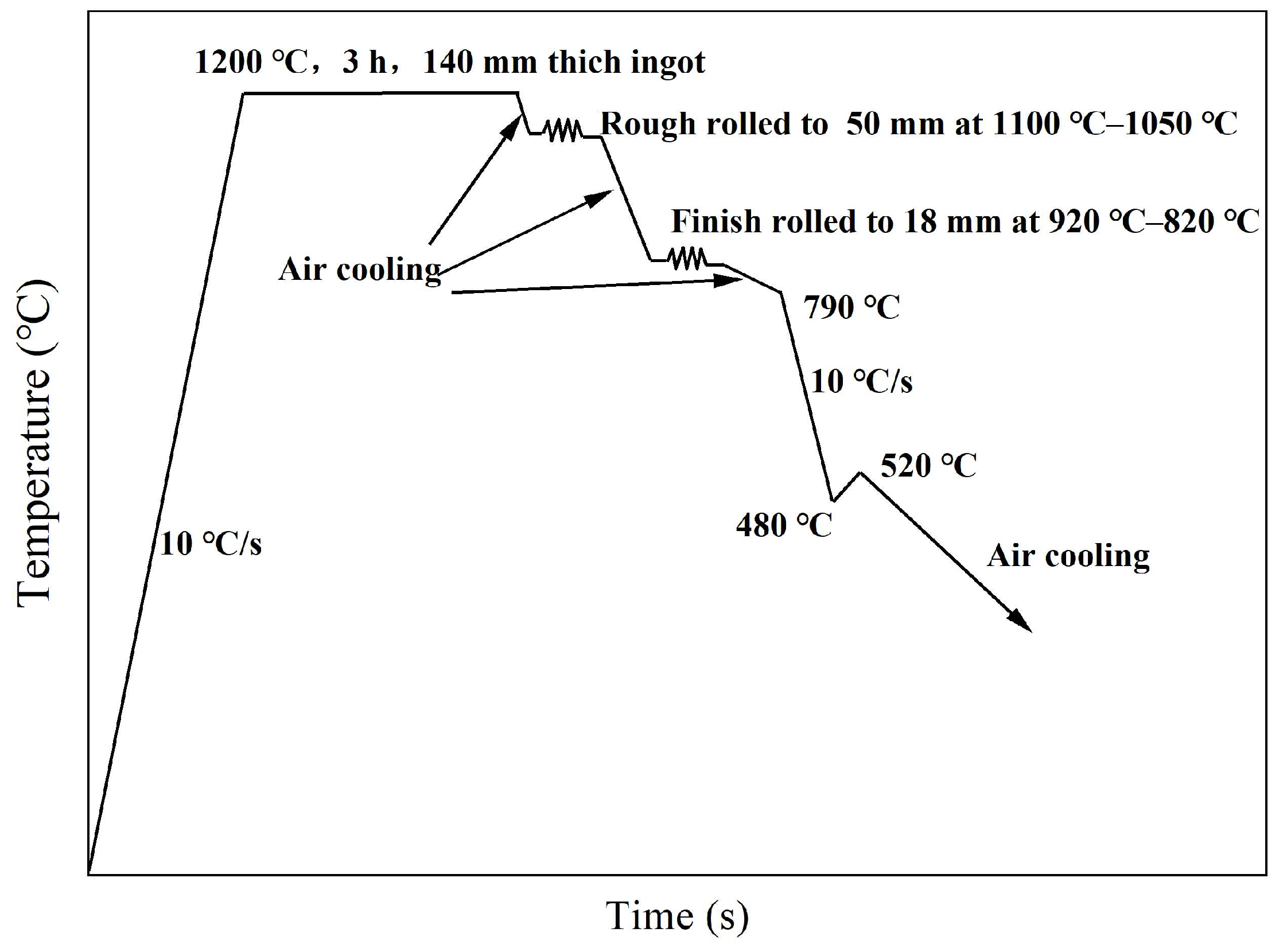

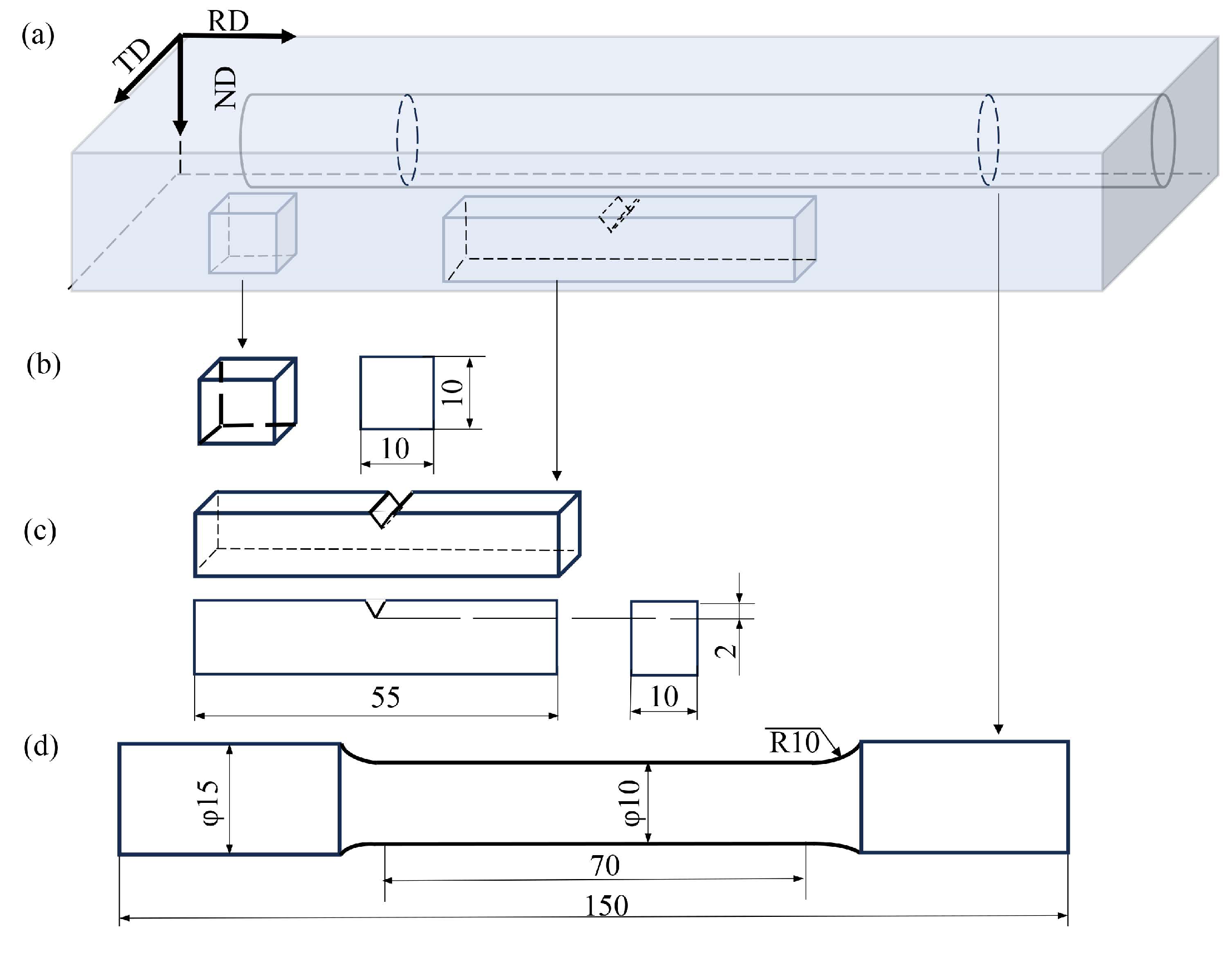

2. Materials and Methods

3. Results

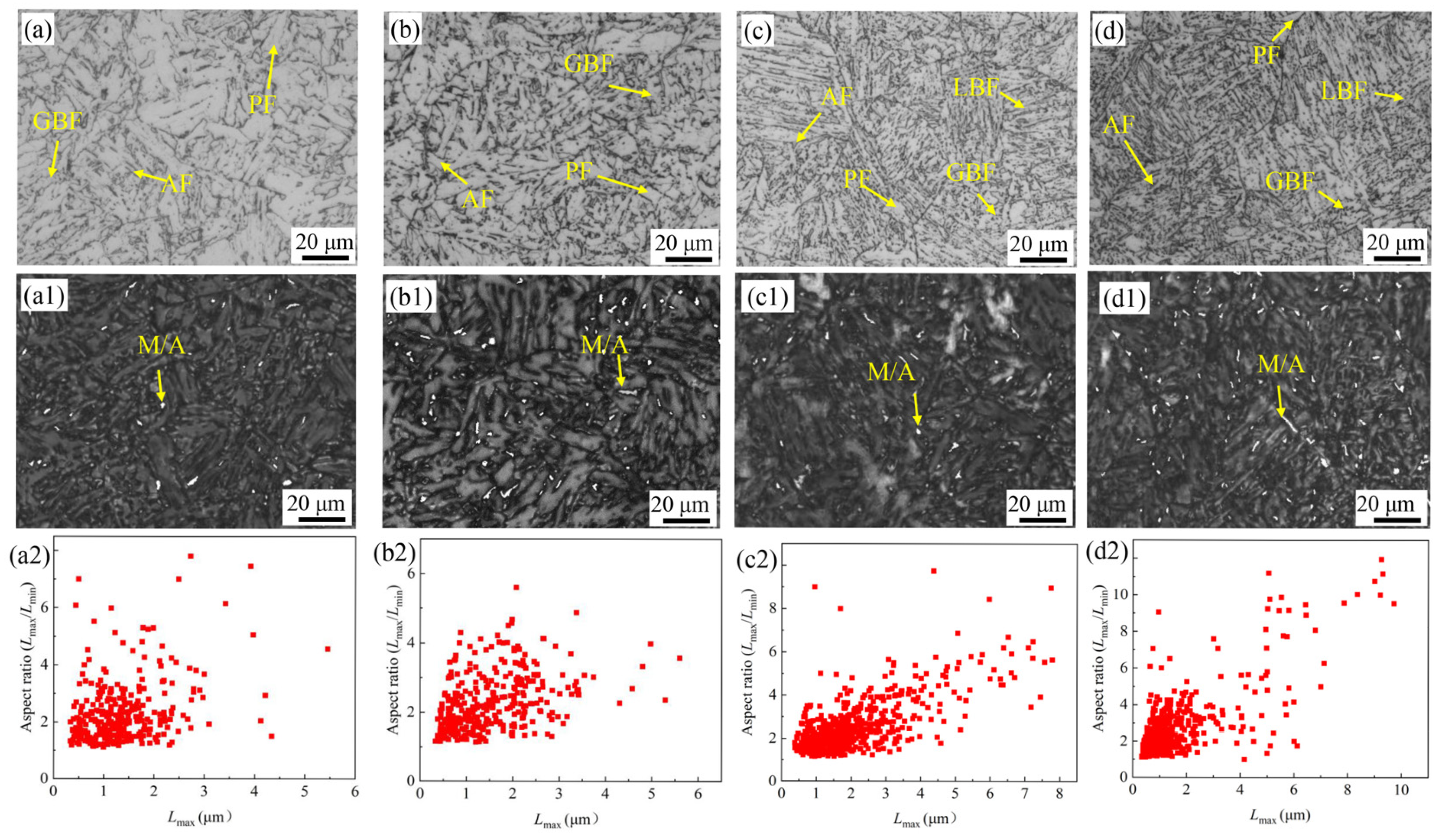

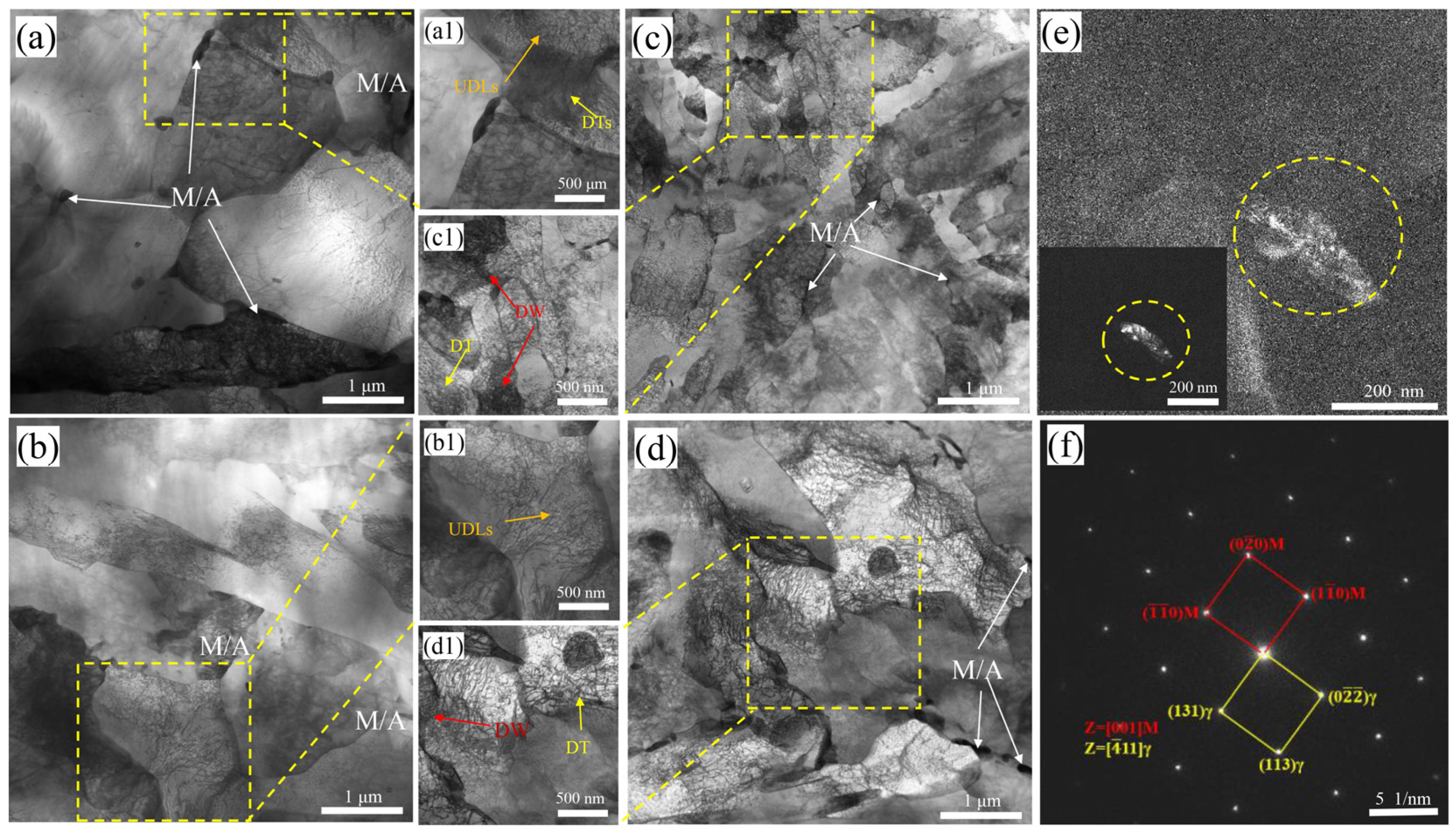

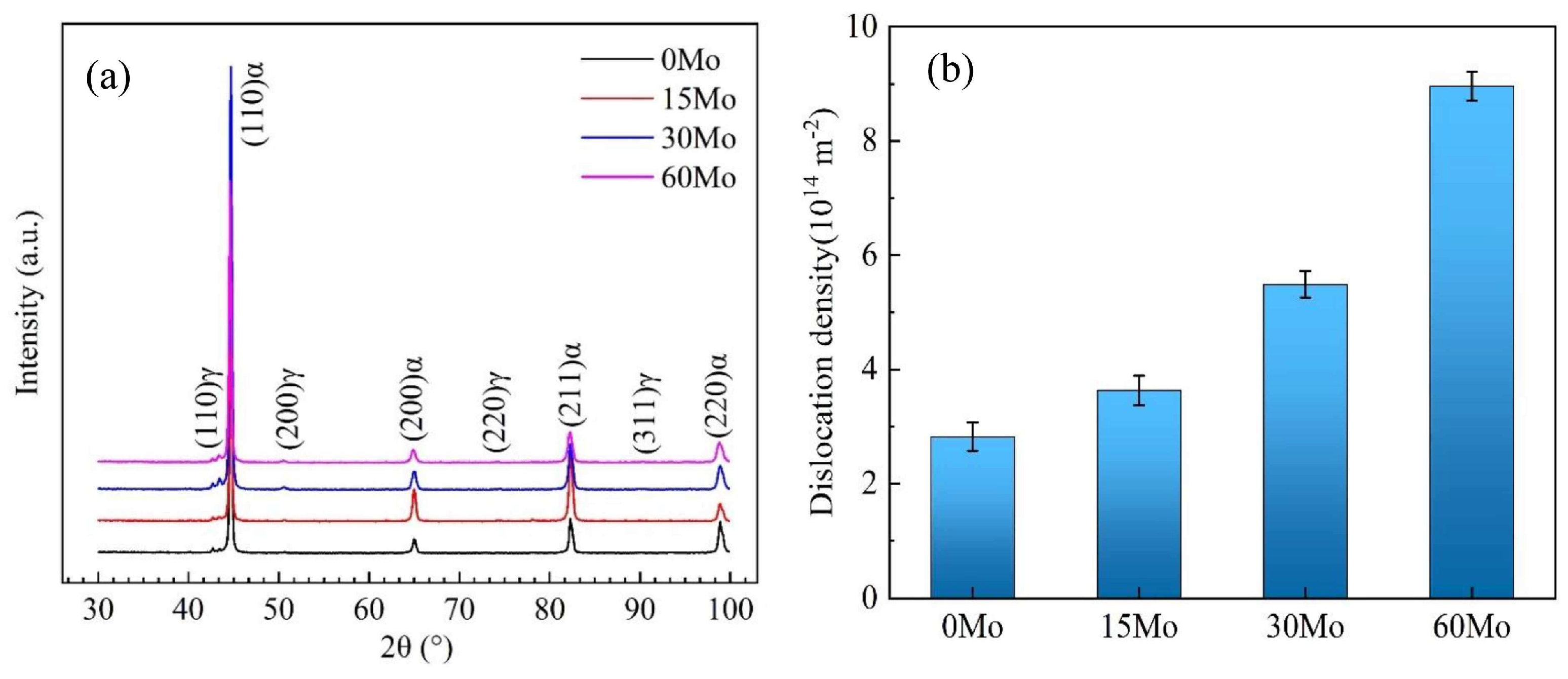

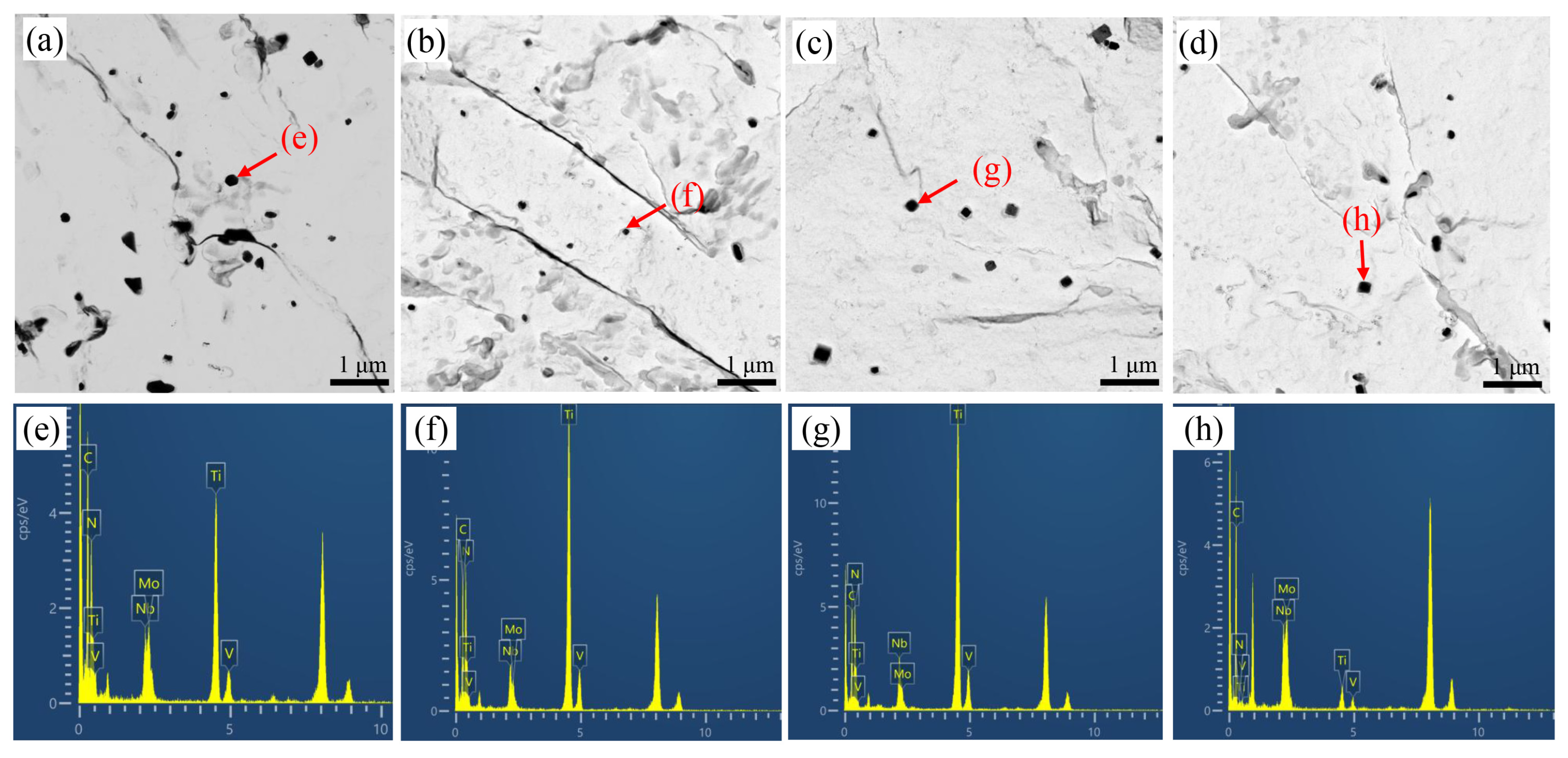

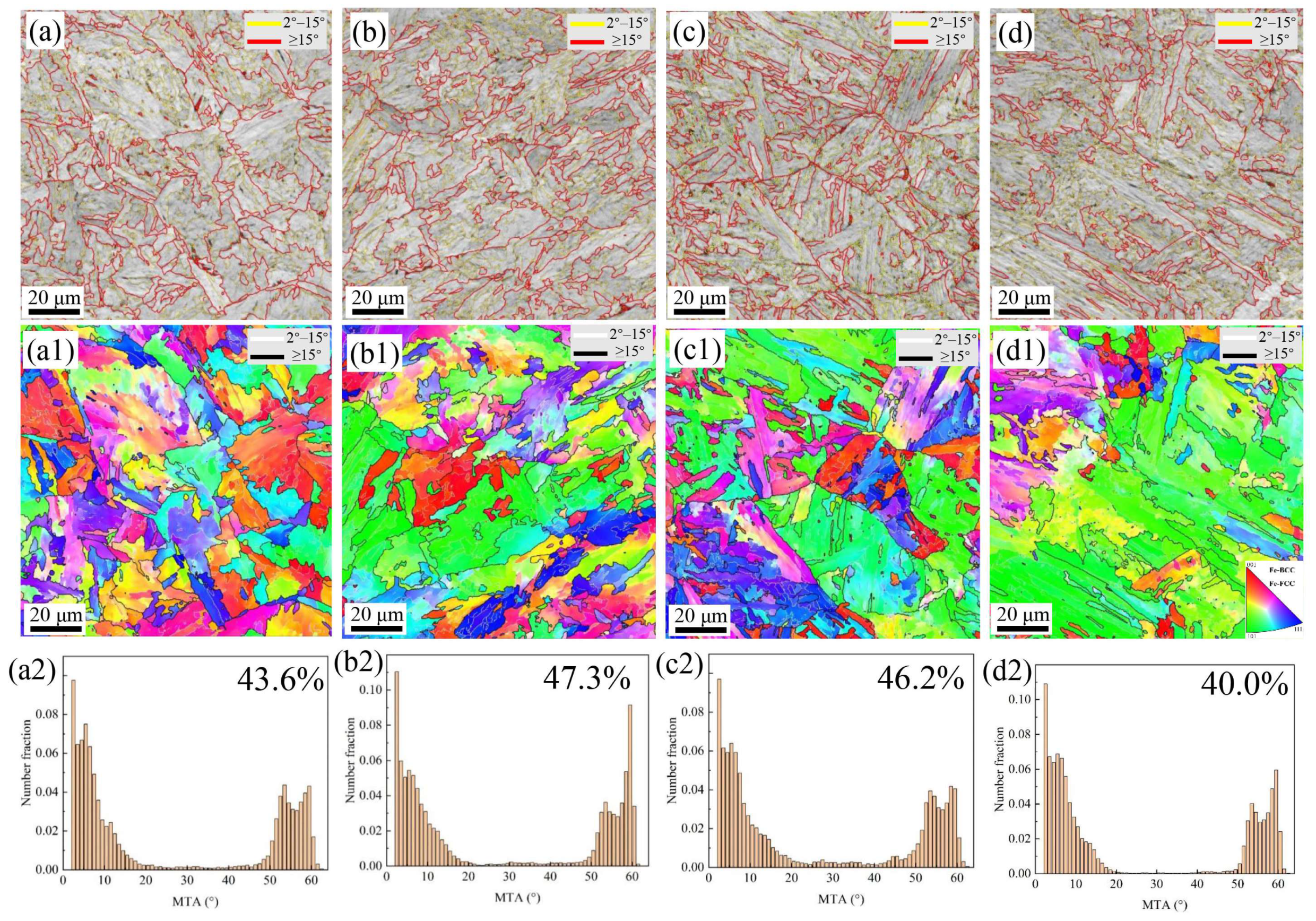

3.1. Microstructural Characterization

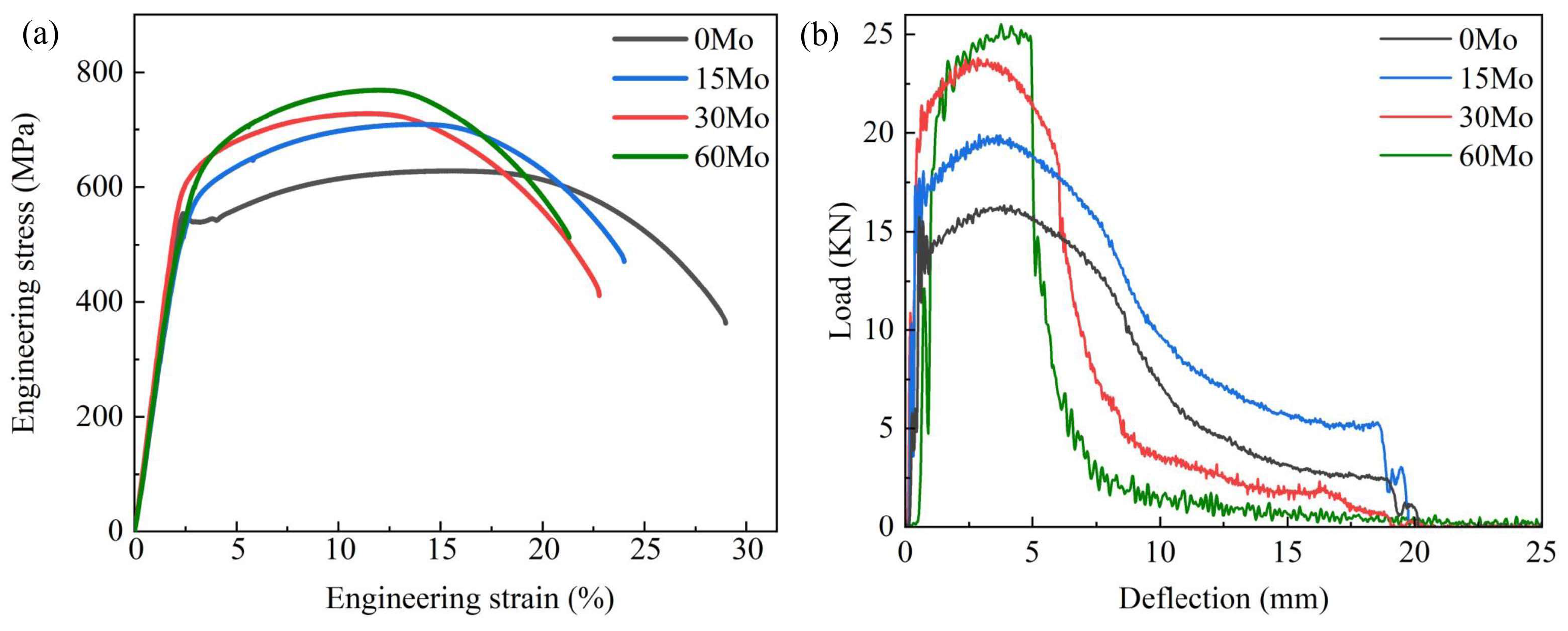

3.2. Mechanical Properties

4. Discussion

4.1. Effect of Mo on Base Metal Strength

4.2. Effect of Mo on Base Metal Toughness

5. Conclusions

- (1)

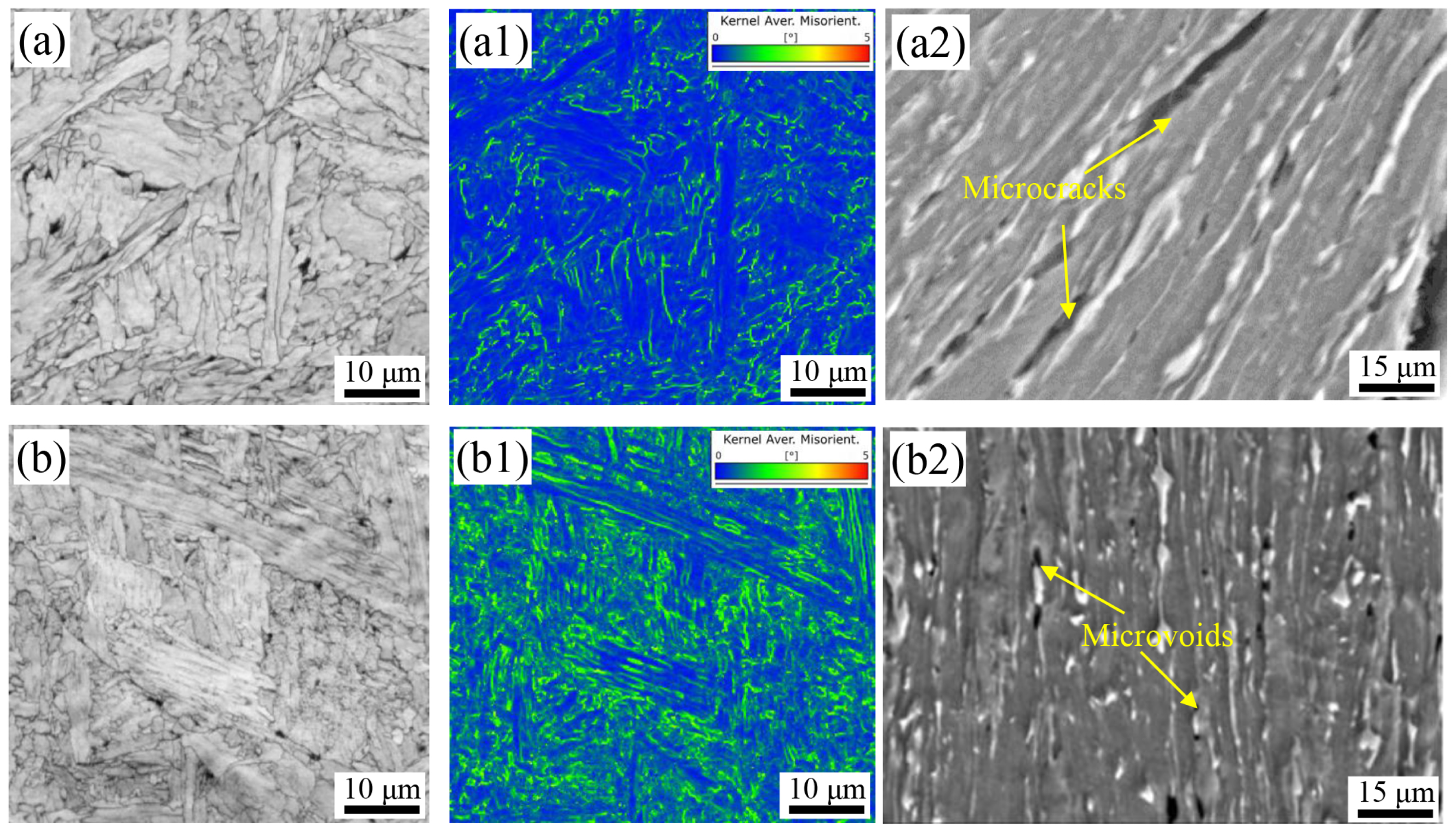

- Microstructural evolution: Steels with 0–0.15 wt% Mo exhibited polygonal ferrite, acicular ferrite, and granular bainitic ferrite. At ≥0.30 wt% Mo, the polygonal ferrite proportion decreased significantly with lath bainitic ferrite formation. Mo addition refined and dispersed hard M/A constituents.

- (2)

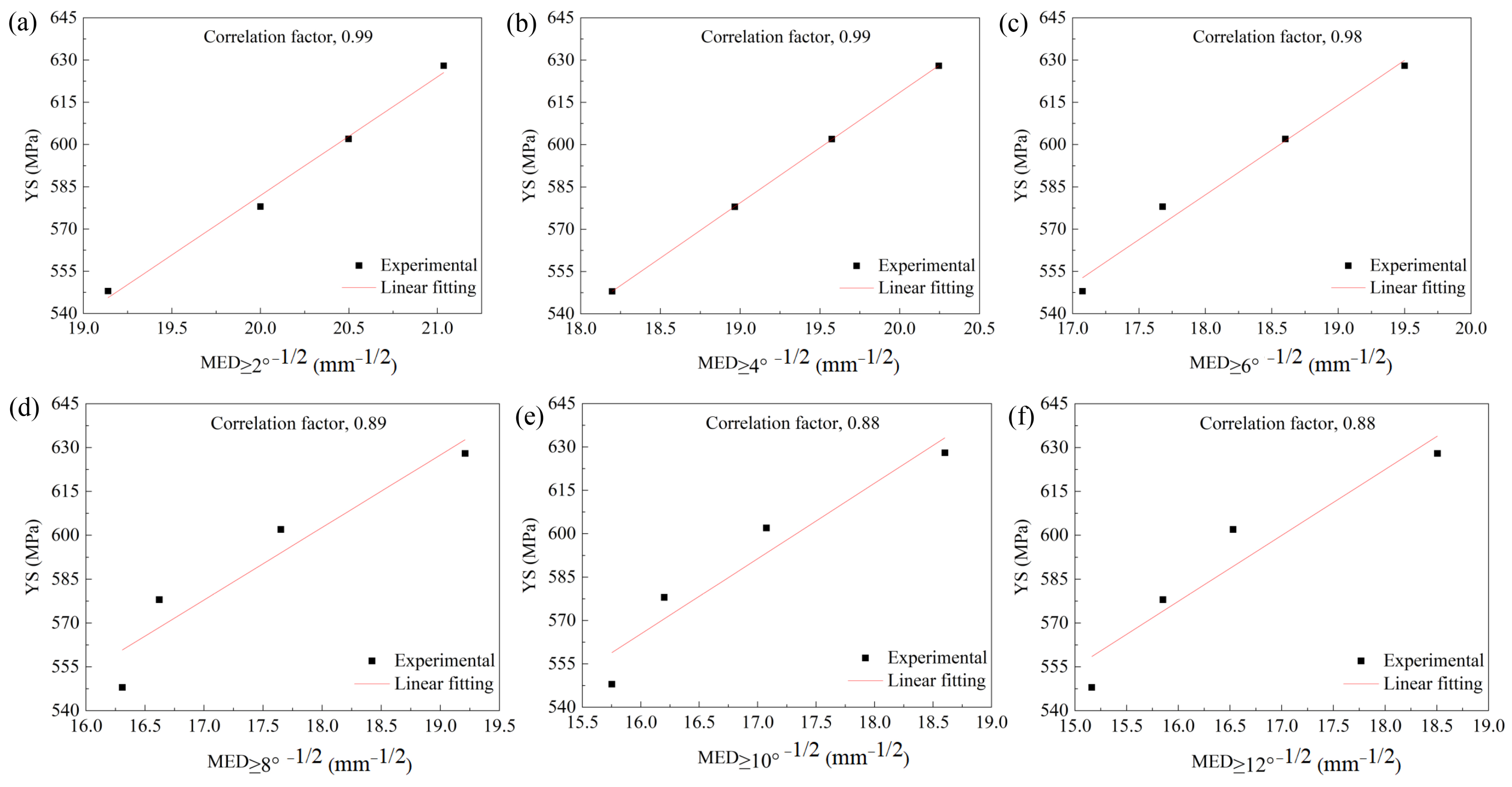

- Strengthening mechanism: Mo content increase enhanced yield/tensile strength. The 2–6° misorientation tolerance angles-defined grain size showed optimal Hall–Petch correlation with yield strength. The 0.15% Mo steel demonstrated the highest strain-hardening capacity and the lowest yield ratio.

- (3)

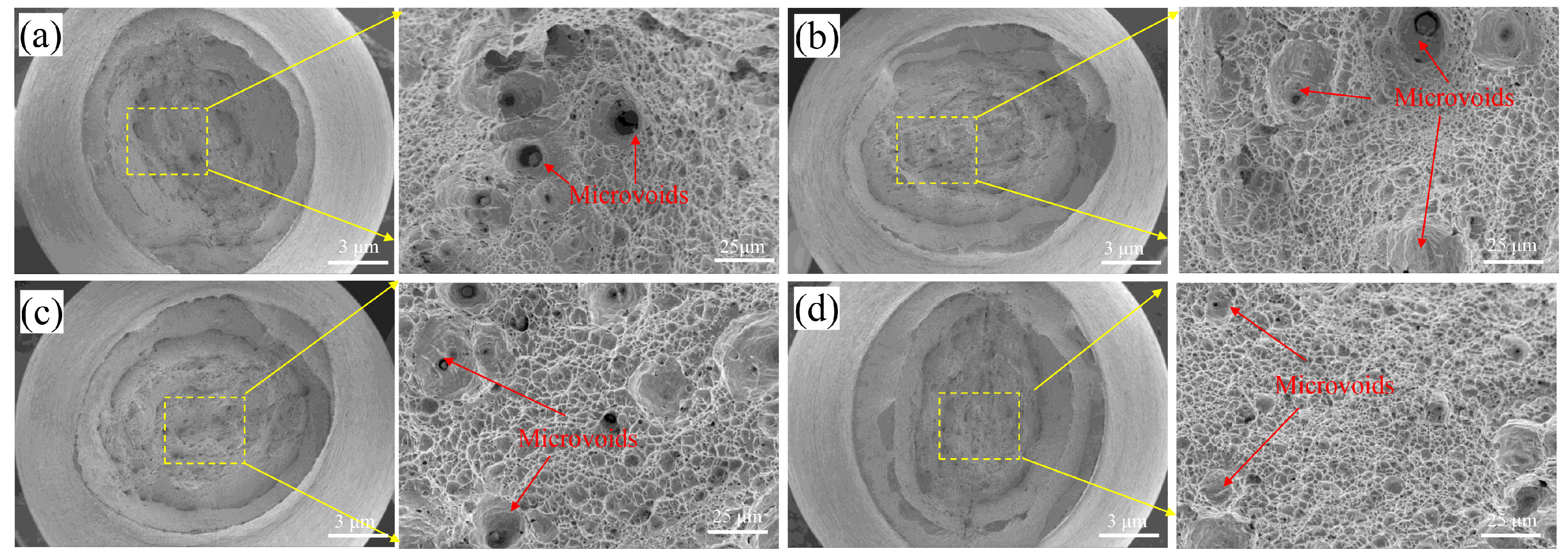

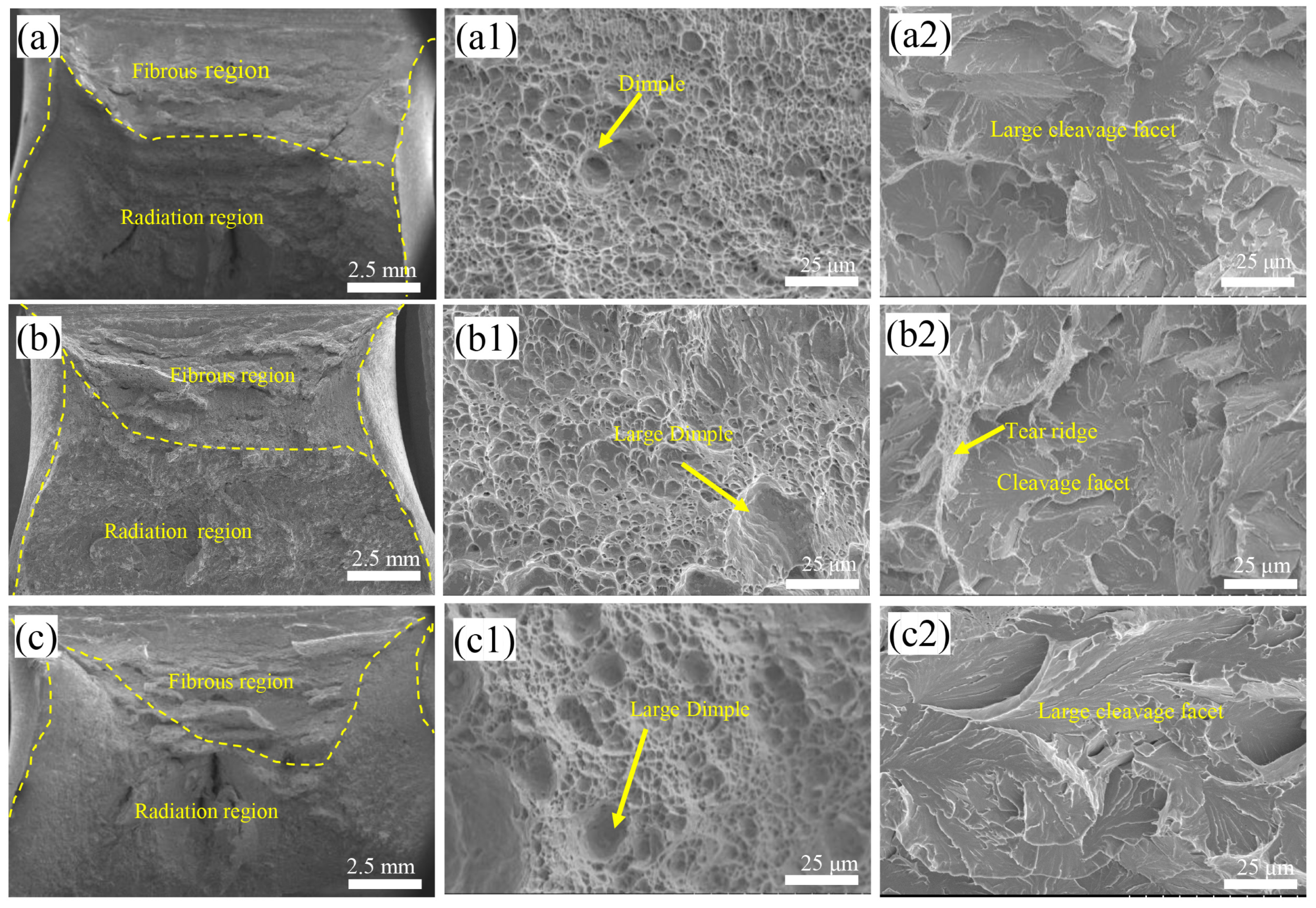

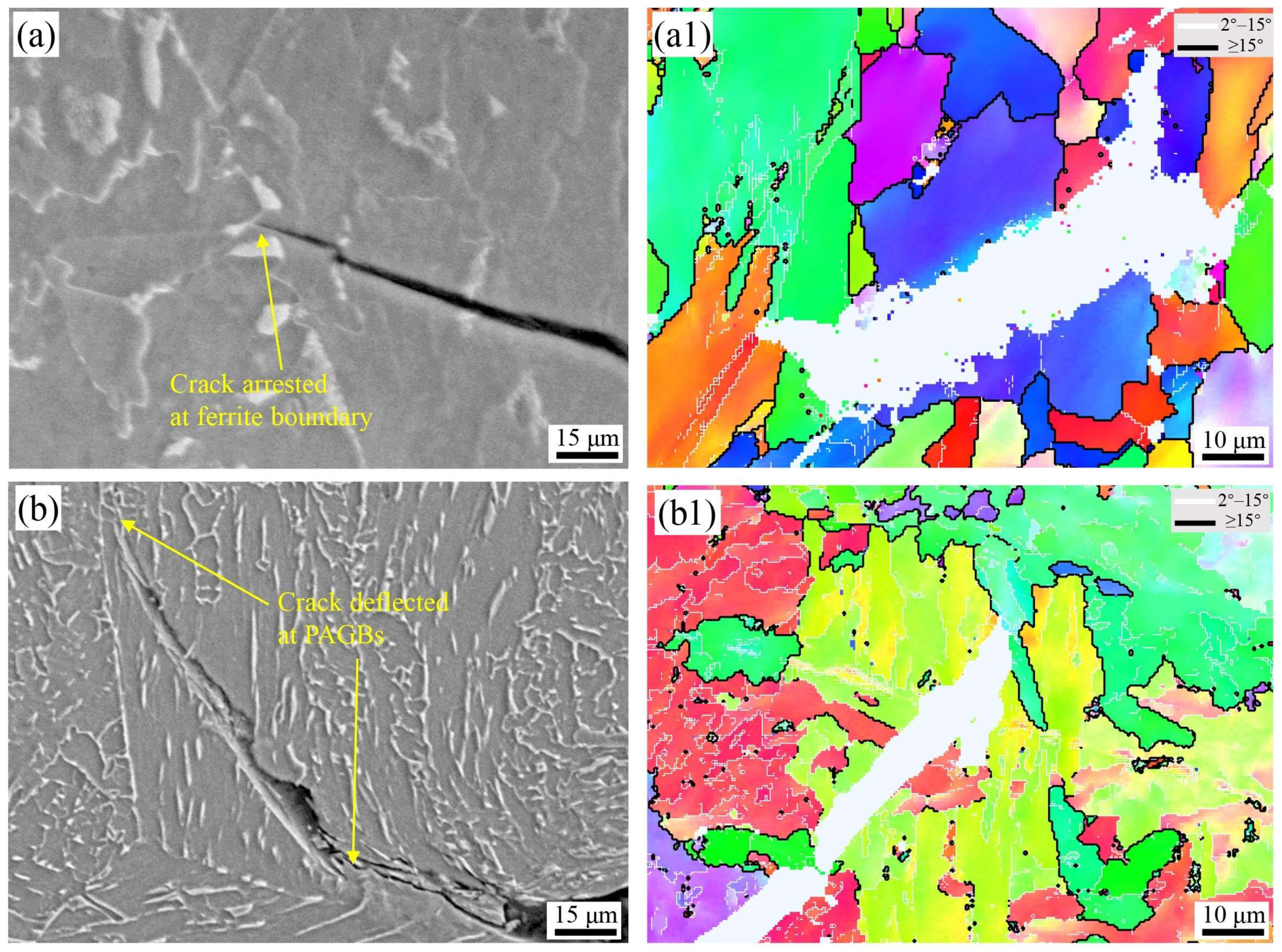

- Toughness mechanism: Elevated Mo reduced local micro-strain concentration and crack initiation susceptibility. Both ferrite lath boundaries and PAGBs acted as HAGBs, effectively retarding crack propagation. Crack propagation energy showed a non-monotonic trend (rise then fall) with Mo content. The 0.15% Mo steel achieved optimal low-temperature impact toughness through synergistic improvement in crack initiation resistance and propagation resistance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Baere, K.; Verstraelen, H.; Willemen, R.; Smet, J.; Tchuindjang, J.; Lecomte-Beckers, J.; Lenaerts, S.; Meskens, R.; Jung, H.; Potters, G. Assessment of Corrosion Resistance, Material Properties, and Weldability of Alloyed Steel for Ballast Tanks. J. Mar. Sci. Technol. 2017, 22, 176–199. [Google Scholar] [CrossRef]

- Wei, J.; Qi, Y.; Tian, Z.; Peng, Y. Corrosion Behavior of Welded Joints for Cargo Oil Tanks of Crude Oil Carrier. J. Iron Steel Res. Int. 2016, 23, 955–962. [Google Scholar] [CrossRef]

- Dalcin, R.; Machado, I.; Gonzalez, A.; Gonzalez, A.; Mazzaferro, J. Effects of Heat Input and Consumable on Simple Bending Strength of Welded Joints in TMCP Steel Tubular Profiles. Soldag. Insp. 2016, 21, 92–102. [Google Scholar] [CrossRef]

- Cai, W.; Wang, Y.; Li, G.; Stroetmann, R. Comparative Study on Strength of TMCP and QT High-Strength Steel Butt-Welded Joints. Constr. Steel Res. 2022, 197, 107447. [Google Scholar] [CrossRef]

- Liu, W.; Zhou, Q.; Li, L.; Wu, Z.; Cao, F.; Cao, Z. Effect of Alloy Element on Corrosion Behavior of the Huge Crude Oil Storage Tank Steel in Seawater. J. Alloys Compd. 2014, 598, 198–204. [Google Scholar] [CrossRef]

- He, Y.; Liu, J.; Huang, G.; Xu, H.; Liu, N.; Qi, J. Elemental Segregation, Microstructure, and Mechanical Properties of TMCP-treated High-Manganese Wear-resistant Ateel. J. Iron Steel Res. Int. 2025, 32, 783–798. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Singh, G.; Msolli, S.; Jhon, M.; Ramamurty, U. Tension-compression Asymmetry and Shear Strength of Titanium Alloys. Acta Mater. 2021, 221, 117392. [Google Scholar] [CrossRef]

- Su, S.; Song, R.; Quan, S.; Wang, Y.; Cai, C. Microstructure-mechanical Properties Relationships and Strain Hardening Mechanism for Medium-Mn steel with Low Yield and Ultra-high Tensile Strength. Mater. Sci. Eng. 2023, A 874, 145085. [Google Scholar] [CrossRef]

- Mandal, G.; Ghosh, S.; Chakrabarti, D. Influence of TMCP Parameters on Structure and Properties of Low Carbon Cu Bearing Ultra-High Strength Steel. Phys. Met. Metall. 2020, 121, 269–275. [Google Scholar] [CrossRef]

- He, B.; Wang, M.; Liu, L.; Huang, M. High-Strength Medium Mn Quenching and Partitioning Steel with Low Yield Ratio. Mater. Sci. Technol. 2019, 35, 2109–2114. [Google Scholar] [CrossRef]

- Liu, D.; Yang, J.; Zhang, Y.; Xu, L. Effect of Mo Content on Nano-Scaled Particles, Prior Austenite Grains and Impact Toughness of CGHAZ in Offshore Engineering Steels. J. Iron Steel Res. Int. 2022, 29, 846–858. [Google Scholar] [CrossRef]

- Kumar, P.; Maity, K.; Dasgupta, A.; Gond, S.; Sarkar, B. Innovations in Thermo-mechanical Processing to Develop High Strength Steel Plates. Trans. Indian Inst. Met. 2022, 75, 2069–2076. [Google Scholar] [CrossRef]

- Urtsev, N.; Platov, S.; Shmakov, A.; Ryzhkov, M.; Lobanov, M. Thermophysical Properties of High-Strength Low-Alloyed Pipe Steel. Phys. Met. Metall. 2024, 125, 1284–1290. [Google Scholar] [CrossRef]

- Kostryzhev, A.; Singh, N.; Chen, L.; Killmore, C.; Pereloma, E. Comparative Effect of Mo and Cr on Microstructure and Mechanical Properties in NbV-Microalloyed Bainitic Steels. Metals 2018, 8, 134. [Google Scholar] [CrossRef]

- Jia, J.; Liu, Z.; Li, X.; Du, C.; Li, W. Comparative Study on The Stress Corrosion Cracking of A New Ni-advanced High Strength Steel Prepared by TMCP, Direct Quenching, and Quenching & Tempering. Mater. Sci. Eng. 2021, A 825, 141854. [Google Scholar]

- Fan, Y.; Wang, Q.; Liu, H.; Wang, T.; Wang, Q.; Zhang, F. Effect of Controlled Cooling on Microstructure and Tensile Properties of Low C Nb-Ti-Containing HSLA Steel for Construction. Metals 2017, 7, 23. [Google Scholar] [CrossRef]

- Bayock, F.; Kah, P.; Layus, P.; Karkhin, V. Numerical and Experimental Investigation of the Heat Input Effect on the Mechanical Properties and Microstructure of Dissimilar Weld Joints of 690-MPa QT and TMCP Steel. Metals 2019, 9, 355. [Google Scholar] [CrossRef]

- Li, Y.; Huang, M. A Method to Calculate the Dislocation Density of a TWIP Steel Based on Neutron Diffraction and Synchrotron X-Ray Diffraction. Acta Metall. Sin. 2020, 56, 487–493. [Google Scholar]

- Suryanarayana, C. Mechanical Alloying: A Critical Review. Mater. Res. Lett. 2022, 10, 619–647. [Google Scholar] [CrossRef]

- Xiao, X.; Peng, Y.; Ma, C.; Tian, Z. Effects of Alloy Element and Microstructure on Corrosion Resistant Property of Deposited Metals of Weathering Steel. J. Iron Steel Res. Int. 2016, 23, 171–177. [Google Scholar] [CrossRef]

- Cao, R.; Han, C.; Guo, X.; Jiang, Y.; Liao, F.; Yang, F.; Dou, G.; Yan, Y.; Chen, J. Effects of Boron on the Microstructure and Impact Toughness of Weathering Steel Weld Metals and Existing Form of Boron. Mater. Sci. Eng. 2022, A 833, 142560. [Google Scholar] [CrossRef]

- Hu, B.; Zhang, Y.; Wu, J.; Wang, Q.; Wang, Q. Mechanisms Underlying the Marked Enhancement of Toughness in the CGHAZ of N-Ti Weathering Steel Subjected to Large Heat Input Through the Trace Addition of Vanadium. Mater. Sci. Eng. 2025, A 925, 147910. [Google Scholar] [CrossRef]

- Lee, C.; Shin, H.; Park, K.; Chang, K. Impact Fracture Energy of Structural Steel Welds Constructed at Low Ambient Temperatures. Constr. Build. Mater. 2014, 50, 394–400. [Google Scholar] [CrossRef]

- Abreu, L.; Faria, G.; de Faria, R.; Matsubara, D.; Porcaro, R. Optimizing Rolling Strategies for API 5L X80 Steel Heavy Plates Produced by Thermomechanical Processing in a Reversible Single-Stand Mill. Metals 2024, 14, 746. [Google Scholar]

- Tian, J.; Wang, W.; Xu, G.; Wang, X.; Zhou, M.; Zurob, H. Microstructure and Properties of a Low Carbon Bainitic Steel Produced by Conventional and Inverted Two-Step Austempering Processes. Met. Mater. Int. 2023, 29, 1298–1310. [Google Scholar] [CrossRef]

- Hu, B.; Wang, Q.; Wang, Q. Effect of Heat Input on Microstructure and Tensile Properties in Simulated CGHAZ of a V-Ti-N Microalloyed Weathering Steel. Metals 2023, 13, 1607. [Google Scholar] [CrossRef]

- Chen, C.; Lv, B.; Feng, X.; Zhang, F.; Beladi, H. Strain Hardening and Nanocrystallization Behaviors in Hadfield Steel Subjected to Surface Severe Plastic Deformation. Mater. Sci. Eng. 2018, A 729, 178–184. [Google Scholar] [CrossRef]

- Kim, J.; Ko, S.; Hwang, B. Effect of Microstructure on Strain Aging and Hydrogen Embrittlement Behavior of Bake Hardening Steels. Korean J. Met. Mater. 2022, 60, 811–818. [Google Scholar] [CrossRef]

- Roccisano, A.; Nafisi, S.; Stalheim, D.; Ghomashchi, R. Effect of TMCP rolling schedules on the microstructure and performance of X70 steel. Mater. Charact. 2021, 178, 111207. [Google Scholar] [CrossRef]

- Bertolo, V.; Jiang, Q.; Sanchez, M.; Riemslag, T.; Walters, C.; Sietsma, J.; Popovich, V. Cleavage Fracture Micromechanisms in Simulated Heat Affected Zones of S690 High Strength Steels. Mater. Sci. Eng. 2023, A 868, 144762. [Google Scholar] [CrossRef]

- Jiang, J.; Bao, W.; Peng, Z.; Wang, Y.; Liu, J.; Dai, X. Experimental Investigation on Mechanical Behaviours of TMCP High Strength Steel. Constr. Build. Mater. 2019, 200, 664–680. [Google Scholar] [CrossRef]

- Liu, M.; Du, C.; Li, Y.; Li, X. A Novel Multiphase Stainless Steel with Ultra-Low Yield Ratio and High Ductility. Acta Metall. Sin (Engl. Lett.) 2024, 37, 1777–1784. [Google Scholar] [CrossRef]

| Designation | C | Si | Mn | P | S | Ni + Cu | Mo | Nb + V + Ti | Mo | Als |

|---|---|---|---|---|---|---|---|---|---|---|

| 0 Mo | 0.090 | 0.30 | 1.40 | 0.009 | 0.002 | 0.55 | 0.15 | 0.070 | 0 | 0.02 |

| 15 Mo | 0.088 | 0.29 | 1.42 | 0.008 | 0.003 | 0.55 | 0.14 | 0.071 | 0.15 | 0.02 |

| 30 Mo | 0.089 | 0.30 | 1.41 | 0.007 | 0.002 | 0.54 | 0.15 | 0.070 | 0.30 | 0.02 |

| 60 Mo | 0.088 | 0.29 | 1.42 | 0.008 | 0.002 | 0.55 | 0.14 | 0.069 | 0.60 | 0.02 |

| Designation | MEDMTA≥2° /μm | MEDMTA≥4° /μm | MEDMTA≥6° /μm | MEDMTA≥8° /μm | MEDMTA≥10° /μm | MEDMTA≥12° /μm | MEDMTA≥15° /μm |

|---|---|---|---|---|---|---|---|

| 0 Mo | 2.73 | 3.02 | 3.43 | 3.76 | 4.03 | 4.35 | 4.89 |

| 15 Mo | 2.50 | 2.78 | 3.20 | 3.62 | 3.81 | 3.98 | 4.43 |

| 30 Mo | 2.38 | 2.61 | 2.89 | 3.21 | 3.43 | 3.66 | 4.56 |

| 60 Mo | 2.26 | 2.44 | 2.63 | 2.71 | 2.89 | 2.92 | 4.68 |

| Mechanical Properties | Tensile Property | Instrumented Impact Test | Average Energy Absorbed AkV/J | |||||

|---|---|---|---|---|---|---|---|---|

| YS ReL/MPa | TS Rm/MPa | YR | Elongation A/% | Ei | Ep | Et | ||

| 0 Mo | 548 ± 6 | 635 ± 8 | 0.86 | 29.1 ± 0.5 | 62 | 105 | 167 | 165 ± 5 |

| 15 Mo | 578 ± 5 | 710 ± 9 | 0.81 | 25.3 ± 0.4 | 78 | 143 | 221 | 223 ± 6 |

| 30 Mo | 602 ± 5 | 731 ± 7 | 0.82 | 23.2 ± 0.5 | 87 | 114 | 201 | 204 ± 5 |

| 60 Mo | 628 ± 4 | 759 ± 8 | 0.83 | 21.9 ± 0.5 | 95 | 91 | 186 | 185 ± 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, J.; Yang, Y.; Wang, Q. Effect of Mo on Microstructure and Mechanical Properties of Corrosion-Resistant Tank Steel. Metals 2025, 15, 926. https://doi.org/10.3390/met15080926

Hong J, Yang Y, Wang Q. Effect of Mo on Microstructure and Mechanical Properties of Corrosion-Resistant Tank Steel. Metals. 2025; 15(8):926. https://doi.org/10.3390/met15080926

Chicago/Turabian StyleHong, Jun, Yongqi Yang, and Qingfeng Wang. 2025. "Effect of Mo on Microstructure and Mechanical Properties of Corrosion-Resistant Tank Steel" Metals 15, no. 8: 926. https://doi.org/10.3390/met15080926

APA StyleHong, J., Yang, Y., & Wang, Q. (2025). Effect of Mo on Microstructure and Mechanical Properties of Corrosion-Resistant Tank Steel. Metals, 15(8), 926. https://doi.org/10.3390/met15080926