Study on the Process Characteristics of Picosecond Laser Trepan Cutting Hole Manufacturing for Heat-Resistant Steel

Abstract

1. Introduction

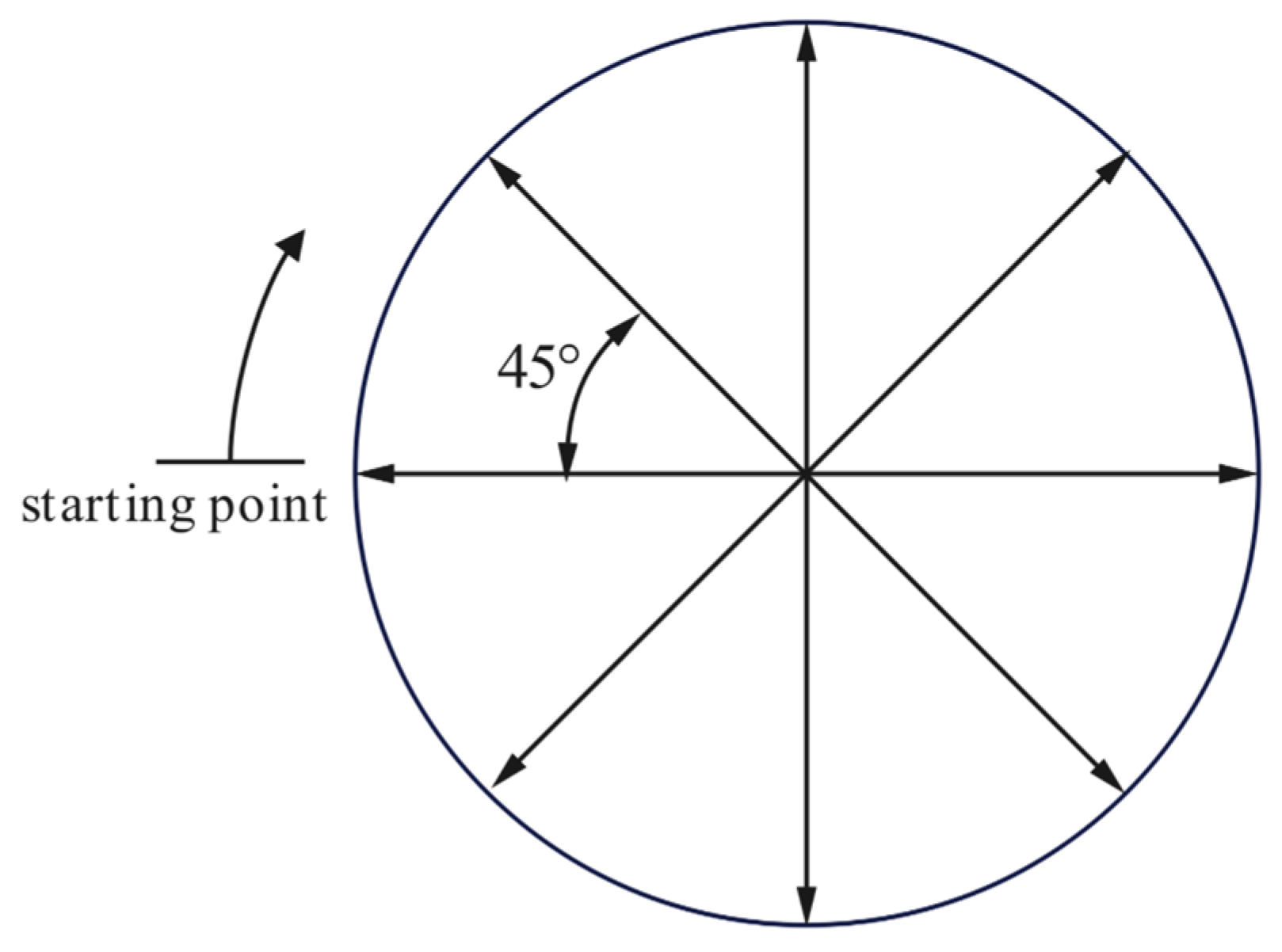

2. Materials and Experimental Setup

3. Numerical Simulation

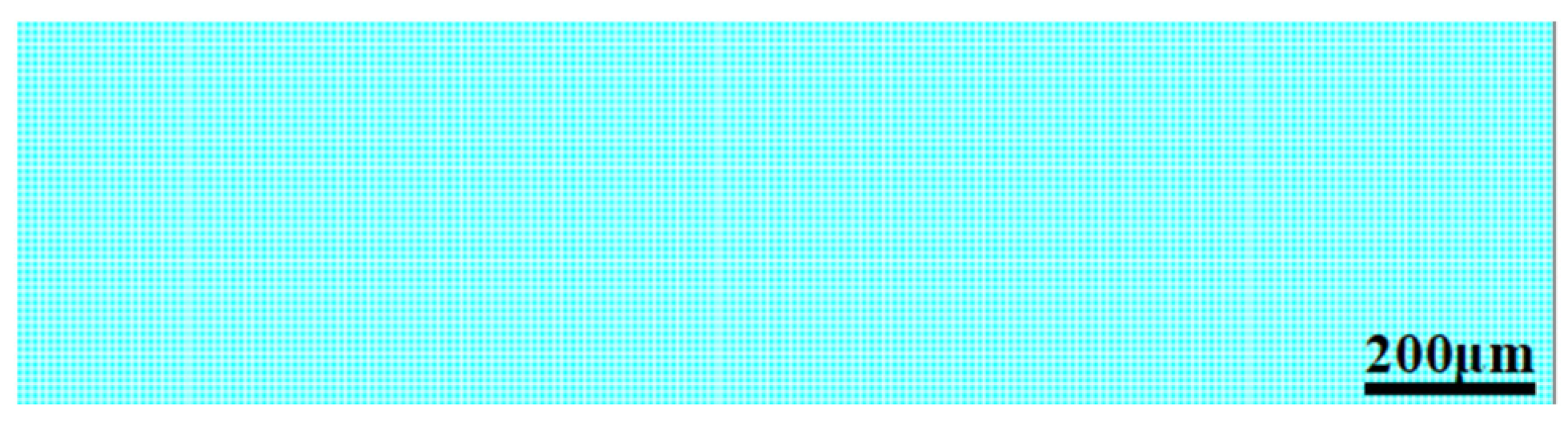

3.1. Model Construction

3.2. Laser Perforation Temperature Field Heat Source Model

- (1)

- Since the laser source used in the experimental part of this paper is characterized by a Gaussian distribution, a Gaussian heat source is used in the simulation, and the expression for the beam heat flux density is shown in Equation (4) [21]:

- (2)

- Initial condition: The initial temperature of the workpiece is the room temperature (25 °C), and it is spatially uniform throughout the workpiece. Boundary conditions: Laser drilling is extremely fast and acts on a very small spot, so the heat-affected zone is limited; therefore, the material can be regarded as an infinite medium. The side and bottom surfaces of the specimen are subjected to no thermal load (no heat flux) and are modeled as adiabatic boundaries in the ANSYS simulation. Hence [21],

- (3)

- During the laser drilling process, phase change processes such as vaporization, melting, and solidification occur [22]. The latent heat of phase change has a significant impact on the temperature field analysis. Therefore, it is essential to consider the latent heat of phase change in the simulation process. In the ANSYS software, the latent heat of phase change is incorporated by using the thermal enthalpy material properties (ENTH).

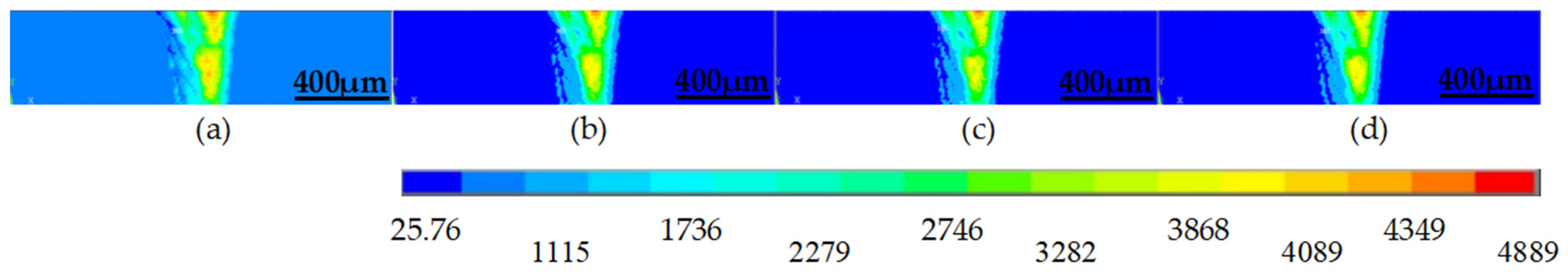

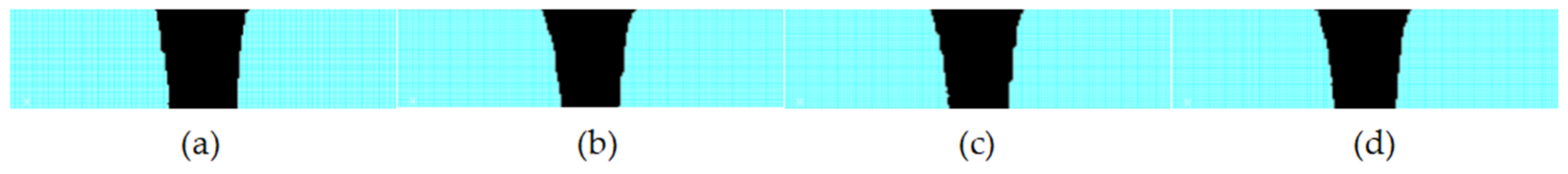

3.3. Simulation Results

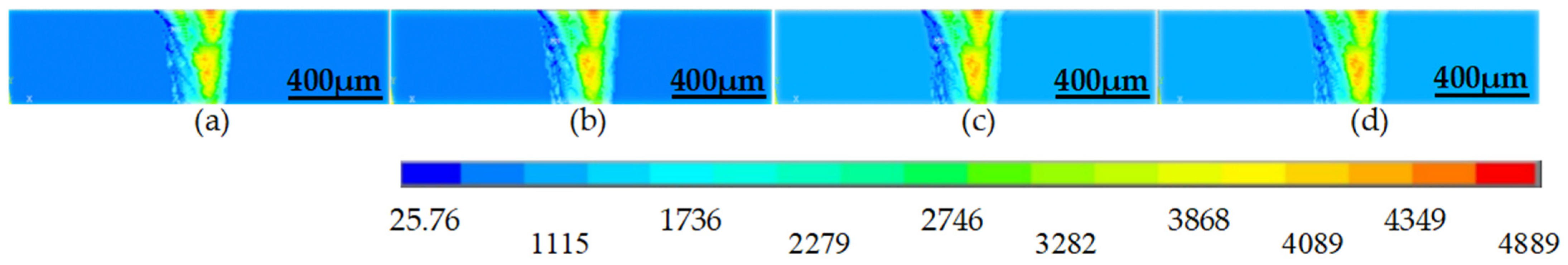

3.3.1. The Effect of Laser Power on Microhole Morphology

3.3.2. The Effect of Scanning Passes on Microhole Morphology

3.3.3. Effect of Scanning Speed on Microhole Morphology

4. Experimental Research

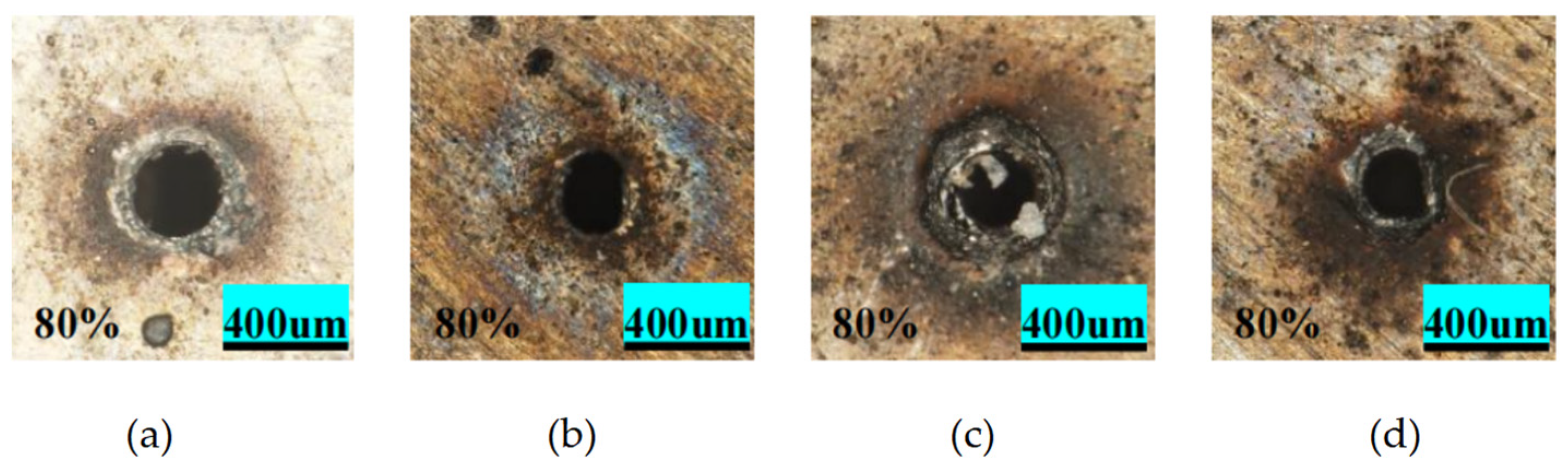

4.1. Analysis of Experimental Results Under the Path of Equidistant Concentric Circles

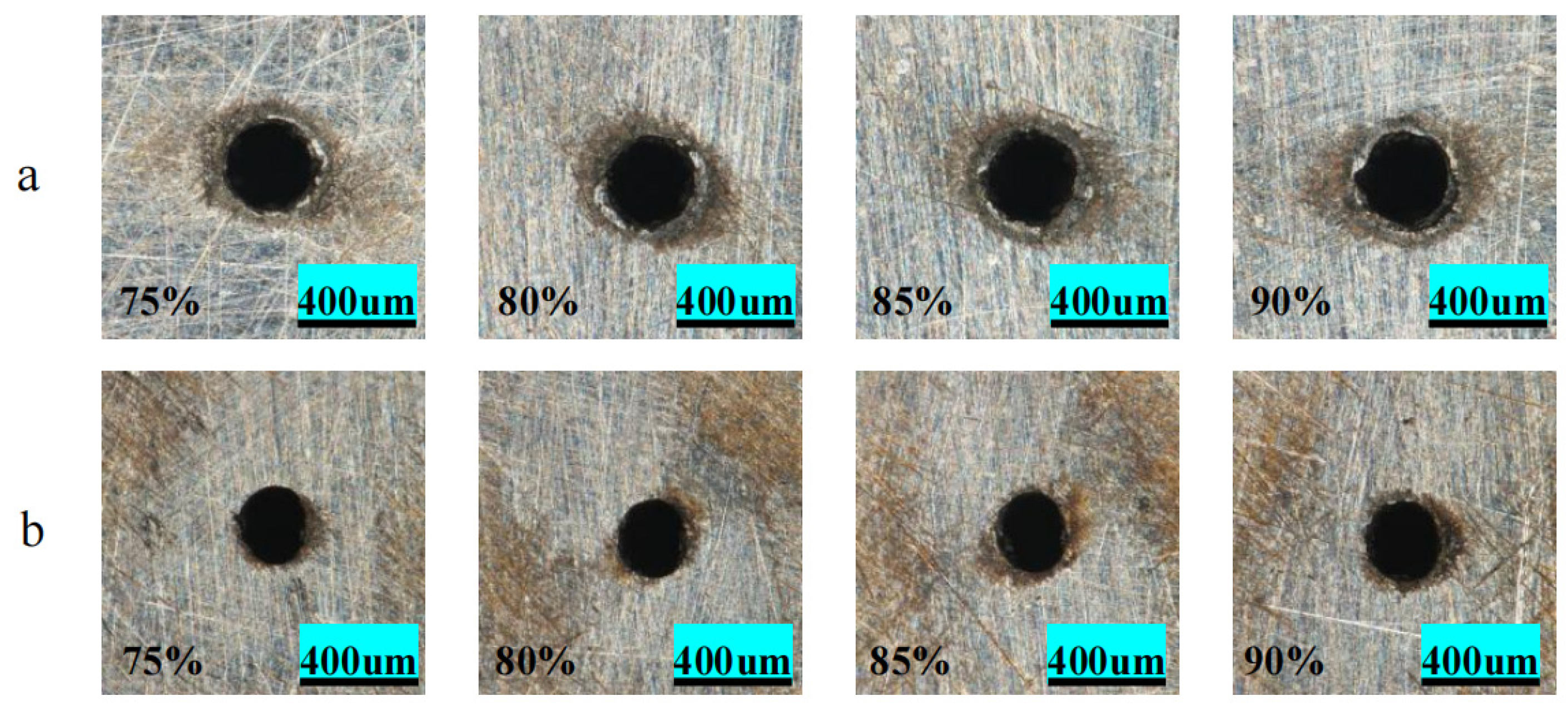

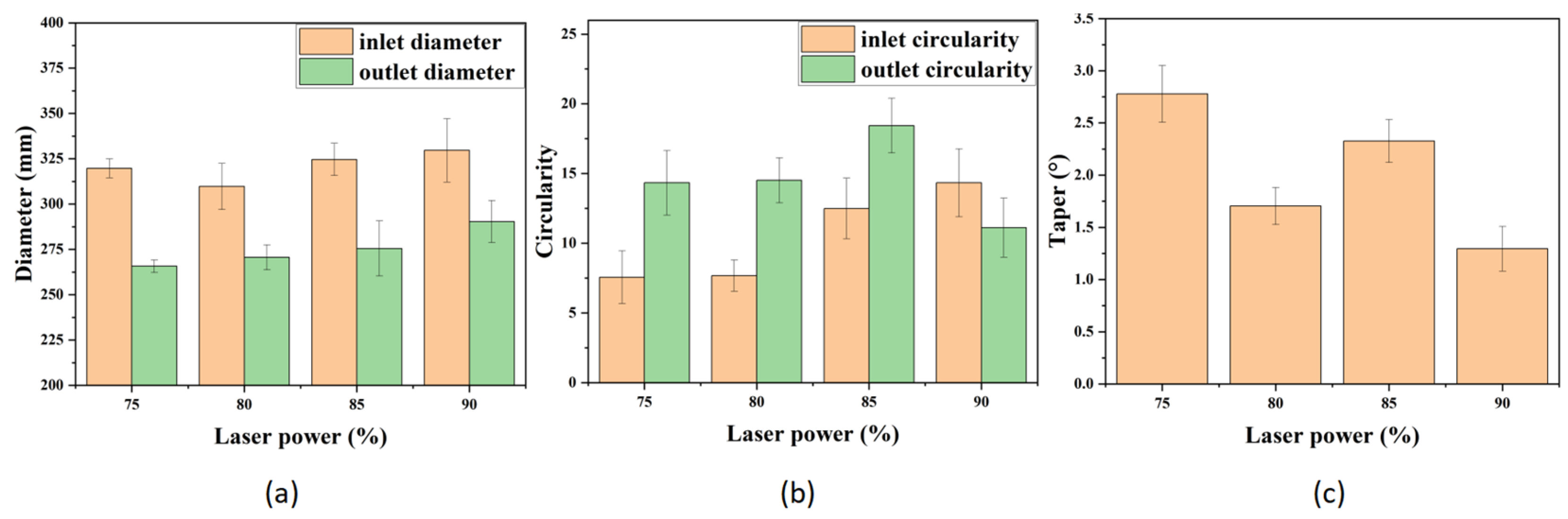

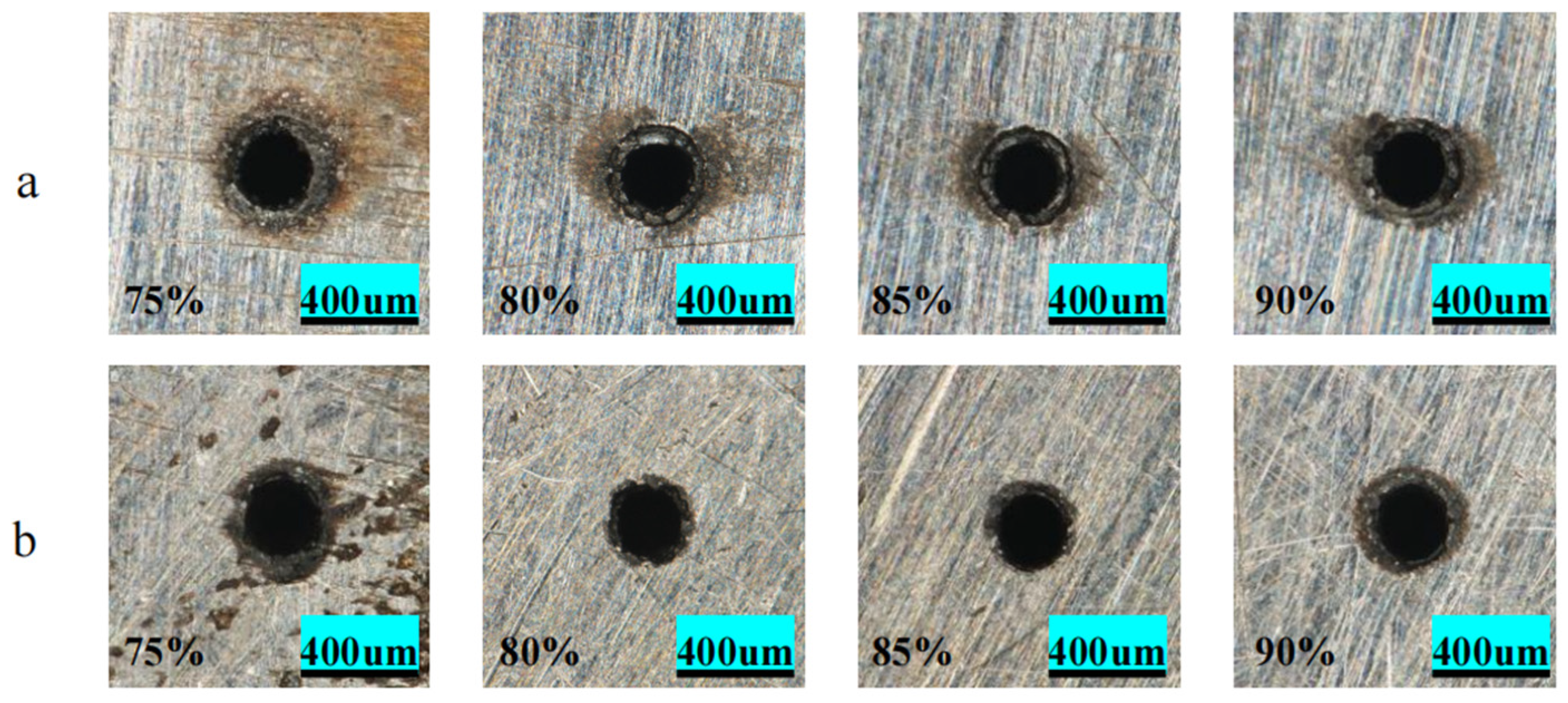

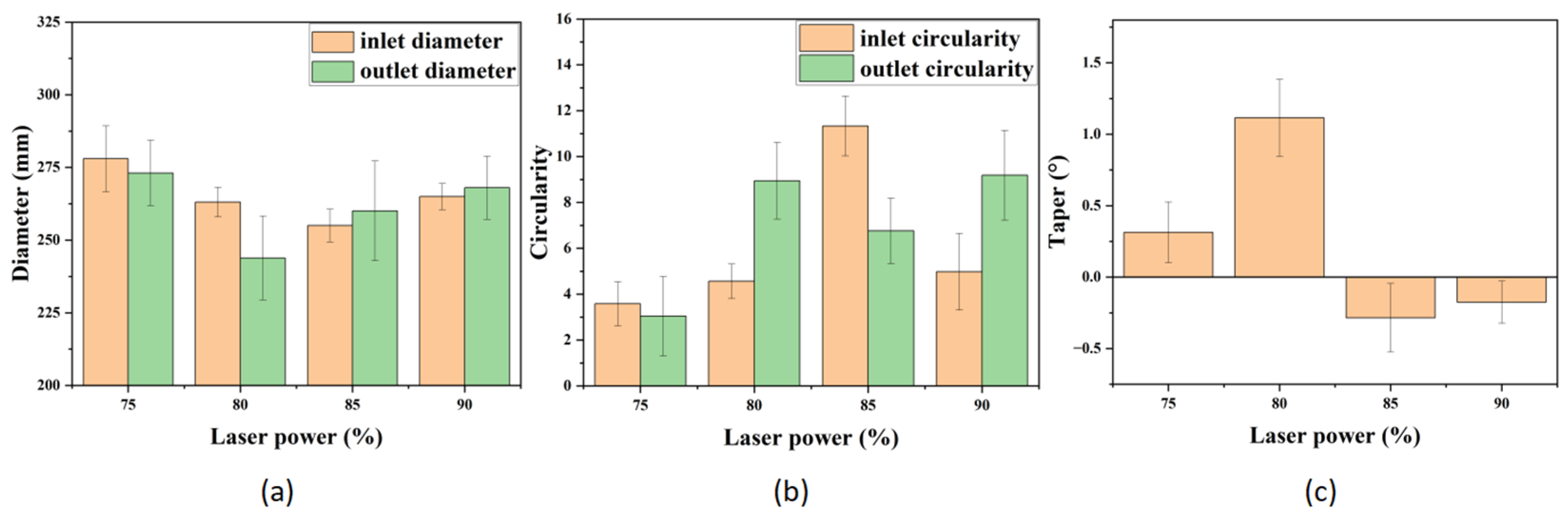

4.1.1. The Effect of Laser Power on Microhole Geometry

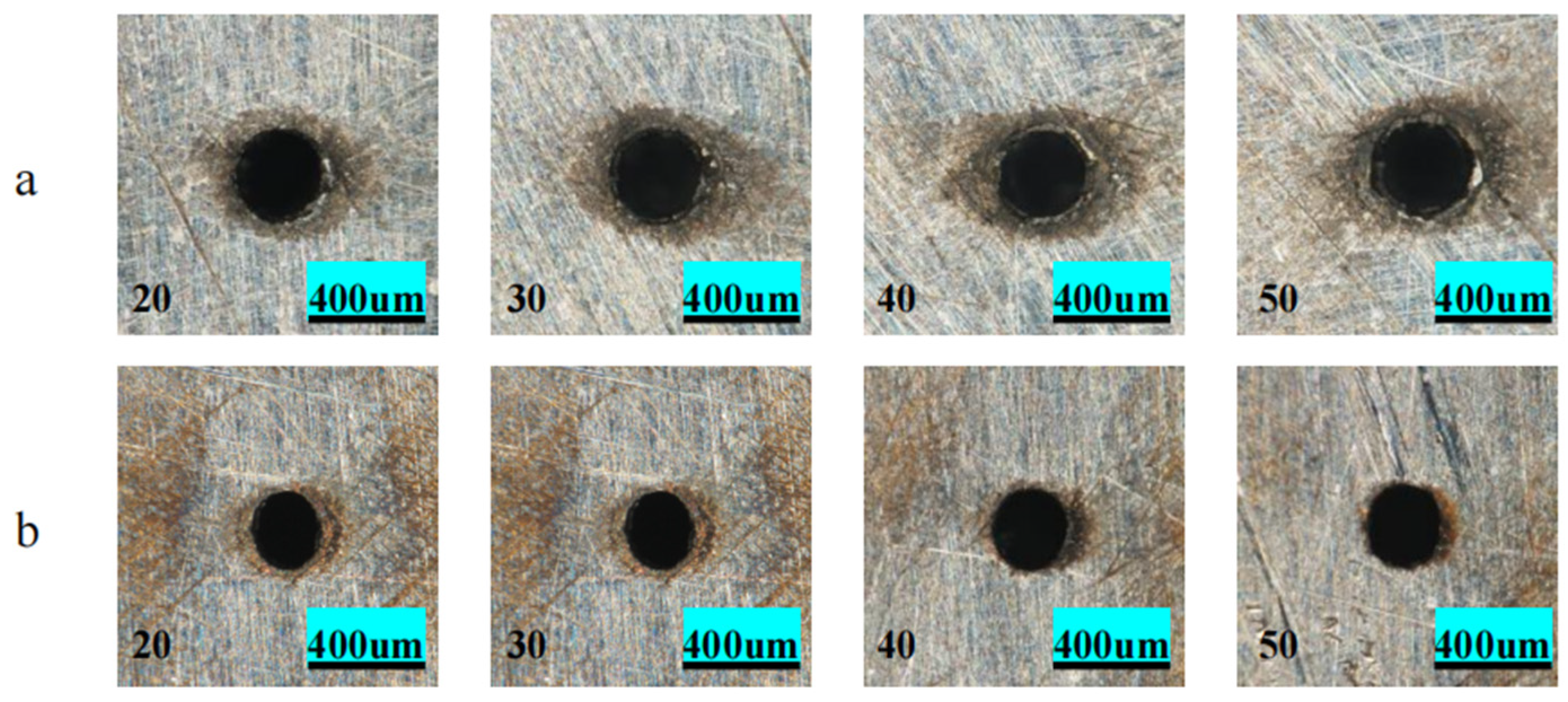

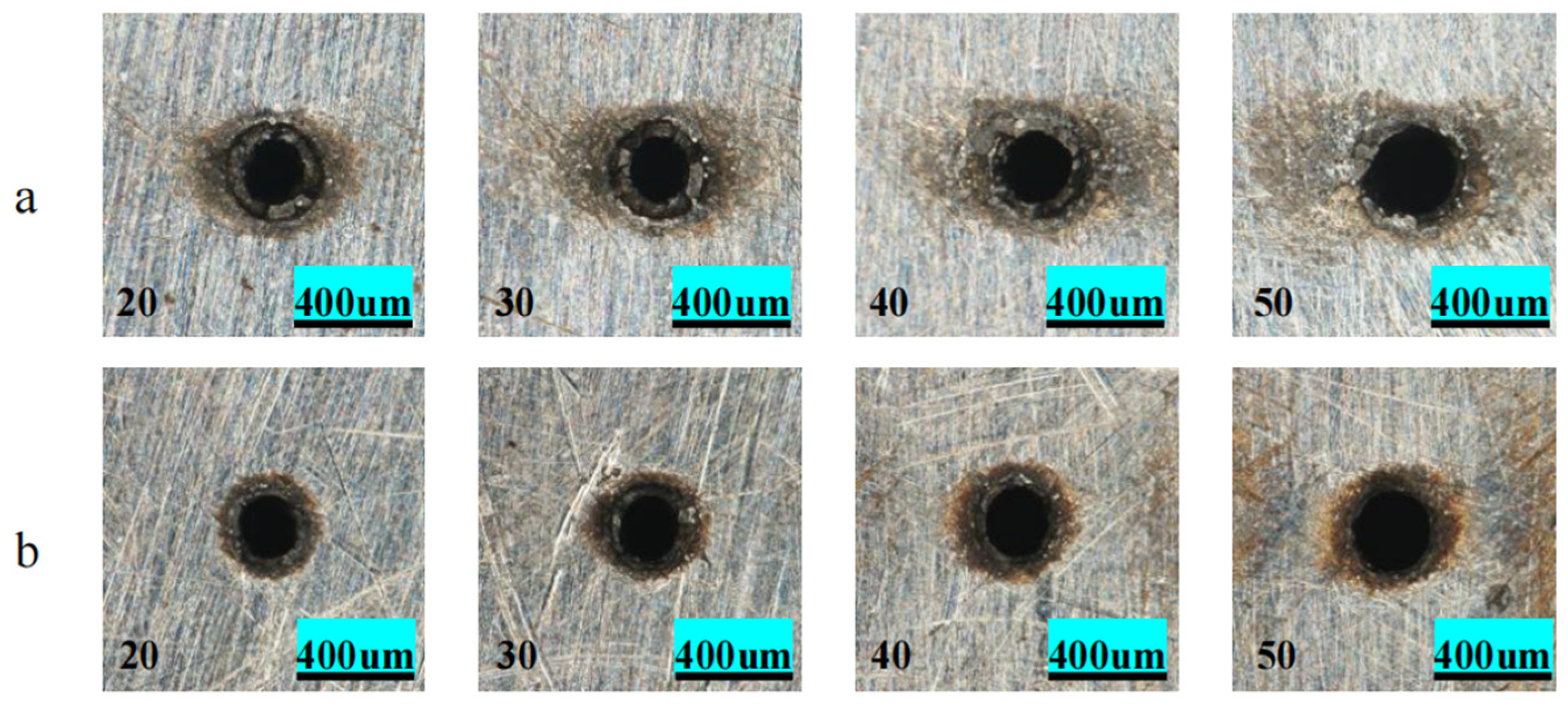

4.1.2. The Effect of Scan Count on Microhole Morphology

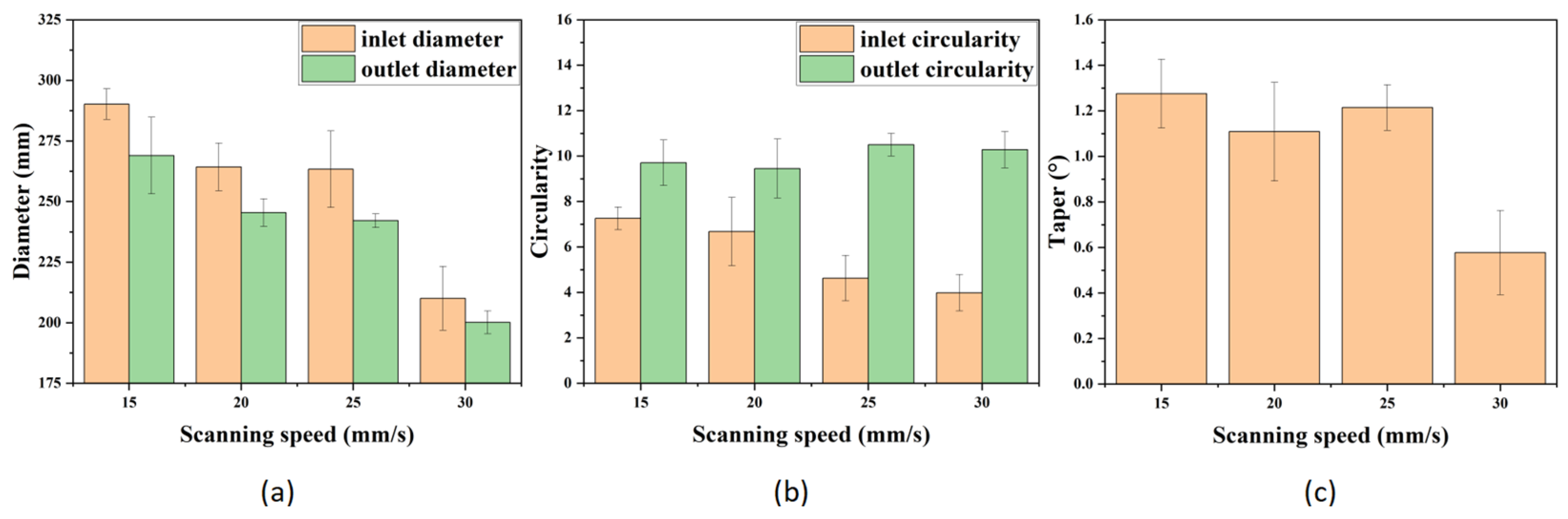

4.1.3. The Effect of Scan Speed on Microhole Morphology

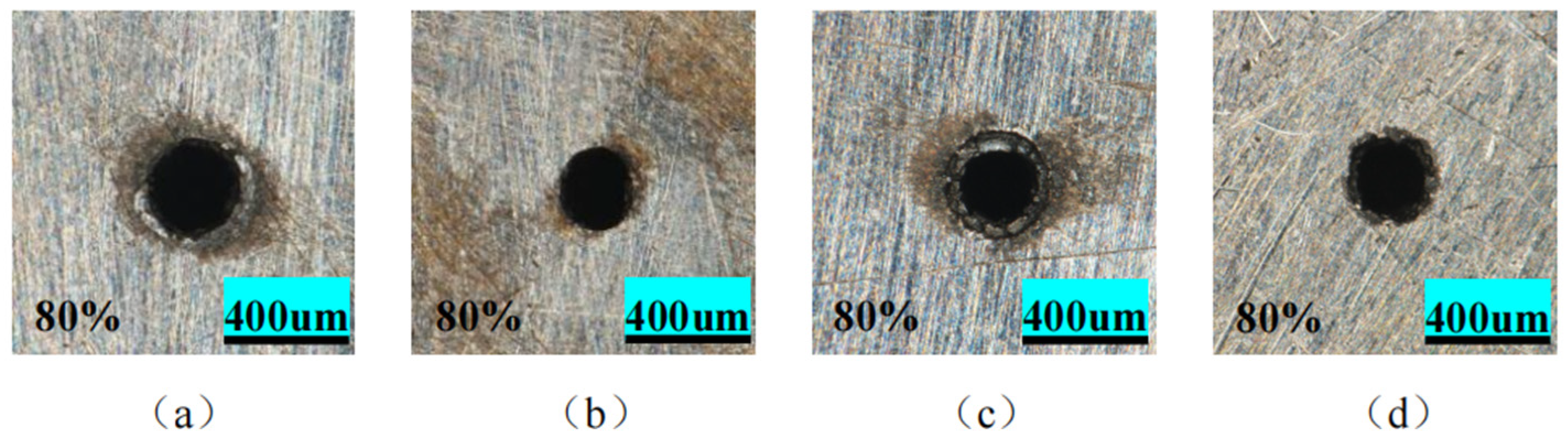

4.2. Experimental Results Analysis Under the Inner-Dense and Outer-Loose Concentric Circle Path

4.2.1. The Effect of Laser Power on Microhole Morphology

4.2.2. The Effect of Scan Count on Microhole Morphology

4.2.3. The Effect of Scan Speed on Microhole Morphology

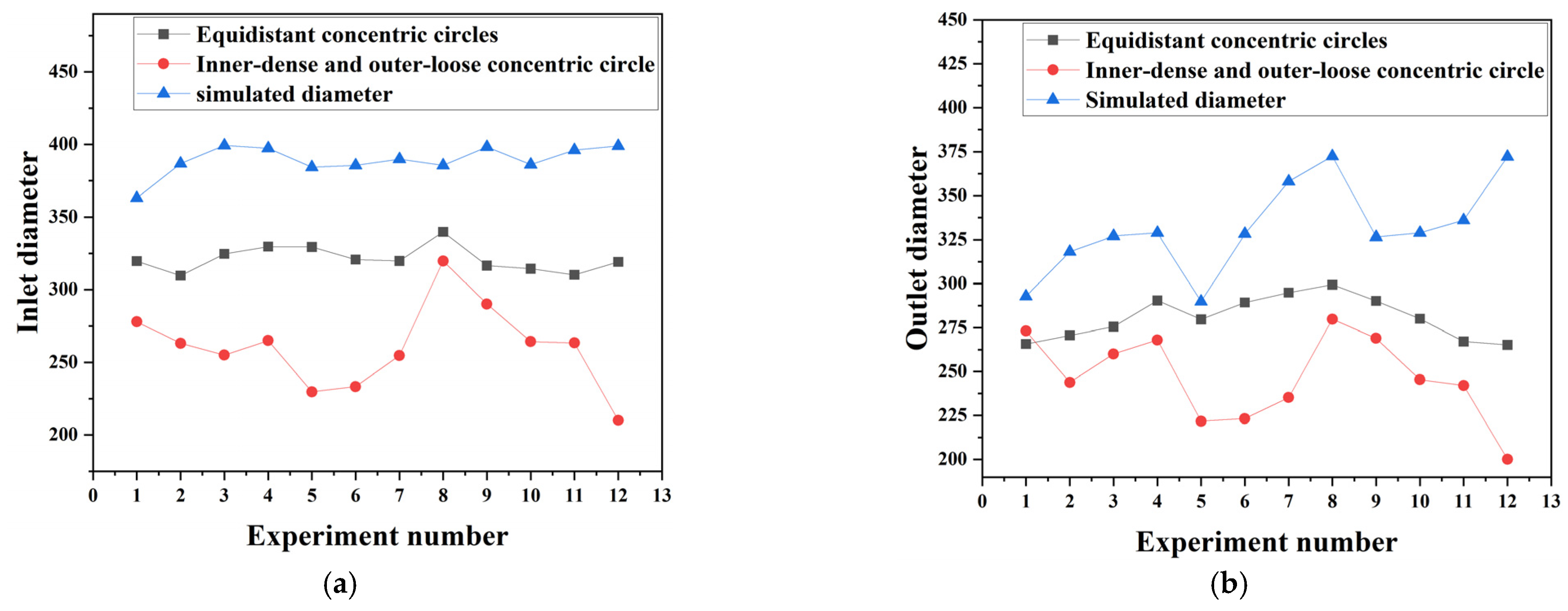

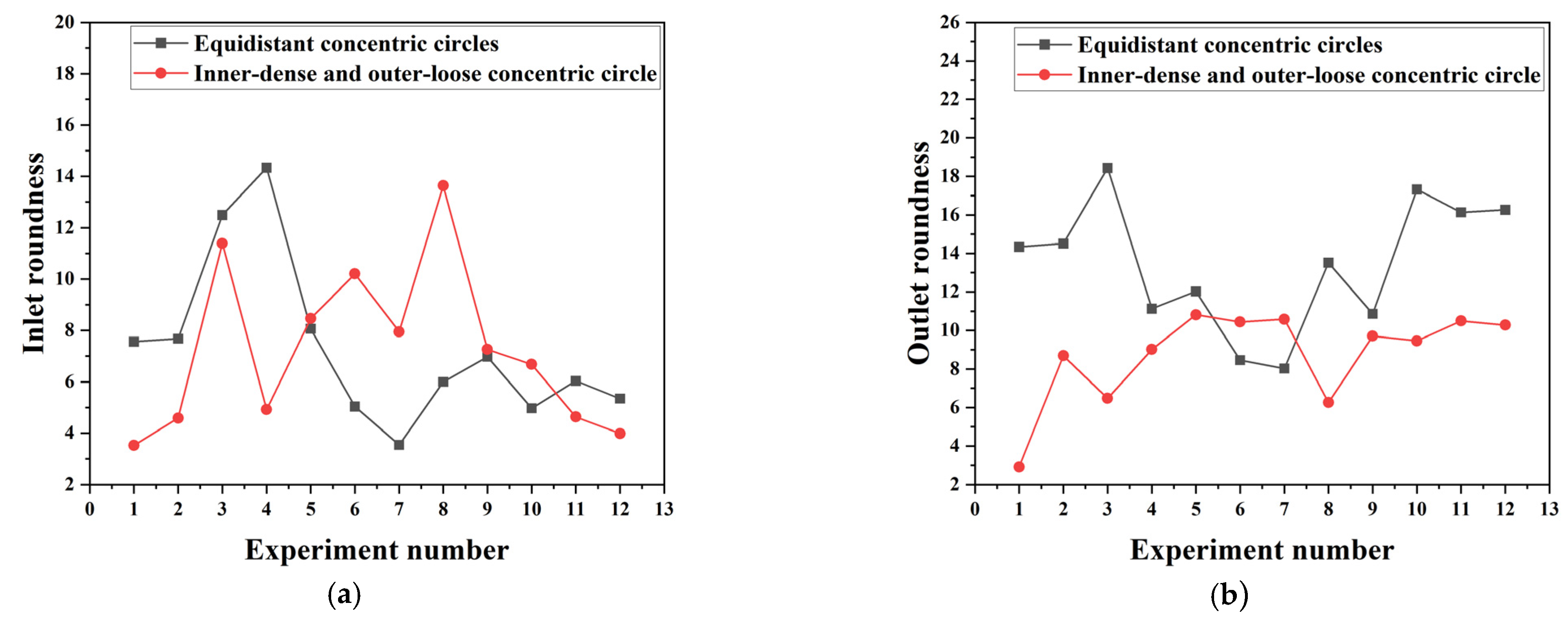

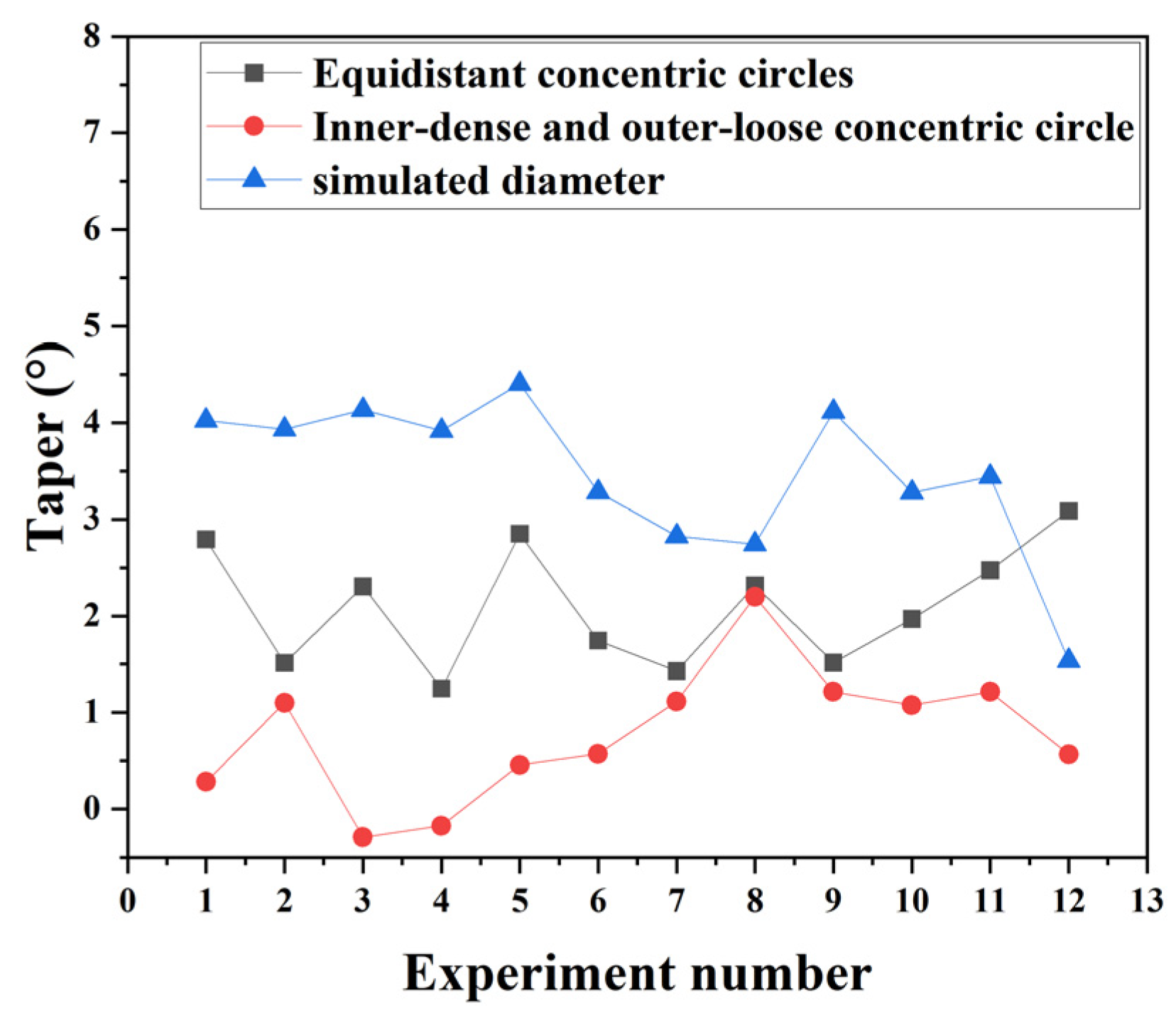

4.3. Analysis of the Characteristics of Two Scanning Paths

5. Conclusions

- (1)

- Trepan cutting simulations were conducted using APDL. The results show that during the trepan scanning process, the temperature inside the hole does not concentrate excessively, and the heat-affected zone around the microhole is small, effectively controlling taper formation.

- (2)

- Under the equidistant concentric circle scanning path, energy distribution is more uniform, improving inlet diameter and circularity. However, the outlet diameter is smaller, and circularity is worse compared to the inlet, with a larger taper. If the primary concern is circularity and taper is less critical, the equidistant concentric circle path can be chosen.

- (3)

- Under the inner-dense outer-loose concentric circle scanning path, the energy is concentrated in the inner ring, which increases the outlet diameter. However, this concentration of energy reduces outlet circularity. The weaker energy in the outer ring reduces the inlet diameter but decreases the difference between inlet and outlet diameters, resulting in a better taper. If taper is a priority and depth is important, the inner-dense, outer-loose concentric circle path is recommended.

- (4)

- From the combined experimental and simulation results, it is evident that simulated inlet and outlet diameters are generally larger than the measured ones, with smaller fluctuations. Between the two scanning strategies, the equal-spacing concentric path produces larger inlet diameters and generally larger outlet diameters than the dense-inside sparse-outside path, but it also shows higher taper and outlet roundness, with poorer shape consistency. In contrast, the dense-inside, sparse-outside path yields smaller inlet diameters, yet its outlet diameters are closer to the inlet size, the taper is the lowest, and the outlet roundness is markedly better than that of the equal-spacing path, producing contours closer to an ideal circle under most conditions. Overall, the dense-inside, sparse-outside path excels in controlling taper and maintaining outlet shape accuracy, whereas the equal-spacing path performs better in inlet size and stability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, K.; Yu, X.Y. Study on Laser Cladding Hard Alloy Composite Coatings and Wear Resistance of 310S Austenitic Stainless Steel. Cast. Technol. 2018, 39, 63–66. [Google Scholar]

- Song, J.B.; Yi, H.Y. Processing Technology for Film Cooling Holes in Turbine Blades of Aircraft Engines. Tool Technol. 2020, 12, 82–86. [Google Scholar]

- Gatzen, H.H.; Klocke, F.; Kamenzky, S.; Traisigkhachol, O. Electroplated Cu micro electrode for the application in micro sinking electro discharge machining (micro-SEDM). ECS Trans. 2009, 16, 255. [Google Scholar] [CrossRef]

- Chen, H.; Geng, D.C.; Chen, T.; Lu, D.L.; Chen, B. Second-derivative laser-induced fluorescence spectroscopy combined with chemometrics for authentication of the adulteration of camellia oil. CyTA-J. Food 2018, 16, 747–754. [Google Scholar] [CrossRef]

- Feng, J.S.; Zhang, R.; Dabbour, M.; Mintah, B.K.; Gao, X.L.; He, R.H.; Ma, H.L. Enhancing acid production of Acetobacter pasteurianus by laser and intense pulsed light mutagenesis and its molecular mechanism based on transcriptomic analysis. LWT-Food Sci. Technol. 2023, 182, 114803. [Google Scholar] [CrossRef]

- Lu, F.; Ruan, S.; Wang, Y.; Li, Y.; Ma, F.; Ma, H. Unveiling the underlying mechanism of combined He–Ne laser and UV mutagenesis in Bacillus subtilis CICC 21927: A transcriptomic analysis. Food Biosci. 2024, 61, 104694. [Google Scholar] [CrossRef]

- Zhang, X.Q.; Xing, S.L.; Liu, L.; Liu, L.; Li, L.; Tong, G.S. Femtosecond Laser Trepan Drilling on Thermal Barrier Coated High-Temperature Alloys. Chin. J. Lasers 2017, 44, 123–128. [Google Scholar]

- Li, J.; Zhang, W.; Zheng, H.; Gao, J.; Jiang, C. Reducing plasma shielding effect for improved nanosecond laser drilling of copper with applied direct current. Opt. Laser Technol. 2023, 163, 109372. [Google Scholar] [CrossRef]

- Jiang, J. Research on Picosecond Laser Micro-Hole Machining Technology for Metal Materials. Ph.D. Thesis, Beijing University of Technology, Beijing, China, 2014. [Google Scholar]

- Sun, X.; Dong, X.; Wang, K.; Wang, R.; Fan, Z.; Duan, W. Experimental Investigation on Thermal Effects in Picosecond Laser Drilling of Thermal Barrier Coated In718. Opt. Laser Technol. 2018, 113, 150–158. [Google Scholar] [CrossRef]

- Zhang, T.; Huang, Y.; Cai, M. Effects of Recast Layer on Fatigue Performance of Laser-Drilled Holes in Nickel-Based Superalloy. J. Am. Acad. Dermatol. 2023, 311, 117821. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, W.; Jiang, R.; Zhang, X.; Xiong, Y.; Mao, Z. Investigation on Geometric Precision and Surface Quality of Microholes Machined by Ultrafast Laser. Opt. Laser Technol. 2020, 121, 105834. [Google Scholar] [CrossRef]

- Wang, X.C.; Zheng, H.Y.; Chu, P.L.; Tan, J.L.; The, K.M.; Liu, T.; Ang, B.C.; Tay, G.H. Femtosecond Laser Drilling of Alumina Ceramic Substrates. Appl. Phys. A 2010, 101, 271–278. [Google Scholar] [CrossRef]

- Zhang, H.L. Research on Backside Water-Assisted Picosecond Laser Drilling Technology. Ph.D. Thesis, Nanjing Agricultural University, Nanjing, China, 2022. [Google Scholar]

- He, C.; Bühring, J.; Gillner, A. Helical Drilling of Three-Dimensional Conical Converging-Diverging Nozzle in Steel Using Ultrafast Laser Pulses. Procedia CIRP 2018, 74, 305–309. [Google Scholar] [CrossRef]

- Wang, R.; Dong, X.; Wang, K.; Sun, X.; Fan, Z.; Duan, W. Two-step approach to improving the quality of Laser Micro-Hole Drilling on Thermal Barrier Coated Nickel Base Alloys. Opt. Lasers Eng. 2019, 121, 406–415. [Google Scholar] [CrossRef]

- Gu, Z.; He, Y.; Yang, J.; Fu, Y.; Ji, J.; Zhang, Y.; Li, J.; Liu, G. Dual-Path Micro-Holes Process for 0Cr17Ni7Al Stainless Steel Thin Plate with Picosecond Laser. J. Manuf. Process. 2023, 101, 1224–1233. [Google Scholar] [CrossRef]

- Li, L.; Low, D.K.; Ghoreshi, M.; Crookall, J.R. Hole Taper Characterization and Control in Laser Percussion Drilling. CIRP Ann.-Manuf. Technol. 2002, 51, 153–156. [Google Scholar] [CrossRef]

- EN 10095:2018-12; Heat-resisting Steels and Nickel Alloys. European Committee for Standardization (CEN): Brussels, Belgium, 2018.

- Collins, J.; Gremaud, P. A Simple Model for Laser Drilling. Math. Comput. Simul. 2010, 81, 1541–1552. [Google Scholar] [CrossRef]

- Qian, X.Z.; Ren, N.F. Study on Laser Drilling Forming Quality of High-Temperature Alloys Based on Orthogonal Experiment. Appl. Laser 2018, 38, 448–453. [Google Scholar]

- Wang, Z.T. Experimental study on Nd:YAG laser precision circular cutting of nozzle orifices. Mod. Veh. Power 2005, 15–16, 50. [Google Scholar]

- Xue, Y. Numerical Simulation and Experimental Research on Temperature Field in Picosecond Laser Drilling of H59 Brass. Ph.D. Thesis, Jiangsu University, Zhenjiang, China, 2017. [Google Scholar]

- Xiao, Z.M. Experimental Study on Picosecond Laser Ring Cutting Process of CFRP. Ph.D. Thesis, Hunan University, Changsha, China, 2023. [Google Scholar]

- Li, C. Numerical Simulation and Process Study of Picosecond Laser Micro-Hole Machining for 2.5D C/SiC Composites Considering Shielding Effects. Ph.D. Thesis, Tianjin University of Technology, Tianjin, China, 2023. [Google Scholar]

- Liu, X.D. Research on the Process and Mechanism of Picosecond Laser Cutting for Hole Formation. Ph.D. Thesis, South-Central University for Nationalities, Wuhan, China, 2021. [Google Scholar]

- Zheng, Z.; Wu, C.; Liu, S.; Yang, X. Analysis of Energy Occupying Ratio of Coulomb Explosion and Thermal Effect in Picosecond Pulse Laser Processing. Opt. Commun. 2018, 424, 190–197. [Google Scholar] [CrossRef]

- Fan, X.; Dong, Z.H.; Zhang, Q.W.; Li, N.; Yang, S.L. Process Study and Quality Analysis of Picosecond Laser Gas-Membrane Hole Machining. Chin. Laser 2025, 52, 253–262. [Google Scholar]

- Wang, X.S.; Huang, Y.K.; Shen, B.; Xu, B.; Zhang, J. Research Progress of Short/Ultra-Short Pulse Laser-Induced Plasma Micro-Machining. Laser Optoelectron. Prog. 2020, 57, 111405. [Google Scholar] [CrossRef]

- Liu, Y.; Feng, A.; Jia, T.; Chen, H. Experimental Study on 515 nm Picosecond Laser Ring Cutting of Microholes. Appl. Laser 2019, 39, 285–290. [Google Scholar]

- AZW, C.L.; Wu, Y.; Du, R.B.; Bai, H.L.; Zou, G.S. Controlling of Diameter and Taper in Ultrafast Laser Helical Drilling. Zhongguo Jiguang/Chin. J. Lasers 2021, 48, 0802017. [Google Scholar]

- Zhang, H.; Di, J.; Zhou, M.; Yan, Y.; Wang, R. Investigation on Hole Quality During Picosecond Laser Helical Drilling of Stainless Steel 304. Appl. Phys. A-Mater. Sci. Process. 2015, 119, 745–752. [Google Scholar] [CrossRef]

- Wang, L.; Rong, Y.; Xu, L.; Wu, C.; Xia, K. Experimental Study and Defect Control in Picosecond Laser Trepanning Drilling of Superalloy. Metals 2025, 15, 893. [Google Scholar] [CrossRef]

- Li, P.X.; Xin, C.C.; Gao, J.; Zhang, T.; Xiao, K.; Dong, X.; Li, S.; Wang, T.; Su, N. Research Progress and Development of Picosecond Laser Processing. Laser Infrared 2018, 48, 1195–1203. [Google Scholar]

- Liu, X.; Chen, L.; Wang, X.; Xiong, Z. Study on Technology of Picosecond Laser Making Micro-Hole with Helical Drilling. Laser Optoelectron Prog. 2022, 59, 0714005. [Google Scholar]

- Liu, L.; Ruan, L.; Zhang, T.; Zhang, W. Experimental Study on Stainless Steel Micro-Hole Drilling with Picosecond Laser. Appl. Laser 2015, 35, 472–478. [Google Scholar]

- Shi, S.; Zhang, M.; Li, L. Analysis of Thermal Effects During Laser Ablation of Materials. Acta Opt. Sin. 2024, 44, 1932001. [Google Scholar]

- He, J.Y.; Xu, F.; Wu, X.J.; Duan, Z.Z.; Zhou, Y.X.; Yao, J.; Zuo, D.W. Numerical Simulation of Temperature Field in Picosecond Laser CVD Diamond Film Drilling. J. Mech. Manuf. Autom. 2010, 40, 106–110. [Google Scholar]

- Sun, S.; Liao, H.; Wu, X.; Zhang, B. Experimental Study on Micro Hole Processing by Picosecond Laser. Laser Technol. 2018, 42, 234–238. [Google Scholar]

- Chen, X.L.; Li, L. Molecular Dynamics Simulation of Femtosecond Laser Irradiation of Gold Foil Under Plasma Shielding Effect. J. At. Mol. Phys. 2022, 39, 75–82. [Google Scholar]

| Element | C | Si | Mn | Cr | P | Ni | S |

|---|---|---|---|---|---|---|---|

| Content (%) | ≤0.08 | ≤1.5 | ≤2 | 24–26 | ≤0.035 | 19–22 | ≤0.03 |

| Temperature (°C) | ENTH (1.0 × 109·J·m−3) | Specific Heat (1.0 × 103·J·kg−1·°C−1) | Thermal Conductivity (W·m−1·°C−1) |

|---|---|---|---|

| 25 | 0.02 | 0.48 | 12.7 |

| 500 | 2.04 | 0.48 | 12.7 |

| 1000 | 4.47 | 0.48 | 12.7 |

| 1500 | 9.65 | 0.48 | 12.7 |

| 2000 | 12.7 | 0.48 | 12.7 |

| Experiment Number | Power (%) | Number of Scans | Scanning Speed (mm/s) |

|---|---|---|---|

| 1 | 75 | 20 | 25 |

| 2 | 80 | 20 | 25 |

| 3 | 85 | 20 | 25 |

| 4 | 90 | 20 | 25 |

| 5 | 80 | 20 | 25 |

| 6 | 80 | 30 | 25 |

| 7 | 80 | 40 | 25 |

| 8 | 80 | 50 | 25 |

| 9 | 80 | 20 | 30 |

| 10 | 80 | 20 | 25 |

| 11 | 80 | 20 | 20 |

| 12 | 80 | 20 | 15 |

| Mesh Height (mm) | Exit Diameter (µm) | Entrance Diameter (µm) | Laser Power (%) | Taper (°) |

|---|---|---|---|---|

| 0.5 | 293 | 363 | 75 | 3.61 |

| 318 | 387 | 80 | 2.57 | |

| 327 | 399 | 85 | 3.54 | |

| 329 | 397 | 90 | 2.53 |

| Mesh Height (mm) | Exit Diameter (µm) | Entrance Diameter (µm) | Scan Count | Taper (°) |

|---|---|---|---|---|

| 0.5 | 290 | 384 | 20 | 4.40 |

| 328 | 386 | 30 | 3.28 | |

| 358 | 390 | 40 | 2.83 | |

| 373 | 386 | 50 | 2.74 |

| Mesh Height (mm) | Exit Diameter (µm) | Entrance Diameter (µm) | Scan Speed (%) | Taper (°) |

|---|---|---|---|---|

| 0.5 | 326 | 398 | 30 | 4.11 |

| 329 | 386 | 25 | 3.28 | |

| 336 | 396 | 20 | 3.44 | |

| 372 | 399 | 15 | 1.53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Xu, L.; Wu, C.; Rong, Y.; Xia, K. Study on the Process Characteristics of Picosecond Laser Trepan Cutting Hole Manufacturing for Heat-Resistant Steel. Metals 2025, 15, 917. https://doi.org/10.3390/met15080917

Wang L, Xu L, Wu C, Rong Y, Xia K. Study on the Process Characteristics of Picosecond Laser Trepan Cutting Hole Manufacturing for Heat-Resistant Steel. Metals. 2025; 15(8):917. https://doi.org/10.3390/met15080917

Chicago/Turabian StyleWang, Liang, Long Xu, Changjian Wu, Yefei Rong, and Kaibo Xia. 2025. "Study on the Process Characteristics of Picosecond Laser Trepan Cutting Hole Manufacturing for Heat-Resistant Steel" Metals 15, no. 8: 917. https://doi.org/10.3390/met15080917

APA StyleWang, L., Xu, L., Wu, C., Rong, Y., & Xia, K. (2025). Study on the Process Characteristics of Picosecond Laser Trepan Cutting Hole Manufacturing for Heat-Resistant Steel. Metals, 15(8), 917. https://doi.org/10.3390/met15080917