CTOD Evaluation of High-Nitrogen Steels for Low-Temperature Welded Structures

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

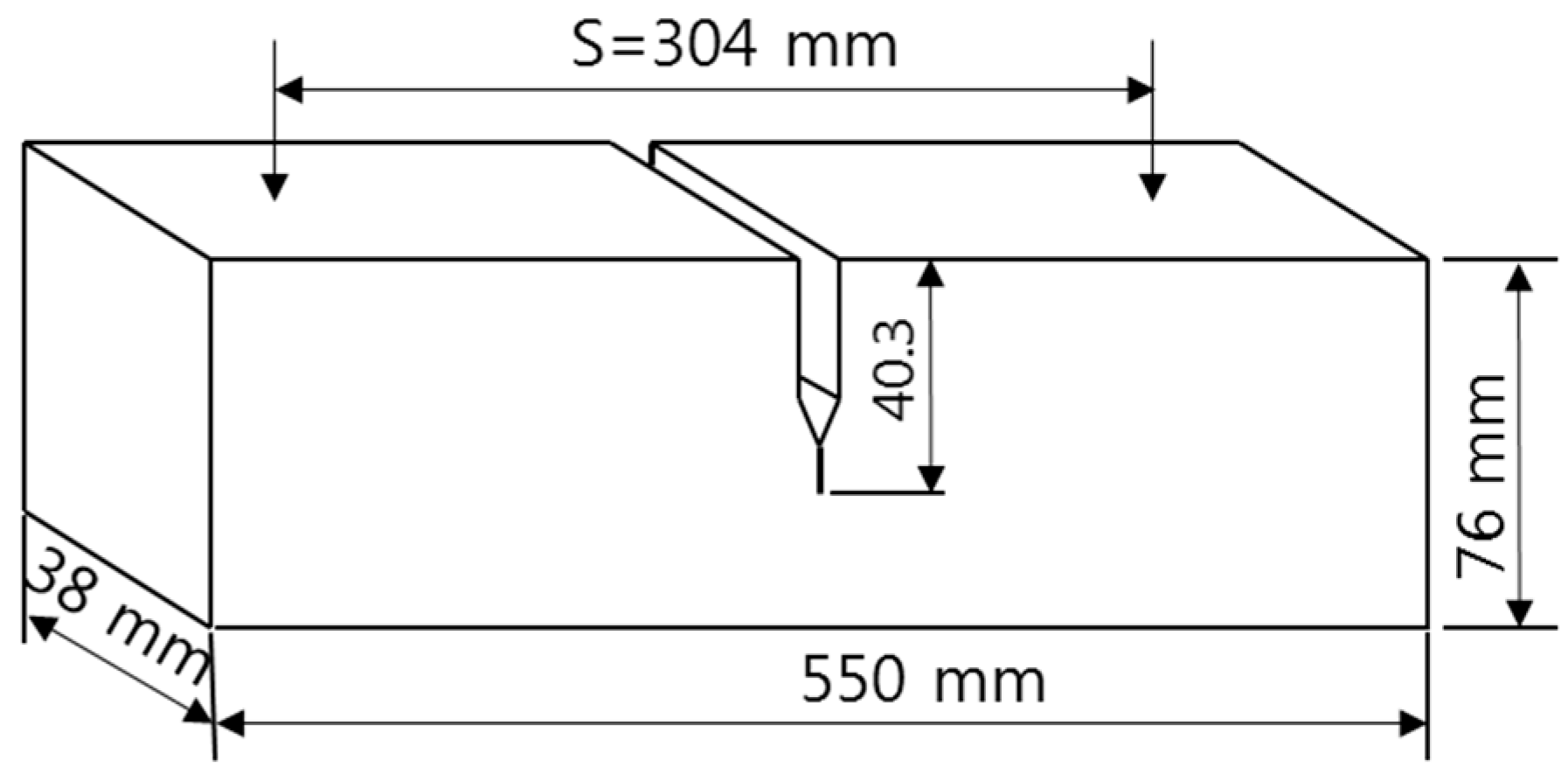

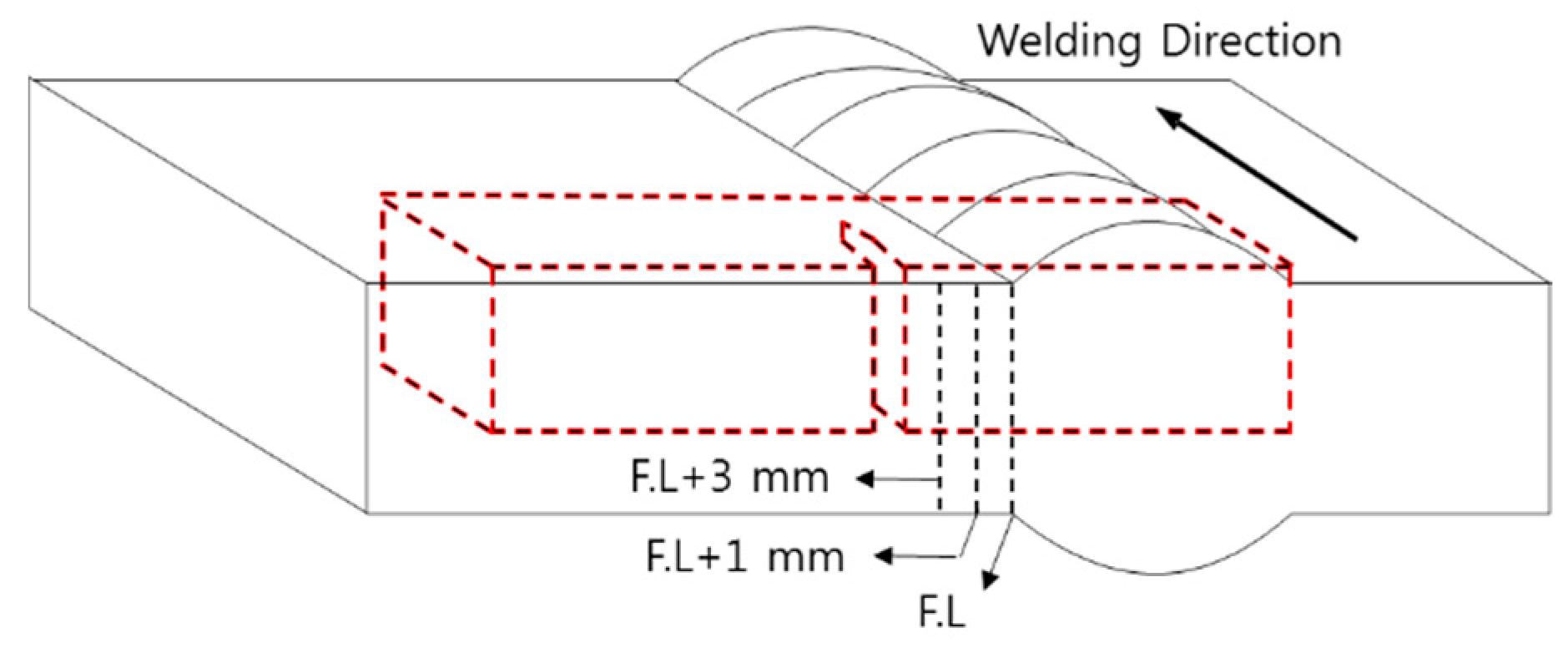

2.2. Welded Specimens

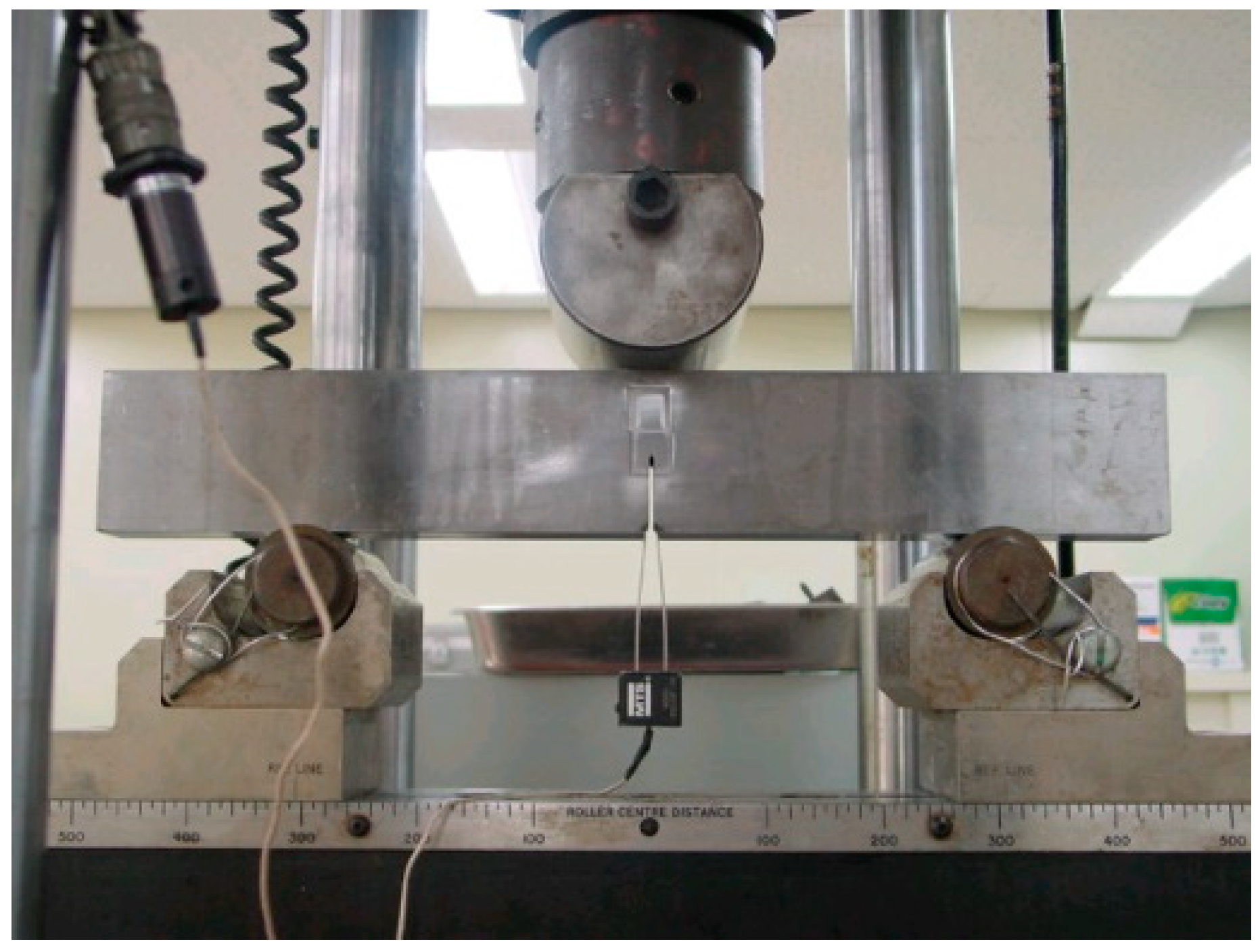

2.3. CTOD Testing

2.4. Microstructural and Fractographic Observations

3. Results and Discussion

3.1. Low-Temperature CTOD and Microstructure

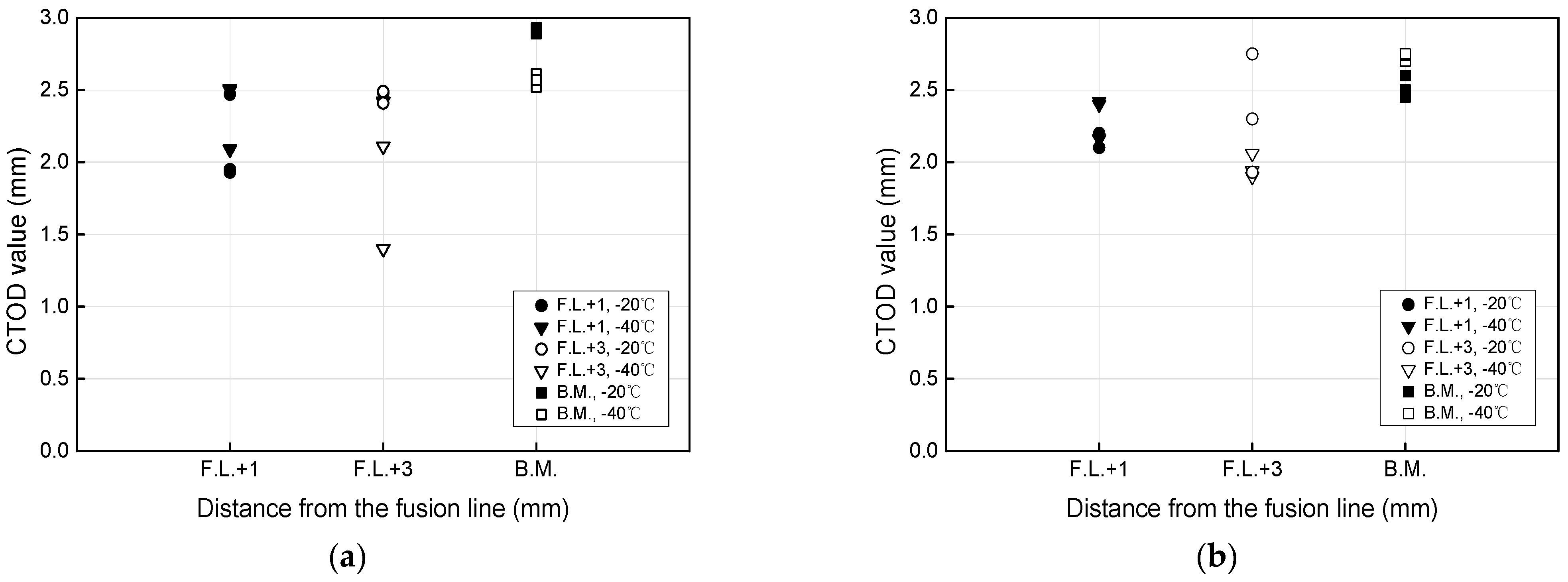

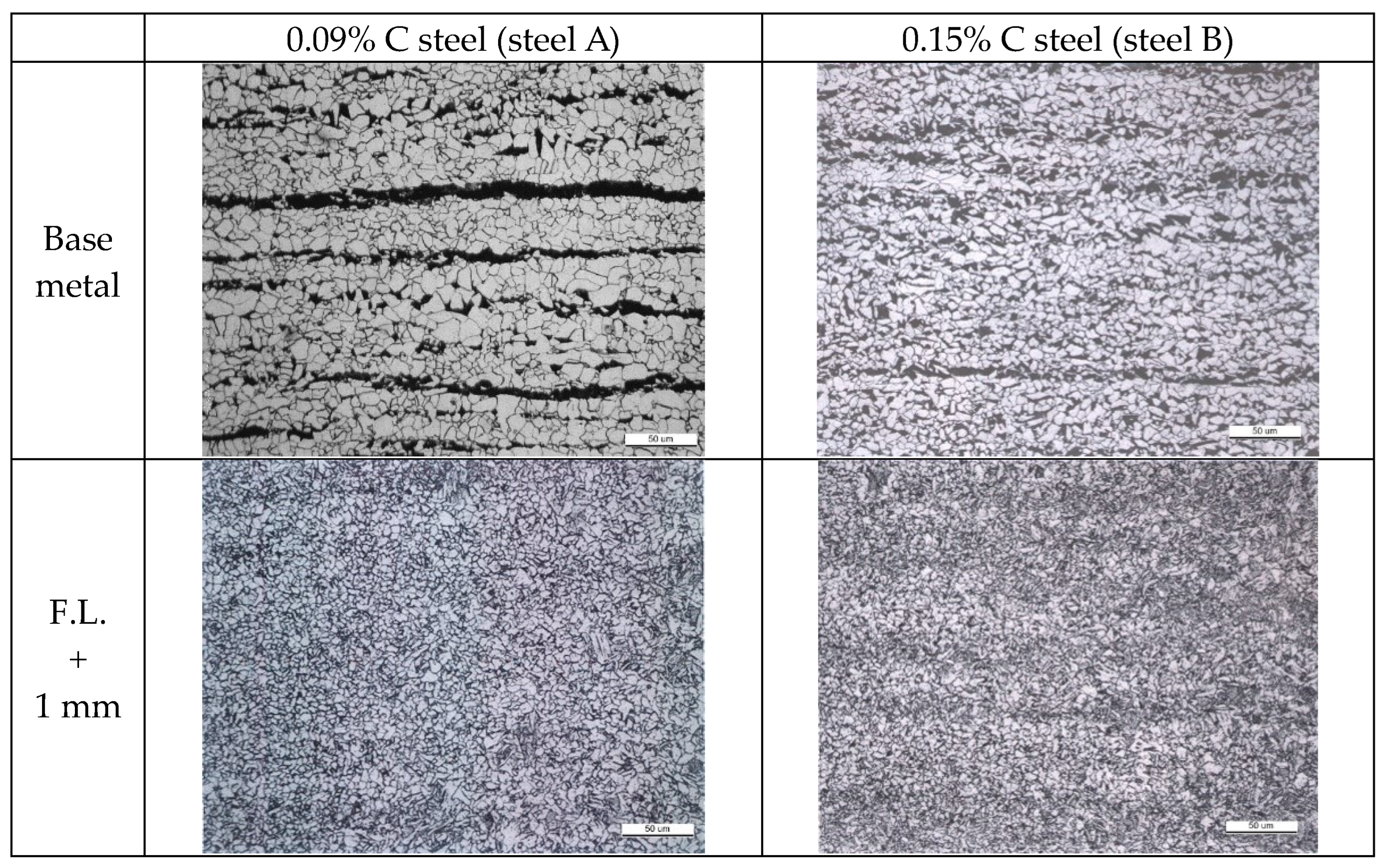

3.1.1. Heat Input of 45 kJ/cm

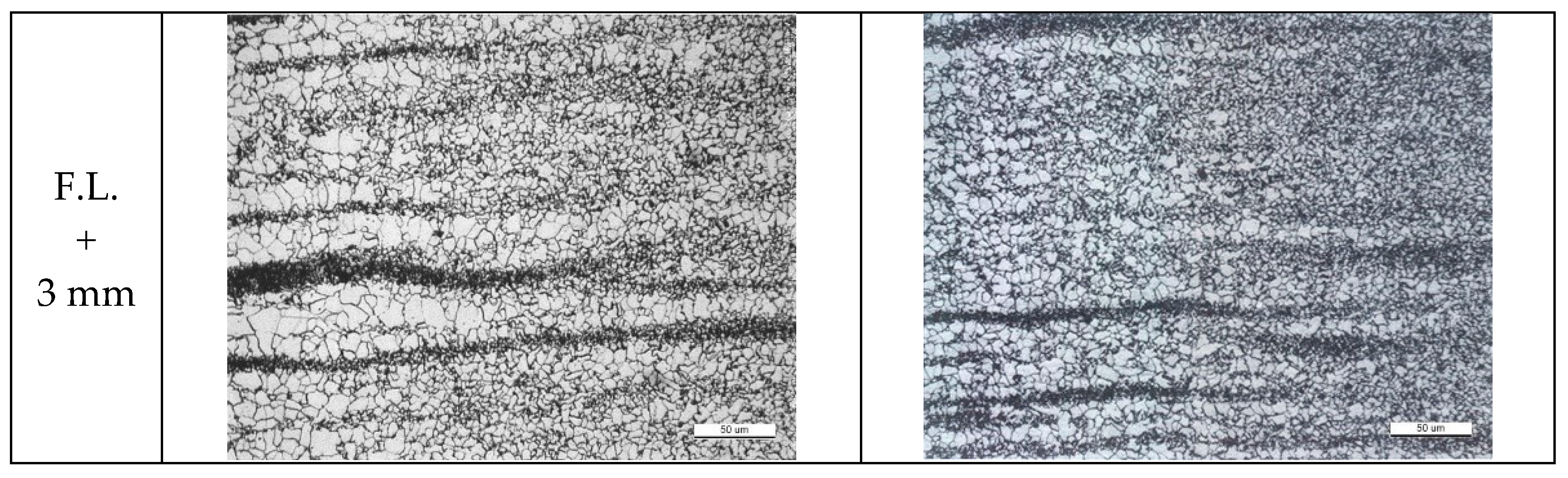

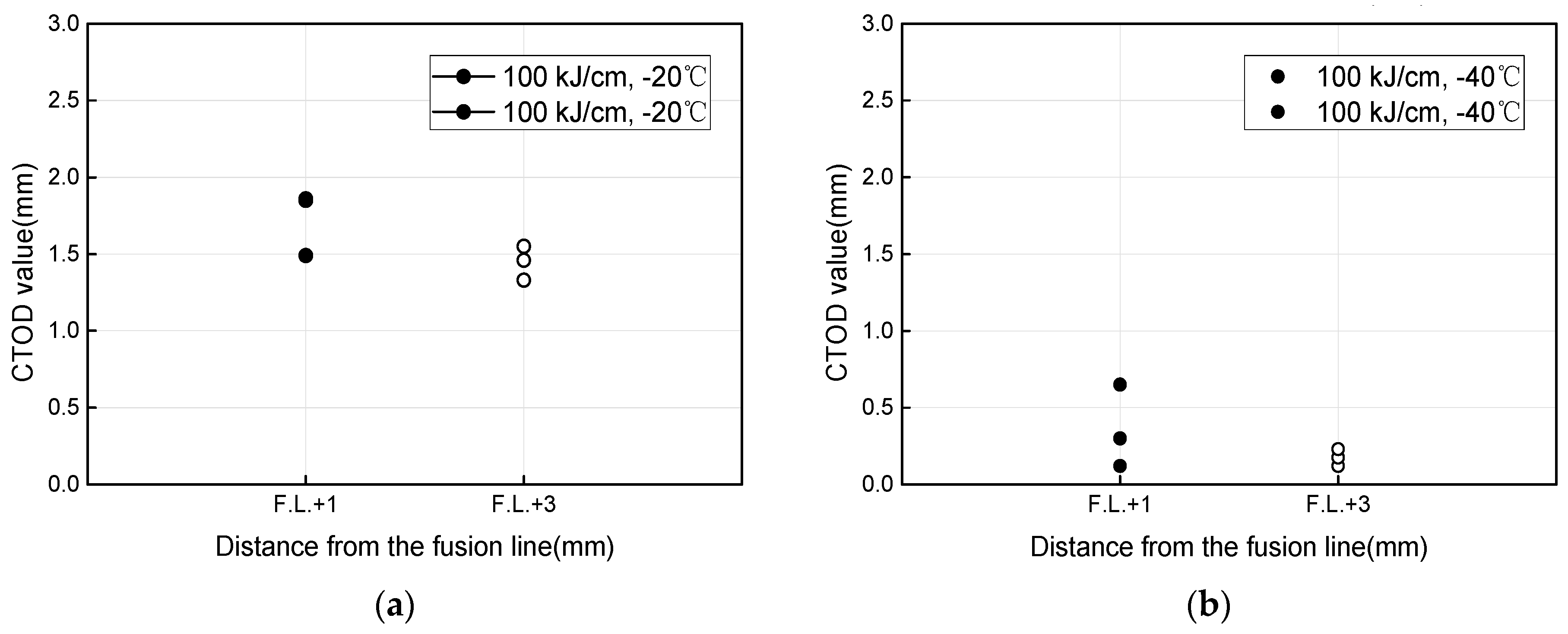

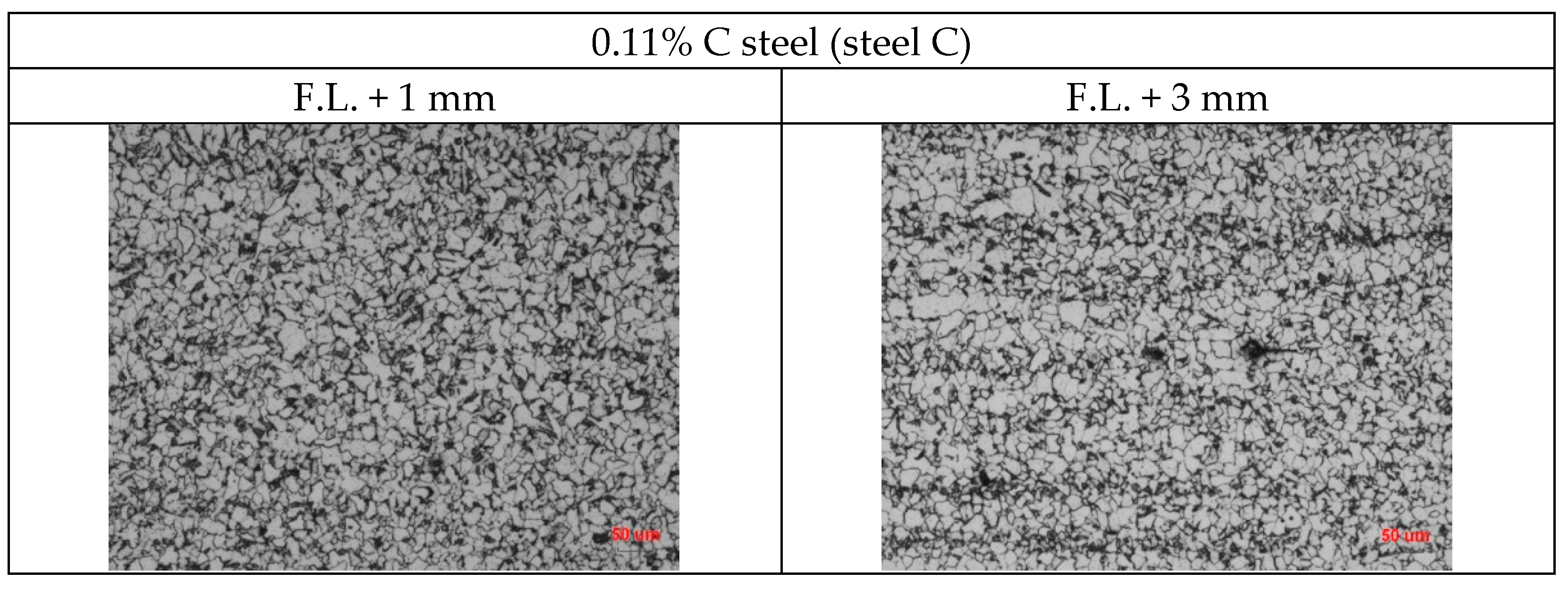

3.1.2. Heat Input of 100 kJ/cm

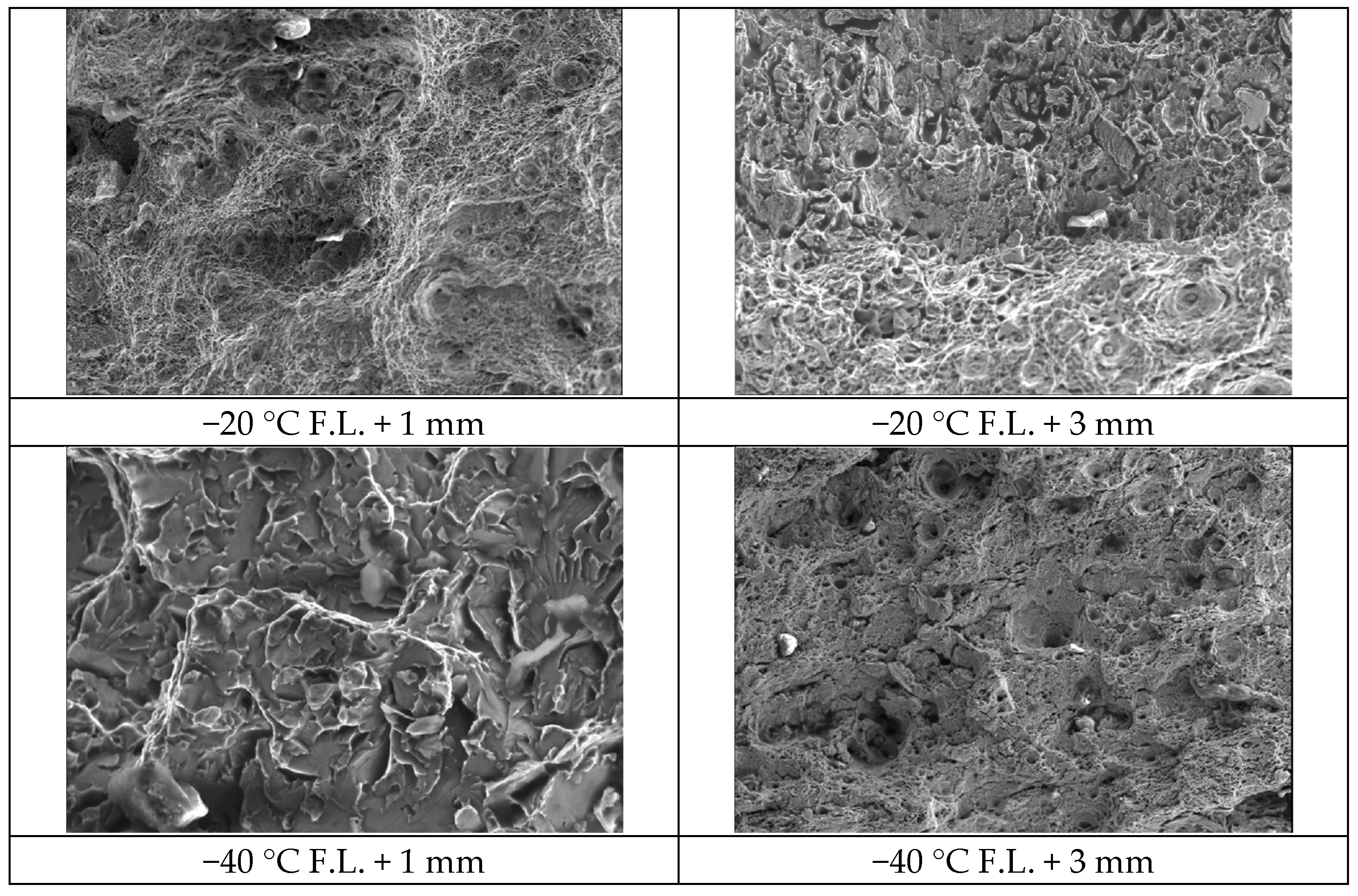

3.1.3. Fracture Observation

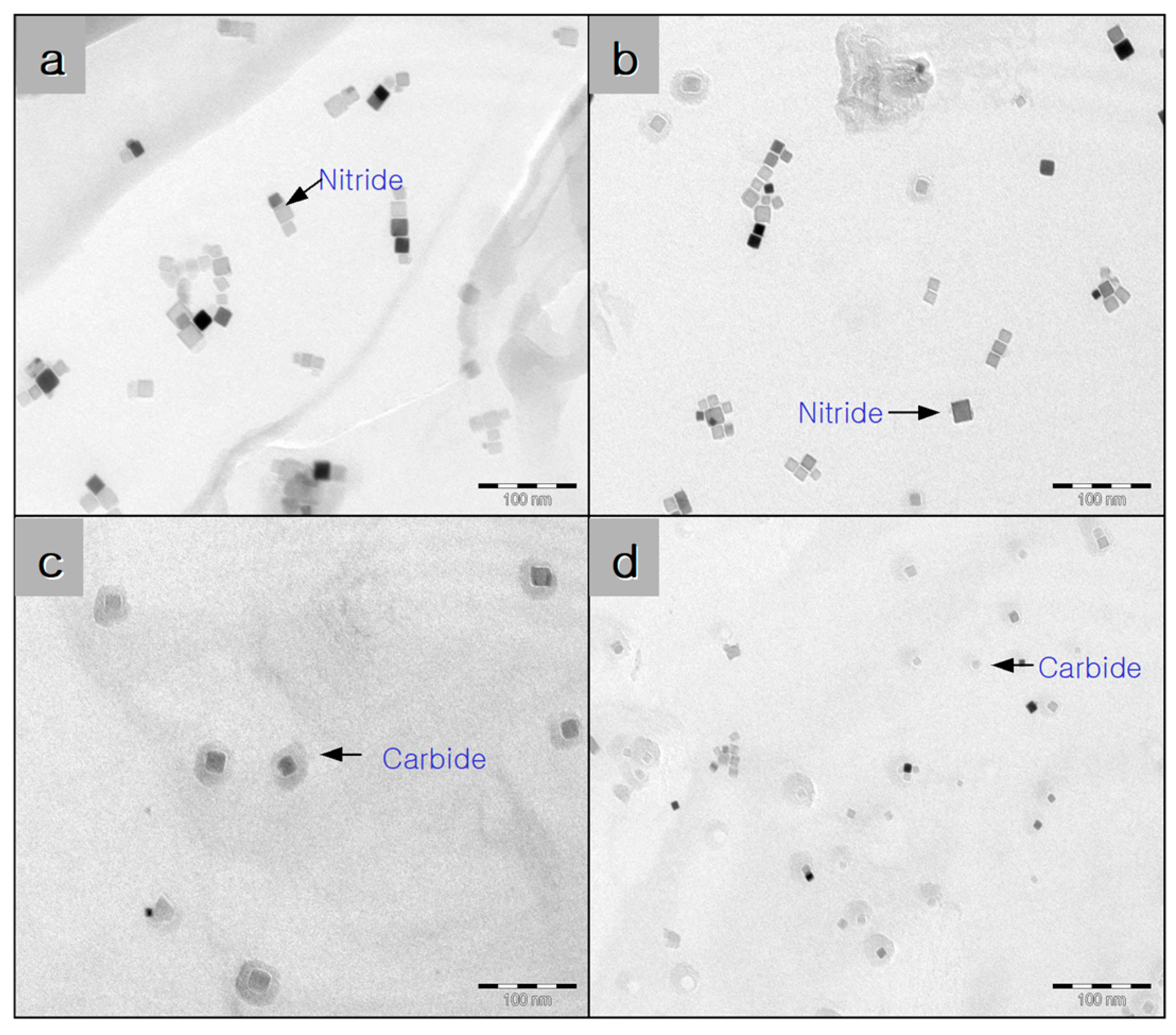

3.1.4. TEM Analysis

4. Conclusions

- (1)

- High-nitrogen TiN steels with carbon contents of 0.09% and 0.15% exhibited CTOD values ranging from 1.38 to 2.73 mm at −20 °C and −40 °C under a 45 kJ/cm heat input, demonstrating superior fracture toughness compared to conventional 490 MPa-class steels. This improvement is attributed to the uniform distribution of fine TiN precipitates, which effectively restricted austenite grain growth in the HAZ.

- (2)

- Specimens welded with a high heat input of 100 kJ/cm exhibited reduced CTOD values of 1.5 mm at −20 °C and 0.3 mm at −40 °C. This deterioration in toughness is attributed to the partial dissolution of TiN particles in the CGHAZ, which resulted in insufficient restriction of austenite grain growth.

- (3)

- Unlike conventional steels, high-nitrogen TiN steels did not show a reduction in CTOD values with increasing carbon content. This stability in toughness is attributed to the formation of TiCN particles in higher-carbon steels, which promoted microstructural refinement and mitigated the adverse effects of carbon.

- (4)

- Fracture surfaces of the HAZ after CTOD testing at −20 °C and −40 °C exhibited mixed ductile and brittle failure modes, with no significant variation observed across different carbon contents or distances from the fusion line.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lan, L.; Kong, X.; Qiu, C.; Zhao, D. Influence of microstructural aspects on impact toughness of multi-pass submerged arc welded HSLA steel joints. Mater. Des. 2016, 90, 488–498. [Google Scholar] [CrossRef]

- Kitani, Y.; Ikeda, R.; Yasuda, K.; Oi, K.; Ichimiya, K. Improvement of HAZ Toughness for High Heat Input Welding by using Boron Diffusion from Weld Metal. Weld. World 2007, 51, 31–36. [Google Scholar] [CrossRef]

- Eom, H.W.; Won, J.Y.; Shin, S.Y. Effect of Cooling Rate on The Microstructure and Cryogenic Impact Toughness of HAZ in 9% Ni Steel. Korean J. Met. Mater. 2021, 59, 781–795. [Google Scholar] [CrossRef]

- Park, J.-S.; Hwang, J.-K.; Cho, J.Y.; Han, I.W.; Lee, M.J.; Kim, S.J. Effects of TiN and B on Grain Refinement of HAZ Microstructure and Improvement of Mechanical Properties of High-strength Structural Steel Under High Heat Input Welding. Korean J. Mater. Res. 2019, 29, 97–105. [Google Scholar] [CrossRef]

- Zhou, P.; Wang, B.; Wang, L.; Hu, Y.; Zhou, L. Effect of welding heat input on grain boundary evolution and toughness properties in CGHAZ of X90 pipeline steel. Mater. Sci. Eng. A 2018, 722, 112–121. [Google Scholar] [CrossRef]

- Ding, Q.; Wang, T.; Shi, Z.; Wang, Q.; Wang, Q.; Zhang, F. Effect of Welding Heat Input on the Microstructure and Toughness in Simulated CGHAZ of 800 MPa-Grade Steel for Hydropower Penstocks. Metals 2017, 7, 115. [Google Scholar] [CrossRef]

- Li, L.; Wang, Y.; Han, T.; Li, C. Embrittlement and toughening in CGHAZ of ASTM4130 steel. Science China Physics. Mech. Astron. 2011, 54, 1447–1454. [Google Scholar] [CrossRef]

- Qi, H.; Pang, Q.; Li, W.; Bian, S. Effect of high welding heat input on the microstructure and low-temperature toughness of heat affected zone in magnesium-treated EH36 steel. Sci. Rep. 2024, 14, 19459. [Google Scholar] [CrossRef]

- Li, Y.; Crowther, D.N.; Green, M.J.W.; Mitchell, P.S.; Baker, T.N. The Effect of Vanadium and Niobium on the Properties and Microstructure of the Intercritically Reheated Coarse Grained Heat Affected Zone in Low Carbon Microalloyed Steels. ISIJ Int. 2001, 41, 46–55. [Google Scholar] [CrossRef]

- Baker, T.N. Processes, microstructure and properties of vanadium microalloyed steels. Mater. Sci. Technol. 2009, 25, 1083–1107. [Google Scholar] [CrossRef]

- Kiviö, M.; Holappa, L.; Iung, T. Addition of Dispersoid Titanium Oxide Inclusions in Steel and Their Influence on Grain Refinement. Metall. Mater. Trans. B 2010, 41, 1194–1204. [Google Scholar] [CrossRef]

- Xie, K.Y.; Zheng, T.; Cairney, J.M.; Kaul, H.; Williams, J.G.; Barbaro, F.J.; Killmore, C.R.; Ringer, S.P. Strengthening from Nb-rich clusters in a Nb-microalloyed steel. Scr. Mater. 2012, 66, 710–713. [Google Scholar] [CrossRef]

- Hu, J.; Du, L.-X.; Wang, J.-J.; Gao, C.-R. Effect of welding heat input on microstructures and toughness in simulated CGHAZ of V–N high strength steel. Mater. Sci. Eng. A 2013, 577, 161–168. [Google Scholar] [CrossRef]

- Haslberger, P.; Ernst, W.; Schneider, C.; Holly, S.; Schnitzer, R. Influence of inhomogeneity on several length scales on the local mechanical properties in V-alloyed all-weld metal. Weld. World 2018, 62, 1153–1158. [Google Scholar] [CrossRef]

- Huang, Y.; Cheng, G.-G.; Li, S.-J.; Dai, W.-X.; Xie, Y. Effect of Ti(C, N) Particle on the Impact Toughness of B-Microalloyed Steel. Metals 2018, 8, 868. [Google Scholar] [CrossRef]

- Wang, X.; Wang, C.; Kang, J.; Yuan, G.; Misra, R.D.K.; Wang, G. Improved toughness of double-pass welding heat affected zone by fine Ti–Ca oxide inclusions for high-strength low-alloy steel. Mater. Sci. Eng. A 2020, 780, 139198. [Google Scholar] [CrossRef]

- Wang, J.; Li, C.; Wang, D.; Di, X. Effect of microalloying with Nb and/or V on the microstructure and mechanical properties of GPa grade deposited metals. Weld. World 2023, 67, 2107–2122. [Google Scholar] [CrossRef]

- Zhang, J.; Xin, W.; Ge, Z.; Luo, G.; Peng, J. Effect of high heat input welding on the microstructures, precipitates and mechanical properties in the simulated coarse grained heat affected zone of a low carbon Nb-V-Ti-N microalloyed steel. Mater. Charact. 2023, 199, 112849. [Google Scholar] [CrossRef]

- Hu, B.; Wang, Q.; Li, F.; Wang, Q.; Liu, R. Refinement mechanism of large heat-input welding CGHAZ microstructure by N addition and its effect on toughness of a V-Ti-N microalloying weathering steel. Mater. Sci. Eng. A 2024, 892, 146019. [Google Scholar] [CrossRef]

- Jiang, J.; Zhang, Z.; Guo, K.; Guan, Y.; Yuan, L.; Wang, Q. Effect of Nb Content on the Microstructure and Impact Toughness of High-Strength Pipeline Steel. Metals 2024, 14, 42. [Google Scholar] [CrossRef]

- Wang, Z.; Li, X.; Wang, X.; Shang, C.; Zhang, Y. Studies on the effect of Nb on microstructure refinement and impact toughness improvement in coarse-grained heat-affected zone of X80 pipeline steels. Mater. Today Commun. 2025, 42, 111605. [Google Scholar] [CrossRef]

- Kundu, A. Austenite Grain Boundary Pinning during Reheating by Mixed AlN and Nb(C,N) Particles. ISIJ Int. 2014, 54, 677–684. [Google Scholar] [CrossRef]

- Nabavi, B.; Goodarzi, M.; Khan, A.K. Investigation of secondary phases and tensile strength of nitrogen-containing Alloy 718 weldment. International Journal of Minerals. Metall. Mater. 2020, 27, 1259–1268. [Google Scholar] [CrossRef]

- Webel, J.; Mohrbacher, H.; Detemple, E.; Britz, D.; Mücklich, F. Quantitative analysis of mixed niobium-titanium carbonitride solubility in HSLA steels based on atom probe tomography and electrical resistivity measurements. J. Mater. Res. Technol. 2022, 18, 2048–2063. [Google Scholar] [CrossRef]

- Chapa, M.; Medina, S.F.; López, V.; Fernández, B. Influence of Al and Nb on Optimum Ti/N Ratio in Controlling Austenite Grain Growth at Reheating Temperatures. ISIJ Int. 2002, 42, 1288–1296. [Google Scholar] [CrossRef]

- Wan, X.; Zhou, B.; Nune, K.C.; Li, Y.; Wu, K.; Li, G. In-situ microscopy study of grain refinement in the simulated heat-affected zone of high-strength low-alloy steel by TiN particle. Sci. Technol. Weld. Join. 2017, 22, 343–352. [Google Scholar] [CrossRef]

- Zhu, Z.X.; Kuzmikova, L.; Marimuthu, M.; Li, H.J.; Barbaro, F. Role of Ti and N in line pipe steel welds. Sci. Technol. Weld. Join. 2013, 18, 1–10. [Google Scholar] [CrossRef]

- Zhu, Z.X.; Marimuthu, M.; Kuzmikova, L.; Li, H.; Barbaro, F.; Zheng, L.; Bai, M.Z.; Jones, C. Influence of Ti/N ratio on simulated CGHAZ microstructure and toughness in X70 steels. Sci. Technol. Weld. Join. 2013, 18, 45–51. [Google Scholar] [CrossRef]

- Gui, L.; Chen, D.; Liu, P.; Liu, T.; Long, M.; Duan, H.; Cao, J. Precipitation of Ti-C-N Particles in Austenite During Cooling Process of High-Ti Microalloyed Steel; Materials Science and Technology Conference and Exhibition: Columbus, OH, USA, 2017; pp. 900–907. [Google Scholar]

- ASTM E1290–08; Standard Test Method for Crack-Tip Opening Displacement (CTOD) Fracture Toughness Measurement. ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM E8–16a; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- Ichimiya, K.; Hase, K.; Endo, S.; Yuga, M.; Hirata, K.; Matsunaga, N.; Suzuki, S. Steel Plates with Excellent HAZ Toughness for Offshore Structure. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Nantes, France, 25–30 June 2013. [Google Scholar]

- Komizo, Y.-I.; Fukada, Y. CTOD properties and M-A constituent in the HAZ of C-Mn microalloyed steel. Q. J. Jpn. Weld. Soc. 1988, 6, 41–46. [Google Scholar] [CrossRef]

| Steel | C | Si | Mn | P | S | Tot- Al | Sol- Al | Ti | B (ppm) | N (ppm) | Ti/N | Ceq 1 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 0.09 | 0.12 | 1.48 | 0.008 | 0.003 | 0.050 | 0.047 | 0.019 | 10 | 130 | 1.5 | 0.34 |

| B | 0.15 | 0.12 | 1.49 | 0.009 | 0.003 | 0.060 | 0.057 | 0.017 | 10 | 110 | 1.6 | 0.40 |

| C | 0.11 | 0.49 | 1.50 | 0.008 | 0.003 | 0.060 | 0.057 | 0.017 | 10 | 110 | 1.5 | 0.38 |

| Steel | Thickness (mm) | YP (MPa) | TS (MPa) | YR (%) | El. (%) | vE−40 °C (J) |

|---|---|---|---|---|---|---|

| A | 40 | 351 | 460 | 76 | 34 | 286 |

| B | 40 | 383 | 518 | 74 | 39 | 235 |

| C | 40 | 405 | 522 | 78 | 27 | 244 |

| Steels | Heat Input | No. of Passes | Groove Angle | Current (A) | Voltage (V) | Welding Speed (cm/min) |

|---|---|---|---|---|---|---|

| A, B | 45 kJ/cm | 8 | 60° K-groove | 650 | 36 | 31 |

| C | 100 kJ/cm | 4 | 45° K-groove | 900 | 36 | 19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oh, M.-S.; Kim, Y.-G.; Joo, S.-M. CTOD Evaluation of High-Nitrogen Steels for Low-Temperature Welded Structures. Metals 2025, 15, 916. https://doi.org/10.3390/met15080916

Oh M-S, Kim Y-G, Joo S-M. CTOD Evaluation of High-Nitrogen Steels for Low-Temperature Welded Structures. Metals. 2025; 15(8):916. https://doi.org/10.3390/met15080916

Chicago/Turabian StyleOh, Min-Suk, Young-Gon Kim, and Sung-Min Joo. 2025. "CTOD Evaluation of High-Nitrogen Steels for Low-Temperature Welded Structures" Metals 15, no. 8: 916. https://doi.org/10.3390/met15080916

APA StyleOh, M.-S., Kim, Y.-G., & Joo, S.-M. (2025). CTOD Evaluation of High-Nitrogen Steels for Low-Temperature Welded Structures. Metals, 15(8), 916. https://doi.org/10.3390/met15080916