Study of Microstructure, Mechanical, and Corrosion Properties of K-TIG Welded Joints of 2205/316L Dissimilar Stainless Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

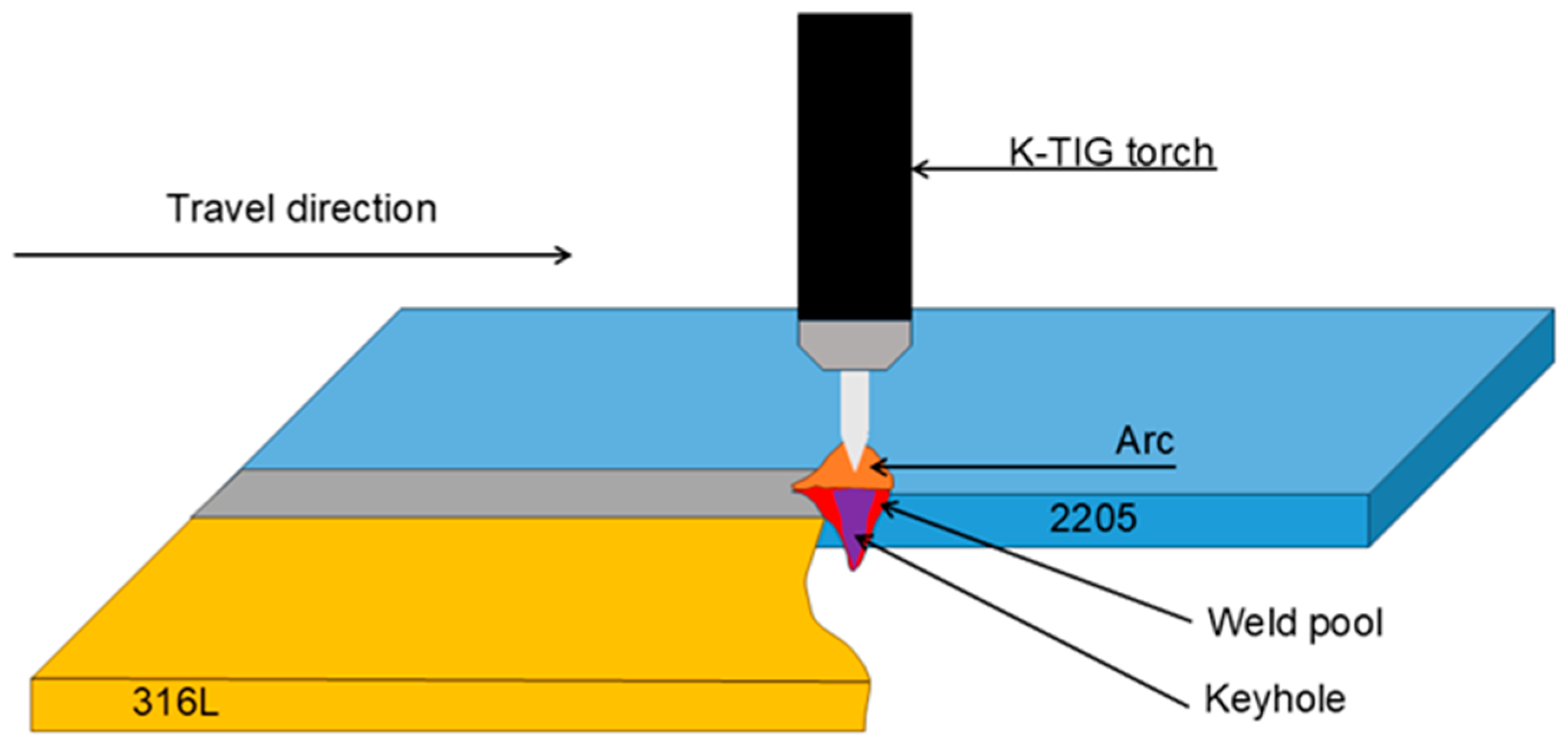

2.2. Welding Procedure

2.3. Microstructural Characterization

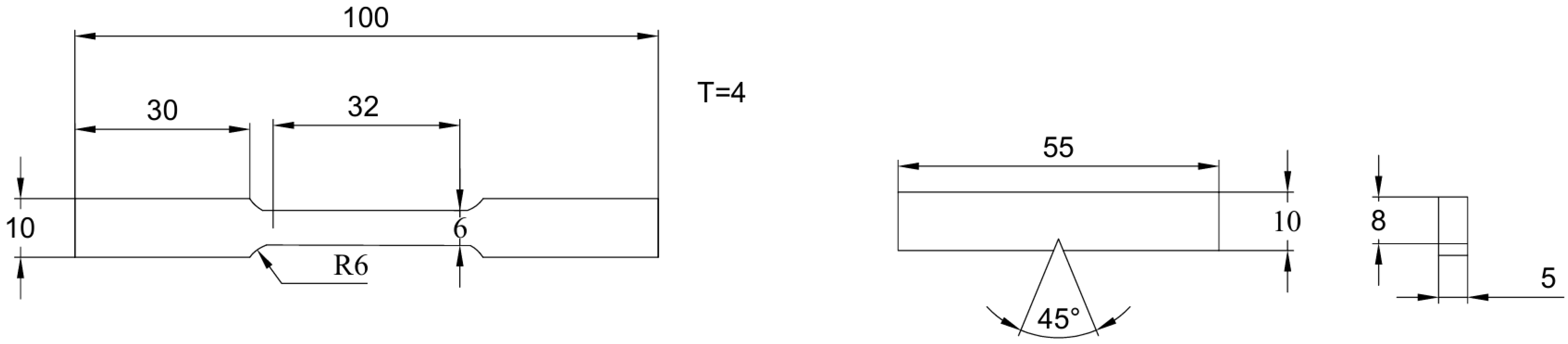

2.4. Mechanical Test

2.5. Electrochemical Characterization

3. Results and Discussion

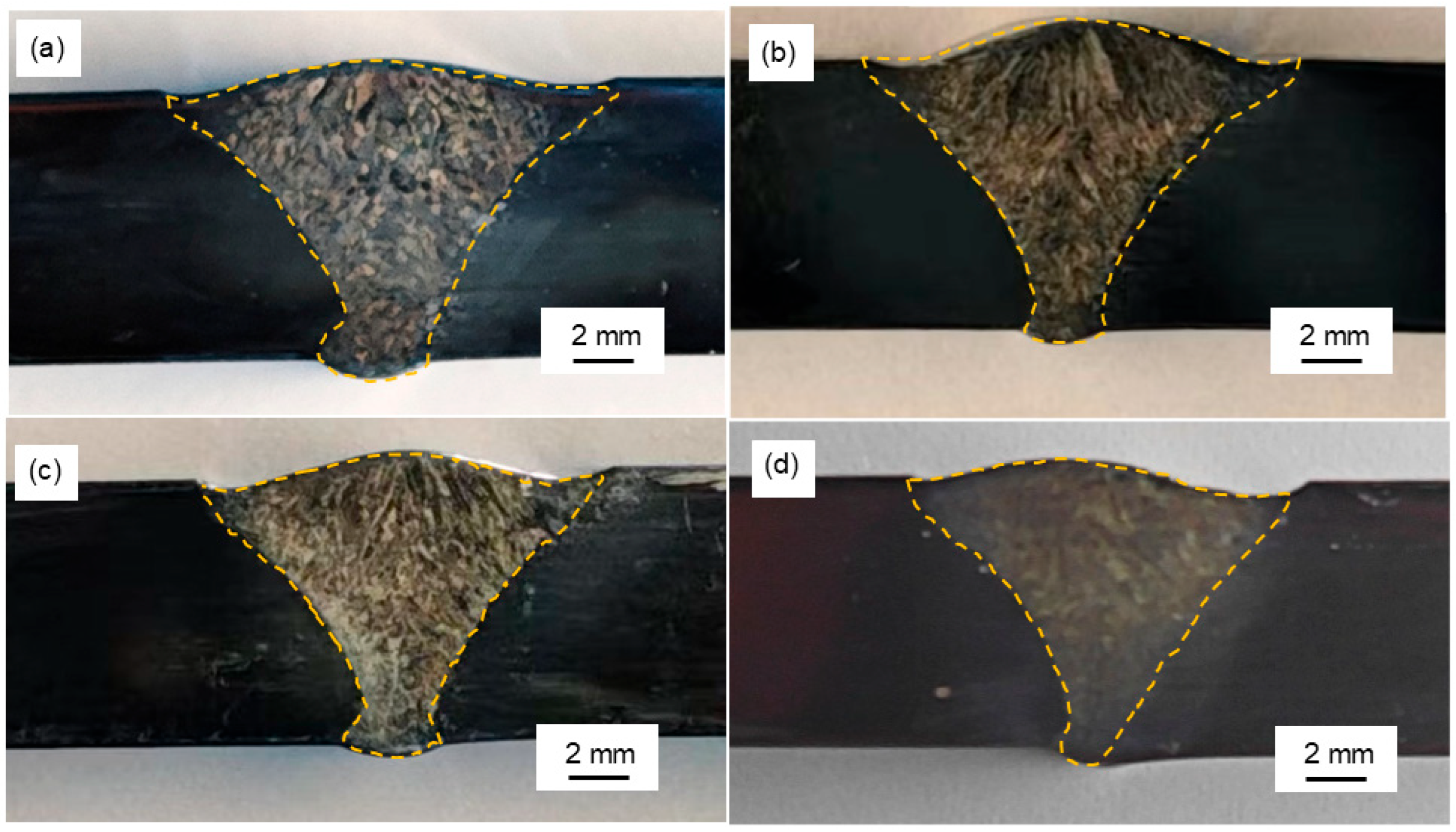

3.1. Macroscopic Morphology of Welded Joints

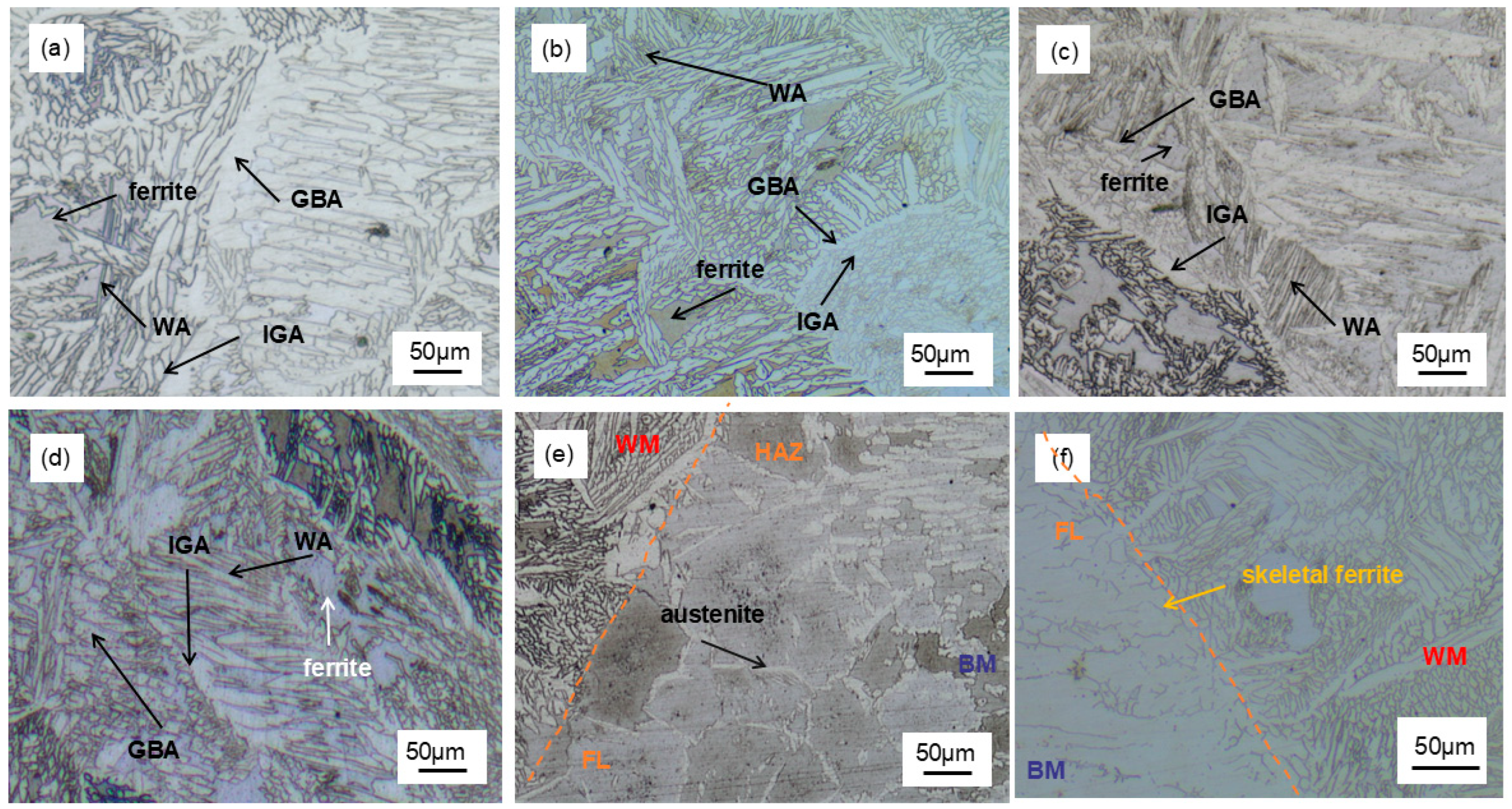

3.2. Microstructure of Joints

3.3. Mechanical Properties

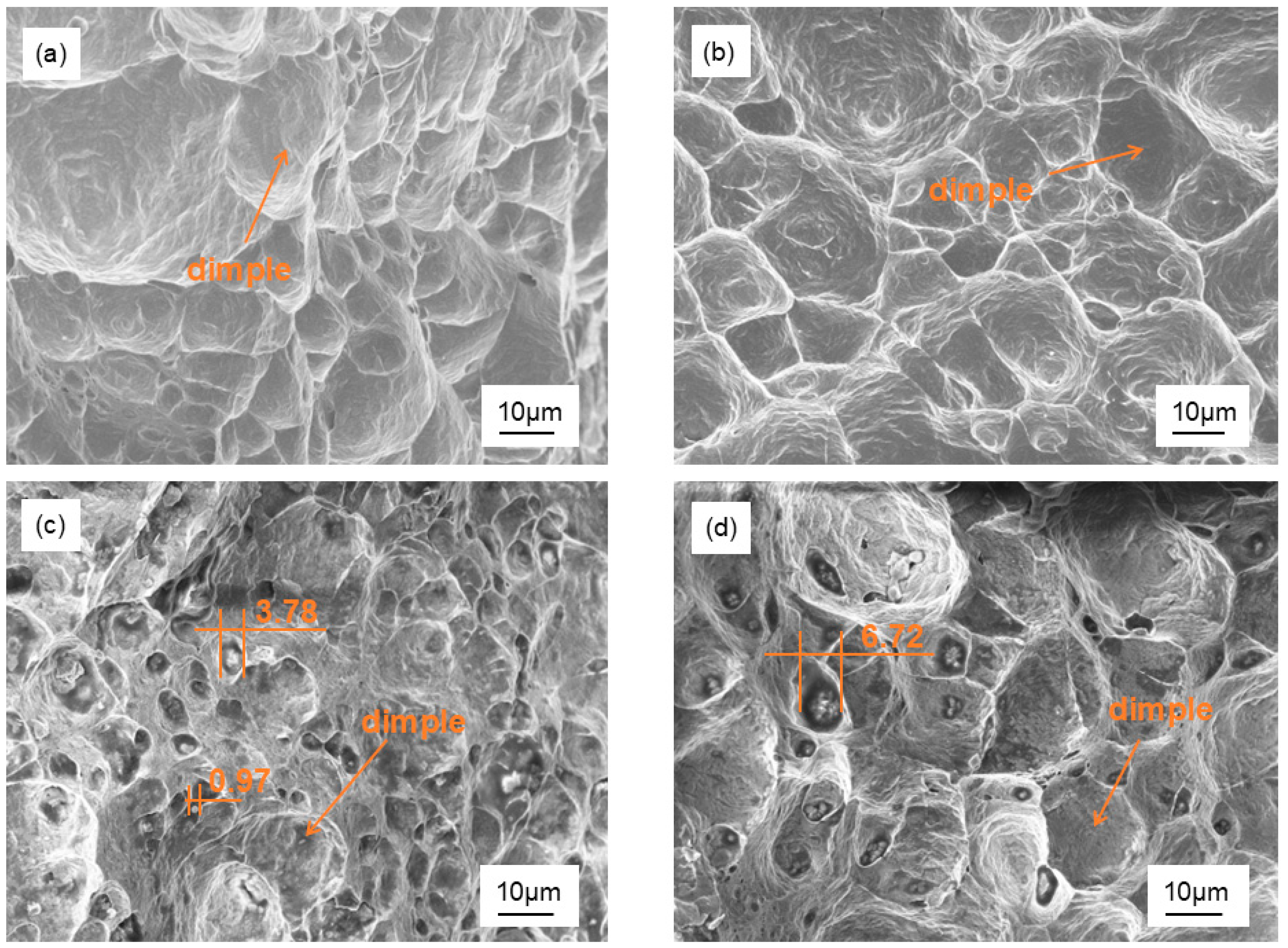

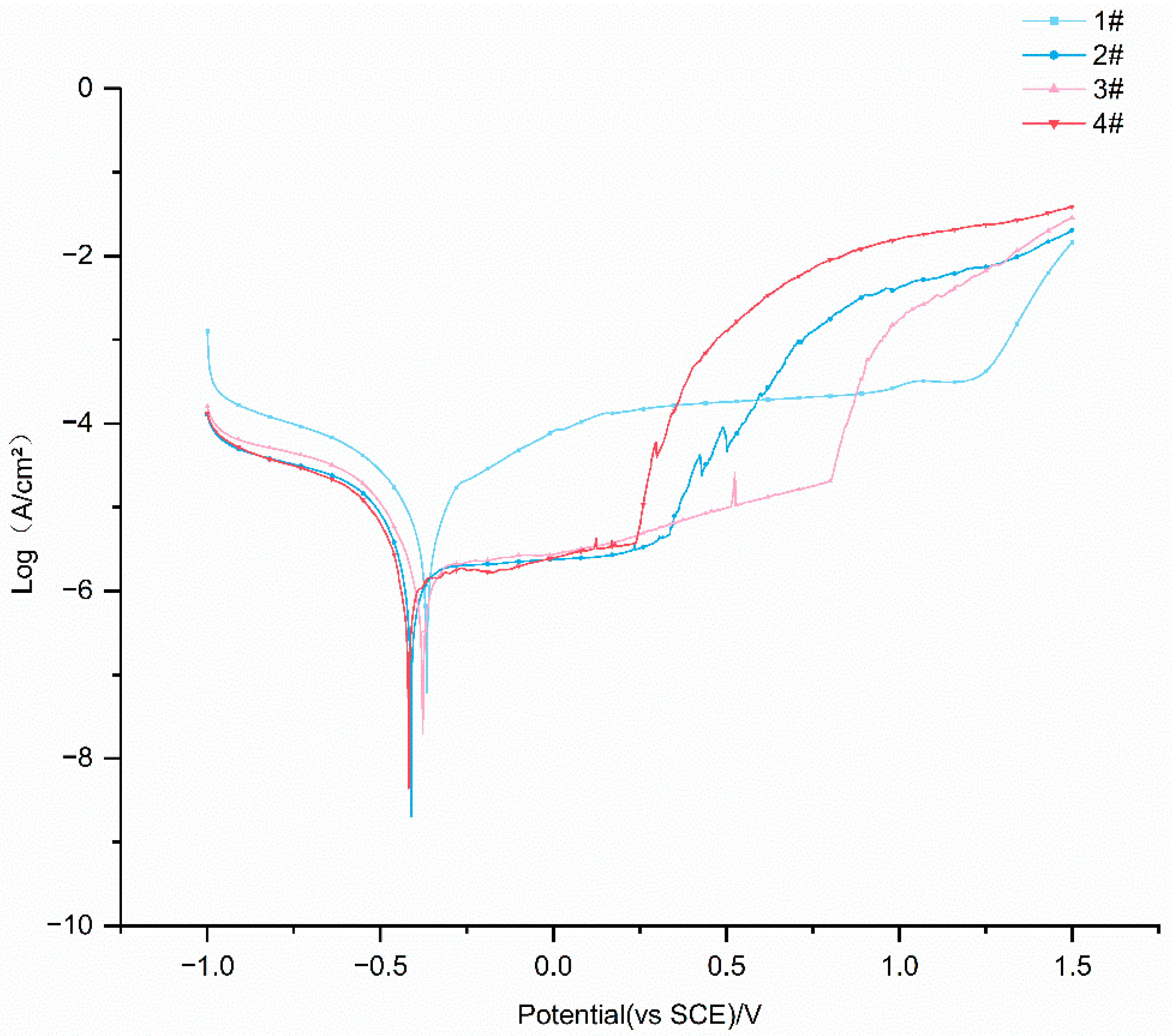

3.4. Electrochemical Corrosion Experiment

4. Conclusions

- K-TIG welding process demonstrated superior efficiency compared to conventional arc welding techniques, achieving defect-free full-penetration joints in 8 mm thick 2205/316L dissimilar combinations without filler metal at travel velocities of 280–320 mm/min. However, a lack of fusion was present at the root side when the welding speed reached 360 mm/min.

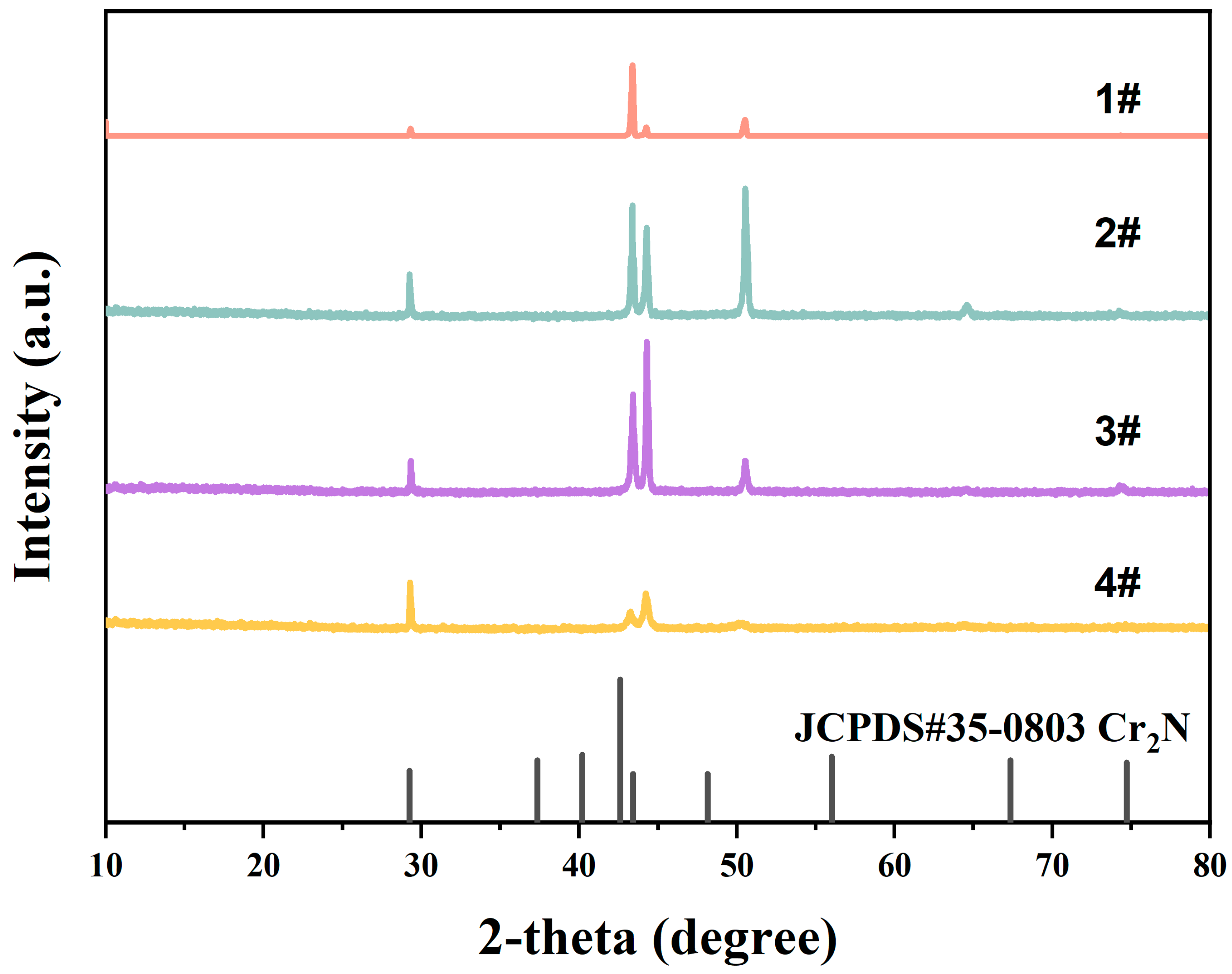

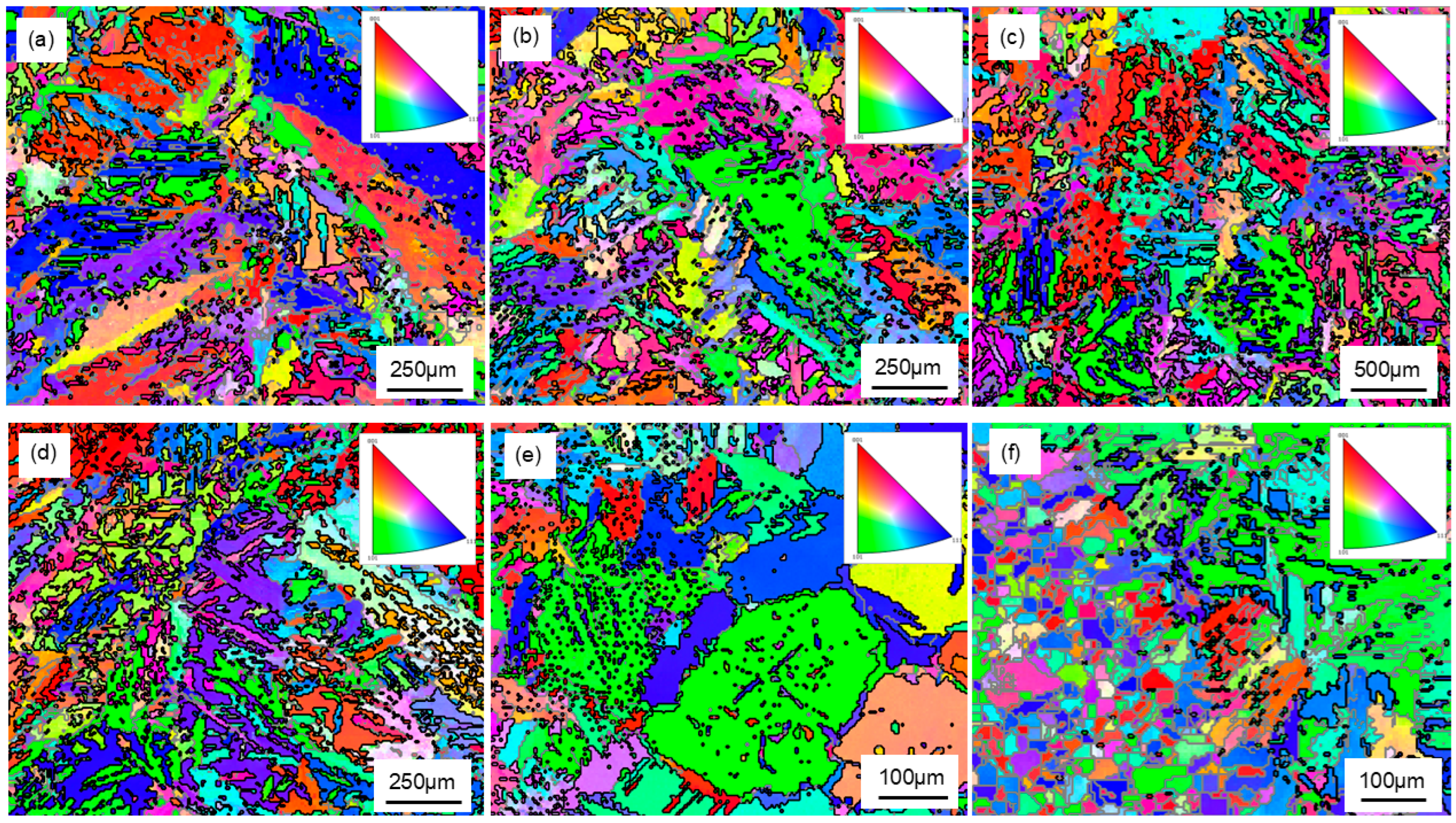

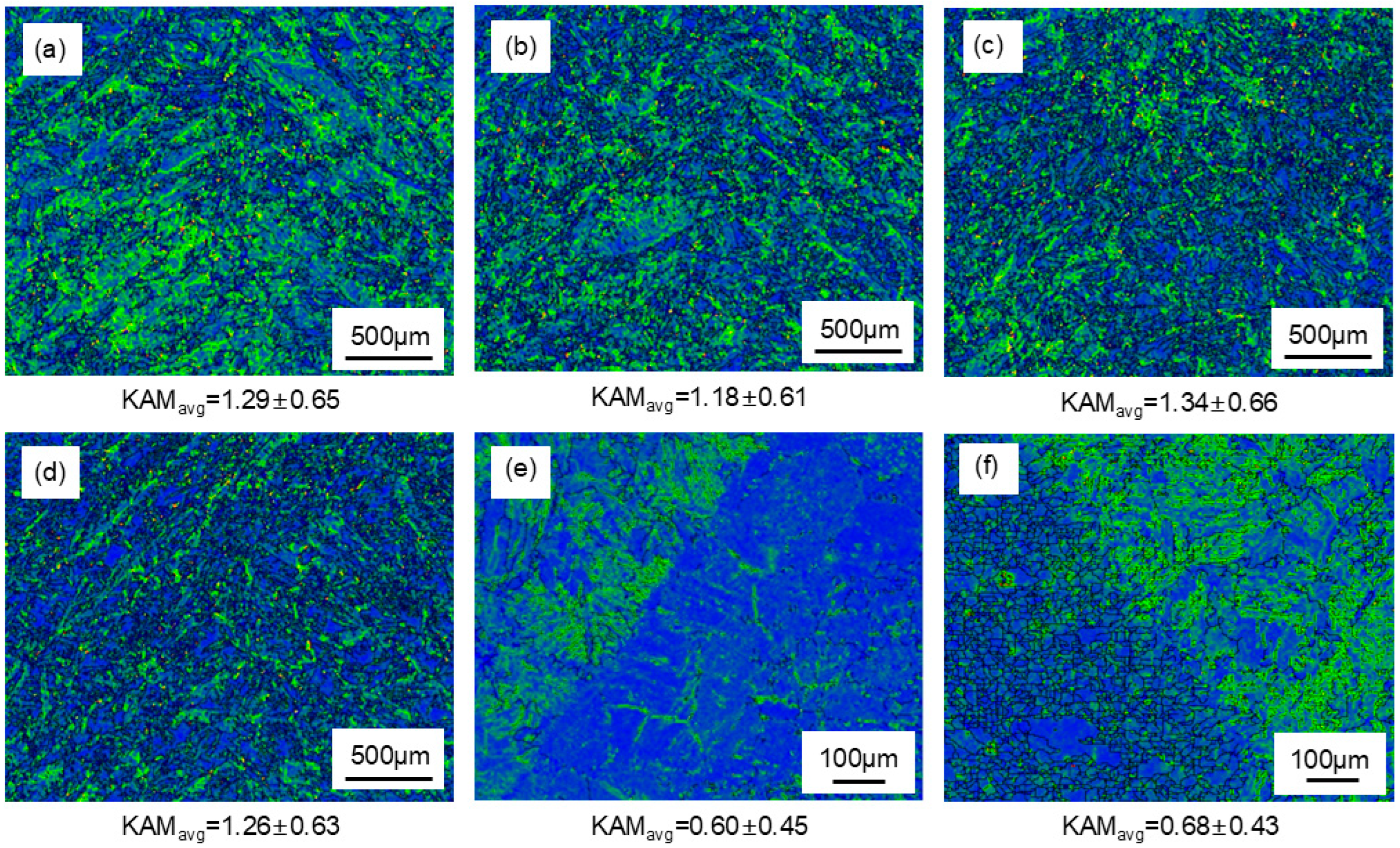

- The austenite and ferrite content of WM varied within reasonable limits. WM formed ferrite and different forms of austenite, such as GBA, IGA, and WA. The austenite grain size decreased with increasing weld speed, and the ferrite percentage increased with increasing weld speed.

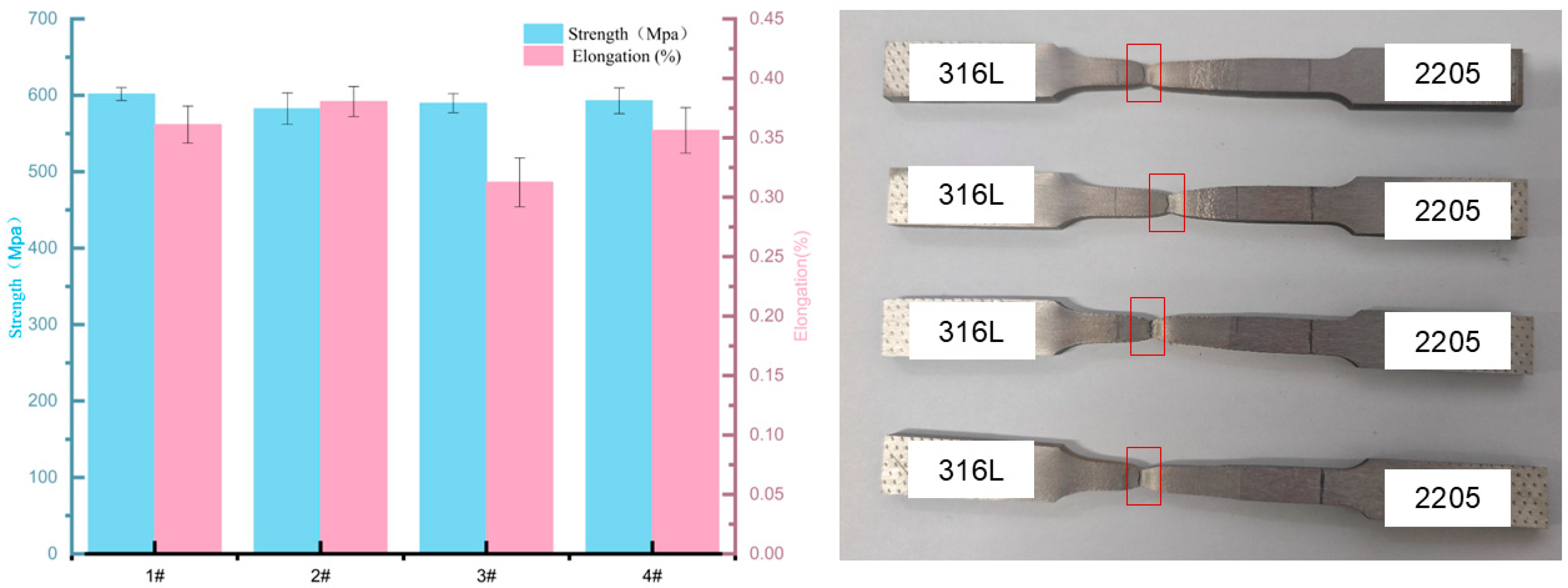

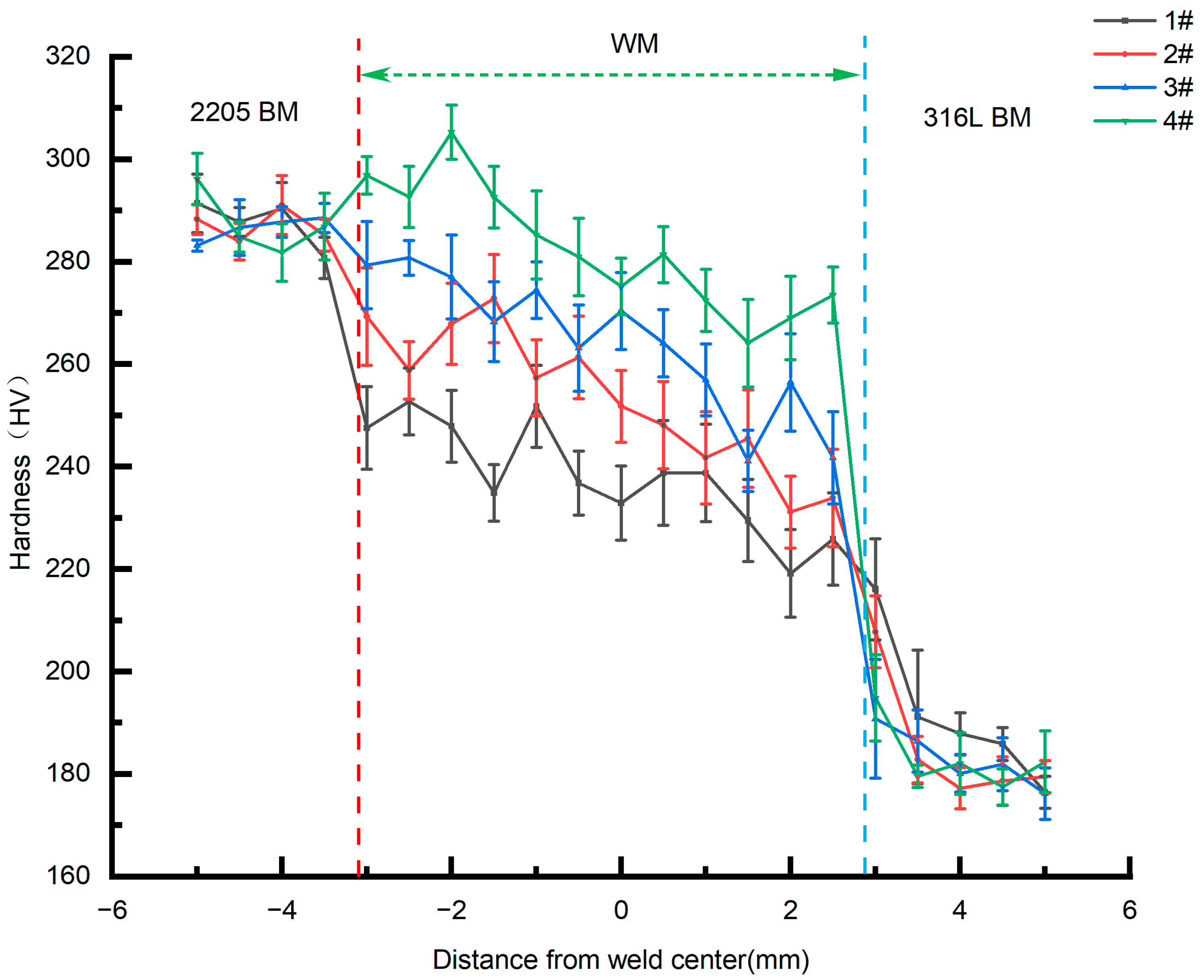

- The tensile properties of K-TIG fittings are similar to those of TIG fittings and are better than the 316L base material, but the hardness of K-TIG joints is higher than that of TIG joints.

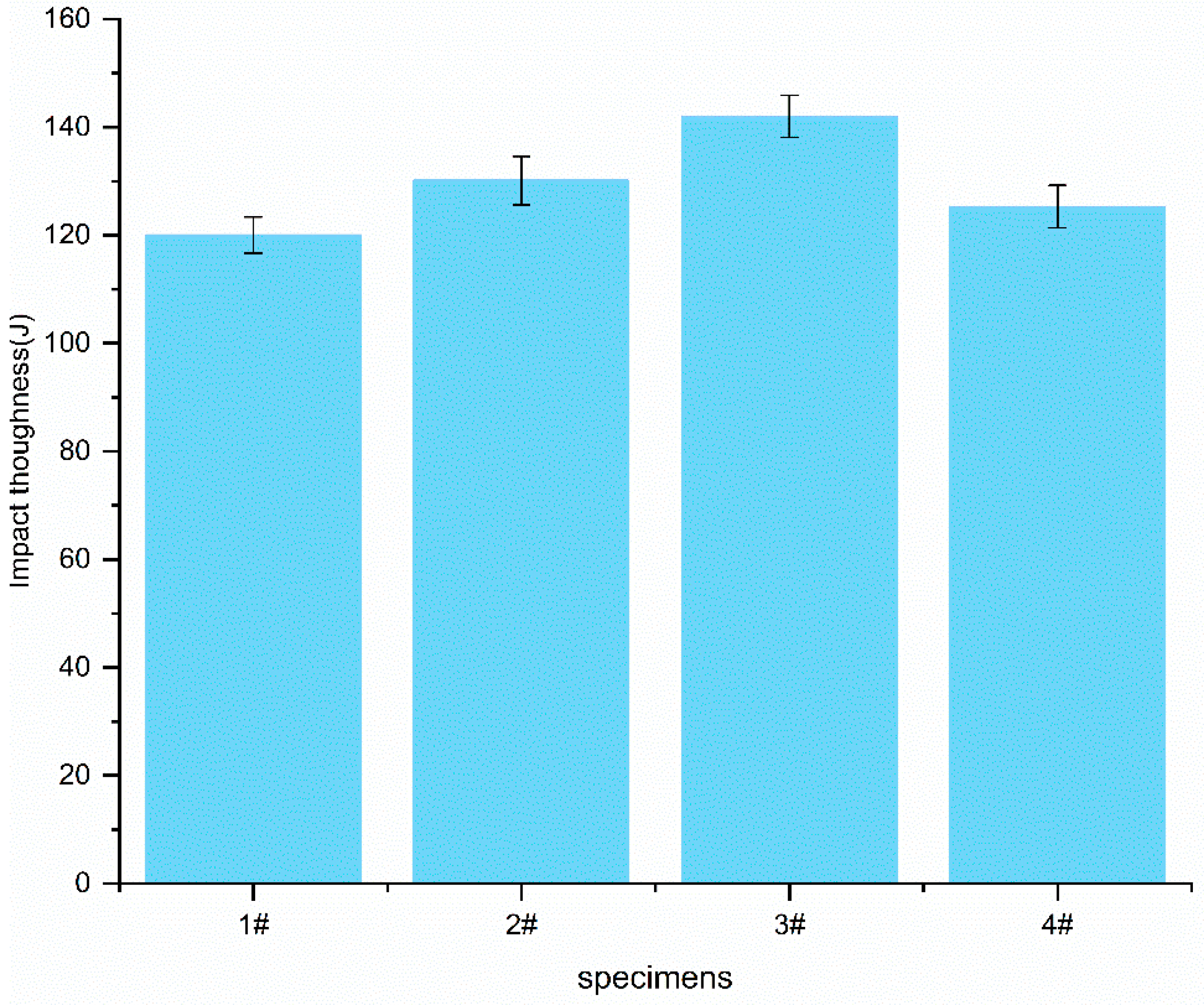

- WM exhibits excellent room temperature impact toughness, which is not weaker than that of TIG joints. Due to the strengthening effect of grain refinement, the impact toughness of K-TIG joints increases with decreasing grain size and reaches a maximum value by specimen 3#. However, when the welding speed reaches 340 mm/min, the toughness decreases due to the increase in the size of oxidized inclusions.

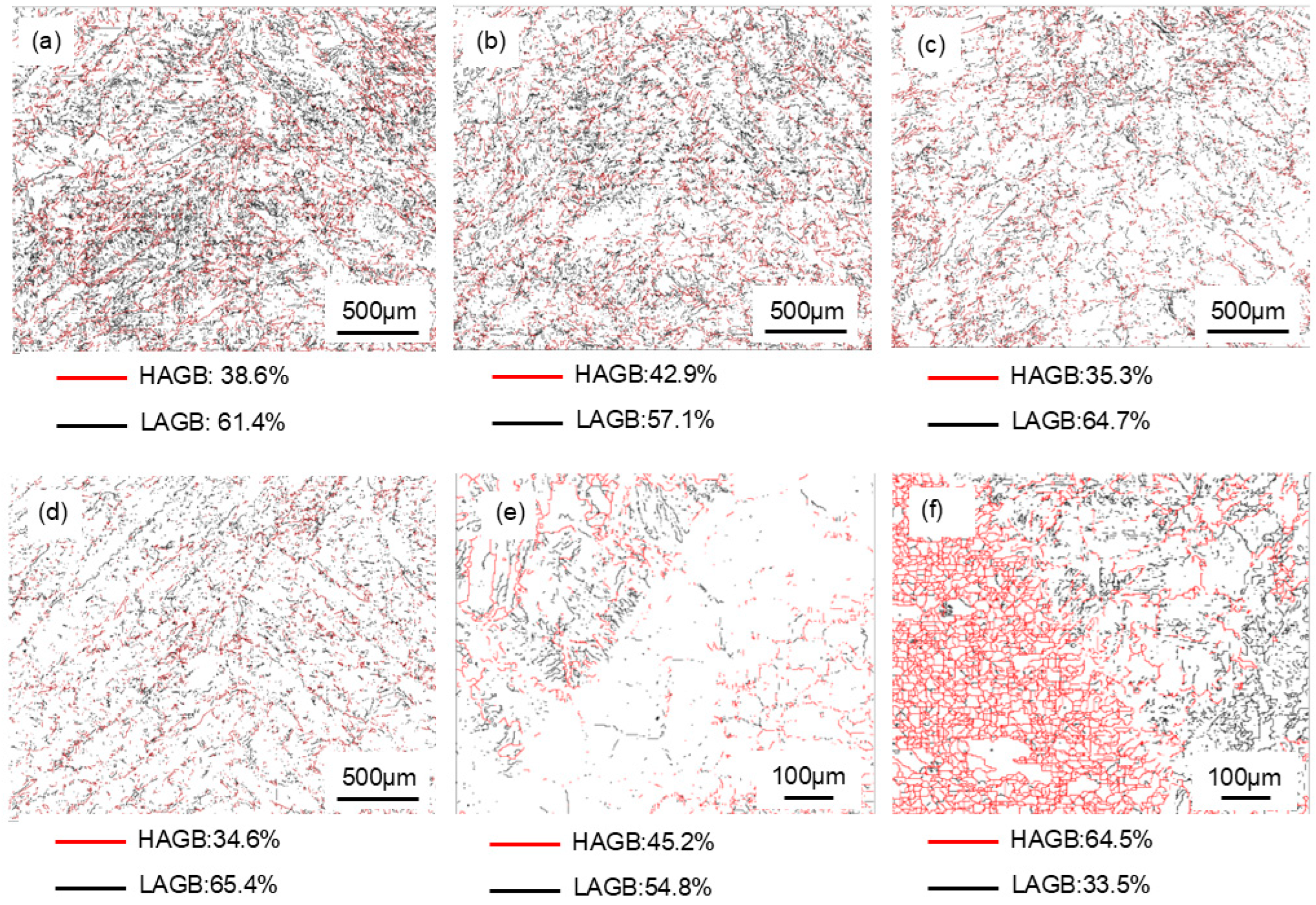

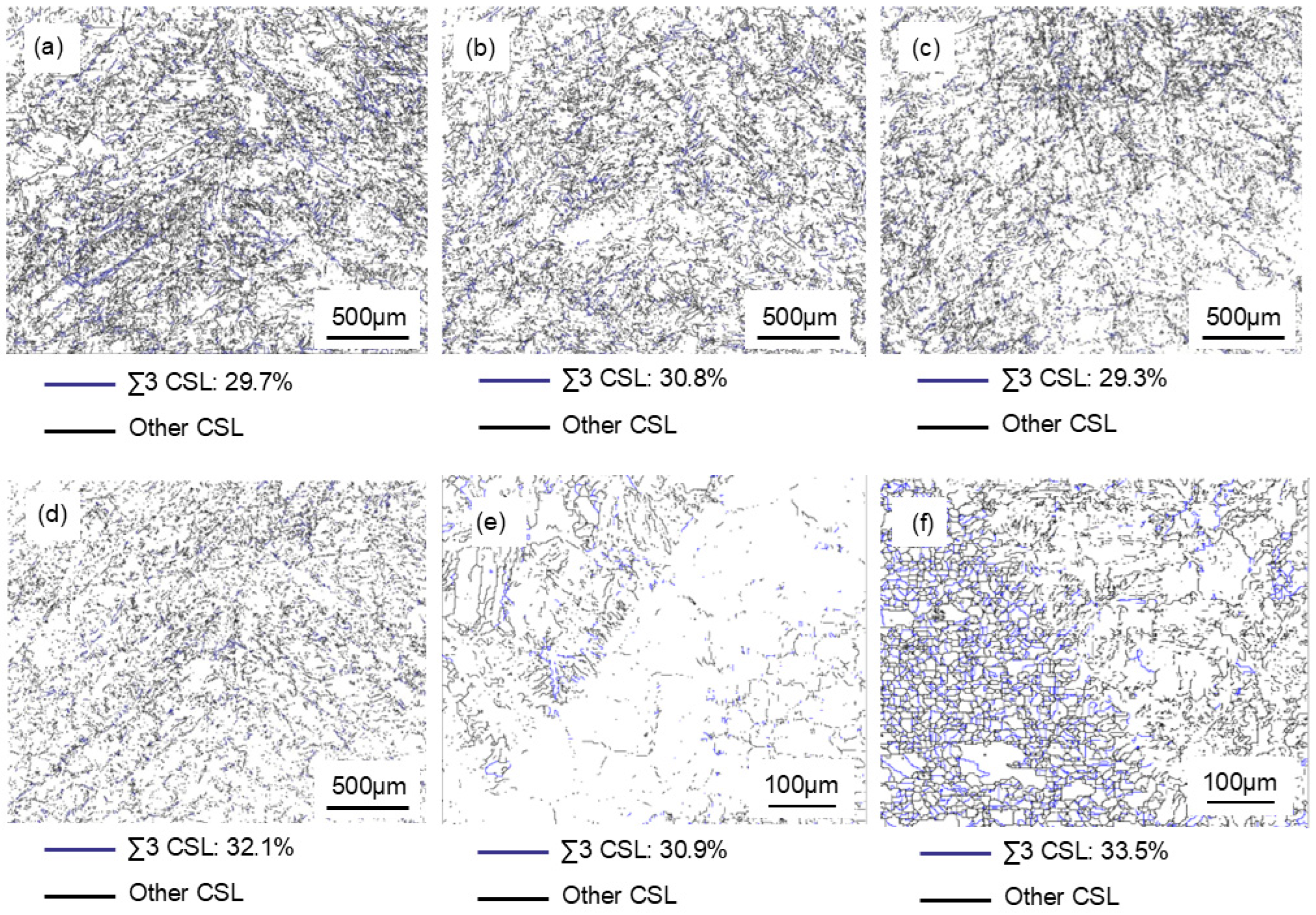

- The overall difference in WM corrosion performance is not significant, with specimen 1# exhibiting the worst corrosion performance due to its coarse grain structure, in contrast to specimen 2#, which achieves the best pitting resistance through combined grain refinement and favorable Σ3CSL boundary density, synergistically enhancing passivation film stability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sabzi, M.; Mousavi Anijdan, S.H.; Eivani, A.R.; Park, N.; Jafarian, H.R. The Effect of Pulse Current Changes in PCGTAW on Microstructural Evolution, Drastic Improvement in Mechanical Properties, and Fracture Mode of Dissimilar Welded Joint of AISI 316L-AISI 310S Stainless Steels. Mater. Sci. Eng. A 2021, 823, 141700. [Google Scholar] [CrossRef]

- Verma, J.; Taiwade, R.V. Dissimilar Welding Behavior of 22% Cr Series Stainless Steel with 316L and Its Corrosion Resistance in Modified Aggressive Environment. J. Manuf. Processes 2016, 24, 1–10. [Google Scholar] [CrossRef]

- Fei, Z.; Pan, Z.; Cuiuri, D.; Li, H.; Wu, B.; Ding, D.; Su, L.; Gazder, A.A. Investigation into the Viability of K-TIG for Joining Armour Grade Quenched and Tempered Steel. J. Manuf. Processes 2018, 32, 482–493. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, H.; Hu, J.; Qi, X.; Bian, Y.; Shen, A.; Xu, P.; Zhao, Y. Microstructure Evolution and Mechanical Properties of Briefly Heat-Treated SAF 2507 Super Duplex Stainless Steel Welds. Constr. Build. Mater. 2018, 168, 338–345. [Google Scholar] [CrossRef]

- Rogalski, G.; Świerczyńska, A.; Landowski, M.; Fydrych, D. Mechanical and Microstructural Characterization of TIG Welded Dissimilar Joints between 304L Austenitic Stainless Steel and Incoloy 800HT Nickel Alloy. Metals 2020, 10, 559. [Google Scholar] [CrossRef]

- Tomków, J.; Fydrych, D.; Rogalski, G. Dissimilar Underwater Wet Welding of HSLA Steels. Int. J. Adv. Manuf. Technol. 2020, 109, 717–725. [Google Scholar] [CrossRef]

- Theodoro, M.C.; Pereira, V.F.; Mei, P.R.; Ramirez, A.J. Dissimilar Friction Stir Welding Between UNS S31603 Austenitic Stainless Steel and UNS S32750 Superduplex Stainless Steel. Metall. Mater. Trans. B 2015, 46, 1440–1447. [Google Scholar] [CrossRef]

- Jayakumar, T.; Mathew, M.D.; Laha, K. High Temperature Materials for Nuclear Fast Fission and Fusion Reactors and Advanced Fossil Power Plants. Procedia Eng. 2013, 55, 259–270. [Google Scholar] [CrossRef]

- Abdollahi, A.; Shamanian, M.; Golozar, M.A. Comparison of Pulsed and Continuous Current Gas Tungsten Arc Welding in Dissimilar Welding between UNS S32750 and AISI 321 in Optimized Condition. Int. J. Adv. Manuf. Technol. 2018, 97, 687–696. [Google Scholar] [CrossRef]

- Moteshakker, A.; Danaee, I. Microstructure and Corrosion Resistance of Dissimilar Weld-Joints between Duplex Stainless Steel 2205 and Austenitic Stainless Steel 316L. J. Mater. Sci. Technol. 2016, 32, 282–290. [Google Scholar] [CrossRef]

- Ridha Mohammed, G.; Ishak, M.; Ahmad, S.; Abdulhadi, H. Fiber Laser Welding of Dissimilar 2205/304 Stainless Steel Plates. Metals 2017, 7, 546. [Google Scholar] [CrossRef]

- Köse, C. Heat Treatment and Heat Input Effects on the Dissimilar Laser Beam Welded AISI 904L Super Austenitic Stainless Steel to AISI 317L Austenitic Stainless Steel: Surface, Texture, Microstructure and Mechanical Properties. Vacuum 2022, 205, 111440. [Google Scholar] [CrossRef]

- Song, Q.; Wang, H.; Wang, W.; Han, Z.; Qian, Y.; Wan, J.; Song, M.; Hu, Y.; Zhao, H. Optimization of Mechanical and Surface Properties of Friction Stir Welded Dissimilar Joint of 2507 SDSS and 317L ASS by Controlling Process Parameters. J. Mater. Res. Technol. 2024, 29, 416–426. [Google Scholar] [CrossRef]

- Güzey, B.N.; İrsel, G. Investigation of Mechanical and Microstructural Properties in Joining Dissimilar P355GH and Stainless 316L Steels by TIG Welding Process. Int. J. Press. Vessel. Pip. 2023, 205, 104965. [Google Scholar] [CrossRef]

- Yelamasetti, B.; Karuna, B.N.R.; Vishnu Vardhan, T.; Dasore, A.; Saxena, K.K.; Faroque, F.A.; Revathi, V.; Abduvalieva, D. Mechanical and Micro-Structural Studies of Pulsed and Constant Current TIG Weldments of Super Duplex Stainless Steels and Austenitic Stainless Steels. High. Temp. Mater. Processes 2024, 43, 20240003. [Google Scholar] [CrossRef]

- Mohan Kumar, S.; Siva Shanmugam, N. Effect of Heat Input and Weld Chemistry on Mechanical and Microstructural Aspects of Double Side Welded Austenitic Stainless Steel 321 Grade Using Tungsten Inert Gas Arc Welding Process. Mater. Werkst. 2020, 51, 349–367. [Google Scholar] [CrossRef]

- Han, L.; Han, T.; Wang, B.; Chen, G.; Sun, J.; Wang, Y. Effects of Keyhole Tungsten Inert Gas Welding Parameters on 2205 Duplex Stainless Steel Welded Joints. J. Mater. Eng. Perform. 2022, 31, 1358–1372. [Google Scholar] [CrossRef]

- Han, L.; Han, T.; Chen, G.; Wang, B.; Sun, J.; Wang, Y. Influence of Heat Input on Microstructure, Hardness and Pitting Corrosion of Weld Metal in Duplex Stainless Steel Welded by Keyhole-TIG. Mater. Charact. 2021, 175, 111052. [Google Scholar] [CrossRef]

- Cui, S.; Shi, Y.; Zhang, C. Microstructure and Mechanical Properties of TC4 Titanium Alloy K-TIG Welded Joints. Trans. Nonferrous Met. Soc. China 2021, 31, 416–425. [Google Scholar] [CrossRef]

- Li, X.; Gong, B.; Deng, C.; Li, Y. Effect of Pre-Strain on Microstructure and Hydrogen Embrittlement of K-TIG Welded Austenitic Stainless Steel. Corros. Sci. 2019, 149, 1–17. [Google Scholar] [CrossRef]

- Cui, S.; Liu, Z.; Fang, Y.; Luo, Z.; Manladan, S.M.; Yi, S. Keyhole Process in K-TIG Welding on 4mm Thick 304 Stainless Steel. J. Mater. Process. Technol. 2017, 243, 217–228. [Google Scholar] [CrossRef]

- Fei, Z.; Pan, Z.; Cuiuri, D.; Li, H.; Wu, B.; Su, L. Improving the Weld Microstructure and Material Properties of K-TIG Welded Armour Steel Joint Using Filler Material. Int. J. Adv. Manuf. Technol. 2019, 100, 1931–1944. [Google Scholar] [CrossRef]

- Fei, Z.; Pan, Z.; Cuiuri, D.; Li, H.; Van Duin, S.; Yu, Z. Microstructural Characterization and Mechanical Properties of K-TIG Welded SAF2205/AISI316L Dissimilar Joint. J. Manuf. Processes 2019, 45, 340–355. [Google Scholar] [CrossRef]

- ASTM E8/E8M-16a; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- ASTM A370-17; Standard Test Methods and Definitions for Mechanical Testing of Steel Products. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- Yurtisik, K.; Tirkes, S.; Dykhno, I.; Gur, C.H.; Gurbuz, R. Characterization of Duplex Stainless Steel Weld Metals Obtained by Hybrid Plasma-Gas Metal Arc Welding. Soldag. Insp. 2013, 18, 207–216. [Google Scholar] [CrossRef]

- Hsiao, Z.-W.; Chen, D.; Kuo, J.-C.; Lin, D.-Y. Effect of Prior Deformation on Microstructural Development and Laves Phase Precipitation in High-chromium Stainless Steel. J. Microsc. 2017, 266, 35–47. [Google Scholar] [CrossRef] [PubMed]

- Githinji, D.N.; Northover, S.M.; Bouchard, P.J.; Rist, M.A. An EBSD Study of the Deformation of Service-Aged 316 Austenitic Steel. Metall. Mater. Trans. A 2013, 44, 4150–4167. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, X.; Hu, Y.; Wang, S. Quantitative Studies of Machining-Induced Microstructure Alteration and Plastic Deformation in AISI 316 Stainless Steel Using EBSD. J. Mater. Eng. Perform. 2018, 27, 434–446. [Google Scholar] [CrossRef]

- Liu, X.; Sun, Y.; Li, W.; He, J.; Pei, M.; Zhang, K. Effect of Welding Current on the Organization and Properties of Welded Joints of Q690D High-Strength Steel. Mater. Today Commun. 2024, 40, 110219. [Google Scholar] [CrossRef]

- Wang, Q.; Gu, G.; Jia, C.; Li, K.; Wu, C. Investigation of Microstructure Evolution, Mechanical and Corrosion Properties of SAF 2507 Super Duplex Stainless Steel Joints by Keyhole Plasma Arc Welding. J. Mater. Res. Technol. 2023, 22, 355–374. [Google Scholar] [CrossRef]

- Touileb, K.; Hedhibi, A.C.; Djoudjou, R.; Ouis, A.; Bensalama, A.; Ibrahim, A.; Abdo, H.S.; Ahmed, M.M.Z. Mechanical, Microstructure, and Corrosion Characterization of Dissimilar Austenitic 316L and Duplex 2205 Stainless-Steel ATIG Welded Joints. Materials 2022, 15, 2470. [Google Scholar] [CrossRef]

- Li, G.; Lu, X.; Zhu, X.; Huang, J.; Liu, L.; Wu, Y. The Interface Microstructure, Mechanical Properties and Corrosion Resistance of Dissimilar Joints during Multipass Laser Welding for Nuclear Power Plants. Opt. Laser Technol. 2018, 101, 479–490. [Google Scholar] [CrossRef]

- Takeda, K.; Nakada, N.; Tsuchiyama, T.; Takaki, S. Effect of Interstitial Elements on Hall–Petch Coefficient of Ferritic Iron. ISIJ Int. 2008, 48, 1122–1125. [Google Scholar] [CrossRef]

- Ahmad, G.N.; Raza, M.S.; Singh, N.K.; Muvvala, G. Investigating the Effect of Process Parameters on Weld Pool Thermal History and Mechanical Properties of Laser Welded Inconel 625 and Duplex Stainless Steel 2205 Dissimilar Welds. Optik 2021, 248, 168134. [Google Scholar] [CrossRef]

- Tavares, S.S.M.; Pardal, J.M.; Almeida, B.B.; Mendes, M.T.; Freire, J.L.F.; Vidal, A.C. Failure of Superduplex Stainless Steel Flange Due to Inadequate Microstructure and Fabrication Process. Eng. Fail. Anal. 2018, 84, 1–10. [Google Scholar] [CrossRef]

- Zheng, J.; Hu, X.; Pan, C.; Fu, S.; Lin, P.; Chou, K. Effects of Inclusions on the Resistance to Pitting Corrosion of S32205 Duplex Stainless Steel. Mater. Corros. 2018, 69, 572–579. [Google Scholar] [CrossRef]

- Sarma, D.S.; Karasev, A.V.; Jönsson, P.G. On the Role of Non-Metallic Inclusions in the Nucleation of Acicular Ferrite in Steels. ISIJ Int. 2009, 49, 1063–1074. [Google Scholar] [CrossRef]

- Li, W.; Zhang, J.; Xin, P.; Wen, Z.; Jing, H.; Zhao, L.; Xu, L.; Han, Y. Corrosion Behavior of the Heat Affected Zone in a 316 L Pipeline Weld. Mater. Test. 2021, 63, 617–622. [Google Scholar] [CrossRef]

- Shi, Y.; Li, W.; Tian, L.; Sun, Y.; Zhang, J.; Jing, H.; Zhao, L.; Xu, L.; Han, Y. Effect of Ferrite and Grain Boundary Characteristics on Corrosion Properties of Thermal Simulated 316 L Heat Affected Zone. Corros. Sci. 2023, 222, 111384. [Google Scholar] [CrossRef]

- Lv, J. Effect of Grain Size on Mechanical Property and Corrosion Resistance of the Ni-Based Alloy 690. J. Mater. Sci. Technol. 2018, 34, 1685–1691. [Google Scholar] [CrossRef]

- Ma, C.Y.; Zhou, L.; Zhang, R.X.; Li, D.G.; Shu, F.Y.; Song, X.G.; Zhao, Y.Q. Enhancement in Mechanical Properties and Corrosion Resistance of 2507 Duplex Stainless Steel via Friction Stir Processing. J. Mater. Res. Technol. 2020, 9, 8296–8305. [Google Scholar] [CrossRef]

- Hug, E.; Keller, C. Passivation Properties of Ultrafine Grain 316L Stainless Steels Manufactured by Ball Milling and Spark Plasma Sintering. Mater. Chem. Phys. 2023, 309, 128398. [Google Scholar] [CrossRef]

- Ralston, K.D.; Birbilis, N.; Davies, C.H.J. Revealing the Relationship between Grain Size and Corrosion Rate of Metals. Scr. Mater. 2010, 63, 1201–1204. [Google Scholar] [CrossRef]

| Materials | Cr | Ni | Mn | Mo | Si | C | N | S | P | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 2205 | 22.46 | 5.7 | 1.248 | 3.02 | 0.057 | 0.019 | 0.156 | 0.0005 | 0.021 | Bal. |

| 316L | 17.92 | 10.06 | 0.95 | 2.06 | 0.33 | 0.018 | 0.02 | 0.01 | 0.017 | Bal. |

| Specimen | Current (A) | Voltage (V) | Welding Speed (mm/min) | Heat Input (KJ/mm) |

|---|---|---|---|---|

| 1# | 500 | 16.7 | 280 | 1.79 |

| 2# | 500 | 16.7 | 300 | 1.67 |

| 3# | 500 | 16.7 | 320 | 1.58 |

| 4# | 500 | 16.7 | 340 | 1.47 |

| 5# | 500 | 16.7 | 360 | 1.39 |

| Specimen | 1# | 2# | 3# | 4# |

|---|---|---|---|---|

| Grain size (μm) | 50.24 ± 41.72 | 48.89 ± 40.4 | 47.03 ± 33.55 | 44.55 ± 32.44 |

| Austenite fraction (%) | 84.7 | 79.3 | 64.0 | 59.9 |

| Specimen | 1# | 2# | 3# | 4# |

|---|---|---|---|---|

| Ecorr (V) | −0.365 | −0.411 | −0.377 | −0.418 |

| Icorr (A/cm2) | 6.1855 × 10−6 | 1.1858 × 10−6 | 1.6881 × 10−6 | 1.2361 × 10−6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, S.; Li, H.; Zhang, B.; Liu, X.; Mo, G. Study of Microstructure, Mechanical, and Corrosion Properties of K-TIG Welded Joints of 2205/316L Dissimilar Stainless Steel. Metals 2025, 15, 910. https://doi.org/10.3390/met15080910

Cui S, Li H, Zhang B, Liu X, Mo G. Study of Microstructure, Mechanical, and Corrosion Properties of K-TIG Welded Joints of 2205/316L Dissimilar Stainless Steel. Metals. 2025; 15(8):910. https://doi.org/10.3390/met15080910

Chicago/Turabian StyleCui, Shuwan, Hongchen Li, Baoyan Zhang, Xiaozhen Liu, and Ganli Mo. 2025. "Study of Microstructure, Mechanical, and Corrosion Properties of K-TIG Welded Joints of 2205/316L Dissimilar Stainless Steel" Metals 15, no. 8: 910. https://doi.org/10.3390/met15080910

APA StyleCui, S., Li, H., Zhang, B., Liu, X., & Mo, G. (2025). Study of Microstructure, Mechanical, and Corrosion Properties of K-TIG Welded Joints of 2205/316L Dissimilar Stainless Steel. Metals, 15(8), 910. https://doi.org/10.3390/met15080910