Effect of La/Zn on Microstructural Evolution and Mechanical Properties of Extruded Mg-9Gd-3Y Alloy

Abstract

1. Introduction

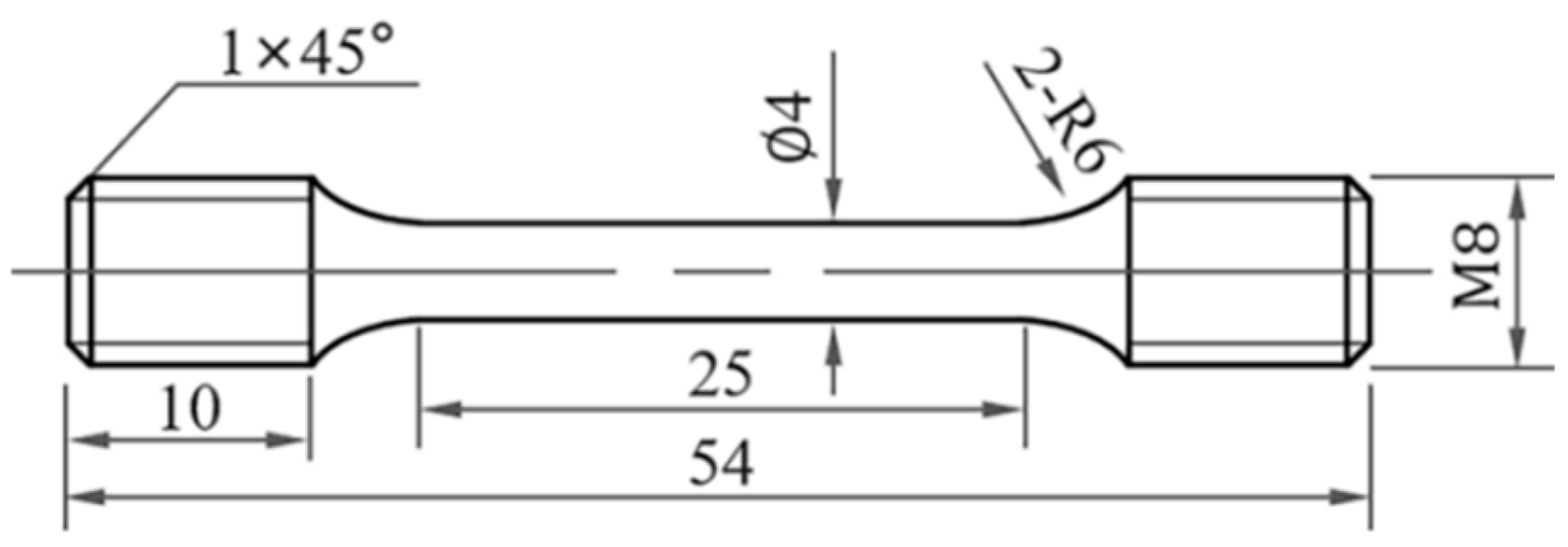

2. Materials and Methods

3. Results and Discussion

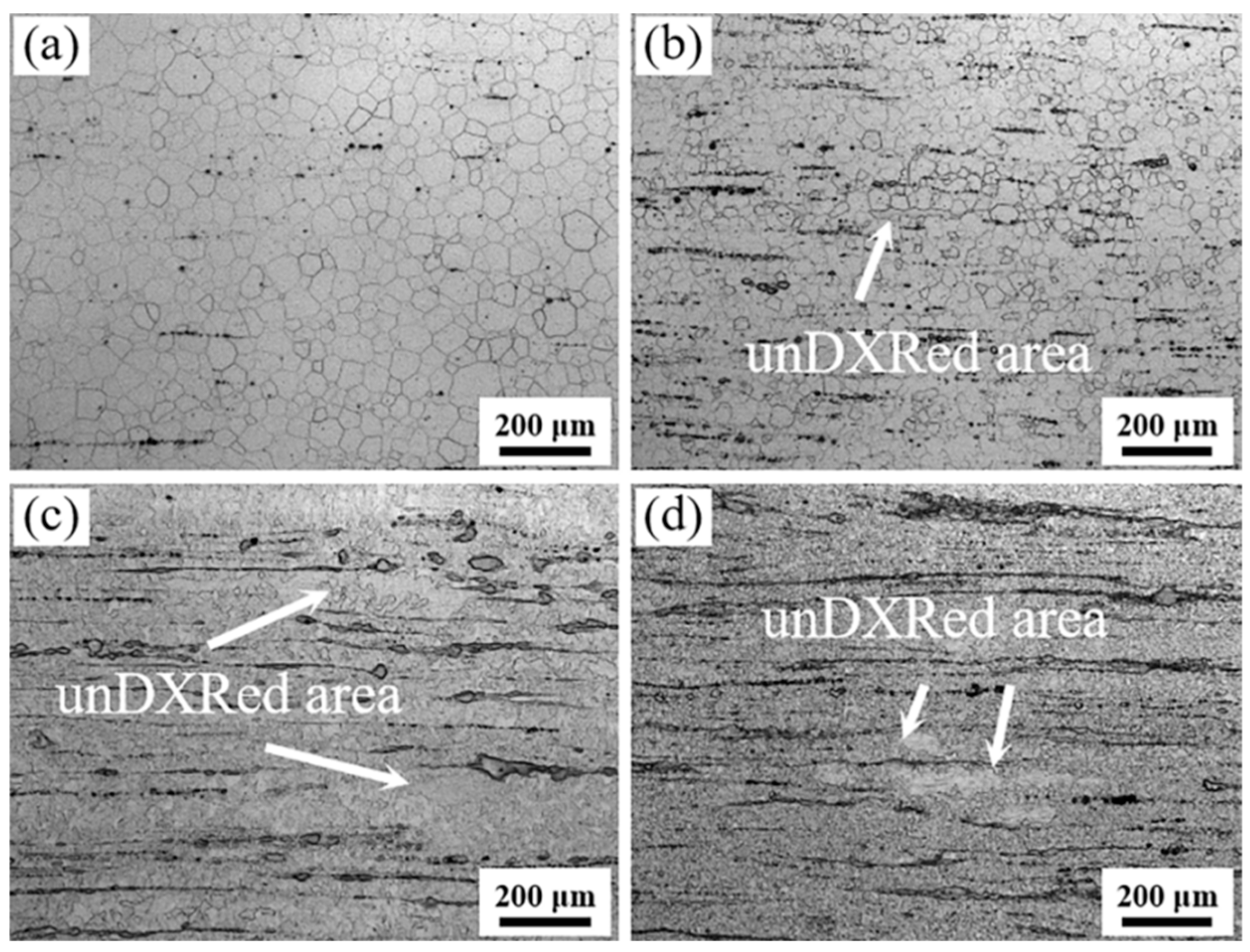

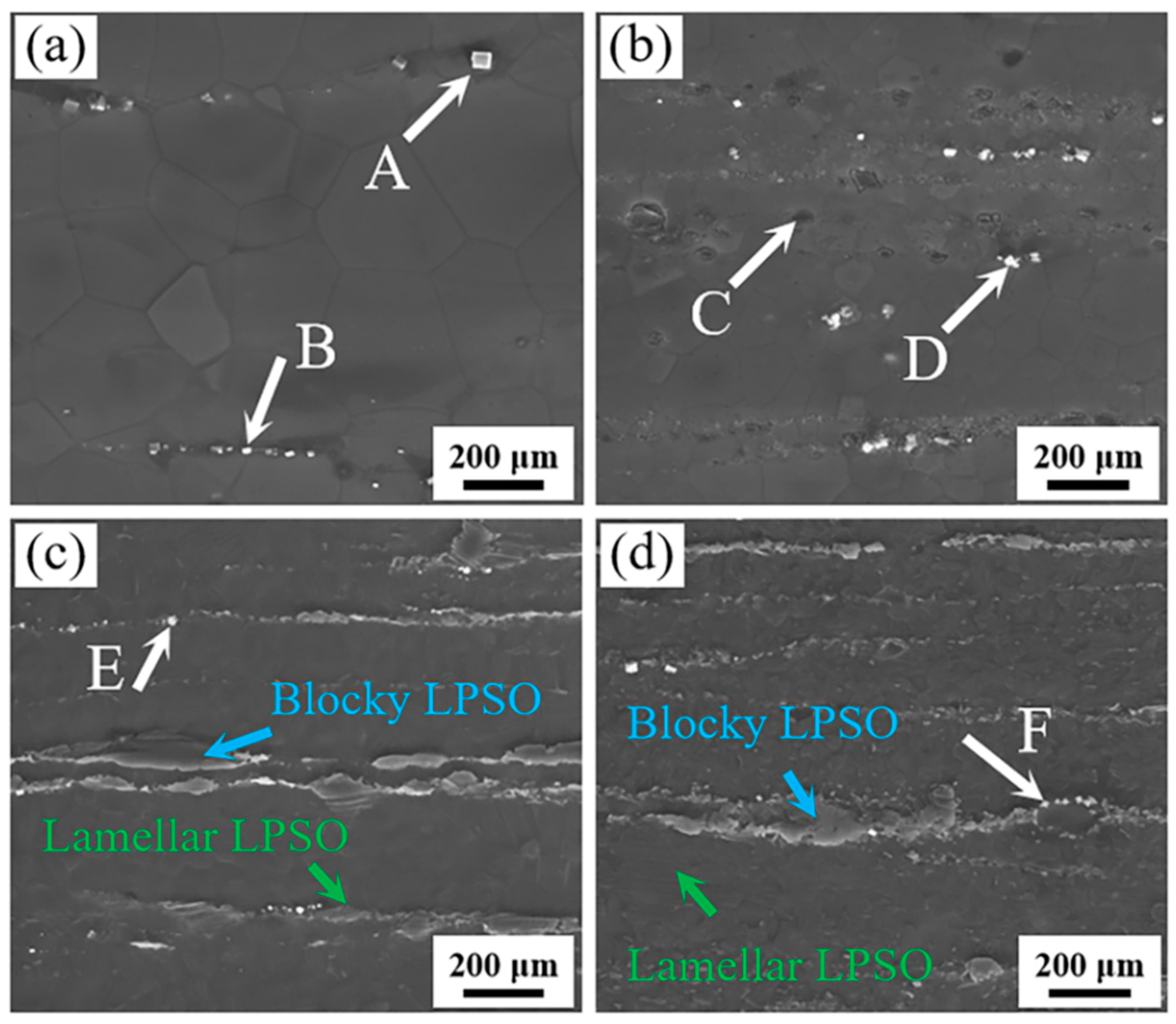

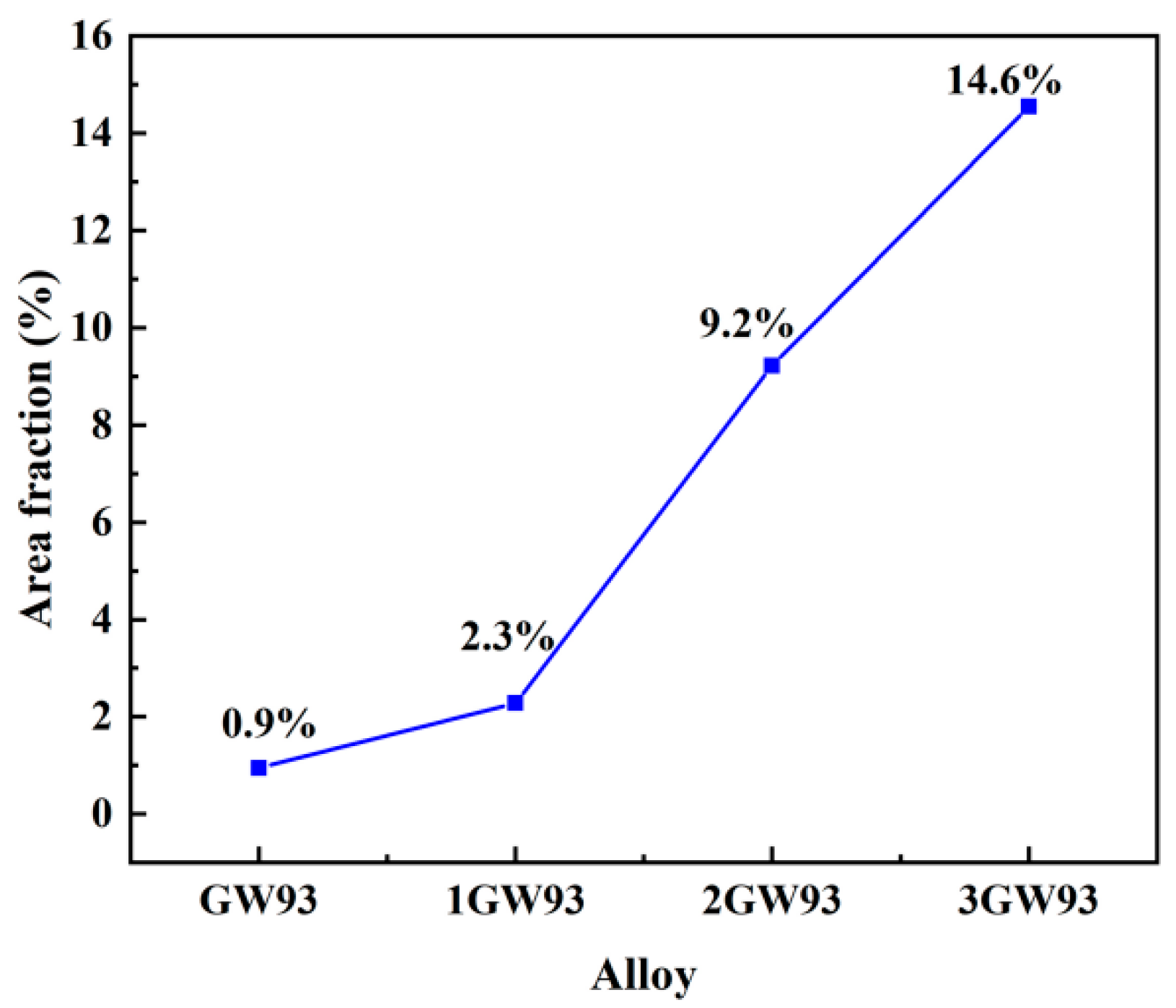

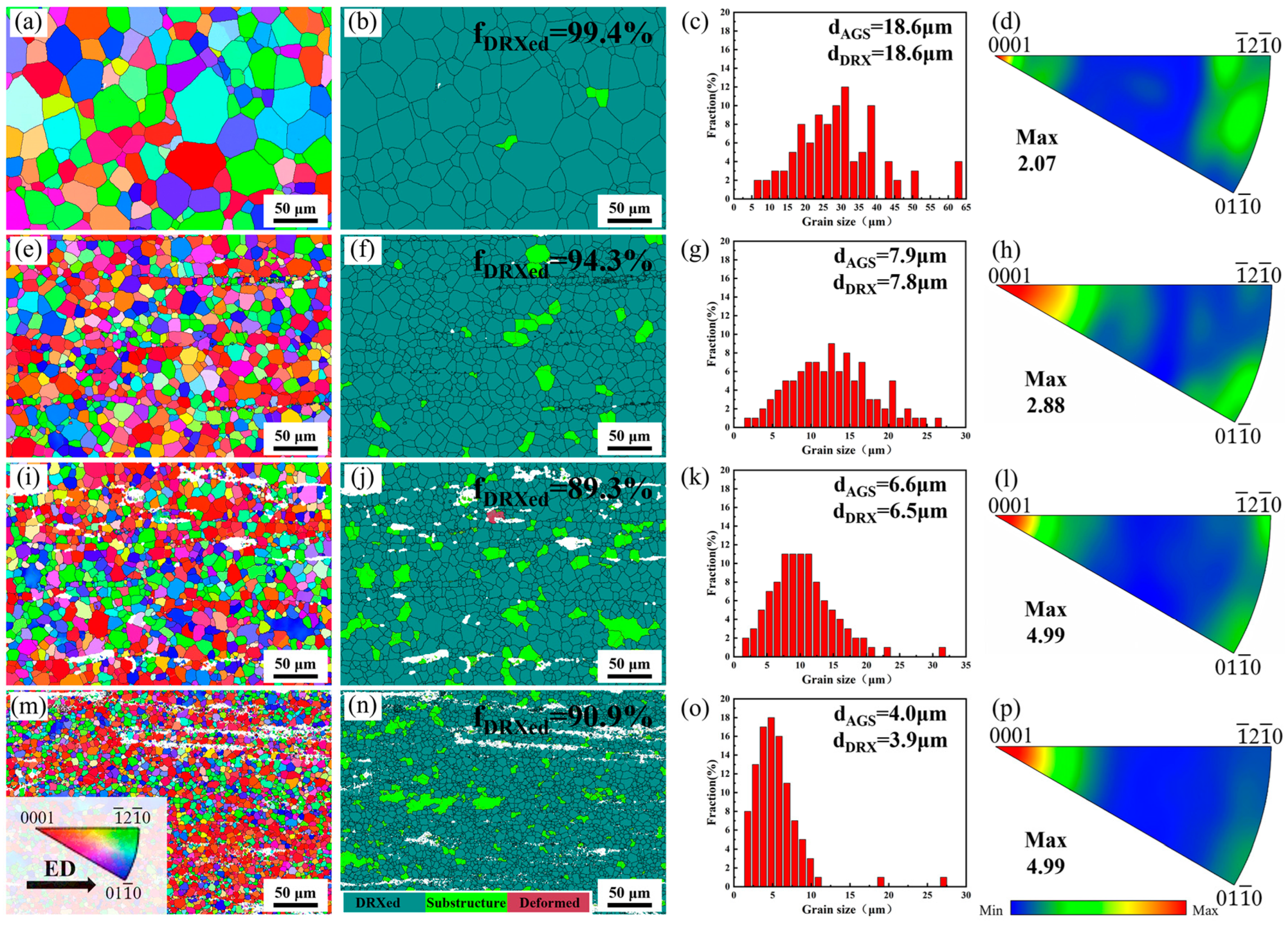

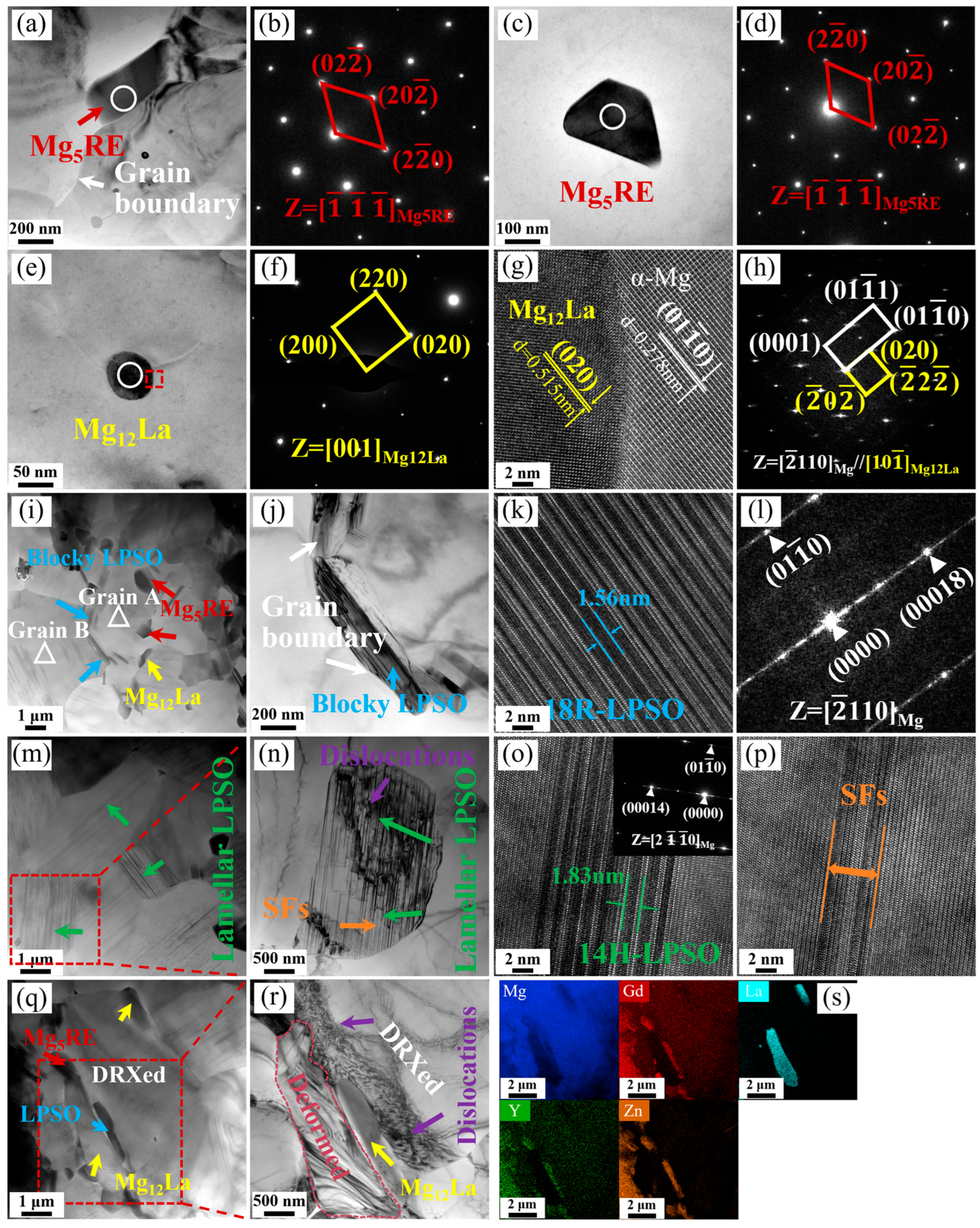

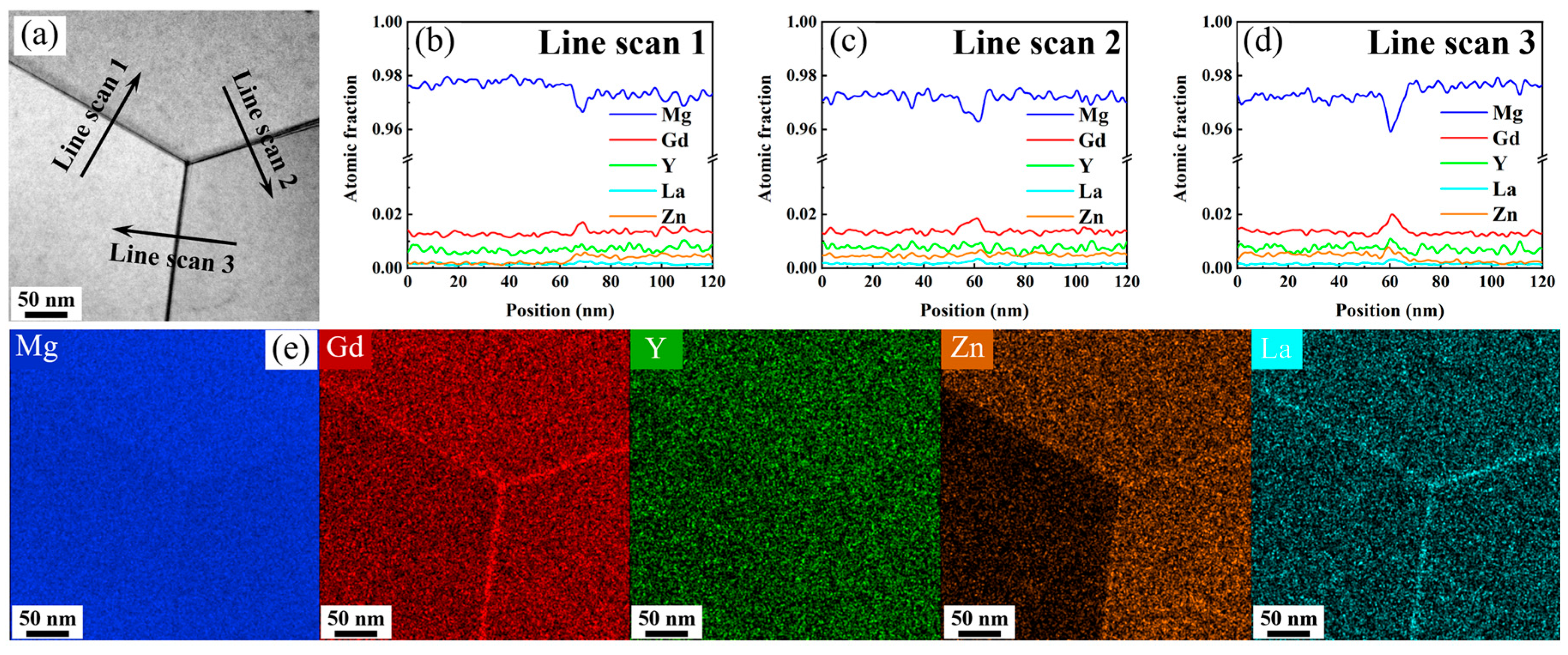

3.1. Microstructural Evolution

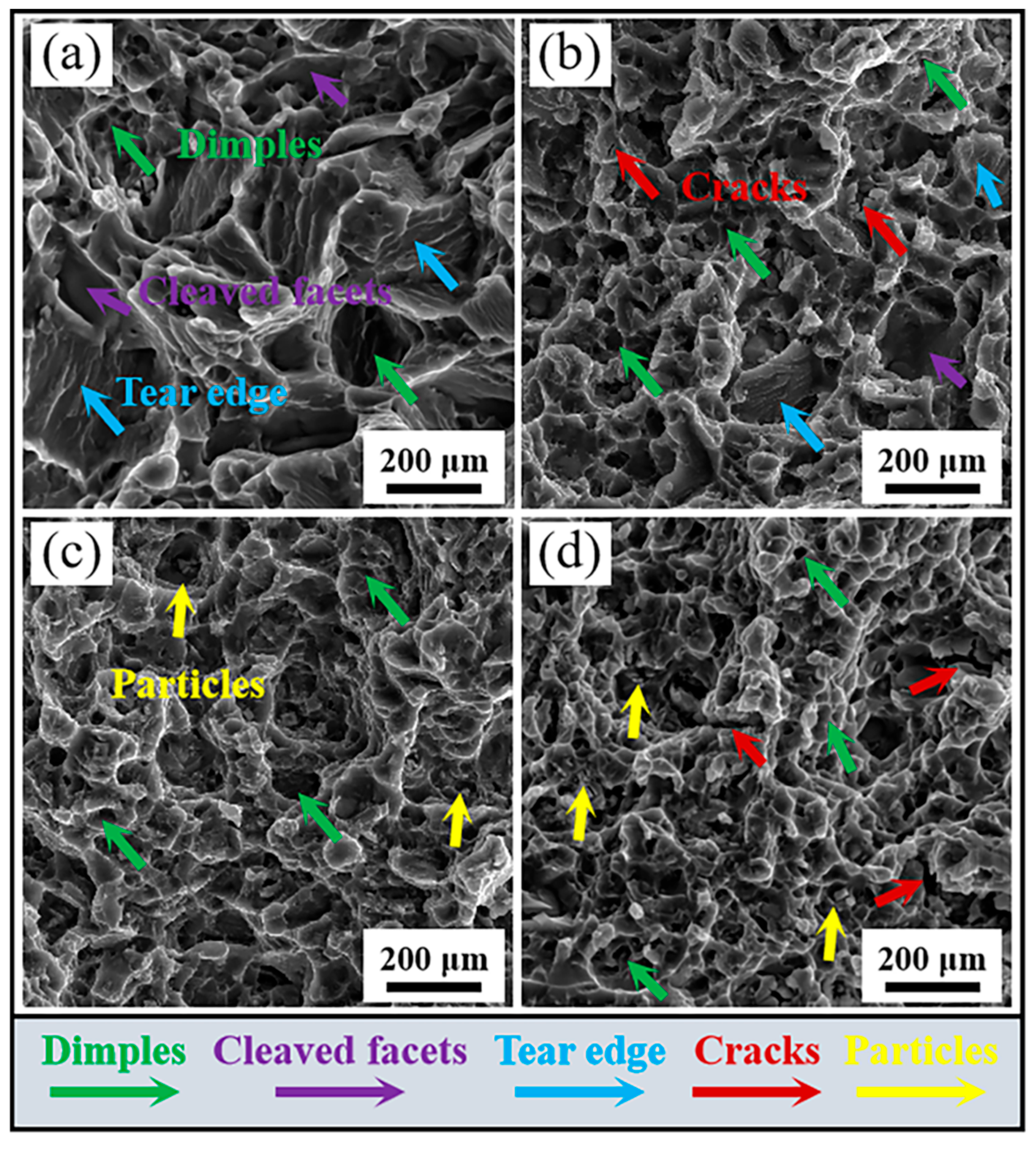

3.2. Mechanical Properties

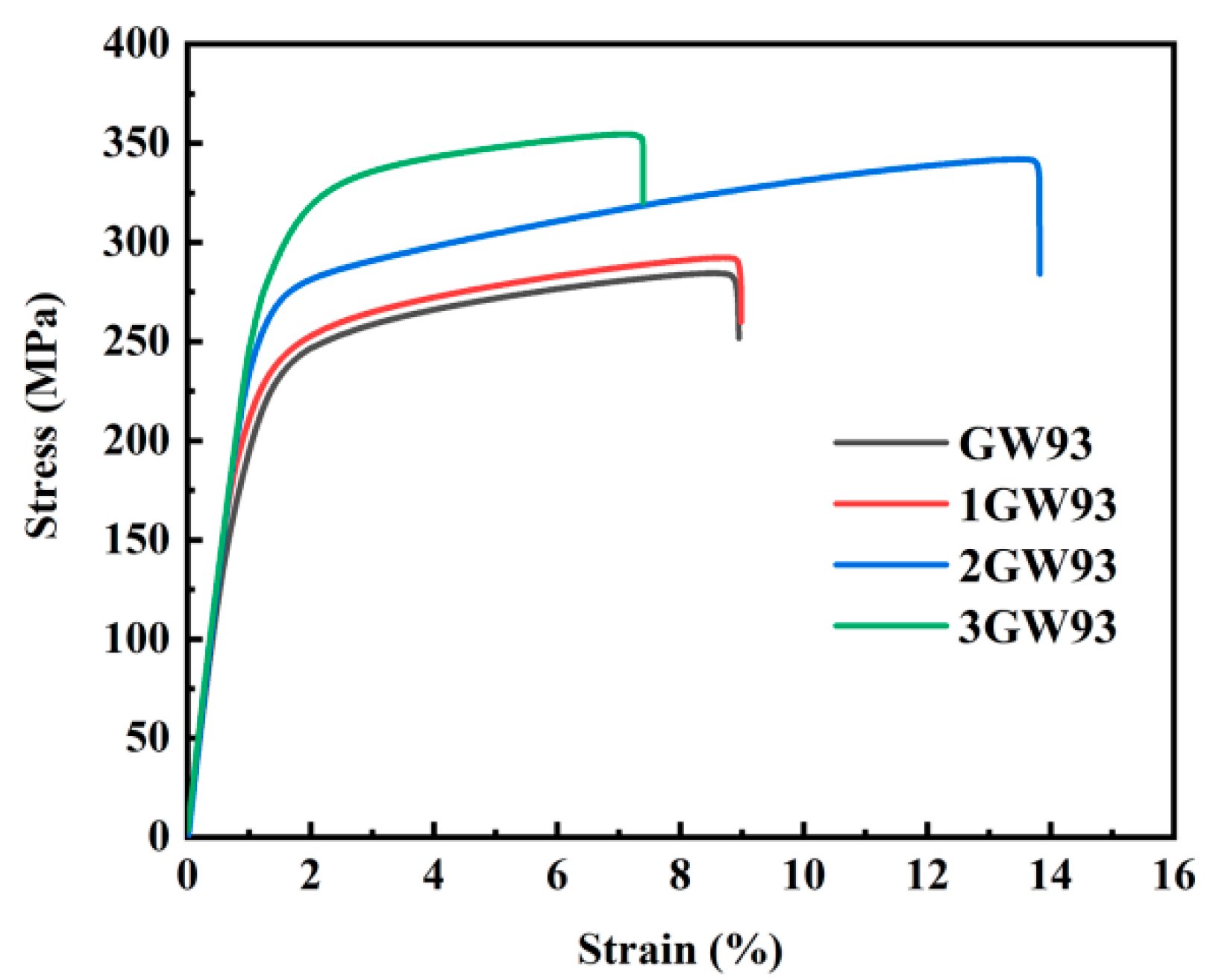

3.2.1. Room Temperature Mechanical Properties

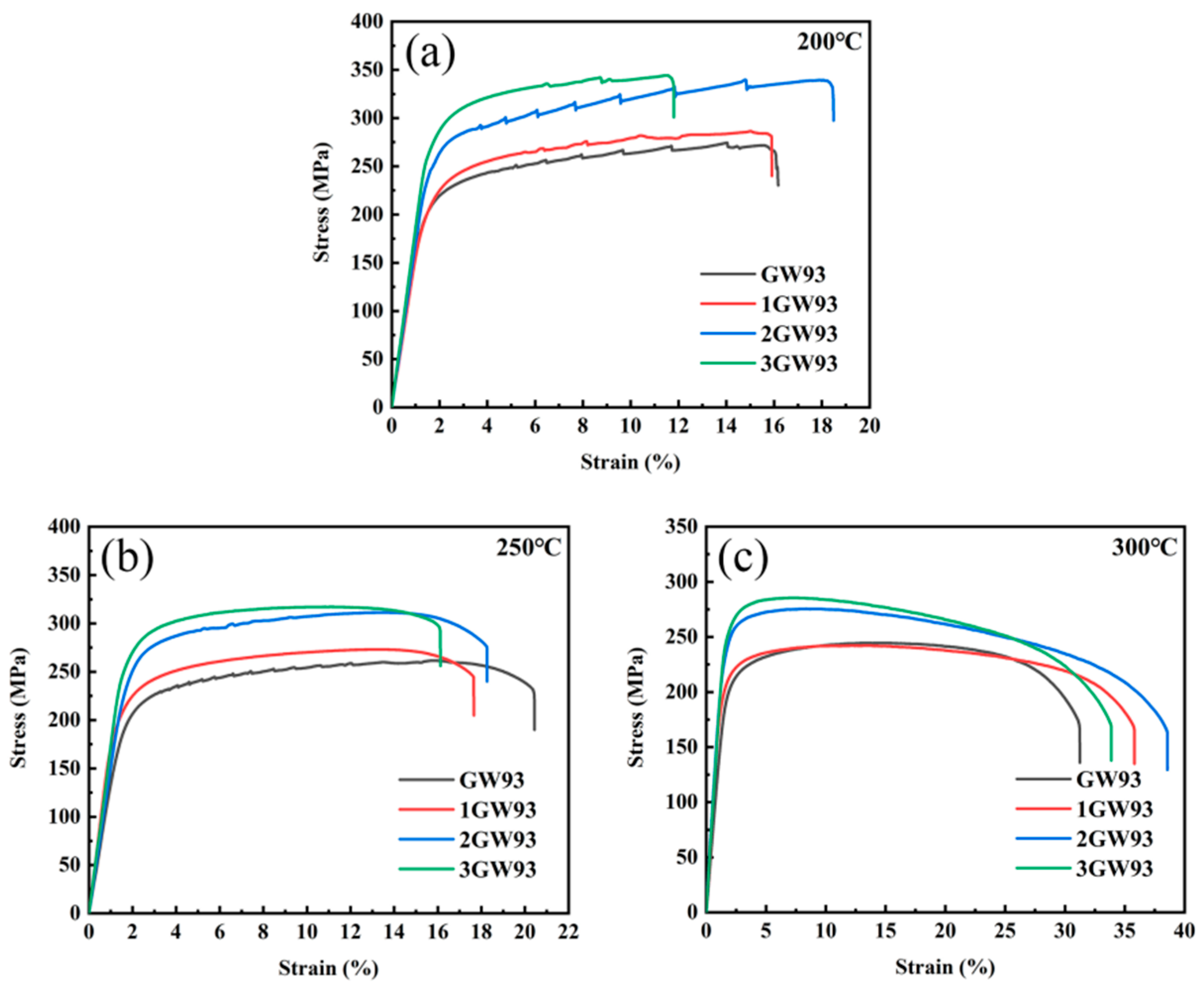

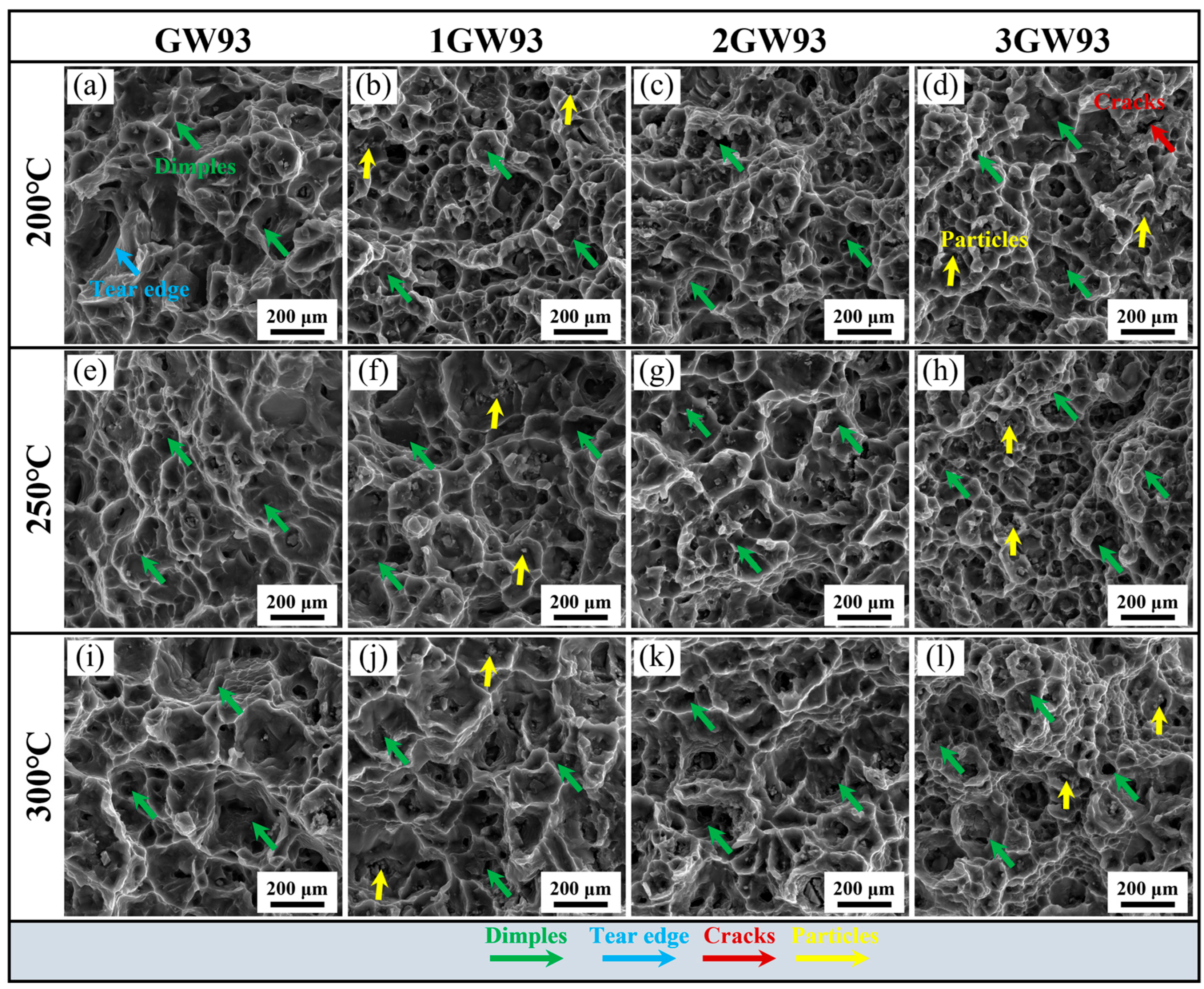

3.2.2. High-Temperature Mechanical Properties

4. Conclusions

- 1.

- The co-addition of La and Zn promoted the precipitation of the particle second (Mg5Gd and Mg12La) phase and the LPSO phase, thereby restraining DRX behavior during the thermal deformation process. As a result, the Mg-9Gd-3Y-0.6La-1Zn alloy had the smallest grain size and the most second phase.

- 2.

- The synergistic effects of grain refinement and second-phase strengthening (LPSO + Mg12La) from La and Zn addition endowed the Mg-9Gd-3Y-0.6La-1Zn alloy with superior room temperature strength, demonstrating 284 MPa in YS and 355 MPa in UTS.

- 3.

- At high temperatures, due to the pinning effect of a large amount of Mg12La and LPSO phases relative to the grain boundaries, as well as the obstruction of dislocation movement, the Mg-9Gd-3Y-0.6La-1Zn alloy exhibited relatively excellent mechanical properties at 200–300 °C. At 300 °C, its YS was 249 MPa and its UTS was 285 MPa.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, G.; Wang, C.; Sun, M.; Ding, W. Recent developments and applications on high-performance cast magnesium rare-earth alloys. J. Magnes. Alloys 2021, 9, 1–20. [Google Scholar] [CrossRef]

- Ni, J.; Jin, L.; Zeng, J.; Li, J.; Wang, F.; Wang, F.; Dong, S.; Dong, J. Development of high-strength magnesium alloys with excellent ignition-proof performance based on the oxidation and ignition mechanisms: A review. J. Magnes. Alloys 2023, 11, 1–14. [Google Scholar] [CrossRef]

- Liu, B.; Yang, J.; Zhang, X.; Yang, Q.; Zhang, J.; Li, X. Development and application of magnesium alloy parts for automotive OEMs: A review. J. Magnes. Alloys 2023, 11, 15–47. [Google Scholar] [CrossRef]

- Gao, S.; Lyu, S.; Zhao, Q.; Chen, M. Effect of Extrusion Temperature on the Microstructure and Properties of Biomedical Mg-1Zn-0.4Ca-1MgO Composite. Metals 2025, 15, 337. [Google Scholar] [CrossRef]

- Pekguleryuz, M.; Celikin, M. Creep resistance in magnesium alloys. Int. Mater. Rev. 2013, 55, 197–217. [Google Scholar] [CrossRef]

- Abazari, S.; Shamsipur, A.; Bakhsheshi-Rad, H.R.; Drelich, J.W.; Goldman, J.; Sharif, S.; Ismail, A.F.; Razzaghi, M. Magnesium-based nanocomposites: A review from mechanical, creep and fatigue properties. J. Alloys Compd. 2023, 11, 2655–2687. [Google Scholar] [CrossRef]

- Mo, N.; Tan, Q.; Bermingham, M.; Huang, Y.; Dieringa, H.; Hort, N.; Zhang, M.-X. Current development of creep-resistant magnesium cast alloys: A review. Mater. Des. 2018, 155, 422–442. [Google Scholar] [CrossRef]

- Yu, Z.P.; Yan, Y.H.; Yao, J.; Wang, C.; Zha, M.; Xu, X.Y.; Liu, Y.; Wang, H.Y.; Jiang, Q.C. Effect of tensile direction on mechanical properties and microstructural evolutions of rolled Mg-Al-Zn-Sn magnesium alloy sheets at room and elevated temperatures. J. Alloys Compd. 2018, 744, 211–219. [Google Scholar] [CrossRef]

- Nie, J.F.; Gao, X.; Zhu, S.M. Enhanced age hardening response and creep resistance of Mg–Gd alloys containing Zn. Scr. Mater. 2005, 53, 1049–1053. [Google Scholar] [CrossRef]

- Zhang, Y.; Hong, Y.; Li, H.; Zhang, D. Creep behavior and dynamic precipitation of highly heat-resistant Mg alloy with low rare-earth content. J. Alloys Compd. 2024, 997, 174960. [Google Scholar] [CrossRef]

- Liu, X.B.; Chen, R.S.; Han, E.H. Effects of ageing treatment on microstructures and properties of Mg–Gd–Y–Zr alloys with and without Zn additions. J. Alloys Compd. 2008, 465, 232–238. [Google Scholar] [CrossRef]

- Kawamura, Y.; Yamasaki, M. Formation and Mechanical Properties of Mg97Zn1RE2 Alloys with Long-Period Stacking Ordered Structure. Mater. Trans. 2007, 48, 2986–2992. [Google Scholar] [CrossRef]

- Hu, J.; Wu, J.; Liu, X.; Zhao, D.; Liang, L.; Peng, J. Influence of Y/Zn Ratio on Secondary Phase Strengthening of Mg-Y-Zn Alloy. Metals 2025, 15, 359. [Google Scholar] [CrossRef]

- Shao, X.H.; Yang, Z.Q.; Ma, X.L. Strengthening and toughening mechanisms in Mg–Zn–Y alloy with a long period stacking ordered structure. Acta Mater. 2010, 58, 4760–4771. [Google Scholar] [CrossRef]

- Shao, X.H.; Peng, Z.Z.; Jin, Q.Q.; Ma, X.L. Atomic-scale segregations at the deformation-induced symmetrical boundary in an Mg-Zn-Y alloy. Acta Mater. 2016, 118, 177–186. [Google Scholar] [CrossRef]

- Tane, M.; Nagai, Y.; Kimizuka, H.; Hagihara, K.; Kawamura, Y. Elastic properties of an Mg–Zn–Y alloy single crystal with a long-period stacking-ordered structure. Acta Mater. 2013, 61, 6338–6351. [Google Scholar] [CrossRef]

- Kang, Y.-B.; Jin, L.; Chartrand, P.; Gheribi, A.E.; Bai, K.; Wu, P. Thermodynamic evaluations and optimizations of binary Mg-light Rare Earth (La, Ce, Pr, Nd, Sm) systems. Calphad 2012, 38, 100–116. [Google Scholar] [CrossRef]

- Lin, J.; Fu, P.; Wang, Y.; Liu, H.; Zheng, Y.; Peng, L.; Ding, W. Effect of La addition on microstructure, mechanical behavior, strengthening and toughening mechanisms of cast Mg-Gd-Zn alloy. Mater. Sci. Eng. A 2023, 866, 144688. [Google Scholar] [CrossRef]

- Fu, L.; Le, Q.; Hu, W.; Zhang, J.; Wang, J. Strengths and ductility enhanced by micro-alloying Sm/La/Ca to Mg–0.5Zn–0.2Mn alloy. J. Mater. Res. Technol. 2020, 9, 6834–6849. [Google Scholar] [CrossRef]

- Maier, P.; Bechly, M.; Mendis, C.L.; Hort, N. Precipitation Hardening on Mechanical and Corrosion Properties of Extruded Mg10Gd Modified with Nd and La. Metals 2018, 8, 640. [Google Scholar] [CrossRef]

- GB/T228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Standardization Administration of the People’s Republic of China: Beijing, China, 2010.

- GB/T228.2-2015; Metallic Materials—Tensile Testing—Part 2: Method of Test at Elevated Temperature. Standardization Administration of the People’s Republic of China: Beijing, China, 2015.

- Lin, J.; Fu, P.; Wang, Y.; Ding, Y.; Liu, H.; Peng, L.; Ding, W. Section dimension induced microstructure and mechanical properties variations of sequential solidified sand–cast Mg–10Gd–0.2La–0.1Zn–0.4Zr (wt%) alloy. Mater. Sci. Eng. A 2024, 897, 146359. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, S.; Wu, R.; Hou, L.; Zhang, M. Recent developments in high-strength Mg-RE-based alloys: Focusing on Mg-Gd and Mg-Y systems. J. Magnes. Alloys 2018, 6, 277–291. [Google Scholar] [CrossRef]

- Maghzi, M.; Mirzadeh, H.; Mahmudi, R. Grain refinement and improved mechanical properties of as-cast Mg-3Gd alloy by Zr addition. J. Mater. Res. Technol. 2025, 35, 2346–2353. [Google Scholar] [CrossRef]

- Wang, D.; Chen, X.; Li, Q.; Zhu, H.; He, H.; Xie, J.; Guo, T. Effect of trace Ce on microstructure, mechanical properties and corrosion behavior of Mg-14Gd-xCe-0.5Zr alloy. J. Alloys Compd. 2025, 1010, 178043. [Google Scholar] [CrossRef]

- Liu, S.; Ma, H.; Huang, Z.; Zhang, Z.; Xu, C.; Li, X.; Chen, F.; Yan, Z.; Kong, F.; Wang, A.; et al. High performance Mg-8Gd-4Y-1Zn-0.5Al alloy with long-period stacking ordered structure by hot rolling. J. Alloys Compd. 2022, 901, 163667. [Google Scholar] [CrossRef]

- Jeong, H.T.; Kim, W.J. The hot compressive deformation behavior of cast Mg-Gd-Y-Zn-Zr alloys with and without LPSO phase in their initial microstructures. J. Magnes. Alloys 2022, 10, 2901–2917. [Google Scholar] [CrossRef]

- Zheng, J.; Yan, Z.; Ji, J.; Shi, Y.; Zhang, H.; Zhang, Z.; Xue, Y. Effect of heat treatment on mechanical properties and microstructure evolution of Mg-9.5Gd-4Y-2.2Zn-0.5Zr alloy. J. Magnes. Alloys 2022, 10, 1124–1132. [Google Scholar] [CrossRef]

- Deng, K.K.; Wang, X.J.; Wu, Y.W.; Hu, X.S.; Wu, K.; Gan, W.M. Effect of particle size on microstructure and mechanical properties of SiCp/AZ91 magnesium matrix composite. Mater. Sci. Eng. A 2012, 543, 158–163. [Google Scholar] [CrossRef]

- Zhou, M.; Liu, X.; Yue, H.; Liu, S.; Ren, L.; Xin, Y.; Lyu, L.; Zhao, Y.; Quan, G.; Gupta, M. Hot deformation behavior and processing maps of hybrid SiC and CNTs reinforced AZ61 alloy composite. J. Alloys Compd. 2021, 868, 159098. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, C.; Gao, Y.; Jiang, S.; Han, X.; Chen, Z. Evolution of LPSO Phases and Their Effect on Dynamic Recrystallization in a Mg-Gd-Y-Zn-Zr Alloy. Metall. Mater. Trans. A 2017, 48, 3060–3072. [Google Scholar] [CrossRef]

- Su, N.; Wu, Q.; Ding, C.; Wu, Y.; Peng, L. Effect of Y and Gd solutes on grain refinement of the as-extruded Mg-Gd(-Y)-Zn-Mn alloys. J. Alloys Compd. 2023, 968, 171804. [Google Scholar] [CrossRef]

- Qian, X.; Gao, Y.; Dong, Z.; Jiang, B.; He, C.; Wang, C.; Zhang, A.; Yang, B.; Zheng, C.; Pan, F. The enhanced Zn and Ca co-segregation and mechanical properties of Mg–Zn–Ce alloy with micro Ca addition. Mater. Sci. Eng. A 2023, 867, 144712. [Google Scholar] [CrossRef]

- Robson, J.D. Effect of Rare-Earth Additions on the Texture of Wrought Magnesium Alloys: The Role of Grain Boundary Segregation. Metall. Mater. Trans. A 2013, 45, 3205–3212. [Google Scholar] [CrossRef]

- Xiao, L.R.; Chen, X.F.; Cao, Y.; Zhou, H.; Ma, X.L.; Yin, D.D.; Ye, B.; Han, X.D.; Zhu, Y.T. Solute segregation assisted nanocrystallization of a cold-rolled Mg–Ag alloy during annealing. Scr. Mater. 2020, 177, 69–73. [Google Scholar] [CrossRef]

- He, S.M.; Zeng, X.Q.; Peng, L.M.; Gao, X.; Nie, J.F.; Ding, W.J. Microstructure and strengthening mechanism of high strength Mg–10Gd–2Y–0.5Zr alloy. J. Alloys Compd. 2007, 427, 316–323. [Google Scholar] [CrossRef]

- Wang, C.Y.; Cepeda-Jiménez, C.M.; Pérez-Prado, M.T. Dislocation-particle interactions in magnesium alloys. Acta Mater. 2020, 194, 190–206. [Google Scholar] [CrossRef]

- Garces, G.; Perez, P.; Cabeza, S.; Kabra, S.; Gan, W.; Adeva, P. Effect of Extrusion Temperature on the Plastic Deformation of an Mg-Y-Zn Alloy Containing LPSO Phase Using In Situ Neutron Diffraction. Metall. Mater. Trans. A 2017, 48, 5332–5343. [Google Scholar] [CrossRef]

- Xu, C.; Fan, G.H.; Nakata, T.; Liang, X.; Chi, Y.Q.; Qiao, X.G.; Cao, G.J.; Zhang, T.T.; Huang, M.; Miao, K.S.; et al. Deformation Behavior of Ultra-Strong and Ductile Mg-Gd-Y-Zn-Zr Alloy with Bimodal Microstructure. Metall. Mater. Trans. A 2018, 49, 1931–1947. [Google Scholar] [CrossRef]

- Wei, J.X.; Yan, H.; Chen, R.S. Notch strength and notch fracture mechanisms of a cast Mg-Gd-Y alloy. Mater. Sci. Eng. A 2022, 835, 142668. [Google Scholar] [CrossRef]

- Maier, P.; Clausius, B.; Richter, A.; Bittner, B.; Hort, N.; Menze, R. Crack Propagation in As-Extruded and Heat-Treated Mg-Dy-Nd-Zn-Zr Alloy Explained by the Effect of LPSO Structures and Their Micro- and Nanohardness. Materials 2021, 14, 3686. [Google Scholar] [CrossRef]

- Wan, X.; Ni, H.; Huang, M.; Zhang, H.; Sun, J. Microstructure, mechanical properties and creep resistance of Mg–(8%–12%)Zn–(2%–6%)Al alloys. Trans. Nonferrous Metals Soc. China 2013, 23, 896–903. [Google Scholar] [CrossRef]

- Dessolier, T.; Lhuissier, P.; Roussel-Dherbey, F.; Charlot, F.; Josserond, C.; Blandin, J.-J.; Martin, G. Effect of temperature on deformation mechanisms of AZ31 Mg-alloy under tensile loading. Mater. Sci. Eng. A 2020, 775, 138957. [Google Scholar] [CrossRef]

- Wang, H.; Boehlert, C.J.; Wang, Q.D.; Yin, D.D.; Ding, W.J. In-situ analysis of the tensile deformation modes and anisotropy of extruded Mg-10Gd-3Y-0.5Zr (wt.%) at elevated temperatures. Int. J. Plasticity 2016, 84, 255–276. [Google Scholar] [CrossRef]

- Yang, X.; Zhou, X.; Yu, S.; Zhang, J.; Lu, X.; Chen, X.; Lu, L.; Huang, W.; Liu, Y. Tensile behavior at various temperatures of the Mg-Gd-Y-Zn-Zr alloys with different initial morphologies of LPSO phases prior to extrusion. Mater. Sci. Eng. A 2022, 851, 143634. [Google Scholar] [CrossRef]

| Point | Mg | Gd | Y | La | Zn |

|---|---|---|---|---|---|

| A | 3.9 ± 0.3 | 36.3 ± 1.5 | 59.8 ± 2.7 | - | - |

| B | 86.4 ± 2.9 | 9.9 ± 1.1 | 3.7 ± 0.5 | - | - |

| C | 93.4 ± 2.3 | 2.7 ± 0.5 | 2.8 ± 0.4 | 1.0 ± 0.2 | - |

| D | 85.7 ± 1.6 | 10.8 ± 0.9 | 2.8 ± 0.5 | 0.7 ± 0.2 | - |

| E | 88.8 ± 2.7 | 9.1 ± 0.8 | 1.8 ± 0.2 | - | 0.3 ± 0.1 |

| F | 85.0 ± 2.3 | 9.4 ± 1.1 | 3.2 ± 0.4 | 0.6 ± 0.1 | 1.8 ± 0.2 |

| Alloy | YS(MPa) | UTS(MPa) | ε(%) |

|---|---|---|---|

| GW93 | 201 ± 4 | 284 ± 2 | 8.9 ± 0.2 |

| 1GW93 | 217 ± 3 | 292 ± 1 | 8.9 ± 0.4 |

| 2GW93 | 255 ± 3 | 341 ± 3 | 13.8 ± 0.5 |

| 3GW93 | 284 ± 2 | 354 ± 2 | 7.4 ± 0.3 |

| Temperature | Alloy | YS (MPa) | UTS (MPa) | ε (%) |

|---|---|---|---|---|

| 200 °C | GW93 | 199 ± 3 | 272 ± 3 | 16.1 ± 0.4 |

| 1GW93 | 201 ± 4 | 285 ± 2 | 15.9 ± 0.6 | |

| 2GW93 | 248 ± 2 | 339 ± 5 | 18.5 ± 0.5 | |

| 3GW93 | 272 ± 3 | 344 ± 3 | 11.8 ± 0.6 | |

| 250 °C | GW93 | 187 ± 2 | 259 ± 3 | 20.4 ± 0.5 |

| 1GW93 | 199 ± 4 | 273 ± 5 | 17.6 ± 0.6 | |

| 2GW93 | 238 ± 3 | 311 ± 5 | 18.3 ± 0.7 | |

| 3GW93 | 257 ± 3 | 317 ± 3 | 16.1 ± 0.4 | |

| 300 °C | GW93 | 182 ± 3 | 244 ± 3 | 31.3 ± 0.3 |

| 1GW93 | 197 ± 2 | 242 ± 4 | 35.7 ± 0.5 | |

| 2GW93 | 238 ± 3 | 275 ± 2 | 38.6 ± 0.5 | |

| 3GW93 | 249 ± 4 | 285 ± 3 | 33.9 ± 0.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Gao, Y.; Zhang, A.; Zhao, J.; Song, Y.; Li, T.; Jiang, B. Effect of La/Zn on Microstructural Evolution and Mechanical Properties of Extruded Mg-9Gd-3Y Alloy. Metals 2025, 15, 906. https://doi.org/10.3390/met15080906

Zhang X, Gao Y, Zhang A, Zhao J, Song Y, Li T, Jiang B. Effect of La/Zn on Microstructural Evolution and Mechanical Properties of Extruded Mg-9Gd-3Y Alloy. Metals. 2025; 15(8):906. https://doi.org/10.3390/met15080906

Chicago/Turabian StyleZhang, Xiang, Yuyang Gao, Ang Zhang, Jing Zhao, Yan Song, Tian Li, and Bin Jiang. 2025. "Effect of La/Zn on Microstructural Evolution and Mechanical Properties of Extruded Mg-9Gd-3Y Alloy" Metals 15, no. 8: 906. https://doi.org/10.3390/met15080906

APA StyleZhang, X., Gao, Y., Zhang, A., Zhao, J., Song, Y., Li, T., & Jiang, B. (2025). Effect of La/Zn on Microstructural Evolution and Mechanical Properties of Extruded Mg-9Gd-3Y Alloy. Metals, 15(8), 906. https://doi.org/10.3390/met15080906