Therefore, the arithmetic mean value (AM) and the standard deviation (SD) of the offset yield stress at 0.2% in the non-aged condition and upper yield strength in aged condition are shown for the 25 settings and the three variants.

3.1. Modelling of Tensile Properties of the Straightened Material in the Non-Aged Condition

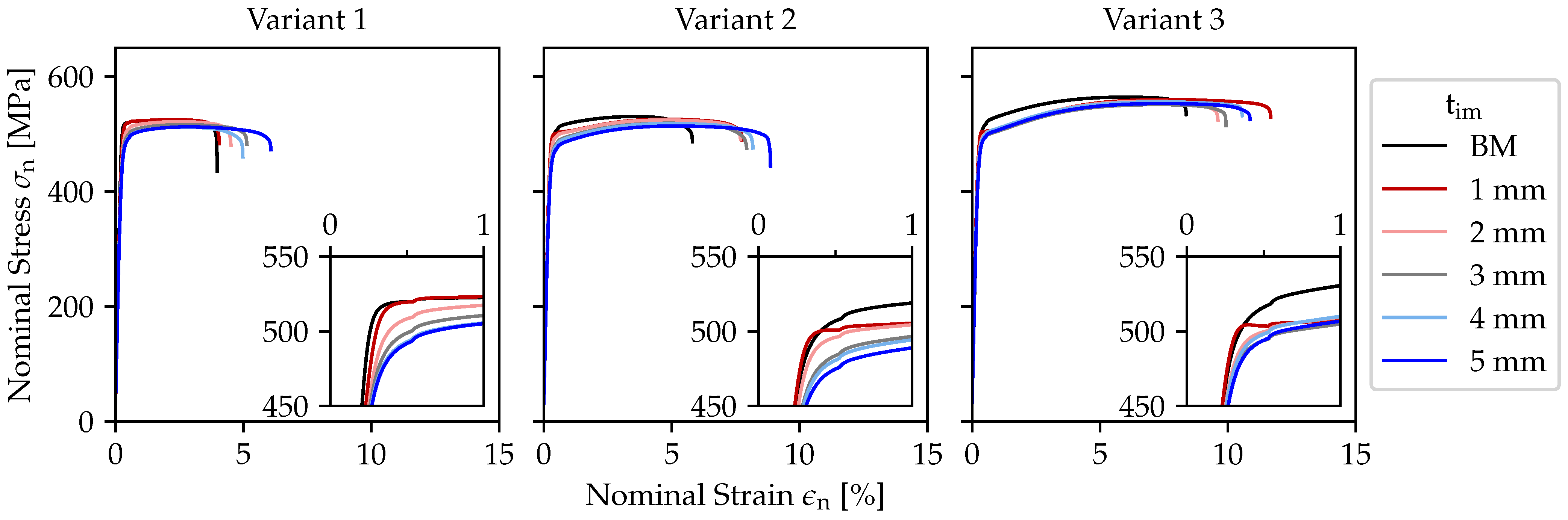

Figure 2 compares the stress–strain diagrams at constant degree of stretching

of 0.125% of the three variants. In addition, the stress–strain diagrams of the five investigated intermeshes

and the base material are compared in every subfigure. The results of the stress–strain diagrams at a constant degree of stretching show that with increasing intermesh, the nominal stress decreases. Also, the strain at break increases with increasing intermesh at all the three investigated variants. The findings of the tensile tests of the remaining stretch-bending straightening settings, as illustrated in

Table 2, indicate that the offset yield stress generally increases with an increasing degree of stretching. Increases in the intermeshes at the investigated degrees of stretching are associated with decreases in the offset yield stress.

For the modelling, an exponential mathematical formula for the description of the dependency between the intermeshes and the offset yield stress in the non-aged condition as well as the upper yield strength in the aged condition is generated. By the PythonTM module SciPy using the function scipy.optimize.curve_fit, the coefficients are calculated for the five set degrees of stretching and the three variants by minimizing the sum of the squared deviations (residuals).

Equation (

1) is used in the first step to model the dependence of the offset yield stress on the stretch-bending straightening parameters. That equation is comprised of two material- and process-specific parameters, denoted by the symbols

and

. In this context, the parameter

is scaled by the function

as a function of the intermesh

. The parameter

represents the asymptotic limit value that the offset yield stress is aiming for:

Based on Equation (

1), the parameters describing the dependency between the offset yield stress and the intermesh for the investigated degrees of stretching are calculated. The results for the three variants can be found in

Table 3.

The results indicate a decrease in the parameter as the degree of stretching increases from 0.125% and 0.75%. As the degree of stretching is increased to 1%, a slight rise is observed. The parameter exhibits a contrary behaviour. The increase is observed to occur within the range of 0.125% and 1%. This behaviour has been observed in all three variants. As the analysis of statistical values indicates, variants 1 and 2 display coefficients of determination of between 0.84 and 0.98. Lower ranging from 0.66 to 0.98 are achieved for variant 3 in comparison to variants 2 and 3. In the case of root mean square error (RMSE) and maximal error (ME), variant 3 reaches smaller values than variants 1 and 2.

Based on the calculated coefficients, Equation (

1) is extended by the degree of stretching

. In this context, the dependence of the parameters

and

, and the degree of stretching of the various variants, is initially analysed. To this end, the parameters previously determined were plotted against the degree of stretching, shown in

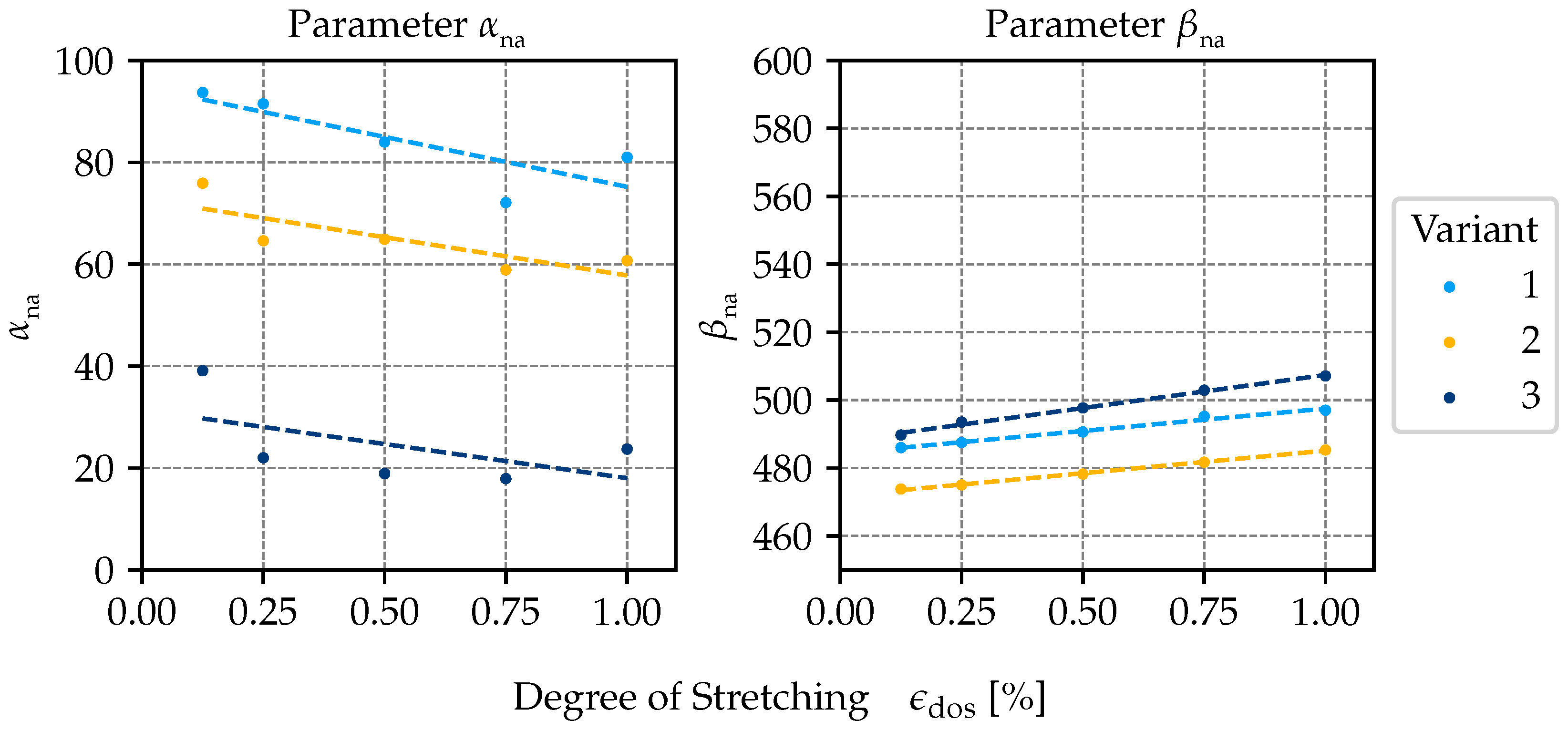

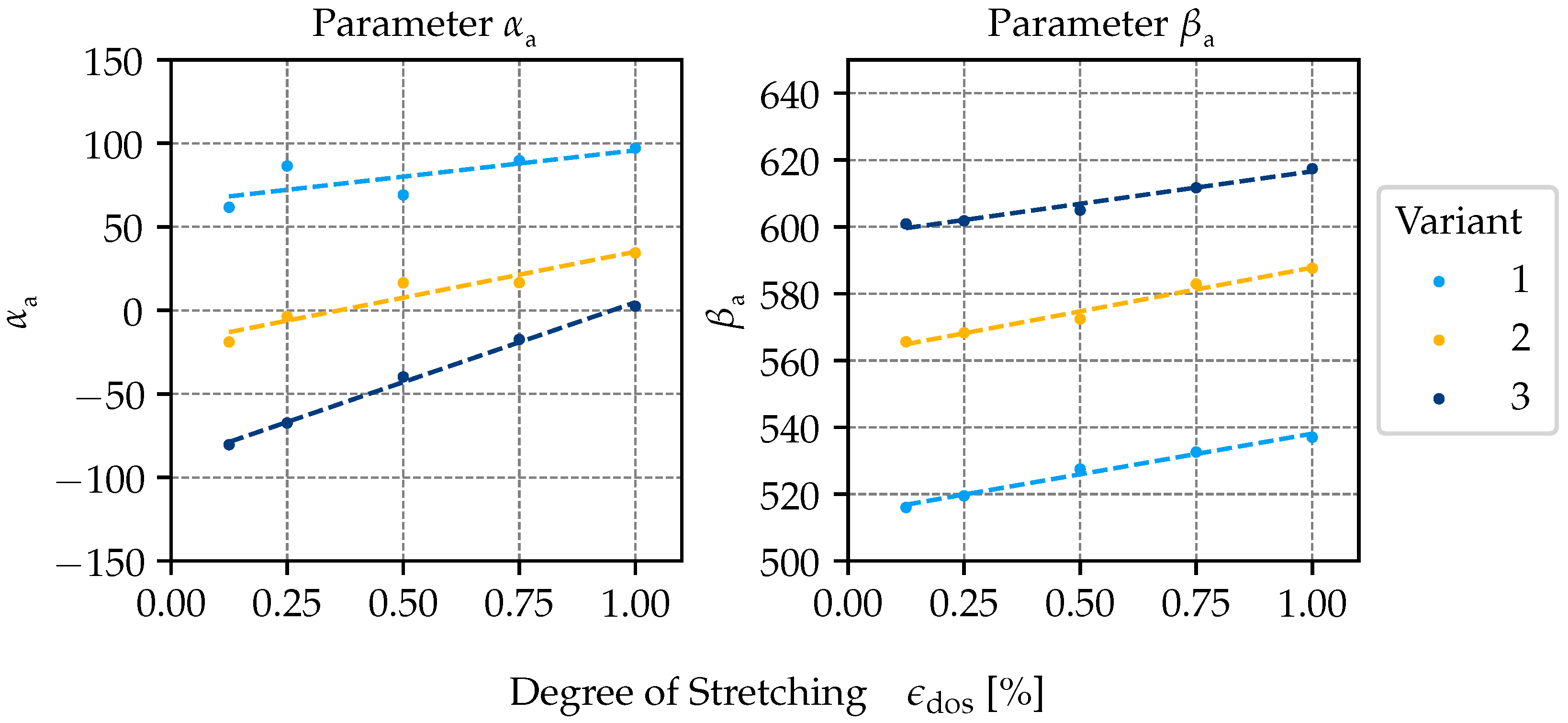

Figure 3.

The establishment of a mathematical relationship between the parameters

as well as

and the degree of stretching

is achieved through the implementation of a linear fit. The ensuing equations are thus derived:

where the parameters

and

describe the gradient, and the parameters

and

describe the ordinate intercept.

The values of the calculated parameters and the corresponding statistical data can be found in

Table 4. The results demonstrate that the parameter

assumes a negative value for all of the analysed variants. Therefore, the parameter

undergoes a decrease in proportion to the degree of stretching. Conversely, the parameter

has been shown to exhibit consistently positive values. Consequently, the parameter

rises in proportion to the degree of stretching. When the parameter

is compared across all variants, the highest value of 94.8 is observed in variant 1, and the lowest value of 31.4 is seen in variant 3. The parameter

exhibits a contradictory behaviour in relation to the variants. The statistical values, which evaluate the linear dependence of

and the degree of stretching, show

of 0.99–1.00 and RMSE of 0.2 and 0.5 for all variants. The

of the linear dependence are between

, and varying degrees of stretching are between 0.31 and 0.66. The calculated RMSEs are between 4.5 and 6.4, and the MEs are between 4.9 and 9.4.

On the basis of the calculated parameters

,

,

and

, the model description used in Equation (

1) can be extended to

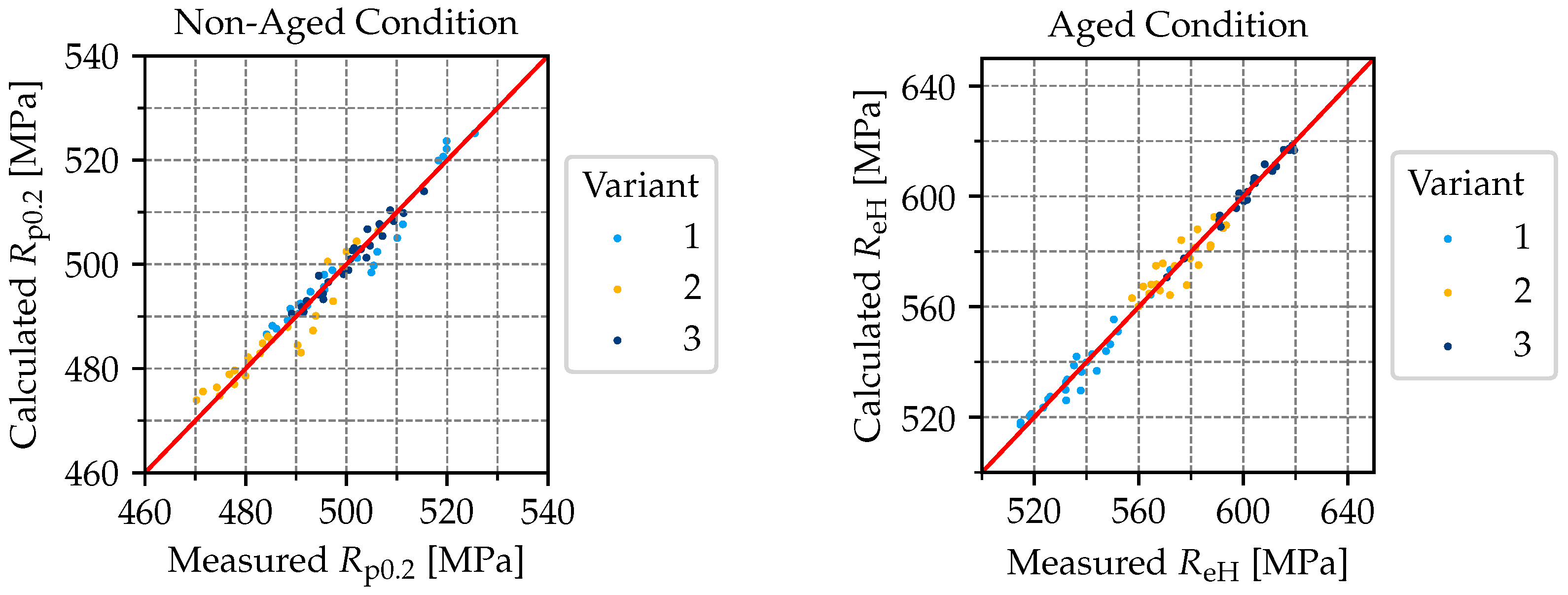

The model parameters determined for the individual variants are then inserted into the equation, and the validity of the model is checked.

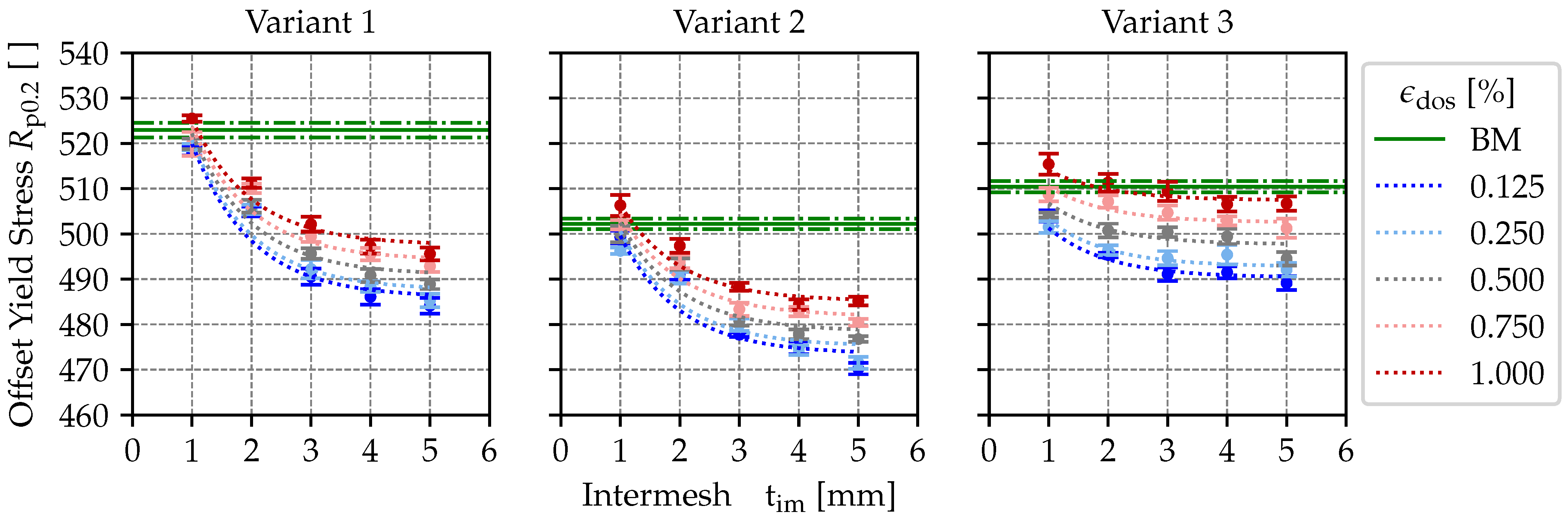

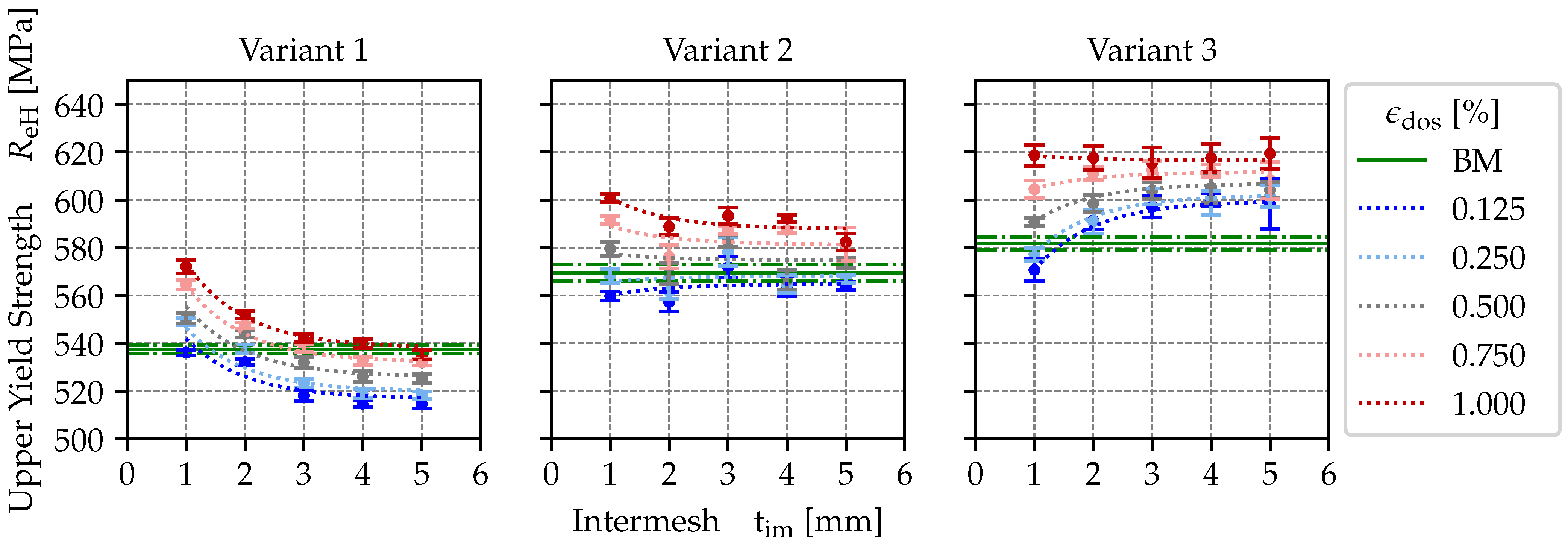

The calculated models are also demonstrated graphically as a relationship between intermesh and offset yield stress. The calculated offset yield stresses of the analysed range are displayed as dotted lines in

Figure 4. Furthermore, the measured offset yield stresses are shown as dots, with the respective SD indicated.

The results demonstrate that the offset yield stress generally decreases with increasing intermesh and increases with an increasing degree of stretching across all the variants analysed. In comparison to the base material, each variant has a tendency to soften. In the range of investigated parameters, exceptions to this are low intermeshes and high degrees of stretching. A comparison of the variants indicates that variant 1 exerts the most significant softening effects, while variant 3 exhibits the least significant impact.

The material- and process-specific parameters and the statistics of the generated models for the analysed variants have been calculated and are presented in

Table 5. As is evident from the data, the models achieve an

ranging from 0.90 to 0.95. The ME of the model of the variants considered is between 3.3 MPa and 7.9 MPa, and the RMSE is between 1.5 MPa and 3.2 MPa.

The approach presented in this publication differs from the approach described in the previous publication [

33], which is based on a different mathematical equation:

The calculated parameters as well as the statistical characteristics are shown in

Table 6. The statistical characteristics demonstrate higher

, as well as lower RSME and ME, compared to the novel modelling approach. It should be noted that this previously generated model approach was based purely on the non-aged state of variant 1, whereby the ageing process and the associated varying behaviour with increasing intermesh were not taken into account. Mathematically, it is not possible to describe the divergent dependence of the upper yield strength on the intermesh with varying degrees of stretching within a variant using the previous multivariate model approach. This can only describe a pure reduction or increase in the yield strength characteristics, with increasing intermesh within a variant. Based on this, the newly presented model approach is used.

3.2. Modelling of Tensile Properties of the Straightened Material in the Aged Condition

Analogous to the prediction modelling in the non-aged condition, the dependence of the upper yield strength

on the parameters intermesh and the degree of stretching is investigated in the aged condition.

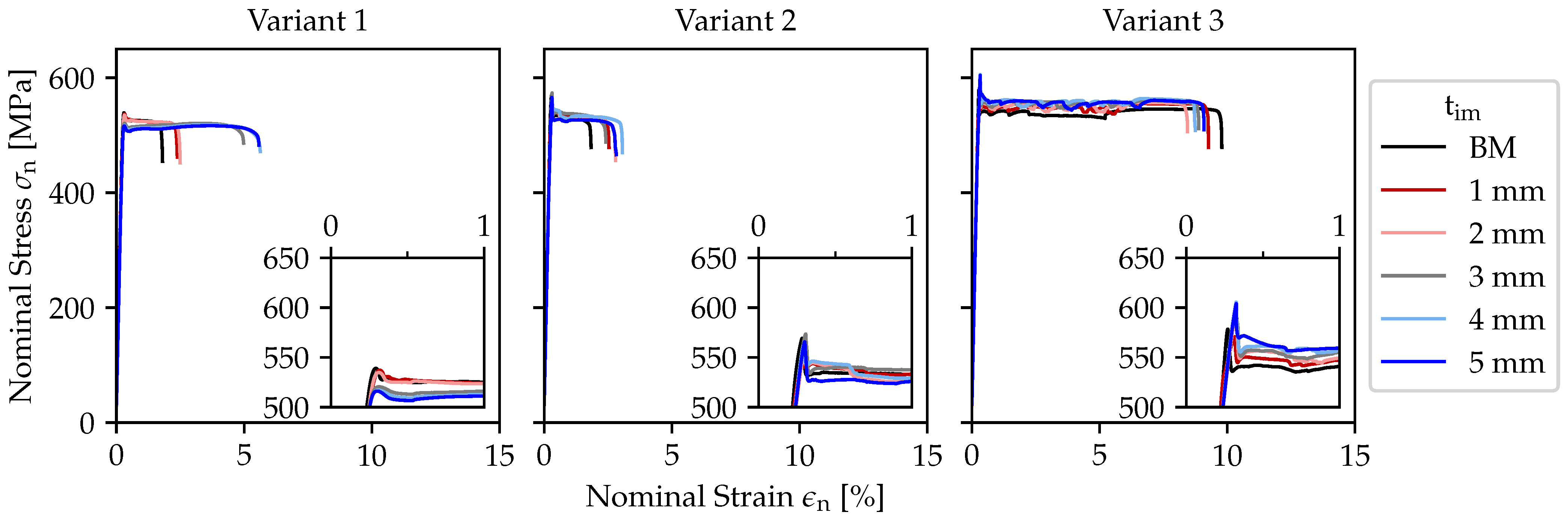

Figure 5 compares the stress–strain diagrams in the aged condition of the same set degree of stretching of 0.125% and intermeshes between 1 mm and 5 mm, as shown for the non-aged condition in

Figure 2.

The results of the stress–strain diagrams at a constant degree of stretching show that with increasing intermesh, the nominal stress decreases at variant 1. Also, the strain at break increases with increasing intermesh at variant 1. Variant 3 exhibits a behaviour that is the opposite of variant 1. As the intermesh increases, the nominal stress increases, and the elongation at break decreases. The findings of the tensile tests of the remaining stretch-bending straightening settings, as illustrated in

Table 2, indicate that the upper yield strength generally increases with an increasing degree of stretching. Increasing the intermesh leads to different upper yield strength changes depending on the degree of stretching and the variants tested.

The dependency between the intermeshes and the upper yield strength of the individual degrees of stretching for the three variants is initially calculated for each variant by the following equation:

The calculated values for the investigated degrees of stretching and variants are shown in

Table 7.

Figure 6 plots the calculated parameters

and

of the three analysed variants against the degree of stretching.

As with the non-aged condition, parameter demonstrates a tendency to increase in proportion to the degree of stretching. A comparison of this parameter reveals that it assumes both positive and negative values in variants 2 and 3. The parameter of variant 1 shows exclusively positive values. An increase in parameter is accompanied by an increase in the degree of stretching. In comparison with the non-aged condition, this parameter is shifted upwards to higher values. It is notable that parameter of variant 1 attains the lowest values, while those of variant 3 reach the highest. This phenomenon can be likened to the non-aged condition.

The linear fit results in the characteristic values for describing the gradient and the ordinate intercept of the individual factors, which can be found in

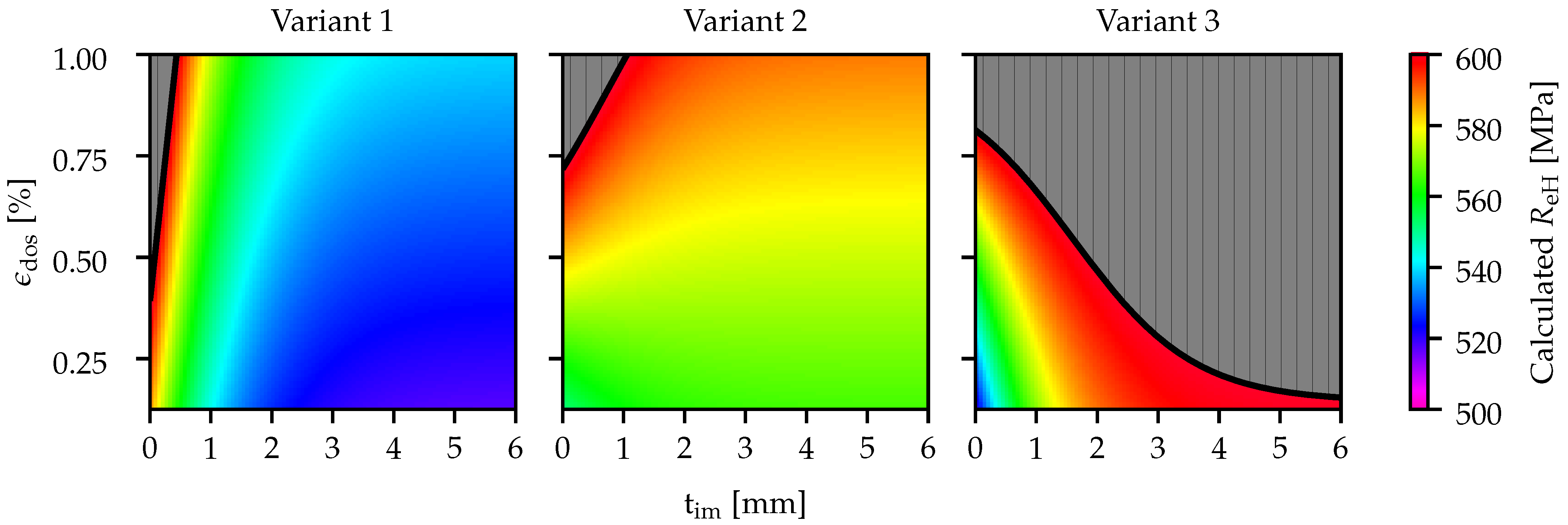

Table 8. It is, therefore, possible to use the equation to calculate the upper yield strengths of the model, based on the given parameters:

As illustrated in

Figure 7, the dependency between the stretch-bending straightening parameters and the measured upper yield strength is comparable to that shown in

Figure 4. Furthermore, the modelled upper yield strength of the three variants for the investigated degrees of stretching are displayed.

It is evident that an increase in the degree of stretching at a constant intermesh results in an increase in the upper yield strength. Variant 1 demonstrates a reduction in upper yield strength with increasing intermesh for all degrees of stretching analysed. In variant 3, an increase in the intermesh generally results in an increase in the upper yield strength for the degrees of stretching analysed between 0.125% and 0.750%. When the degree of stretching is set at 1%, the upper yield strength plateaus at the level of the intermeshes that have been analysed. Variant 2 shows an increase in upper yield strength when increasing intermesh is evident for degrees of stretching of 0.125% and 0.250%. For degrees of stretching of 0.750% and 1%, a decrease in upper yield strength with increasing intermesh can be identified. In comparison to the base material, it has been observed that low intermeshes tend to result in an increase in the upper yield strength for variant 1. It has been demonstrated that high intermeshes result in a reduction in the upper yield strength. In the case of variant 3, the stretch-bending straightening parameters that are investigated resulted in an increase in the upper yield strength. Exceptions are the set intermesh of 1 mm and the degree of stretching of 0.125%. Variant 2 demonstrates a reduction in the upper yield strength compared to the base material at straight degrees of stretching of 0.125% and 0.250% and an increase at degrees of stretching of 0.750% and 1%.

The modelling of the dependence of the upper yield strength on the stretch-bending straightening parameters for the three investigated variants in aged condition shows a

between 0.82 and 0.98, shown in

Table 9. The RMSEs of the modelled variants are between 1.7 and 5 MPa, and the MEs are between 3.5 and 10.4 MPa.