Abstract

430 stainless steel exhibits soft magnetic properties, excellent formability, and corrosion resistance, making it widely used in industrial applications. This study investigates the effects of different cold working rates on the properties of 430 stainless steel subjected to various magnetic annealing atmospheres (F-1.5Si, F-1.5Si-10%, F-1.5Si-40%, F-1.5Si-10% (MA), F-1.5Si-40% (MA), F-1.5Si-10% (H2), and F-1.5Si-40% (H2)). The results indicate that increasing the cold working rate improves the material’s mechanical properties; however, it negatively impacts its magnetic and corrosion resistance properties. Additionally, the magnetic annealing process improves the mechanical properties, while atmospheric magnetic annealing optimizes the overall magnetic performance. In contrast, magnetic annealing in a hydrogen atmosphere does not enhance the magnetic properties as effectively as atmospheric magnetic annealing. Still, it promotes the formation of a protective layer, preserving the mechanical properties and providing better corrosion resistance. Furthermore, regardless of whether magnetic annealing is conducted in an atmospheric or hydrogen environment, materials with 10% cold work rate (F-1.5Si-10% (MA) and F-1.5Si-10% (H2)) exhibit the lowest coercive force (286 and 293 A/m in the 10 Hz test condition), making them ideal for electromagnetic applications.

1. Introduction

430 stainless steel is a ferritic stainless steel that contains 12~30 wt.% chromium, and offers excellent corrosion resistance, high-temperature resistance, and formability. Its body-centered cubic (BCC) crystal structure provides ample space for free rotation of magnetic moments, resulting in superior soft magnetic properties [1]. These characteristics make 430 stainless steels widely used in electromagnetic applications, such as electronic devices and magnetic induction components.

As an electromagnetic steel, 430 stainless steel exhibits rapid magnetization and demagnetization capabilities [2], making it an essential soft magnetic material in electrical machine magnetic circuits. It is inherently non-magnetic but becomes magnetized when exposed to an electric current. It is an essential material for transformers, motors, generators, and solenoid valves, where it converts electrical energy into mechanical energy [3]. Soft magnetic stainless steel possesses magnetic properties; for example, industrial pure iron exhibits excellent dynamic magnetic characteristics and corrosion resistance. It has a low coercive force and high magnetic permeability, ensuring stable magnetic performance even in high-frequency environments. However, the magnetic properties of 430 stainless steel under different frequency conditions, particularly its magnetic hysteresis behavior, have not yet been fully clarified [4].

The magnetic and mechanical properties of 430 stainless steel are closely related [5]. The cold working procedure is commonly used to enhance the material’s mechanical properties by increasing its strength and hardness through work hardening and ensuring precise dimensional control. Cold working is performed below the recrystallization temperature and is widely used in metal manufacturing. Standard cold working techniques include cold drawing, rolling, forging, and extrusion. These methods improve the mechanical properties of 430 stainless steel and introduce stored energy that affects the following magnetic annealing processes [6]. Based on this, the present study combines the effects of cold work and magnetic annealing to investigate the differences in microstructure, mechanical properties, and electromagnetic performance of 430 stainless steel.

430 stainless steel possesses excellent corrosion resistance and magnetic properties. The annealing environment significantly affects its performance. Notably, the differences between atmospheric and hydrogen magnetic annealing have not been extensively reported in the literature [7]. Therefore, this study systematically examines the microstructural, mechanical, and magnetic properties of 430 stainless steel to elucidate the metallurgical mechanisms underlying its electromagnetic characteristics. Additionally, it provides critical data on cold working rates and hydrogen annealing, contributing to the assessment of corrosion resistance. By integrating knowledge from metallurgy, mechanical engineering, and magnetism, this research analyzes the effects of increased cold work rates followed by magnetic annealing on material performance. The findings serve as a reference for designing electromagnetic steel materials and establishing theoretical material data for electromagnetic components. This study uniquely combines cold working and dual-mode magnetic annealing (air vs. hydrogen) to determine the optimal processing for soft magnetic 430 stainless steel.

2. Experimental Procedures

The composition of the 430 stainless steels with 1.5 wt.% silicon (F-1.5Si) [8], where “F” refers to the “free machining” grade of 430 stainless steel, is detailed in Table 1. The effects of different cold working rates were investigated using reduction rates of 0%, 10%, and 40% (F-1.5Si, F-1.5Si-10%, and F-1.5Si-40%). Additionally, the study analyzed the effects of atmospheric magnetic annealing (F-1.5Si (MA), F-1.5Si-10% (MA), and F-1.5Si-40% (MA)) and hydrogen magnetic annealing (F-1.5Si (H2), F-1.5Si-10% (H2), and F-1.5Si-40% (H2)). The heat treatment conditions for magnetic annealing were as follows: atmospheric magnetic annealing was performed at 850 °C for 4 h in air, followed by air cooling to room temperature (AC), whereas hydrogen magnetic annealing was conducted at 760 °C for 4 h in a hydrogen atmosphere, followed by furnace cooling to room temperature (FC). Additionally, the Curie temperature of 430 stainless steel is approximately 760–780 °C, within which magnetic annealing enables the transition from ferromagnetic to soft magnetic behavior [9,10]. In this study, the magnetic annealing refers to annealing performed at the Curie temperature to improve the magnetic properties of the material (no external magnetic field during annealing). Therefore, this study employed 850 °C for atmospheric magnetic annealing and 760 °C for hydrogen magnetic annealing, with the latter chosen for safety considerations and its common industrial application. The experimental magnetic annealing conditions and sample designations are summarized in Table 2.

Table 1.

Composition of F-1.5Si.

Table 2.

Magnetic annealing process parameters and name.

The phase composition of each sample was analyzed using an X-ray diffractometer (XRD, Bruker D8D Plus-TXS, Billerica, MA, USA) with a diffraction angle (2θ) range of 20–90° (0.02°/0.4 s, 45 kV).

The mechanical properties of the materials were assessed using a Rockwell hardness tester (Hardness Tester, Mitutoyo AR-10, Kawasaki, Japan) for hardness measurements. The tests were conducted following ASTM E18 standards, using a 1/16-inch steel ball indenter with a 100 kgf major load and a dwell time of 15 s. Tensile tests were conducted using a universal testing machine (SHIMADZU AGX-V2, Kyoto, Japan) at a strain rate of 1 × 10−3 s−1. The specimen had a gauge length (L0) of 20 mm and a diameter of 5.8 mm. After testing, the fracture surfaces of the tensile specimens were observed using a scanning electron microscope (SEM, Hitachi 700H, Tokyo, Japan) to analyze the material’s deformation and failure mechanisms.

Electrical properties were evaluated using a power supply unit (PSW30-36, GW INSTEK, New Taipei City, Taiwan). The specimens were fixed within 0.5 cm in length for axial electrical measurements. The applied current ranged from 0.00 to 0.30 A, with voltage values recorded at 0.01 A increments to analyze the dynamic resistance of the material [11].

For magnetic measurements, the specimens were precisely machined into ring-shaped samples. Copper wire coils were wound around the rings with a turn ratio of N1:N2 = 15:5. The magnetic hysteresis curves were measured using a B-H analyzer (Lwatsu SY-8219, Iwatsu Electric Co., Ltd., Tokyo, Japan) under a fixed external current of 1 A at measurement frequencies of 10 Hz, 100 Hz, and 1000 Hz. Since the specimen size was relatively small, a 1 A current was sufficient to distinguish the magnetic properties at different frequencies.

Corrosion resistance was evaluated using an electrochemical impedance analyzer (PARSTAT2273, Princeton Applied Research, Oak Ridge, TN, USA). The specimens were fixed in molds and immersed in a 3.5 wt.% saturated NaCl solution. Polarization curve tests were conducted following the ASTM-A262 standard [12] to assess the corrosion resistance of the samples.

Since increased cold working has little effect on surface element distribution, the experiment focused on comparing the surface element distribution of the F-1.5Si, F-1.5Si (MA), and F-1.5Si (H2) specimens using an electron probe micro-analyzer (EPMA, JEOL/JXA-8230, Tokyo, Japan) to observe the elemental distribution across the surface, and regions of interest were selected for precise quantitative analysis via wavelength-dispersive spectroscopy (WDS).

Transmission electron microscopy (TEM) was utilized to analyze the phase structure of F-1.5Si (MA), which showed the most favorable magnetic annealing effects, to further compare the phase structures within the matrix. Selected area electron diffraction (SAED) was used to compare the matrix with secondary phases, such as MnS and carbides, and to investigate their structural characteristics and distribution differences. Energy-dispersive X-ray spectroscopy (EDS) was also utilized to examine the material’s elemental distribution and chemical composition.

3. Results and Discussion

3.1. Analysis of Fundamental Material Properties

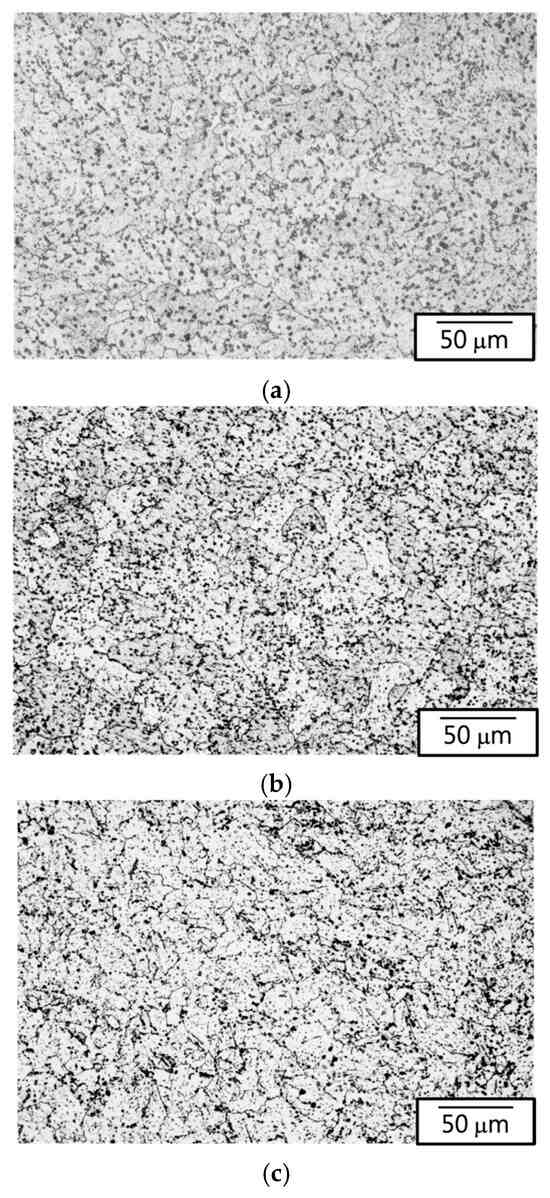

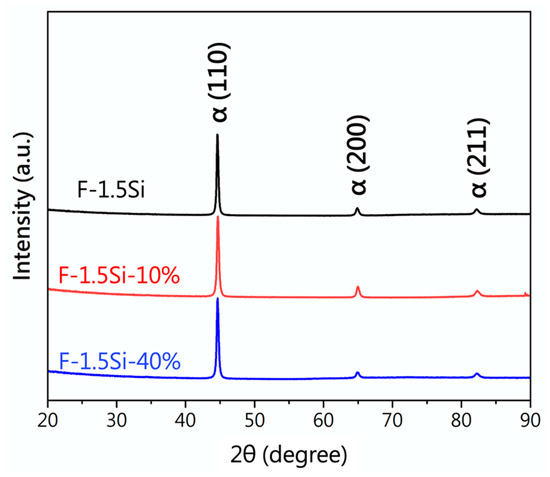

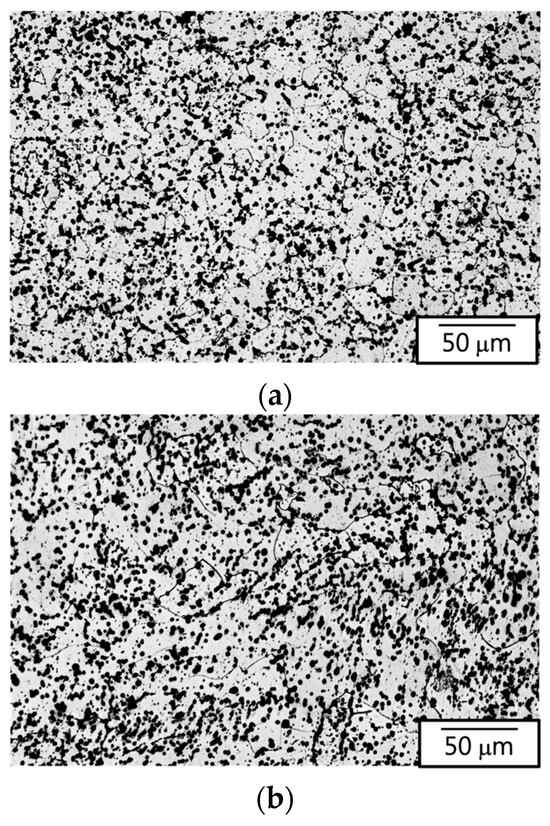

To enhance the material’s performance for practical applications, this study investigated the effects of different cold working rates on various properties of 430 stainless steel (F-1.5Si, F-1.5Si-10%, and F-1.5Si-40%). The microstructures of these samples were observed and are shown in Figure 1. The average grain size of each specimen was measured using the linear interception method, revealing that all base structures consisted of equiaxed grains, and the average grain size decreased with increasing cold working rates, which correlated with strengthening. Additionally, secondary phases were observed in all base structures. XRD phase analysis (Figure 2) confirmed that all three stainless steels exhibited the same ferritic matrix containing micro-scale secondary phase particles (MnS).

Figure 1.

Microstructure of F-1.5Si under different cold working rates: (a) F-1.5Si (grain size: 16.7 μm), (b) F-1.5Si-10% (grain size: 14.9 μm), (c) F-1.5Si-40% (grain size: 13.5 μm).

Figure 2.

X-ray diffraction pattern of F-1.5Si under different cold working rates.

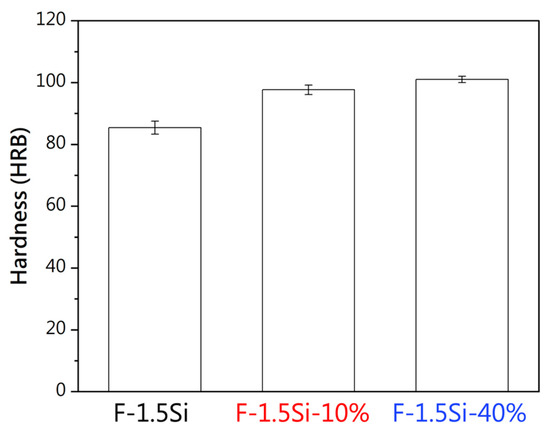

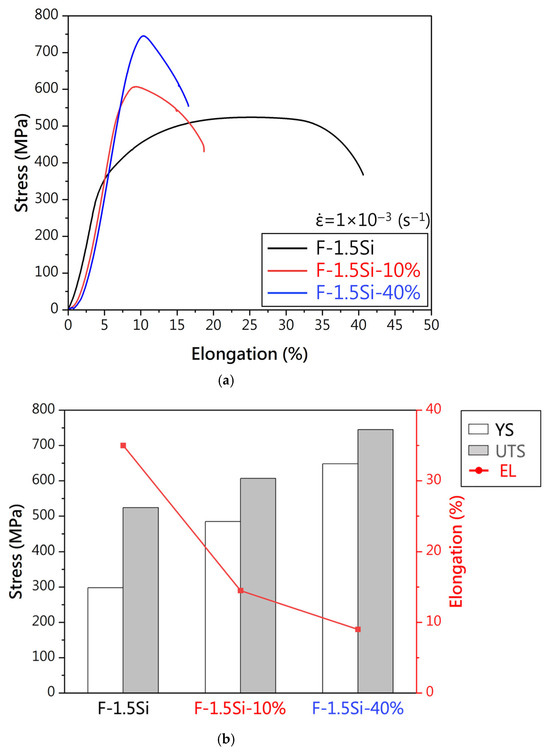

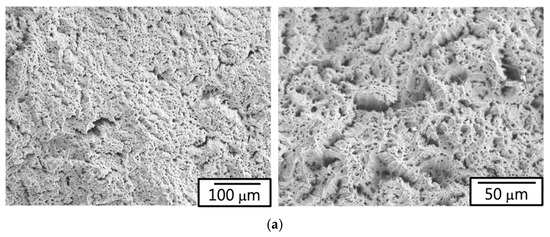

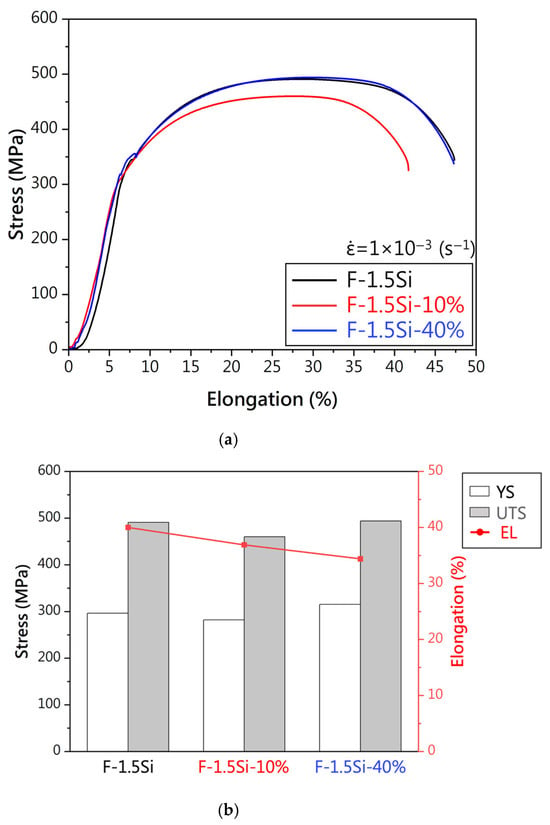

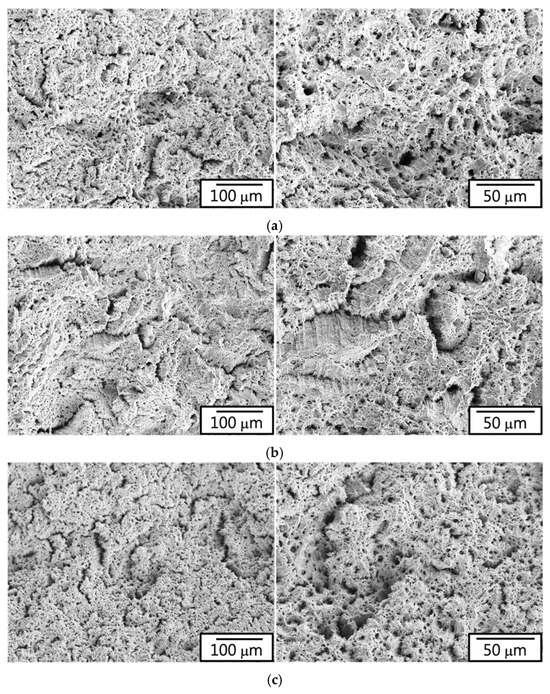

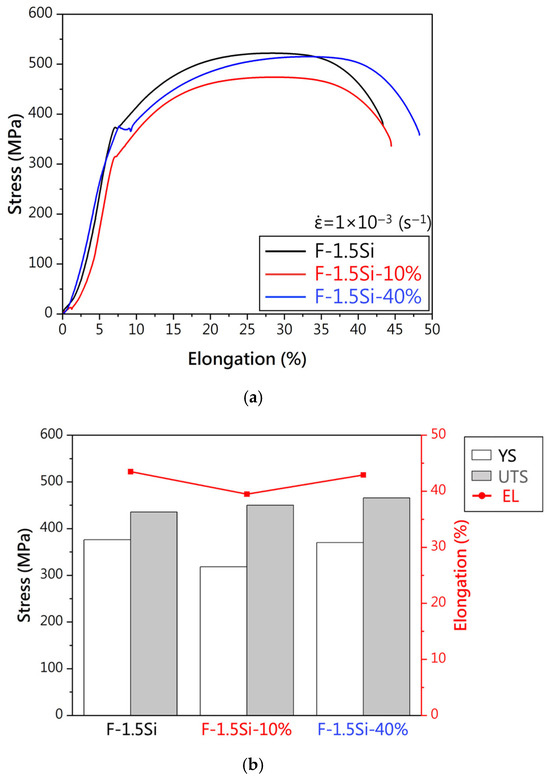

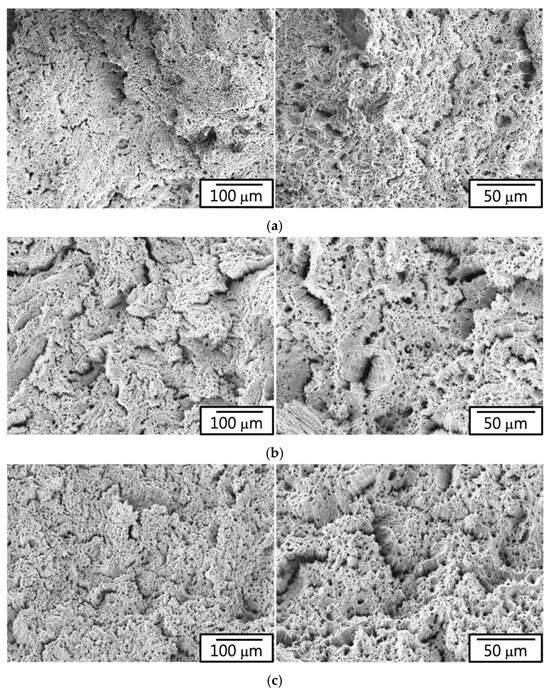

The hardness measurements for the three materials, as shown in Figure 3, indicate an increasing trend with decreasing grain size, showing a strong connection between hardness and grain size in F-1.5Si samples. Figure 4 presents the engineering stress–strain curves under different cold working rate conditions (strain rate: 1 × 10−3 s−1) and corresponding tensile data. As the cold working rates increased, both the yield strength and ultimate tensile strength rose while ductility decreased. The SEM fracture surface observations (Figure 5) show distinct failure characteristics. The fracture surface of the F-1.5Si specimen exhibited uniformly dispersed microcracks with minimal surface roughness (Figure 5a). However, increasing the cold working rate to 10% (Figure 5b) and 40% (Figure 5c), fewer microcracks and more pronounced surface roughness were observed, with some areas displaying lamellar delamination, indicative of slip-induced failure mechanisms [13].

Figure 3.

Hardness of F-1.5Si under different cold working rates.

Figure 4.

F-1.5Si under different cold working rates: (a) Tensile stress–strain curves; (b) tensile data.

Figure 5.

Fracture surface characteristics of F-1.5Si under different cold working rates: (a) F-1.5Si, (b) F-1.5Si-10%, (c) F-1.5Si-40%.

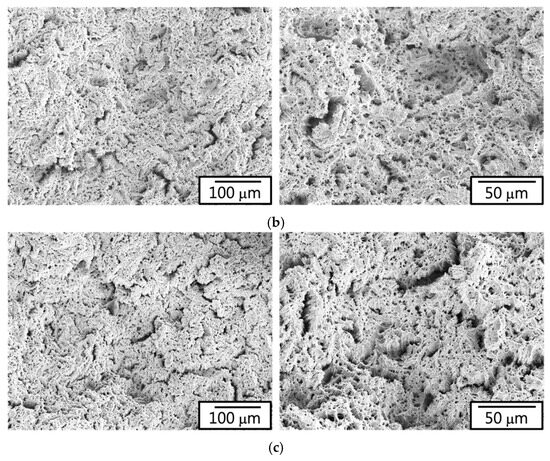

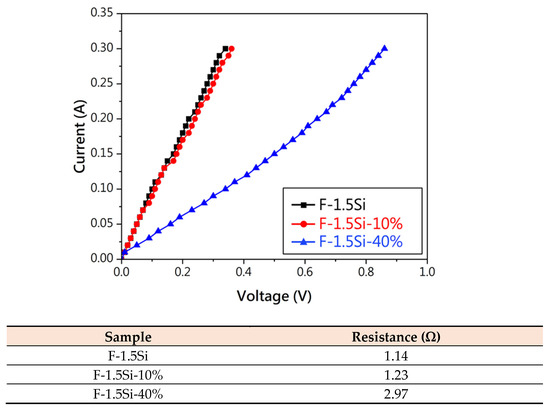

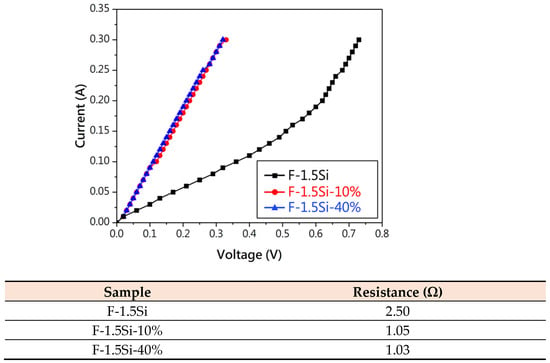

Axial electrical measurements were conducted on specimens with different cold working rates, using a current range of 0.00–0.30 A, recorded in increments of 0.01 A. The I-V Curve (Figure 6) was plotted, and the slope of the curve represents dynamic resistance. The results show that as the cold working rate increased, the dislocation density in the matrix also rose, resulting in a higher electrical resistance [14].

Figure 6.

I-V curves for F-1.5Si under different cold working rates.

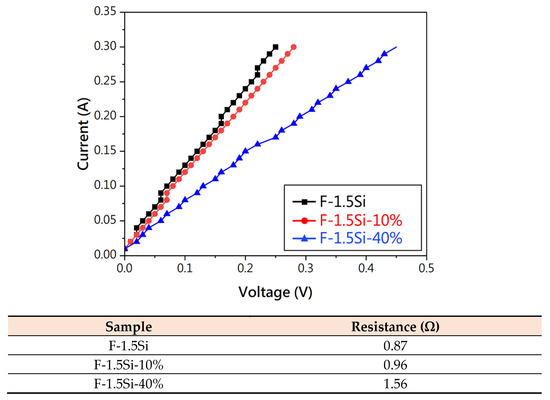

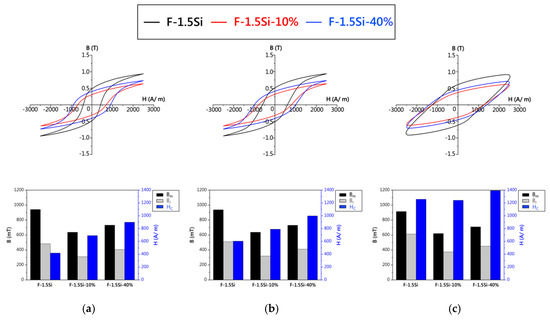

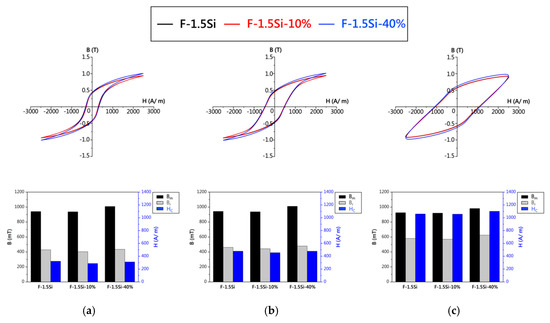

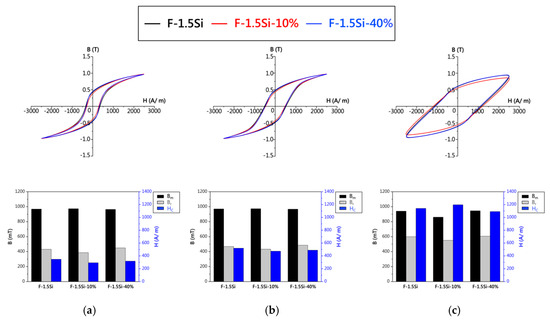

The magnetic hysteresis curves and related data for F-1.5Si under different cold working rates are shown in Figure 7. Figure 7a presents the hysteresis curves at 10 Hz. The main findings are as follows: (1) The saturation magnetization (Bm) and remanence (Br) exhibited an inflection point, reaching their lowest values at a 10% cold working rate. (2) Coercive force (Hc) increased with a higher cold working rate, probably because of a higher density of dislocations, which obstructs the rotation of magnetic domains [15]. Similar trends were observed when the measurement frequency is increased to 100 Hz (Figure 7b) and 1000 Hz (Figure 7c). The magnetic properties for each sample are listed in Table 3.

Figure 7.

Hysteresis curves and data for F-1.5Si under different cold working rates: (a) AC-10 Hz, (b) AC-100 Hz, (c) AC-1000 Hz.

Table 3.

Magnetic properties of F-1.5Si at different frequencies.

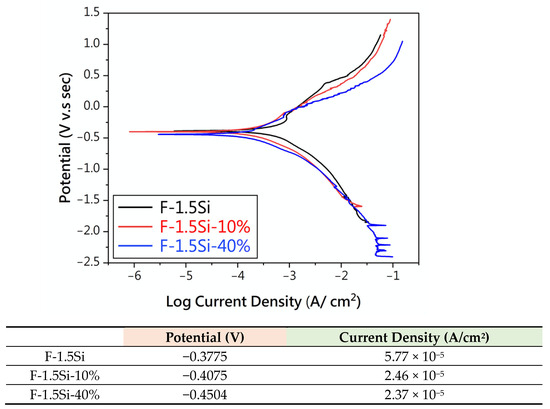

Figure 8 shows the polarization curves obtained from corrosion resistance tests for the different cold working rates. The data shows that as the cold working rate increased, the dislocation density also rose, creating more sites for corrosion initiation in the matrix [16]. This phenomenon reduces the material’s corrosion resistance. In summary, while increasing the cold working rate provides limited improvements in fundamental material properties, it significantly enhances stored energy within the material. This stored energy plays a crucial role in subsequent annealing processes. Therefore, this study further investigated the effects of atmospheric and hydrogen magnetic annealing on the three different cold-worked 430 stainless steel samples (F-1.5Si, F-1.5Si-10%, and F-1.5Si-40%) to evaluate their metallurgical and electromagnetic application characteristics.

Figure 8.

Polarization curves and data for F-1.5Si under different cold working rates.

3.2. Atmospheric Magnetic Annealing Process

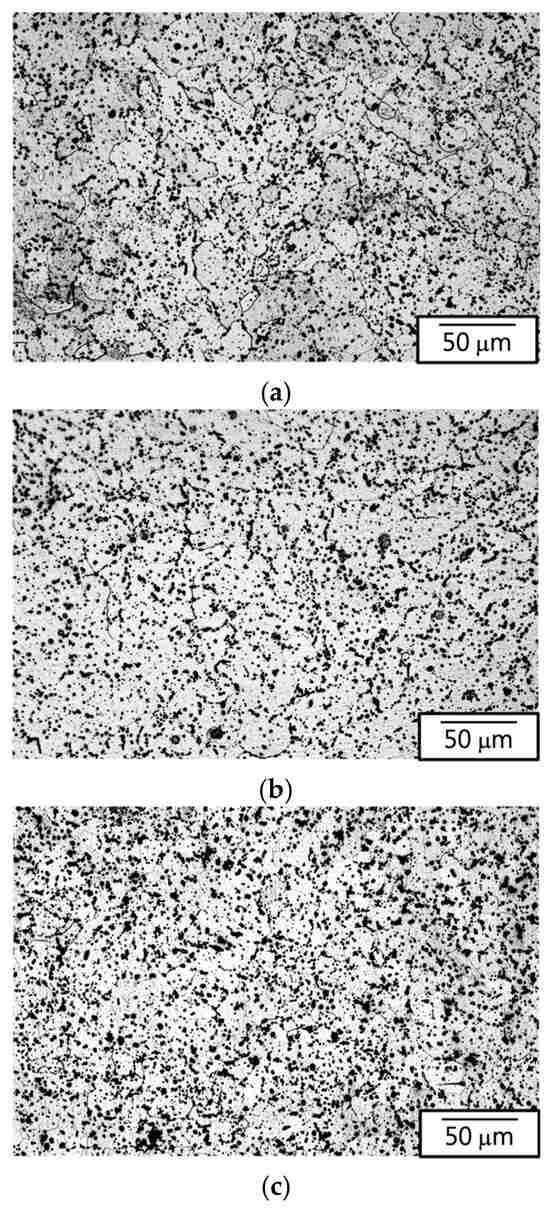

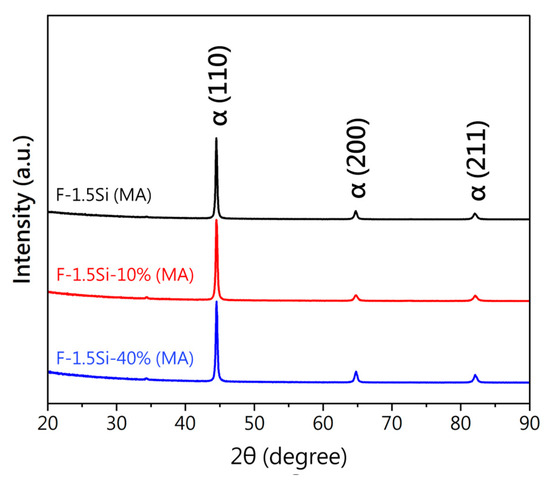

The cold-worked 430 stainless steel samples (F-1.5Si, F-1.5Si-10%, and F-1.5Si-40%) were subjected to atmospheric magnetic annealing at 850 °C for 4 h, followed by air cooling to room temperature. The microstructural observations after annealing are presented in Figure 9. The results indicate that the microstructure remained equiaxed, and the average grain size still exhibited a decreasing trend with an increasing cold working rate. However, no significant grain size changes were observed after atmospheric magnetic annealing. XRD phase analysis (Figure 10) confirmed that the ferritic matrix remained unchanged after annealing without forming new phases.

Figure 9.

Microstructure of F-1.5Si after atmospheric magnetic annealing with different cold working rates: (a) F-1.5Si (MA) (grain size: 12.9 μm), (b) F-1.5Si-10% (MA) (grain size: 12.5 μm), (c) F-1.5Si-40% (MA) (grain size: 11.7 μm).

Figure 10.

X-ray diffraction pattern of F-1.5Si after atmospheric magnetic annealing with different cold working rates.

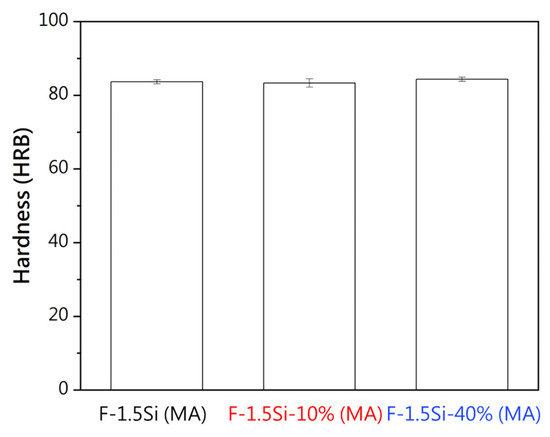

The hardness measurements (Figure 11) show that partial recrystallization occurred in the structure after atmospheric magnetic annealing, producing a uniform overall hardness [17]. The hardness of F-1.5Si decreased from 85.4 (HRB) to 83.6 (HRB) after annealing, indicating that the annealing process results in matrix softening. Figure 12 presents the stress–strain curves of the three samples after atmospheric magnetic annealing (strain rate: 1 × 10−3 s−1). The results indicate that tensile strength remained similar across different cold working rates after annealing. However, ductility decreased as the cold working rate increased due to dislocation movement restrictions in the matrix [18]. The SEM fracture surface observations of the annealed tensile specimens (Figure 13) revealed distinct failure characteristics. The fracture surface of F-1.5Si (Figure 13a) exhibited dimpled ductile fracture features. In contrast, F-1.5Si-10% (MA) (Figure 13b) displayed more pronounced fracture surface roughness. When the cold working rate increased to 40% (Figure 13c), the surface roughness became more significant, and lamellar delamination was observed in certain areas, indicating cleavage fracture caused by dislocation motion restrictions.

Figure 11.

Hardness of F-1.5Si after atmospheric magnetic annealing with different cold working rates.

Figure 12.

F-1.5Si after atmospheric magnetic annealing with different cold working rates: (a) tensile stress–strain curves; (b) tensile data.

Figure 13.

Fracture surface characteristics of F-1.5Si after atmospheric magnetic annealing with different cold working rates: (a) F-1.5Si (MA), (b) F-1.5Si-10% (MA), (c) F-1.5Si-40% (MA).

Axial electrical measurements were conducted on the annealed samples within the current range of 0.00–0.30 A, recorded in increments of 0.01 A. The I-V Curves are shown in Figure 14, where the slope represents dynamic resistance. The results show that the electrical properties of the lower cold working rate sample (F-1.5Si-10% (MA)) were similar to those of the unprocessed raw material (F-1.5Si). However, F-1.5Si-40% (MA), which underwent a higher cold working rate before annealing, exhibited increased dynamic resistance due to more dislocation entanglement. This led to recrystallization and sub-grain formation, enhancing the grain boundary effects [19].

Figure 14.

I-V curves for F-1.5Si after atmospheric magnetic annealing with different cold working rates.

The magnetic hysteresis curves and data for different cold-worked samples after atmospheric magnetic annealing are shown in Figure 15. Figure 15a presents the hysteresis curves at 10 Hz. Compared to untreated samples, atmospheric magnetic annealing effectively reduced the coercive force (Hc) values (F-1.5Si (MA): 23%; F-1.5Si-10% (MA): 59%; F-1.5Si-40% (MA): 65%) while also increasing the maximum magnetization (Bm). Similar trends were observed at higher measurement frequencies of 100 Hz (Figure 15b) and 1000 Hz (Figure 15c). Additionally, the Hc values of all the samples increased as the measurement frequency increased. The detailed magnetic properties of the samples are listed in Table 3.

Figure 15.

Hysteresis curves and data for F-1.5Si after atmospheric magnetic annealing with different cold working rates: (a) AC-10 Hz, (b) AC-100 Hz, (c) AC-1000 Hz.

3.3. Hydrogen Magnetic Annealing Process

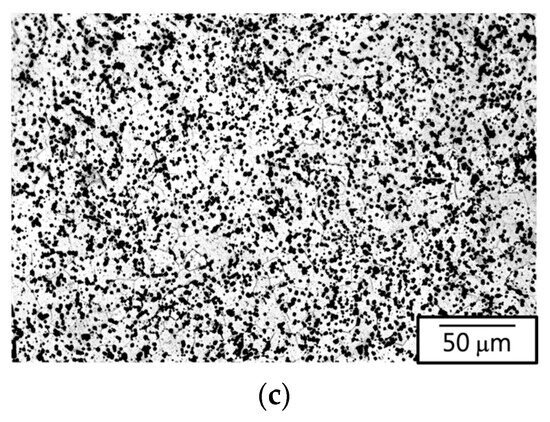

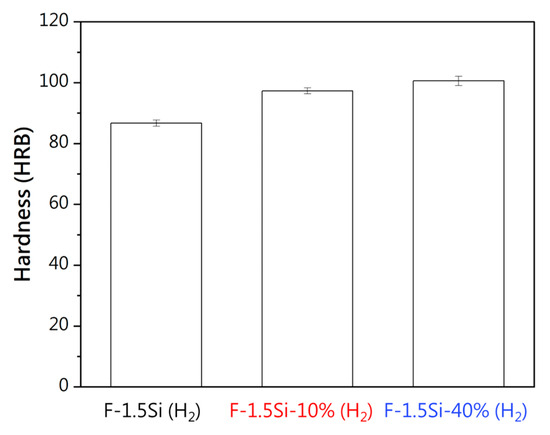

The cold-worked 430 stainless steel samples (F-1.5Si, F-1.5Si-10%, F-1.5Si-40%) were subjected to hydrogen magnetic annealing at 760 °C for 4 h, followed by furnace cooling to room temperature. The objective was to compare the effects of different magnetic annealing atmospheres. The microstructures of the samples after hydrogen magnetic annealing are shown in Figure 16; all the samples exhibited equiaxed grains, and the average grain size decreased with increasing cold working rate. Additionally, a second phase was observed in all samples. The XRD phase analysis results (Figure 17) confirmed that all three stainless steel samples retained a ferritic matrix with micro-sized MnS second-phase particles.

Figure 16.

Microstructure of F-1.5Si after hydrogen magnetic annealing with different cold working rates: (a) F-1.5Si (H2) (grain size: 12.4 μm), (b) F-1.5Si-10% (H2) (grain size: 12.1 μm), (c) F-1.5Si-40% (H2) (grain size: 11.2 μm).

Figure 17.

X-ray diffraction pattern of F-1.5Si after hydrogen magnetic annealing with different cold working rates.

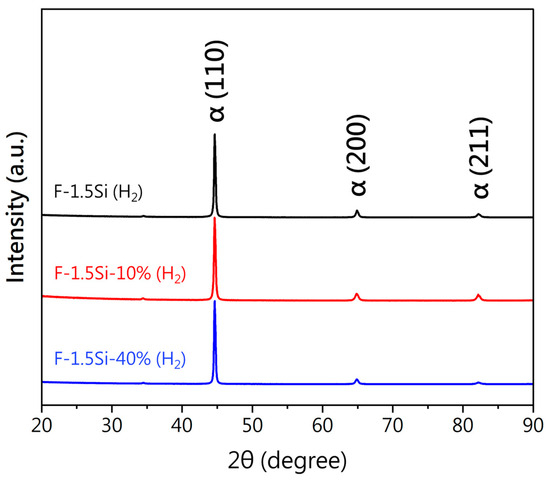

The hardness measurements (Figure 18) indicate that the hardness increased more with the cold working rate compared to atmospheric magnetic annealing. This suggests that magnetic annealing in a hydrogen atmosphere minimizes surface oxidation and facilitates the formation of a protective layer [20] while promoting more significant recrystallization. Figure 19 presents the stress–strain curves of the samples after hydrogen magnetic annealing (strain rate: 1 × 10−3 s−1); the following observations were made: (1) The tensile properties generally did not change significantly with an increase in the cold working rate. (2) The F-1.5Si-10% (H2) sample exhibited lower elongation, while the F-1.5Si-40% sample showed upper and lower yield points in the stress–strain curve, likely due to reduced available slip systems. The SEM fracture surface observations (Figure 20) revealed that, after hydrogen magnetic annealing, the number of microcracks decreased, and fracture surface roughness became more pronounced. Lamellar delamination was also observed, suggesting the possibility of localized hydrogen embrittlement after annealing [21].

Figure 18.

Hardness of F-1.5Si after hydrogen magnetic annealing with different cold working rates.

Figure 19.

F-1.5Si after hydrogen magnetic annealing with different cold working rates: (a) tensile stress–strain curves; (b) tensile data.

Figure 20.

Fracture surface characteristics of F-1.5Si after hydrogen magnetic annealing with different cold working rates: (a) F-1.5Si (H2), (b) F-1.5Si-10% (H2), (c) F-1.5Si-40% (H2).

Axial electrical measurements were conducted on the samples within a current range of 0.00–0.30 A, at increments of 0.01 A. The dynamic resistance values were obtained from the I-V plots (Figure 21). The results indicate that hydrogen annealing reduced surface oxidation, leading to lower electrical resistance in the highest cold-worked sample.

Figure 21.

I-V curves for F-1.5Si after hydrogen magnetic annealing with different cold working rates.

The magnetic hysteresis curves and data for different cold-worked samples after hydrogen magnetic annealing are shown in Figure 22. Figure 22a presents the hysteresis curves at 10 Hz. Compared to the untreated materials, hydrogen magnetic annealing reduced the coercive force (Hc) (F-1.5Si (H2): 17%; F-1.5Si-10% (H2): 58%; F-1.5Si-40% (H2): 65%) while improving the maximum magnetization (Bm) in cold-worked samples (F-1.5Si-10% (H2) and F-1.5Si-40% (H2)). F-1.5Si-10% exhibited the lowest Hc values after atmospheric and hydrogen magnetic annealing. Similar trends were observed at the higher frequency of 100 Hz (Figure 22b). When the measurement frequency increased to 1000 Hz (Figure 22c), the F-1.5Si-10% (H2) sample experienced the most significant Hc increase due to its superior soft magnetic properties, making the coercive force more sensitive to frequency variations [22]. The detailed magnetic properties of the samples are listed in Table 3.

Figure 22.

Hysteresis curves and data for F-1.5Si after hydrogen magnetic annealing with different cold working rates: (a) AC-10 Hz, (b) AC-100 Hz, (c) AC-1000 Hz.

3.4. Surface Element Analysis and Related Mechanisms

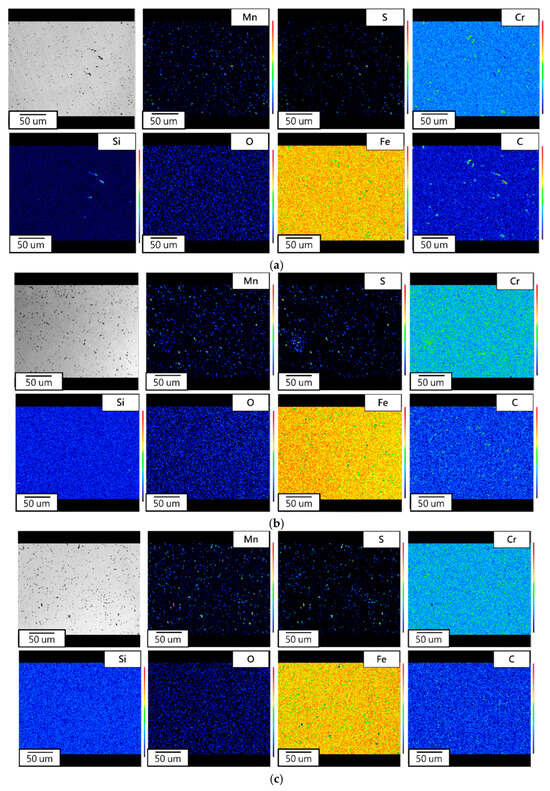

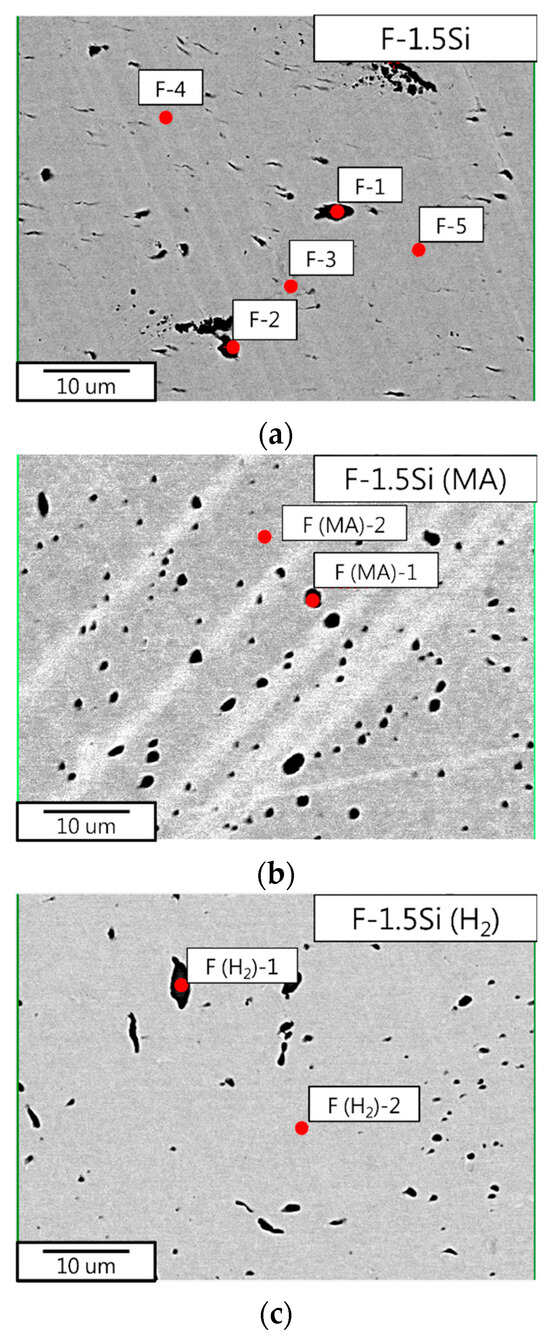

The F-1.5Si, F-1.5Si (MA), and F-1.5Si (H2) samples were analyzed using electron probe microanalysis (EPMA) (Figure 23). The analyzed elements included Fe, Cr, C, O, Si, Mn, and S. Based on image contrast, dark particles were identified as manganese sulfide compounds. As the magnetic annealing temperature increased, chromium enrichment in the matrix and precipitation of MnS compounds were observed. Wavelength-dispersive spectroscopy (WDS) was also performed on the matrix regions, with the analyzed positions shown in Figure 24 and the phase compositions summarized in Table 4. We conducted an identification of the matrix phase and the black particles. The results indicated that the secondary MnS phase precipitated from the matrix, and the magnetic annealing process promoted matrix homogenization, resulting in a more uniform elemental distribution.

Figure 23.

EPMA analysis: (a) F-1.5Si, (b) F-1.5Si (MA), (c) F-1.5Si (H2).

Figure 24.

Surface element analysis: (a) F-1.5Si, (b) F-1.5Si (MA), (c) F-1.5Si (H2).

Table 4.

Surface element analysis data.

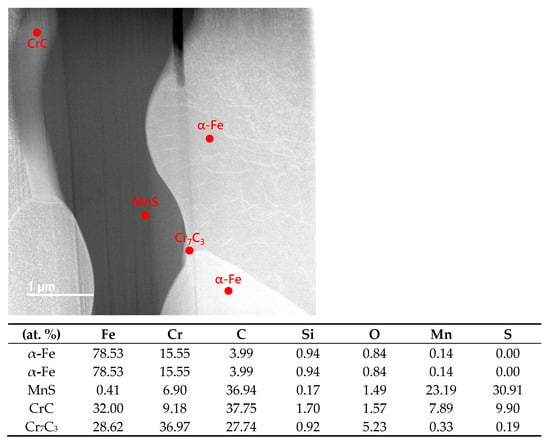

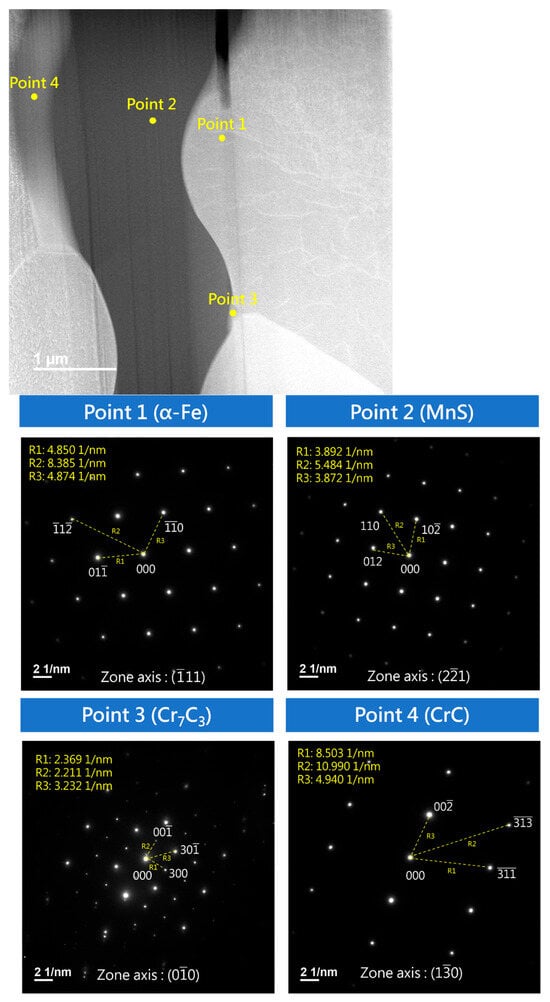

Transmission electron microscopy (TEM) analysis was performed on F-1.5Si (MA), which showed the most favorable magnetic annealing effects, to further compare the phase structures within the matrix. The energy-dispersive X-ray spectroscopy (EDS) analysis (Figure 25) revealed the presence of micron-sized MnS precipitates, along with the formation of carbides (Cr7C3, CrC) in the matrix after annealing. The matrix and carbide phase structures were further characterized. Figure 26 presents the selected area electron diffraction (SAED) pattern of the matrix, showing that the MnS phase possessed a cubic structure and was antiferromagnetic. This suggests that the precipitation of MnS stabilizes the BCC structure of the matrix, thereby enhancing the soft magnetic properties. In addition, structural analysis of the carbides revealed the presence of nanoscale Cr7C3 and micron-scale CrC within the matrix, with the precipitation of chromium carbides also contributing to improving the material’s soft magnetic performance.

Figure 25.

EDS elemental analysis of F-1.5Si (MA).

Figure 26.

SAED pattern analysis of F-1.5Si (MA).

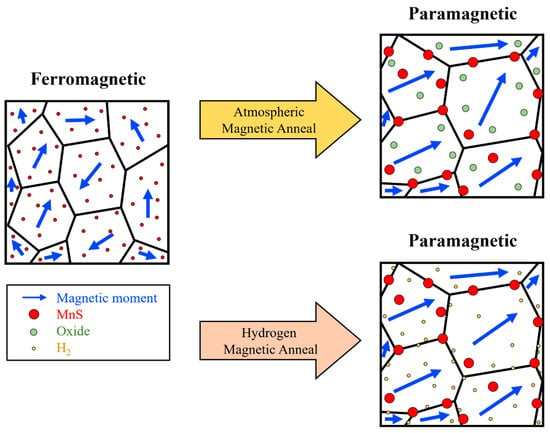

The experimental results presented in Figure 27 indicate that grain growth occurred in the F-1.5Si specimen following magnetic annealing, which was accompanied by the precipitation and aggregation of MnS within the matrix. These precipitates create additional space within the matrix, facilitating the rotation of magnetic moments. Furthermore, hydrogen magnetic annealing suppresses the formation of oxides; hydrogen atoms diffuse into the matrix, displacing oxides and allowing for even greater freedom of magnetic moment rotation. Consequently, after undergoing hydrogen magnetic annealing, the F-1.5Si (H2) specimen displayed enhanced soft magnetic properties.

Figure 27.

Diagram of the magnetizing mechanism after magnetic annealing of F-1.5Si.

4. Limitation

In future research, an Electron Spectroscopy for Chemical Analysis (ESCA) will be employed to investigate the diffusion behavior of hydrogen atoms on the material surface during the hydrogen annealing process. Furthermore, the impact of temperature variations on the magnetic properties of electromagnetic steel is significant. Future studies will examine the differences in magnetic properties before and after thermal cycling.

5. Conclusions

- Increasing the cold working rate of F-1.5Si effectively enhances its mechanical properties. However, no significant changes in corrosion resistance were observed under different cold working rates.

- After atmospheric magnetic annealing, the grain size of F-1.5Si with different cold working rates is reduced, and partial recrystallization occurs in the matrix, resulting in uniform hardness and increased yield strength. Additionally, atmospheric magnetic annealing effectively reduces the material’s coercive force (Hc).

- Hydrogen magnetic annealing leads to a reduction in grain size and hardness. Regarding yield strength and magnetic properties, the F-1.5Si-10% material exhibited the best electromagnetic application performance after hydrogen magnetic annealing.

- The TEM analysis revealed that the second phase, manganese sulfide (MnS), has an FCC structure and exhibits diamagnetic behavior. This indicates that MnS precipitation can stabilize the BCC structure of the matrix, thereby enhancing its soft magnetic properties.

Author Contributions

Conceptualization, C.-W.L. and F.-Y.H.; Methodology, C.-W.L., F.-Y.H. and T.-W.C.; Software, F.-Y.H.; Validation, C.-W.L., F.-Y.H. and T.-W.C.; formal analysis, C.-W.L. and T.-W.C.; Investigation, C.-W.L. and T.-W.C.; Resources, F.-Y.H.; Data curation, C.-W.L.; Writing—original draft preparation, C.-W.L.; Writing—review and editing, F.-Y.H.; Visualization, C.-W.L.; Supervision, F.-Y.H.; Project administration, F.-Y.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors express their gratitude to Walsin Lihwa Co., Ltd., for their assistance with their materials. They also thank the Instrument Center of National Cheng Kung University of the Ministry of Science and Technology of Taiwan for their assistance in the material analysis (NSTC 111-2221-E-006-061-MY2).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jia, X.; Li, Y.; Xie, G.; Qi, T.; Zhang, W. Role of Mo addition on structure and magnetic properties of the Fe85Si2B8P4Cu1 nanocrystalline alloy. J. Non-Cryst. Solids 2018, 481, 590–593. [Google Scholar] [CrossRef]

- Fiorillo, F.; Bertotti, G.; Appino, C.; Pasquale, M. Soft magnetic materials. In Wiley Encyclopedia of Electrical and Electronics Engineering; John Wiley Sons, Inc.: Hoboken, NJ, USA, 2016; pp. 1–42. [Google Scholar]

- Lashgari, H.R.; Chu, D.; Xie, S.; Sun, H.; Ferry, M.; Li, S. Composition dependence of the microstructure and soft magnetic properties of Fe-based amorphous/nanocrystalline alloys: A review study. J. Non-Cryst. Solids 2014, 391, 61–82. [Google Scholar] [CrossRef]

- Ho, K. A constitutive model for the frequency dependence of magnetic hysteresis. Phys. B Condens. Matter 2014, 450, 143–145. [Google Scholar] [CrossRef]

- Mostaan, H.; Rafiei, M. Prediction and optimization of magnetic properties of laser welded AISI 430 Stainless steels. Arch. Metall. Mater. 2018, 63, 1673–1682. [Google Scholar] [CrossRef]

- Zhang, X.; Wen, Z.; Dou, R.; Zhou, G.; Li, Z. Evolution of microstructure and mechanical properties of cold-rolled SUS430 stainless steel during a continuous annealing process. Mater. Sci. Eng. A 2014, 598, 22–27. [Google Scholar] [CrossRef]

- Levchuk, L.; Shkarban, R.; Kotenko, I.; Graivoronska, K.; Fesenko, O.; Lukianenko, I.; Verbytska, T.; Makogon, I.; Barabash, M. Changes in raman spectra upon formation of ordered l10 FePd phase during annealing in vacuum and in hydrogen atmosphere. Thin Solid Films 2024, 789, 140200. [Google Scholar] [CrossRef]

- Lu, C.W.; Hung, F.Y.; Chang, T.W.; Hsieh, H.Y. Study and application on the electromagnetic stainless steel: Microstructure, tensile mechanical behavior, and magnetic properties. Materials 2024, 17, 2998. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.D.; Yen, T.Y.; Chen, J.Y. Electrical resistivity and magnetization studies of some commercial steels. Phys. Status Solidi 1986, 98, 285–289. [Google Scholar] [CrossRef]

- Hinton, J.S.; Beynon, J.H. A laboratory steckel mill simulation. Steel Res. Int. 2008, 79, 278–286. [Google Scholar] [CrossRef]

- Chang, Y.T.; Hung, F.Y.; Wu, B.D. Comparison of the microstructural characteristics and the electrothermal fracture mechanism of Au-Pd-Coated Copper wire and Cu-Ti micro-alloyed wire. J. Electron. Mater. 2024, 53, 1695–1707. [Google Scholar] [CrossRef]

- ASTM A262; Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels. American Society for Testing and Materials: West Conshohocken, PA, USA, 2011.

- Yang, K.; Gou, H.; Zhang, B.; Huang, R.; Li, H.; Lu, M.; Zhang, X.; Zhang, J. Microstructures and fracture features of cold-rolled low carbon steel sheet after annealing and mechanical stress concurrently loaded. Mater. Sci. Eng. A 2009, 502, 126–130. [Google Scholar] [CrossRef]

- Karolik, A.S.; Luhvich, A.A. Calculation of electrical resistivity produced by dislocations and grain boundaries in metals. J. Phys. Condens. Matter 1994, 6, 873–880. [Google Scholar] [CrossRef]

- Yaegashi, K. Dependence of magnetic susceptibility on dislocation density in tensile deformed iron and Mn-steel. ISIJ Int. 2007, 47, 327–332. [Google Scholar] [CrossRef]

- Meletis, E.I.; Lian, K. A vacancy/dislocation interaction mechanism of transgranular stress corrosion cracking. J. Mech. Behav. Mater. 1995, 6, 69–84. [Google Scholar] [CrossRef]

- Wang, J.A.; Chen, Y.; Luo, L.; Chen, J.; He, Y. Influence of cold rolling on the recrystallization texture and ridging of AISI 430 type ferritic stainless steel. J. Mater. Eng. Perform. 2021, 30, 3342–3351. [Google Scholar] [CrossRef]

- Hansen, N.; Jensen, D.J. Development of microstructure in FCC metals during cold work. Philos. Trans. R. Soc. London. Ser. A Math. Phys. Eng. Sci. 1999, 357, 1447–1469. [Google Scholar] [CrossRef]

- Bishara, H.; Lee, S.; Brink, T.; Ghidelli, M.; Dehm, G. Understanding grain boundary electrical resistivity in Cu: The effect of boundary structure. ACS Nano 2021, 15, 16607–16615. [Google Scholar] [CrossRef] [PubMed]

- Smialowski, M. Hydrogen in Steel: Effect of Hydrogen on Iron and Steel During Production, Fabrication, and Use; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Neeraj 2014, T.; Srinivasan, R.; Li, J. Hydrogen embrittlement of ferritic steels: Observations on deformation microstructure, nanoscale dimples and failure by nanovoiding. Acta Mater. 2012, 60, 5160–5171. [Google Scholar] [CrossRef]

- Calin, M.D.; Helerea, E.; Oltean, I.D. New considerations regarding frequency influence on soft magnetic materials characteristics. In Proceedings of the 2010 3rd International Symposium on Electrical and Electronics Engineering (ISEEE), Galati, Romania, 16–18 September 2010; pp. 39–44. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).