Application of CH241 Stainless Steel with High Concentration of Mn and Mo: Microstructure, Mechanical Properties, and Tensile Fatigue Life

Abstract

1. Introduction

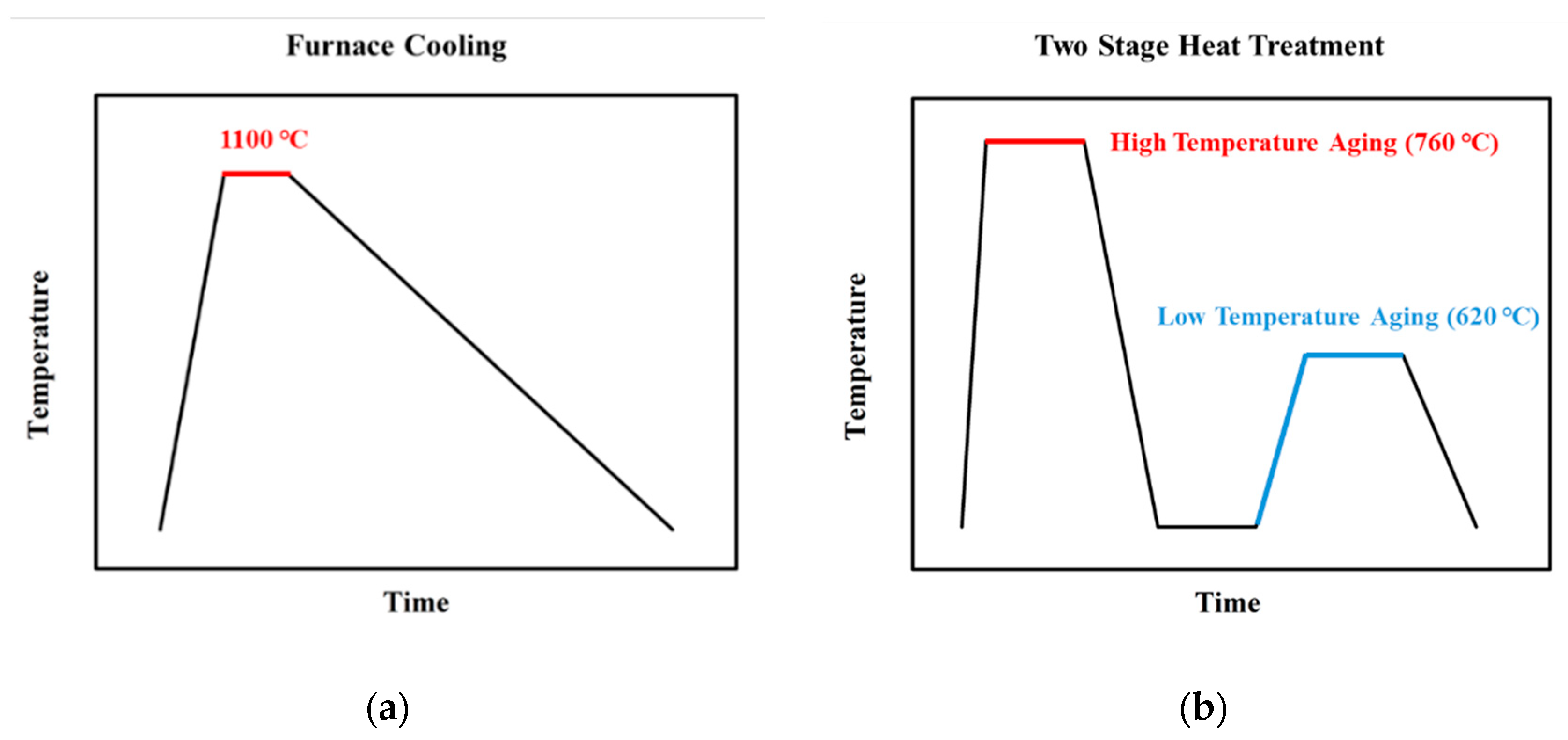

2. Experimental Procedure

3. Results and Discussion

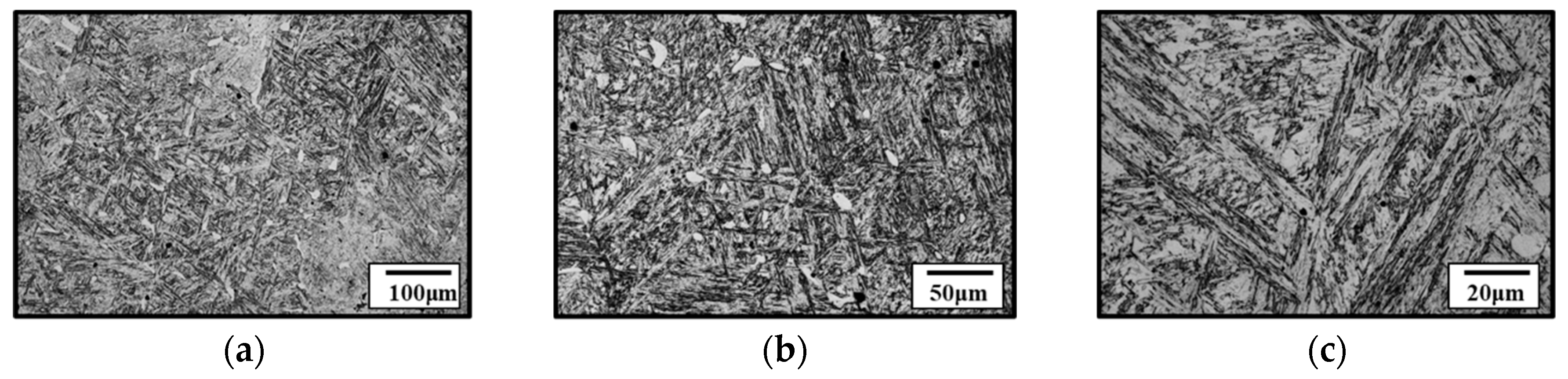

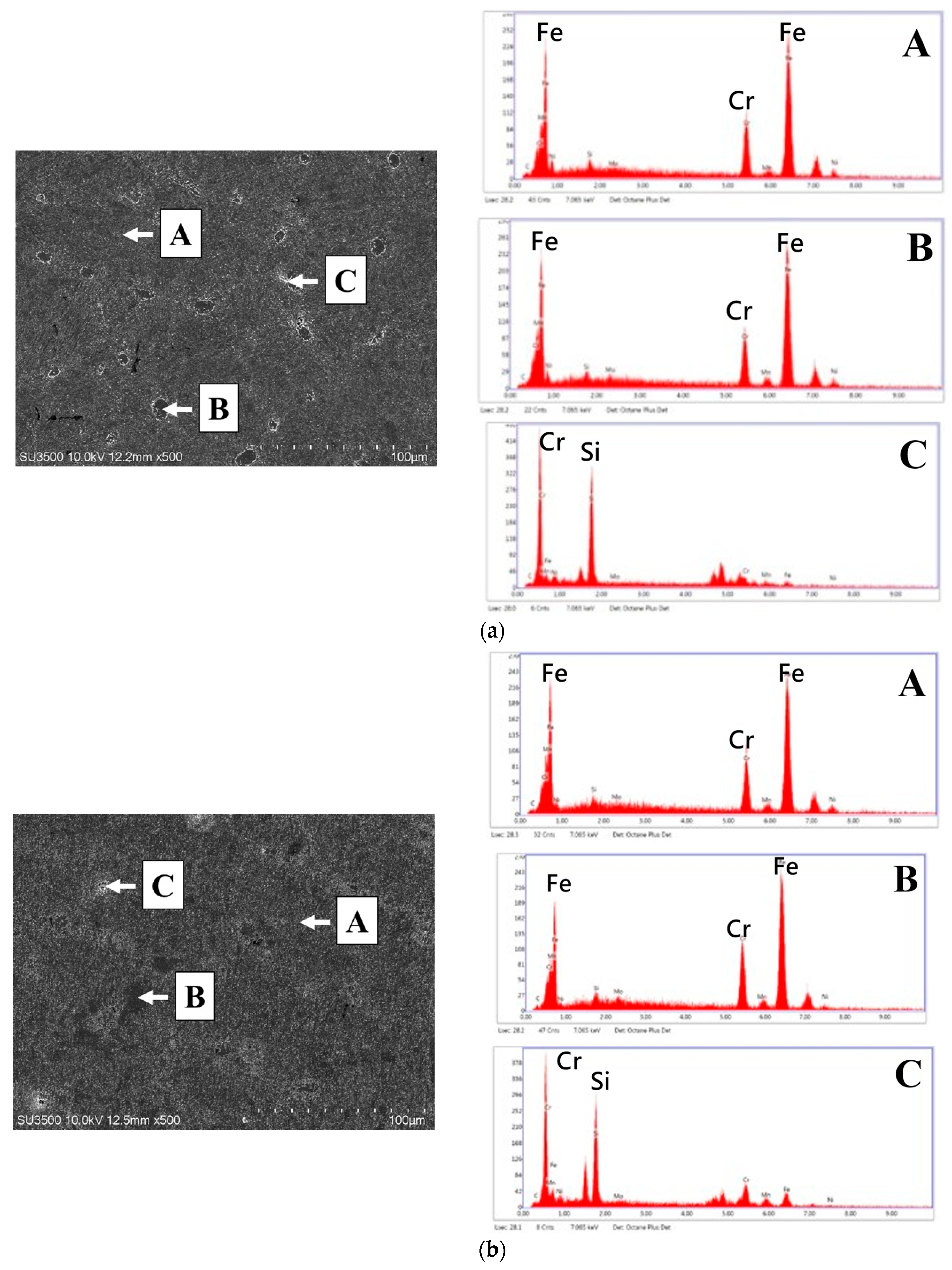

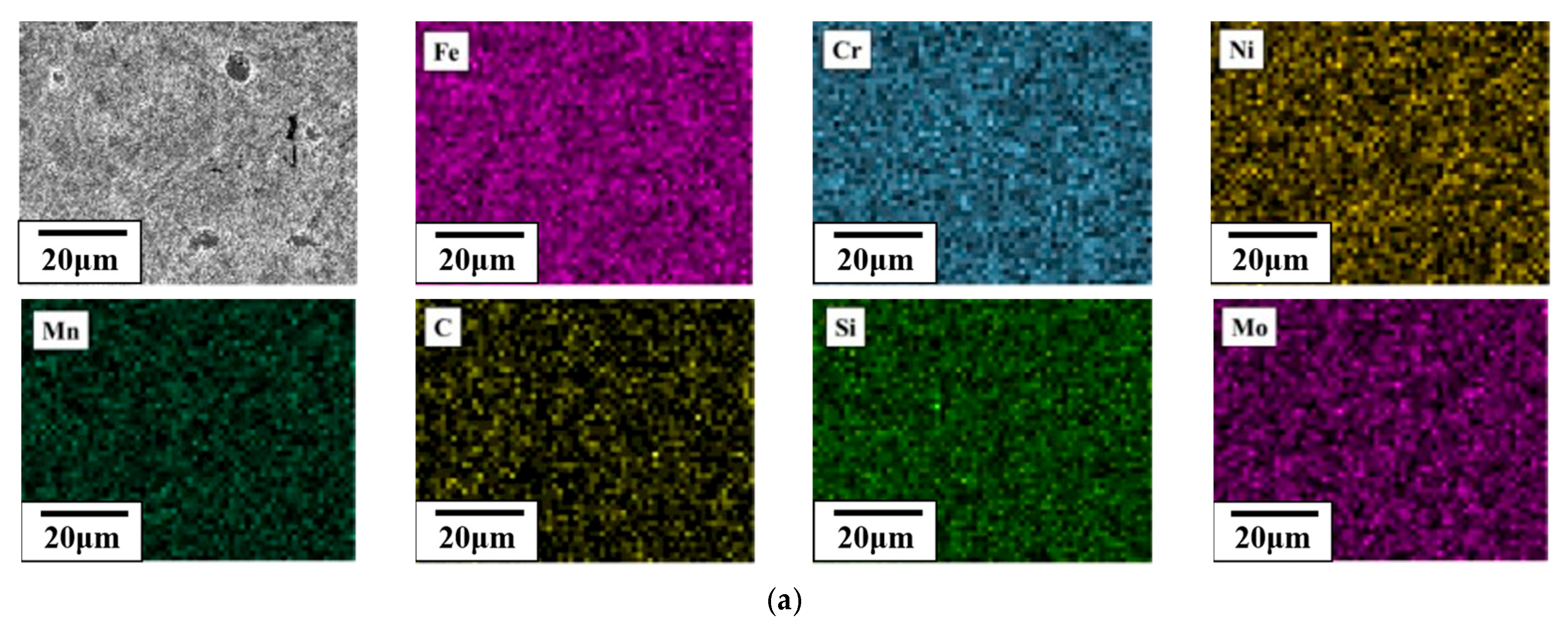

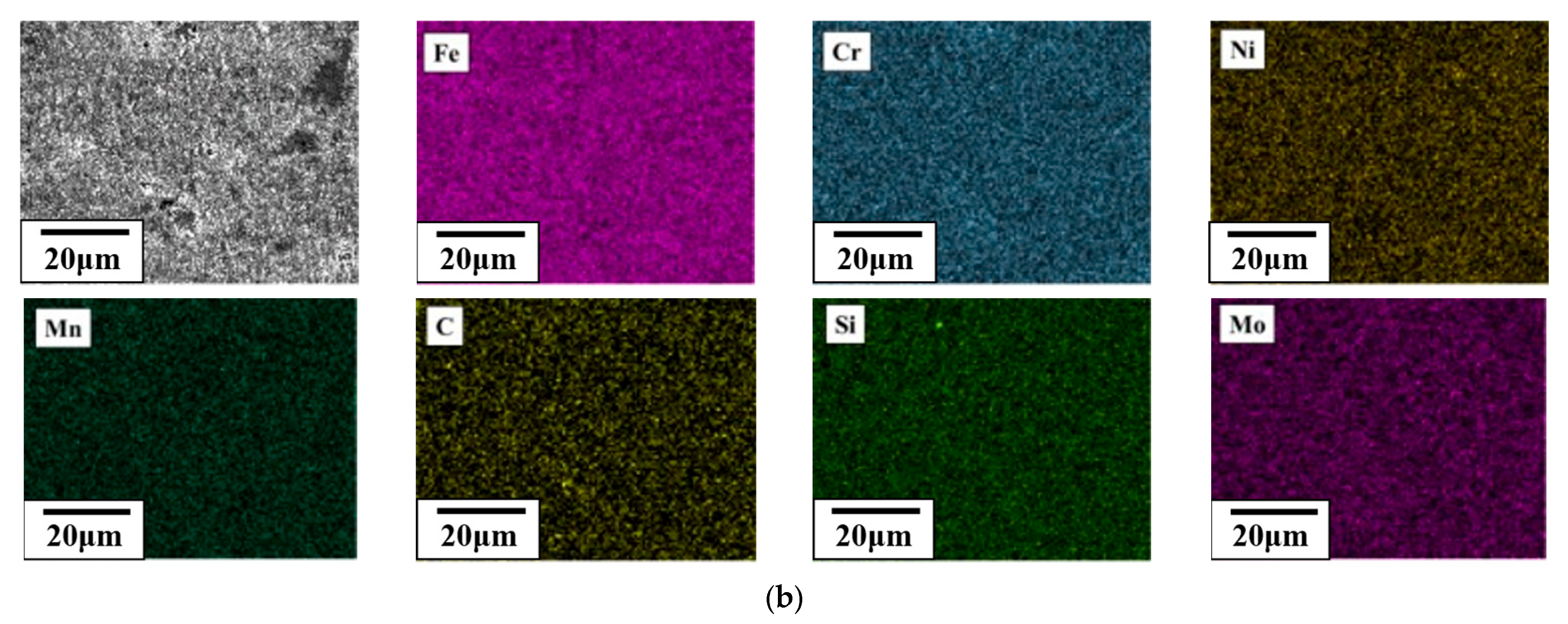

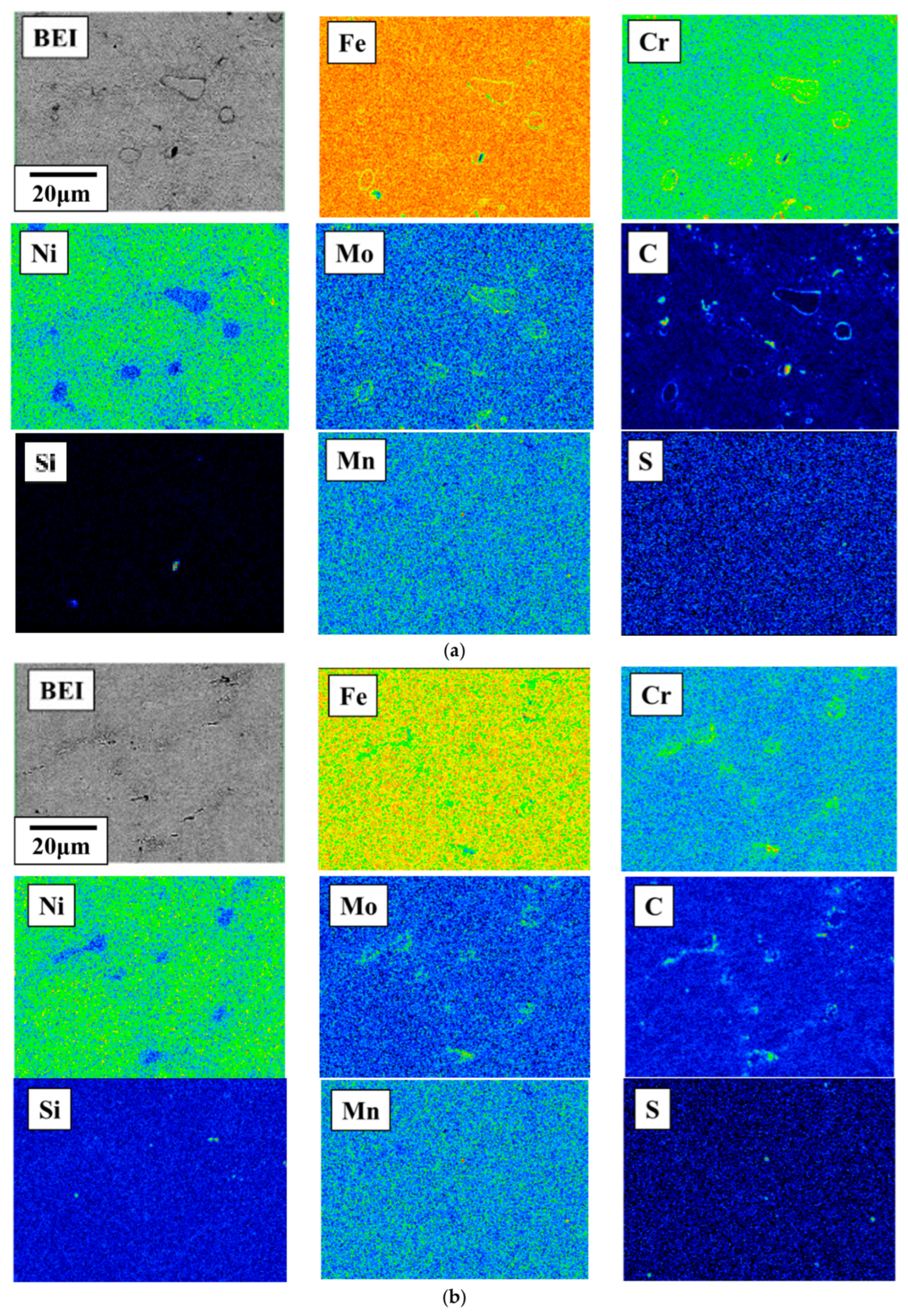

3.1. Microstructure of CH241-C and CH241-FC

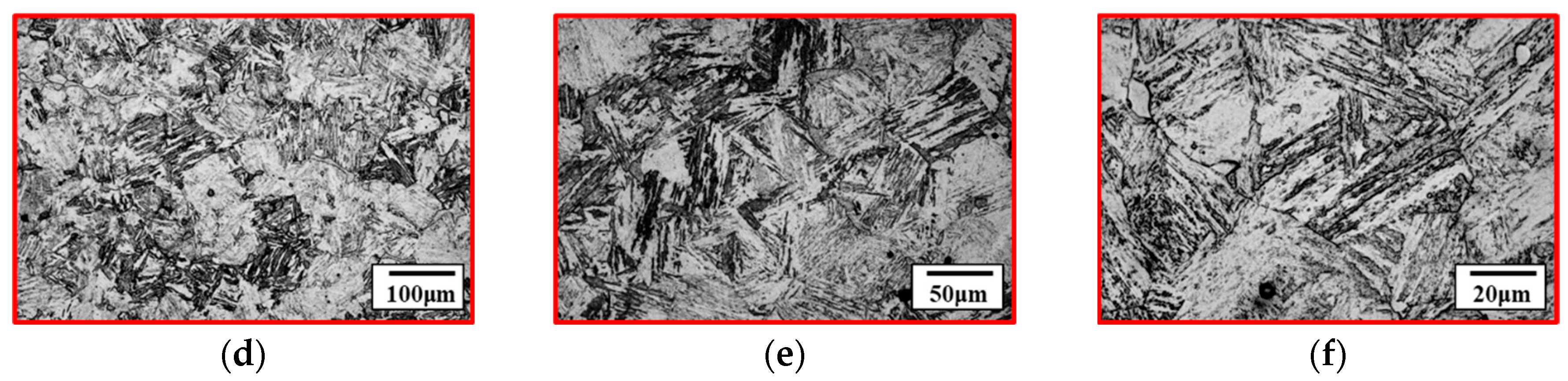

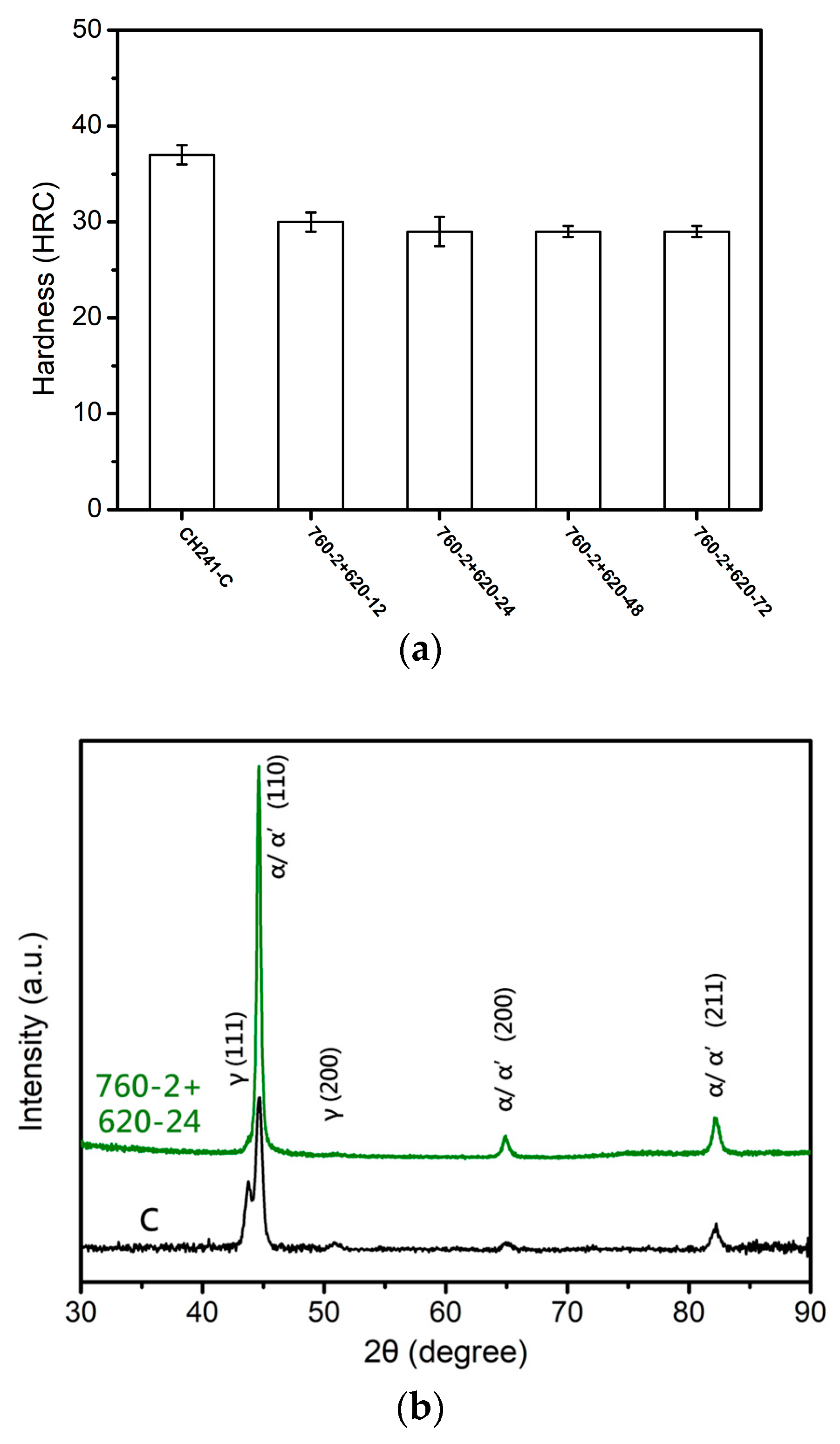

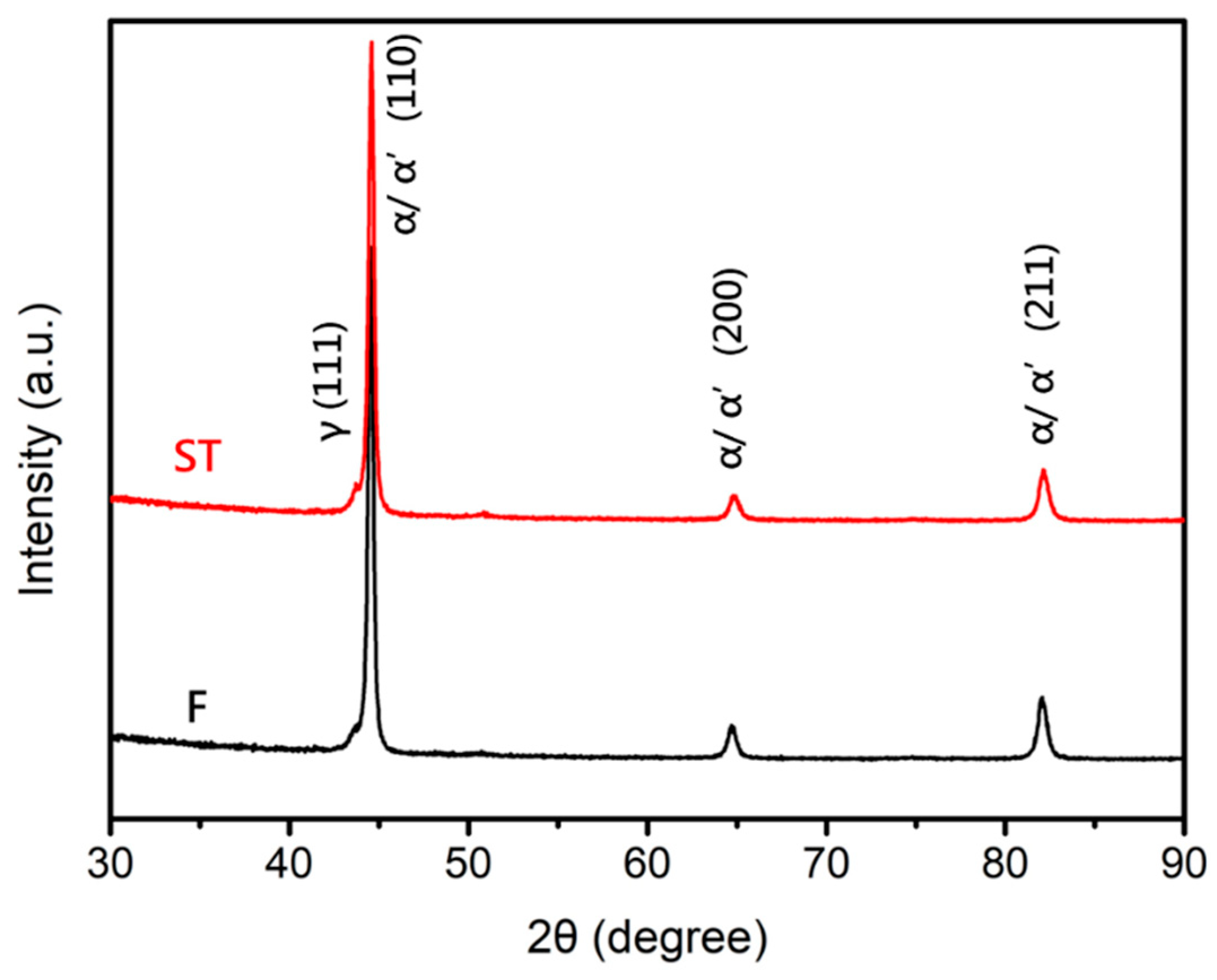

3.2. Phase Transformation of CH241 with Two-Stage Heat Treatment

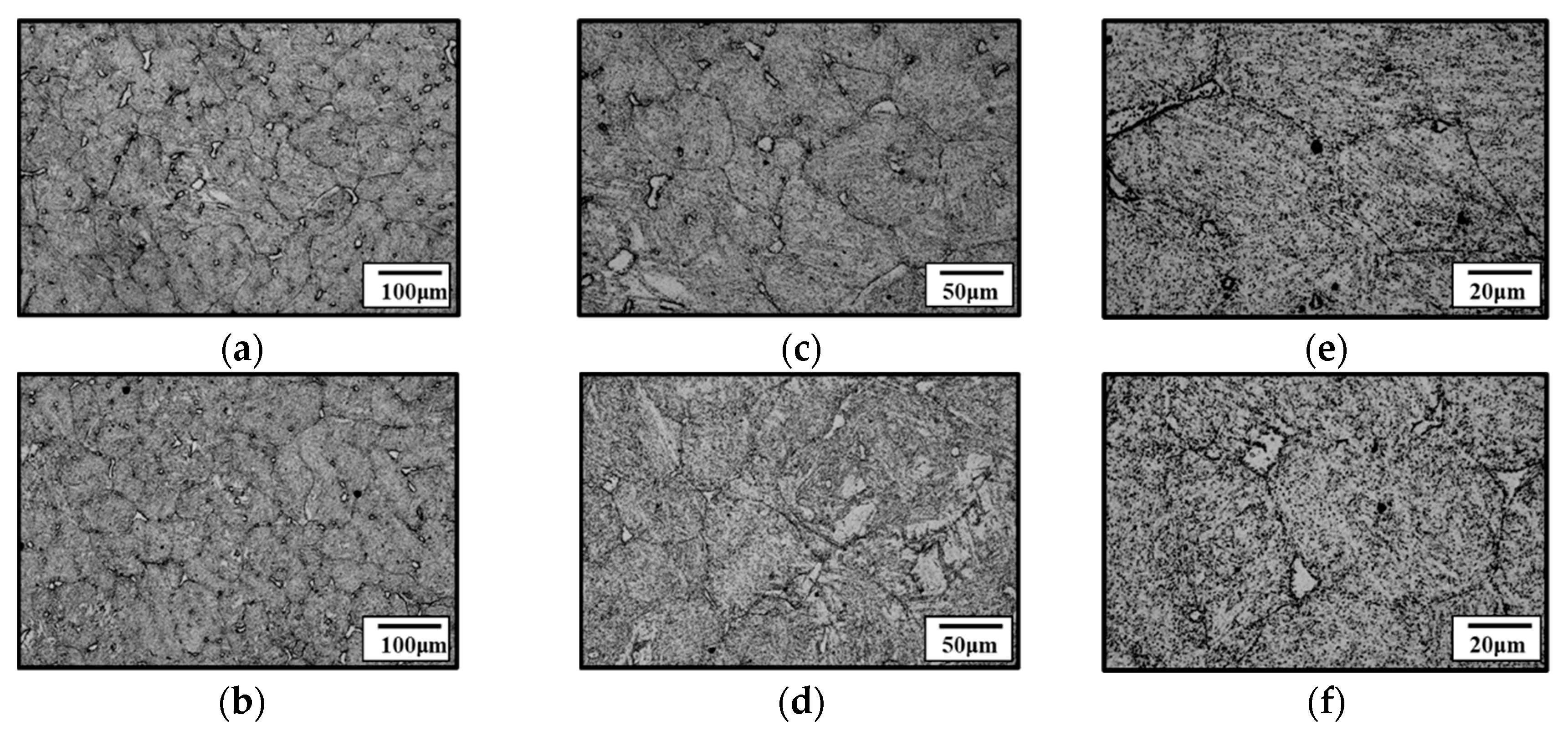

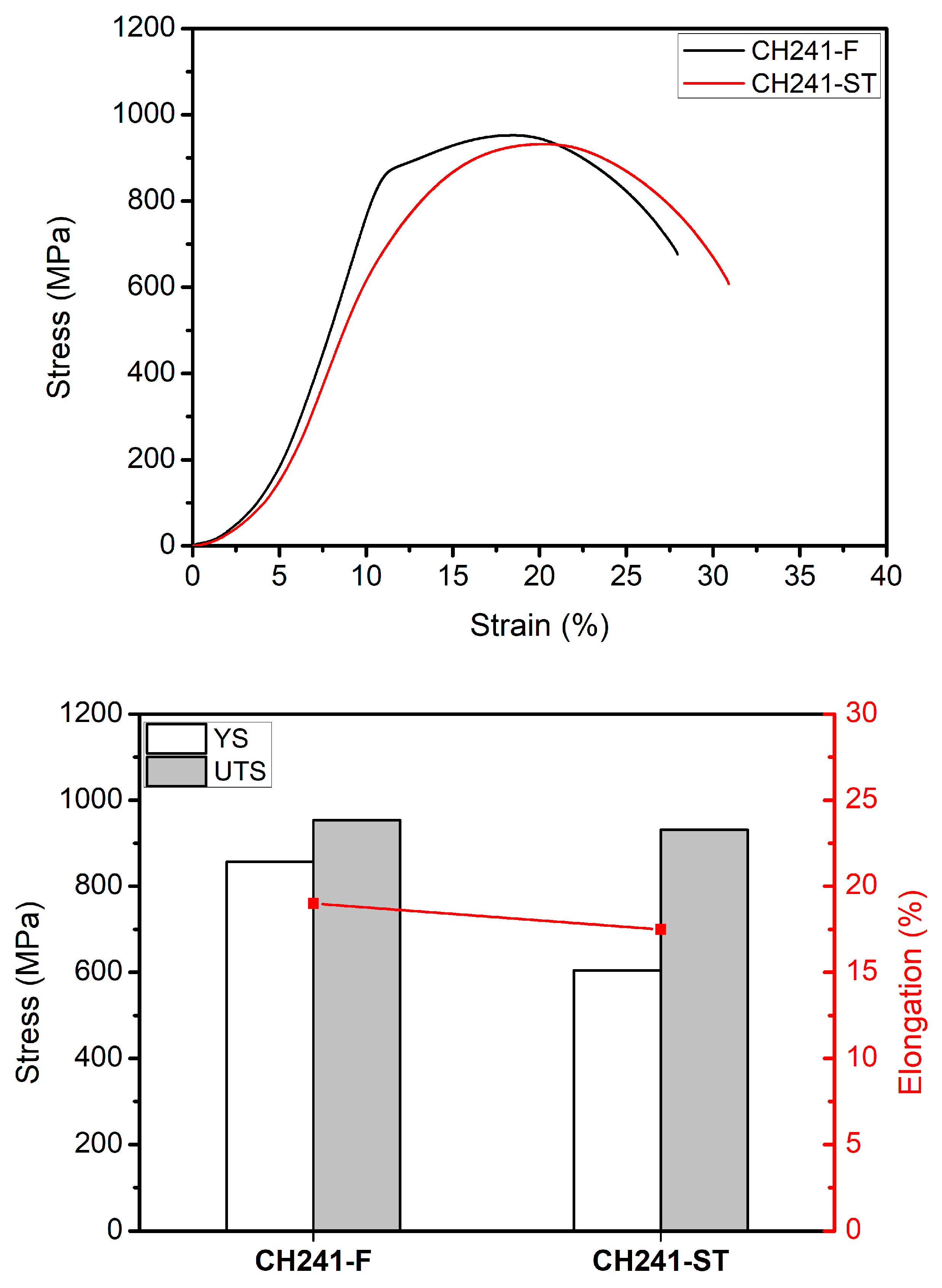

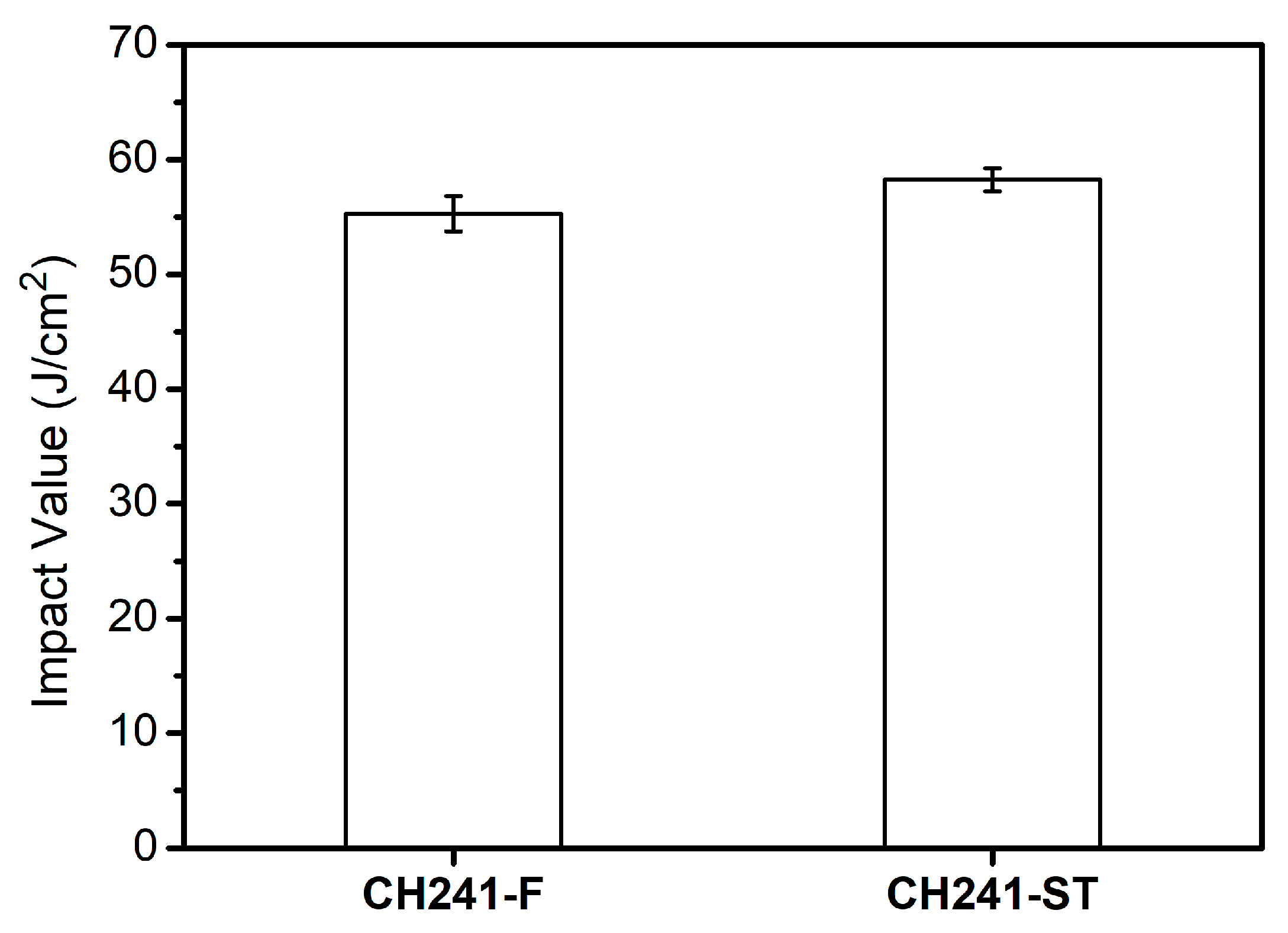

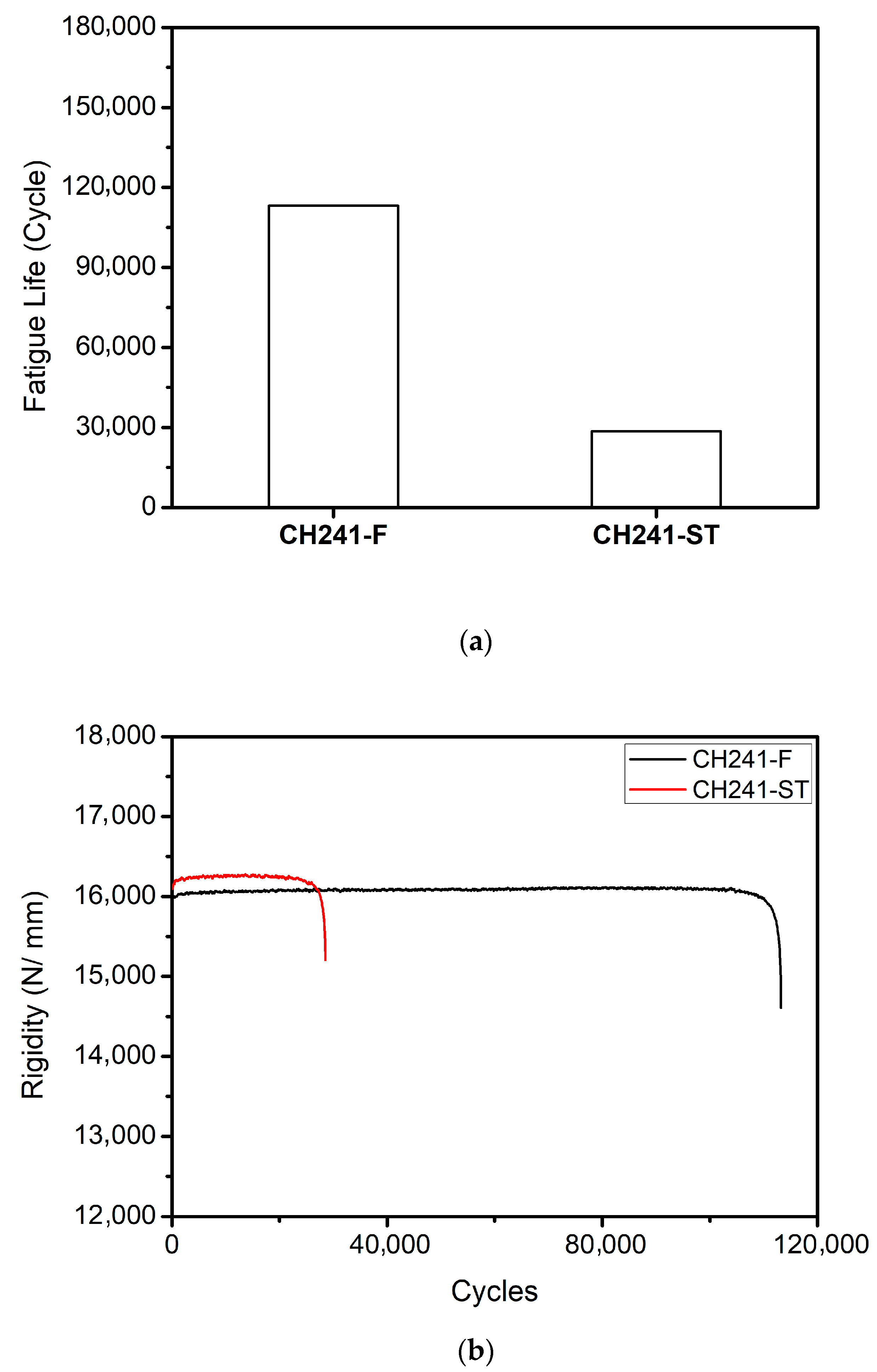

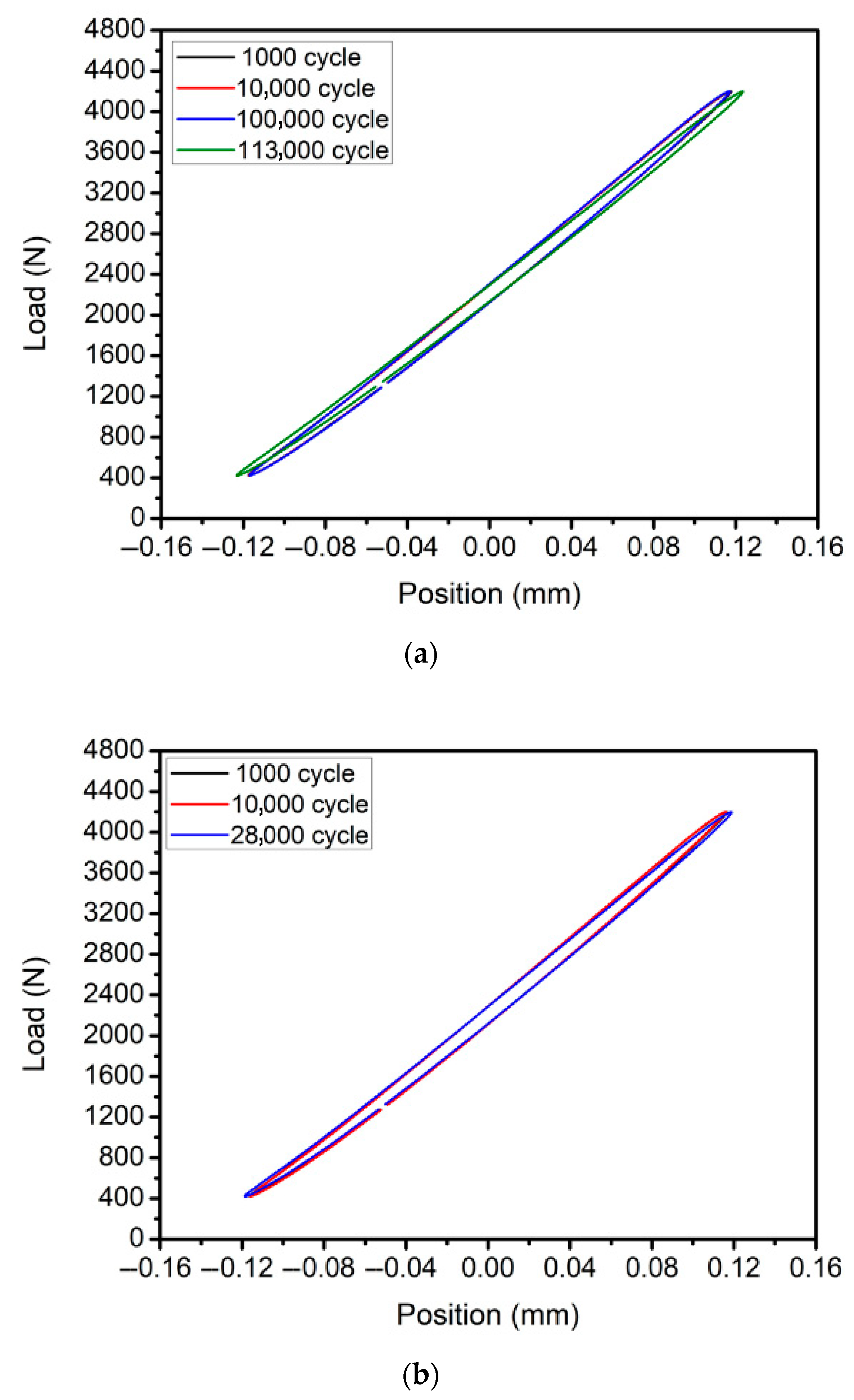

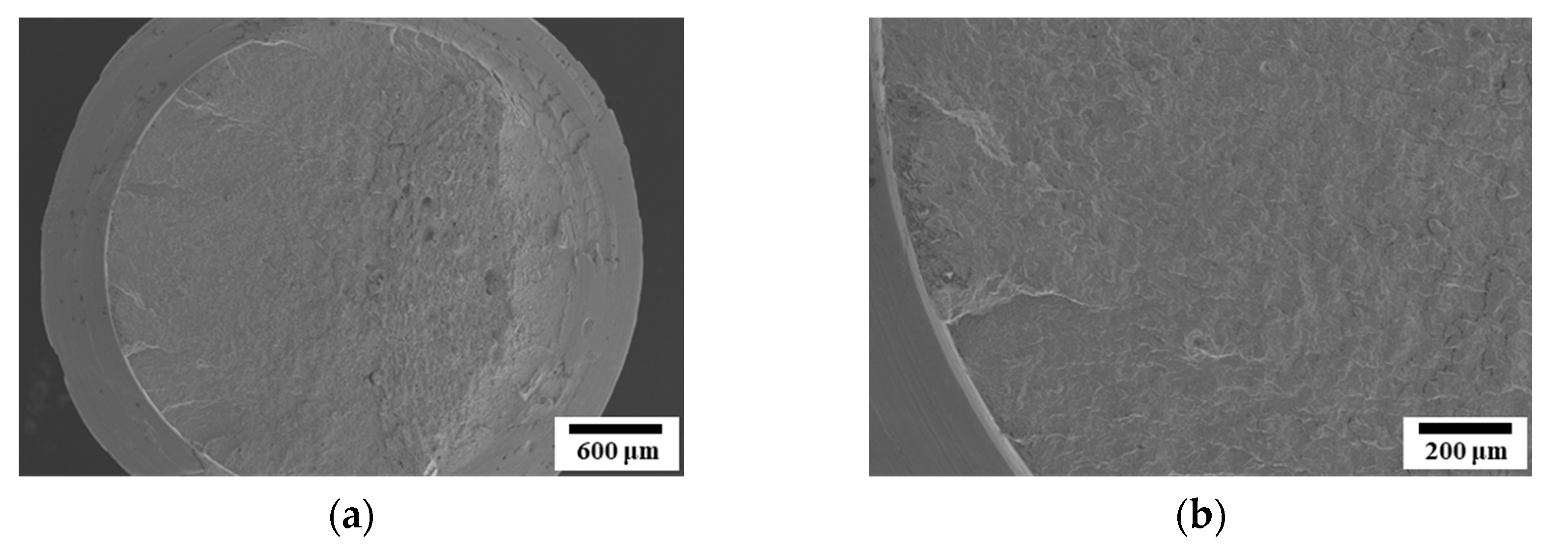

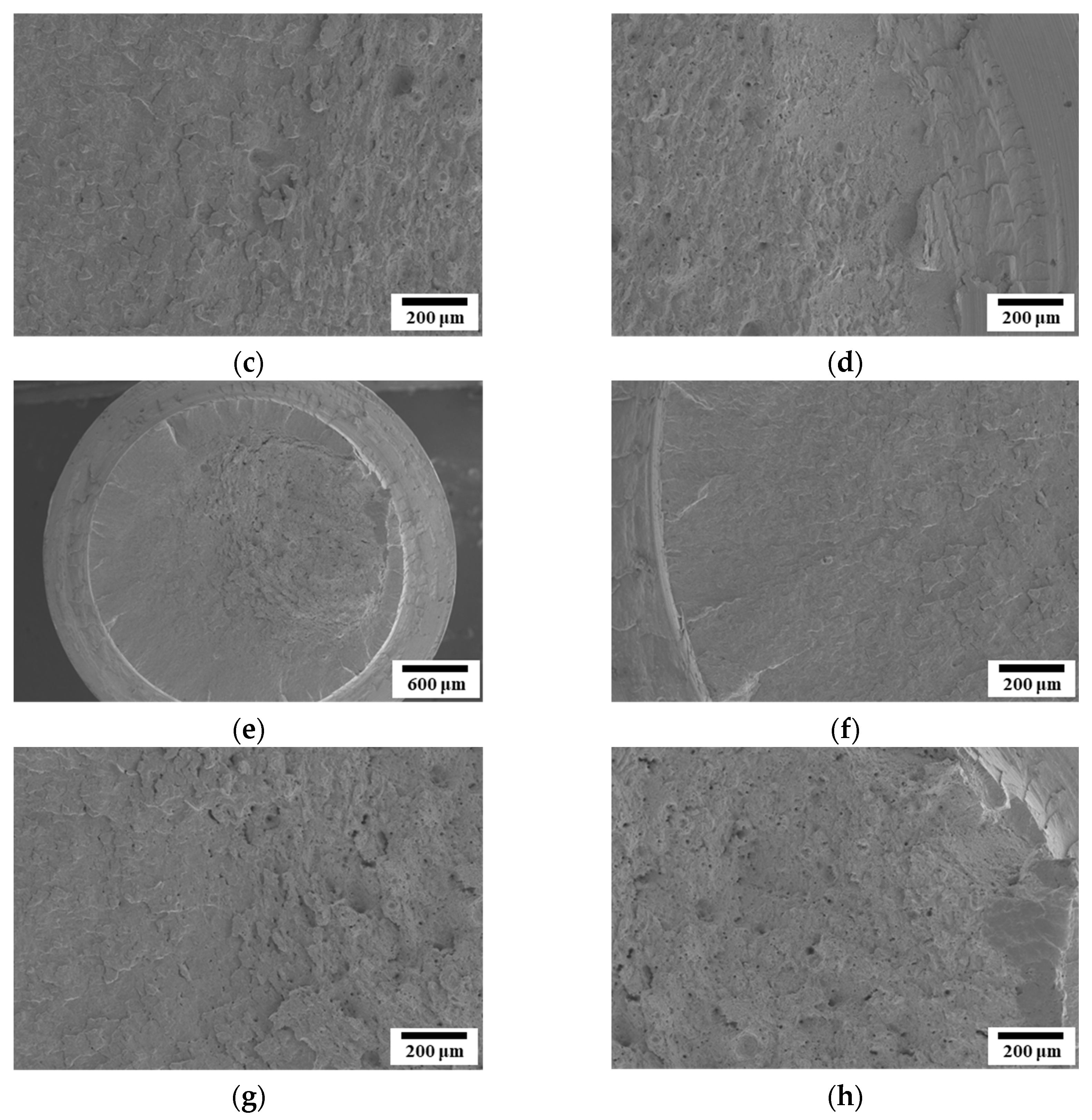

3.3. Mechanical Properties and Tensile Fatigue Life of CH241

4. Conclusions

- (1)

- CH241-C was designed and developed primarily to consist of ferrite (α), martensite (ά), austenite (γ), and carbides. After furnace cooling, the content of the martensite phase (ά) increased with the precipitation of carbides, resulting in an increase in the hardness from HRC 37 to 46.

- (2)

- The two-stage heat treatment facilitated the transformation of the martensitic phase of CH241-C into CH241-C-ST with ferrite and carbides. The coarsening of precipitates (Cr(Ni-Mo)C carbides) resulted in a decrease in hardness from HRC 37 to HRC 29, thereby meeting the conditions required for the cold-forging process.

- (3)

- CH241-F exhibited high strength and excellent ductility. The refined grain structure and precipitation strengthening effectively delayed fracture crack formation. In contrast, the CH241-ST material retained austenite after undergoing a two-stage heat treatment owing to an incomplete γ ά transformation, which influenced its mechanical properties.

- (4)

- CH241-ST satisfies the mechanical requirements for cold forging and exhibits superior mechanical strength and impact toughness. Tensile fatigue test confirmed that CH241-ST has an excellent fatigue life. The fracture characteristics show that the soft-tough matrix can inhibit the propagation of fatigue cracks.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dalmau, A.; Richard, C.; Igual–Muñoz, A. Degradation mechanisms in martensitic stainless steels: Wear, corrosion and tribo-corrosion appraisal. Tribol. Int. 2018, 121, 167–179. [Google Scholar] [CrossRef]

- Bai, Z.; Su, N.; Yang, H.; Wu, X. Wear characteristics of austenitic steel and martensitic steel at high temperature. Mater. Res. Express 2022, 9, 086504. [Google Scholar] [CrossRef]

- Yeddu, H.K.; Shaw, B.A.; Somers, M.A.J. Effect of thermal cycling on martensitic transformation and mechanical strengthening of stainless steels-A phase-field study. Mater. Sci. Eng. A 2017, 690, 1–5. [Google Scholar] [CrossRef]

- Manne, V.; Singh, S.K.; Sateesh, N.; Subbiah, R. A review on influence of nitriding on AISI430 ferritic stainless steel. Mater. Today Proc. 2020, 26, 1010–1013. [Google Scholar] [CrossRef]

- Yu, Y.C.; Zhang, S.H.; Wang, S.B. Effects of Cerium on the inclusions and pitting corrosion behavior of 434 ferritic stainless steel. High Temp. Mater. Process. 2018, 37, 807–814. [Google Scholar] [CrossRef]

- Wang, J.-M.; Qian, S.-S.; Liu, Y.-Y.; Sun, Y.-T.; Jiang, Y.-M.; Li, J.M. Crevice corrosion performance of 436 Ferritic stainless steel studied by different electrochemical techniques in sodium chloride solutions with sulfate addition. Acta Metall. Sin. (Engl. Lett.) 2018, 31, 815–822. [Google Scholar] [CrossRef]

- Chakraborty, G.; Das, C.R.; Albert, S.K.; Bhaduri, A.K.; Paul, V.T.; Panneerselvam, G.; Dasgupta, A. Study on tempering behavior of AISI 410 stainless steel. Mater. Charact. 2015, 100, 81–87. [Google Scholar] [CrossRef]

- Lin, Y.; Lin, C.-C.; Tsai, T.-H.; Lai, H.-J. Microstructure and mechanical properties of 0.63 C-12.7 Cr martensitic stainless steel during various tempering treatments. Mater. Manuf. Process. 2010, 25, 246–248. [Google Scholar] [CrossRef]

- Tian, Q.; Xu, X.; Li, J.; Liu, N.; Wu, X.; Shen, P.; Fu, J. Formation mechanism of band delta-ferrite in 416 stainless steel and its relationship with MnS and M23C6. Metall. Mater. Trans. B 2021, 52, 2355–2363. [Google Scholar] [CrossRef]

- Mabruri, E.; Prifiharni, S.; Anwar, M.S.; Romijarso, T.B.; Adjiantoro, B. Mechanical properties optimization of the modified 410 martensitic stainless steel by heat treatment process. Mater. Today Proc. 2018, 5, 14918–14922. [Google Scholar] [CrossRef]

- Ezechidelu, J.C.; O Enibe, S.; O Obikwelu, D.; Nnamchi, P.S.; Obayi, C.S. Effect of heat treatment on the microstructure and mechanical properties of a welded AISI 410 martensitic stainless steel. Int. Adv. Res. J. Sci. Eng. Technol. 2016, 3, 6–12. [Google Scholar] [CrossRef]

- Viswanathan, U.K.; Banerjee, S.; Krishnan, R. Effects of aging on the microstructure of 17-4 PH stainless steel. Mater. Sci. Eng. A 1988, 104, 181–189. [Google Scholar] [CrossRef]

- Maki, T.; Tsuzaki, K.; Tamura, I. The morphology of microstructure composed of lath martensites in steels. Trans. Iron Steel Inst. Jpn. 1980, 20, 207–214. [Google Scholar] [CrossRef]

- Morito, S.; Huang, X.; Furuhara, T.; Maki, T.; Hansen, N. The morphology and crystallography of lath martensite in alloy steels. Acta Mater. 2006, 54, 5323–5331. [Google Scholar] [CrossRef]

- Fan, Y.; Liu, T.G.; Xin, L.; Han, Y.M.; Lu, Y.H.; Shoji, T. Thermal aging behaviors of duplex stainless steels used in nuclear power plant: A review. J. Nucl. Mater. 2021, 544, 152693. [Google Scholar] [CrossRef]

- Cardoso, P.H.S.; Kwietniewski, C.; Porto, J.P.; Reguly, A.; Strohaecker, T.R. The influence of delta ferrite in the AISI 416 stainless steel hot workability. Mater. Sci. Eng. A 2003, 351, 1–8. [Google Scholar] [CrossRef]

- Zhou, Y.; Engelberg, D.L. Accessing the full spectrum of corrosion behaviour of tempered type 420 stainless steel. Mater. Corros. 2021, 72, 1718–1729. [Google Scholar] [CrossRef]

- Chang, K.-C.; Kuo, Y.-A.; Hung, F.-Y. Ga-bath austempering for sustainable heat treatment: Microstructure, mechanical properties, and corrosion resistance of martensitic stainless steel. Next Mater. 2025, 8, 100712. [Google Scholar] [CrossRef]

- Dev, S.; Ramkumar, K.D.; Arivazhagan, N.; Rajendran, R. Investigations on the microstructure and mechanical properties of dissimilar welds of inconel 718 and sulphur rich martensitic stainless steel, AISI 416. J. Manuf. Process. 2018, 32, 685–698. [Google Scholar] [CrossRef]

| wt.% | Cr | Ni | C | Si | Mn | P | S | Mo | Fe |

|---|---|---|---|---|---|---|---|---|---|

| CH241 | 18.00 | 4.00 | 0.15 | 1.00 | 1.30 | 0.04 | 0.03 | 0.60 | Bal. |

| Furnace Cooling | 1100 °C-0.5 h |

|---|---|

| Two-Stage Heat Treatments | 760 °C-2 h (AC) + 620 °C-12 h (AC) |

| 760 °C-2 h (AC) + 620 °C-24 h (AC) | |

| 760 °C-2 h (AC) + 620 °C-48 h (AC) | |

| 760 °C-2 h (AC) + 620 °C-72 h (AC) |

| wt.% | No. | Fe | Cr | Ni | Mn | C | Si | Mo |

|---|---|---|---|---|---|---|---|---|

| CH241-C | A | 73.46 | 19.28 | 2.86 | 1.55 | 1.46 | 0.70 | 0.69 |

| B | 80.90 | 14.49 | 1.57 | 0.01 | 1.85 | 0.78 | 0.40 | |

| C | 13.26 | 39.37 | 5.96 | 10.84 | 6.63 | 22.81 | 0.85 | |

| CH241-FC | A | 75.91 | 14.94 | 5.43 | 1.14 | 1.47 | 0.59 | 0.51 |

| B | 74.62 | 19.06 | 2.40 | 0.95 | 1.70 | 0.66 | 0.61 |

| wt.% | No. | Fe | Cr | Ni | Mn | C | Si | Mo |

|---|---|---|---|---|---|---|---|---|

| 760C-2 h + 620C-24 h | A | 74.48 | 16.32 | 5.94 | 1.27 | 1.15 | 0.49 | 0.34 |

| B | 74.98 | 19.10 | 2.92 | 0.99 | 0.91 | 0.55 | 0.55 | |

| C | 23.97 | 32.49 | 3.80 | 9.45 | 8.58 | 20.79 | 0.92 | |

| 760C-2 h + 620C-72 h | A | 73.11 | 16.83 | 5.46 | 1.49 | 1.66 | 0.73 | 0.72 |

| B | 76.31 | 15.18 | 5.70 | 1.00 | 1.13 | 0.38 | 0.30 | |

| C | 11.01 | 32.96 | 4.49 | 9.35 | 10.16 | 31.55 | 0.48 |

| Types | I (J/cm2) | |

|---|---|---|

| CH241 | F | 55.306 |

| ST | 58.276 | |

| Material | Hardness (HRC) | YS (MPa) | UTS (MPa) |

|---|---|---|---|

| CH241-F | 32 | 857 | 953 |

| CH241-ST | 26 | 605 | 932 |

| AISI-416 | 17 | 545 | 681 |

| Material | Elongation (%) | Impact Value (J/cm2) | Fatigue Life-600 MPa (Cycles) |

| CH241-F | 19.0 | 55.306 | 113,207 |

| CH241-ST | 17.5 | 58.276 | 28,519 |

| AISI-416 | 24.5 | 50.996 | 16,011 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsieh, P.-Y.; Wu, B.-D.; Hung, F.-Y. Application of CH241 Stainless Steel with High Concentration of Mn and Mo: Microstructure, Mechanical Properties, and Tensile Fatigue Life. Metals 2025, 15, 863. https://doi.org/10.3390/met15080863

Hsieh P-Y, Wu B-D, Hung F-Y. Application of CH241 Stainless Steel with High Concentration of Mn and Mo: Microstructure, Mechanical Properties, and Tensile Fatigue Life. Metals. 2025; 15(8):863. https://doi.org/10.3390/met15080863

Chicago/Turabian StyleHsieh, Ping-Yu, Bo-Ding Wu, and Fei-Yi Hung. 2025. "Application of CH241 Stainless Steel with High Concentration of Mn and Mo: Microstructure, Mechanical Properties, and Tensile Fatigue Life" Metals 15, no. 8: 863. https://doi.org/10.3390/met15080863

APA StyleHsieh, P.-Y., Wu, B.-D., & Hung, F.-Y. (2025). Application of CH241 Stainless Steel with High Concentration of Mn and Mo: Microstructure, Mechanical Properties, and Tensile Fatigue Life. Metals, 15(8), 863. https://doi.org/10.3390/met15080863