Residual Stress and Corrosion Performance in L-PBF Ti6Al4V: Unveiling the Optimum Stress Relieving Temperature via Microcapillary Electrochemical Characterisation

Abstract

1. Introduction

2. Materials and Methods

2.1. L-PBF Processing and Sample Preparation

2.2. Microstructural Characterization and XRD Analysis

2.3. Electrochemical Analysis

2.3.1. Electrochemical Response in Borate Buffer Solution Without Applied Load

2.3.2. Stress-Assisted Electrochemical Response in Saliva Solution with NaF Contamination

3. Results and Discussion

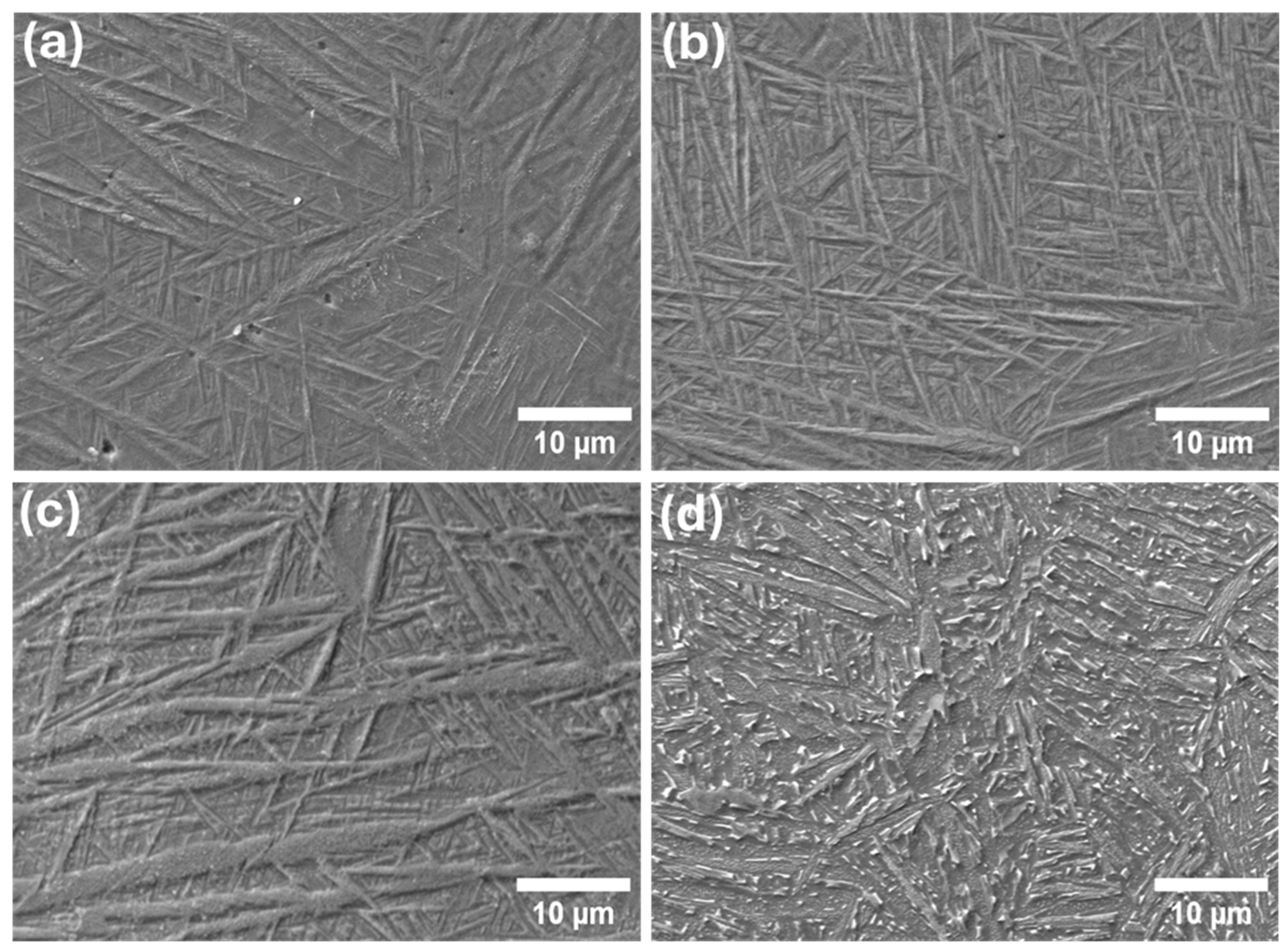

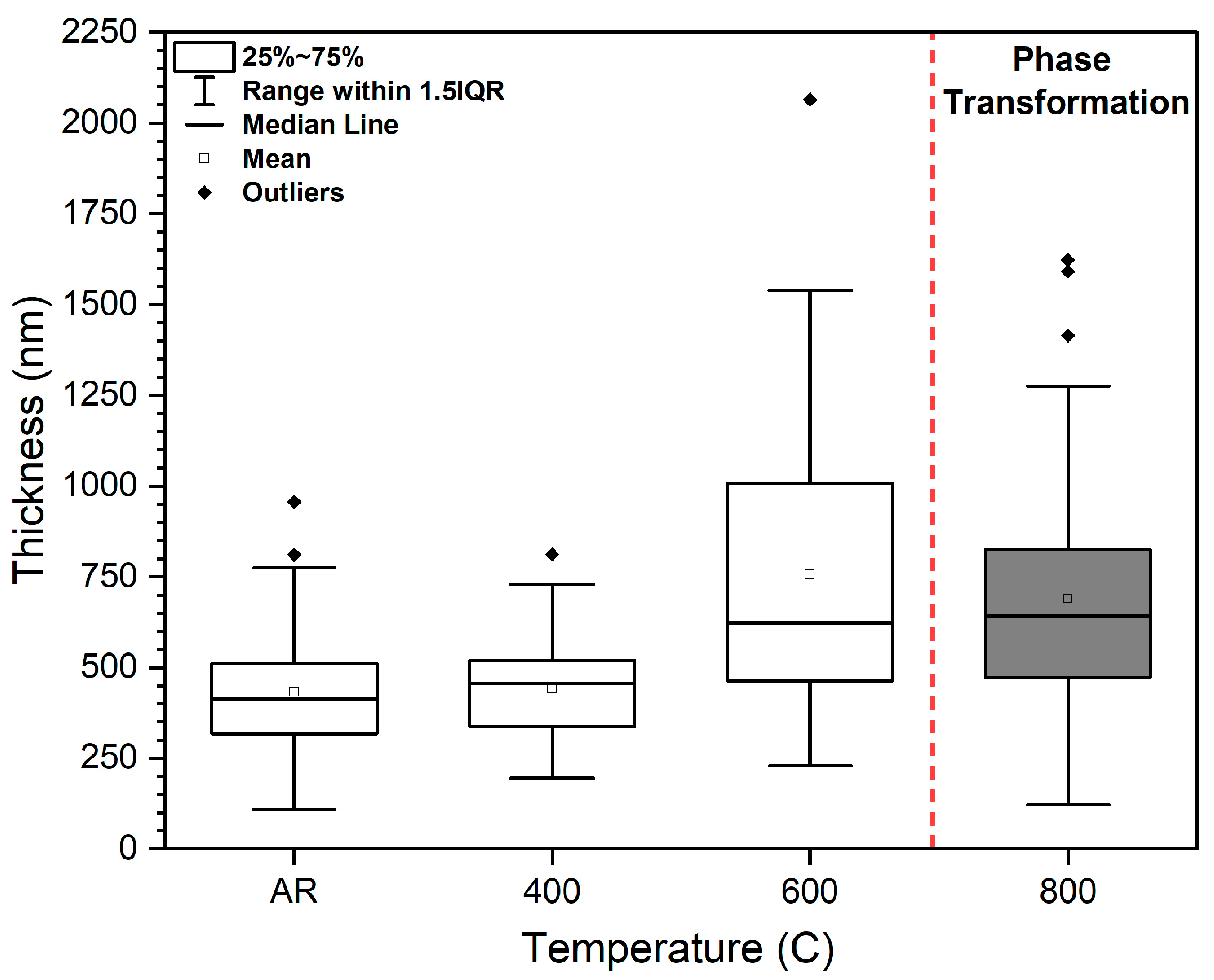

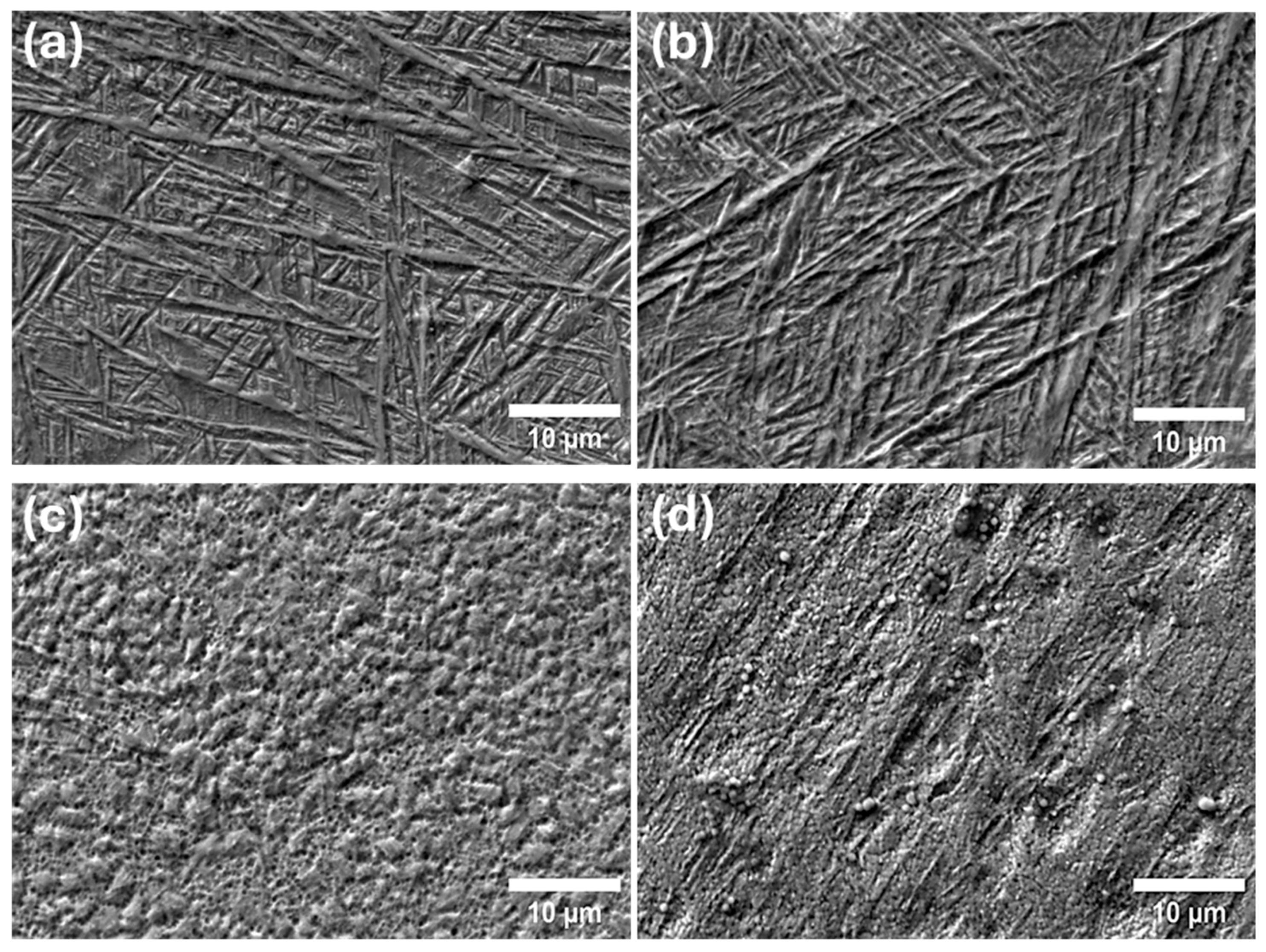

3.1. Microstructural Analysis

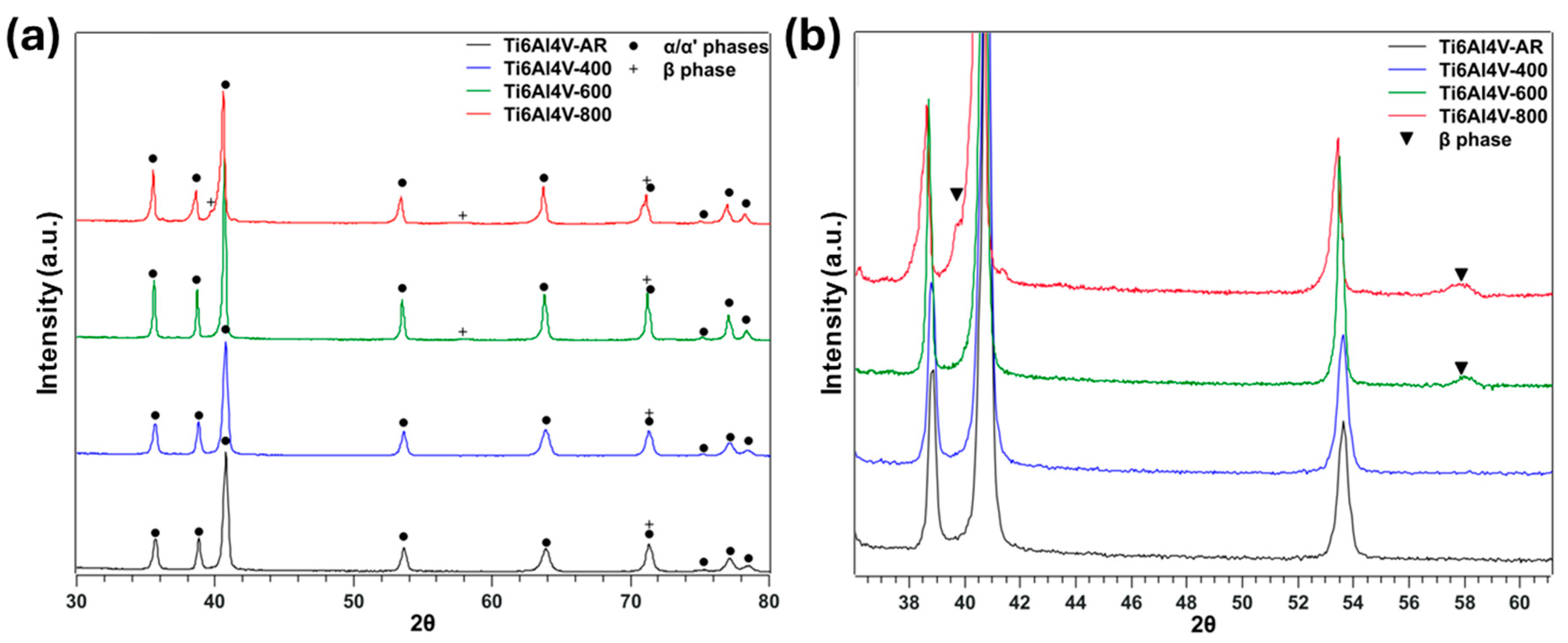

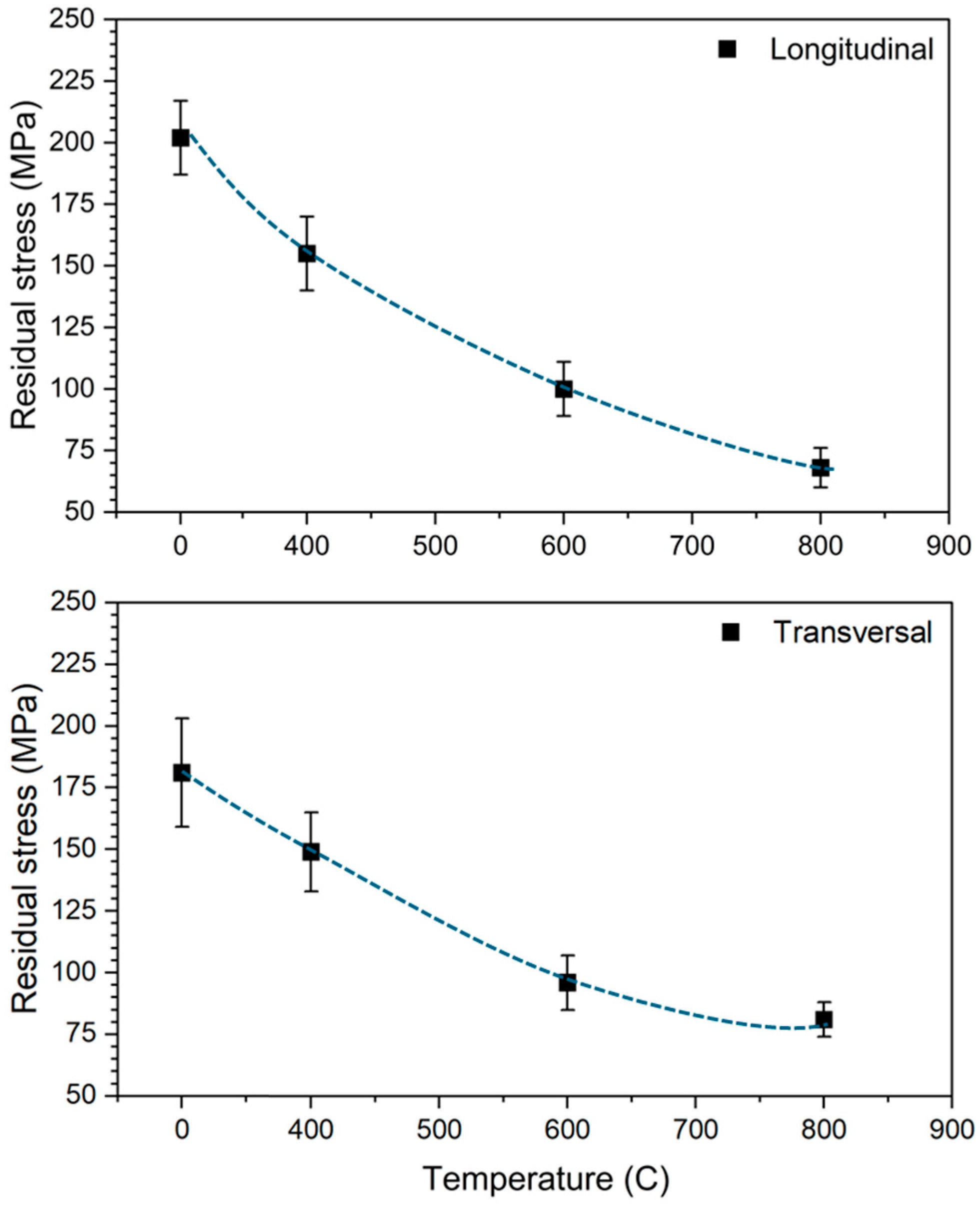

3.2. XRD Analysis

3.3. Electrochemical Analysis

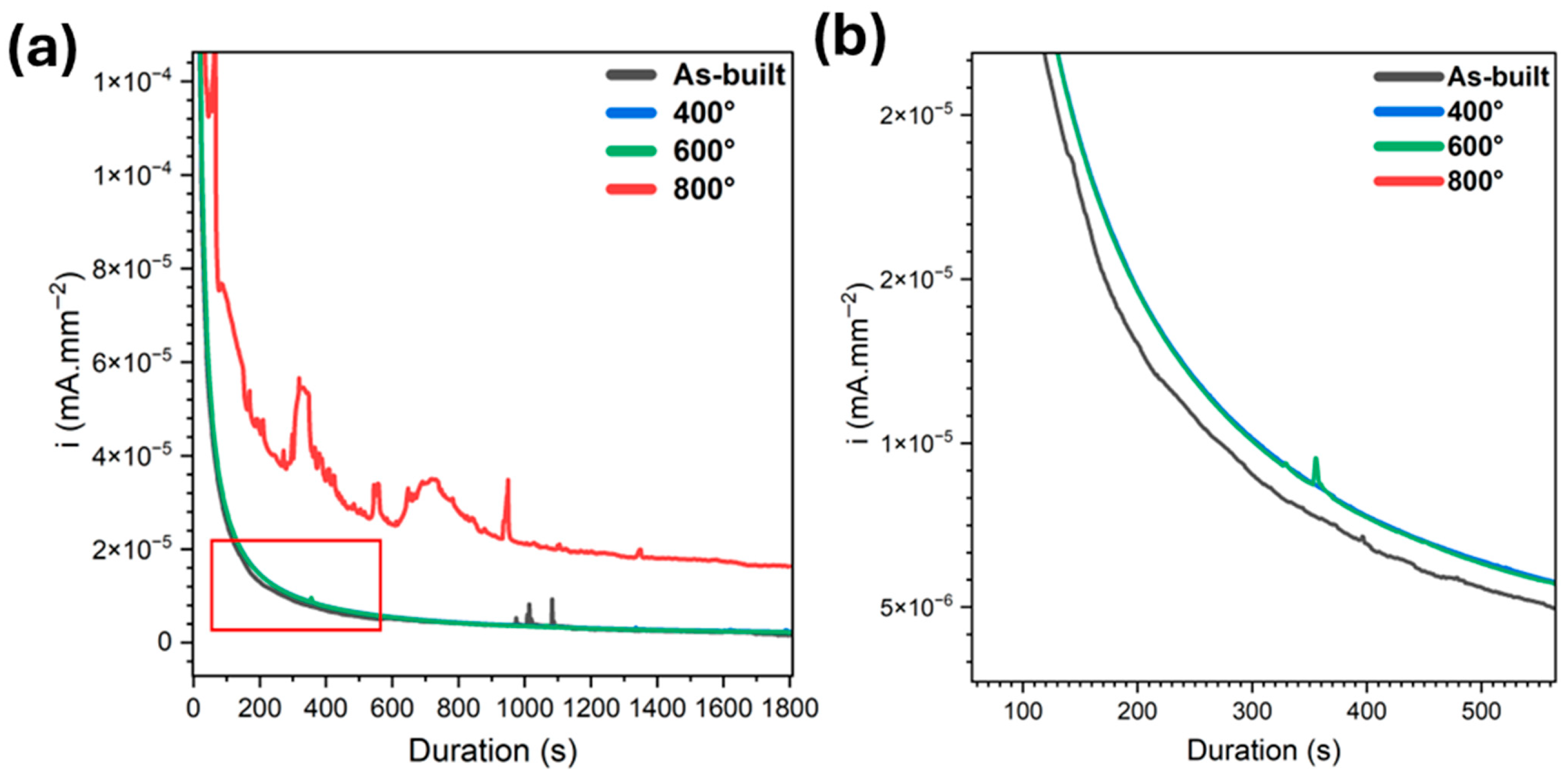

3.3.1. Electrochemical Impedance Spectroscopy (EIS) Analysis in Borate Buffer Solution

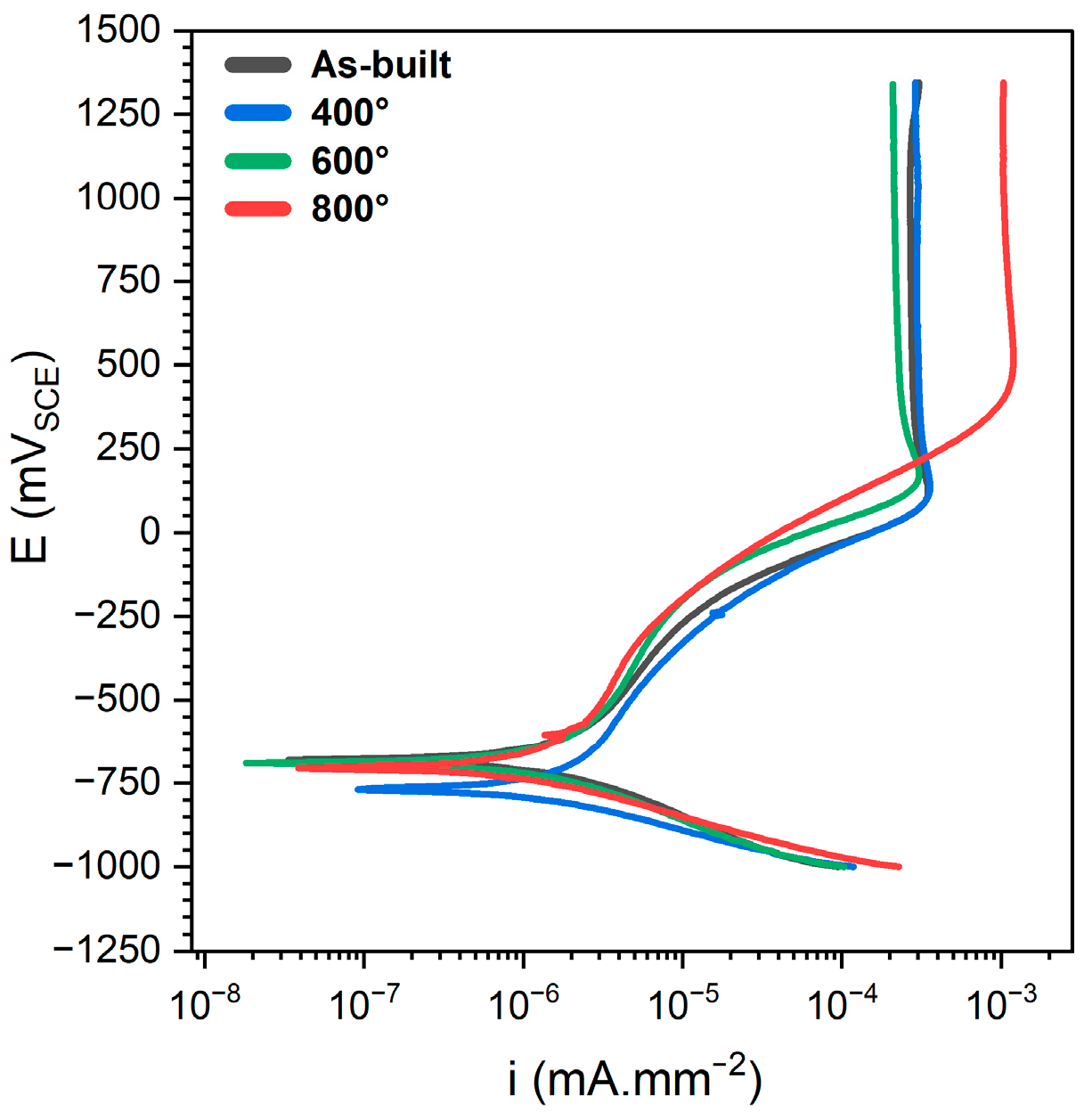

3.3.2. Potentiodynamic Polarisation in Borate Buffer Solution

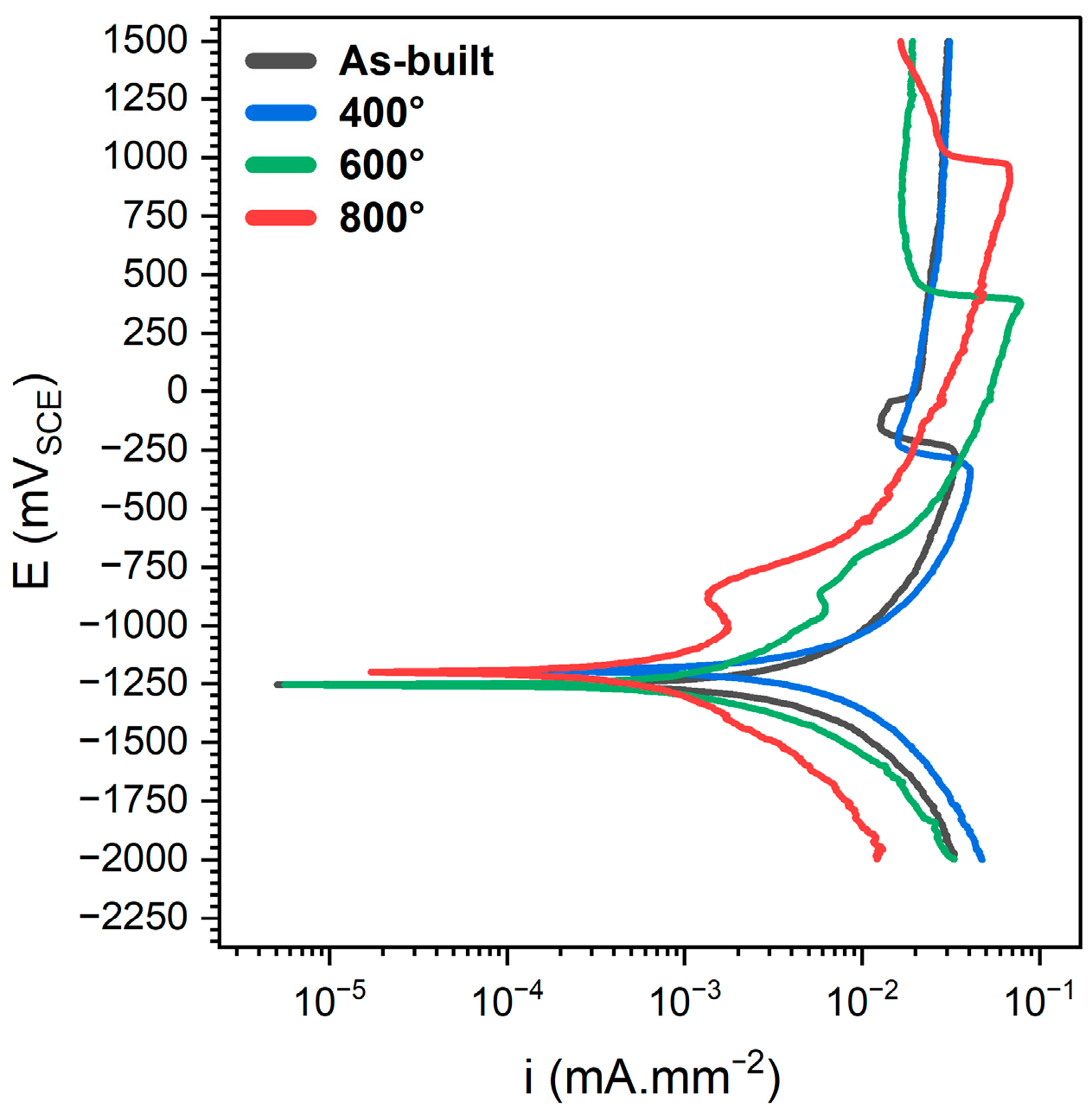

3.3.3. Electrochemical Polarization in NaF Containing Solution Under Stress-Assisted Conditions

3.3.4. SEM Analysis of Corrosion Morphology

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wong, K.V.; Hernandez, A. A Review of Additive Manufacturing. Int. Sch. Res. Not. 2012, 2012, 208760. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive manufacturing: Challenges, trends, and applications. Adv. Mech. Eng. 2019, 11, 1687814018822880. [Google Scholar] [CrossRef]

- Ti-6al-4v Alloy—An Overview|ScienceDirect Topics. Available online: https://www.sciencedirect.com/topics/engineering/ti-6al-4v-alloy (accessed on 13 March 2025).

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Buhairi, M.A.; Foudzi, F.M.; Jamhari, F.I.; Sulong, A.B.; Radzuan, N.A.M.; Muhamad, N.; Mohamed, I.F.; Azman, A.H.; Harun, W.S.W.; Al-Furjan, M.S.H. Review on volumetric energy density: Influence on morphology and mechanical properties of Ti6Al4V manufactured via laser powder bed fusion. Prog. Addit. Manuf. 2023, 8, 265–283. [Google Scholar] [CrossRef]

- Li, C.; Liu, Z.Y.; Fang, X.Y.; Guo, Y.B. Residual Stress in Metal Additive Manufacturing. Procedia CIRP 2018, 71, 348–353. [Google Scholar] [CrossRef]

- Jamhari, F.I.; Foudzi, F.M.; Buhairi, M.A.; Sulong, A.B.; Radzuan, N.A.M.; Muhamad, N.; Mohamed, I.F.; Jamadon, N.H.; Tan, K.S. Influence of heat treatment parameters on microstructure and mechanical performance of titanium alloy in LPBF: A brief review. J. Mater. Res. Technol. 2023, 24, 4091–4110. [Google Scholar] [CrossRef]

- Haubrich, J.; Gussone, J.; Barriobero-Vila, P.; Kürnsteiner, P.; Jägle, E.A.; Raabe, D.; Schell, N.; Requena, G. The role of lattice defects, element partitioning and intrinsic heat effects on the microstructure in selective laser melted Ti-6Al-4V. Acta Mater. 2019, 167, 136–148. [Google Scholar] [CrossRef]

- Syed, A.K.; Ahmad, B.; Guo, H.; Machry, T.; Eatock, D.; Meyer, J.; Fitzpatrick, M.E.; Zhang, X. An experimental study of residual stress and direction-dependence of fatigue crack growth behaviour in as-built and stress-relieved selective-laser-melted Ti6Al4V. Mater. Sci. Eng. A 2019, 755, 246–257. [Google Scholar] [CrossRef]

- Gaiani, S.; Ferrari, E.; Gozzi, M.; Di Giovanni, M.T.; Gualtieri, M.; Colombini, E.; Veronesi, P. Impact of Post-Process Heat Treatments Performed on Ti6Al4V Titanium Alloy Specimens Obtained Using LPBF Technology. Technologies 2023, 11, 100. [Google Scholar] [CrossRef]

- Pathania, A.; Subramaniyan, A.K.; Nagesha, B.K. Influence of post-heat treatments on microstructural and mechanical properties of LPBF-processed Ti6Al4V alloy. Prog. Addit. Manuf. 2022, 7, 1323–1343. [Google Scholar] [CrossRef]

- Bologna, O.; Cecchel, S.; Cornacchia, G.; Avanzini, A.; Sepe, R.; Berto, F.; Razavi, N. Investigating post-processing impact on fatigue performance of LPBF Ti6Al4V with heat treatment, high pressure heat treatment, and dry electropolishing strategies. Int. J. Fatigue 2024, 185, 108365. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Kermanpur, A.; Kharaziha, M. The effects of pore size and heat treatment on compression and corrosion behaviors of Ti–6Al–4V sheet-based gyroid implants fabricated by laser powder-bed fusion process. J. Mater. Res. Technol. 2023, 26, 7707–7721. [Google Scholar] [CrossRef]

- Sabban, R.; Bahl, S.; Chatterjee, K.; Suwas, S. Globularization using heat treatment in additively manufactured Ti-6Al-4V for high strength and toughness. Acta Mater. 2019, 162, 239–254. [Google Scholar] [CrossRef]

- Foudzi, F.M.; Sulong, A.B.; Muhamad, N.; Radzuan, N.A.M.; Mohamed, I.F.; Jamhari, F.I.; Buhairi, M.A.; Lin, N.H.; Hung, L.Y.; Chia, C.C.; et al. Effect of Heat Treatment on Hardness and Microstructure of Titanium Alloy (Ti6Al4V) via Laser Powder Bed Fusion (LPBF). In Proceedings of the Intelligent Manufacturing and Mechatronics, iM3F 2023, Pekan, Malaysia, 7–8 August 2023; Aziz, R.A., Ismail, Z., Iqbal, A.K.M.A., Ahmed, I., Eds.; Springer Nature: Singapore, 2024; pp. 469–478. [Google Scholar] [CrossRef]

- Zhao, Y.; Yue, Y.; Deng, W.; Li, J.; Chen, M.; Liu, S.; Li, W.; Liu, Y.; Ji, V. Effects of post-heat treatments on the microstructure and mechanical properties of Ti–6Al–4V alloy fabricated by selective laser melting. J. Mater. Res. Technol. 2024, 33, 1155–1164. [Google Scholar] [CrossRef]

- Yazdanpanah, A.; Capuzzo, N.; Khodabakhshi, M.; Dabalà, M. Evaluation of stress-assisted corrosion performance of L-PBF processed Ti6Al4V: A microcapillary electrochemical approach. Eng. Fail. Anal. 2024, 166, 108891. [Google Scholar] [CrossRef]

- Zhan, Z.; Zhang, Q.; Wang, S.; Liu, X.; Zhang, H.; Sun, Z.; Ge, Y.; Du, N. Comparison on the Electrochemical Corrosion Behavior of Ti6Al4V Alloys Fabricated by Laser Powder Bed Fusion and Casting. Materials 2024, 17, 3322. [Google Scholar] [CrossRef]

- Luo, Y.; Wang, M.; Zhu, J.; Tu, J.; Jiao, S. Microstructure and Corrosion Resistance of Ti6Al4V Manufactured by Laser Powder Bed Fusion. Metals 2023, 13, 496. [Google Scholar] [CrossRef]

- Cabrini, M.; Carrozza, A.; Lorenzi, S.; Pastore, T.; Testa, C.; Manfredi, D.; Fino, P.; Scenini, F. Influence of surface finishing and heat treatments on the corrosion resistance of LPBF-produced Ti-6Al-4V alloy for biomedical applications. J. Mater. Process. Technol. 2022, 308, 117730. [Google Scholar] [CrossRef]

- Chiu, T.-M.; Mahmoudi, M.; Dai, W.; Elwany, A.; Liang, H.; Castaneda, H. Corrosion assessment of Ti-6Al-4V fabricated using laser powder-bed fusion additive manufacturing. Electrochim. Acta 2018, 279, 143–151. [Google Scholar] [CrossRef]

- Chen, X.; Liao, Q.; Gong, M.; Fu, Q. Corrosion Performances of Selective Laser Melting Ti6Al4V Alloy in Different Solutions. Metals 2023, 13, 192. [Google Scholar] [CrossRef]

- Zhang, H.; Man, C.; Dong, C.; Wang, L.; Li, W.; Kong, D.; Wang, L.; Wang, X. The corrosion behavior of Ti6Al4V fabricated by selective laser melting in the artificial saliva with different fluoride concentrations and pH values. Corros. Sci. 2021, 179, 109097. [Google Scholar] [CrossRef]

- Seo, D.-I.; Lee, J.-B. Influence of Heat Treatment Parameters on the Corrosion Resistance of Additively Manufactured Ti–6Al–4V Alloy. J. Electrochem. Soc. 2020, 167, 101509. [Google Scholar] [CrossRef]

- Rani, S.U.; Thampi, V.V.A.; Kesavan, D.; Ramanathan, S.; Kamaraj, M. An integrated investigation of the effect of sub-transus treatment on the microstructure and corrosion behaviour of the LPBF Ti–6Al–4V alloy. Mater. Chem. Phys. 2024, 322, 129555. [Google Scholar] [CrossRef]

- Yeo, I.; Bae, S.; Amanov, A.; Jeong, S. Effect of Laser Shock Peening on Properties of Heat-Treated Ti–6Al–4V Manufactured by Laser Powder Bed Fusion. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 1137–1150. [Google Scholar] [CrossRef]

- Cecchel, S.; Ferrario, D.; Cornacchia, G.; Gelfi, M. Correction to [Development of Heat Treatments for Selective Laser Melting Ti6Al4V Alloy: Effect on Microstructure, Mechanical Properties, and Corrosion Resistance]. Adv. Eng. Mater. 2024, 26, 2400901. [Google Scholar] [CrossRef]

- Cecchel, S.; Ferrario, D.; Cornacchia, G.; Gelfi, M. Development of Heat Treatments for Selective Laser Melting Ti6Al4V Alloy: Effect on Microstructure, Mechanical Properties, and Corrosion Resistance. Adv. Eng. Mater. 2020, 22, 2000359. [Google Scholar] [CrossRef]

- Ettefagh, A.H.; Zeng, C.; Guo, S.; Raush, J. Corrosion behavior of additively manufactured Ti-6Al-4V parts and the effect of post annealing. Addit. Manuf. 2019, 28, 252–258. [Google Scholar] [CrossRef]

- Fitzpatrick, M.; Fry, A.; Holdway, P.; Kandil, F.; Shackleton, J.; Suominen, L. Determination of Residual Stresses by X-ray Diffraction. In A National Measurement Good Practice Guide No. 52; National Physical Laboratory (NPL): Middlesex, UK, 2002. [Google Scholar]

- Yazdanpanah, A.; Pietri, A.D.; Hjal, A.B.; Khodabakhshi, M.; Biasiolo, L.; Dabalà, M. Electrochemical and localized corrosion characteristics of kolsterised and DLC-coated 316LVM stainless steel for biomedical applications. Appl. Surf. Sci. 2025, 693, 162808. [Google Scholar] [CrossRef]

- Yazdanpanah, A.; Revilla, R.I.; Franceschi, M.; Pagot, G.; Khodabakhshi, M.; De Graeve, I.; Di Noto, V.; Dabalà, M.; Lozano-Perez, S. Exploring the mechanism of stress-induced passive layer degradation in additively manufactured Ni-Fe-Cr-based alloy 718. Corros. Sci. 2024, 241, 112523. [Google Scholar] [CrossRef]

- Yazdanpanah, A.; Pagot, G.; Franceschi, M.; Rebesan, P.; Venturin, M.; Botinha, J.; Gerhmann, B.; De Graeve, I.; Noto, V.D.; Revilla, R.I.; et al. Mechanism of alteration in passivity of additively manufactured Ni-Fe-Cr Alloy 718 caused by minor carbon variation. Electrochim. Acta 2024, 503, 144925. [Google Scholar] [CrossRef]

- Gasparrini, C.; Douglas, J.O.; Yazdanpanah, A.; Stroud, R.; Divitini, G.; Dabalà, M.; Scatigno, G.G.; Pedrazzini, S.; Wenman, M.R.; Badocco, D.; et al. Corrosion of 316L exposed to highly concentrated borated water used as shield in nuclear fusion experimental reactors cooling circuits. Corros. Sci. 2024, 230, 111902. [Google Scholar] [CrossRef]

- Yazdanpanah, A.; Revilla, R.I.; Franceschi, M.; Fabrizi, A.; Khademzadeh, S.; Khodabakhshi, M.; De Graeve, I.; Dabalà, M. Unveiling the impact of laser power variations on microstructure, corrosion, and stress-assisted surface crack initiation in laser powder bed fusion-processed Ni-Fe-Cr alloy 718. Electrochim. Acta 2024, 476, 143723. [Google Scholar] [CrossRef]

- Yazdanpanah, A.; Revilla, R.; Graeve, I.D.; Dabalà, M. Correlation of Microstructural Events with Stress Corrosion Cracking Initiation Behaviour in Additively Manufactured Ni-Based Alloy 718: Microcapillary Electrochemical Technique Implementation. ECS Meet. Abstr. 2023, MA2023-02, 1057. [Google Scholar] [CrossRef]

- Yazdanpanah, A.; Franceschi, M.; Pagot, G.; Khodabakhshi, M.; Fassinato, E.; Zotta, L.; Hanemann, T.; Shaikh, A.S.; Di Noto, V.; De Graeve, I.; et al. Passivity and breakdown mechanisms in laser powder bed fusion processed Ni-based Alloy 625: Influence of scan strategy. Corros. Sci. 2025, 255, 113129. [Google Scholar] [CrossRef]

- Newman, J.; Balsara, N.P. Electrochemical Systems; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Heakal, F.; Shehata, O. Insight into the Electrochemical and Semiconducting Properties of Native Oxide Films on Ti Metal and Its Ti–6Al–4V Alloy in Borate Buffer Solutions. Prot. Met. Phys. Chem. Surf. 2020, 56, 333–342. [Google Scholar] [CrossRef]

- Duffo, G.; Castillo, E. Development of an Artificial Saliva Solution for Studying the Corrosion Behavior of Dental Alloys. Corrosion 2004, 60, 594–602. [Google Scholar] [CrossRef]

- Robin, A.; Meirelis, J.P. Influence of fluoride concentration and pH on corrosion behavior of Ti-6Al-4V and Ti-23Ta alloys in artificial saliva. Mater. Corros. 2007, 58, 173–180. [Google Scholar] [CrossRef]

- Jones, R.H. Stress-Corrosion Cracking. In Corrosion: Fundamentals, Testing, and Protection; ASM International: Almere, The Netherlands, 2003. [Google Scholar] [CrossRef]

- Ni, C.; Zhu, J.; Zhang, B.; An, K.; Wang, Y.; Liu, D.; Lu, W.; Zhu, L.; Liu, C. Recent advance in laser powder bed fusion of Ti–6Al–4V alloys: Microstructure, mechanical properties and machinability. Virtual Phys. Prototyp. 2025, 20, e2446952. [Google Scholar] [CrossRef]

- Cao, S.; Chen, Z.; Lim, C.V.S.; Yang, K.; Jia, Q.; Jarvis, T.; Tomus, D.; Wu, X. Defect, Microstructure, and Mechanical Property of Ti-6Al-4V Alloy Fabricated by High-Power Selective Laser Melting. JOM 2017, 69, 2684–2692. [Google Scholar] [CrossRef]

- Krakhmalev, P.; Fredriksson, G.; Yadroitsava, I.; Kazantseva, N.; Plessis, A.D.; Yadroitsev, I. Deformation Behavior and Microstructure of Ti6Al4V Manufactured by SLM. Phys. Procedia 2016, 83, 778–788. [Google Scholar] [CrossRef]

- Song, Z.; Liu, Y.; Wang, J.; Zhu, G.; Wang, L.; Zeng, X.; Knezevic, M. Advanced phenomenological models guided heat treating processes for LPBF Ti-6Al-4V alloy. Mater. Today Commun. 2025, 42, 111186. [Google Scholar] [CrossRef]

- Zhang, W.; Xing, L.; Zhang, S.; Wang, K.; Chen, J.; Chen, J.; Fang, G.; Liu, W. The reverse transformation mechanism of β phase and its stability of Ti-6Al-4V alloy fabricated via laser powder bed fusion. Mater. Des. 2024, 241, 112926. [Google Scholar] [CrossRef]

- Joshi, V.A. Titanium Alloys: An Atlas of Structures and Fracture Featuresl; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar] [CrossRef]

- Sallica-Leva, E.; Caram, R.; Jardini, A.L.; Fogagnolo, J.B. Ductility improvement due to martensite α′ decomposition in porous Ti–6Al–4V parts produced by selective laser melting for orthopedic implants. J. Mech. Behav. Biomed. Mater. 2016, 54, 149–158. [Google Scholar] [CrossRef]

- Xu, W.; Lui, E.W.; Pateras, A.; Qian, M.; Brandt, M. In situ tailoring microstructure in additively manufactured Ti-6Al-4V for superior mechanical performance. Acta Mater. 2017, 125, 390–400. [Google Scholar] [CrossRef]

- Xie, D.; Lv, F.; Yang, Y.; Shen, L.; Tian, Z.; Shuai, C.; Chen, B.; Zhao, J. A Review on Distortion and Residual Stress in Additive Manufacturing. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100039. [Google Scholar] [CrossRef]

- Megahed, M.; Mindt, H.-W.; N’Dri, N.; Duan, H.; Desmaison, O. Metal additive-manufacturing process and residual stress modeling. Integr. Mater. Manuf. Innov. 2016, 5, 61–93. [Google Scholar] [CrossRef]

- Mansfeld, F.; Shih, H.; Greene, H.; Tsai, C.H. Analysis of EIS Data for Common Corrosion Processes. In Electrochemical Impedance: Analysis and Interpretation; ASTM Selected Technical Papers; ASM International: Almere, The Netherlands, 1993. [Google Scholar] [CrossRef]

- Boudinar, Y.; Belmokre, K.; Touzet, M.; Devos, O.; Puiggali, M. Investigation of the passivation process of plastically deformed 316L stainless steel using the high frequency capacitance obtained by EIS. Mater. Corros. 2019, 70, 206–215. [Google Scholar] [CrossRef]

- Zuo, Y.; Pang, R.; Li, W.; Xiong, J.P.; Tang, Y.M. The evaluation of coating performance by the variations of phase angles in middle and high frequency domains of EIS. Corros. Sci. 2008, 50, 3322–3328. [Google Scholar] [CrossRef]

- Martinez, S.; Hudec, B.; Šoić, I. Low-frequency EIS interpretation with the potential to predict the durability of protective coatings. Prog. Org. Coat. 2024, 197, 108811. [Google Scholar] [CrossRef]

- Ibriş, N.; Rosca, J.C.M. EIS study of Ti and its alloys in biological media. J. Electroanal. Chem. 2002, 526, 53–62. [Google Scholar] [CrossRef]

- Sofuoğlu, M.A.; Haydarlar, G.; Sheikhi, M.R.; Hopali, C.; Tekkalmaz, M. Detection of residual stresses with impedance spectroscopy: A novel approach. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2024, 09544089241285084. [Google Scholar] [CrossRef]

- Yuan, X.-Z.; Song, C.; Wang, H.; Zhang, J. (Eds.) EIS Equivalent Circuits. In Electrochemical Impedance Spectroscopy in PEM Fuel Cells; Springer: London, UK, 2010; pp. 139–192. [Google Scholar] [CrossRef]

- Yuan, X.-Z.; Song, C.; Wang, H.; Zhang, J. (Eds.) Impedance and its Corresponding Electrochemical Processes. In Electrochemical Impedance Spectroscopy in PEM Fuel Cells; Springer: London, UK, 2010; pp. 95–138. [Google Scholar] [CrossRef]

- Orazem, M.E. Measurement model for analysis of electrochemical impedance data. J. Solid State Electrochem. 2024, 28, 1273–1289. [Google Scholar] [CrossRef]

- Orazem, M.E.; Tribollet, B. An integrated approach to electrochemical impedance spectroscopy. Electrochim. Acta 2008, 53, 7360–7366. [Google Scholar] [CrossRef]

- Ruiz, A.; Hernández, H.; Hernández, J.; Orozco-Cruz, R.; Reynoso, A.R.; González, C.; Miranda-Hernández, J. Electrochemical Impedance Spectroscopy (EIS): A Review Study of Basic Aspects of the Corrosion Mechanism Applied to Steels; Springer: London, UK, 2020. [Google Scholar] [CrossRef]

- Orazem, M.E.; Frateur, I.; Tribollet, B.; Vivier, V.; Marcelin, S.; Pébère, N.; Bunge, A.L.; White, E.A.; Riemer, D.P.; Musiani, M. Dielectric Properties of Materials Showing Constant-Phase-Element (CPE) Impedance Response. J. Electrochem. Soc. 2013, 160, C215. [Google Scholar] [CrossRef]

- Aslam, R. Chapter 2—Potentiodynamic polarization methods for corrosion measurement. In Electrochemical and Analytical Techniques for Sustainable Corrosion Monitoring; Aslam, J., Verma, C., Hussain, C.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 25–37. [Google Scholar] [CrossRef]

- Medjedovic, E.; Medjedovic, S.; Deljo, D.; Sukalo, A. Impact of Fluoride on Dental Health Quality. Mater. Socio-Medica 2015, 27, 395–398. [Google Scholar] [CrossRef]

- Schiff, N.; Grosgogeat, B.; Lissac, M.; Dalard, F. Influence of fluoride content and pH on the corrosion resistance of titanium and its alloys. Biomaterials 2002, 23, 1995–2002. [Google Scholar] [CrossRef]

- Licausi, M.P.; Muñoz, A.I.; Borrás, V.A. Influence of the fabrication process and fluoride content on the tribocorrosion behaviour of Ti6Al4V biomedical alloy in artificial saliva. J. Mech. Behav. Biomed. Mater. 2013, 20, 137–148. [Google Scholar] [CrossRef]

| Temperature | AR | 400° | 600° | 800° |

|---|---|---|---|---|

| Longitudinal | 202 ± 15 MPa | 155 ± 15 MPa | 100 ± 14 MPa | 68 ± 8 MPa |

| Transversal | 181 ± 23 MPa | 149 ± 16 MPa | 96 ± 11 MPa | 81 ± 7 MPa |

| Sample | Rct (Ω.cm−2) | Rs (Ω.cm−2) | Q (F.s−(1−α).cm−2) | n | Ceff (F.cm−2) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Value | Error | Value | Error | Value | Error | Value | Error | ||

| AR | 2.5 × 107 | 1.7 × 106 | 20.3 | 0.18 | 1.9 × 10−6 | 1.0 × 10−8 | 0.93 | 8.8 × 10−4 | 2.7 × 10−6 |

| 400° | 9.8 × 106 | 3.4 × 105 | 17.4 | 0.15 | 2.4 × 10−6 | 1.2 × 10−8 | 0.92 | 8.9 × 10−4 | 2.3 × 10−6 |

| 600° | 8.8 × 106 | 2.7 × 105 | 17.1 | 0.15 | 2.3 × 10−6 | 1.2 × 10−8 | 0.92 | 8.9 × 10−4 | 3.0 × 10−6 |

| 800° | 1.0 × 106 | 4.5 × 105 | 17.5 | 0.16 | 2.0 × 10−6 | 1.5 × 10−8 | 0.91 | 8.9 × 10−4 | 3.2 × 10−6 |

| Parameter | icorr (mA.mm−2) | Ecorr (mVSCE) | ipass (mA.mm−2) | Epass (mVSCE) |

|---|---|---|---|---|

| AR | 1.37 × 10−6 | −677.84 | 3.46 × 10−4 | 115 |

| 400° | 1.46 × 10−6 | −764.43 | 3.57 × 10−4 | 140.1 |

| 600° | 9.69 × 10−7 | −689.73 | 3.04 × 10−4 | 170 |

| 800° | 8.85 × 10−7 | −700.76 | 11.9 × 10−4 | 465 |

| Parameter | icorr (mA.mm−2) | Ecorr (mVSCE) | ipass (mA.mm−2) | Epass (mVSCE) |

|---|---|---|---|---|

| AR-0.06 mm | 2.84 × 10−3 | −1262.3 | 3.37 × 10−2 | −280.1 |

| 400°-0.06 mm | 3.66 × 10−3 | −1201.2 | 4.07 × 10−2 | −340 |

| 600°-0.06 mm | 1.21 × 10−3 | −1253.4 | 7.83 × 10−2 | 364.9 |

| 800°-0.06 mm | 5.86 × 10−4 | −1210.1 | 6.72 × 10−2 | 965 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

D’Ambrosi, L.; Brunelli, K.; Cammelli, F.; Revilla, R.I.; Yazdanpanah, A. Residual Stress and Corrosion Performance in L-PBF Ti6Al4V: Unveiling the Optimum Stress Relieving Temperature via Microcapillary Electrochemical Characterisation. Metals 2025, 15, 855. https://doi.org/10.3390/met15080855

D’Ambrosi L, Brunelli K, Cammelli F, Revilla RI, Yazdanpanah A. Residual Stress and Corrosion Performance in L-PBF Ti6Al4V: Unveiling the Optimum Stress Relieving Temperature via Microcapillary Electrochemical Characterisation. Metals. 2025; 15(8):855. https://doi.org/10.3390/met15080855

Chicago/Turabian StyleD’Ambrosi, Lorenzo, Katya Brunelli, Francesco Cammelli, Reynier I. Revilla, and Arshad Yazdanpanah. 2025. "Residual Stress and Corrosion Performance in L-PBF Ti6Al4V: Unveiling the Optimum Stress Relieving Temperature via Microcapillary Electrochemical Characterisation" Metals 15, no. 8: 855. https://doi.org/10.3390/met15080855

APA StyleD’Ambrosi, L., Brunelli, K., Cammelli, F., Revilla, R. I., & Yazdanpanah, A. (2025). Residual Stress and Corrosion Performance in L-PBF Ti6Al4V: Unveiling the Optimum Stress Relieving Temperature via Microcapillary Electrochemical Characterisation. Metals, 15(8), 855. https://doi.org/10.3390/met15080855