Effect of W Contents and Annealing Temperatures on the Microstructure and Mechanical Properties of CoFeNi Medium Entropy Alloys

Abstract

1. Introductions

2. Experiment Methods

3. Results

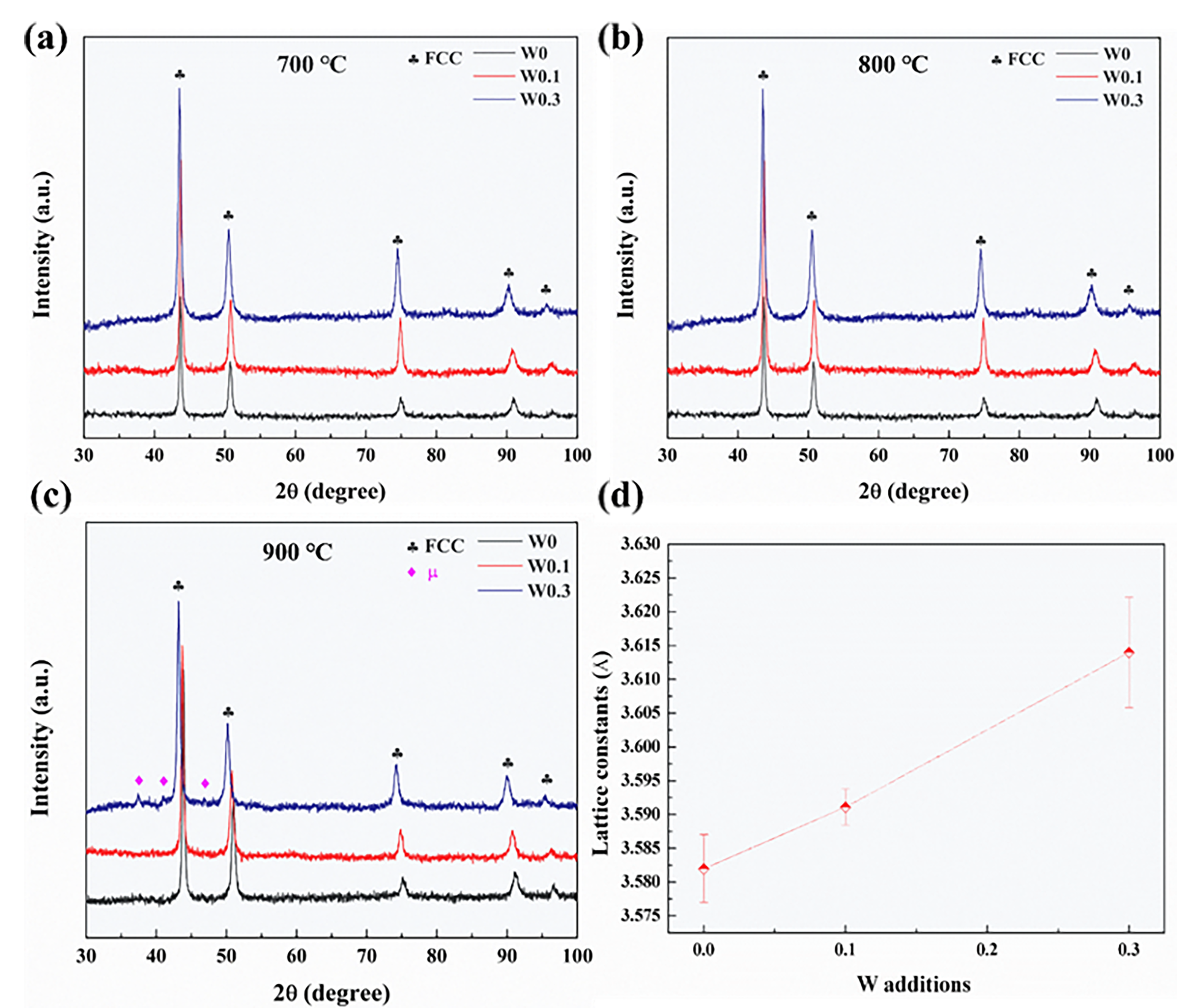

3.1. Crystal Structures

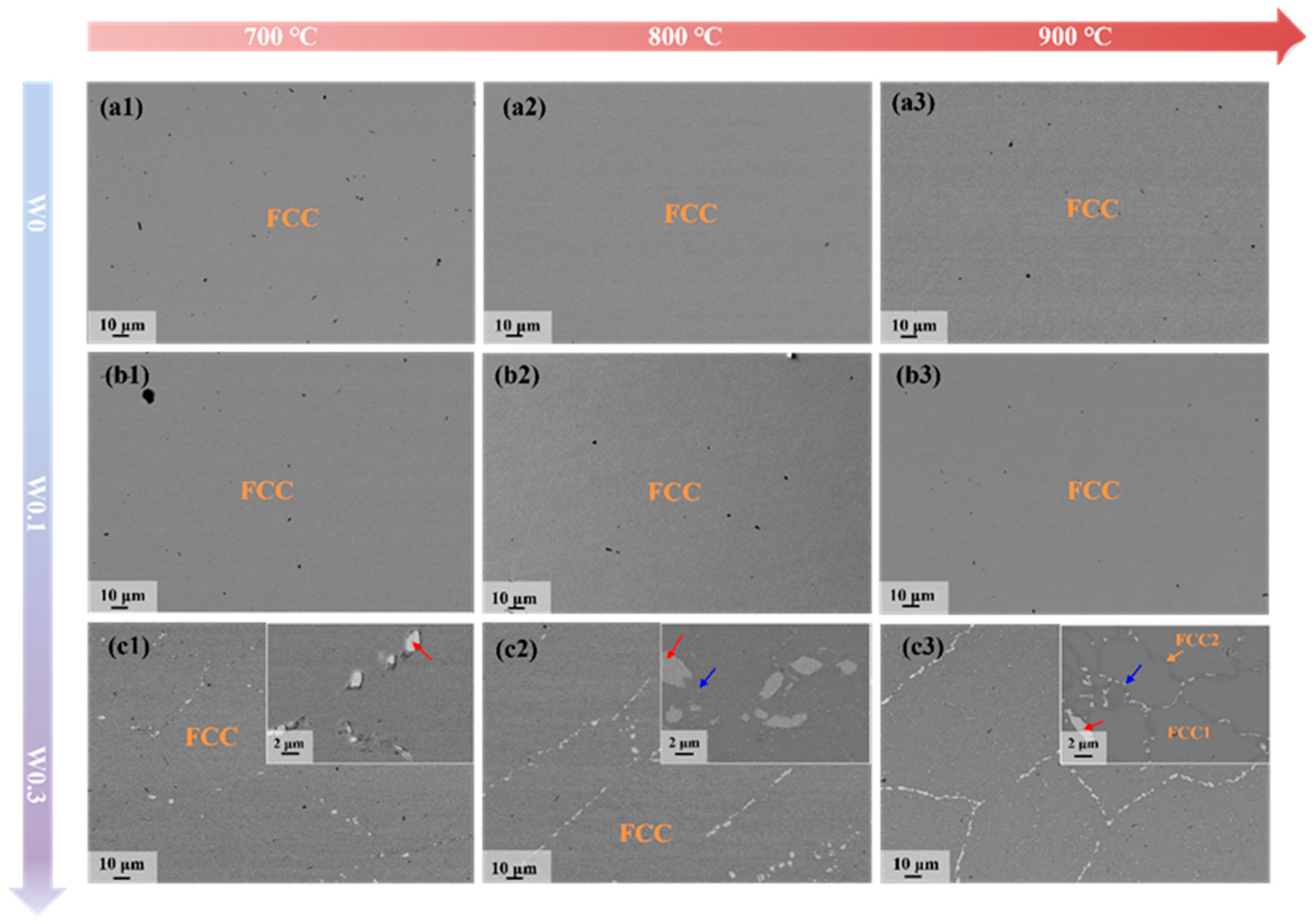

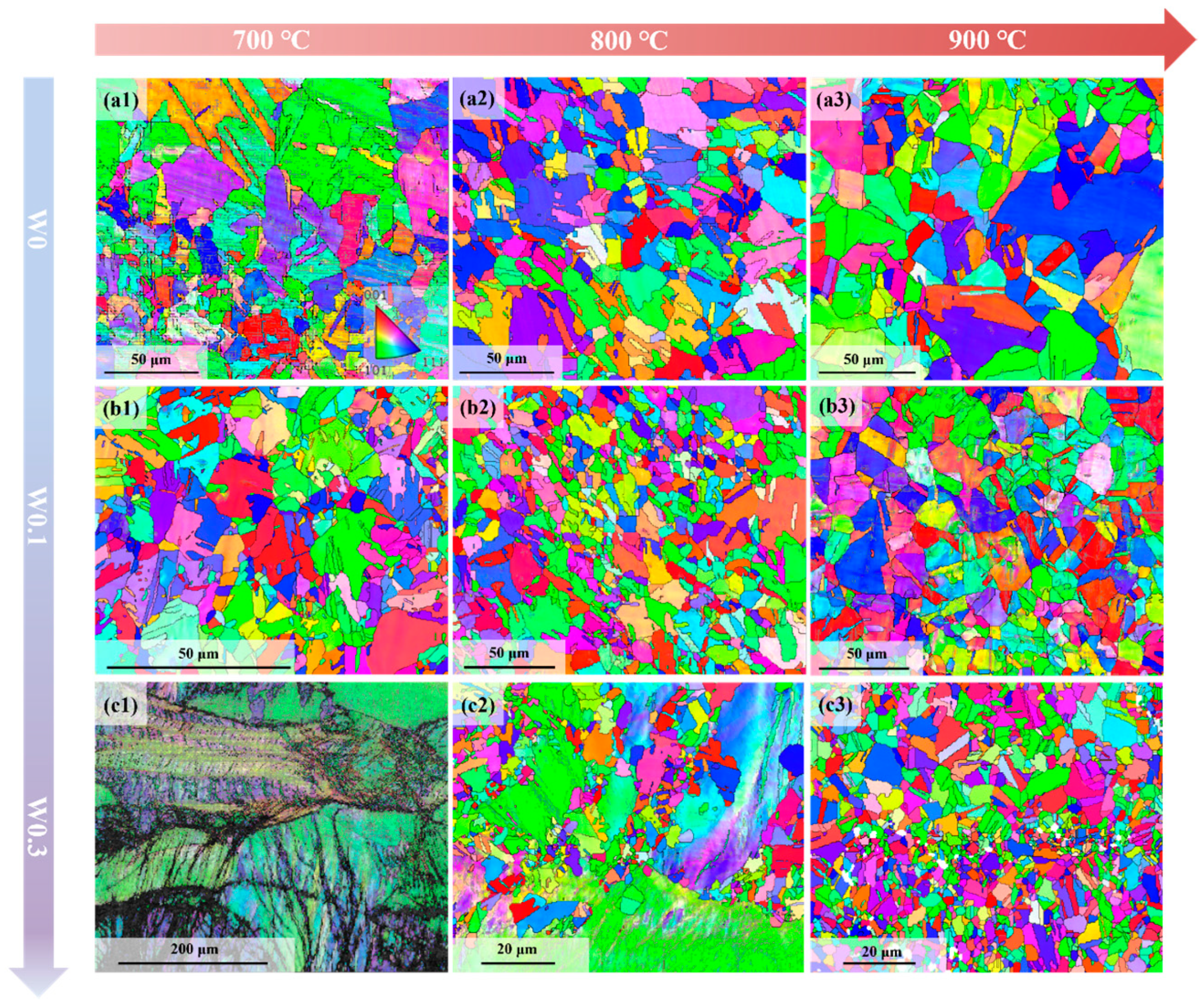

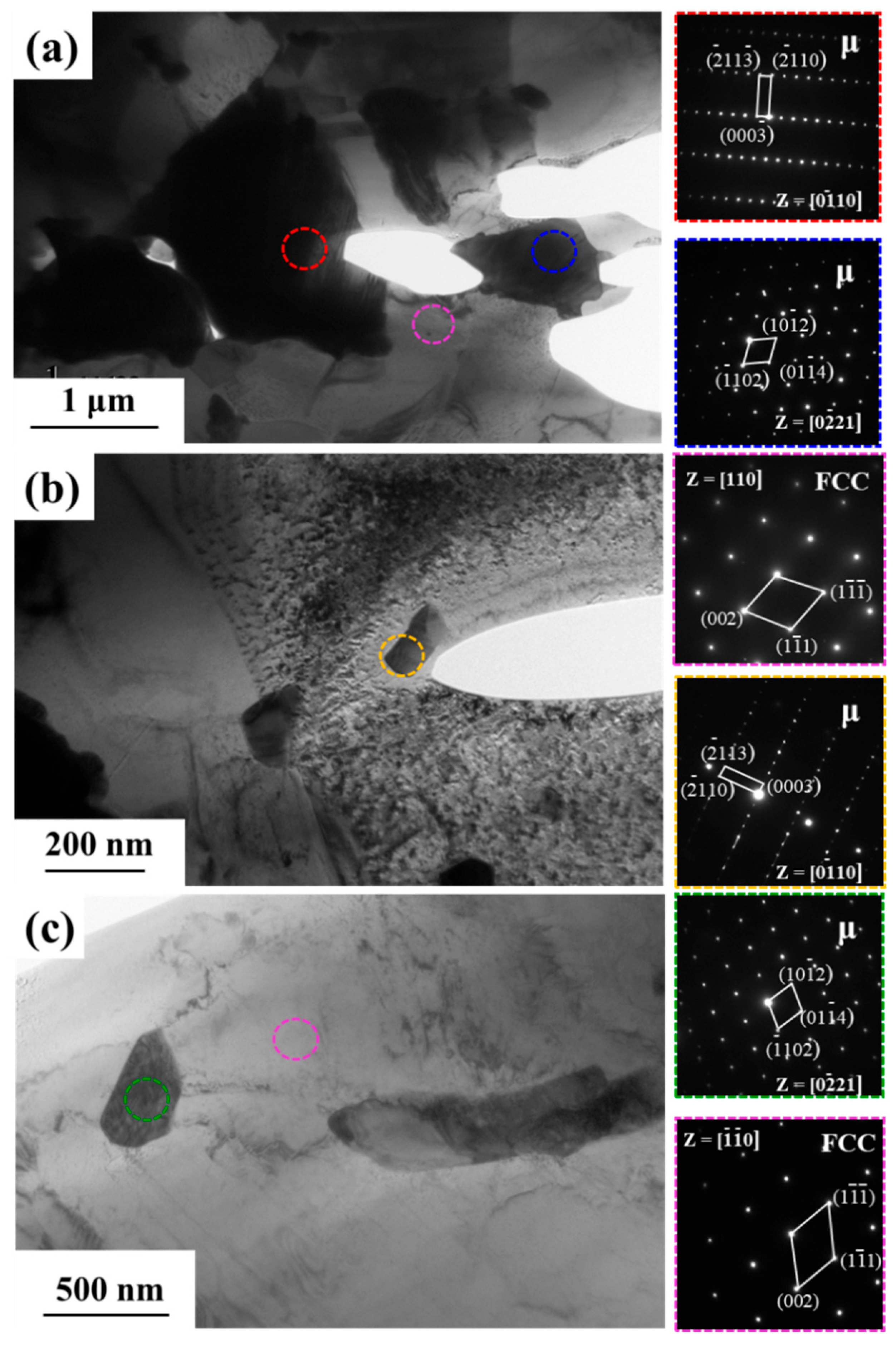

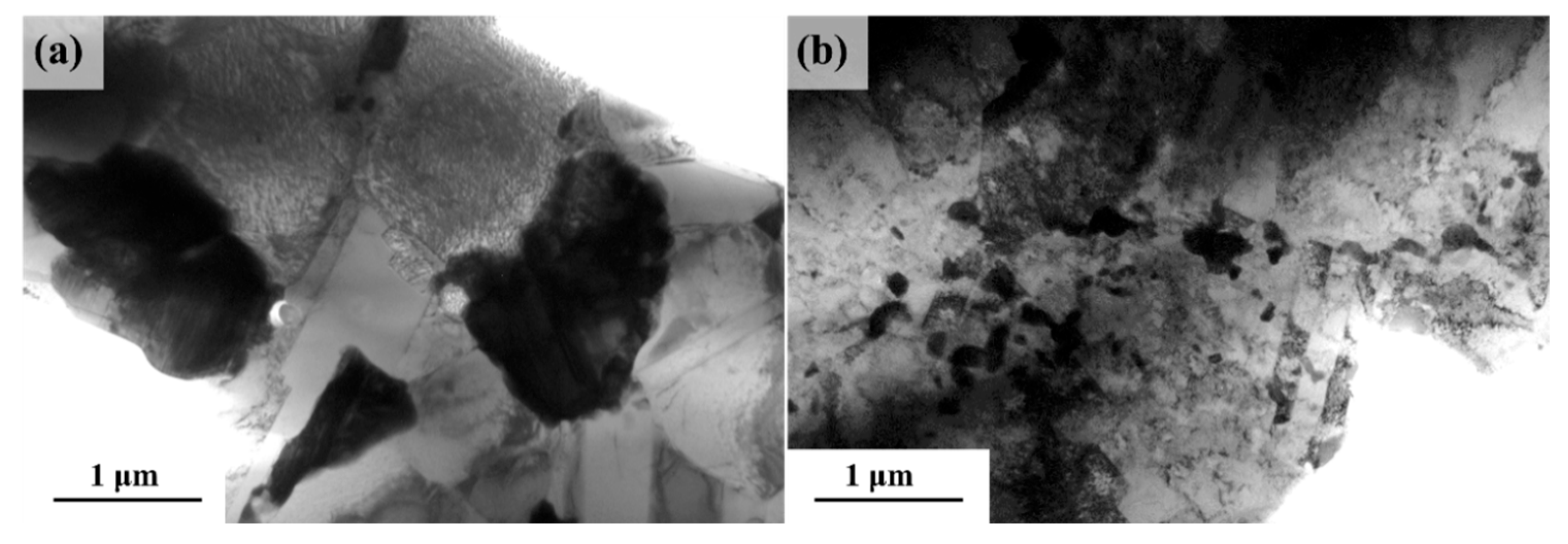

3.2. Microstructure Analysis

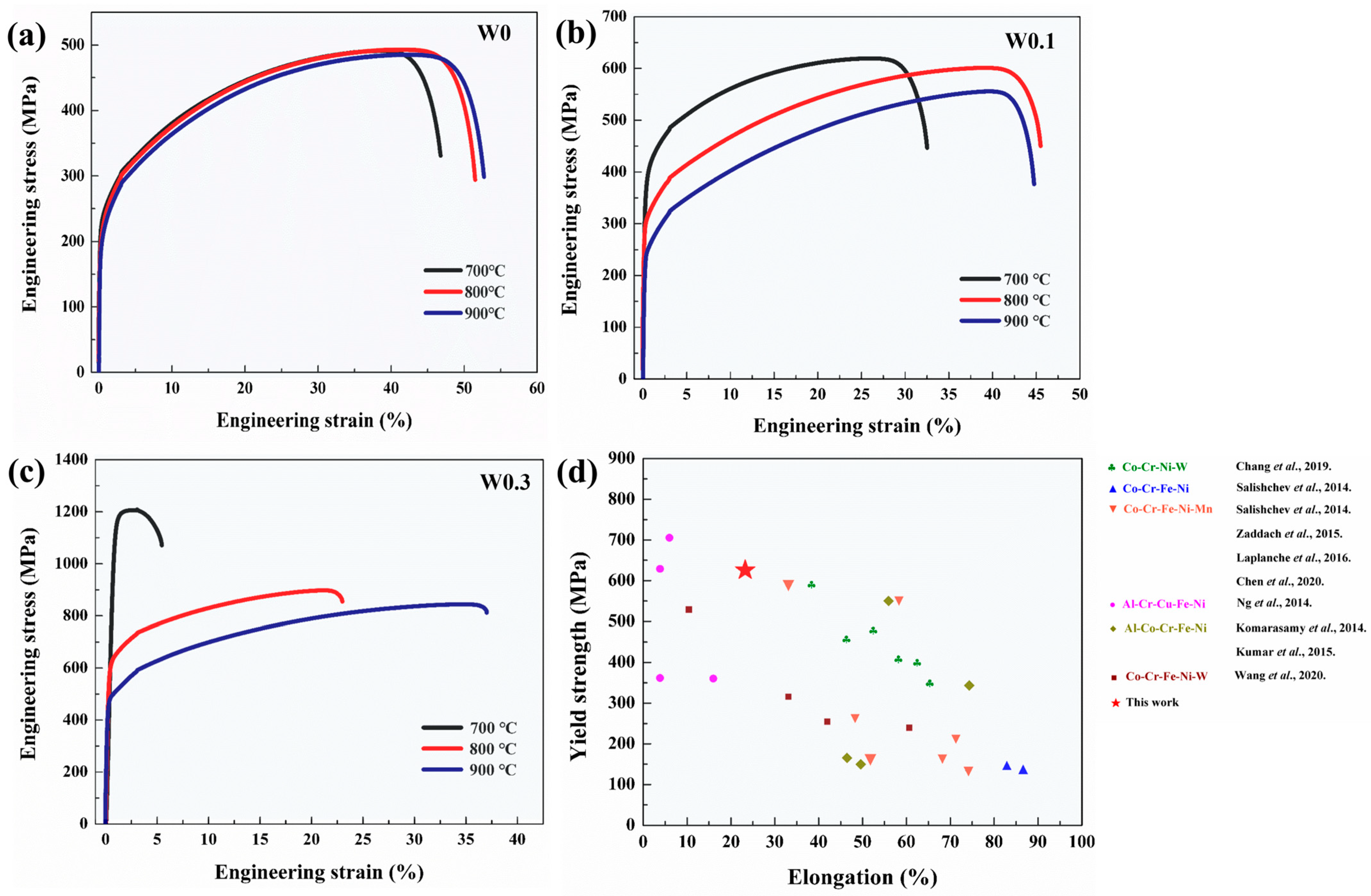

3.3. Mechanical Properties

4. Discussions

4.1. Phase Formations

4.2. Strengthening Mechanisms

4.3. Deformation Mechanisms

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ye, Y.F.; Wang, Q.; Lu, J.; Liu, C.T.; Yang, Y. High-entropy alloy: Challenges and prospects. Mater. Today 2016, 19, 349–362. [Google Scholar] [CrossRef]

- Yeh, J.W. Recent progress in high-entropy alloys. Ann. Chim. Sci. Mat. 2006, 31, 633–648. [Google Scholar] [CrossRef]

- Li, Z.Z.; Zhao, S.T.; Ritchie, R.O.; Meyers, M.A. Mechanical properties of high-entropy alloys with emphasis on face-centered cubic alloys. Prog. Mater. Sci. 2019, 102, 296–345. [Google Scholar] [CrossRef]

- Liu, W.H.; Yang, T.; Liu, C.T. Precipitation hardening in CoCrFeNi-based high entropy alloys. Mater. Chem. Phys. 2018, 210, 2–11. [Google Scholar] [CrossRef]

- Wu, Z.; Bei, H.; Pharr, G.M.; George, E.P. Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures. Acta Mater. 2014, 81, 428–441. [Google Scholar] [CrossRef]

- Wang, L.; Wu, X.Y.; Su, H.J.; Deng, B.; Liu, G.; Han, Z.H.; Su, Y.N.; Huang, Y.D.; Zhang, Y.P.; Shen, J.; et al. Microstructure and mechanical property of novel L12 nanoparticles-strengthened CoFeNi-based medium entropy alloys. Mater. Sci. Eng. A 2022, 840, 142917. [Google Scholar] [CrossRef]

- Chen, Y.; Deng, H.W.; Xie, Z.M.; Wang, M.M.; Yang, J.F.; Zhang, T.; Xiong, Y.; Liu, R.; Wang, X.P.; Fang, Q.F.; et al. Tailoring microstructures and tensile properties of a precipitation-strengthened (FeCoNi)94Ti6 medium-entropy alloy. J. Alloys Compd. 2020, 828, 154457. [Google Scholar] [CrossRef]

- Ye, Z.H.; Li, C.W.; Zhang, X.Y.; Liao, Y.; Gu, J.F. The influence of vanadium element on the microstructure and mechanical properties of (FeCoNi)100-xVx high-entropy alloys. Mater. Charact. 2022, 192, 112232. [Google Scholar] [CrossRef]

- Yang, T.; Zhao, Y.L.; Tong, Y.; Jiao, Z.B.; Wei, J.; Cai, J.X.; Han, X.D.; Chen, D.; Hu, A.; Kai, J.J.; et al. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science 2018, 362, 933–937. [Google Scholar] [CrossRef]

- He, J.Y.; Wang, H.; Huang, H.L.; Xu, X.D.; Chen, M.W.; Wu, Y.; Liu, X.J.; Nieh, T.G.; An, K.; Lu, Z.P. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 2016, 102, 187–196. [Google Scholar] [CrossRef]

- Liu, W.H.; He, J.Y.; Huang, H.L.; Wang, H.; Lu, Z.P.; Liu, C.T. Effects of Nb additions on the microstructure and mechanical property of CoCrFeNi high-entropy alloys. Intermetallics 2015, 60, 1–8. [Google Scholar] [CrossRef]

- Chang, R.B.; Fang, W.; Bai, X.; Xia, C.Q.; Zhang, X.; Yu, H.Y.; Liu, B.X.; Yin, F.X. Effects of tungsten additions on the microstructure and mechanical properties of CoCrNi medium entropy alloys. J. Alloys Compd. 2019, 790, 732–743. [Google Scholar] [CrossRef]

- Cheng, G.S.; Shi, Y.Z.; Wang, Y.H.; Zhang, F.; Li, R.; Zhou, Y.H.; Wu, Z.G.; Ma, C.; Lei, Z.F.; Lu, Z.P. Enhancing strengthening effect of topologically close-packed superlattices in medium-entropy alloys via enabling imperfect atomic packing. Acta Mater. 2024, 271, 119903. [Google Scholar] [CrossRef]

- Cui, Y.Q.; Ma, H.; Yang, L.; Shao, Y.; Pang, H.F.; Zhu, H.H.; Zhang, J.; Sun, W.T.; Guan, R.G. A multiscale-phase-structured CrFeNiW0.1 medium entropy alloy with outstanding strength-ductility synergy. Mater. Sci. Eng. A 2025, 933, 148300. [Google Scholar] [CrossRef]

- Wu, Z.G.; Guo, W.; Jin, K.; Poplawsky, J.D.; Gao, Y.F.; Bei, H.B. Enhanced strength and ductility of a tungsten-doped CoCrNi medium-entropy alloy. J. Mater. Res. 2018, 33, 3301–3309. [Google Scholar] [CrossRef]

- Salishchev, G.A.; Tikhonovsky, M.A.; Shaysultanov, D.G.; Stepanov, N.D.; Kuznetsov, A.V.; Kolodiy, I.V.; Tortika, A.S.; Senkov, O.N. Effect of Mn and V on structure and mechanical properties of high-entropy alloys based on CoCrFeNi system. J. Alloys Compd. 2014, 591, 11–21. [Google Scholar] [CrossRef]

- Zaddach, A.J.; Scattergood, R.O.; Koch, C.C. Tensile properties of low-stacking fault energy high-entropy alloys. Mater. Sci. Eng. A 2015, 636, 373–378. [Google Scholar] [CrossRef]

- Laplanche, G.; Kostka, A.; Horst, O.M.; Eggeler, G.; George, E.P. Microstructure evolution and critical stress for twinning in the CrMnFeCoNi high-entropy alloy. Acta Mater. 2016, 118, 152–163. [Google Scholar] [CrossRef]

- Chen, S.J.; Oh, H.S.; Gludovatz, B.; Kim, S.J.; Park, E.S.; Zhang, Z.; Ritchie, R.O.; Yu, Q. Real-time observations of TRIP-induced ultrahigh strain hardening in a dual-phase CrMnFeCoNi high-entropy alloy. Nat. Commun. 2020, 11, 826. [Google Scholar] [CrossRef]

- Ng, C.; Guo, S.; Luan, J.H.; Wang, Q.; Lu, J.; Shi, S.Q.; Liu, C.T. Phase stability and tensile properties of Co-free Al0.5CrCuFeNi2 high-entropy alloys. J. Alloys Compd. 2014, 584, 530–537. [Google Scholar] [CrossRef]

- Komarasamy, M.; Kumar, N.; Tang, Z.; Mishra, R.S.; Liaw, P.K. Effect of Microstructure on the Deformation Mechanism of Friction Stir-Processed Al0.1CoCrFeNi High Entropy Alloy. Mater. Res. Lett. 2014, 3, 30–34. [Google Scholar] [CrossRef]

- Kumar, N.; Komarasamy, M.; Nelaturu, P.; Tang, Z.; Liaw, P.K.; Mishra, R.S. Friction Stir Processing of a High Entropy Alloy Al0.1CoCrFeNi. JOM 2015, 67, 1007–1013. [Google Scholar] [CrossRef]

- Wang, L.; Wang, L.; Tang, Y.C.; Luo, L.; Luo, L.S.; Su, Y.Q.; Guo, J.J.; Fu, H.Z. Microstructure and mechanical properties of CoCrFeNiWx high entropy alloys reinforced by μ phase particles. J. Alloys Compd. 2020, 843, 155997. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.J.; Lin, J.P.; Chen, G.L.; Liaw, P.K. Solid-Solution Phase Formation Rules for Multi-component Alloys. Adv. Eng. Mater. 2008, 10, 534–538. [Google Scholar] [CrossRef]

- Singh, A.K.; Kumar, N.; Dwivedi, A.; Subramaniam, A. A geometrical parameter for the formation of disordered solid solutions in multi-component alloys. Intermetallics 2014, 53, 112–119. [Google Scholar] [CrossRef]

- Wang, Z.J.; Huang, Y.H.; Yang, Y.; Wang, J.C.; Liu, C.T. Atomic-size effect and solid solubility of multicomponent alloys. Scr. Mater. 2015, 94, 28–31. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y. Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater. Chem. Phys. 2012, 132, 233–238. [Google Scholar] [CrossRef]

- Zhang, L.J.; Yu, P.F.; Zhang, M.D.; Liu, D.J.; Zhou, Z.; Ma, M.Z.; Liaw, P.K.; Li, G.; Liu, R.P. Microstructure and mechanical behaviors of GdxCoCrCuFeNi high-entropy alloys. Mater. Sci. Eng. A 2017, 707, 708–716. [Google Scholar] [CrossRef]

- Dong, Y.; Lu, Y.P. Effects of Tungsten Addition on the Microstructure and Mechanical Properties of Near-Eutectic AlCoCrFeNi2 High-Entropy Alloy. J. Mater. Eng. Perform. 2017, 27, 109–115. [Google Scholar] [CrossRef]

- Yuan, Y.; Han, Y.; Xu, K.; Tang, S.S.; Zhang, Y.H.; Lv, Y.Z.; Yang, Y.H.; Jiang, X.; Chang, K.K. Revealing the solidification microstructure evolution and strengthening mechanisms of additive-manufactured W-FeCrCoNi alloy: Experiment and simulation. J. Mater. Sci. Technol. 2025, 204, 302–313. [Google Scholar] [CrossRef]

- Li, H.C.; Wang, J.; Zhang, W.Y.; Zhao, J.W.; Li, J.S.; Fu, M.W. Achieving superior ductility with ultrahigh strength via deformation and strain hardening in the non-recrystallized regions of the heterogeneous-structured high-entropy alloy. Acta Mater. 2025, 283, 120572. [Google Scholar] [CrossRef]

- Deng, H.W.; Jiang, Y.; Liao, B.K.; Zhao, Z.; Wang, L.; Zhang, T. Mechanical properties and corrosion behavior of precipitation-strengthened FeCoNi-Tix (x = 0, 3, 6 at. %) multi-principal element alloys. J. Mater. Res. Technol. 2023, 27, 2922–2928. [Google Scholar] [CrossRef]

- Sun, W.T.; Fu, Y.; Ma, H.; Wang, Y.; Gao, M.Q.; Kong, X.Q.; Guan, R.G. High-strength AlCoCrFeNi2.1 eutectic high entropy alloy skeleton with hollow brick wall structures by selective laser melting. Mater. Sci. Eng. A 2023, 887, 145757. [Google Scholar]

| Alloys | Regions | Co | Fe | Ni | W |

|---|---|---|---|---|---|

| W0-700 °C | FCC | 33.77 | 33.56 | 32.67 | 0 |

| W0-800 °C | FCC | 33.75 | 33.60 | 32.64 | 0 |

| W0-900 °C | FCC | 33.37 | 33.60 | 33.03 | 0 |

| W0.1-700 °C | FCC | 32.53 | 32.52 | 31.44 | 3.50 |

| W0.1-800 °C | FCC | 32.50 | 32.45 | 31.21 | 3.83 |

| W0.1-900 °C | FCC | 32.41 | 32.63 | 31.09 | 3.87 |

| W0.3-700 °C | FCC | 29.98 | 30.28 | 30.19 | 9.55 |

| Coarse particle | 25.60 | 19.22 | 11.75 | 43.43 | |

| W0.3-800 °C | FCC | 30.59 | 30.14 | 29.55 | 9.73 |

| Coarse particle | 25.79 | 18.79 | 11.22 | 44.19 | |

| Fine particle | 29.90 | 26.11 | 20.34 | 23.64 | |

| W0.3-900 °C | FCC1 | 28.40 | 30.78 | 25.93 | 14.89 |

| FCC2 | 29.87 | 30.41 | 27.01 | 12.71 | |

| Coarse particle | 22.60 | 19.65 | 11.26 | 46.49 | |

| Fine particle | 24.86 | 22.51 | 13.62 | 39.01 |

| MEAs | YS (MPa) | UTS (MPa) | EL (%) |

|---|---|---|---|

| W0-700 °C | 232 | 491 | 47.1 |

| W0-800 °C | 205 | 493 | 51.7 |

| W0-900 °C | 192 | 485 | 52.9 |

| W0.1-700 °C | 373 | 619 | 32.5 |

| W0.1-800 °C | 306 | 601 | 45.5 |

| W0.1-900 °C | 242 | 554 | 44.8 |

| W0.3-700 °C | 1063 | 1207 | 5.5 |

| W0.3-800 °C | 620 | 898 | 23 |

| W0.3-900 °C | 484 | 845 | 37 |

| MEAs | (kJ/mol) | (%) | (J/mol/K) | (J/mol/K) | ||

|---|---|---|---|---|---|---|

| CoFeNi | −1.333 | 0.653 | 9.134 | 21.407 | 1.017 | 12.118 |

| CoFeNiW0.1 | −1.415 | 2.073 | 10.024 | 2.332 | 1.134 | 12.970 |

| CoFeNiW0.3 | −1.543 | 3.246 | 10.836 | 1.028 | 1.133 | 13.654 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, Y.; Ma, H.; Yang, L.; Shao, Y.; Guan, R. Effect of W Contents and Annealing Temperatures on the Microstructure and Mechanical Properties of CoFeNi Medium Entropy Alloys. Metals 2025, 15, 854. https://doi.org/10.3390/met15080854

Cui Y, Ma H, Yang L, Shao Y, Guan R. Effect of W Contents and Annealing Temperatures on the Microstructure and Mechanical Properties of CoFeNi Medium Entropy Alloys. Metals. 2025; 15(8):854. https://doi.org/10.3390/met15080854

Chicago/Turabian StyleCui, Yaqi, Huan Ma, Li Yang, Yang Shao, and Renguo Guan. 2025. "Effect of W Contents and Annealing Temperatures on the Microstructure and Mechanical Properties of CoFeNi Medium Entropy Alloys" Metals 15, no. 8: 854. https://doi.org/10.3390/met15080854

APA StyleCui, Y., Ma, H., Yang, L., Shao, Y., & Guan, R. (2025). Effect of W Contents and Annealing Temperatures on the Microstructure and Mechanical Properties of CoFeNi Medium Entropy Alloys. Metals, 15(8), 854. https://doi.org/10.3390/met15080854