Effects of Temperature, Stress, and Grain Size on the High-Temperature Creep Mechanism of FeCrAl Alloys

Abstract

1. Introduction

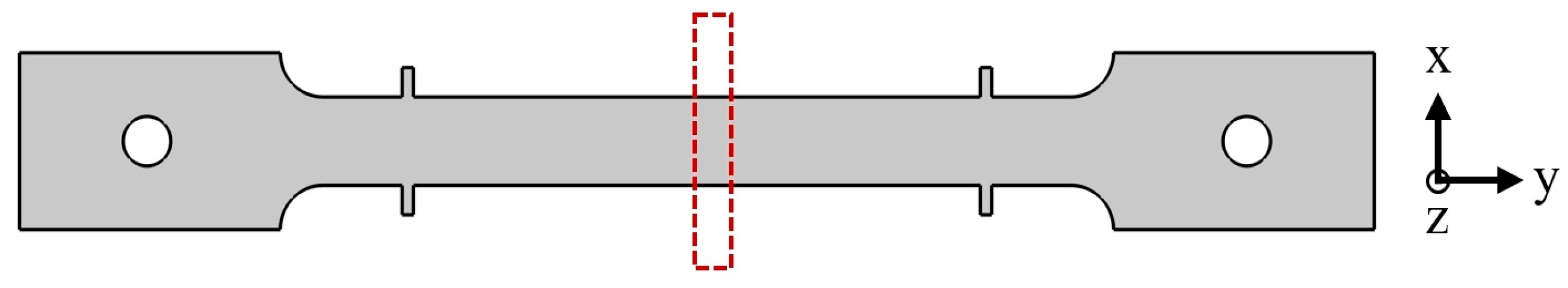

2. Materials and Methods

3. Results and Discussion

3.1. Preliminary Determination of Creep Mechanism

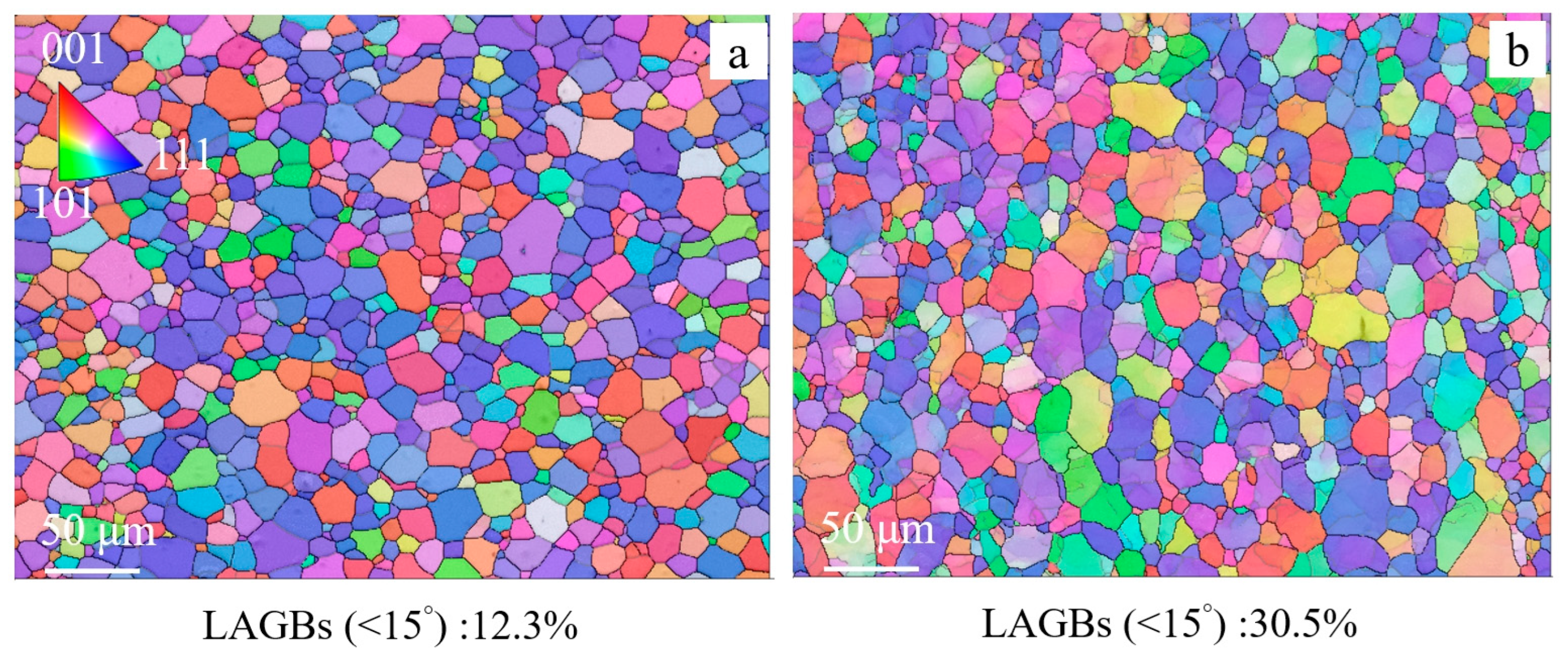

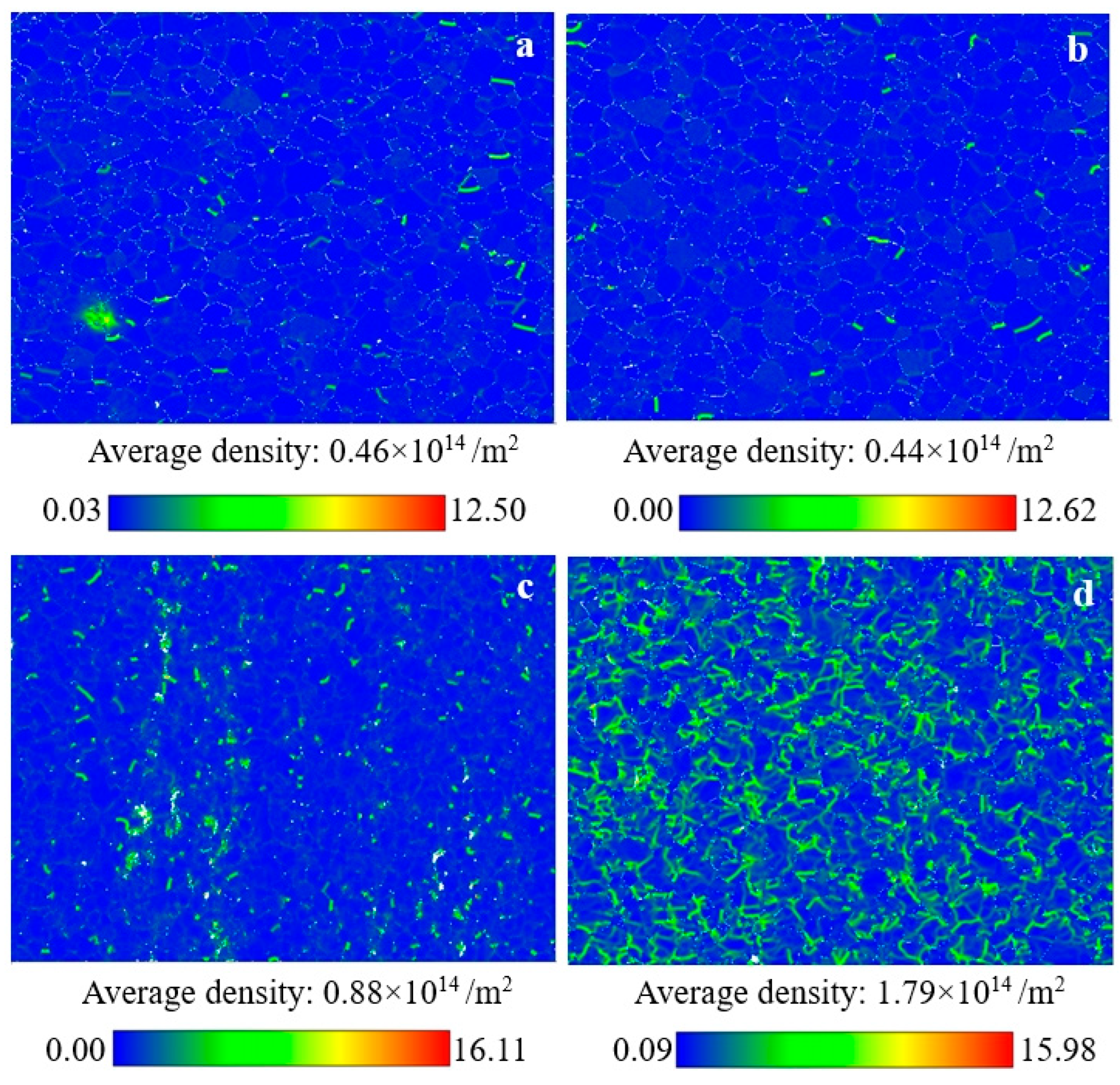

3.2. Stress Effect

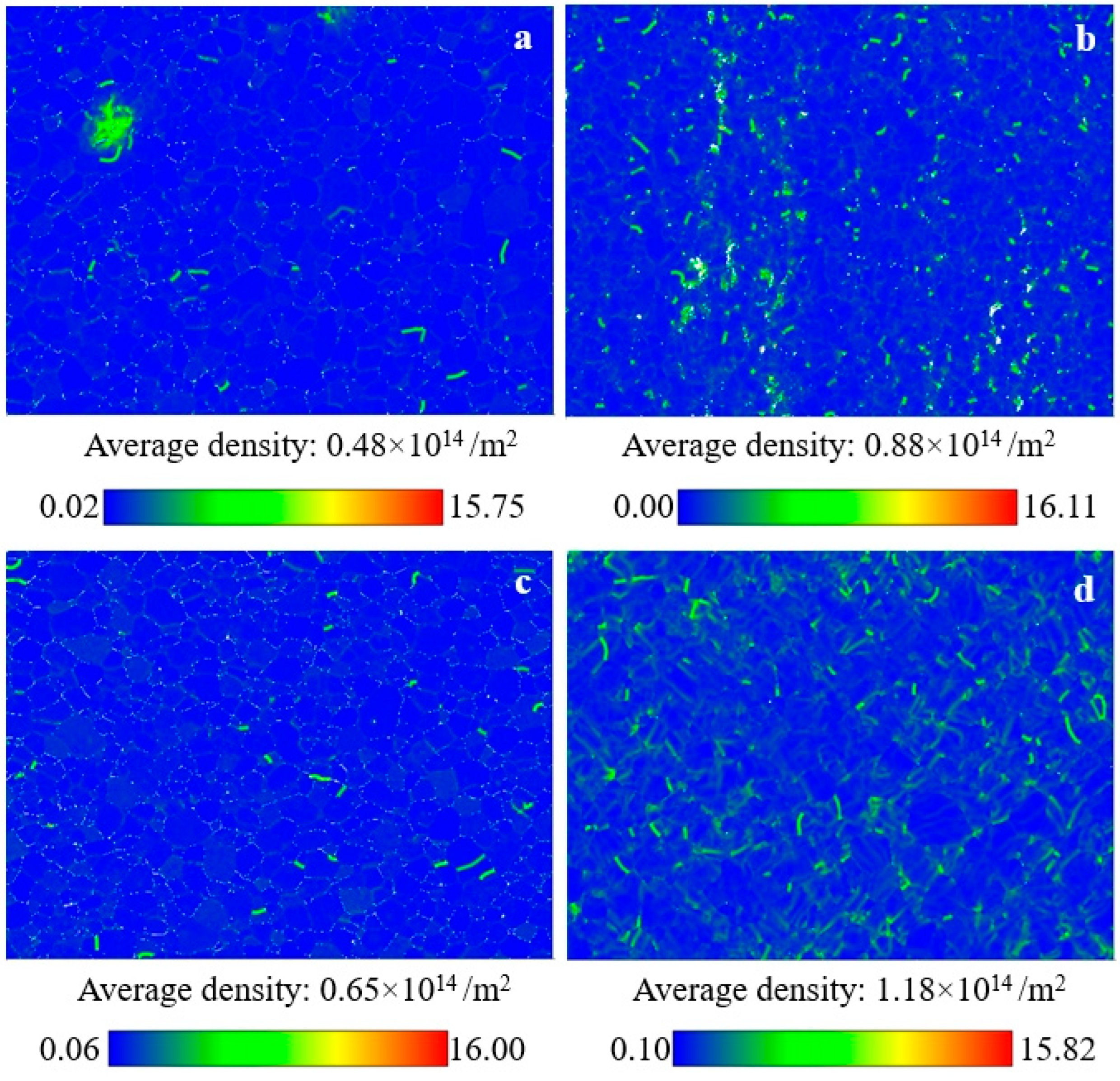

3.3. Temperature Effect

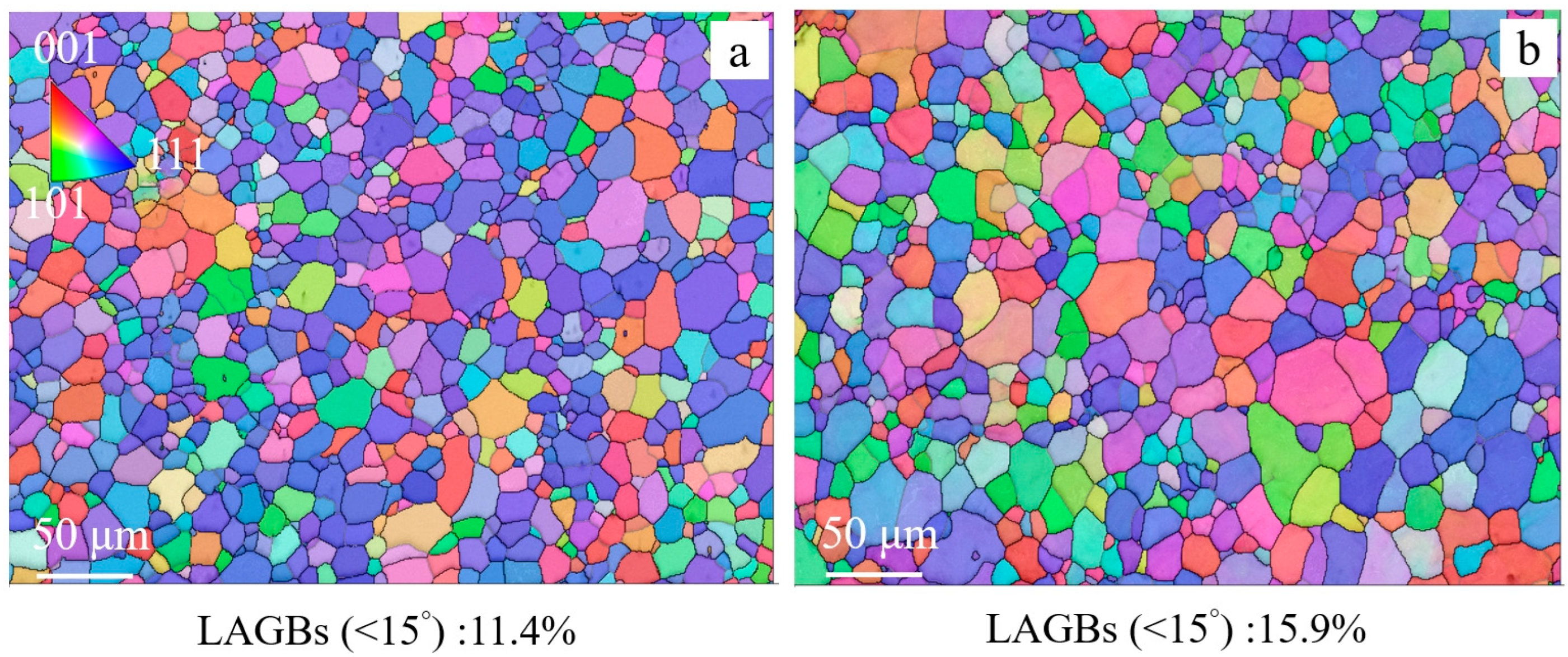

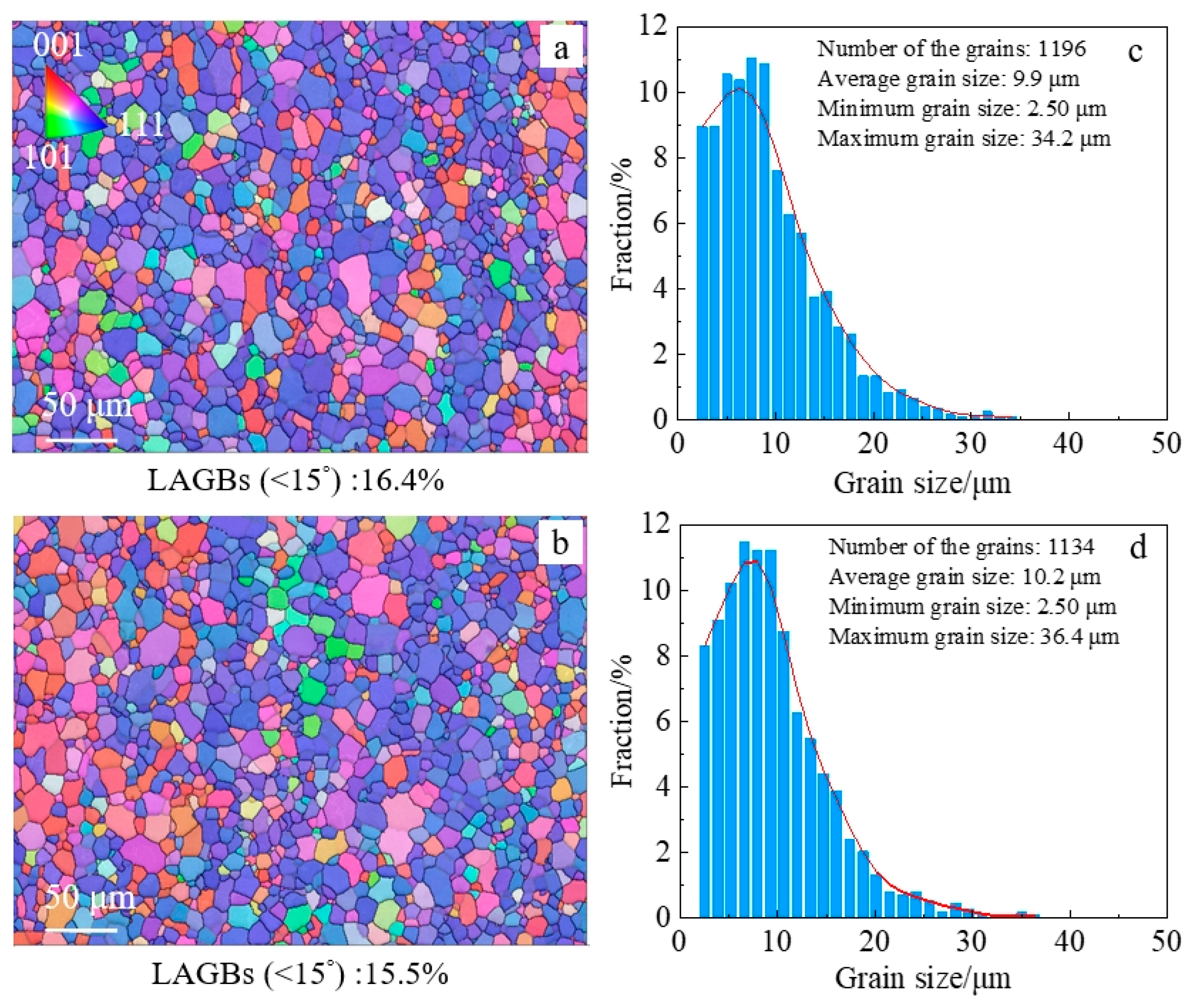

3.4. Grain Size Effect

3.5. Texture Effect

4. Conclusions

- (1)

- Temperature, stress, and grain size are primary factors influencing creep behavior, whereas the effect of texture is relatively weak. Large grains tend to engulf smaller grains at lower temperatures and stresses, reducing the proportion of LAGBs after creep. Under high-temperature or high-stress conditions, a substantial multiplication of dislocations within the crystal increases the number of LAGBs.

- (2)

- As stress increases, the dominant mechanism tends to transition from GB sliding to a dislocation motion within the present research scope. The number and density of dislocations do not change significantly, and GB sliding dominates the deformation process at low stress. Under high-stress conditions, the dislocation density is elevated through strain accumulation, enabling the dislocation motion to dominate the creep process.

- (3)

- Temperature and grain size have an impact on the mechanisms for dislocation motion under high stress. The higher the temperature or the smaller the grain size, the lower the critical stress required to initiate dislocation motion, thus leading to a marked increase in dislocation density and weakening the alloy’s high-temperature creep resistance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ni, Y.; Qi, W.; Zhao, L.; Li, D.; Qiao, Y.; Zhou, J.; Wang, P.; Yang, K. Thermo-Mechanical Properties and Oxidation Behavior of FeCrAl Alloys with Si and Y Addition. Metals 2025, 15, 433. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Pint, B.A.; Terrani, K.A.; Field, K.G.; Yang, Y.; Snead, L.L. Development and property evaluation of nuclear grade wrought FeCrAl fuel cladding for light water reactors. J. Nucl. Mater. 2015, 467, 703–716. [Google Scholar] [CrossRef]

- Dryepondt, S.; Unocic, K.A.; Hoelzer, D.T.; Massey, C.P.; Pint, B.A. Development of low-Cr ODS FeCrAl alloys for accident-tolerant fuel cladding. J. Nucl. Mater. 2018, 501, 59–71. [Google Scholar] [CrossRef]

- Qiu, B.; Wang, J.; Deng, Y.; Wang, M.; Qiu, S.Z. A review on thermohydraulic and mechanical-physical properties of SiC, FeCrAl and Ti3SiC2 for ATF cladding. Nucl. Eng. Technol. 2020, 52, 1–13. [Google Scholar] [CrossRef]

- Ma, H.; Wang, H.; Zhang, W.; Lin, X.; Xue, J.; Ren, Q.; Liao, Y.; Hu, L.; Sun, R.; Liang, X.; et al. Corrosion Behavior of Fe13Cr5Al4Mo Alloy in Lithiated Water at 360 °C, 18.6 MPa. Rare Met. Mater. Eng. 2024, 53, 2018–2024. [Google Scholar]

- Qi, W.; Qiao, Y.; Ru, W.; Wang, X.; Zhang, X.; Zheng, T.; Du, S.; Wang, P.; Yang, K. High-Temperature Steam Oxidation and Surface Microstructure Evolution of Fe13Cr6Al(1–4)Mo0.15Y Alloys. Metals 2024, 14, 1229. [Google Scholar] [CrossRef]

- Zhao, H.; Yang, C.; Guo, D.; Wu, L.; Pan, R.; Qin, J.; Shi, B. Thermomechanical Response Simulation of FeCrAl and Zr-2 Fuel Claddings Under Neutron Irradiation. Rare Met. Mater. Eng. 2022, 51, 2460–2466. [Google Scholar]

- Massey, C.P.; Terrani, K.A.; Dryepondt, S.N.; Pint, B.A. Cladding burst behavior of Fe-based alloys under LOCA. J. Nucl. Mater. 2016, 470, 128–138. [Google Scholar] [CrossRef]

- Thompson, Z.T.; Terrani, K.A.; Yamamoto, Y. Elastic Modulus Measurement of ORNL ATF FeCrAl Alloys; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2015. [Google Scholar]

- Gussev, M.N.; Byun, T.S.; Yamamoto, Y.; Maloy, S.A.; Terrani, K.A. In-situ tube burst testing and high-temperature deformation behavior of candidate materials for accident tolerant fuel cladding. J. Nucl. Mater. 2015, 466, 417–425. [Google Scholar] [CrossRef]

- Artz, E. Creep of dispersion strengthened materials: A critical assessment. Res. Mech. 1991, 31, 399–453. [Google Scholar]

- Kamikawa, R.; Ukai, S.; Kasai, S.; Oono, N.; Zhang, S.; Yoshito, S.; Masuda, H.; Sato, E. Cooperative grain boundary sliding in creep deformation of FeCrAl-ODS steels at high temperature and low strain rate. J. Nucl. Mater. 2018, 511, 591–597. [Google Scholar] [CrossRef]

- Sun, T.; Cho, J.; Shang, Z.; Niu, T.; Ding, J.; Wang, J.; Wang, H.; Zhang, X. Deformation mechanism in nanolaminate FeCrAl alloys by in situ micromechanical strain rate jump tests at elevated temperatures. Scr. Mater. 2022, 215, 114698. [Google Scholar] [CrossRef]

- Jaumier, T.; Vincent, S.; Vincent, L.; Desmorat, R. Creep and damage anisotropies of 9%Cr and 14%Cr ODS steel cladding. J. Nucl. Mater. 2019, 518, 274–286. [Google Scholar] [CrossRef]

- Yano, Y.; Tanno, T.; Oka, H.; Ohtsuka, S.; Inoue, T.; Kato, S.; Furukawa, T.; Uwaba, T.; Kaito, T.; Ukai, S. Ultra-high temperature tensile properties of ODS steel claddings under severe accident conditions. J. Nucl. Mater. 2017, 487, 229–237. [Google Scholar] [CrossRef]

- Joshi, P.; Kombaliah, B.; Cinbiz, M.N.; Murty, K.L. Characterization of stress-rupture behavior of nuclear-grade C26M2 FeCrAl alloy for accident-tolerant fuel cladding via burst testing. Mater. Sci. Eng. A 2020, 791, 139753. [Google Scholar] [CrossRef]

- Powers, J.; Worrall, A.; Robb, K.; George, N.; Maldonado, G. ORNL analysis of operational and safety performance for candidate accident tolerant fuel and cladding concepts. In Proceedings of the IAEA Technical Meeting on Accident Tolerant Fuel Concepts for Light Water Reactors, Oak Ridge, TN, USA, 13–16 October 2014; p. 253. [Google Scholar]

- Coble, R.L. A model for boundary diffusion controlled creep in polycrystalline materials. J. Appl. Phys. 1963, 34, 1679–1682. [Google Scholar] [CrossRef]

- Herring, C. Diffusional viscosity of a polycrystalline solid. J. Appl. Phys. 1950, 21, 437–445. [Google Scholar] [CrossRef]

- Nabarro, F. Deformation of crystals by motion of single ions. In Proceedings of the Report of Conference on Strength of Solids, London, UK, 7–9 July 1947; pp. 1–19. [Google Scholar]

- Blum, W.; Zeng, X. A simple dislocation model of deformation resistance of ultrafine-grained materials explaining Hall-Petch strengthening and enhanced strain rate sensitivity. Acta Mater. 2009, 57, 1966–1974. [Google Scholar] [CrossRef]

- Weertman, J.R. Theory of steady-state creep based on dislocation climb. J. Appl. Phys. 1955, 26, 1213–1217. [Google Scholar] [CrossRef]

- Wang, M.; Sun, H.; Zheng, W.; Zhou, Z. Creep behavior of an alumina-forming austenitic steel with simple alloy design. Mater. Today Commun. 2020, 25, 101303. [Google Scholar] [CrossRef]

- Yao, H.; Ye, T.; Wang, P.; Wu, J.; Zhang, J.; Chen, P. Structural Evolution and Transitions of Mechanisms in Creep Deformation of Nanocrystalline FeCrAl Alloys. Nanomaterials 2023, 13, 631. [Google Scholar] [CrossRef] [PubMed]

- Yao, H.; Ye, T.; Yu, W.; Wang, P.; Wu, J.; Wu, Y.; Chen, P. Atomic-scale investigation of creep behavior and deformation mechanism in nanocrystalline FeCrAl alloys. Mater. Des. 2021, 206, 109766. [Google Scholar] [CrossRef]

- Ye, T.; Yao, H.; Wu, Y.; Zhang, J.; Wang, M.; Chen, P.; Tian, W.; Qiu, S.; Su, G. Molecular dynamics study on tensile mechanical properties of FeCrAl alloy. Rare Met. Mater. Eng. 2023, 52, 777–784. [Google Scholar]

- Sun, H.; Wang, H.; He, X.; Wang, F.; An, X.; Wang, Z. Study on high temperature creep behavior of the accident-resistant cladding Fe–13Cr–4Al-1.85Mo-0.85Nb alloy. Mater. Sci. Eng. A 2021, 802, 140688. [Google Scholar] [CrossRef]

- Lapera, M.; Spader, D.; Ghonem, H. A coupled, physics-based matrix-grain boundary model for creep of carbide strengthened nickel-based superalloys—I. Concepts and formulation. Mater. Sci. Eng. A 2020, 769, 138421. [Google Scholar] [CrossRef]

- Spader, D.; Lapera, M.; Ghonem, H. A coupled, physics-based matrix-grain boundary model for creep of carbide strengthened nickel-based superalloys—II. Experimental results and model application. Mater. Sci. Eng. A 2020, 769, 138355. [Google Scholar] [CrossRef]

- Niu, B.; Wang, Z.; Wang, Q.; Pan, Q.; Dong, C.; Zhang, R.; Liu, H.; Liaw, P.K.; Xu, W. Dual-phase synergetic precipitation in Nb/Ta/Zr co-modified Fe–Cr–Al–Mo alloy. Intermetallics 2020, 124, 106848. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, J.; Liu, W.; Liu, H.; Du, P.; Zhang, R. Recrystallization and texture evolution of cold-rolled FeCrAl thin-wall tube with large Laves phase during annealing: Effect of Nb content. J. Cent. South Univ. 2021, 28, 2612–2627. [Google Scholar] [CrossRef]

- Zhong, Y.; Du, P.; Chen, Y.; Zhou, J.; Lai, H.S.; Zhang, R. Axial creep behavior of FeCrAl nuclear cladding tubes at a temperature of 600 °C. J. Mater. Res. Technol. 2025, 37, 841–850. [Google Scholar] [CrossRef]

- Liu, W.; Liu, Z.; Luo, W.; Zuo, D.; Liu, H.; Zhang, R.; Wang, Q. Effect of Zr addition on coarse Laves phase stimulated nucleation of recrystallization in FeCrAl alloy. Mater. Sci. Eng. A 2022, 840, 142964. [Google Scholar] [CrossRef]

| T/°C | σ/MPa | Duration (h) | Creep Rate (s−1) | Stress Exponent n |

|---|---|---|---|---|

| 450 | 150 | 189.5 | 3.1 × 10−11 | 3.4 |

| 175 | 104.2 | 5.0 × 10−11 | ||

| 200 | 50.3 | 8.3 × 10−11 | ||

| 475 | 125 | 198.0 | 1.5 × 10−10 | 3.4 |

| 150 | 137.2 | 2.5 × 10−10 | ||

| 175 | 84.3 | 4.7 × 10−10 | ||

| 500 | 125 | 141.8 | 9.1 × 10−10 | 3.3 |

| 150 | 107.6 | 1.8 × 10−9 | ||

| 175 | 57.3 | 3.0 × 10−9 | ||

| 200 | 32.7 | 4.2 × 10−9 | ||

| 525 | 100 | 80.2 | 6.0 × 10−9 | 3.5 |

| 125 | 60.7 | 1.4 × 10−8 | ||

| 150 | 35.8 | 2.4 × 10−8 | ||

| 550 | 100 | 47.2 | 3.8 × 10−8 | 3.3 |

| 125 | 33.5 | 1.1 × 10−7 | ||

| 150 | 27.5 | 1.4 × 10−7 | ||

| 600 | 75 | 28.2 | 2.2 × 10−7 | 2.1 |

| 100 | 20.4 | 3.2 × 10−7 | ||

| 125 | 11.7 | 5.2 × 10−7 | ||

| 150 | 6.3 | 9.4 × 10−7 |

| T/°C | σ/MPa | Minimum GS/μm | Maximum GS/μm | Average GS/μm |

|---|---|---|---|---|

| Before creep | 2.5 | 40.9 | 12.0 | |

| 525 | 125 | 2.5 | 39.6 | 12.1 |

| 600 | 100 | 2.5 | 46.5 | 12.1 |

| 600 | 150 | 2.5 | 45.9 | 13.0 |

| 650 | 75 | 2.5 | 57.2 | 14.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, H.; Wu, C.; Ye, T.; Wang, P.; Wu, J.; Wu, Y.; Chen, P. Effects of Temperature, Stress, and Grain Size on the High-Temperature Creep Mechanism of FeCrAl Alloys. Metals 2025, 15, 845. https://doi.org/10.3390/met15080845

Yao H, Wu C, Ye T, Wang P, Wu J, Wu Y, Chen P. Effects of Temperature, Stress, and Grain Size on the High-Temperature Creep Mechanism of FeCrAl Alloys. Metals. 2025; 15(8):845. https://doi.org/10.3390/met15080845

Chicago/Turabian StyleYao, Huan, Changwei Wu, Tianzhou Ye, Pengfei Wang, Junmei Wu, Yingwei Wu, and Ping Chen. 2025. "Effects of Temperature, Stress, and Grain Size on the High-Temperature Creep Mechanism of FeCrAl Alloys" Metals 15, no. 8: 845. https://doi.org/10.3390/met15080845

APA StyleYao, H., Wu, C., Ye, T., Wang, P., Wu, J., Wu, Y., & Chen, P. (2025). Effects of Temperature, Stress, and Grain Size on the High-Temperature Creep Mechanism of FeCrAl Alloys. Metals, 15(8), 845. https://doi.org/10.3390/met15080845