Deposition Process and Interface Performance of Aluminum–Steel Joints Prepared Using CMT Technology

Abstract

1. Introduction

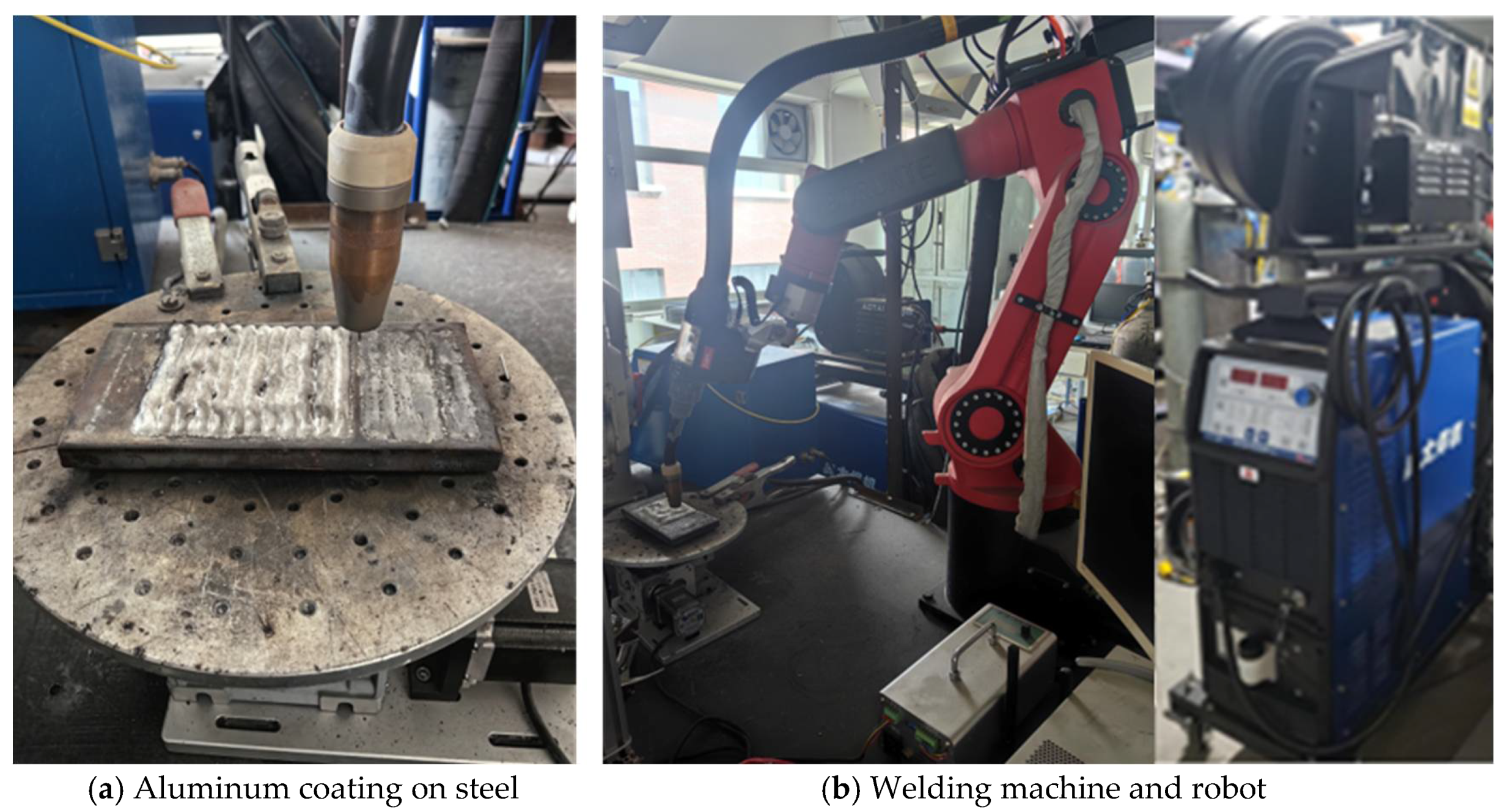

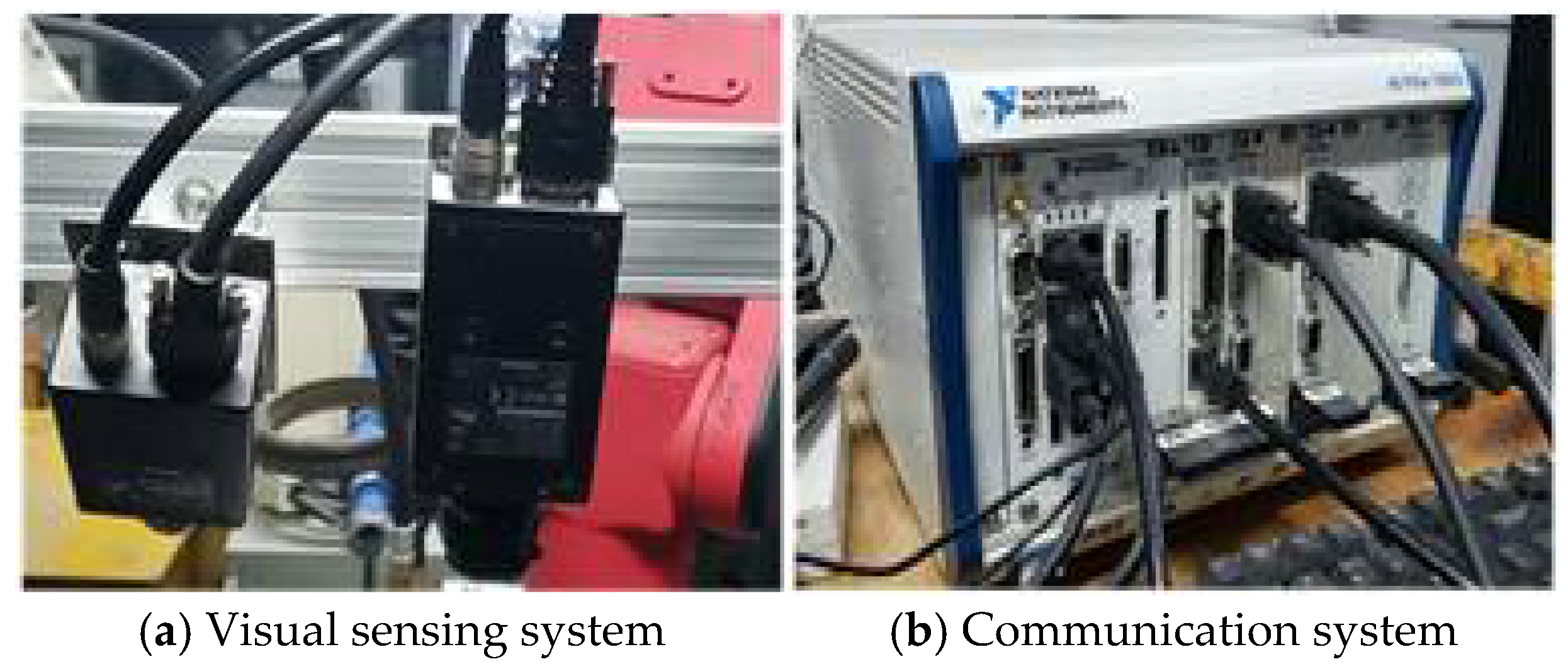

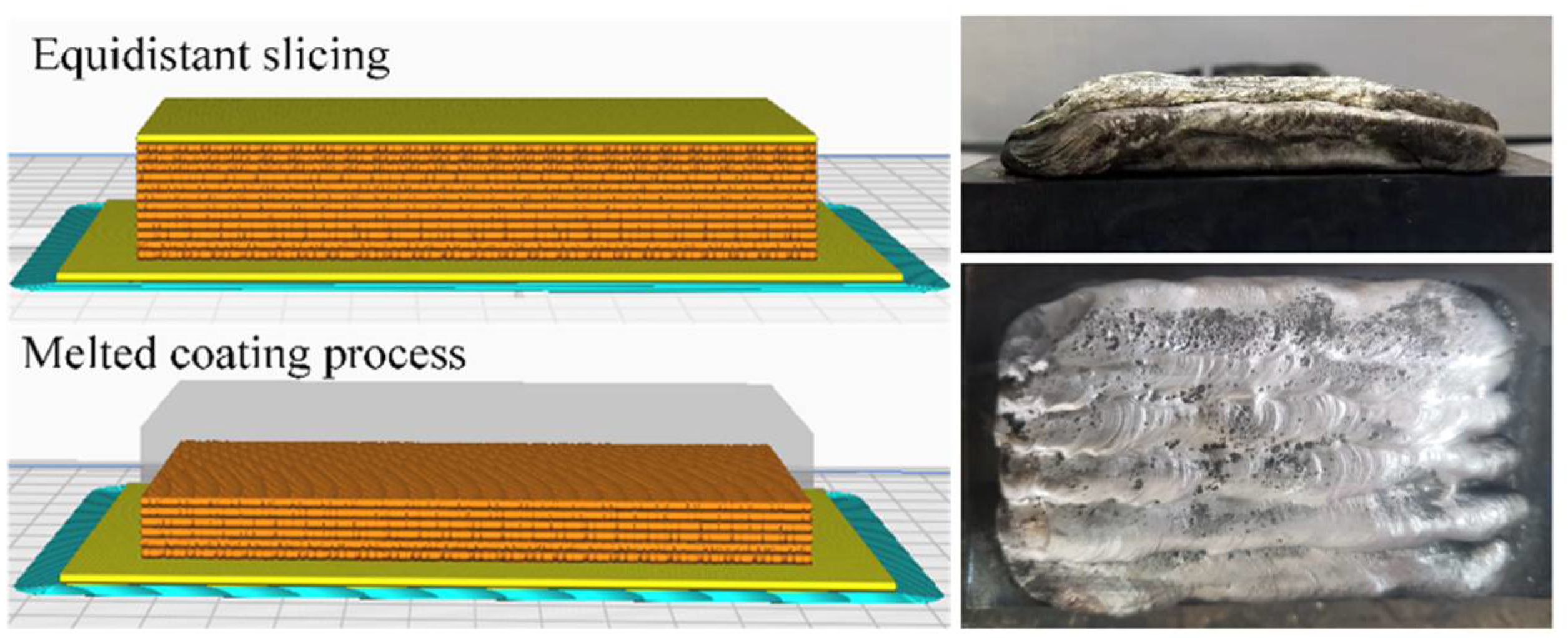

2. Anode Steel Claw Aluminum Deposition and Forming Control

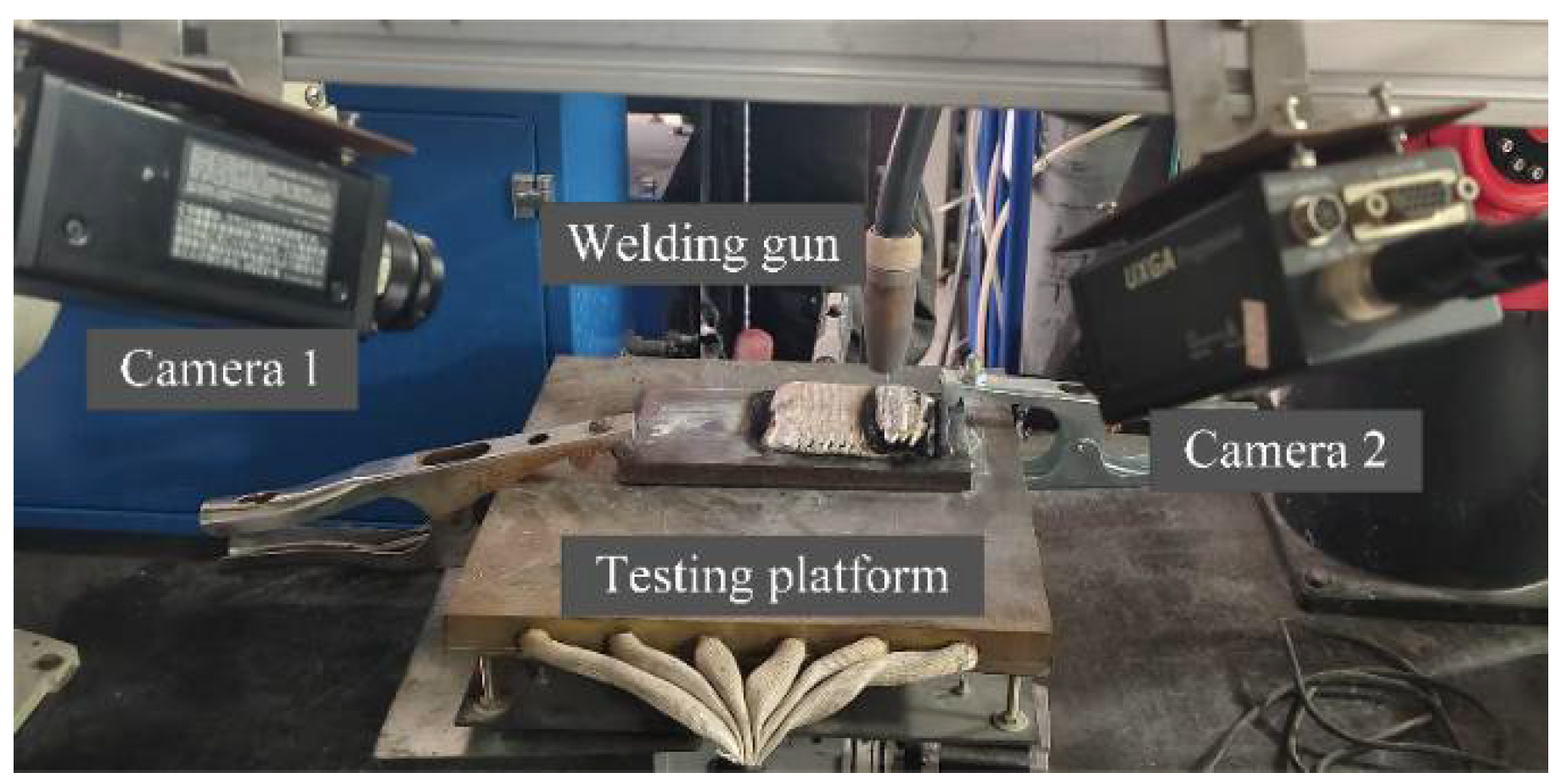

2.1. Experimental System

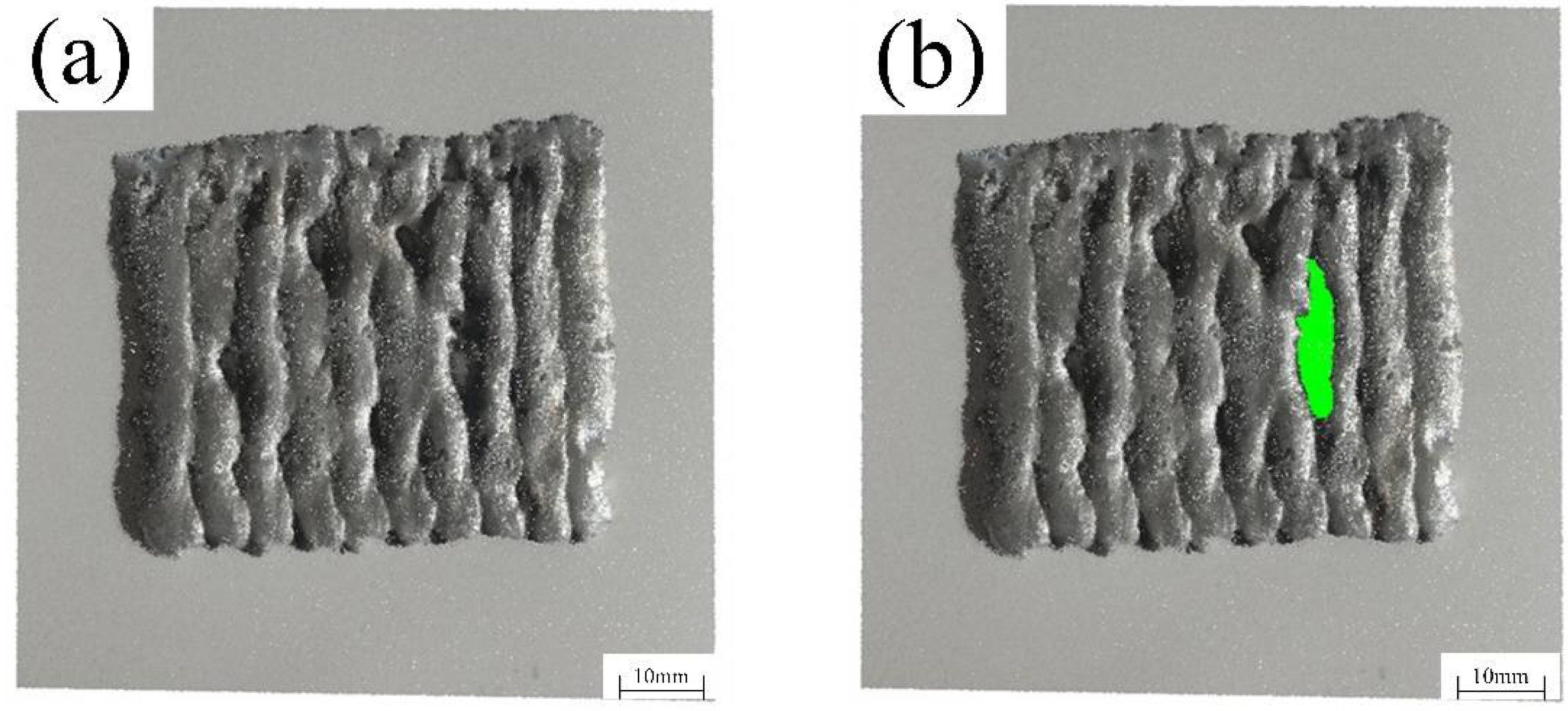

2.2. Steel Surface Cladding and Defect Detection

2.3. Defect Compensation

3. Microstructure and Mechanical Property Analysis

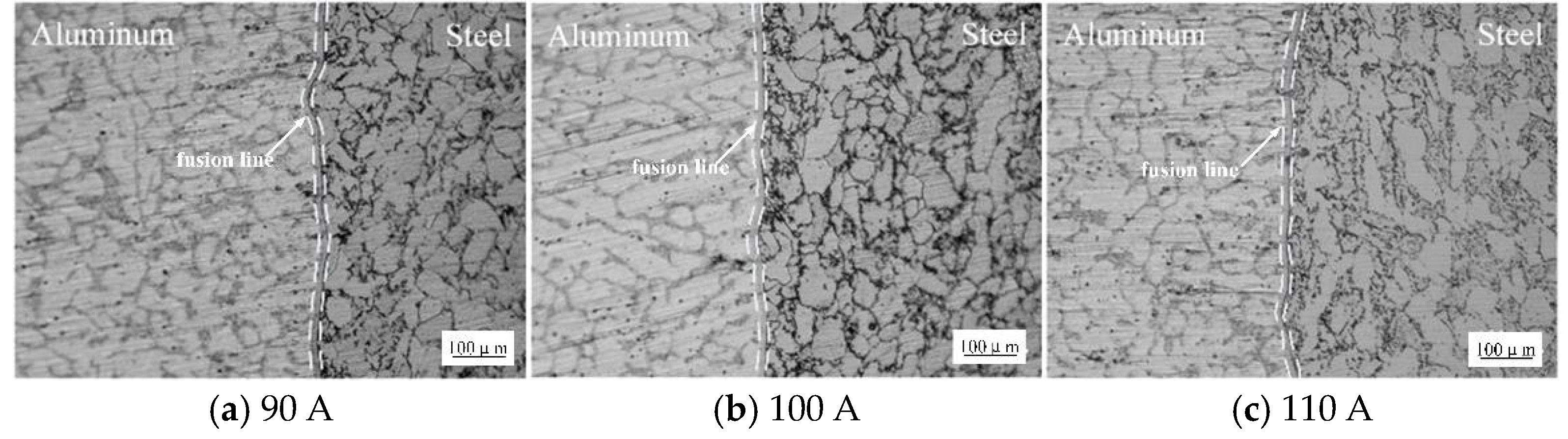

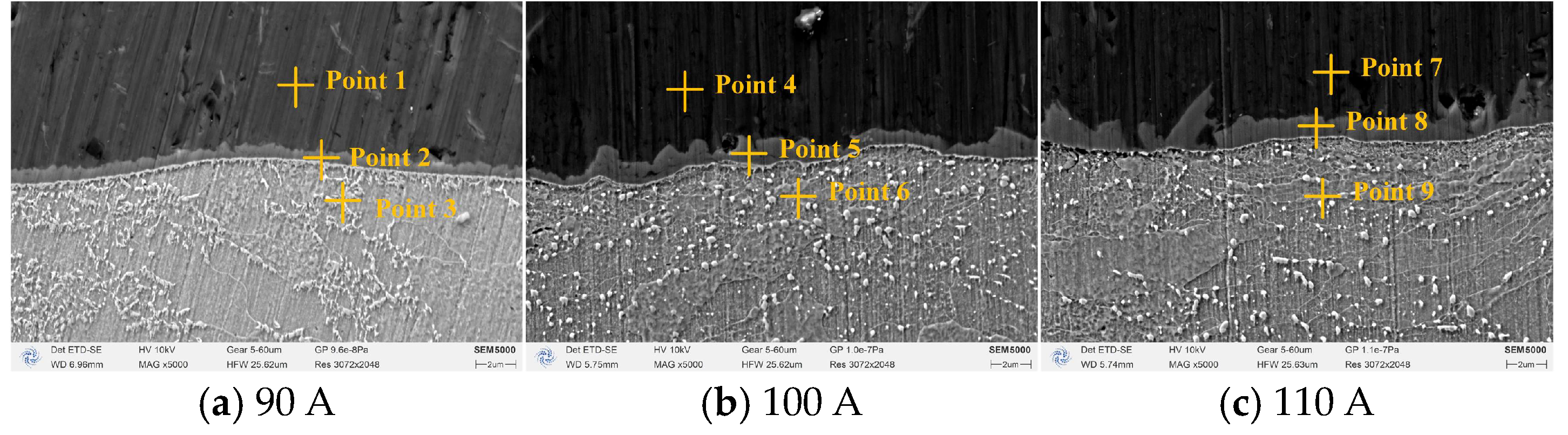

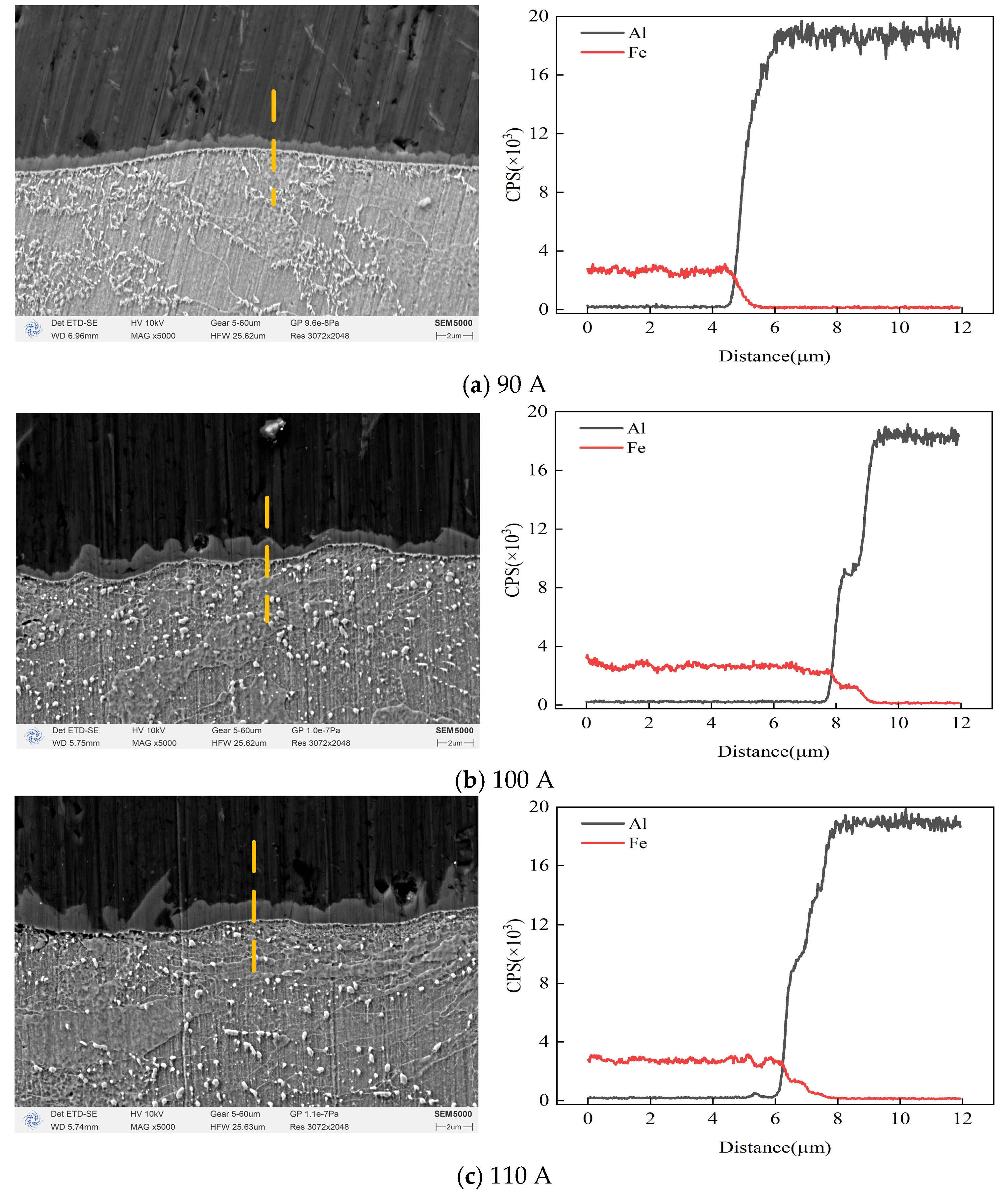

3.1. Microstructure Analysis

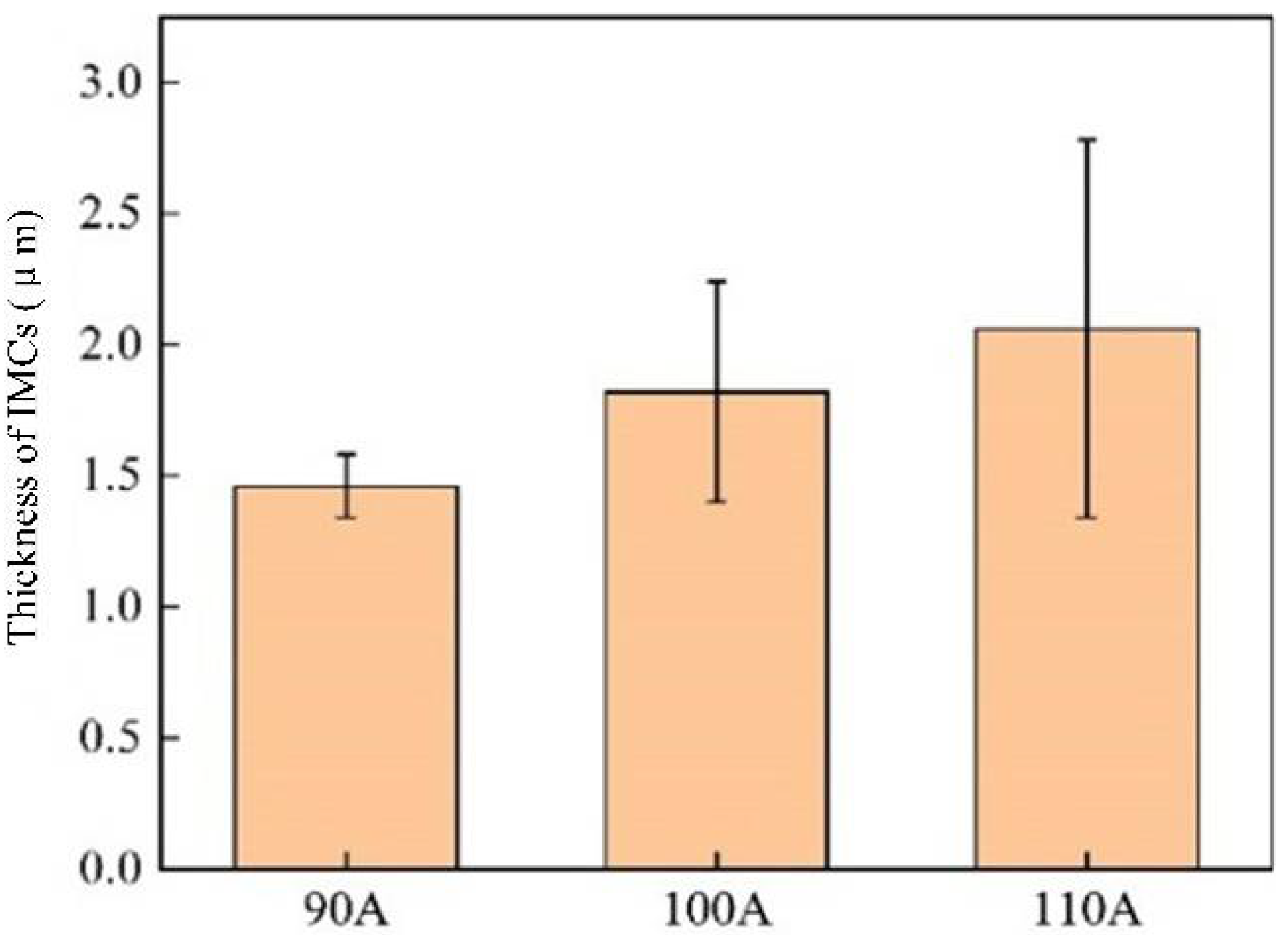

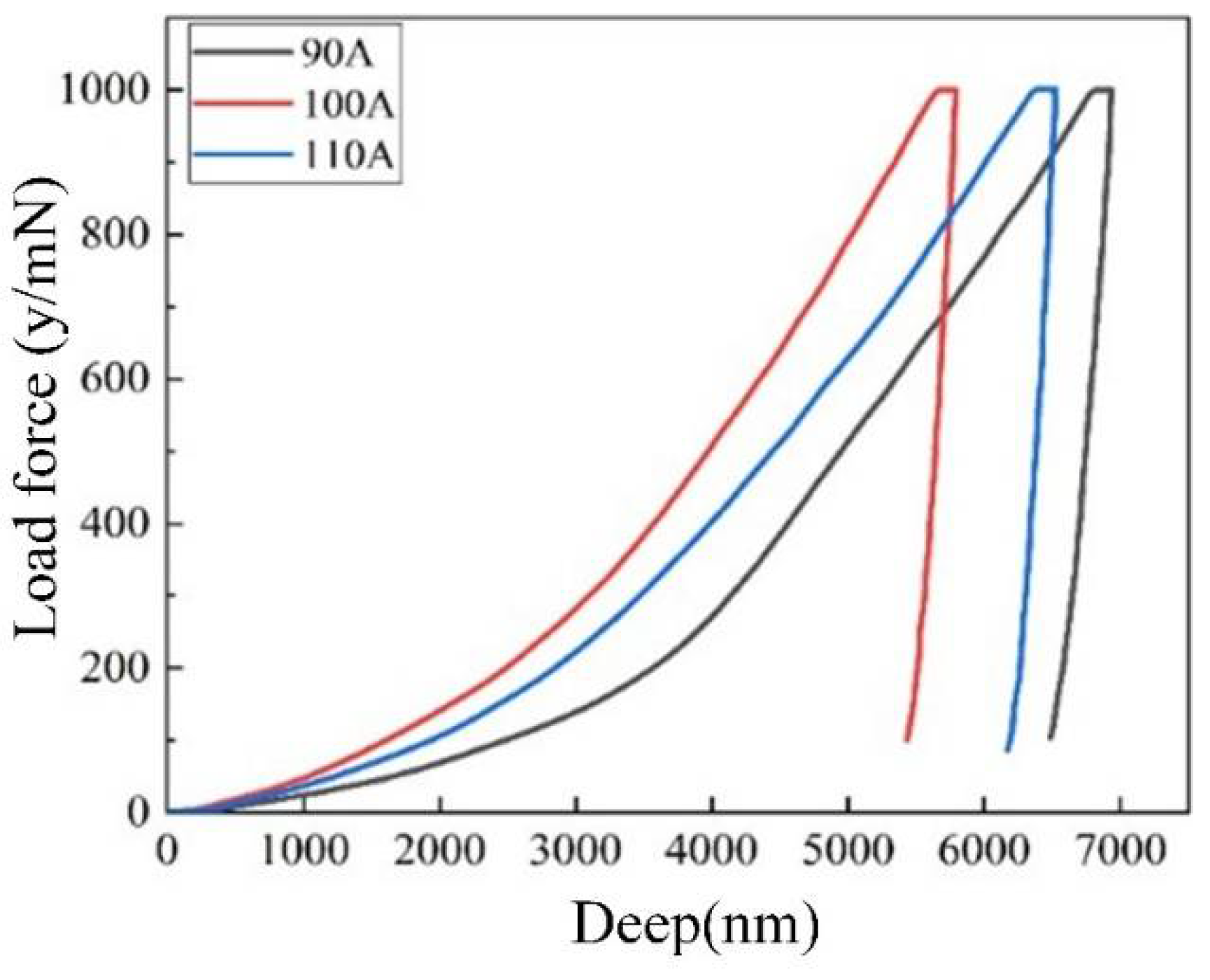

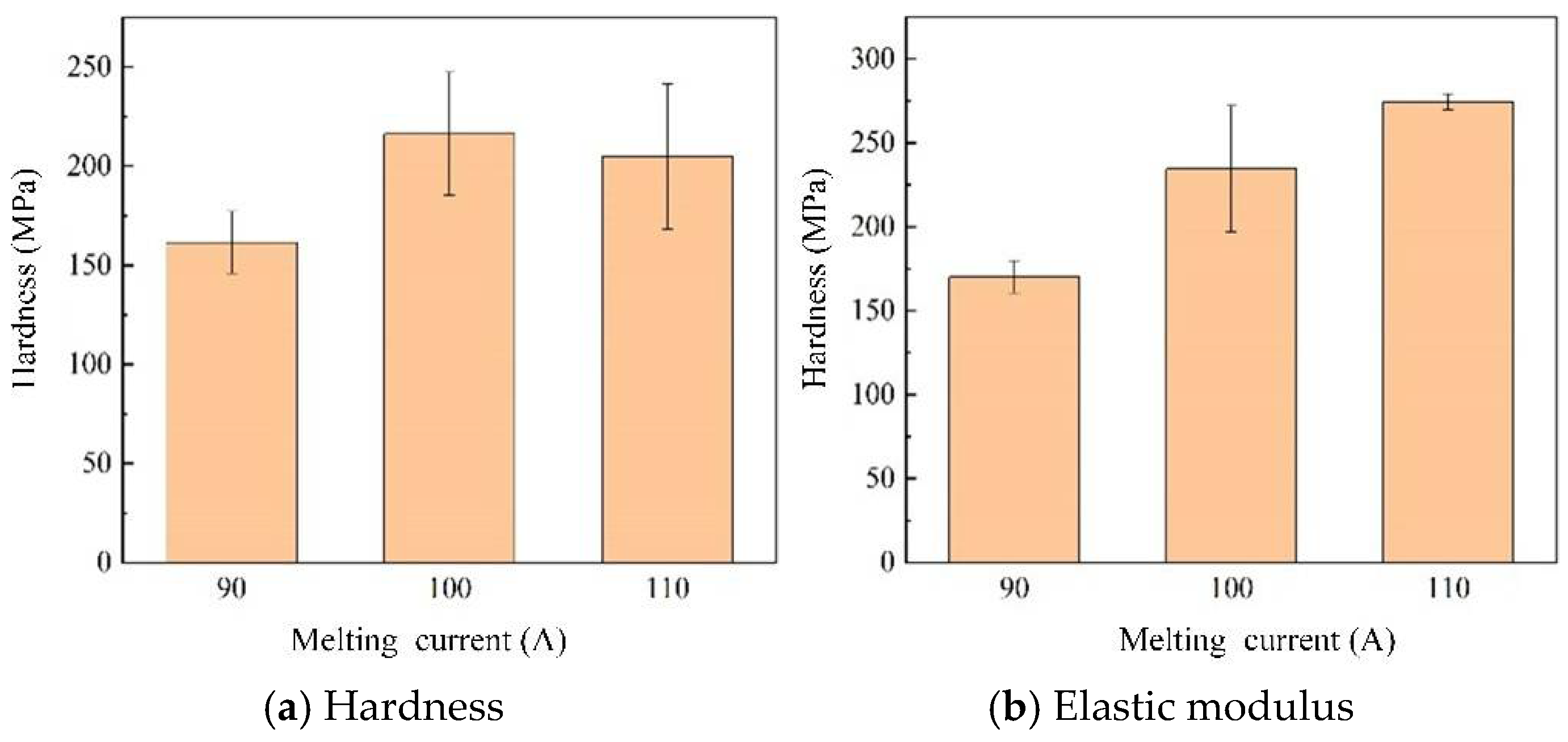

3.2. Nanoindentation Analysis

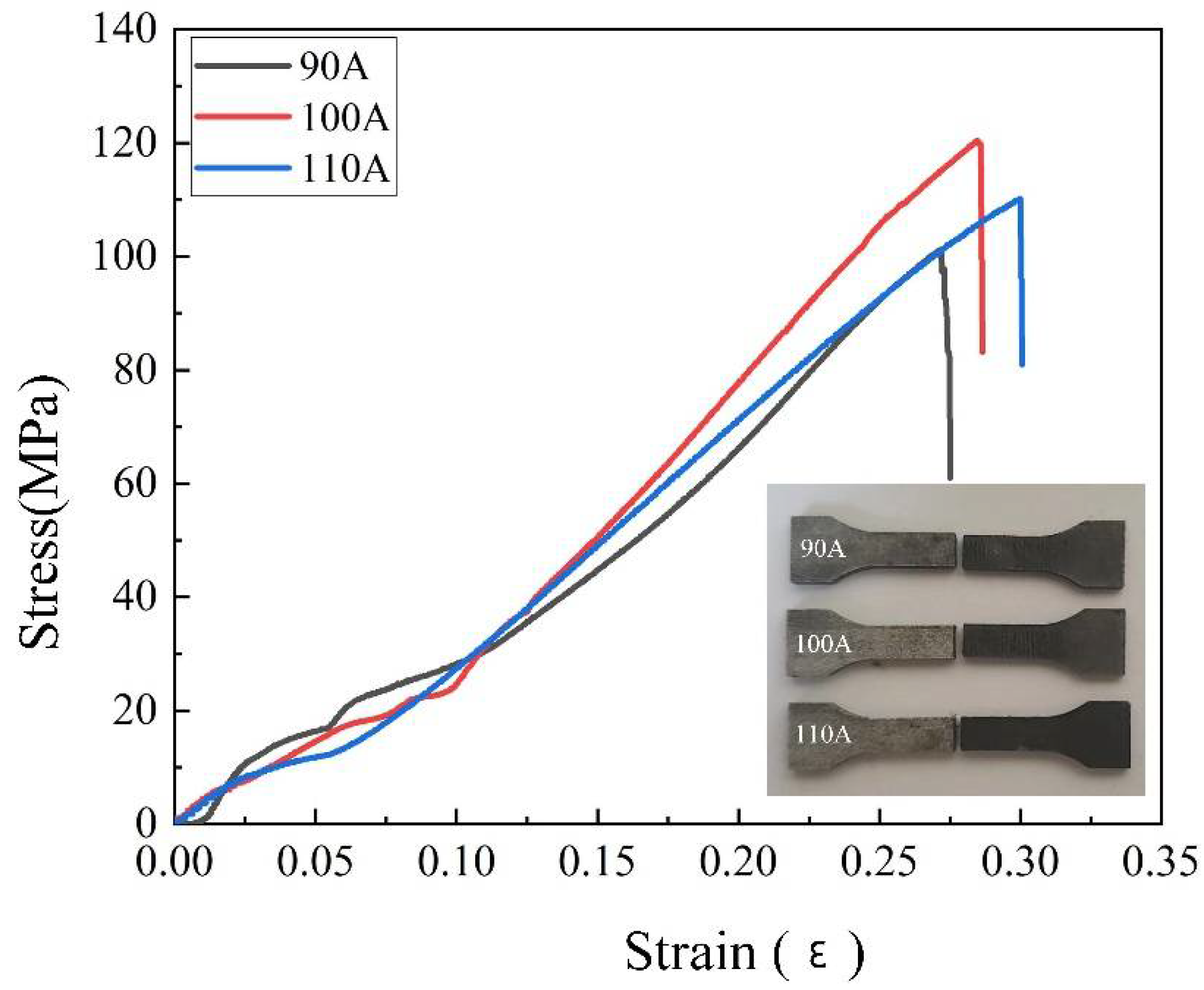

3.3. Tensile Performance Analysis

4. Results Discussion

5. Conclusions

- (1)

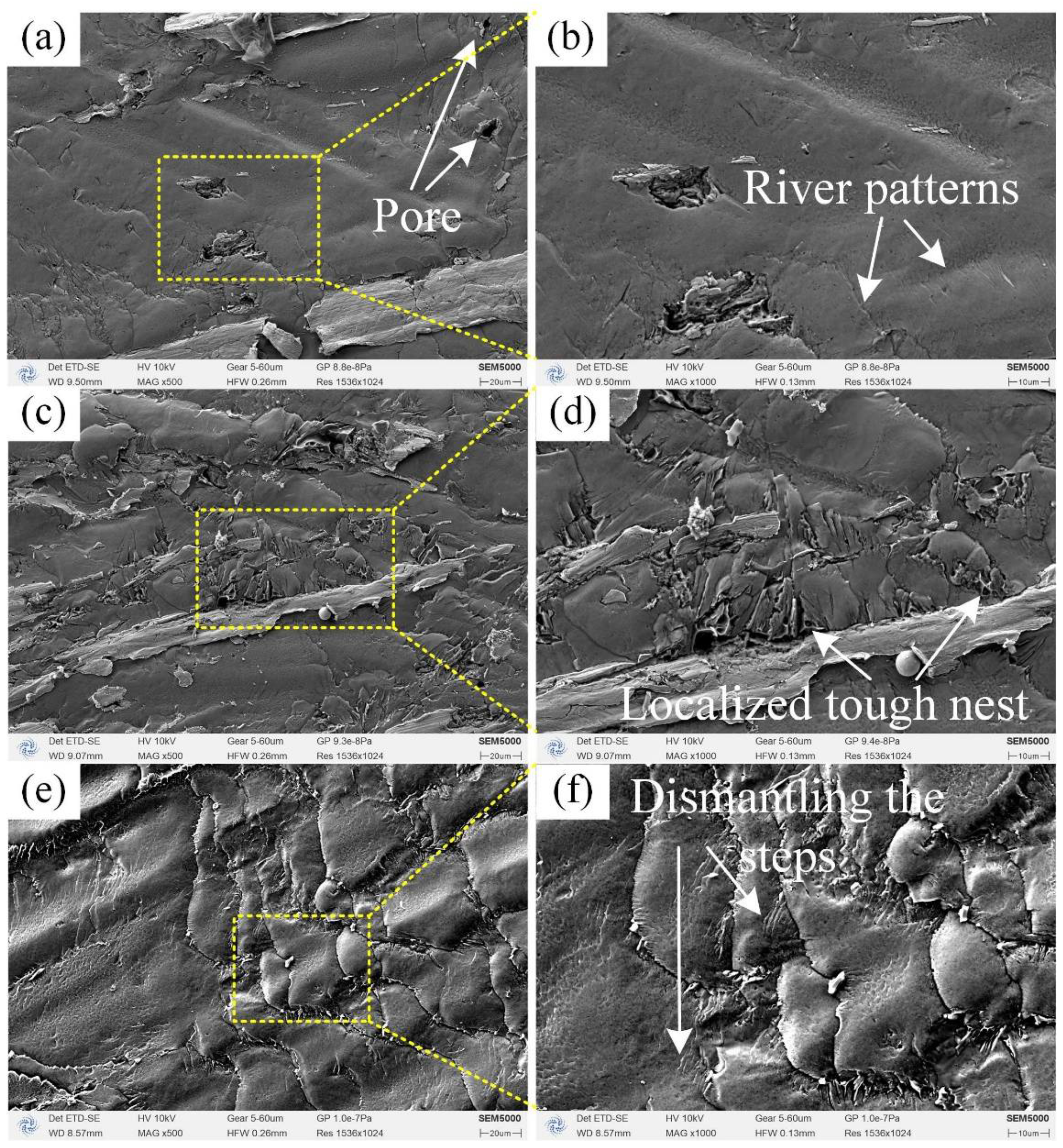

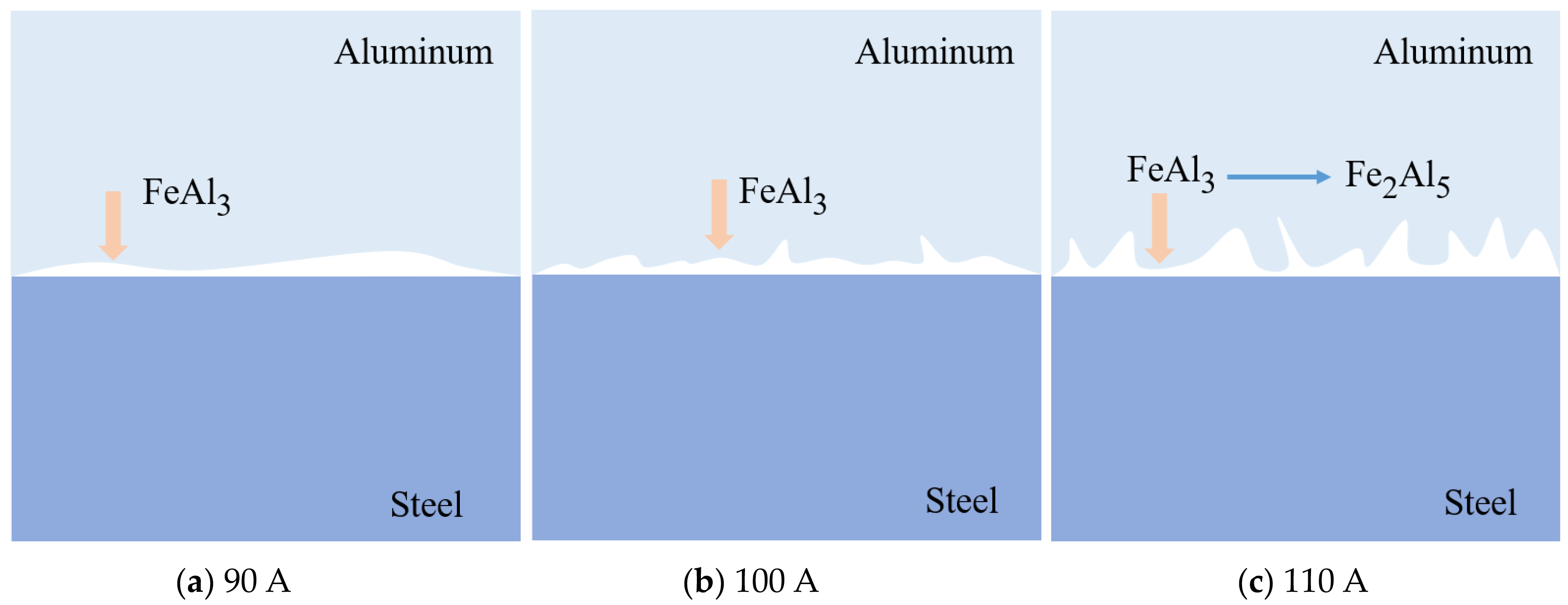

- Microstructural analysis showed that with increasing deposition current, grain size near the fusion line increased, and the thickness of the interfacial layer grew. The thicknesses of intermetallic compounds (IMCs) increased with current, and the brittle Fe2Al5 phase began to appear at 110 A, confirming that welding current has a significant impact on IMC growth at the interface.

- (2)

- Mechanical testing revealed that the joint strength peaked at 100 A (120.45 MPa) and decreased at both lower and higher currents. The fusion zone exhibited the highest hardness, and all specimens showed brittle fracture characteristics.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, J.; Li, J.; Zhang, J.L. Analysis of aluminum resource supply and demand situation in China from a global perspective. China Min. Mag. 2024, 33, 54–62. [Google Scholar]

- Zhang, X.; Hu, X.; Zhao, J.; Chen, C.; He, G.; Zhang, L. The study of thermal-electrical coupling numerical simulation of aluminum electrolytic cell anode assembly and parameter optimization of steel claws. Results Eng. 2025, 26, 104738. [Google Scholar] [CrossRef]

- Zhang, Y.; Zou, N.; Xu, J.; Wang, M.; Wang, X. Numerical Simulations and Experimental Studies for Optimization of Anode Assembly in Aluminum Reduction Cell Using Cast Iron for Anode Fixation Thimble. J. Sustain. Metall. 2024, 10, 2668–2695. [Google Scholar] [CrossRef]

- Wu, J.; Xie, P.; Hao, W.; Lu, D.; Qi, Y.; Mi, Y. Ionic liquids as electrolytes in aluminum electrolysis. Front. Chem. 2022, 10, 1014893. [Google Scholar] [CrossRef] [PubMed]

- Feng, X.; Mao, H.; Liu, C. The Control System of Friction Welding Machine for 5000kN Large Electrolytic Aluminum Prebaked Anode Conductor. J. Phys. Conf. Seri. 2021, 1748, 052016. [Google Scholar] [CrossRef]

- Han, J.; Feng, B.; Chen, Z.; Liang, Z.; Chen, Y.; Liang, X. Simulation and Application of a New Type of Energy-Saving Steel Claw for Aluminum Electrolysis Cells. Sustainability 2024, 16, 8061. [Google Scholar] [CrossRef]

- Liu, J.; Wu, B.; Wang, Z. Microstructure and mechanical properties of aluminum-steel dissimilar metal welded using arc and friction stir hybrid welding. Mater. Des. 2023, 225, 111520. [Google Scholar] [CrossRef]

- Li, P.; Chen, S.; Dong, H.; Ji, H.; Li, Y.; Guo, X.; Yang, G.; Zhang, X.; Han, X. Interfacial microstructure and mechanical properties of dissimilar aluminum/steel joint fabricated via refilled friction stir spot welding. J. Manuf. Process. 2020, 49, 385–396. [Google Scholar] [CrossRef]

- Nandan, G.; Kumar, G.; Arora, K.S.; Kumar, A. MIG and CMT brazing of aluminum alloys and steel: A review. Mater. Today Proc. 2022, 56, 481–488. [Google Scholar] [CrossRef]

- Das, A.; Bang, H.S. Laser and Gas Metal Arc Based Dissimilar Joining of Automotive Aluminium Alloys and Steel Sheets—A Review. J. Weld. Join. 2018, 36, 1–11. [Google Scholar] [CrossRef]

- Acarer, M.; Demir, B. An investigation of mechanical and metallurgical properties of explosive welded aluminum–dual phase steel. Mater. Lett. 2008, 62, 4158–4160. [Google Scholar] [CrossRef]

- Liu, P.; Li, Y.; Wang, J.; Geng, H. Microstructure in interface zone of diffusion-bonded joint of Mg/Al dissimilar materials. Trans. China Weld. Inst. 2004, 5–8. [Google Scholar]

- Macwan, A.; Mirza, F.A.; Bhole, S.D.; Chen, D.L. Similar and Dissimilar Ultrasonic Spot Welding of 5754 Aluminum Alloy for Automotive Applications. Mater. Sci. Forum 2016, 877, 561–568. [Google Scholar] [CrossRef]

- Macwan, A.; Kumar, A.; Chen, D.L. Ultrasonic spot welded 6111-T4 aluminum alloy to galvanized high-strength low-alloy steel: Microstructure and mechanical properties. Mater. Des. 2017, 113, 284–296. [Google Scholar] [CrossRef]

- Xia, H.; Tao, W.; Li, L.; Tan, C.; Zhang, K.; Ma, N. Effect of laser beam models on la ser welding-brazing Al to steel. Opt. Laser Technol. 2020, 122, 105845. [Google Scholar] [CrossRef]

- van der Rest, C.; Jacques, P.J.; Simar, A. On the joining of steel and aluminium by means of a new friction melt bonding process. Scr. Mater. 2014, 77, 25–28. [Google Scholar] [CrossRef]

- Li, R.; Yuan, X.J.; Zhang, H.B. Effect of axial magnetic field on TIG welding–brazing of AA6061 aluminum alloy to HSLA350 steel. J. Mater. Res. Technol. 2021, 12, 882–893. [Google Scholar] [CrossRef]

- Shi, H.; Qiao, S.; Qiu, R.; Zhang, X.; Yu, H. Effect of Welding Time on the Joining Phenomena of Diffusion Welded Joint between Aluminum Alloy and Stainless Steel. Mater. Manuf. Process. 2012, 27, 1366–1369. [Google Scholar] [CrossRef]

- Patel, V.K.; Bhole, S.D.; Chen, D.L. Ultrasonic spot welding of aluminum to high-strength low-alloy steel: Microstructure, tensile and fatigue properties. Metall. Mater. Trans. A 2014, 45, 2055–2066. [Google Scholar] [CrossRef]

- Zhang, H.; Feng, J.; He, P.; Hackl, H. Interfacial microstructure and mechanical properties of aluminium–zinc-coated steel joints made by a modified metal inert gas welding–brazing process. Mater. Charact. 2007, 58, 588–592. [Google Scholar] [CrossRef]

- Cao, R.; Yu, G.; Chen, J.; Wang, P. Cold metal transfer joining aluminum alloys-to-galvanized mild steel. J. Mater. Process. Technol. 2013, 213, 1753–1763. [Google Scholar] [CrossRef]

- Peng, M.; Liu, H.; Liang, Y.; Xu, W.; Zhao, Y.; Chen, S.; Weng, J.; Yang, J. CMT welding-brazing of al/steel dissimilar materials using cycle-step mode. J. Mater. Res. Technol. 2022, 18, 1267–1280. [Google Scholar] [CrossRef]

- Romankov, S.; Park, Y.; Semin, V.; Komarov, S.; Serikkanov, A.; Louzguine-Luzgin, D.V. Solid-state aluminizing process for high-adhesion composite coatings: Synergistic effects of plastic flow, atomic mixing and interaction on structure and properties. Surf. Coat. Technol. 2024, 489, 131099. [Google Scholar] [CrossRef]

- Xu, W.; He, H.; Yi, Y.; Wang, H.; Yu, C.; Fang, W. Dissimilar joining of stainless steel and aluminum using twin-wire CMT. Weld. World 2021, 65, 1541–1551. [Google Scholar] [CrossRef]

- Zhang, S.; Li, S.; Meng, X. Effect of intermetallic compound on the corrosion behaviour of resistance spot welding joints between 5182 aluminium alloy and galvanized DP780 dual-phase steel. Mater. Res. Express 2023, 10, 026515. [Google Scholar] [CrossRef]

- Shi, Y.; Li, J.; Zhang, G.; Huang, J.; Gu, Y. Corrosion behavior of aluminum-steel weld-brazing joint. J. Mater. Eng. Perform. 2016, 25, 1916–1923. [Google Scholar] [CrossRef]

- Atabaki, M.M.; Nikodinovski, M.; Chenier, P.; Ma, J.; Harooni, M.; Kovacevic, R. Welding of aluminum alloys to steels: An overview. J. Manuf. Sci. Prod. 2014, 14, 59–78. [Google Scholar] [CrossRef]

- Dong, P. Quantitative weld quality acceptance criteria: An enabler for structural lightweighting and additive manufacturing. Weld. J. 2020, 99, 39S–51S. [Google Scholar] [CrossRef]

- Wu, S.; Dong, P. Modeling of distributed defects and a proposed fatigue interaction criterion for additively manufactured metal parts. Int. J. Press. Vessel. Pip. 2023, 206, 105048. [Google Scholar] [CrossRef]

- Wu, S.; Cheng, J.; Dong, P.; Zhang, Y.; Zhang, L. Defect Interactions and Effects on Fatigue Behaviors of Additively Manufactured Parts. In Proceedings of the Pressure Vessels and Piping Conference, Atlanta, GA, USA, 16–21 July 2023; Volume 87486, p. V005T06A002. [Google Scholar]

- Feng, J.; Zhang, H.; He, P. The CMT short-circuiting metal transfer process and its use in thin aluminium sheets welding. Mater. Des. 2009, 30, 1850–1852. [Google Scholar] [CrossRef]

- Selvi, S.; Vishvaksenan, A.; Rajasekar, E. Cold metal transfer (CMT) technology—An overview. Def. Technol. 2018, 14, 28–44. [Google Scholar] [CrossRef]

- Hu, Y.; Chen, F.; Cao, S.; Fan, Y.; Xie, R. Preparation and Characterization of CMT Wire Arc Additive Manufac-turing Al-5%Mg Alloy Depositions Through Assisted Longitudinal Magnetic Field. J. Manuf. Process. 2023, 101, 576–588. [Google Scholar] [CrossRef]

- Guo, W.; Huang, X.; Qi, B.; Ren, X.; Chen, H.; Chen, X. Vision-guided path planning and joint configuration optimization for robot grinding of spatial surface weld beads via point cloud. Adv. Eng. Inform. 2024, 61, 102465. [Google Scholar] [CrossRef]

- Xiao, J.L.; Fan, J.S.; Liu, Y.F.; Li, B.L.; Nie, J.G. Region of interest (ROI) extraction and crack detection for UAV-based bridge inspection using point cloud segmentation and 3D-to-2D projection. Autom. Constr. 2024, 158, 105226. [Google Scholar] [CrossRef]

- Zhang, Y.; Geng, Y.; Tian, X.; Sun, Y.; Xu, X. A novel weld seam extraction method with semantic segmentation and point cloud feature for irregular structure workpieces. Robot. Comput. Integr. Manuf. 2025, 95, 102987. [Google Scholar] [CrossRef]

- GB/T 3246.1-2024; National Technical Committee for Standardization of Nonferrous Metals (SAC/TC 243). Inspection Methods for Microstructure of Wrought Aluminium and Aluminium Alloys—Part 1: Microscopic Examination Method. Standards Press of China: Beijing, China, 2024.

- Xu, D.; Harvey, T.; Begiristain, E.; Domínguez, C.; Sánchez-Abella, L.; Browne, M.; Cook, R.B. Measuring the elastic modulus of soft biomaterials using nanoindentation. J. Mech. Behav. Biomed. Mater. 2022, 133, 105329. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Huang, J.; Yang, T.; Fan, D. The growth behavior for intermetallic compounds at the interface of aluminum-steel weld joint. Materials 2022, 15, 3563. [Google Scholar] [CrossRef] [PubMed]

- Chen, N.; Wang, M.; Wang, H.; Wan, Z.; Blair, E.C. Microstructural and mechanical evolution of Al/steel interface with Fe2Al5 growth in resistance spot welding of aluminum to steel. J. Manuf. Process. 2018, 34, 424–434. [Google Scholar] [CrossRef]

- Huang, S.; Yu, H.; Lou, M.; Xu, L.; Lu, R.; Li, Z.; Li, Y. Effect of Ti interlayers on microstructure and mechanical properties of laser spiral fusion welded steel/aluminum lap joints. J. Mater. Res. Technol. 2025, 35, 1752–1763. [Google Scholar] [CrossRef]

- Wang, H.; Yang, F.; Zhang, Z.; Liu, L. Bonding mechanism of Al/steel interface formed by laser-TIG welding assisted riveting technology. Mater. Today Commun. 2020, 25, 101487. [Google Scholar] [CrossRef]

- Li, Q.; Yang, S.; Hu, B.; Xue, S. Laser welding of aluminum/steel dissimilar metals and control of intermetallic compounds: A review. Int. J. Adv. Manuf. Technol. 2025, 137, 4283–4308. [Google Scholar] [CrossRef]

| Elements | C | Mn | Si | S | P | Fe |

| Content | ≤0.22 | ≤1.4 | ≤0.35 | ≤0.050 | ≤0.045 | Remainder |

| Elements | Mg | Fe | Cu | Mn | Si | Cr | Zn | Ti | Al |

| Content | 5.5 | 0.40 | 0.10 | 0.20 | 0.25 | 0.20 | 0.10 | 0.20 | Remainder |

| Point | Fe | Al | Mg |

|---|---|---|---|

| 1 | 1.87 | 98.13 | 0 |

| 2 | 18.85 | 81.15 | 0 |

| 3 | 99.40 | 0.57 | 0.03 |

| 4 | 0 | 100 | 0 |

| 5 | 23.73 | 76.27 | 0 |

| 6 | 99.35 | 0.58 | 0.07 |

| 7 | 0.03 | 99.97 | 0 |

| 8 | 27.18 | 72.82 | 0 |

| 9 | 98.97 | 1.01 | 0.02 |

| Welding Current (A) | Hardness (MPa) | Elastic Modulus Er (GPa) |

|---|---|---|

| 90 | 161.57 | 170.12 |

| 100 | 216.29 | 234.63 |

| 110 | 204.77 | 274.49 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Du, H.; Wang, X.; Zhang, Y.; Zhao, J.; Zhang, P.; Huang, J.; Fan, D. Deposition Process and Interface Performance of Aluminum–Steel Joints Prepared Using CMT Technology. Metals 2025, 15, 844. https://doi.org/10.3390/met15080844

Zhang J, Du H, Wang X, Zhang Y, Zhao J, Zhang P, Huang J, Fan D. Deposition Process and Interface Performance of Aluminum–Steel Joints Prepared Using CMT Technology. Metals. 2025; 15(8):844. https://doi.org/10.3390/met15080844

Chicago/Turabian StyleZhang, Jie, Hao Du, Xinyue Wang, Yinglong Zhang, Jipeng Zhao, Penglin Zhang, Jiankang Huang, and Ding Fan. 2025. "Deposition Process and Interface Performance of Aluminum–Steel Joints Prepared Using CMT Technology" Metals 15, no. 8: 844. https://doi.org/10.3390/met15080844

APA StyleZhang, J., Du, H., Wang, X., Zhang, Y., Zhao, J., Zhang, P., Huang, J., & Fan, D. (2025). Deposition Process and Interface Performance of Aluminum–Steel Joints Prepared Using CMT Technology. Metals, 15(8), 844. https://doi.org/10.3390/met15080844