The Influence of Temperature on the Fracture Toughness and Fracture Mechanism of Ferritic Nodular Cast Iron

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

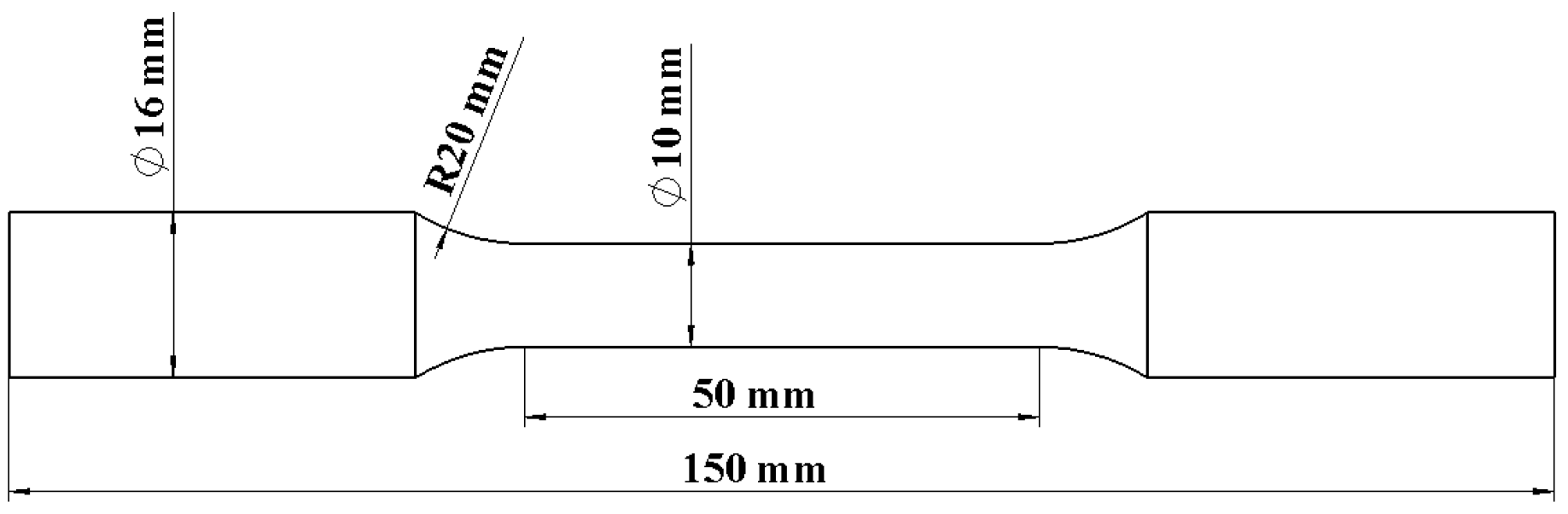

2.2. Tensile Test

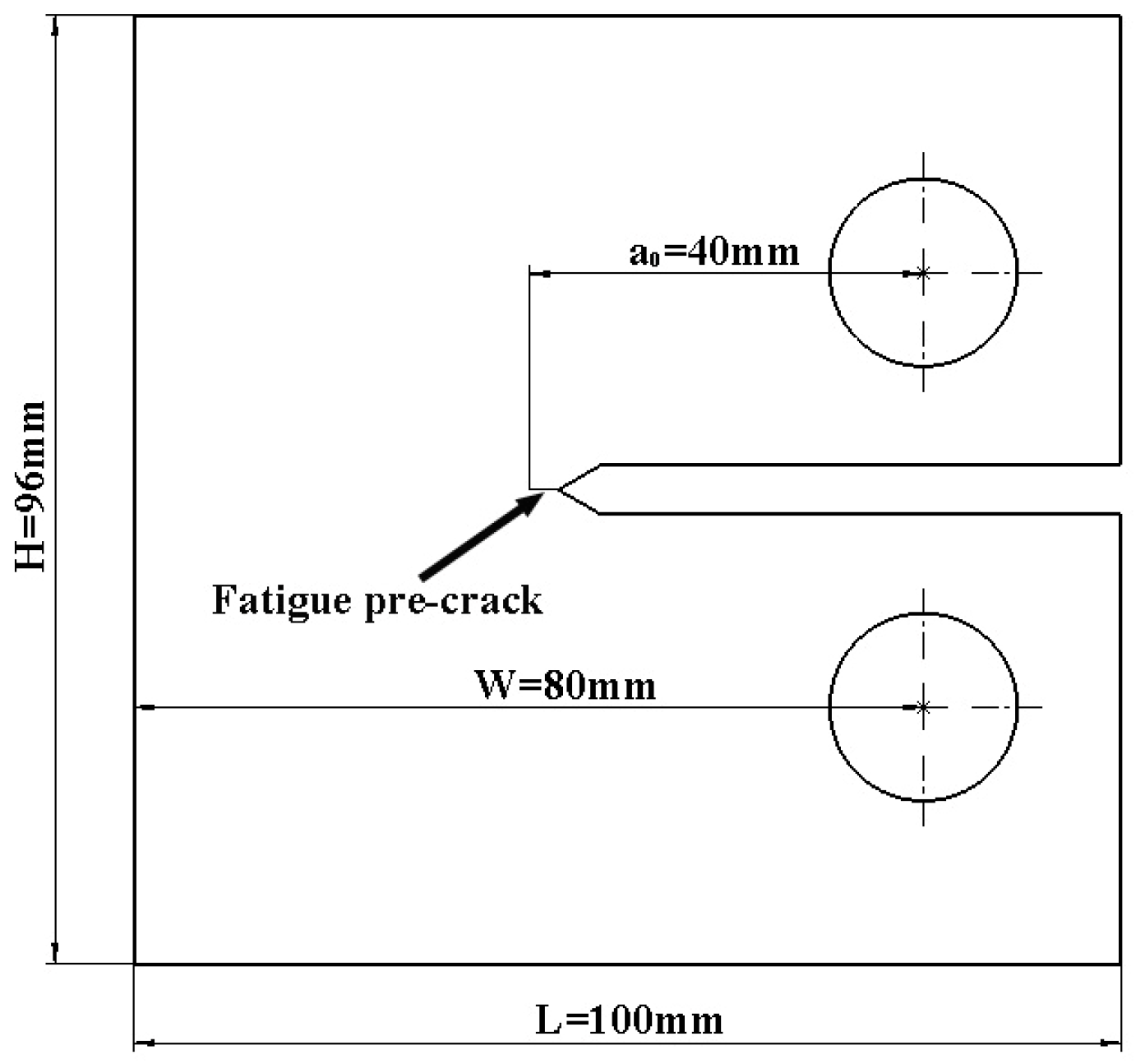

2.3. Fracture Toughness Tests

2.4. Microscopic Observation of Fracture Surfaces

3. Results

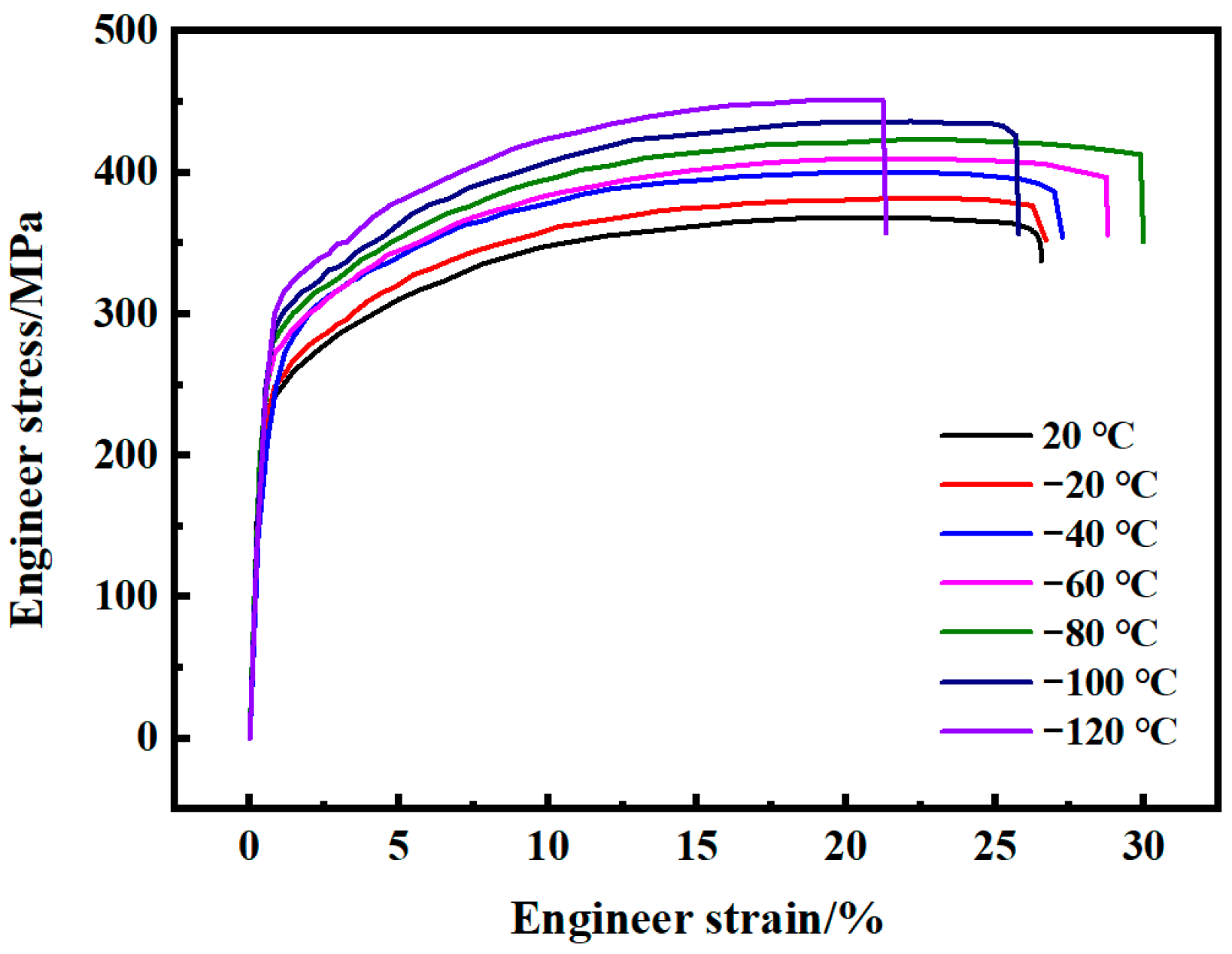

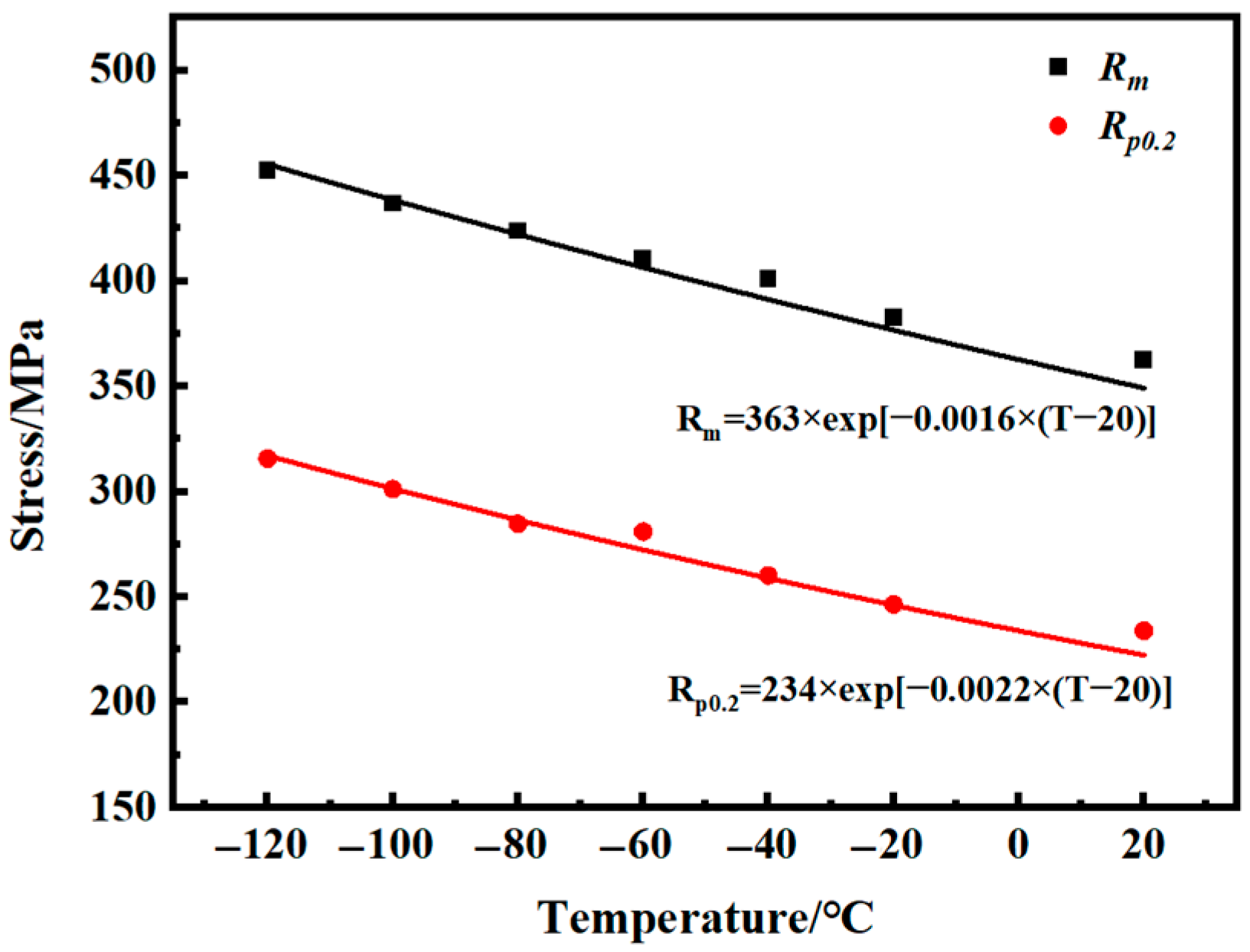

3.1. Tensile Properties Results

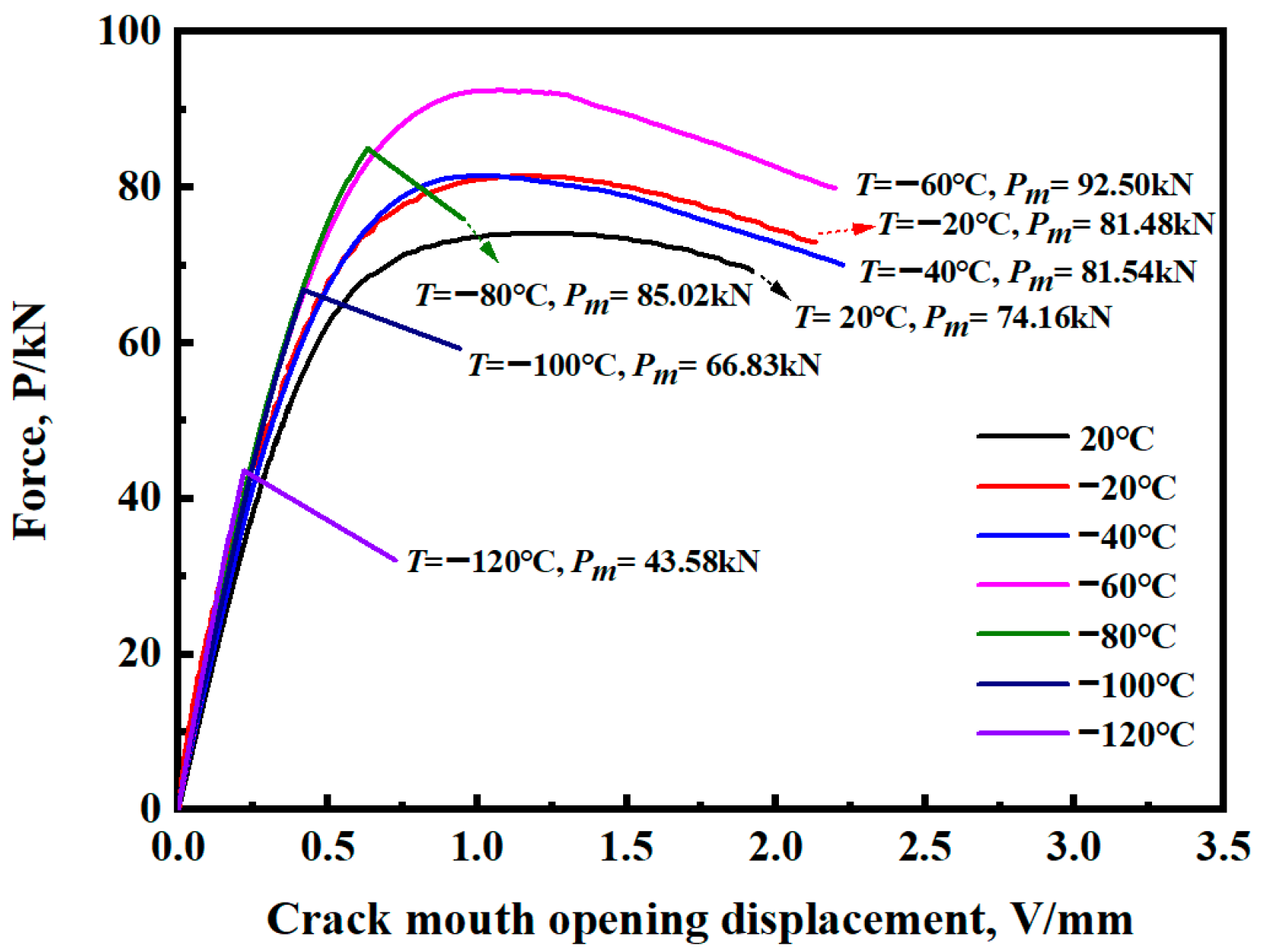

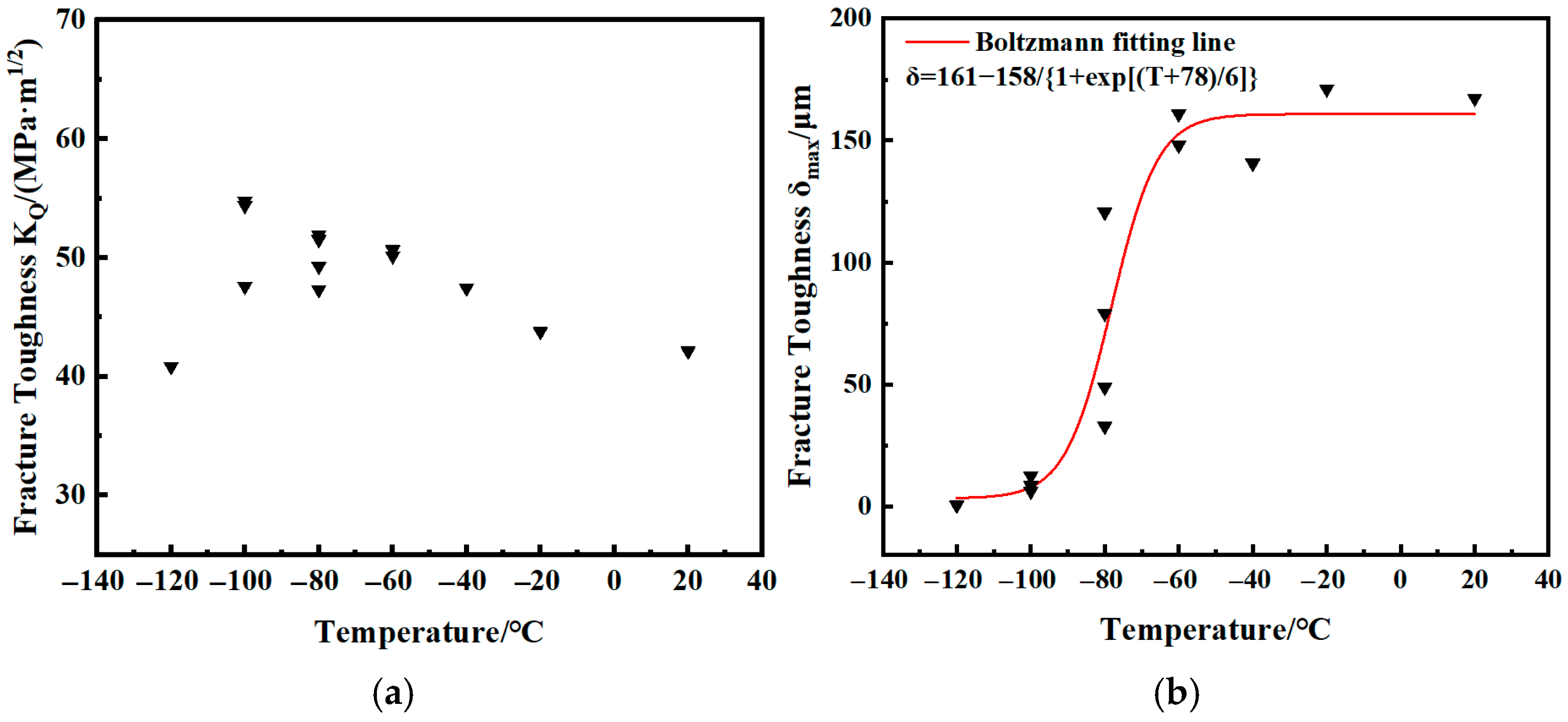

3.2. Fracture Test Results

4. Discussion

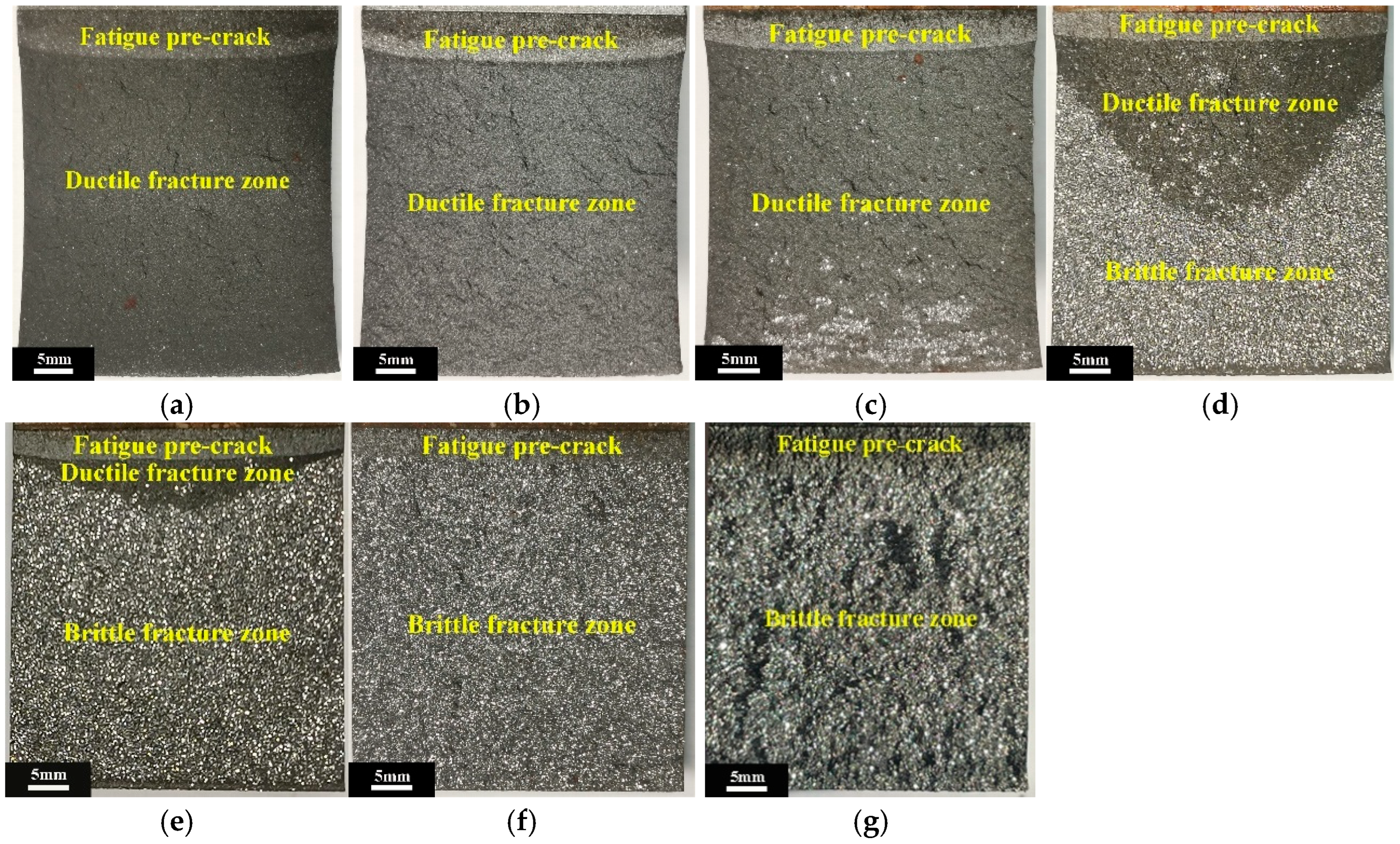

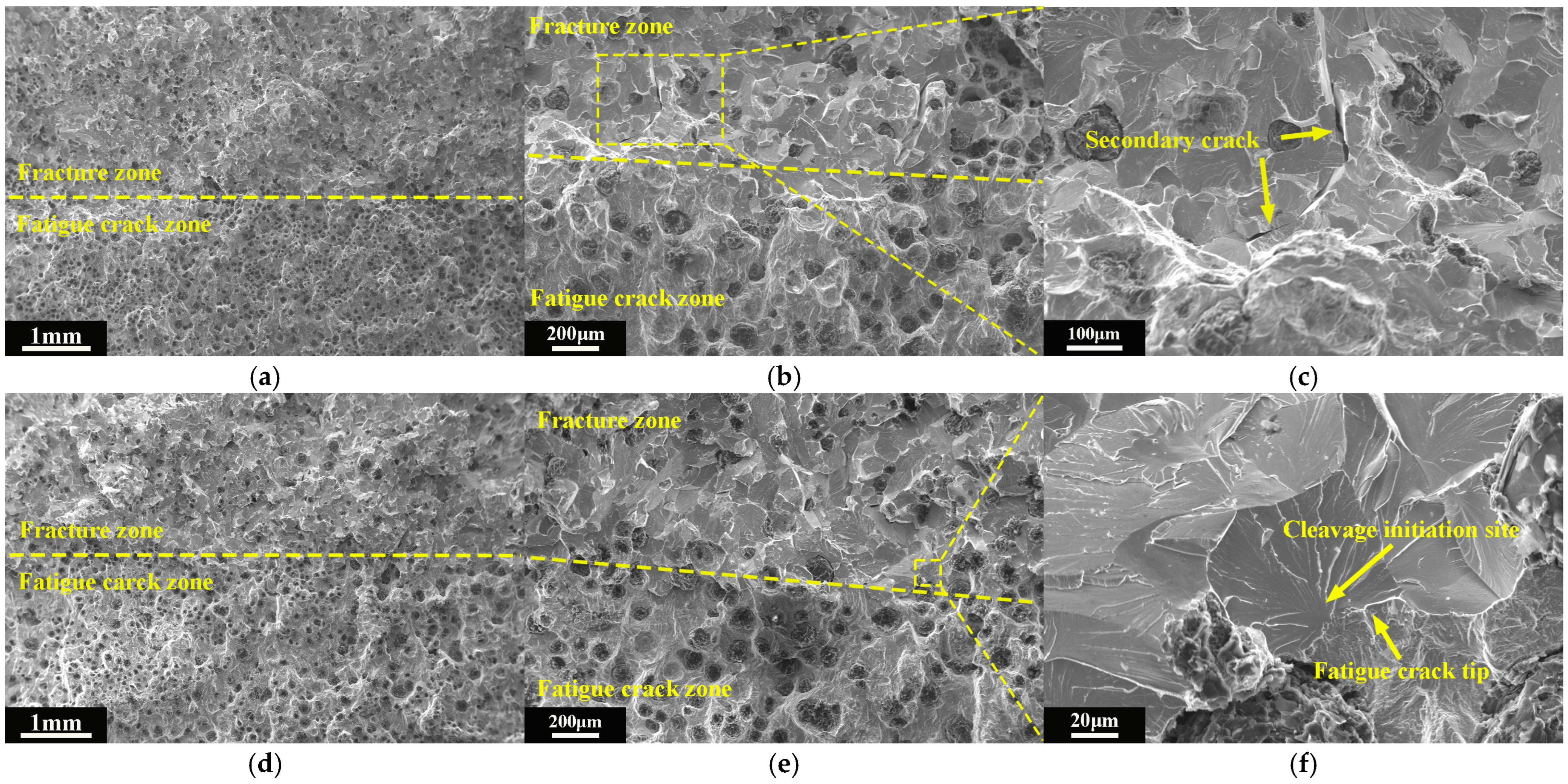

4.1. Fracture Mechanisms in Different Temperature Regions

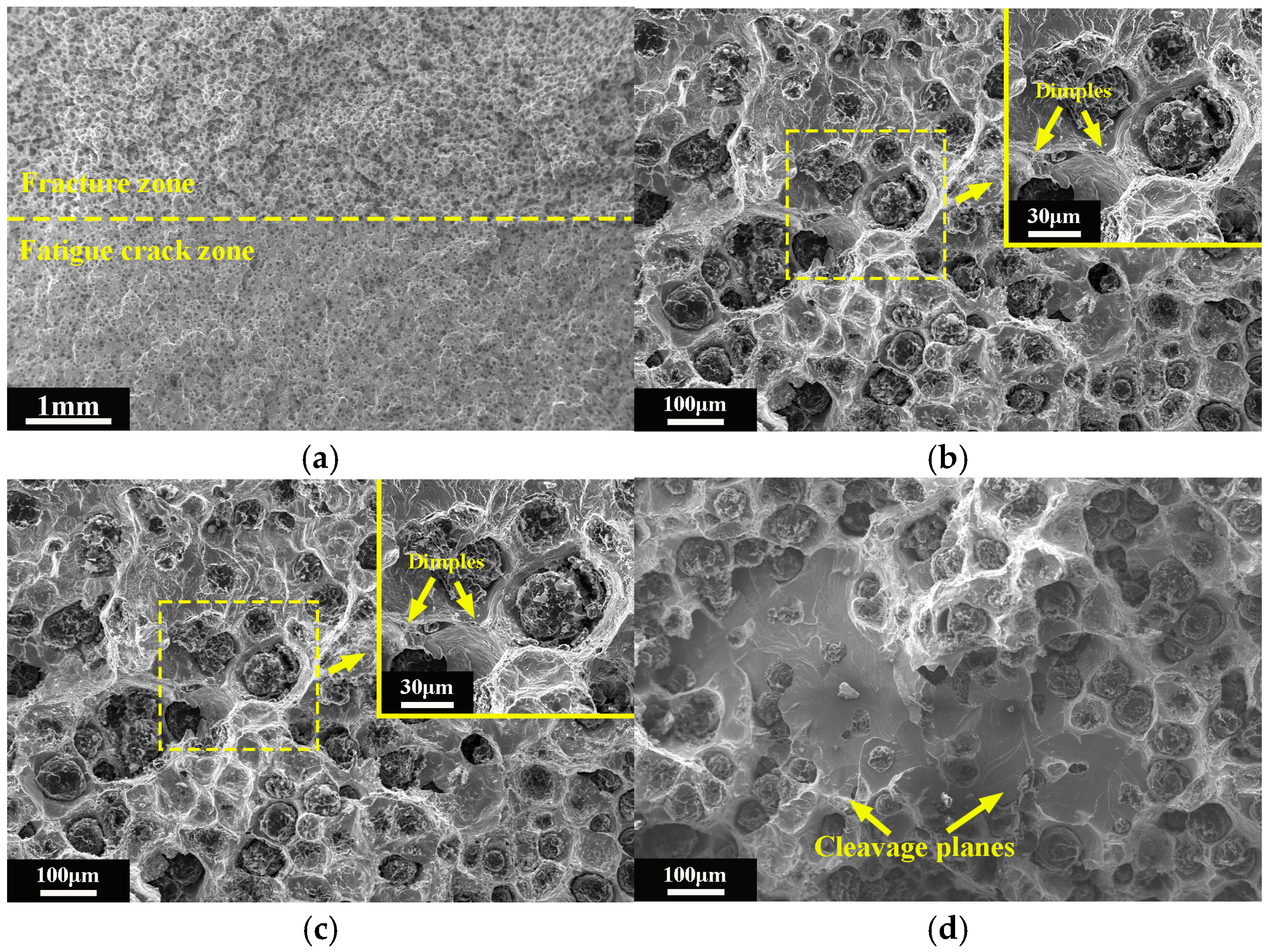

4.1.1. Fracture Mechanisms in the Upper Shelf Region

4.1.2. Fracture Mechanisms in the Transition Region

4.1.3. Fracture Mechanisms in the Lower Shelf Region

4.2. The Role of Graphite Nodules in the Crack Propagation Process

5. Conclusions

- (1)

- The fracture toughness of NCI demonstrates a temperature-dependent trend. KQ increased with decreasing temperature when the temperature was above −80 °C, and then decreased with decreasing temperature. δm shows a significant ductile–brittle transition behavior with the decrease in temperature.

- (2)

- The increased yield strength and reconstructed crack-tip stress field at low temperatures lead to the progressive fulfillment of cleavage fracture conditions in localized regions. The fracture mechanism undergoes progressive transition from ductile micro-void coalescence (above −60 °C) through mixed-mode propagation (−60 °C to −100 °C) to fully brittle cleavage fracture (below −100 °C).

- (3)

- In the case of ductile fracture, graphite nodules will promote the formation of dimples. At low temperature, the formation of dimples was inhibited, and the crack continued to expand in its original direction after bypassing the graphite nodule.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Morrogh, H.; Williams, W.J. The production of nodular graphite structures in cast iron. J. Iron Steel Inst. 1948, 158, 306–322. [Google Scholar]

- Bradley, W.L.; Srinivasan, M.N. Fracture and fracture toughness of cast irons. Int. Mater. Rev. 1990, 35, 129–161. [Google Scholar] [CrossRef]

- Bralower Paul, M. Ductile Iron Cask Cleared for Nuclear Fuel Storage. Mod. Cast. 1987, 77, 21–23. [Google Scholar]

- GB11806-2019; Regulations for the Safe Transport of Radioactive Materials. Standardization Administration of China: Beijing, China, 2019.

- Yu, P.S.; Zhao, J.H.; Guo, W.L. Three-dimensional Damage Tolerance Design: Out-of-plane Constraint Theory and Fatigue/Fracture Criteria. Jixie Gongcheng Xuebao/J. Mech. Eng. 2021, 57, 87–105. [Google Scholar]

- Ikeda, T.; Umetani, T.; Kai, N.; Noda, N.-A.; Sano, Y. Strain rate and temperature insensitiveness of notch-bend strength for high Si ductile cast iron. ISIJ Int. 2016, 56, 868–874. [Google Scholar] [CrossRef][Green Version]

- Wang, W.; Wang, Z.; Sun, Z.; Zhou, Z.; Zhang, K.; Ma, L.; Wang, Y.; Yang, S.; Huang, Z.; Wang, K. Study of fractography of ferritic ductile iron at different temperatures and loading conditions. Mater. Res. Express 2024, 11, 016511. [Google Scholar] [CrossRef]

- Minnebo, P.; Nilsson, K.F.; Blagoeva, D. Tensile, compression and fracture properties of thick-walled ductile cast iron components. J. Mater. Eng. Perform. 2007, 16, 35–45. [Google Scholar] [CrossRef]

- Hütter, G.; Zybell, L.; Kuna, M. Micromechanisms of fracture in nodular cast iron: From experimental findings towards modeling strategies—A review. Eng. Fract. Mech. 2015, 144, 118–141. [Google Scholar] [CrossRef]

- Ghahremaninezhad, A.; Ravi-Chandar, K. Deformation and failure in nodular cast iron. Acta Mater. 2012, 60, 2359–2368. [Google Scholar] [CrossRef]

- Salzbrenner, R. Fracture toughness behaviour of ferritic ductile cast iron. J. Mater. Sci. 1987, 22, 2135–2147. [Google Scholar] [CrossRef]

- Kobayashi, T.; Yamada, S. Evaluation of static and dynamic fracture toughness in ductile cast iron. Metall. Mater. Trans. A 1994, 25, 2427–2436. [Google Scholar] [CrossRef]

- Baer, W. Performance of modern DCI materials—Investigation of microstructural, temperature and loading rate effects on mechanical and fracture mechanical properties. Mater. Sci. Forum 2014, 783–786, 2244–2249. [Google Scholar] [CrossRef]

- Zhu, M.L.; Xuan, F.Z. Effects of temperature on tensile and impact behavior of dissimilar welds of rotor steels. Mater. Des. 2010, 31, 3346–3352. [Google Scholar] [CrossRef]

- Jang, Y.C.; Lee, Y. A model to predict the fracture distance of cleavage fracture as a function of temperature. Eng. Fract. Mech. 2011, 78, 2082–2087. [Google Scholar] [CrossRef]

- Shashank Dutt, B.; Nani Babu, M.; Venugopal, S.; Sasikala, G.; Bhaduri, A.K. Effect of test temperature on fracture toughness of modified 9Cr-1Mo steel. Mater. Sci. Technol. 2011, 27, 1527–1533. [Google Scholar] [CrossRef]

- Xue, C.; Yang, M.; Liu, P.; Yan, L.; Shang, X.; Liang, Z.; Ren, X. Effects of rolling process and microstructure on the brittle crack initiation and arrest of a marine steel under low-temperature. Fatigue Fract. Eng. Mater. Struct. 2024, 47, 2841–2856. [Google Scholar] [CrossRef]

- Menzemer, C.C.; Srivatsan, T.S.; Ortiz, R. Influence of temperature on impact fracture behavior of an alloy steel. Mater. Des. 2001, 22, 659–667. [Google Scholar] [CrossRef]

- Zhang, X.N.; Qu, Y.D.; Li, R.D. Low Temperature Impact Toughness and Fracture Analysis of EN-GJS-400-18-LT Ductile Iron under Instrumented Impact Load. J. Iron Steel Res. Int. 2015, 22, 864–869. [Google Scholar] [CrossRef]

- Shaw, N.B.; Spink, G.M. Effect of Temperature, Specimen Size, and Geometry on the Fracture Toughness of a 3 Pct NiCrMoV Low Pressure Turbine Disc Steel. Metall. Trans. A 1983, 14, 751–759. [Google Scholar] [CrossRef]

- Xue, C.; Yang, M.; Liu, P.; Cheng, Y.; Shang, X.; Ren, X. Fracture Toughness and Fracture Mechanism of EH47 High-Strength Steel Subjected to Different Temperatures. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2022, 53, 3588–3603. [Google Scholar] [CrossRef]

- ISO 945-4; Microstructure of Cast Irons—Part 4. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 12135; Metallic Materials—Unified Method of Test for the Determination of Quasistatic Fracture Toughness. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 1083; Spheroidal Graphite Cast Irons—Classification. International Organization for Standardization: Geneva, Switzerland, 2018.

- Spätig, P.; Odette, G.R.; Lucas, G.E. Low temperature yield properties of two 7-9Cr ferritic/martensitic steels. J. Nucl. Mater. 1999, 275, 324–331. [Google Scholar] [CrossRef]

- Chen, J.H.; Wang, G.Z. Study of mechanism of cleavage fracture at low temperature. Metall. Trans. A 1992, 23, 509–517. [Google Scholar] [CrossRef]

- Cao, R.; Li, G.; Fang, X.Y.; Song, J.; Chen, J.H. Investigation on the effects of microstructure on the impact and fracture toughness of a C-Mn steel with various microstructures. Mater. Sci. Eng. A 2013, 564, 509–524. [Google Scholar] [CrossRef]

- Østby, E.; Thaulow, C.; Zhang, Z.L. Numerical simulations of specimen size and mismatch effects in ductile crack growth—Part II: Near-tip stress fields. Eng. Fract. Mech. 2007, 74, 1793–1809. [Google Scholar] [CrossRef]

- Dai, P.Q.; He, Z.R.; Zheng, C.M.; Mao, Z.Y. In-situ SEM observation on the fracture of austempered ductile iron. Mater. Sci. Eng. A 2001, 319, 531–534. [Google Scholar] [CrossRef]

- Fan, Z.K.; Smallman, R.E. Some observations on the fracture of austempered ductile iron. Scr. Metall. Mater. 1994, 31, 137–142. [Google Scholar] [CrossRef]

- Di Cocco, V.; Iacoviello, F.; Cavallini, M. Damaging micromechanisms characterization of a ferritic ductile cast iron. Eng. Fract. Mech. 2010, 77, 2016–2023. [Google Scholar] [CrossRef]

- Zhang, X.N.; Qu, Y.D.; Li, R.D.; You, J.H. Mechanism of crack nucleation and propagation of ferrite ductile iron during impact fracture under low temperatures. Jinshu Xuebao/Acta Metall. Sin. 2015, 51, 1333–1340. [Google Scholar]

| C | Si | Ni | p | Mn | Al | Cr | Ti | S | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 2.97 | 1.85 | 0.55 | 0.028 | 0.025 | 0.012 | 0.011 | 0.01 | 0.0046 | Balance |

| Temperature T (°C) | Yield Strength Rp0.2 (MPa) | Ultimate Tensile Strength Rm (MPa) | Elongation (Pct) | Reduction in Area (Pct) |

|---|---|---|---|---|

| 20 | 230.84 | 361.75 | 26.00 | 21.68 |

| −20 | 246.50 | 382.51 | 26.80 | 20.79 |

| −40 | 260.17 | 400.79 | 25.80 | 23.44 |

| −60 | 281.00 | 410.23 | 27.00 | 22.56 |

| −80 | 284.70 | 423.71 | 28.80 | 20.79 |

| −100 | 301.20 | 436.76 | 25.00 | 17.19 |

| −120 | 315.70 | 452.29 | 20.20 | 15.36 |

| Temperature (°C) | Sample ID | α0/W | FQ or Fmax (kN) | KQ (Mpa m0.5) | (mm) | δm (μm) | |

|---|---|---|---|---|---|---|---|

| 20 | 1-1 | 0.52 | 46.35 | 1.63 | 42.14 | 81.07 | 167.30 |

| −20 | 2-1 | 0.50 | 51.29 | 1.60 | 43.79 | 78.57 | 171.10 |

| −40 | 3-1 | 0.52 | 52.15 | 1.56 | 47.45 | 83.27 | 140.59 |

| −60 | 4-1 | 0.50 | 58.61 | 1.58 | 50.66 | 81.26 | 160.85 |

| 4-2 | 0.50 | 58.20 | 1.60 | 50.15 | 79.63 | 148.08 | |

| −80 | 5-1 | 0.50 | 63.04 | 1.35 | 51.94 | 82.62 | 48.79 |

| 5-2 | 0.50 | 63.22 | 1.29 | 51.52 | 81.30 | 32.77 | |

| 5-3 | 0.51 | 46.83 | 1.63 | 49.28 | 74.39 | 120.57 | |

| 5-4 | 0.51 | 46.57 | 1.57 | 47.31 | 68.55 | 79.04 | |

| −100 | 6-1 | 0.51 | 62.04 | 1.08 | 54.77 | 82.77 | 8.39 |

| 6-2 | 0.50 | 62.81 | 1.01 | 54.40 | 81.65 | 6.17 | |

| 6-3 | 0.51 | 49.37 | 1.22 | 47.60 | 62.52 | 12.38 | |

| −120 | 7-1 | 0.50 | 43.63 | 1.00 | 40.84 | 41.76 | 0.41 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, G.; Jiang, Y.; Zhang, Y.; Zhang, J.; Ren, X. The Influence of Temperature on the Fracture Toughness and Fracture Mechanism of Ferritic Nodular Cast Iron. Metals 2025, 15, 828. https://doi.org/10.3390/met15080828

Duan G, Jiang Y, Zhang Y, Zhang J, Ren X. The Influence of Temperature on the Fracture Toughness and Fracture Mechanism of Ferritic Nodular Cast Iron. Metals. 2025; 15(8):828. https://doi.org/10.3390/met15080828

Chicago/Turabian StyleDuan, Guobin, Yu Jiang, Yongxin Zhang, Jibin Zhang, and Xuechong Ren. 2025. "The Influence of Temperature on the Fracture Toughness and Fracture Mechanism of Ferritic Nodular Cast Iron" Metals 15, no. 8: 828. https://doi.org/10.3390/met15080828

APA StyleDuan, G., Jiang, Y., Zhang, Y., Zhang, J., & Ren, X. (2025). The Influence of Temperature on the Fracture Toughness and Fracture Mechanism of Ferritic Nodular Cast Iron. Metals, 15(8), 828. https://doi.org/10.3390/met15080828