Effect of Ni-Based Buttering on the Microstructure and Mechanical Properties of a Bimetallic API 5L X-52/AISI 316L-Si Welded Joint

Abstract

1. Introduction

2. Experimentation

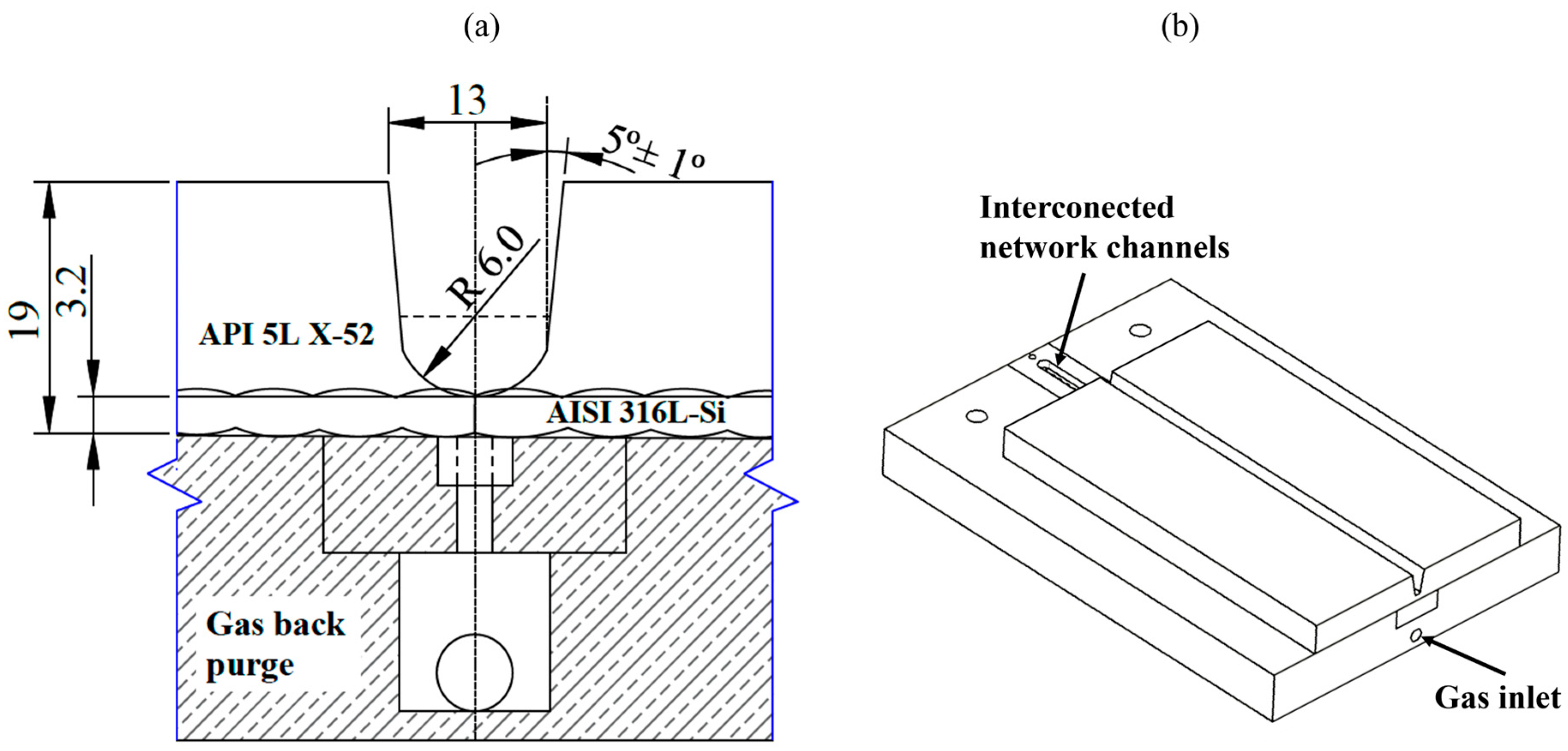

2.1. Materials, Cladding and Welding

2.2. Microstructural Characterization

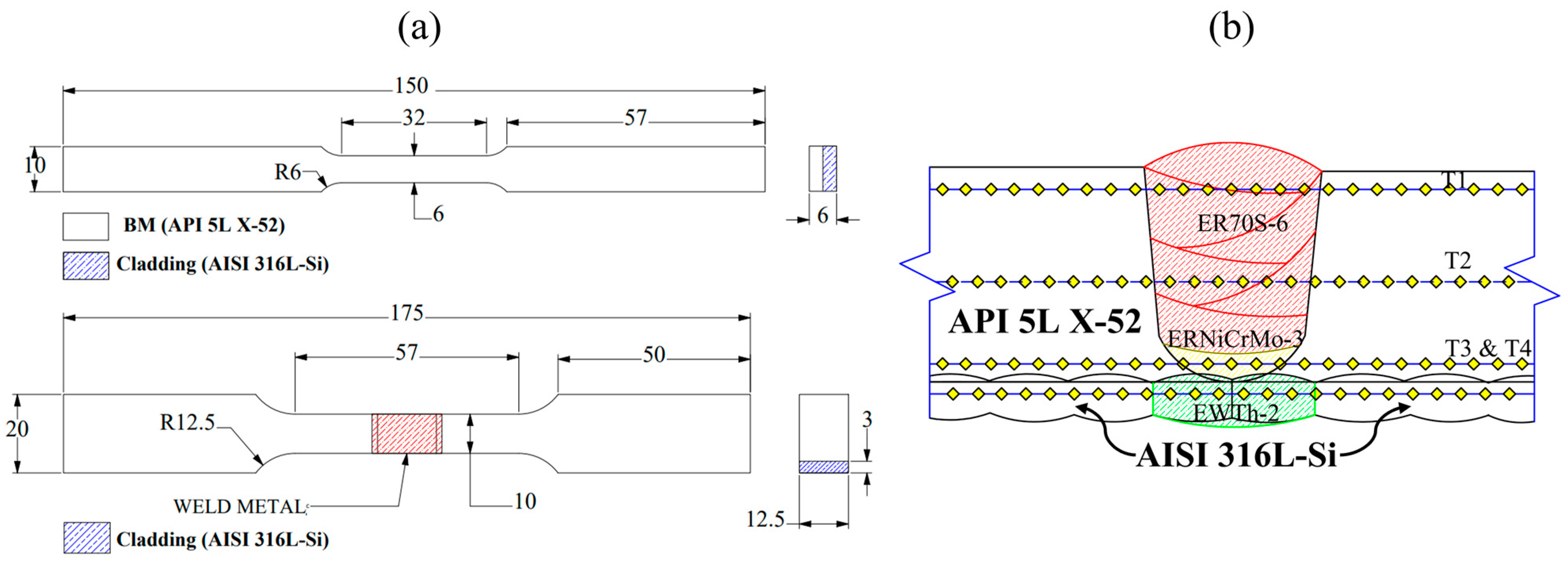

2.3. Mechanical Characterization

Microhardness Measurements and Tensile Tests

3. Results

3.1. Root and Hot Pass Welding

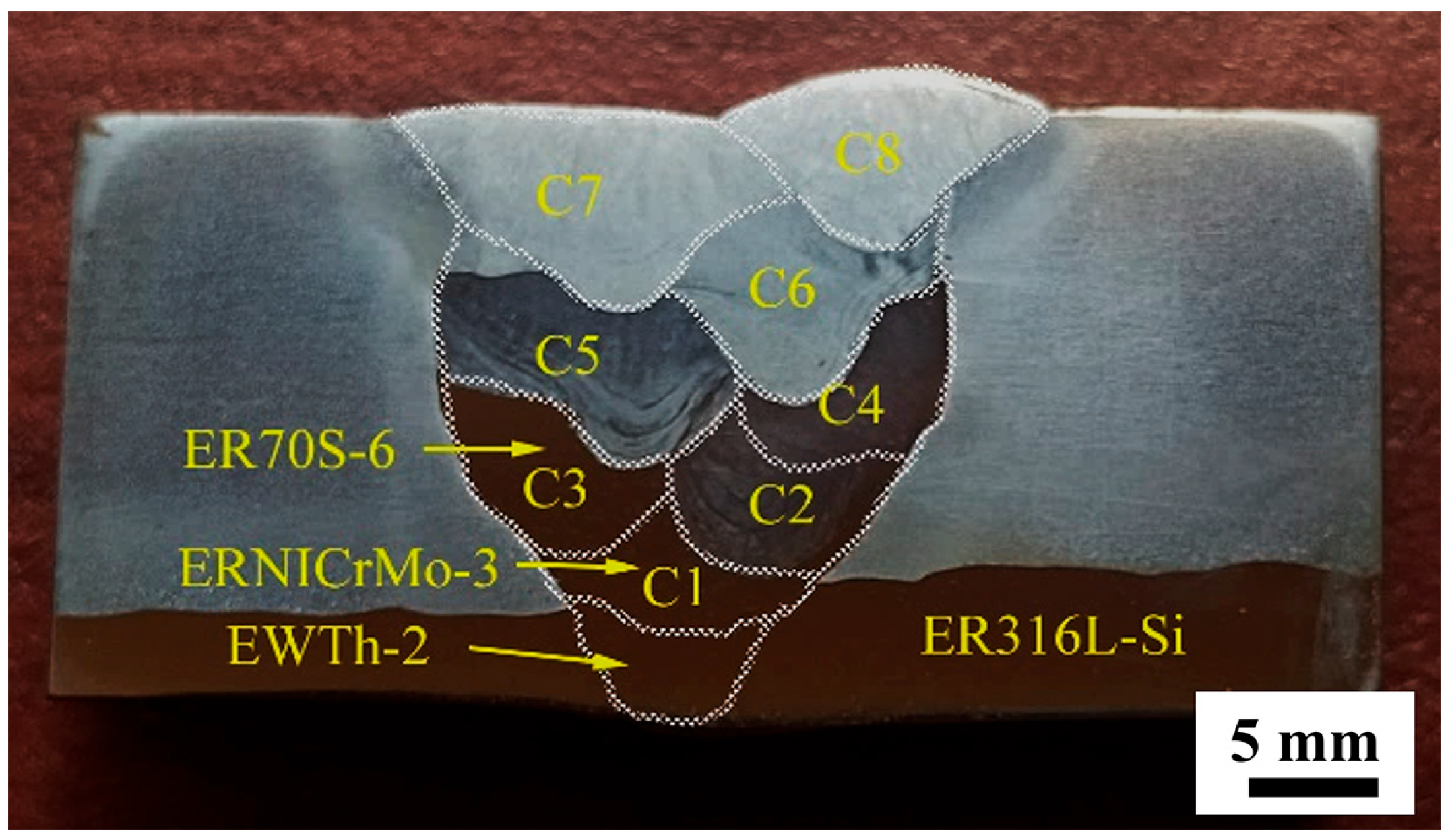

3.2. Macrostructural Observation of BWJ

3.3. Microstructural Characterization of BM API 5L X-52 and Cladding (AISI 316LSi)

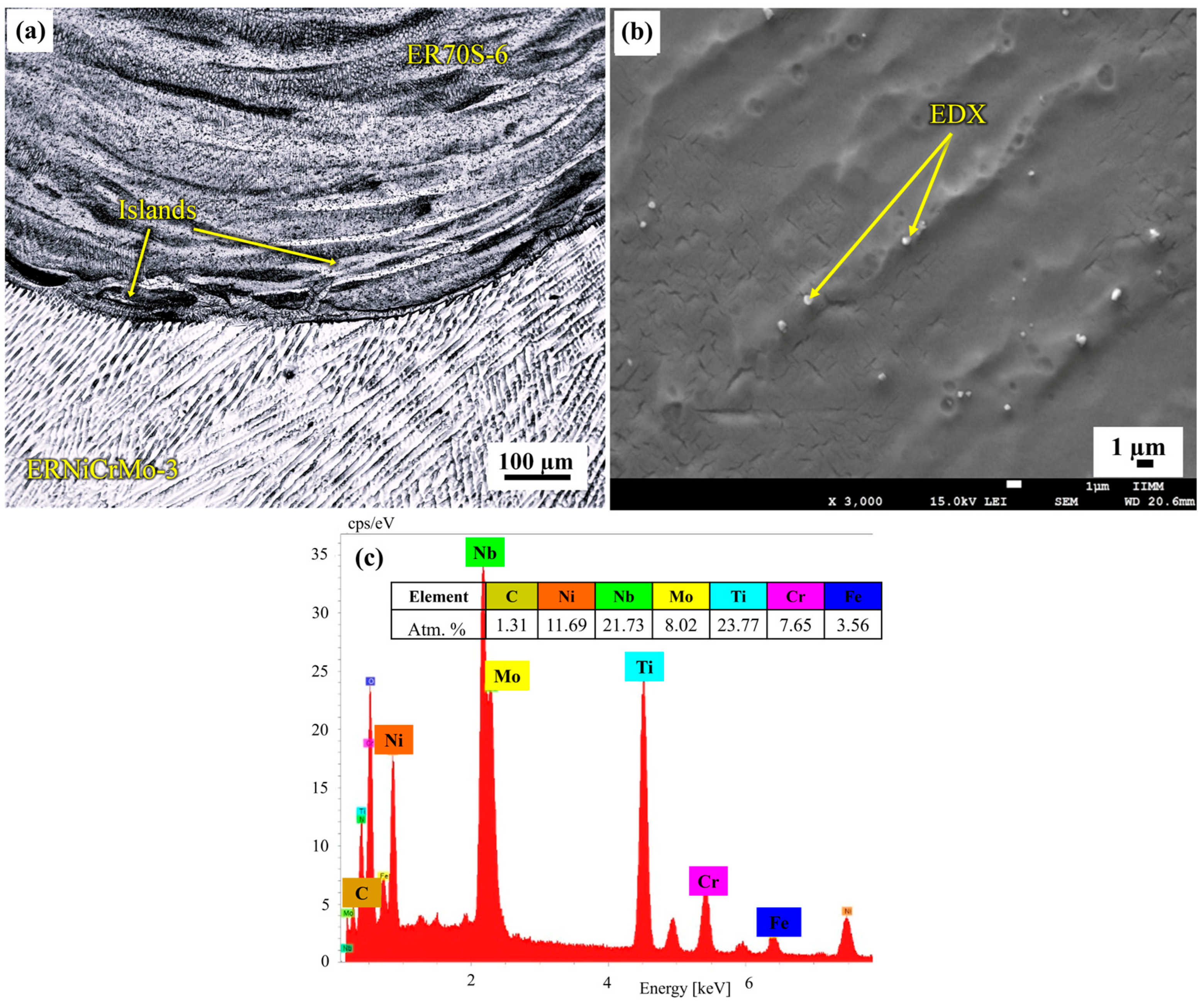

3.4. Microstructural Characterization of the Mixture Weld Metal ERNiCrMo-3 and ER70S-6 Interface

3.5. Mechanical Characterization of BM and BWJ

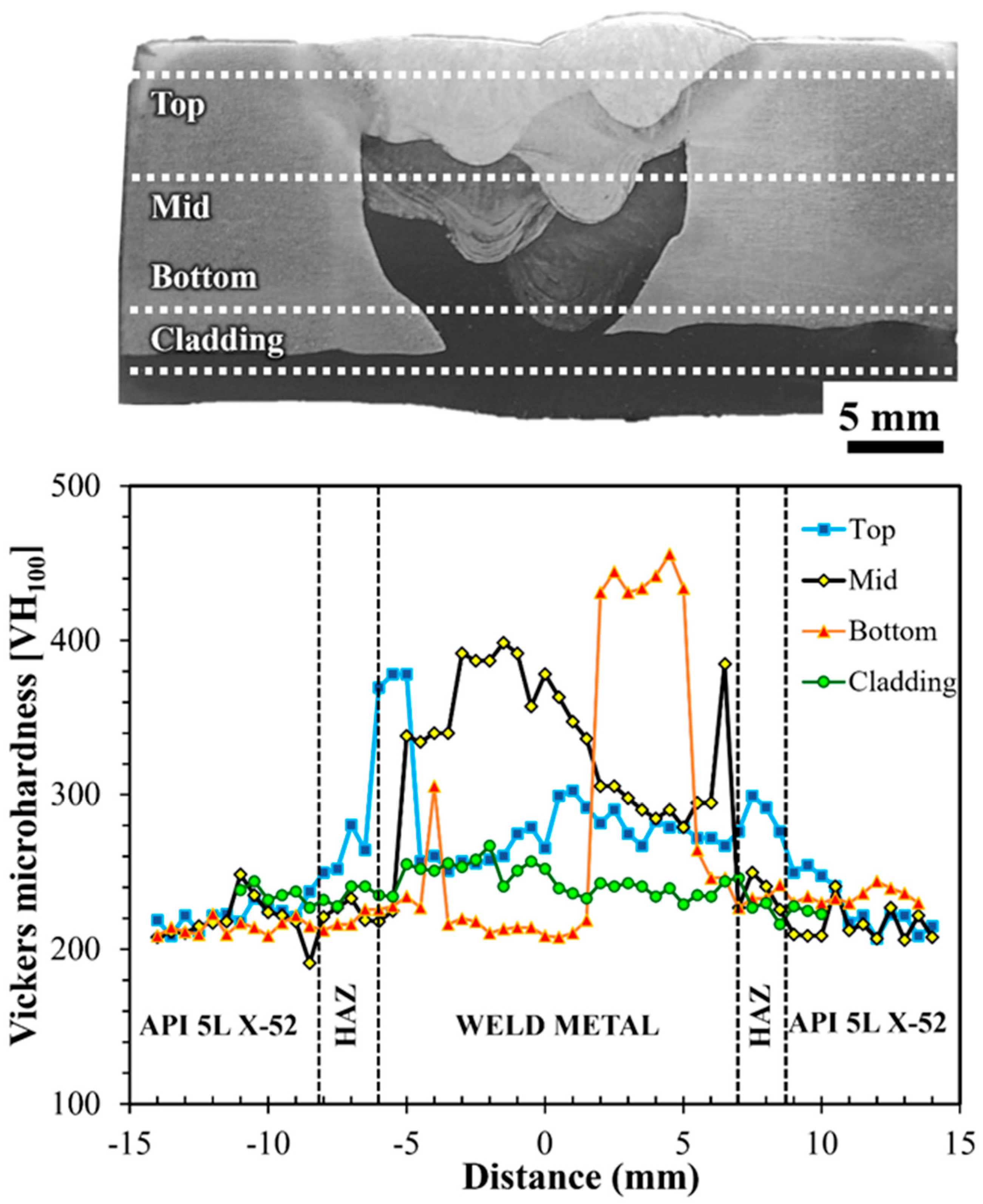

3.5.1. Microhardness

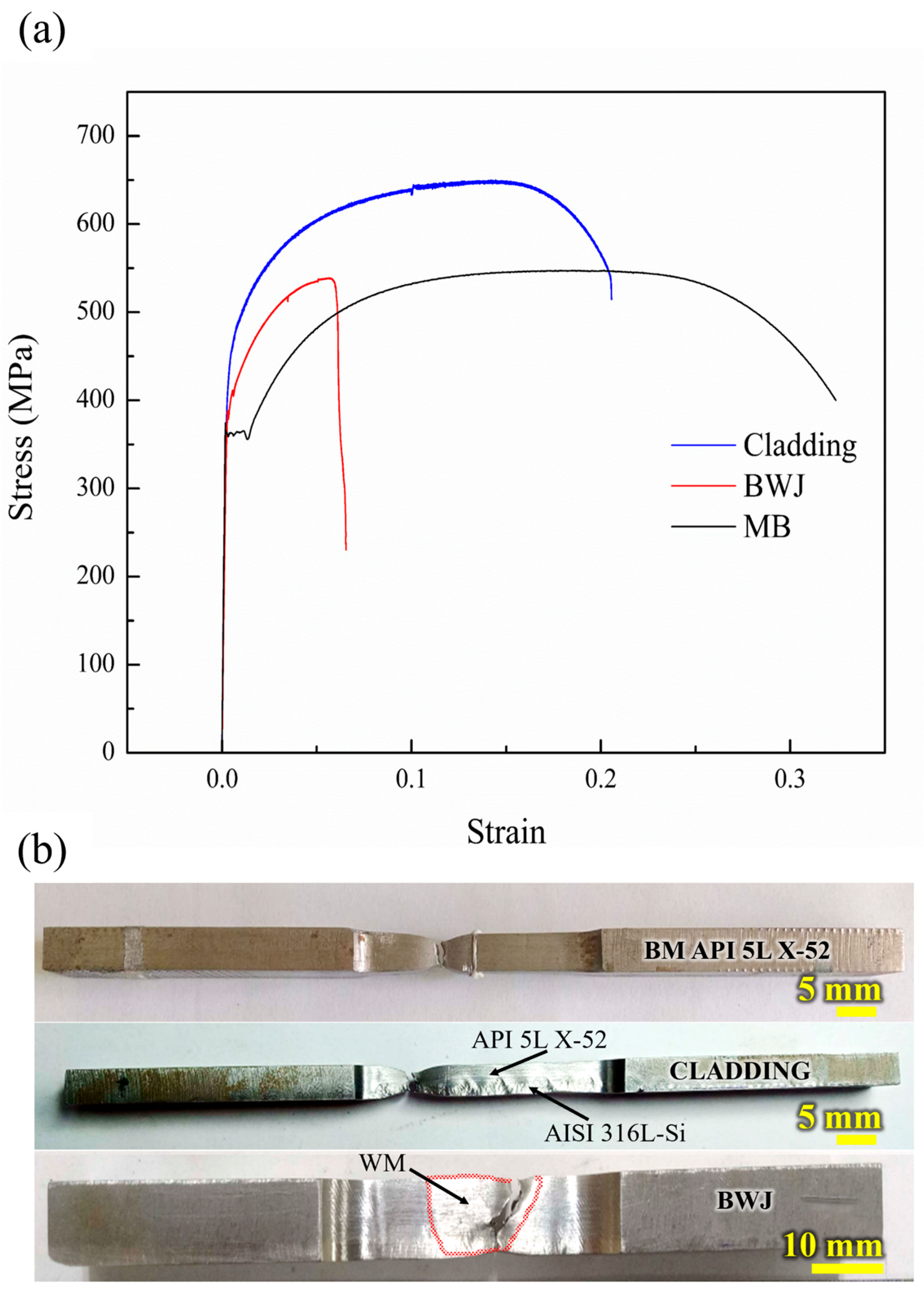

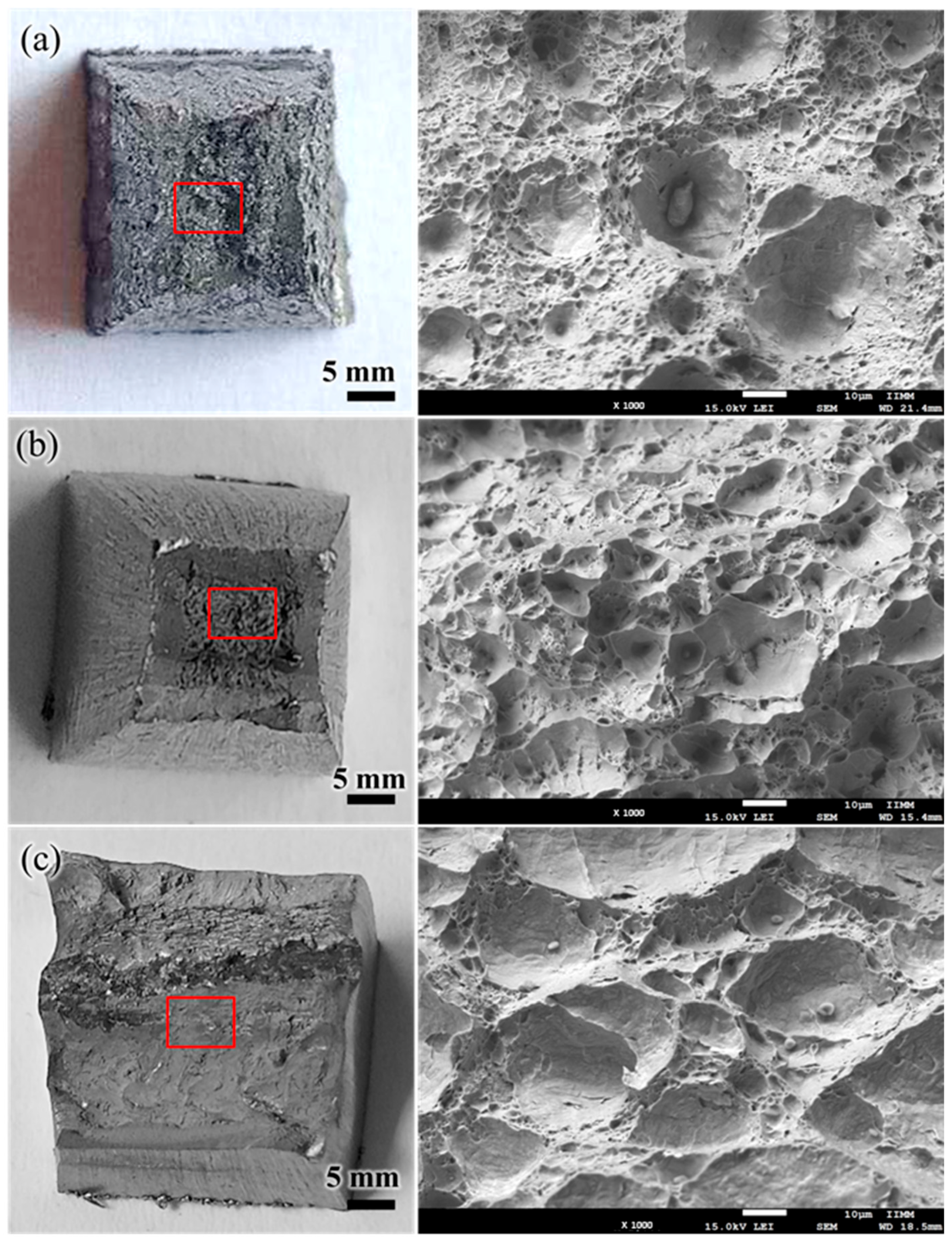

3.5.2. Tensile Results

4. Conclusions

- The correlation between transfer mode and electric arc oscillation can be considered a useful tool in improving the deposition of filler metal in the hot welding pass for BWJ.

- The interplay of interpass temperature and cooling rate during solidification allowed for the maintenance of a narrow bandwidth of the same ferrite transformation throughout the HAZ of the API 5L X-52 steel.

- The mixture of the ER70S-6/ERNiCrMo-3 filler wires in the first filling welding pass is sensitive to the variation of the heat input and cooling rate, showing the formation of martensite lath and precipitation of carbides.

- The increase in hardness is also due to the presence of titanium and niobium precipitates within the austenite by the application of the ERNiCrMo-3 electrode on the hot welding pass.

- Special care must be taken in the heat input generated in welding steps subsequent to the hot welding pass to avoid the formation of hard phases.

- The mechanical strength of the BWJ joint showed a decrease in comparison with the BM and cladding due to the formation of martensite and the precipitation of carbides.

- The effect of the heat input influences the fracture failure mechanisms, showing an increment in microhardness value and low tensile strength in the middle region of BWJ.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, L.; Wu, D.; Xu, M.; Zhou, P.; Hu, Y. The fracture resistance and crack propagation path of L415/N08825 bimetallic composite pipe welded joint. Theor. Appl. Fract. Mech. 2022, 122, 103656. [Google Scholar] [CrossRef]

- Bunaziv, I.; Olden, V.; Akselsen, O.M. Metallurgical aspects in the welding of clad pipelines—A global outlook. Appl. Sci. 2019, 9, 3118. [Google Scholar] [CrossRef]

- Smith, L.M. (Ed.) Engineering with Clad Steel; Nickel Development Institute: Toronto, ON, Canada, 1994; pp. 1–24. [Google Scholar]

- Li, L.; Xiao, J.; Han, B.; Zhou, C.; Wang, X. Welding L415/316L bimetal composite pipe using post-internal-welding process. Trans. Indian Inst. Met. 2020, 73, 675–689. [Google Scholar] [CrossRef]

- Blanca, A.P.Á.; Melchor, S.M.; Victor, H.L.M.; García, R.; Francisco, F.C.L. Application of Magnetic Fields to Weld Overlay Cladding to Improve Its Performance in the Oil and Gas Industry. J. Manuf. Sci. Eng. 2022, 144, 094501. [Google Scholar] [CrossRef]

- Subhan, A.; Zahoor, A.; Mourad, A.-H.I. Advances in manufacturing techniques of cladding steel pipes using corrosion-resistant alloy material for offshore oil and gas pipelines. In Proceedings of the 2022 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 21–24 February 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar]

- Saha, M.K.; Das, S. Gas metal arc weld cladding and its anti-corrosive performance: A brief review. AJTE 2018, 5, 155–174. [Google Scholar] [CrossRef]

- Papavinasam, S. (Ed.) Corrosion Control in the Oil and Gas Industry; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Shuo, L.; Lingzhi, B.; Chengning, L.; Xinjie, D. Comparison of Fracture Toughness in the Coarse-Grain Heat-Affected Zone of X80 Pipelines Girth-Welded under Conventional and Ultra-Low Heat Input. Materials 2022, 15, 7701. [Google Scholar]

- Wang, B.; Lan, H.; Lei, B. Analysis on Fracture Toughness of the L360QS/N08825 Bimetallic Composite Pipe Welded Joint. Adv. Mater. Sci. Eng. 2019, 2019, 1–13. [Google Scholar] [CrossRef]

- Dos Santos, E.B.; Pistor, R.; Gerlich, A.P. High frequency pulsed gas metal arc welding (GMAW-P): The metal beam process. Manuf. Lett. 2017, 11, 1–4. [Google Scholar] [CrossRef]

- Schaupp, T.; Schroeder, N.; Schroepfer, D.; Kannengiesser, T. Hydrogen-Assisted Cracking in GMA Welding of High-Strength Structural Steel—A New Look into This Issue at Narrow Groove. Metals 2021, 11, 904. [Google Scholar] [CrossRef]

- Zondi, M.C. Factors that affect welding-induced residual stress and distortions in pressure vessel steels and their mitigation techniques: A review. J. Press. Vessel Technol. 2014, 136, 040801. [Google Scholar] [CrossRef]

- Palani, P.; Murugan, N. Selection of parameters of pulsed current gas metal arc welding. J. Mater. Process. Technol. 2006, 172, 1–10. [Google Scholar] [CrossRef]

- Kumar, N.; Pandey, C.; Kumar, P. Dissimilar welding of Inconel alloys with austenitic stainless-steel: A review. J. Press. Vessel Technol. 2023, 145, 011506. [Google Scholar] [CrossRef]

- Garcia, D.N.; Ferraresi, V.A.; Mota, C.A.M.d. Metallurgical and Mechanical Behaviors of 309L-Si and ERNiCrMo-3 Dissimilar Weld on ASTM A182 F22 Steel. Mater. Res. 2020, 23, e20190680. [Google Scholar] [CrossRef]

- Lee, S.H. A hot cracking on dissimilar metal weld between A106Gr. B and A312 TP316L with buttering ERNiCr-3. Metals 2019, 9, 533. [Google Scholar] [CrossRef]

- Sohn, S.S.; Han, S.Y.; Bae, J.-h.; Kim, H.S.; Lee, S. Effects of microstructure and pipe forming strain on yield strength before and after spiral pipe forming of API X70 and X80 linepipe steel sheets. Mater. Sci. Eng. A 2013, 573, 18–26. [Google Scholar] [CrossRef]

- Wang, J.; Atrens, A. Microstructure and grain boundary microanalysis of X70 pipeline steel. J. Mater. Sci. 2003, 38, 323–330. [Google Scholar] [CrossRef]

- Das, S.; Saha, M.K. Investigating The Effect of Nickel Buttering on Corrosion Resistance. Spektr. Ind. 2022, 20, 57–68. [Google Scholar] [CrossRef]

- Hang, K.; Cao, Y.; Li, H.; Hu, C.; Wang, J.; Zhu, Q. Influence of butter layer thickness on microstructure and mechanical properties of underwater wet 16Mn/304L dissimilar welded joint. Maters 2023, 16, 6646. [Google Scholar]

- Kumar, A.; Sirohi, S.; Singh, M.; Fydrih, D.; Pandey, C. Microstructure and mechanical properties of a dissimilar metal welded joint of Inconel 617 and P92 steel with Inconel 82 buttering layer for AUSC boiler application. Int. J. Press. Vessel. Pip. 2024, 209, 105–196. [Google Scholar] [CrossRef]

- Sirohi, S.; Kumar, A.; Singh, M.; Fydrih, D.; Pandey, C. Pulsed GTAW joint of P92 steel and Inconel 625: Microstructure and mechanical properties. Arch. Civ. Mech. Eng. 2025, 25, 93. [Google Scholar] [CrossRef]

- ASTM E8/E8M-22; E8M Standard Test Methods for Tension Testing of Metallic Materials. ASTM: West Conshohocken, PA, USA, 2001.

- ASTM E92-82; Standard Test Method for Vickers Hardness of Metallic Materials. ASTM: West Conshohocken, PA, USA, 2003; pp. 1–9.

- ASTM E384-22; Standard Test Method for Microindentation Hardness of Materials. ASTM: West Conshohocken, PA, USA, 1999; p. 399.

- Argumedo, J.G.; Mahmoudiniya, M.; Reinton, T.; Kestens, L.; Hermans, M.; Popovich, V. Functional grading of low alloy steel to 316 L by Wire Arc Additive Manufacturing–Microstructural and mechanical characterization of bi-metal interface. J. Mater. Process. Technol. 2024, 325, 118305. [Google Scholar] [CrossRef]

- Soudani, M.; Hadj Meliani, M.; El-Miloudi, K.; Bouledroua, O.; Fares, C.; Benghalia, M.; Azari, Z.; Capelle, J.; Sorour, A.A.; Pluvinage, G. Efficiency of green inhibitors against hydrogen embrittlement on mechanical properties of pipe steel API 5L X52 in hydrochloric acid medium. JBTC 2018, 4, 1–11. [Google Scholar] [CrossRef]

- Godefroid, L.B.; Cândido, L.C.; Toffolo, R.V.B.; Barbosa, L.H.S. Microstructure and mechanical properties of two API steels for iron ore pipelines. Mater. Res. 2014, 17, 114–120. [Google Scholar] [CrossRef]

- Guilherme, L.; Benedetti, A.; Fugivara, C.; Magnabosco, R.; Oliveira, M.F.d. Effect of MAG welding transfer mode on sigma phase precipitation and corrosion performance of 316L stainless steel multi-pass welds. J. Mater. Res. Technol. 2020, 9, 10537–10549. [Google Scholar] [CrossRef]

- Tabrizi, T.R.; Sabzi, M.; Anijdan, S.H.M.; Eivani, A.R.; Park, N.; Jafarian, H.R. Comparing the effect of continuous and pulsed current in the GTAW process of AISI 316L stainless steel welded joint: Microstructural evolution, phase equilibrium, mechanical properties and fracture mode. J. Mater. Res. Technol. 2021, 15, 199–212. [Google Scholar] [CrossRef]

- Souto, J.I.V.d.; Ferreira, S.D.; Lima, J.S.d.; Castro, W.B.d.; Grassi, E.N.D.; Santos, T.F.d.A. Effect of GMAW Process Parameters and Heat Input on Weld Overlay of Austenitic Stainless Steel 316L-Si. Soldag. Inspeçã 2023, 28, e2809. [Google Scholar] [CrossRef]

- Dovgyy, B.; Piglione, A.; Hooper, P.A.; Pham, M.-S. Comprehensive assessment of the printability of CoNiCrFeMn in laser powder bed fusion. Mater. Des. 2020, 194, 108845. [Google Scholar] [CrossRef]

- Wu, B.; Qiu, Z.; Pan, Z.; Carpenter, K.; Wang, T.; Ding, D.; Van Duin, S.; Li, H. Enhanced interface strength in steel-nickel bimetallic component fabricated using wire arc additive manufacturing with interweaving deposition strategy. J. Mater. Sci. Technol. 2020, 52, 226–234. [Google Scholar] [CrossRef]

- Gonzaga, R.S.; Farias, F.W.C.; da Cruz Payão Filho, J. Microstructural characterization of the transition zone between a C–Mn steel pipe and a 70% Ni30% Cu alloy cladding welded by HW-GTAW. Int. J. Press. Vessel. Pip. 2021, 192, 104433. [Google Scholar] [CrossRef]

- Cipriano Farias, F.W.; Payão Filho, J.d.C.; Barreto de Azevedo, L.M. Microstructural and mechanical characterization of the transition zone of 9% Ni steel cladded with Ni-based superalloy 625 by GTAW-HW. Metals 2018, 8, 1007. [Google Scholar] [CrossRef]

- Rathod, D.W.; Pandey, S.; Aravindan, S.; Singh, P. Diffusion control and metallurgical behavior of successive buttering on sa508 steel using Ni–Fe alloy and inconel 182. MMA 2016, 5, 450–460. [Google Scholar] [CrossRef]

- Jafarzadegan, M.; Ahangaryan, M.; Taghiabadi, R. Heat Input Effect on Microstructure and Mechanical Properties in Shielded Metal Arc Welding of Dissimilar AISI 316L/St-37 Steel. Int. J. Iron Steel Soc. Iran 2021, 17, 1–10. [Google Scholar]

- Zhang, T.; Zhao, W.; Deng, Q.; Jiang, W.; Wang, Y.; Wang, Y.; Jiang, W. Effect of microstructure inhomogeneity on hydrogen embrittlement susceptibility of X80 welding HAZ under pressurized gaseous hydrogen. Int. J. Hydrogen Energy 2017, 42, 25102–25113. [Google Scholar] [CrossRef]

- Kumar, S.; Nath, S.; Kumar, V. Effect of single and multiple thermal cycles on microstructure and mechanical properties of simulated HAZ in low carbon bainitic steel. Mater. Perform. Charact. 2015, 4, 365–380. [Google Scholar] [CrossRef]

- Qin, G.; Tang, Y.; Zhang, B.; Lin, S.; Geng, P. Microstructures and mechanical properties of stainless steel clad plate joint with diverse filler metals. J. Mater. Res. Technol. 2020, 9, 2522–2534. [Google Scholar] [CrossRef]

- An, Q.; Fan, K.; Ge, Y.; Liu, B.; Liu, Y.; Wang, S.; Chen, C.; Ji, P.; Yin, F. Microstructure and mechanical properties of stainless steel clad plate joints produced by TIG and MAG hybrid welding. J. Adhes. Sci. Technol. 2020, 34, 670–685. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, B.; Xu, Y.; Wang, L.; Cheng, W. Investigation on the fatigue crack propagation behavior of L360MS pipeline steel welded joints with Inconel 625 weld metal. Trans. Indian Inst. Met. 2020, 73, 2387–2402. [Google Scholar] [CrossRef]

- Yu, W.; Liu, B.; Chen, C.; Liu, M.; Zhang, X.; Fang, W.; Ji, P.; He, J.; Yin, F. Microstructure and mechanical properties of stainless steel clad plate welding joints by different welding processes. Sci. Technol. Weld. Join. 2020, 25, 571–580. [Google Scholar] [CrossRef]

| Material | C | Mn | Cr | Ni | Mo | Si | P | S | Nb | Ti | V | Fe | W | Th02 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X-52 | 0.162 | 1.44 | - | - | 0.005 | 0.190 | 0.015 | 0.005 | 0.10 | 0.005 | 0.005 | Bal. | - | - |

| ER316L | 0.03 | 1.9 | 18.5 | 12 | 2.70 | 0.80 | 0.03 | 0.03 | - | - | - | Bal. | - | - |

| ERNiCrMo-3 | 0.01 | 0.1 | 22 | 64.38 | 8.7 | 0.15 | 0.01 | 0.01 | 3.6 | 0.2 | - | Bal. | - | - |

| ER70S-6 | 0.16 | 1.2 | - | 0.15 | 0.15 | 0.85 | 0.02 | 0.03 | - | - | 0.03 | Bal. | - | - |

| EWTh-2 | - | - | - | - | - | - | - | - | - | - | - | - | 97.3 | 2.2 |

| Parameters | Root Pass | Hot Pass | Weld Beads |

|---|---|---|---|

| Electrode (AWS) | EWTh-2 | ERNiCrMo-3 | ER70S-6 |

| Peak current (Ip) | 145 | 64 | 127 |

| Background current (Ib) | 73 | 15 | - |

| Pulse frequency (Hz) | 2 | 10 | - |

| Voltage (V) | 18.3 | 135 | 23 |

| Travel welding (mm/s) | 2.4 | 2.03 | 3 |

| Wire feed speed (mm/s) | - | 112.18 | 76.2 |

| Gas flow rate (L/min) | 9.44 | 14.16 | 11.8 |

| Gas purge flow rate (L/min) | 4.72 | - | - |

| Stick out (mm) | - | 14 | 14 |

| Material | E (GPa) | σy (MPa) | σUTS (MPa) | ε (%) |

|---|---|---|---|---|

| X-52 | 208 ± 3.54 | 366 ± 3.54 | 546 ± 2.49 | 32 ± 1.65 |

| Cladding | 196 ± 2.2 | 443 ± 3.54 | 661 ±15.34 | 22 ± 2.00 |

| BWJ | 186 ± 6.43 | 380 ± 28.28 | 520 ± 27.54 | 7 ± 0.46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lázaro-Lobato, L.Á.; Gutiérrez-Vargas, G.; Curiel-López, F.F.; López-Morelos, V.H.; Ramírez-López, M.d.C.; Verduzco-Juárez, J.C.; Taha-Tijerina, J.J. Effect of Ni-Based Buttering on the Microstructure and Mechanical Properties of a Bimetallic API 5L X-52/AISI 316L-Si Welded Joint. Metals 2025, 15, 824. https://doi.org/10.3390/met15080824

Lázaro-Lobato LÁ, Gutiérrez-Vargas G, Curiel-López FF, López-Morelos VH, Ramírez-López MdC, Verduzco-Juárez JC, Taha-Tijerina JJ. Effect of Ni-Based Buttering on the Microstructure and Mechanical Properties of a Bimetallic API 5L X-52/AISI 316L-Si Welded Joint. Metals. 2025; 15(8):824. https://doi.org/10.3390/met15080824

Chicago/Turabian StyleLázaro-Lobato, Luis Ángel, Gildardo Gutiérrez-Vargas, Francisco Fernando Curiel-López, Víctor Hugo López-Morelos, María del Carmen Ramírez-López, Julio Cesar Verduzco-Juárez, and José Jaime Taha-Tijerina. 2025. "Effect of Ni-Based Buttering on the Microstructure and Mechanical Properties of a Bimetallic API 5L X-52/AISI 316L-Si Welded Joint" Metals 15, no. 8: 824. https://doi.org/10.3390/met15080824

APA StyleLázaro-Lobato, L. Á., Gutiérrez-Vargas, G., Curiel-López, F. F., López-Morelos, V. H., Ramírez-López, M. d. C., Verduzco-Juárez, J. C., & Taha-Tijerina, J. J. (2025). Effect of Ni-Based Buttering on the Microstructure and Mechanical Properties of a Bimetallic API 5L X-52/AISI 316L-Si Welded Joint. Metals, 15(8), 824. https://doi.org/10.3390/met15080824