1. Introduction

Metal matrix composites (MMCs), such as those based on aluminum, magnesium, and titanium, have garnered significant attention due to their high strength-to-weight ratios and enhanced mechanical properties, making them ideal for aerospace, automotive, and structural applications. Among them, titanium matrix composites (TMCs) stand out for their superior high-temperature performance and corrosion resistance, particularly when reinforced with TiB and TiC particles, making them critical for advanced aerospace components [

1,

2,

3,

4]. These attributes, coupled with their lightweight and high-strength advantages, have led to their widespread application in aerospace, automotive, and medical fields [

5,

6,

7,

8]. However, extensive research has revealed a critical challenge: while the incorporation of reinforcing phases enhances the strength and specific modulus of TMCs, it often results in compromised plasticity, making it difficult to achieve a balance between high strength and good ductility [

9,

10,

11,

12]. Consequently, the development of TMCs that simultaneously possess high strength and excellent plasticity has emerged as a pivotal issue in the advancement of next-generation materials.

Currently, TMCs reinforced with low-cost TiB and TiC particles, which exhibit excellent chemical compatibility with titanium and its alloys, have demonstrated remarkable specific strength, specific modulus, and wear resistance, showcasing significant potential for various applications [

13,

14,

15,

16]. However, traditional manufacturing techniques, such as vacuum-assisted casting, powder metallurgy, and sintering, are increasingly unable to meet the stringent quality requirements for modern metal components [

17,

18,

19,

20]. As a result, emerging laser-based additive manufacturing technologies, including directed energy deposition, selective laser melting/fusion, direct metal deposition, and laser powder deposition, have become indispensable for the fabrication of high-performance TMCs [

21,

22,

23,

24].

In recent years, extensive research has been conducted on the additive manufacturing of TMCs, with a primary focus on microstructure evolution and mechanical properties. For instance, S. Pouzet et al. [

21]. successfully fabricated TMCs using direct metal deposition technology by combining Ti6Al4V (TC4/Ti 64) alloy with B4C mixed powder, demonstrating that the reinforcing particles significantly enhance grain boundary strengthening. Chang et al. [

14]. utilized directed energy deposition to prepare TMCs by mixing nano-sized B4C particles with TC4 powder, observing that the addition of 3 wt.% 50 nm B4C led to the complete equiaxed transformation of β columnar grains and a substantial increase in strength. Banerjee et al. [

25]. employed selective laser melting technology to produce high-performance TMCs, achieving both significant microstructural refinement and improved mechanical properties. Huo et al. [

26]. investigated the deformation strengthening mechanism of TiC/TC4 alloy nanocomposites fabricated via selective laser melting (SLM), highlighting the role of TiC nanoparticles in enhancing the titanium matrix.

However, a key challenge in DED-fabricated TMCs is achieving a balance between high strength and sufficient plasticity, as reinforcing phases like TiB and TiC often reduce ductility due to interfacial debonding. For example, Wang et al. reported that during directed energy deposition (DED) or the initial stages of plastic deformation, premature damage to larger unmelted TiC particles and interfacial debonding between TiC particles and the matrix can deteriorate the tensile properties of composites prepared using large-sized mixed powders [

24,

27]. Similarly, the presence of unreacted B4C layers at the interface of (TiB + TiC)/TC4 in situ composites fabricated via laser direct deposition was found to weaken interfacial bonding, resulting in suboptimal performance [

28]. Zhang et al. also observed that coarse dendritic TiC and unmelted TiC particles in TiC/Ti6Al4V composites prepared by directional energy deposition acted as brittle phases, reducing the material’s tensile properties [

29]. While nanoparticle-reinforced TMCs have advanced aerospace and automotive applications, the role of post-processing heat treatments in optimizing their microstructure remains underexplored, positioning this study at the forefront of TMC development.

These studies highlight that the microstructure uniformity and mechanical performance of TMCs produced by additive manufacturing are often unstable, primarily due to incomplete melting and insufficient integration of TiB/TiC reinforcing particles into the titanium matrix. To address these issues, this study investigates the annealing treatment of (TiB + TiC)/TC4 composites with varying compositions, analyzing the microstructural evolution, including changes in α phase morphology and size, as well as the transformation of the reinforcement phase morphology post-annealing. Additionally, hardness tests are conducted on the as-cast, as-deposited, and annealed states of (TiB + TiC)/TC4 composites to explore hardness variations. Furthermore, the influence of microstructural morphology, phase structure, and grain size in the as-cast and as-deposited states (along the XOY, XOZ, and YOZ directions) on mechanical properties is systematically analyzed. The distribution of the reinforcement phase (TiB + TiC) and its impact on mechanical properties are also discussed, alongside an analysis of the fracture mechanisms under different preparation methods.

Unlike prior studies focusing on as-deposited TMCs, this work systematically investigates annealing-induced microstructural transitions, particularly the equiaxed transformation of the α phase and TiC growth above 1000 °C, offering a new approach to optimize strength–plasticity synergy. This study aims to systematically investigate the effects of annealing heat treatments on the microstructure and mechanical properties of (TiB + TiC)/TC4 composites fabricated via directed energy deposition (DED). By analyzing microstructural evolution, phase transformations, and mechanical performance across various annealing conditions, we seek to optimize the strength–plasticity balance, addressing the critical challenge of interfacial debonding in TMCs. This work provides insights into tailoring post-processing strategies for high-performance TMCs in aerospace and automotive applications.

2. Experiment and Methods

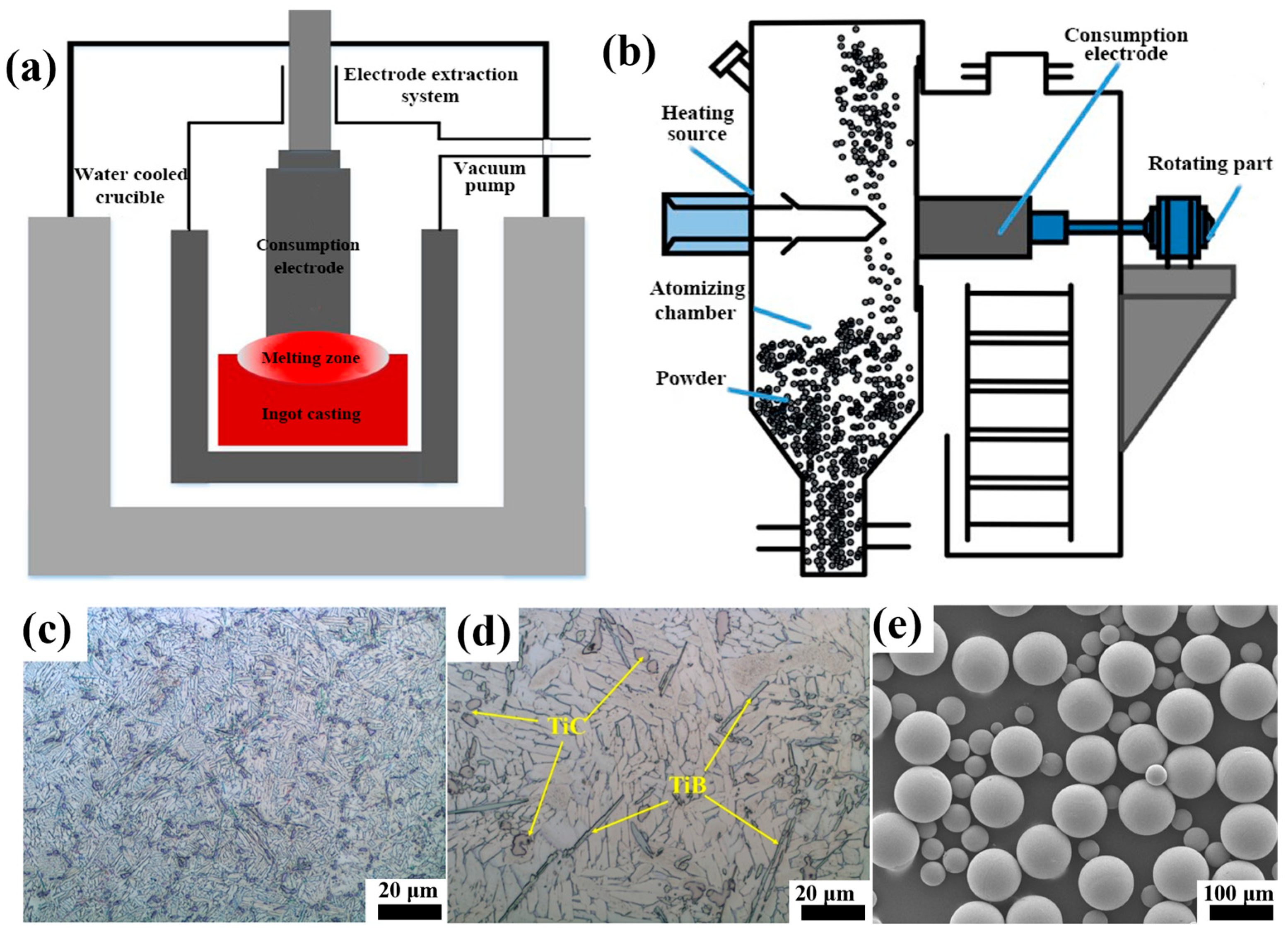

This experiment uses grade 0 sponge titanium, Al-V master alloy, B4C, and C powder as raw materials. The raw materials were pressed into consumable electrodes, and three repeated consumable melting processes were carried out to ensure uniform composition of the ingot. The specific process flow is shown in

Figure 1. Furthermore, Plasma Rotating Electrode Process (PREP) technology is adopted to prepare composite spherical powders that meet the requirements of additive manufacturing for (TiB + TiC)/TC4 composite ingot shape and size in order to satisfy the needs of plasma rotating electrode equipment. During the powder preparation process, the end face of the as-cast composite ingot is melted by plasma gun heating, and then alloy liquid droplets are melted and ejected under high-speed rotation, followed by solidification in an argon atmosphere to obtain composite material powders with excellent sphericity and flowability. For detailed chemical composition and powder properties of the composite material powders, please refer to

Table 1.

As-cast samples refer to the (TiB + TiC)/TC4 composite material produced through vacuum-assisted casting, where the raw materials (sponge titanium, B4C, and C powders) are melted and solidified into an ingot without further additive manufacturing processes. As-deposited samples refer to the (TiB + TiC)/TC4 composite material fabricated via directed energy deposition (DED), where composite powders are deposited layer-by-layer using a laser to form the final component before any post-processing heat treatment.

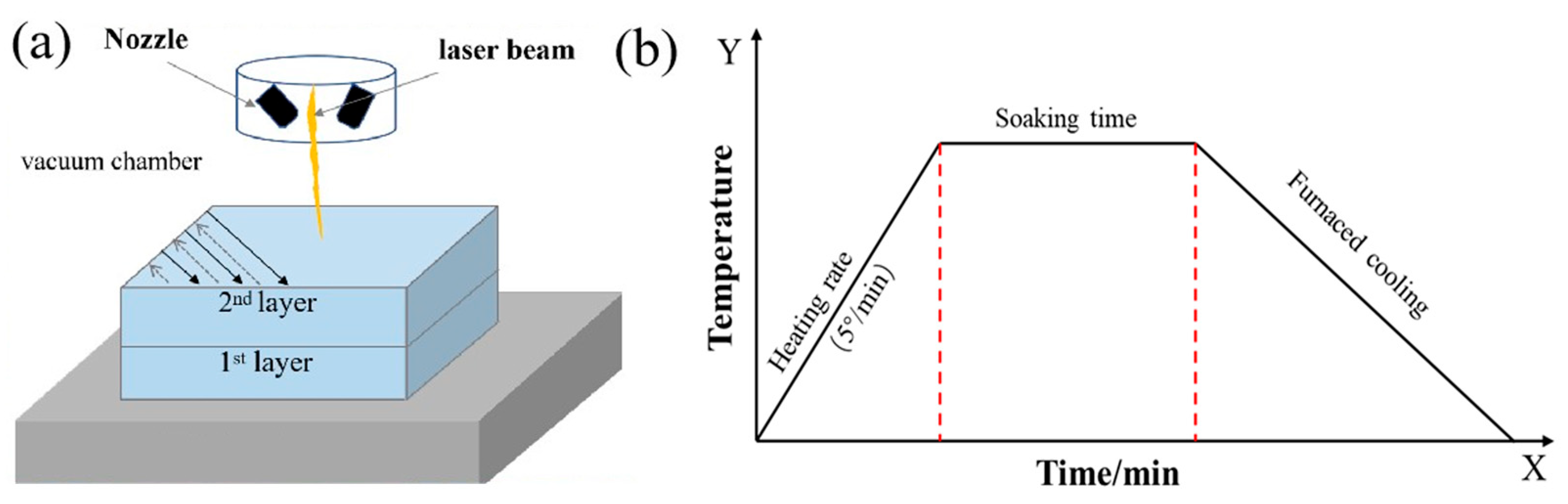

The main equipment of the directed energy deposition system used in this experiment is manufactured by Siemens AG, Munich, Germany, and the auxiliary equipment is developed by Zhongke Yuchen Laser Equipment Co., Ltd., Nanjing, China. The system is equipped with an IPG-YLS-3000 fiber laser emitter (IPG Photonics Corporation, Oxford, MA, USA), a four-channel coaxial powder feeding processing head, a gas-loaded dual-barrel powder feeder, a CNC machining platform, and a high-power water chiller. Among them, the spot diameter of the laser during operation is 3 mm, the scanning pitch is 1.6 mm, the powder feeding rate is 1.5 rpm, and each layer has a lift height of 0.4 mm. In order to protect titanium alloy from oxidation in high-temperature environment during directed energy deposition and sample cooling process, pure argon (purity ≥99.99%) needs to be continuously supplied into the sealed working chamber to ensure that the oxygen content in the environment remains below 200 ppm throughout the entire experimental process. However, the internal microstructure of the parts formed through the directed energy deposition process differs significantly from that obtained by traditional forging processes. Therefore, annealing treatment is necessary to optimize alloy performance, achieve a uniform structure, and eliminate internal stress. Among various heat treatment methods, annealing treatment is particularly suitable for laser melted deposition samples. Thus, in this experiment, a conventional annealing process was employed, as shown in

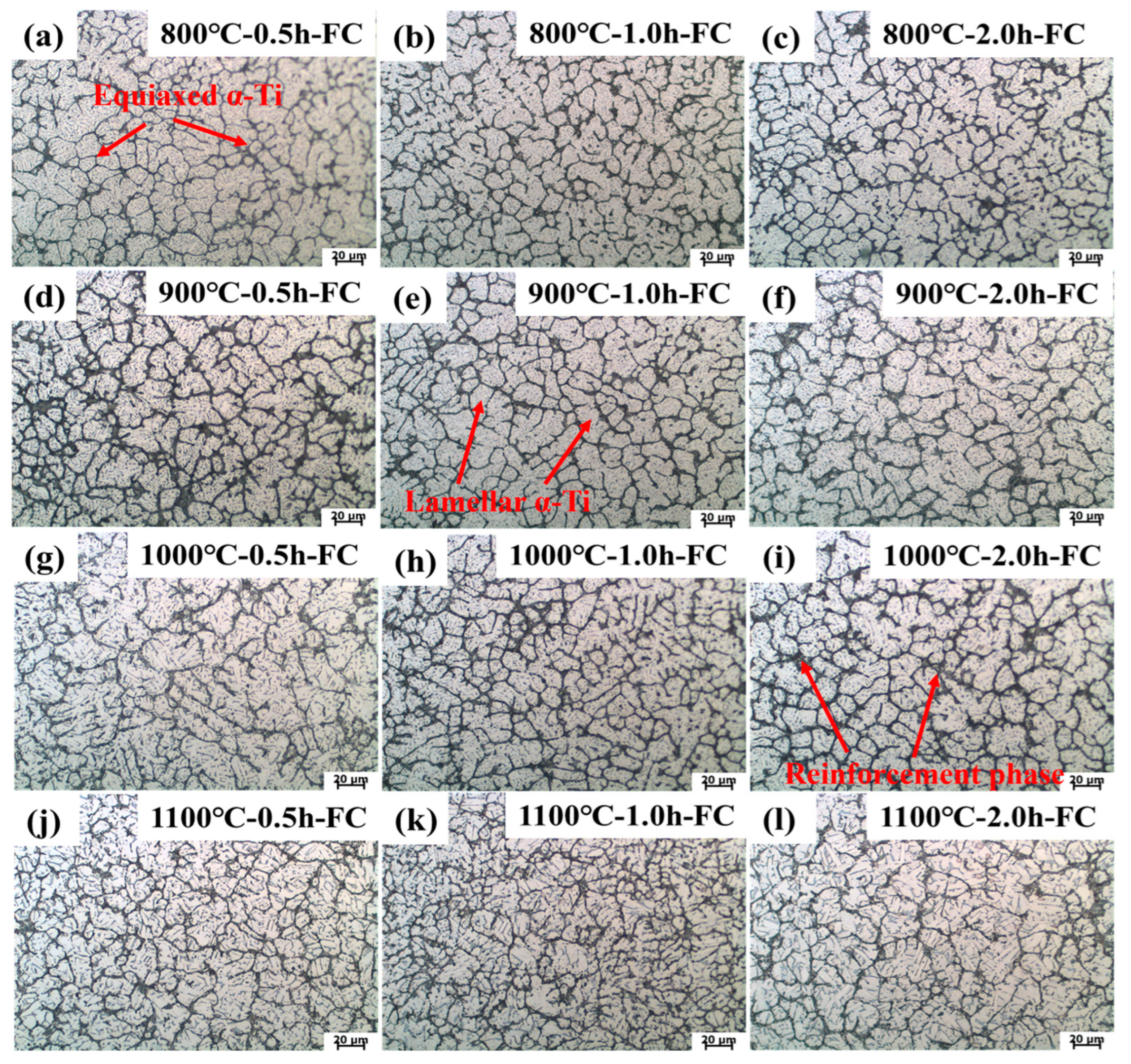

Figure 2. The temperature was gradually increased from room temperature to 800 °C/900 °C/1000 °C/1100 °C at a heating rate of 5 °C/min and held for 0.5 h/1.0 h/2.0 h before cooling down to room temperature in a muffle furnace. The entire annealing process was conducted under vacuum conditions; the muffle furnace was initially evacuated and then filled with argon gas with purity ≥99.9%. This evacuation and filling operation were repeated five times to ensure proper vacuum conditions.

Furnace cooling was selected to achieve a controlled, slow cooling rate (~5 °C/min), minimizing thermal stresses and promoting diffusion-driven microstructural evolution. While furnace cooling typically results in a Widmanstätten microstructure in Ti-6Al-4V alloys due to directional growth of α-phase lamellae during cooling from the β-phase field [

30], the presence of TiB and TiC reinforcements in the (TiB + TiC)/TC4 composite alters phase transformation kinetics. These reinforcements act as nucleation sites, promoting non-directional nucleation of α-phase at β grain boundaries during cooling, leading to partial equiaxed α-phase formation at 1000–1100 °C [

31]. This is further supported by prolonged holding times (up to 2.0 h), which enhance diffusion and stress relaxation, facilitating equiaxed transformation.

The microstructural morphology and distribution were examined utilizing the optical microscope (ZEISS Axio Cam MRc5, Oberkochen, Germany) for various heat treatment conditions. It is worth noting that the metallographic sample underwent etching after soaking in Kroll reagent (1 mL HF + 2 mL HNO3 + 7 mL H2O) for 5–10 s. In order to detect the phase composition of the as-cast, powder, deposited and heat-treated samples, a SmarLabTM 3KW X-ray diffractometer (XRD) (Rigaku Corporation, Tokyo, Japan) equipped with Cu Kα radiation (λ = 0.15406 nm) was used for qualitative analysis of the alloy’s phase composition. Scanning was performed in the range of 30–80° at a rate of 10°/min under a voltage of 40 kV and current of 30 mA, and the test results were analyzed using Jade5.0 software. In addition, scanning electron microscopy (SEM) was performed using a ZEISS Sigma 300 microscope (Oberkochen, Germany) to observe microstructural morphology and phase distribution. Transmission electron microscopy (TEM) was conducted using a JEOL JEM-2100 F microscope (Tokyo, Japan) to analyze phase morphology, crystal structure, and defects, with selected area electron diffraction (SAED) patterns used for phase identification.

In terms of mechanical performance, the electronic universal testing machine (Bairoe-5KN, Shanghai Bairuo Testing Instrument Co., Ltd., Shanghai, China) was selected for conducting room temperature tensile tests at a strain rate of 1 × 10

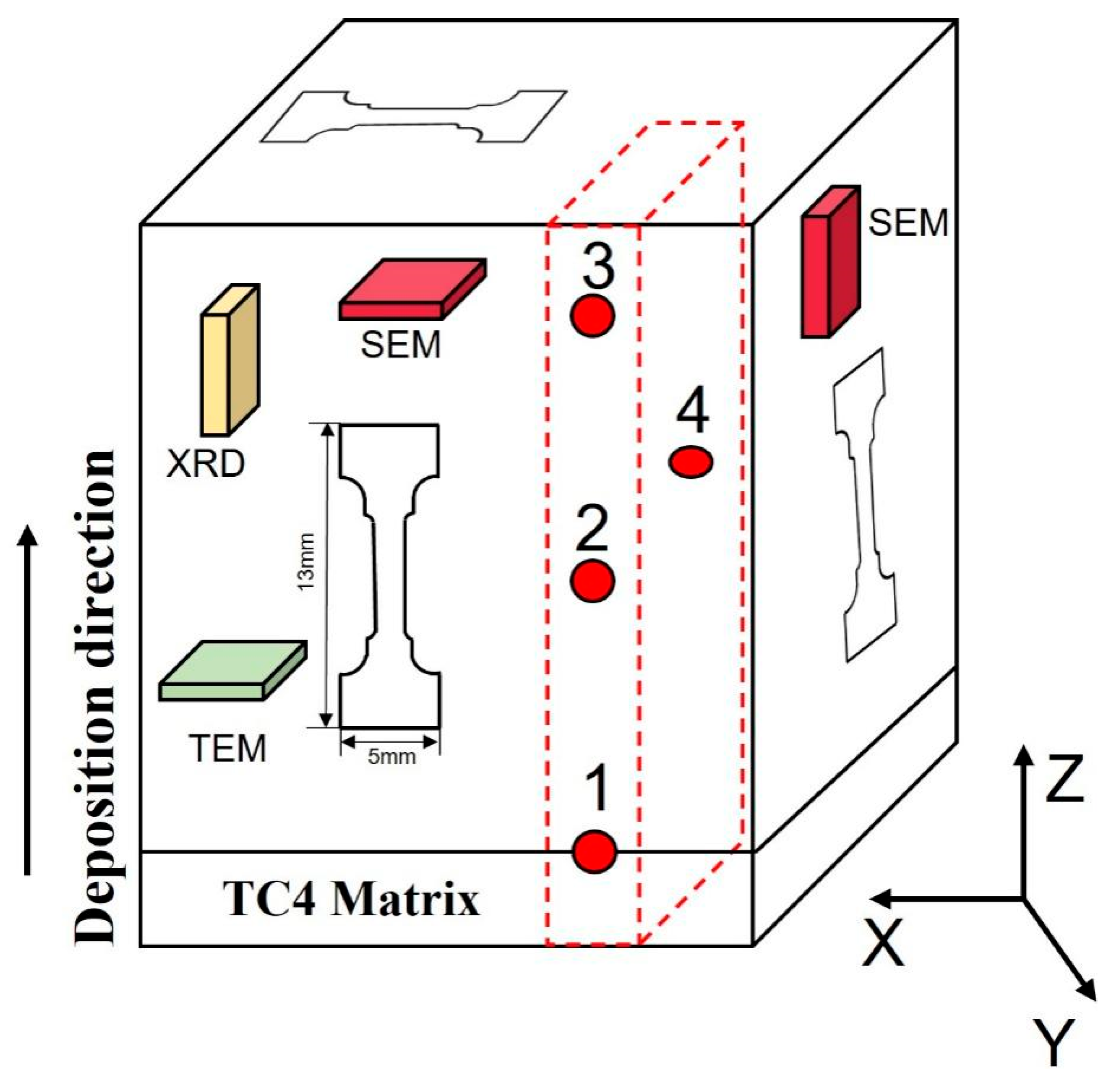

−3/s. Additionally, the single-point automatic Vickers hardness tester (TouchVicker-1000 A, Mage Instrument, Bologna, Italy) was utilized to measure the surface hardness of the specimens. During testing, a force of 0.2 kN was applied by the instrument and maintained for a duration of 10 s as load duration. Each specimen had 20 test areas with an interval of 0.5 mm between them for measurement purposes, and the results were averaged to ensure experimental accuracy. The sampling positions of the characterization specimens and tensile specimens for composite materials are shown in

Figure 3. Among them, the cross-sectional directions (XOZ1, XOZ2, XOZ3) are represented as 1, 2, and 3, respectively, while the surface position is represented as 4 (XOY). The sampling positions for metallographic specimens and tensile specimens include three directions: cross-section of the substrate (XOZ), longitudinal section (YOZ), and surface (XOY). Locations 2 (XOZ2) and 4 (XOY) are sampled at different heights along the

Z-axis.

Uncertainty estimates were calculated for key measurements. Annealing temperatures were controlled within ±5 °C, as verified by the muffle furnace’s thermocouple calibration. Statistical analysis of tensile and hardness data was performed using the mean and standard deviation of measurements from triplicate samples (tensile) and 20 test areas per sample (hardness). The root-sum-square method was used to calculate combined standard uncertainties, ensuring statistical reliability. Analysis of variance (ANOVA) was applied to assess the significance of microstructural changes (e.g., TiB aspect ratio, p > 0.05).

Author Contributions

H.G.: Conceptualization, Funding acquisition, Methodology, Resources, Writing—review and editing. Writing—original draft; G.D.: Data curation, Writing—review and editing; J.J.: Resources, Validation, Writing—review and editing; Z.L.: Data curation, Conceptualization; J.S.: Data curation, Formal analysis, Investigation; J.Z.: Conceptualization, Resources, Supervision; B.L.: Data curation, Formal analysis, Investigation. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the Project of Laser Processing and Metal Additive Manufacturing Technology and Application (SJK2023-3), the Top Talent Project of Nantong Institute of Technology (XBJRC2021003), Key disciplines of the 14th five year plan in Jiangsu Province: Mechanical Engineering (SJYH2022-2), First-class specialty in Jiangsu Province: Mechanical Design, Manufacturing and Automation (2020-9), Science and Technology Project of Nantong (JC2023007), Jiangsu Engineering Research Center of Marine Equipment Life Extension and Low Carbon Technology (SFGGJF2023-1026). In addition, the authors gratefully acknowledge Zhonggang Sun for his valuable suggestions and insightful comments.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Hu, Z.Y.; Cheng, X.W.; Li, S.L.; Zhang, H.M.; Wang, H.; Zhang, Z.H.; Wang, F.C. Investigation on the microstructure, room and high temperature mechanical behaviors and strengthening mechanisms of the (TiB+TiC)/TC4 composites. J. Alloys Compd. 2017, 726, 240–253. [Google Scholar] [CrossRef]

- Zhang, C.; Li, X.; Zhang, S.; Chai, L.; Chen, Z.; Kong, F.; Chen, Y. Effects of direct rolling deformation on the microstructure and tensile properties of the 2.5 vol% (TiB w +TiC p)/Ti composites. Mater. Sci. Eng. A 2017, 684, 645–651. [Google Scholar] [CrossRef]

- Aliyu, I.K.; Saheb, N.; Hassan, S.F.; Al-Aqeeli, N. Effect of SiC nanoparticles on the microstructure and mechanical properties of aluminum matrix composites fabricated by spark plasma sintering. Mater. Chem. Phys. 2019, 229, 476–482. [Google Scholar]

- Wang, M.; Chen, D.; Chen, Z.; Wu, Y.; Wang, F.; Ma, N.; Wang, H. Microstructure and mechanical properties of in-situ TiB2/Mg composites fabricated by powder metallurgy. Trans. Nonferrous Met. Soc. China 2022, 32, 3495–3506. [Google Scholar]

- Jiao, T.; Jiang, T.; Dai, G.; Guo, Y.; Sun, Z.; Chang, H.; Han, Y.; Li, S.; Alexandrov, I.V. The microstructure evolution of TC4-(TiB+TiC)/TC4 laminated composites by laser melting deposition. Mater. Charact. 2023, 197, 112665. [Google Scholar] [CrossRef]

- Meng, X.; Sun, Z.; Chu, X.; Guo, Y.; Chang, H.; Wang, Y. Microstructural evolution and wear properties of in-situ (TiB+TiC)-reinforced Ti6Al4V matrix composite coating by laser melting deposition. Mater. Charact. 2023, 205, 113192. [Google Scholar] [CrossRef]

- Dai, G.; Sun, Z.; Li, Y.; Jain, J.; Bhowmik, A.; Shinjo, J.; Lu, J.; Panwisawas, C. Grain refinement and columnar-to-equiaxed transition of Ti6Al4V during additive manufacturing via different laser oscillations. Int. J. Mach. Tools Manuf. 2023, 189, 104031. [Google Scholar] [CrossRef]

- Yang, Z.-R.; Huan, H.-X.; Jiang, C.-F.; Li, W.-M.; Liu, X.-R.; Lyu, S. Evaluation on dry sliding wear behavior of (TiB+TiC)/Ti-6Al-4V matrix composite, International. J. Precis. Eng. Manuf. 2017, 18, 1139–1146. [Google Scholar]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D.; Dargusch, M.S. Recent developments and opportunities in additive manufacturing of titanium-based matrix composites: A review, International. J. Mach. Tools Manuf. 2018, 133, 85–102. [Google Scholar] [CrossRef]

- Yu, J.; Zhao, Y.; Zhang, W.; Zhao, Q.; Lu, J.; Huo, W.; Zhang, Y. A novel heterogeneous network structure titanium matrix composite with a combination of strength and ductility. Mater. Sci. Eng. A 2022, 840, 142954. [Google Scholar] [CrossRef]

- Li, S.; Xu, X.; Luo, Y.; Huang, L.; Wu, J. Study on Hot Corrosion Resistance of In Situ Generated TiC and TiC + TiB Reinforced TB8 Titanium Matrix Composite by Powder Metallurgy. J. Mater. Eng. Perform. 2022, 32, 835–846. [Google Scholar] [CrossRef]

- Pan, D.; Li, S.; Liu, L.; Zhang, X.; Li, B.; Chen, B.; Chu, M.; Hou, X.; Sun, Z.; Umeda, J.; et al. Enhanced strength and ductility of nano-TiBw-reinforced titanium matrix composites fabricated by electron beam powder bed fusion using Ti6Al4V–TiBw composite powder. Addit. Manuf. 2022, 50, 102519. [Google Scholar] [CrossRef]

- Cao, B.; Xu, X.; Li, C.; Zhang, R.; Liu, Q.; Zhang, X.; Chen, H.; Bai, X.; Hu, C. High-temperature oxidation behavior of TiC and TiC + TiB reinforced TB8 matrix composites prepared by spark plasma sintering. Appl. Phys. A 2021, 127, 303. [Google Scholar] [CrossRef]

- Meng, X.; Min, J.; Sun, Z.; Zhang, W.; Chang, H.; Han, Y. Columnar to equiaxed grain transition of laser deposited Ti6Al4V using nano-sized B4C particles. Compos. Part B Eng. 2021, 212, 108667. [Google Scholar] [CrossRef]

- Tabrizi, S.G.; Sajjadi, S.A.; Babakhani, A.; Lu, W. Influence of spark plasma sintering and subsequent hot rolling on microstructure and flexural behavior of in-situ TiB and TiC reinforced Ti6Al4V composite. Mater. Sci. Eng. A 2015, 624, 271–278. [Google Scholar] [CrossRef]

- Le, J.; Boehlert, C.J.; Huang, G.; Mao, J.; Lei, L.; Han, Y.; Lu, W. TiB whisker induced variant selection in titanium matrix composites. Scr. Mater. 2022, 217, 114772. [Google Scholar] [CrossRef]

- Huang, G.; Guo, X.; Han, Y.; Wang, L.; Lu, W.; Zhang, D. Effect of extrusion dies angle on the microstructure and properties of (TiB+TiC)/Ti6Al4V in situ titanium matrix composite. Mater. Sci. Eng. A 2016, 667, 317–325. [Google Scholar] [CrossRef]

- Wang, J.; Guo, X.; Xiao, L.; Wang, L.; Lu, W.; Li, B.; Li, Z.; Zhang, D. Effect of B4C on the Microstructure and Mechanical Properties of As-Cast TiB+TiC/TC4 Composites. Acta Metall. Sin. (Engl. Lett.) 2014, 27, 205–210. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Peng, H.X.; Kaveendran, B. High temperature tensile properties of in situ TiBw/Ti6Al4V composites with a novel network reinforcement architecture. Mater. Sci. Eng. A 2012, 534, 688–692. [Google Scholar] [CrossRef]

- Lu, J.; Qin, J.; Chen, Y.; Zhang, Z.; Lu, W.; Zhang, D. Superplasticity of coarse-grained (TiB+TiC)/Ti–6Al–4V composite. J. Alloys Compd. 2010, 490, 118–123. [Google Scholar] [CrossRef]

- Pouzet, S.; Peyre, P.; Gorny, C.; Castelnau, O.; Baudin, T.; Brisset, F.; Colin, C.; Gadaud, P. Additive layer manufacturing of titanium matrix composites using the direct metal deposition laser process. Mater. Sci. Eng. A 2016, 677, 171–181. [Google Scholar] [CrossRef]

- Niu, J.; Dai, G.; Guo, Y.; Sun, Z.; Dan, Z.; Dong, Y.; Chang, H.; Alexandrov, I.V.; Zhou, L. Microstructure and mechanical properties of B modified Ti–Fe alloy manufactured by casting, forging and laser melting deposition. Compos. Part B Eng. 2021, 216, 108854. [Google Scholar] [CrossRef]

- Hua, Z.; Xiong, L.; Zhang, M.; Wang, C.; Mi, G.; Jiang, P. Microstructure evolution and tribological properties of (TiB+TiC)/Ti–6Al–4V composites fabricated via in situ laser-directed energy deposition of wire and powders in an underwater environment. Compos. Part B Eng. 2023, 263, 110817. [Google Scholar] [CrossRef]

- Wang, T.; Liu, X.; Chen, S.; Lei, J.; Song, X. Study on microstructure and tribological properties of nano/micron TiC/TC4 composites fabricated by laser melting deposition. J. Manuf. Process. 2022, 82, 296–305. [Google Scholar] [CrossRef]

- Banerjee, R.; Collins, P.C.; Genç, A.; Fraser, H.L. Direct laser deposition of in situ Ti–6Al–4V–TiB composites. Mater. Sci. Eng. A 2003, 358, 343–349. [Google Scholar] [CrossRef]

- Huo, P.; Zhao, Z.; Du, W.; Zhang, Z.; Bai, P.; Tie, D. Deformation strengthening mechanism of in situ TiC/TC4 alloy nanocomposites produced by selective laser melting. Compos. Part B Eng. 2021, 225, 109305. [Google Scholar] [CrossRef]

- Wang, J.; Li, L.; Lin, P.; Wang, J. Effect of TiC particle size on the microstructure and tensile properties of TiCp/Ti6Al4V composites fabricated by laser melting deposition. Opt. Laser Technol. 2018, 105, 195–206. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, J.; Vilar, R. Characterization of (TiB+TiC)/TC4 in situ titanium matrix composites prepared by laser direct deposition. J. Mater. Process. Technol. 2011, 211, 597–601. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, L.; Zhao, K.; Qi, C.; Shi, B.; Zhang, Y.; Yuan, S.; Zhan, X. Thermal analysis and microstructure evolution of TiC/Ti6Al4V functionally graded material by direct energy deposition. Mater. Sci. Eng. A 2024, 893, 146136. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J.C. Titanium, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Cai, C.; He, S.; Li, L.; Teng, Q.; Song, B.; Yan, C.; Wei, Q.; Shi, Y. Microstructure and properties of in-situ TiB/Ti-6Al-4V composites. J. Mater. Sci. 2018, 53, 12345–12356. [Google Scholar]

- Bakshi, S.R.; Lahiri, D.; Agarwal, A. Carbon nanotube reinforced metal matrix composites—A review. Int. Mater. Rev. 2010, 55, 41–64. [Google Scholar] [CrossRef]

- Huang, L.J.; Yang, F.Y.; Hu, H.T.; Rong, X.D.; Geng, L.; Wu, L.Z. TiB whiskers reinforced high temperature titanium Ti60 alloy composites with novel network microstructure. Mater. Des. 2013, 51, 421–426. [Google Scholar] [CrossRef]

- Kobryn, P.A.; Moore, E.H.; Semiatin, S.L. The effect of laser power and traverse speed on microstructure, porosity, and build height in laser-deposited Ti-6Al-4V. Scr. Mater. 2000, 43, 299–305. [Google Scholar] [CrossRef]

Figure 1.

Preparation process of as-cast and powder (TiB + TiC)/TC4 composites: (a) Consumable electrode melting, (b) Plasma rotating electrode, and Microstructure of as-casted (TiB + TiC)/TC4 composites: (c) 100×; (d) 500×, (e) Composite material powder.

Figure 2.

(a) DED print procedure of (TiB + TiC)/TC4 composites; (b) Heat treatment parameter diagram.

Figure 3.

Schematic diagram of XRD, SEM, TEM and tensile sampling positions of as-deposited composites: 1, 2, and 3 are cross-sectional directions (XOZ1, XOZ2, and XOZ3), and 4 are surface (XOY) sampling locations.

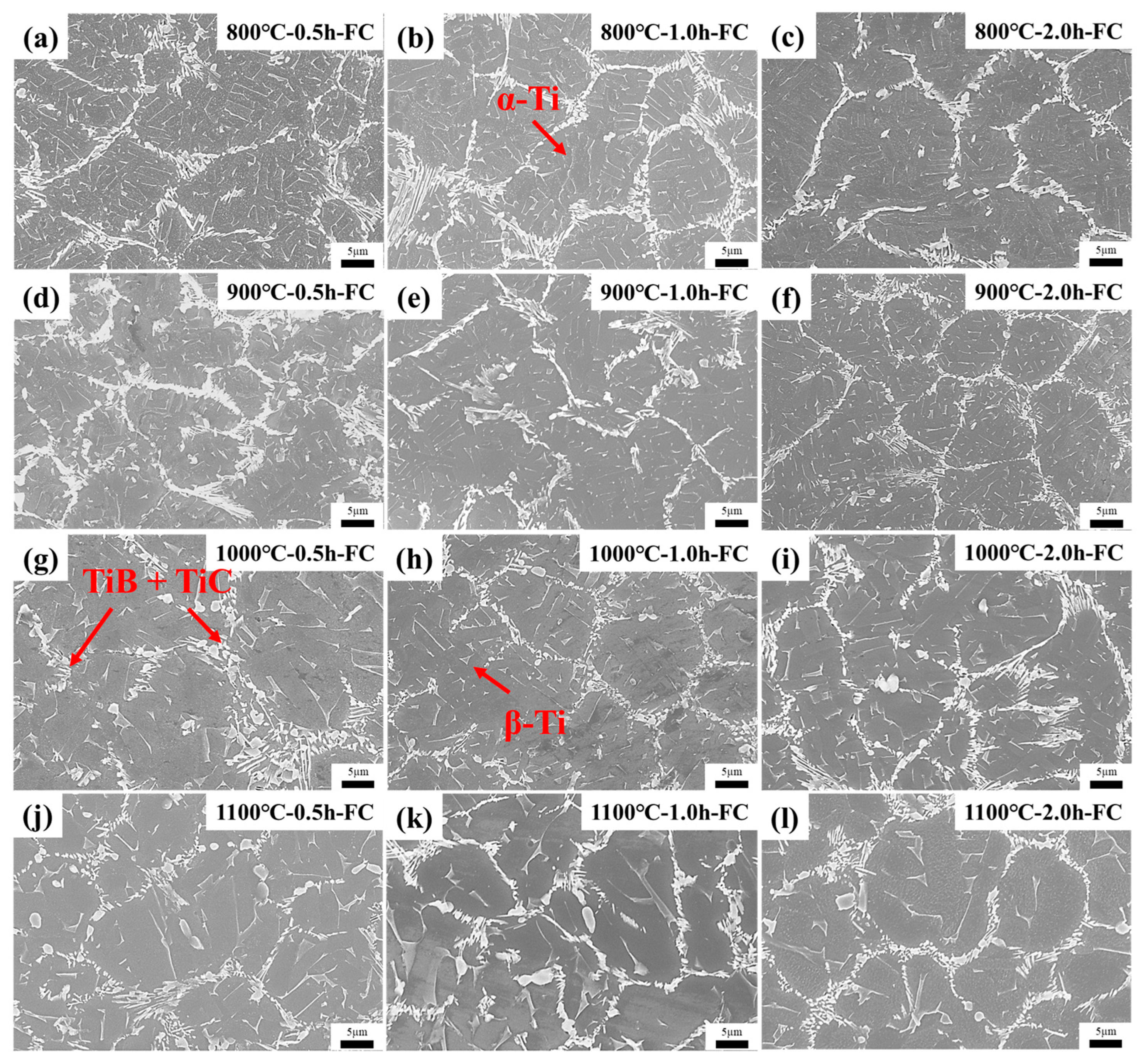

Figure 4.

Optical image of the deposited (TiB + TiC)/TC4 after different annealing processes. (a) 800 °C-0.5 h-FC (b) 800 °C-1.0 h-FC (c) 800 °C-2.0 h-FC (d) 900 °C-0.5 h-FC (e) 900 °C-1.0 h-FC (f) 900 °C-2.0 h-FC (g) 1000 °C-0.5 h-FC (h) 1000 °C-1.0 h-FC (i) 1000 °C-2.0 h-FC (j) 1100 °C-0.5 h-FC (k) 1100 °C-1.0 h-FC (l) 1100 °C-2.0 h-FC.

Figure 5.

SEM images of deposited (TiB + TiC)/TC4 composites after different annealing processes (a) 800 °C-0.5 h-FC (b) 800 °C-1.0 h-FC (c) 800 °C-2.0 h-FC (d) 900 °C-0.5 h-FC (e) 900 °C-1.0 h-FC (f) 900 °C-2.0 h-FC (g) 1000 °C-0.5 h-FC (h) 1000 °C-1.0 h-FC (i) 1000 °C-2.0 h-FC (j) 1100 °C-0.5 h-FC (k) 1100 °C-1.0 h-FC (l) 1100 °C-2.0 h-FC.

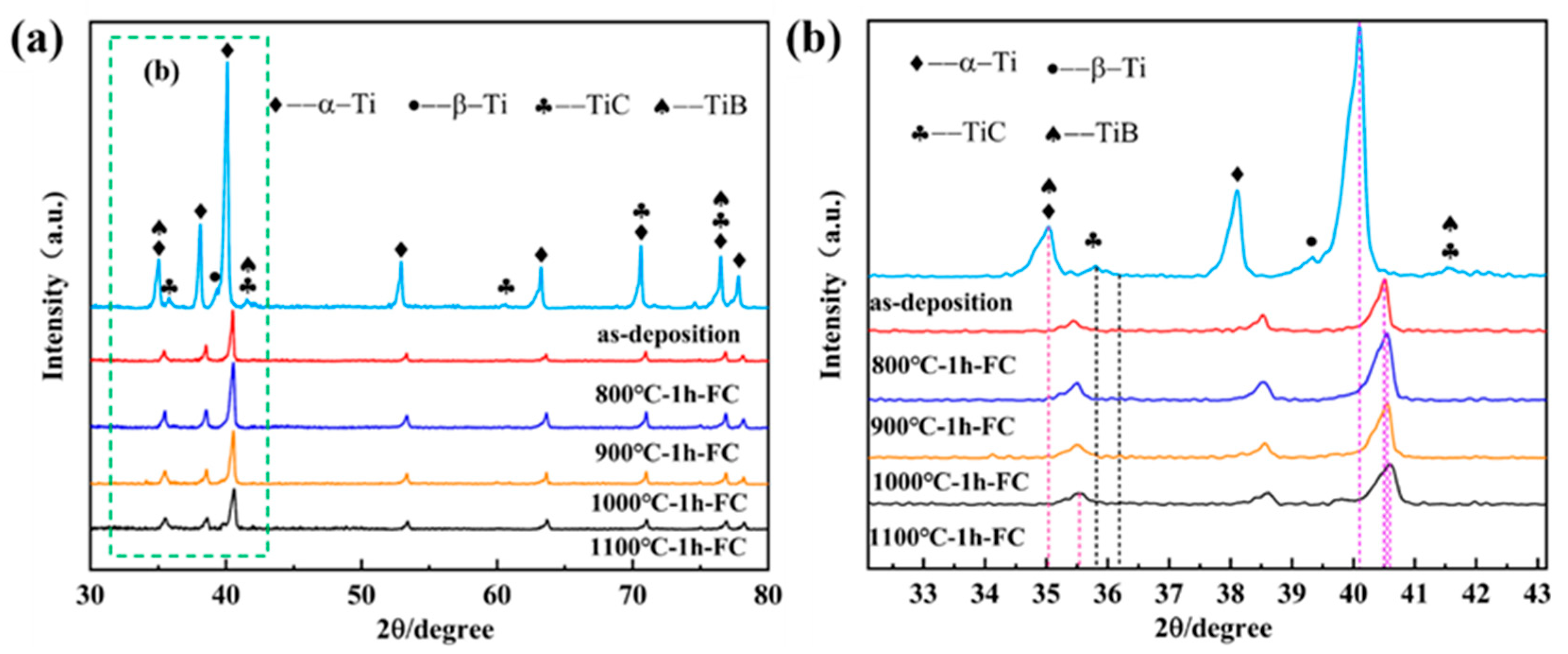

Figure 6.

X-ray diffraction pattern. (a) annealed (TiB + TiC)/TC4 composites (b) local enlarged view of green areas in (a).

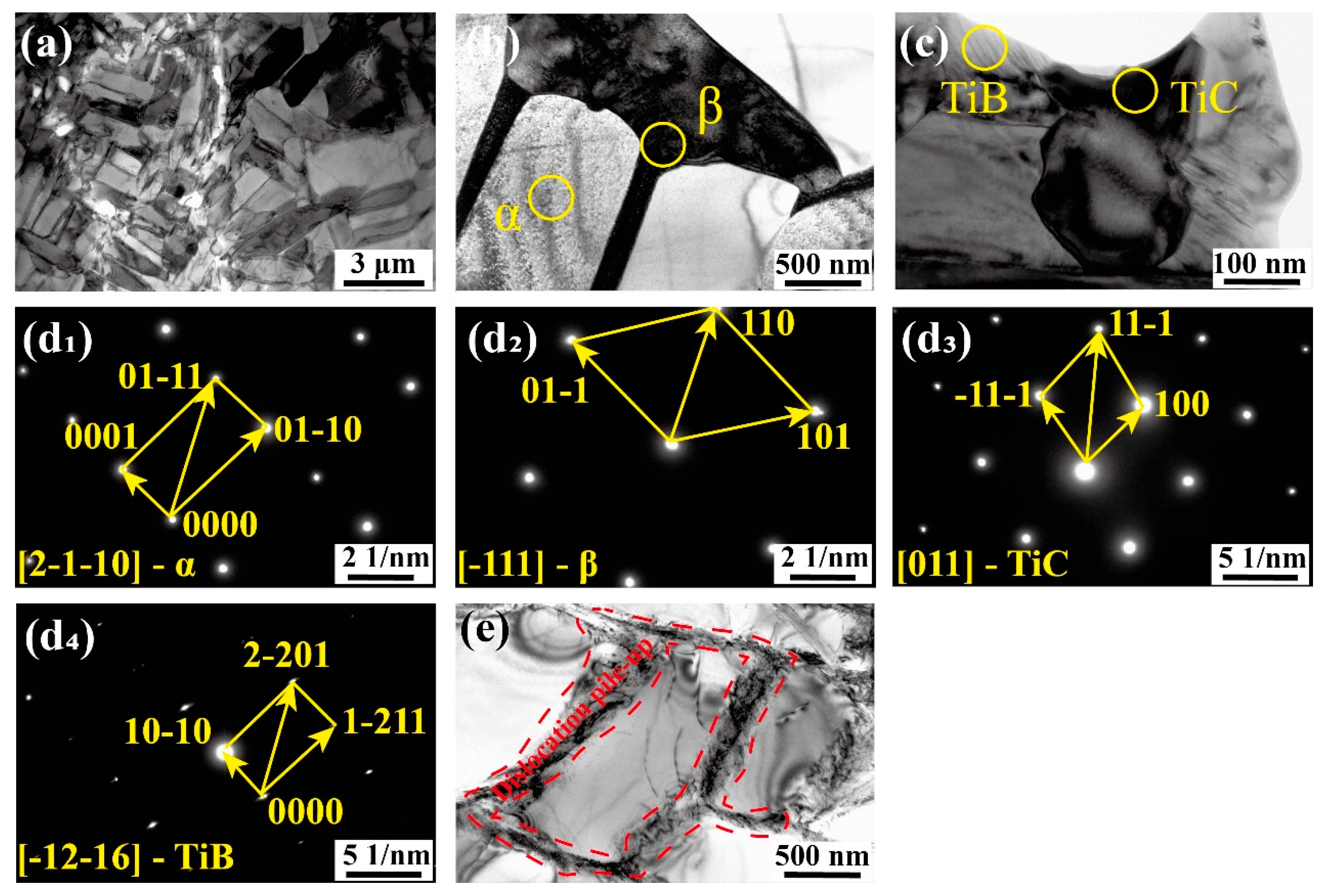

Figure 7.

TEM analysis of (TiB + TiC)/TC4 composites after heat treatment (a) Macroscopic morphology (b) α and β phase (c) TiC and TiB (d1–d4) SAED of α, β, TiC, TiB (e) Dislocation pile-up.

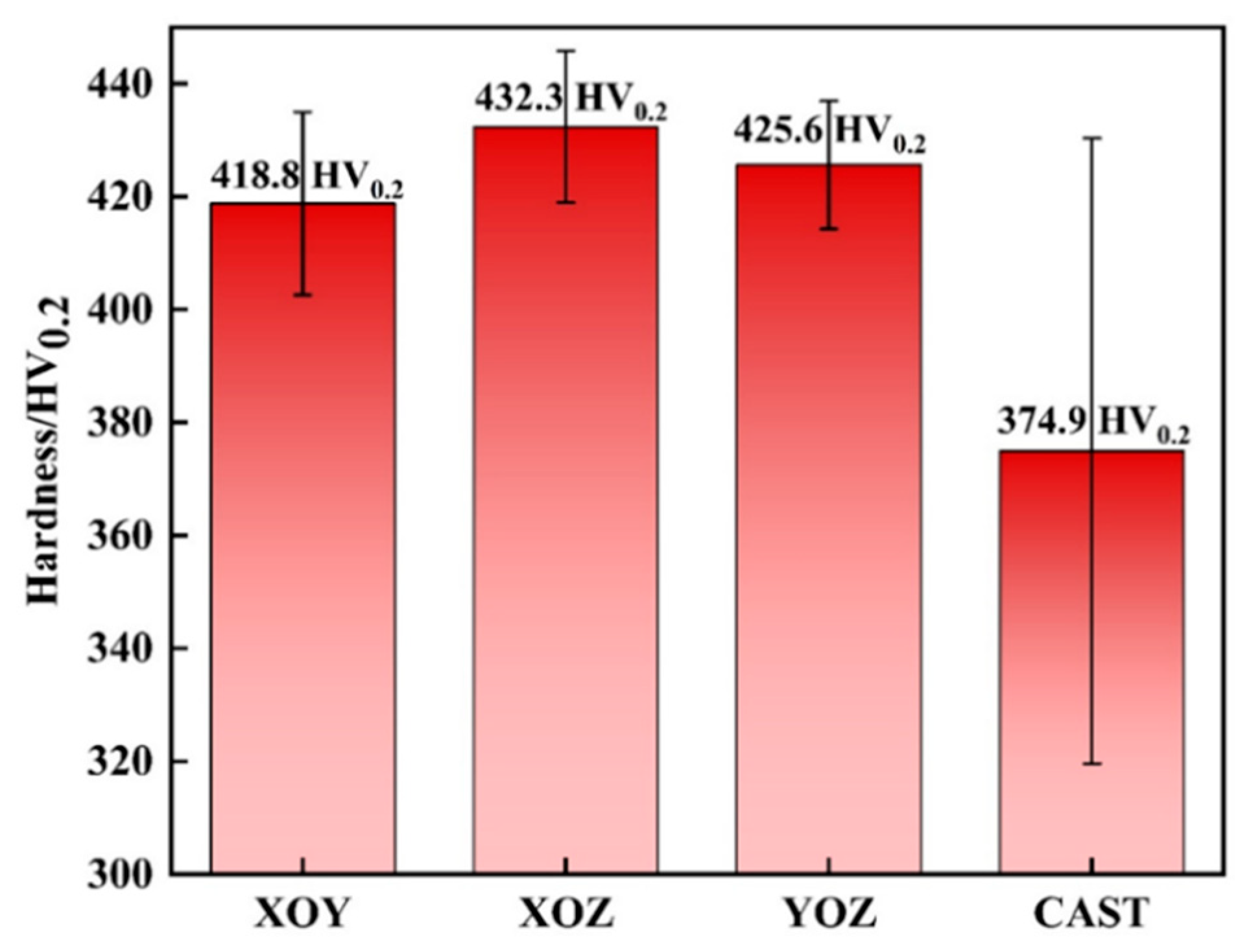

Figure 8.

Hardness distribution of as-cast and deposited (TiB + TiC)/TC4 composites in different directions.

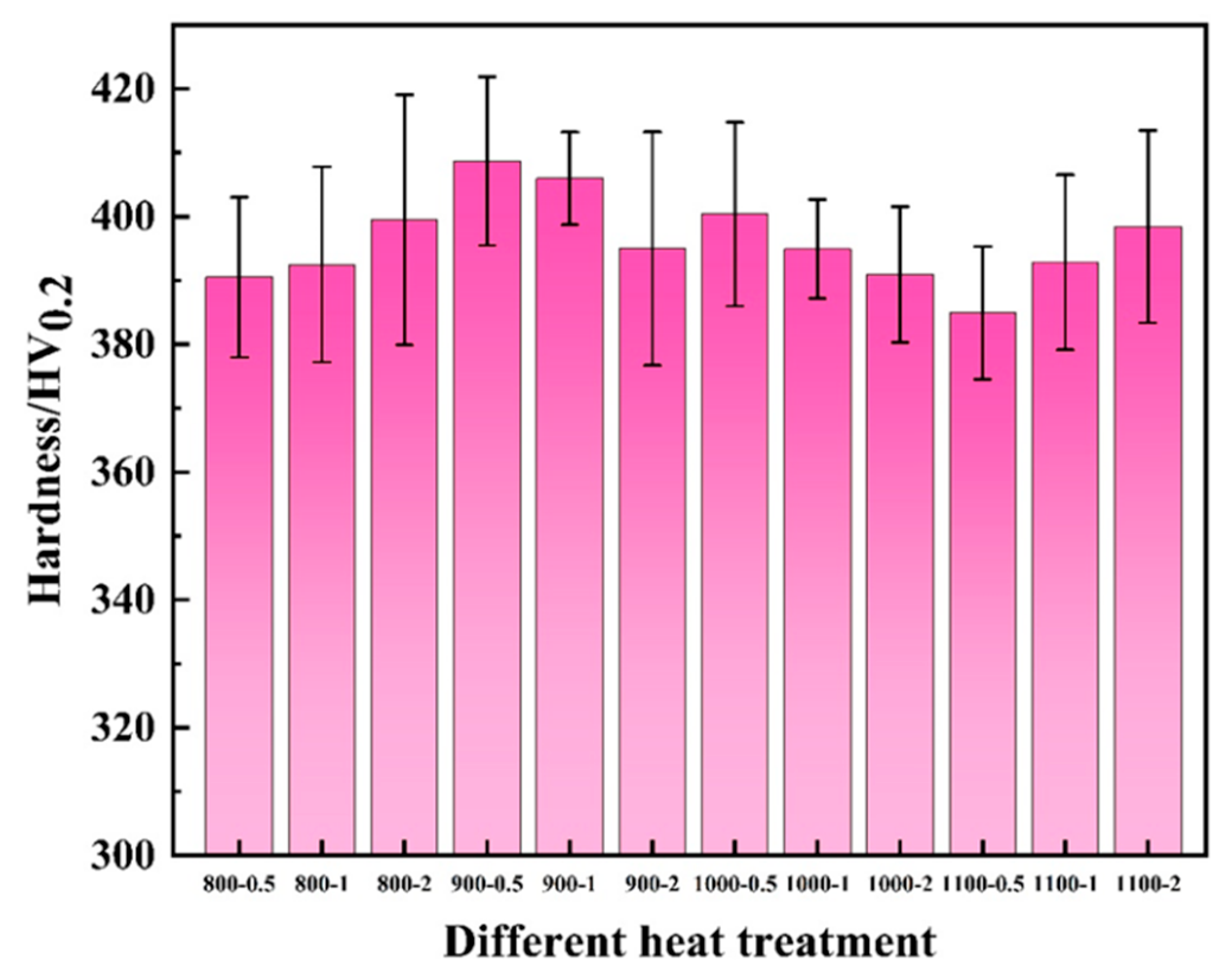

Figure 9.

Surface hardness distribution of annealed (TiB + TiC)/TC4 composites.

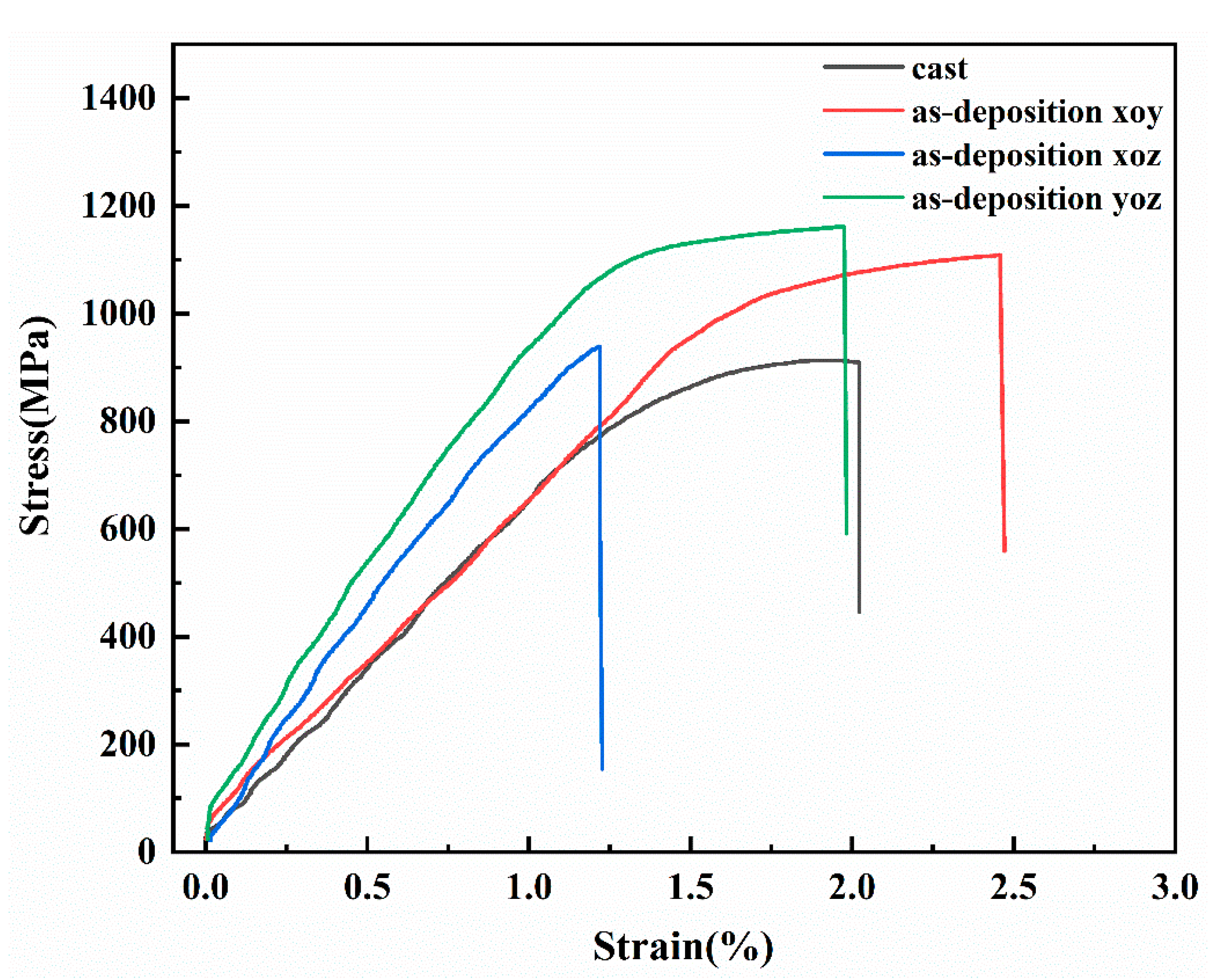

Figure 10.

Engineering strain–stress curve of as-cast and as-deposited (TiB + TiC)/TC4 composites.

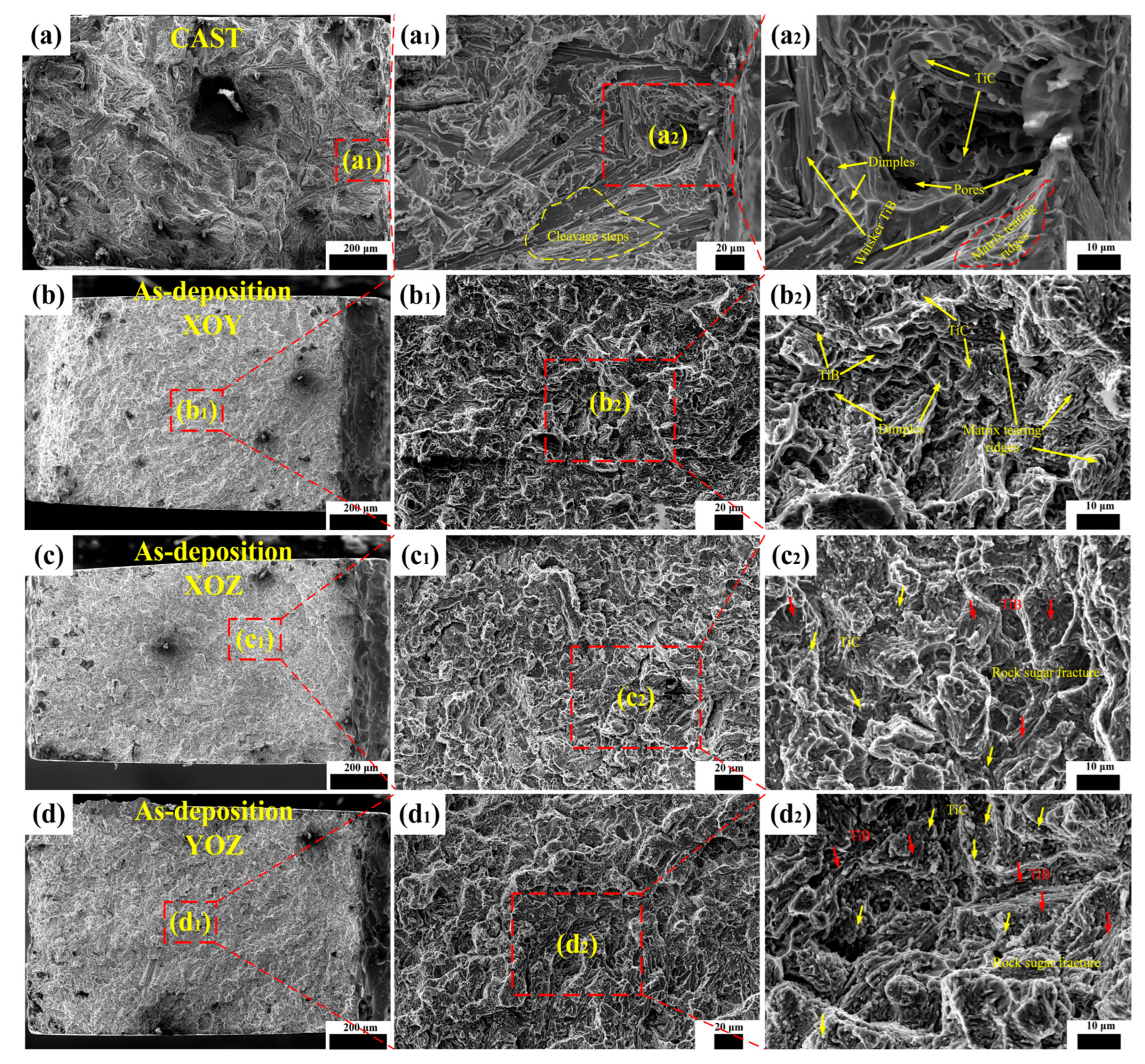

Figure 11.

The fracture morphologies of as-casted and as-deposited (TiB + TiC)/TC4 composites tensile sample. (a) Cast, (b) As-deposition XOY, (c) As-deposition XOZ, (d) As-deposition YOZ, (a1–d1) Larger magnification image of (a–d), (a2–d2) Larger magnification image of (a1–d1).

Table 1.

Chemical composition (wt.%) and powder properties of (TiB + TiC)/TC4 composites powder.

| Element (wt.%) | Al | V | Fe | C | B | N | O | H | Ti |

|---|

| 5.58 | 3.88 | 0.066 | 0.53 | 0.55 | 0.047 | 0.09 | 0.002 | Bal. |

|---|

| property | Mobility (s/50 g) | Loose density (g/cm3) | vibration density (g/cm3) |

| 24.2 | 2.57 | 2.8 |

Table 2.

Tensile properties of as-cast and as-deposited (TiB + TiC)/TC4 composites at room temperature.

| Direction | Rp0.2/MPa | Rm/MPa | A/% |

|---|

| XOY | 1067 | 1109 | 2.47 |

| XOZ | 937 | 939 | 1.22 |

| YOZ | 1037 | 1161 | 1.98 |

| CAST | 895 | 913 | 2.00 |

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).