Interplay of C Alloying, Temperature, and Microstructure in Governing Mechanical Behavior and Deformation Mechanisms of High-Manganese Steels

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. Initial State Microstructure Characterization

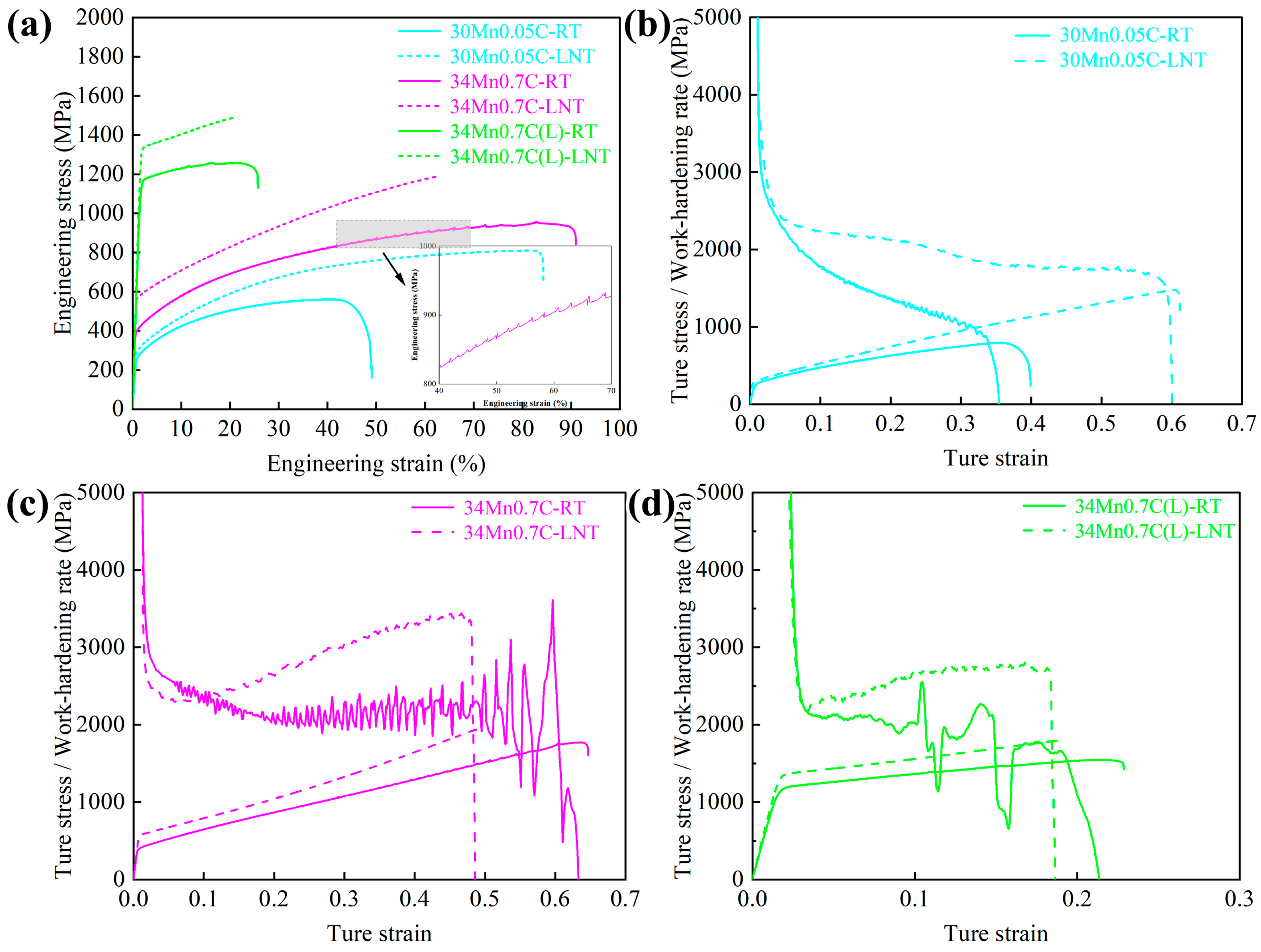

3.2. Tensile Properties and Work-Hardening Behavior

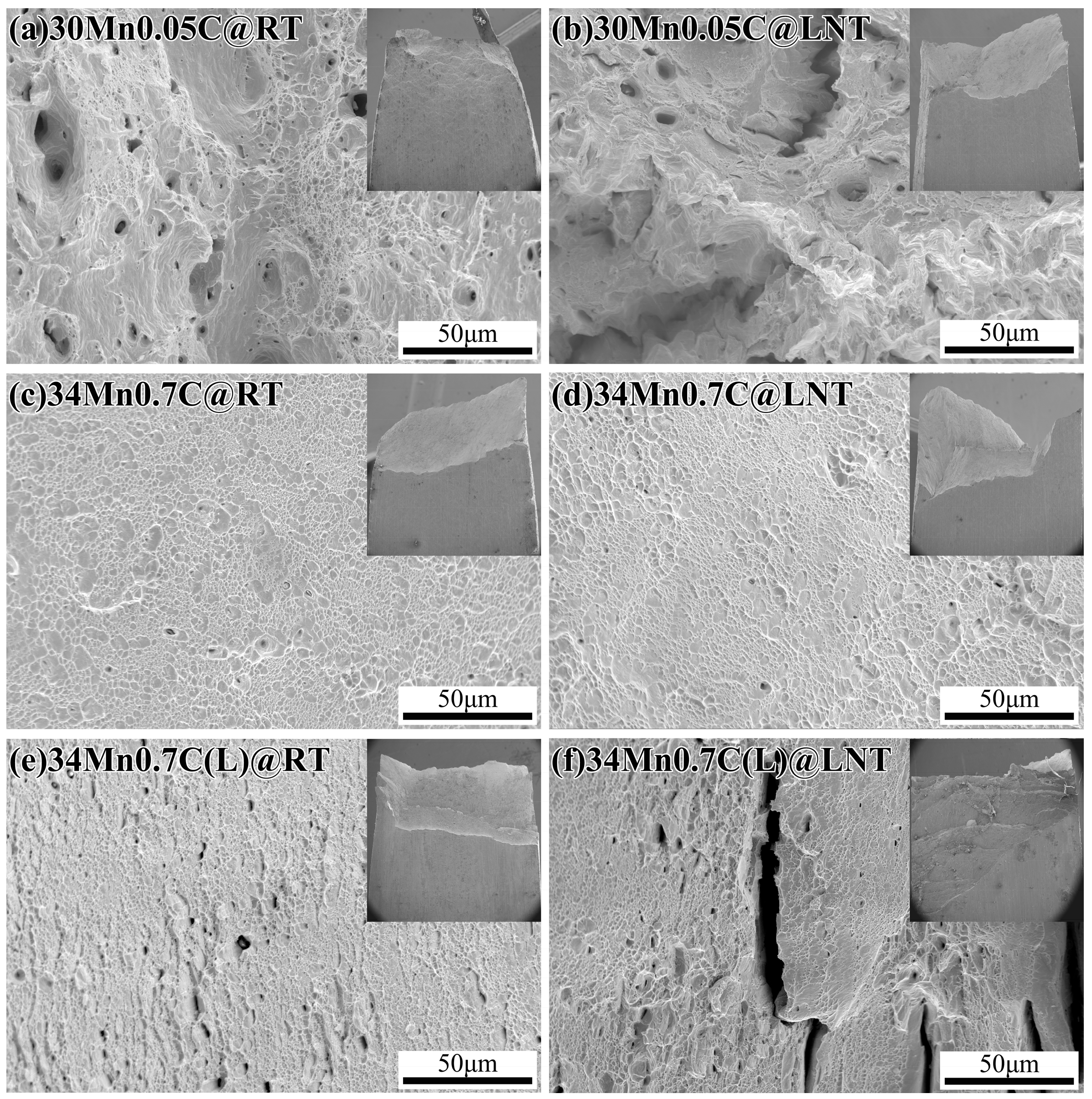

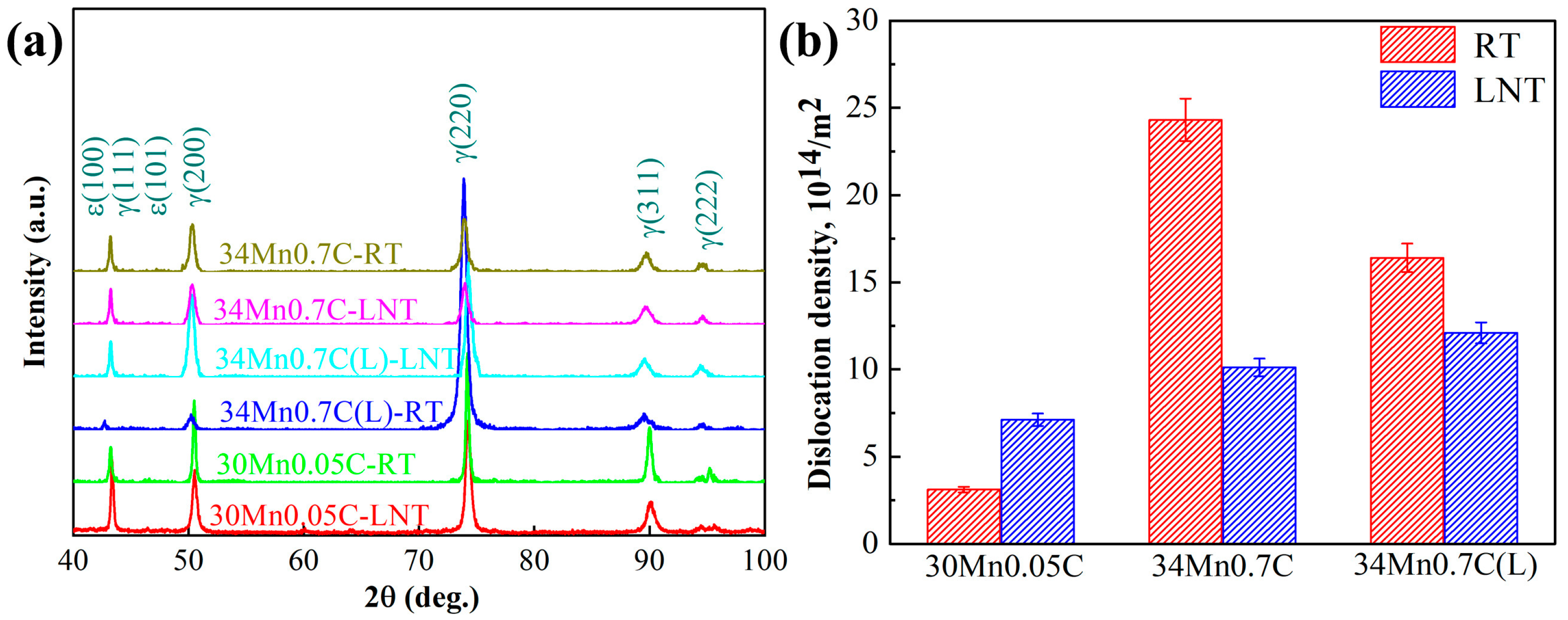

3.3. Evolution of Dislocation Density

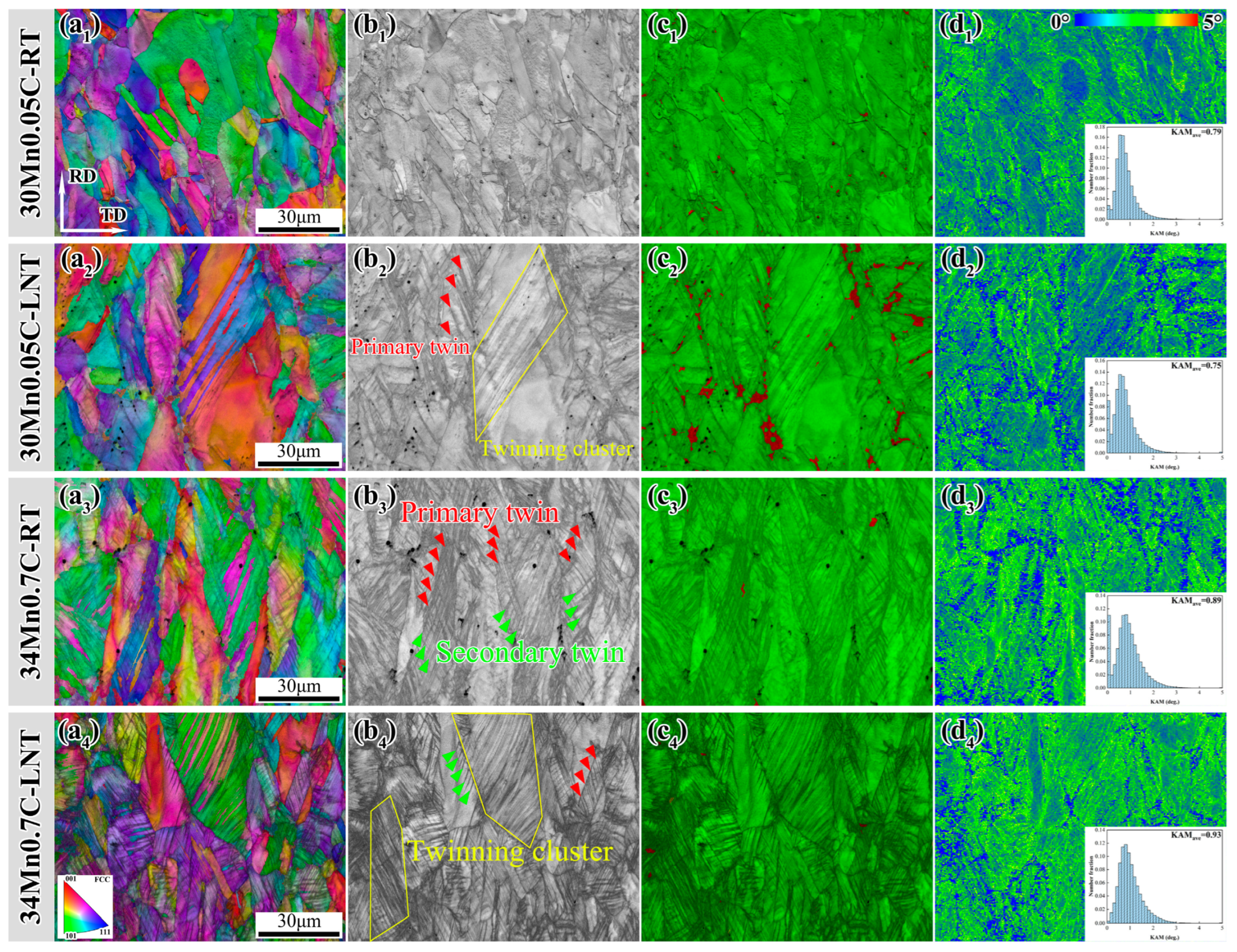

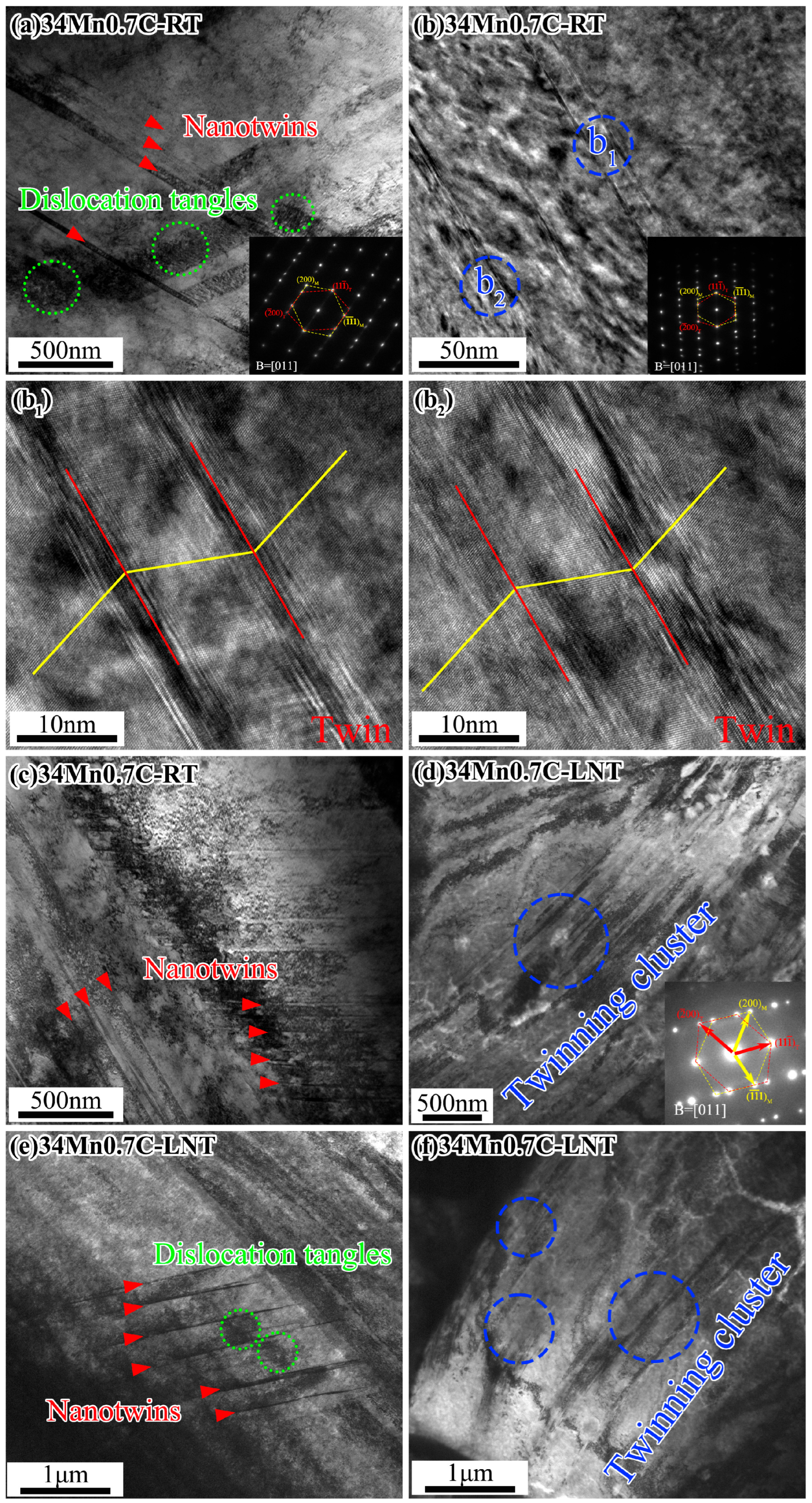

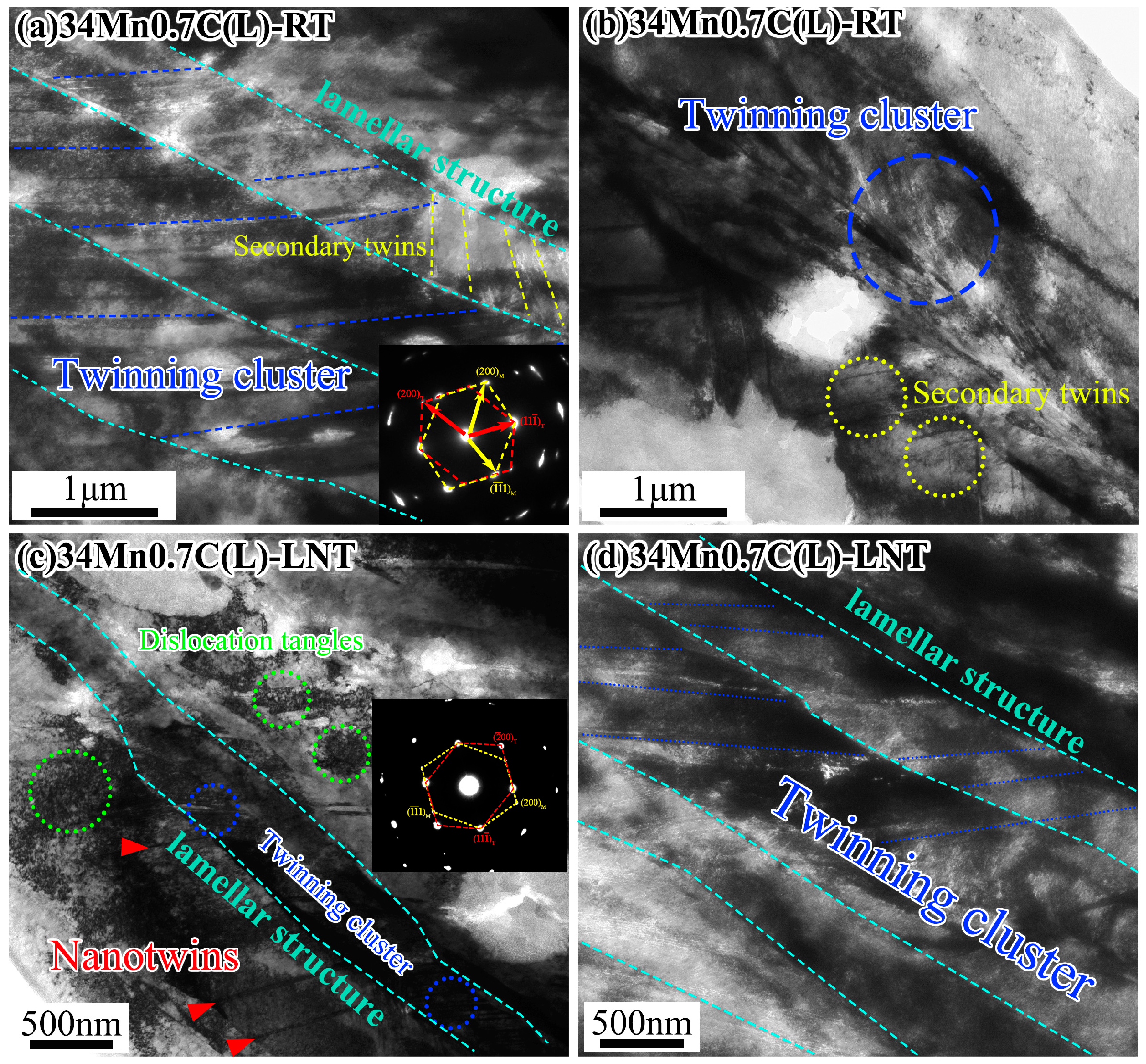

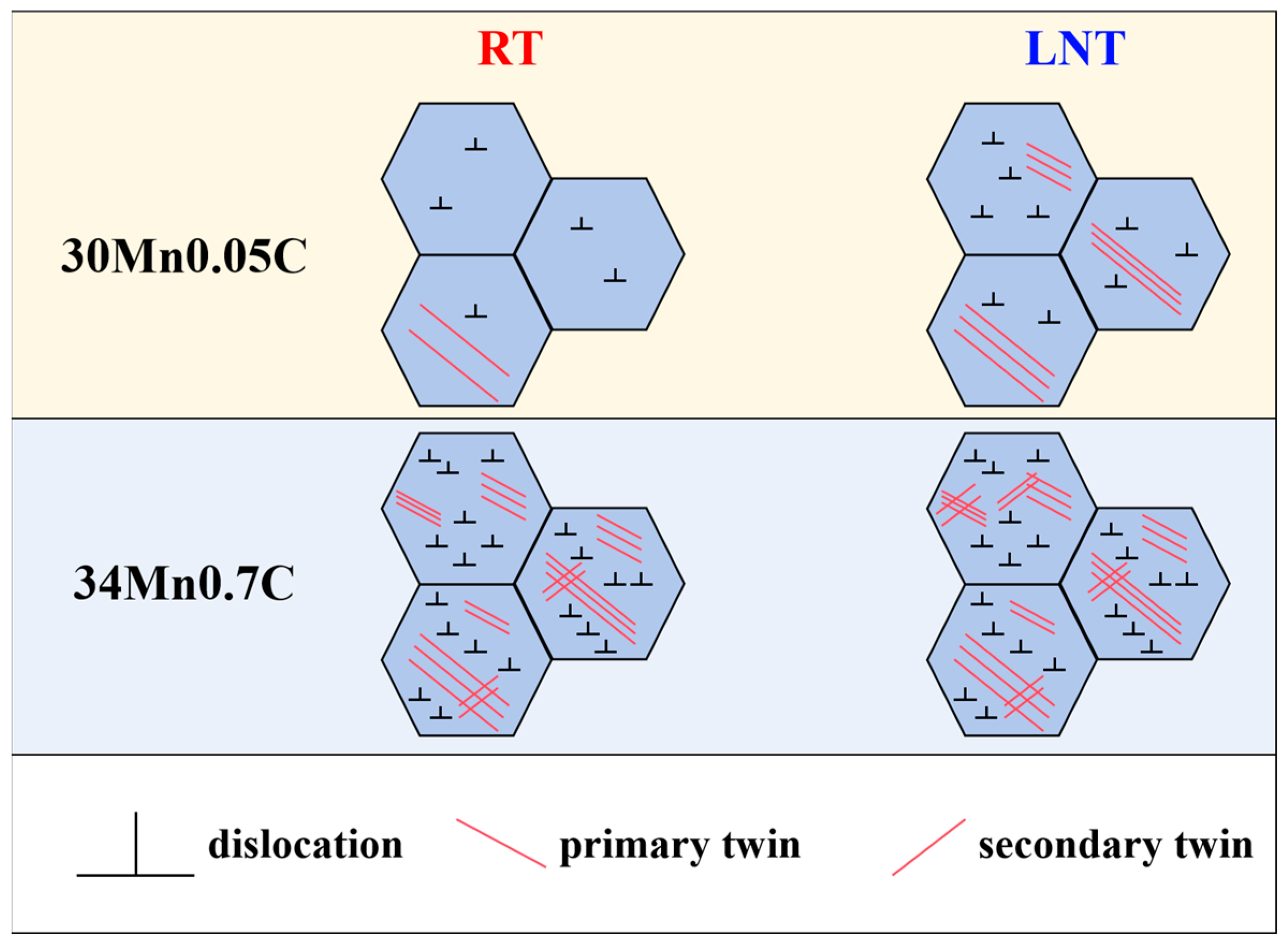

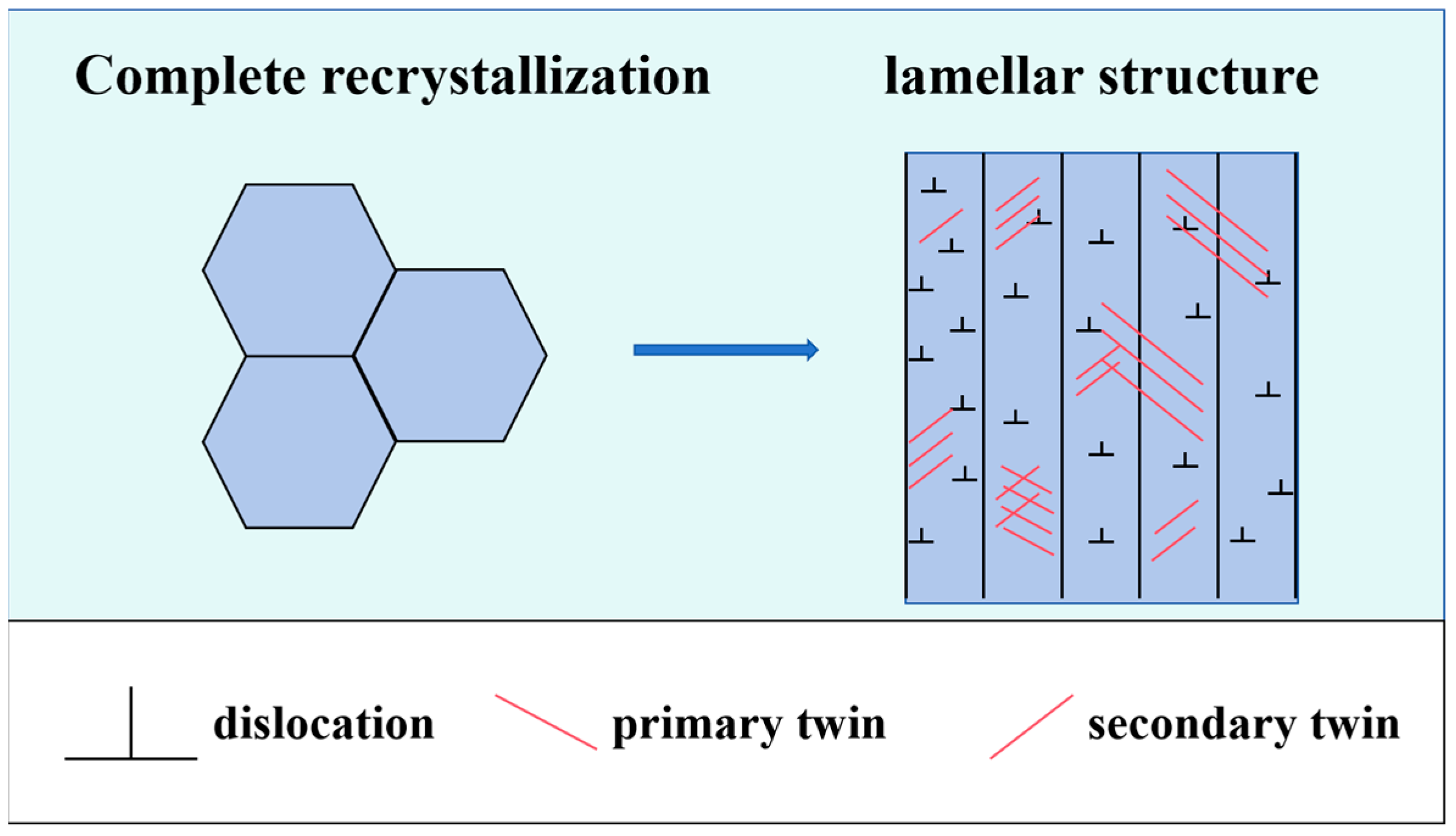

3.4. Evolution of Deformation Twin

4. Discussion

5. Conclusions

- Increased C content enhances the DSA effect by increasing dislocation density and promoting Mn-C complex formation, which improves strength but reduces plasticity;

- At LNT, the dominant deformation mechanism shifts from dislocation slip to twinning, driving changes in DSA behavior;

- The DSA effect is stronger in fully recrystallized specimens than in lamellar structures due to pre-existing dislocations and deformation twins that limit C atom diffusion.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fu, P.; Zheng, Z.B.; Yang, W.P.; Yang, H.K. Influence of carbon addition on mechanical properties of Fe-Mn-C twinning-induced plasticity steels. J. Iron Steel Res. Int. 2022, 29, 1446–1454. [Google Scholar] [CrossRef]

- Qi, X.Y.; Chen, C.; Li, Y.G.; Yang, Z.N.; Shen, S.C.; Lv, B.; Zhang, F.C. Flow softening behavior associated with dynamic recrystallization and preferential growth of a multielement strengthening high-Mn austenitic steel. J. Iron Steel Res. Int. 2025. [Google Scholar] [CrossRef]

- Koyama, M.; Sawaguchi, T.; Tsuzaki, K. Overview of Dynamic Strain Aging and Associated Phenomena in Fe-Mn-C Austenitic Steels. ISIJ Int. 2018, 58, 1383–1395. [Google Scholar] [CrossRef]

- Oh, S.-K.; Kwon, H.-J.; Lee, Y.-K. Reconsideration of the dislocation arrest model for dynamic strain aging in C-bearing high Mn steel with low stacking fault energy. Mater. Sci. Eng. A 2024, 897, 146304. [Google Scholar] [CrossRef]

- Yang, H.K.; Zhang, Z.J.; Tian, Y.Z.; Zhang, Z.F. Negative to positive transition of strain rate sensitivity in Fe-22Mn-0.6C-x(Al) twinning-induced plasticity steels. Mater. Sci. Eng. A 2017, 690, 146–157. [Google Scholar] [CrossRef]

- Nam, J.-H.; Oh, S.-K.; Park, M.-H.; Lee, Y.-K. The mechanism of dynamic strain aging for type A serrations in tensile curves of a medium-Mn steel. Acta Mater. 2021, 206, 116613. [Google Scholar] [CrossRef]

- Yilmaz, A. The Portevin–Le Chatelier effect: A review of experimental findings. Sci. Technol. Adv. Mater. 2011, 12, 063001. [Google Scholar] [CrossRef]

- McCormick, P.G. The Portevin-Le Chatelier effect in a pressurized low carbon steel. Acta Metall. 1973, 21, 873–878. [Google Scholar] [CrossRef]

- Cottrell, A.H. LXXXVI. A note on the Portevin-Le Chatelier effect. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1953, 197, 829–832. [Google Scholar] [CrossRef]

- Caillard, D. Dynamic strain ageing in iron alloys: The shielding effect of carbon. Acta Mater. 2016, 112, 273–284. [Google Scholar] [CrossRef]

- Van den Beukel, A. Theory of the effect of dynamic strain aging on mechanical properties. Phys. Stat. Solidi (a) 1975, 30, 197–206. [Google Scholar] [CrossRef]

- Hwang, S.; Park, M.-H.; Bai, Y.; Lavakumar, A.; Shibata, A.; Adachi, H.; Sato, M.; Tsuji, N. Mechanism of DSA effect correlating to the macroscopic PLC banding in high-Mn austenitic steel. Scr. Mater. 2024, 249, 1359–6462. [Google Scholar] [CrossRef]

- Yang, H.K.; Tian, Y.Z.; Zhang, Z.J.; Zhang, P.; Zhang, Z.F. Temperature-Dependence of the Mechanical Responses for Two Types of Twinning-Induced Plasticity Steels. Metall. Mater. Trans. A 2018, 49, 1475–1480. [Google Scholar] [CrossRef]

- Yang, H.K.; Tian, Y.Z.; Zhang, Z.F. Dramatic Increase of Strength and Ductility in Fe-22Mn-1.0C Twinning-Induced Plasticity Steel at Elevated Temperature. Adv. Eng. Mater. 2019, 21, 1438–1656. [Google Scholar] [CrossRef]

- Lee, S.-J.; Kim, J.; Kane, S.N.; De Cooman, B.C. On the origin of dynamic strain aging in twinning-induced plasticity steels. Acta Mater. 2011, 59, 6809–6819. [Google Scholar] [CrossRef]

- Grässel, O.; Krüger, L.; Frommeyer, G.; Meyer, L.W. High strength Fe-Mn-(Al, Si) TRIP/TWIP steels development-properties-application. Int. J. Plast. 2000, 16, 1391–1409. [Google Scholar] [CrossRef]

- Madivala, M.; Schwedt, A.; Wong, S.L.; Roters, F.; Prahl, U.; Bleck, W. Temperature dependent strain hardening and fracture behavior of TWIP steel. Int. J. Plast. 2018, 104, 80–103. [Google Scholar] [CrossRef]

- Renard, K.; Ryelandt, S.; Jacques, P.J. Characterisation of the Portevin-Le Châtelier effect affecting an austenitic TWIP steel based on digital image correlation. Mater. Sci. Eng. A 2010, 527, 2969–2977. [Google Scholar] [CrossRef]

- Litovchenko, I.; Akkuzin, S.; Polekhina, N.; Spiridonova, K.; Osipova, V.; Kim, A.; Moskvichev, E.; Chernov, V.; Kuznetsov, A. Microstructure Features and Mechanical Properties of Modified Low-Activation Austenitic Steel in the Temperature Range of 20 to 750 °C. Metals 2023, 13, 2015. [Google Scholar] [CrossRef]

- Khedr, M.; Li, W.; Min, N.; Liu, W.; Jin, X. Effects of increasing the strain rate on mechanical twinning and dynamic strain aging in Fe-12.5Mn-1.1C and Fe–24Mn-0.45C–2Al austenitic steels. Mater. Sci. Eng. A 2022, 842, 143024. [Google Scholar] [CrossRef]

- Seol, J.B.; Kim, J.G.; Na, S.H.; Park, C.G.; Kim, H.S. Deformation rate controls atomic-scale dynamic strain aging and phase transformation in high Mn TRIP steels. Acta Mater. 2017, 131, 187–196. [Google Scholar] [CrossRef]

- Saeed-Akbari, A.; Mishra, A.K.; Mayer, J.; Bleck, W. Characterization and Prediction of Flow Behavior in High-Manganese Twinning Induced Plasticity Steels: Part II. Jerky Flow and Instantaneous Strain Rate. Metall. Mater. Trans. A 2012, 43, 1705–1723. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Lee, S.-I.; Hwang, B. Effect of strain rate on tensile and serration behaviors of an austenitic Fe-22Mn-0.7C twinning-induced plasticity steel. Mater. Sci. Eng. A 2018, 711, 22–28. [Google Scholar] [CrossRef]

- Liang, Z.Y.; Wang, X.; Huang, W.; Huang, M.X. Strain rate sensitivity and evolution of dislocations and twins in a twinning-induced plasticity steel. Acta Mater. 2015, 88, 170–179. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Koyama, M.; Sawaguchi, T.; Tsuzaki, K. Deformation Twinning Behavior of Twinning-induced Plasticity Steels with Different Carbon Concentrations—Part 2: Proposal of Dynamic-strain-aging-assisted Deformation Twinning. ISIJ Int. 2015, 55, 1754–1761. [Google Scholar] [CrossRef]

- Oh, S.-K.; Kilic, M.E.; Seol, J.-B.; Hong, J.-S.; Soon, A.; Lee, Y.-K. The mechanism of dynamic strain aging for type A serrations in tensile flow curves of Fe-18Mn-0.55C (wt.%) twinning-induced plasticity steel. Acta Mater. 2020, 188, 366–375. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhý, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef]

- Chen, S.; Xie, X.; Li, W.; Feng, R.; Chen, B.; Qiao, J.; Ren, Y.; Zhang, Y.; Dahmen, K.A.; Liaw, P.K. Temperature effects on the serrated behavior of an Al0.5CoCrCuFeNi high-entropy alloy. Mater. Chem. Phys. 2018, 210, 20–28. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, J.P.; Chen, S.Y.; Xie, X.; Liaw, P.K.; Dahmen, K.A.; Qiao, J.W.; Wang, Y.L. Serration and noise behaviors in materials. Prog. Mater. Sci. 2017, 90, 358–460. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Godfrey, A.; Kang, J.; Peng, Y.; Wang, T.; Hansen, N.; Huang, X. Cryogenic toughness in a low-cost austenitic steel. Commun. Mater. 2021, 2, 44. [Google Scholar] [CrossRef]

- Koyama, M.; Shimomura, Y.; Chiba, A.; Akiyama, E.; Tsuzaki, K. Room-temperature blue brittleness of Fe-Mn-C austenitic steels. Scr. Mater. 2017, 141, 20–23. [Google Scholar] [CrossRef]

- Xiong, J.; Liu, E.; Zhang, C.; Kong, L.; Yang, H.; Zhang, X.; Wang, Y. Tuning mechanical behavior and deformation mechanisms in high-manganese steels via carbon content modification. Mater. Sci. Eng. A 2023, 881, 145401. [Google Scholar] [CrossRef]

- Dini, G.; Ueji, R.; Najafizadeh, A.; Monir-Vaghefi, S.M. Flow stress analysis of TWIP steel via the XRD measurement of dislocation density. Mater. Sci. Eng. A 2010, 527, 2759–2763. [Google Scholar] [CrossRef]

- Jeong, K.; Jin, J.-E.; Jung, Y.-S.; Kang, S.; Lee, Y.-K. The effects of Si on the mechanical twinning and strain hardening of Fe–18Mn–0.6C twinning-induced plasticity steel. Acta Mater. 2013, 61, 3399–3410. [Google Scholar] [CrossRef]

- Hutchinson, B.; Ridley, N. On dislocation accumulation and work hardening in Hadfield steel. Scr. Mater. 2006, 55, 299–302. [Google Scholar] [CrossRef]

- Mohammadzadeh, R.; Mohammadzadeh, M. Inverse grain size effect on twinning in nanocrystalline TWIP steel. Mater. Sci. Eng. A 2019, 747, 265–275. [Google Scholar] [CrossRef]

- Koyama, M.; Lee, T.; Lee, C.S.; Tsuzaki, K. Grain refinement effect on cryogenic tensile ductility in a Fe-Mn-C twinning-induced plasticity steel. Mater. Des. 2013, 49, 234–241. [Google Scholar] [CrossRef]

- Wang, Y.; Kang, J.; Peng, Y.; Wang, T.; Hansen, N.; Huang, X. Laminated Fe-34.5 Mn-0.04C composite with high strength and ductility. J. Mater. Sci. Technol. 2018, 34, 1939–1943. [Google Scholar] [CrossRef]

- Sun, S.; Xue, Z. Effect of Aging Process on the Strain Rate Sensitivity in V-Containing TWIP Steel. Metals 2021, 11, 126. [Google Scholar] [CrossRef]

- Li, S.; Withers, P.J.; Kabra, S.; Yan, K. The behaviour and deformation mechanisms for 316L stainless steel deformed at cryogenic temperatures. Mater. Sci. Eng. A 2023, 880, 145279. [Google Scholar] [CrossRef]

- Wang, Y.H.; Kang, J.M.; Peng, Y.; Wang, T.S.; Hansen, N.; Huang, X. Hall-Petch strengthening in Fe-34.5Mn-0.04C steel cold-rolled, partially recrystallized and fully recrystallized. Scr. Mater. 2018, 155, 41–45. [Google Scholar] [CrossRef]

- Steinmetz, D.R.; Jäpel, T.; Wietbrock, B.; Eisenlohr, P.; Gutierrez-Urrutia, I.; Saeed, A.; Hickel, T.; Roters, F.; Raabe, D. Revealing the strain-hardening behavior of twinning-induced plasticity steels: Theory, simulations, experiments. Acta Mater. 2013, 61, 494–510. [Google Scholar] [CrossRef]

| Steel | C | Mn | Si | Cr | Ni | Fe |

|---|---|---|---|---|---|---|

| 30Mn0.05C | 0.05 | 30.2 | <0.01 | <0.01 | <0.01 | Bal. |

| 34Mn0.7C | 0.7 | 34.4 | <0.01 | <0.01 | 0.19 | Bal. |

| Sample | Temp. | YS (MPa) | UTS (MPa) | UE (%) | TE (%) |

|---|---|---|---|---|---|

| 30Mn0.05C | RT | 241 ± 4.6 | 530 ± 30.5 | 40 ± 2.4 | 49 ± 1.2 |

| LNT | 307 ± 15.6 | 809 ± 11.9 | 82 ± 4.7 | 85 ± 3.2 | |

| 34Mn0.7C | RT | 389 ± 24.8 | 958 ± 30.6 | 82 ± 4.7 | 90 ± 5.5 |

| LNT | 573 ± 11.9 | 1189 ± 27.7 | 69 ± 4.8 | 69 ± 4.7 | |

| 34Mn0.7C(L) | RT | 1087 ± 1.5 | 1260 ± 2.5 | 18 ± 1.7 | 25 ± 1.6 |

| LNT | 1367 ± 23.4 | 1488 ± 18.5 | 24 ± 3.6 | 24 ± 3.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Zhao, J.; Zhao, T.; Kong, L.; Zheng, C.; Yang, H.; Wang, Y. Interplay of C Alloying, Temperature, and Microstructure in Governing Mechanical Behavior and Deformation Mechanisms of High-Manganese Steels. Metals 2025, 15, 779. https://doi.org/10.3390/met15070779

Zhang C, Zhao J, Zhao T, Kong L, Zheng C, Yang H, Wang Y. Interplay of C Alloying, Temperature, and Microstructure in Governing Mechanical Behavior and Deformation Mechanisms of High-Manganese Steels. Metals. 2025; 15(7):779. https://doi.org/10.3390/met15070779

Chicago/Turabian StyleZhang, Chenghao, Jinfu Zhao, Tengxiang Zhao, Ling Kong, Chunlei Zheng, Haokun Yang, and Yuhui Wang. 2025. "Interplay of C Alloying, Temperature, and Microstructure in Governing Mechanical Behavior and Deformation Mechanisms of High-Manganese Steels" Metals 15, no. 7: 779. https://doi.org/10.3390/met15070779

APA StyleZhang, C., Zhao, J., Zhao, T., Kong, L., Zheng, C., Yang, H., & Wang, Y. (2025). Interplay of C Alloying, Temperature, and Microstructure in Governing Mechanical Behavior and Deformation Mechanisms of High-Manganese Steels. Metals, 15(7), 779. https://doi.org/10.3390/met15070779