Laser Powder Bed Fusion of a Ti-16Nb-Based Alloy: Processability, Microstructure, and Mechanical Properties

Abstract

1. Introduction

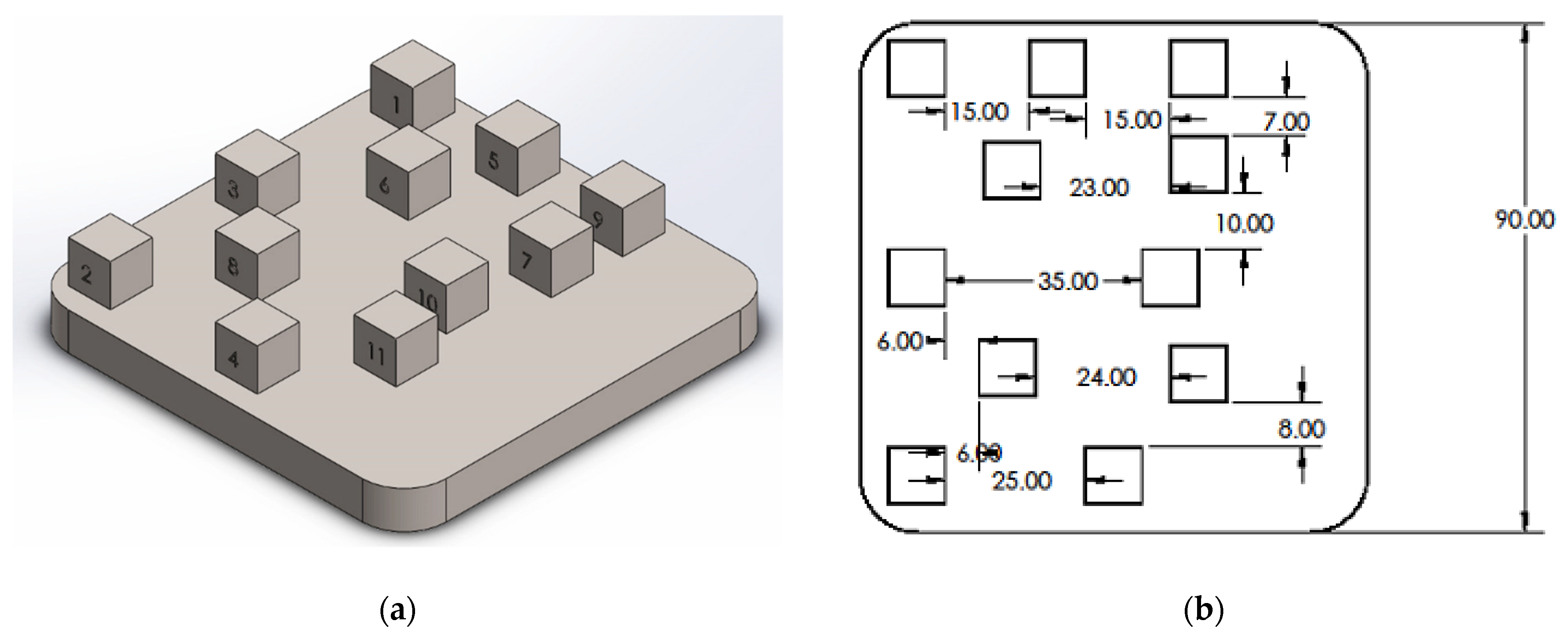

2. Materials and Methods

3. Results and Discussions

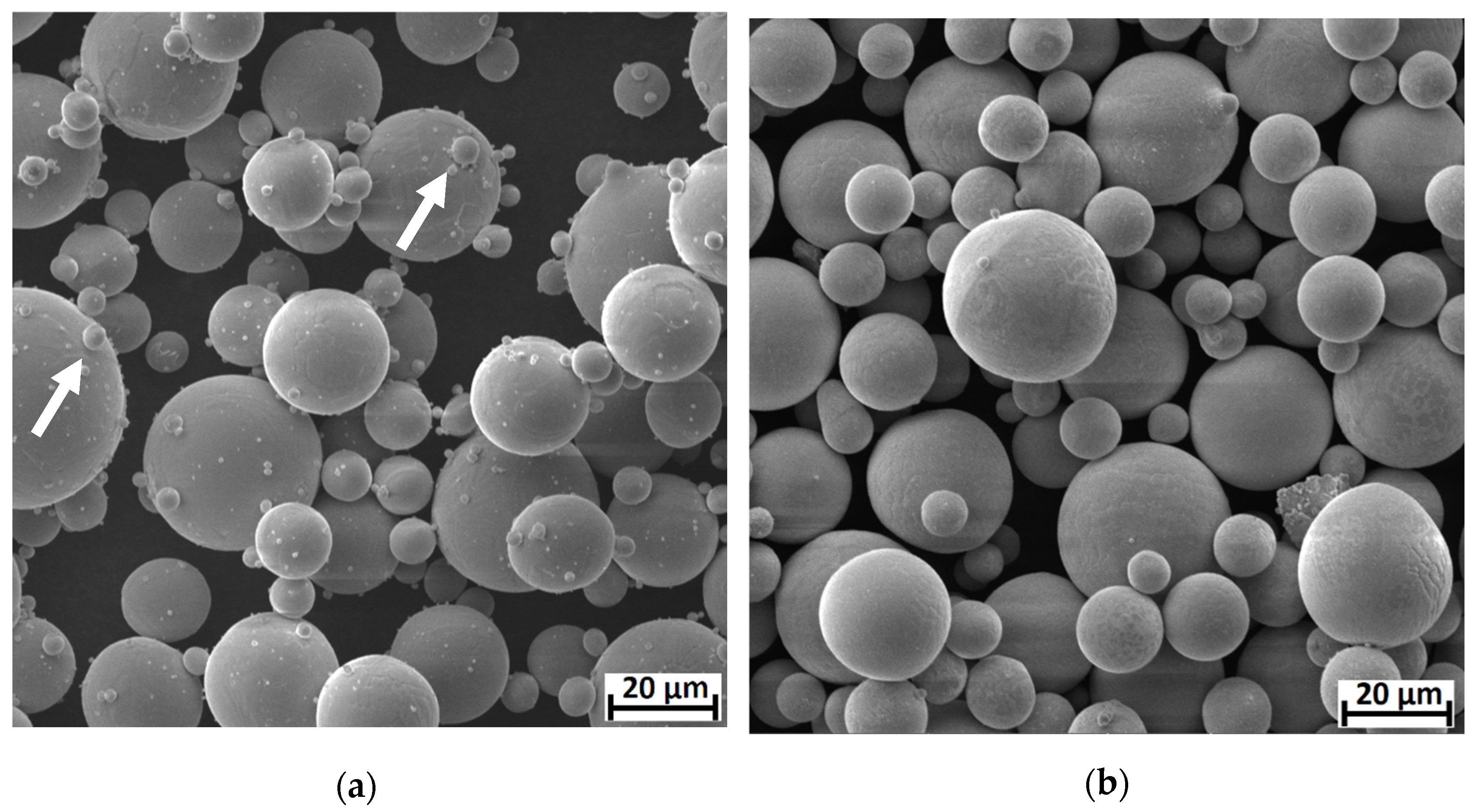

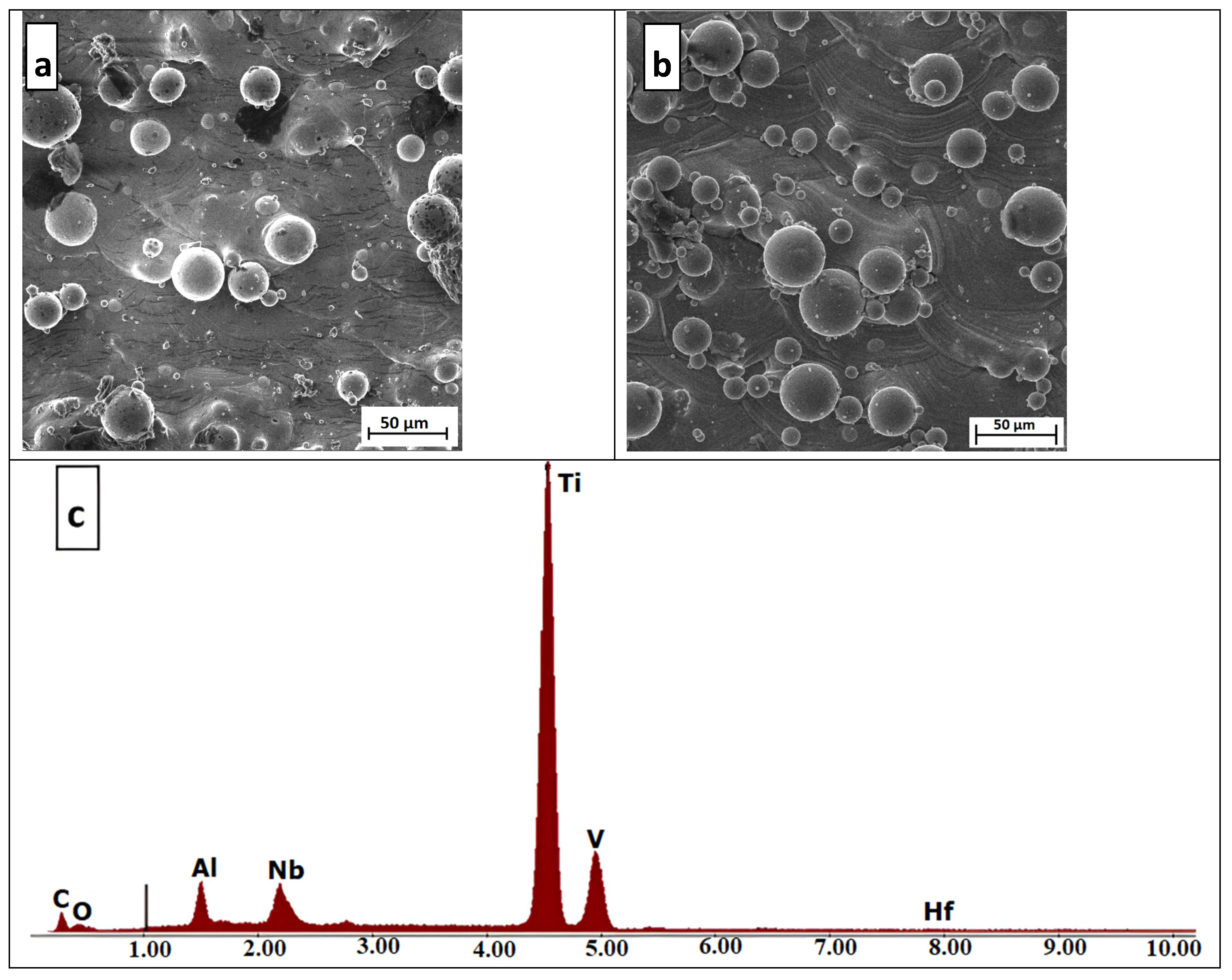

3.1. Powder Characteristics

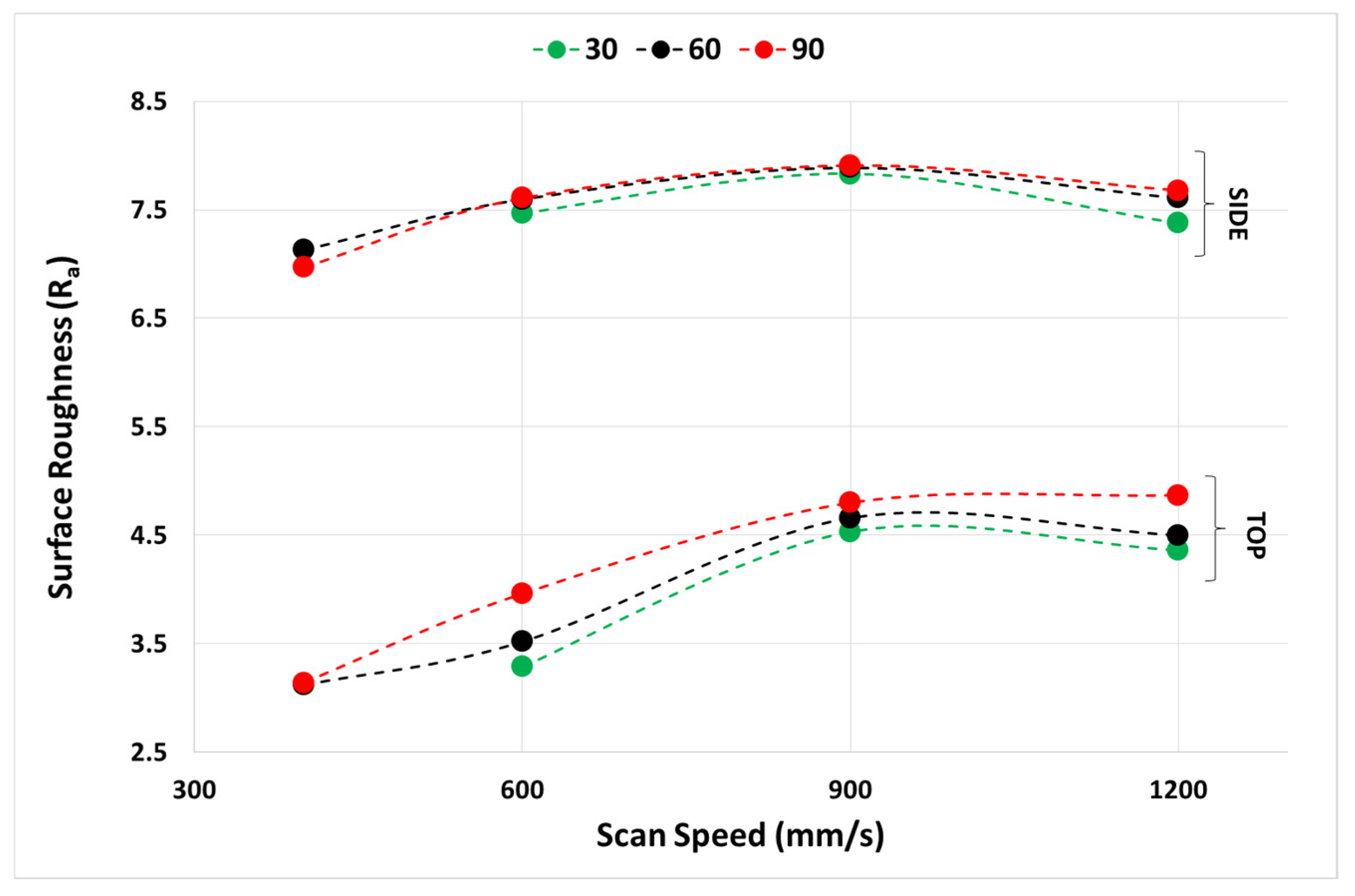

3.2. Surface Roughness

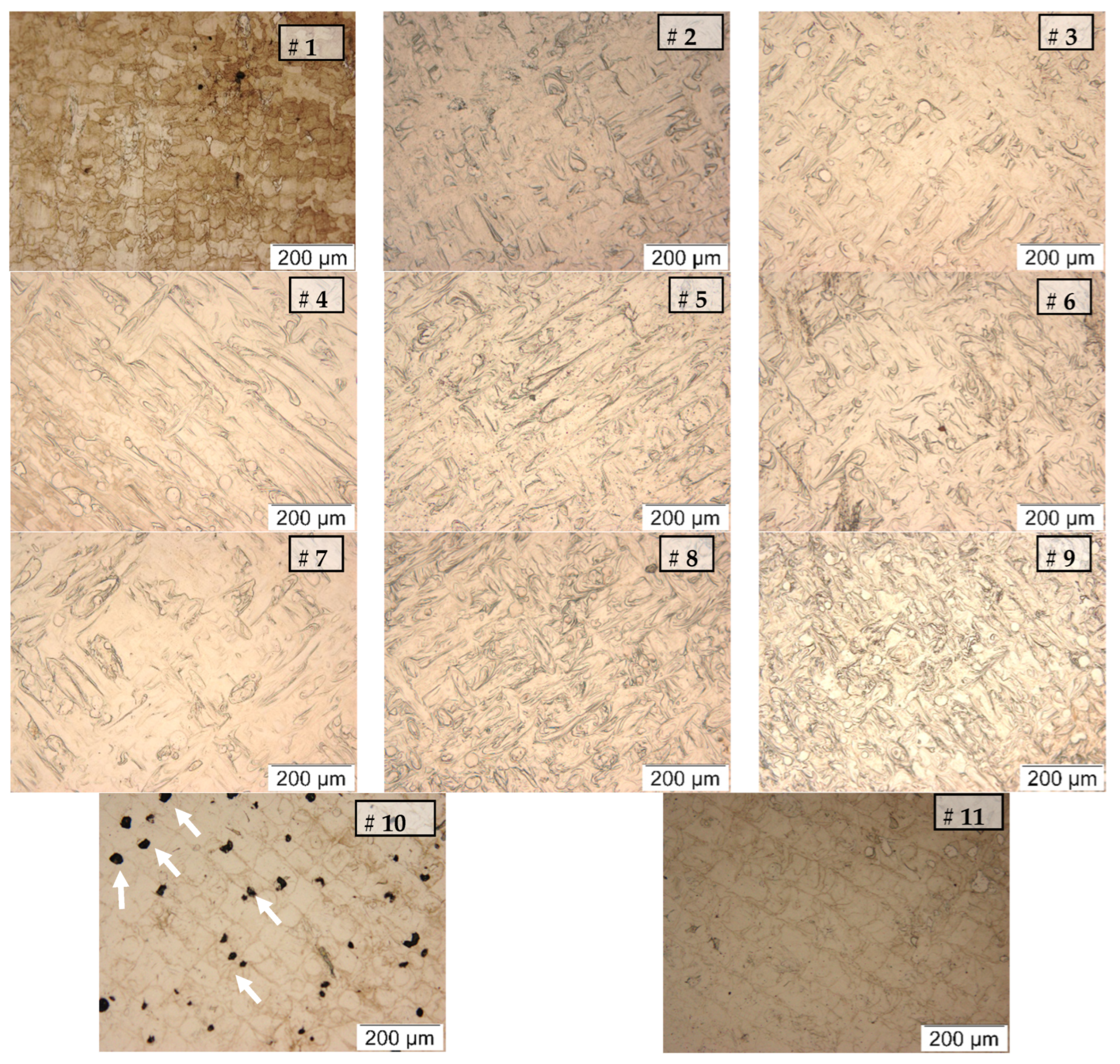

3.3. Density

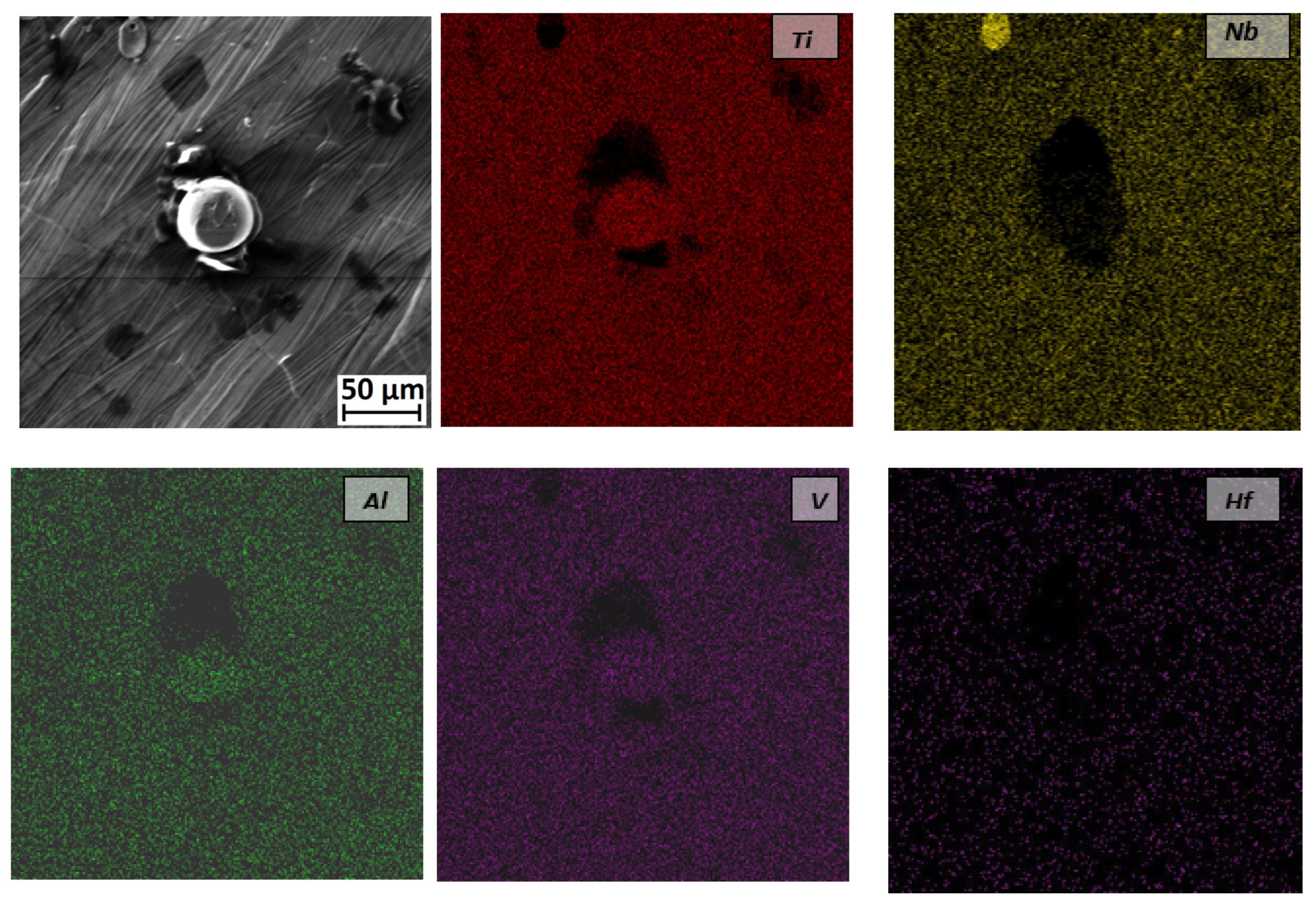

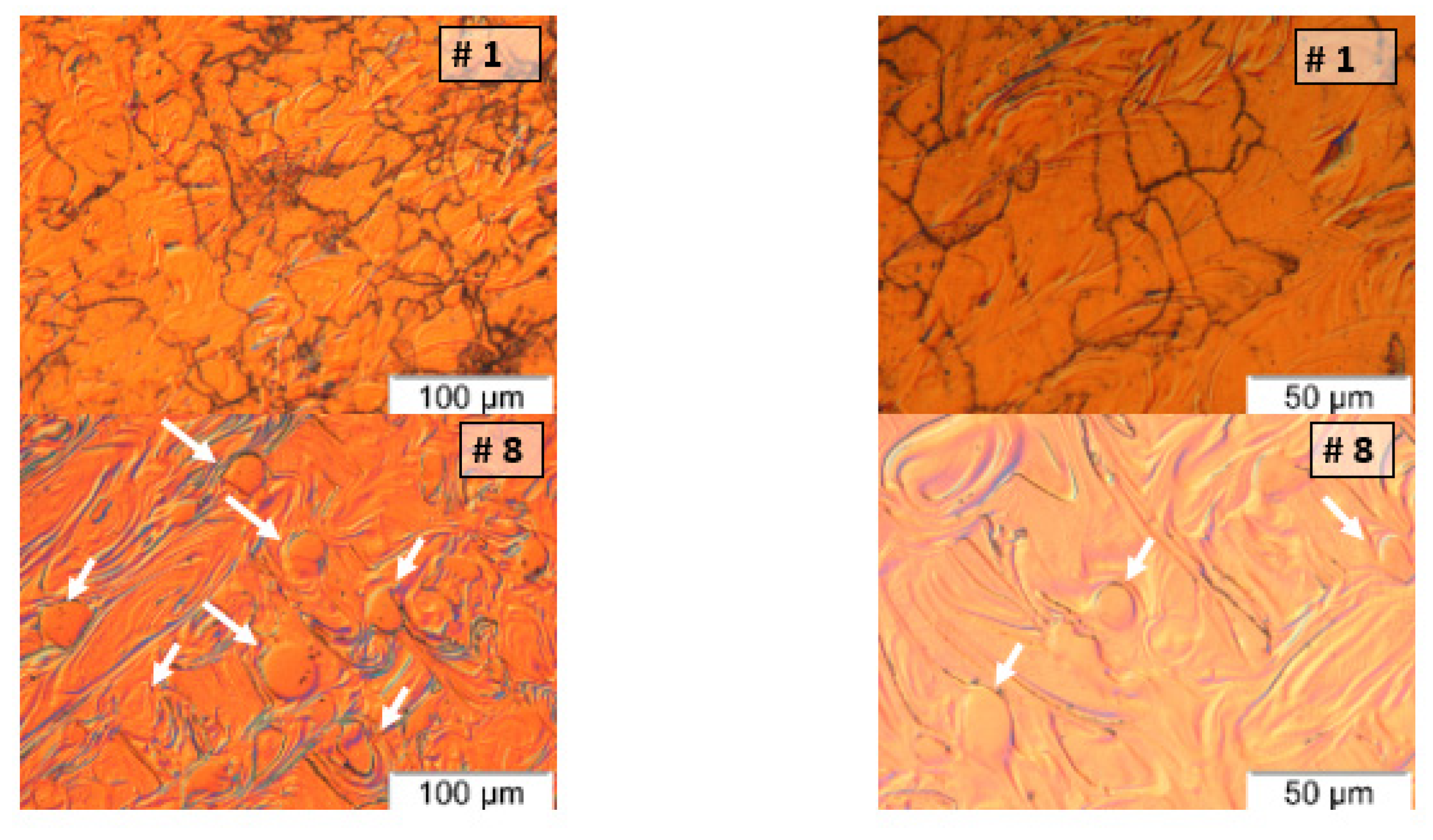

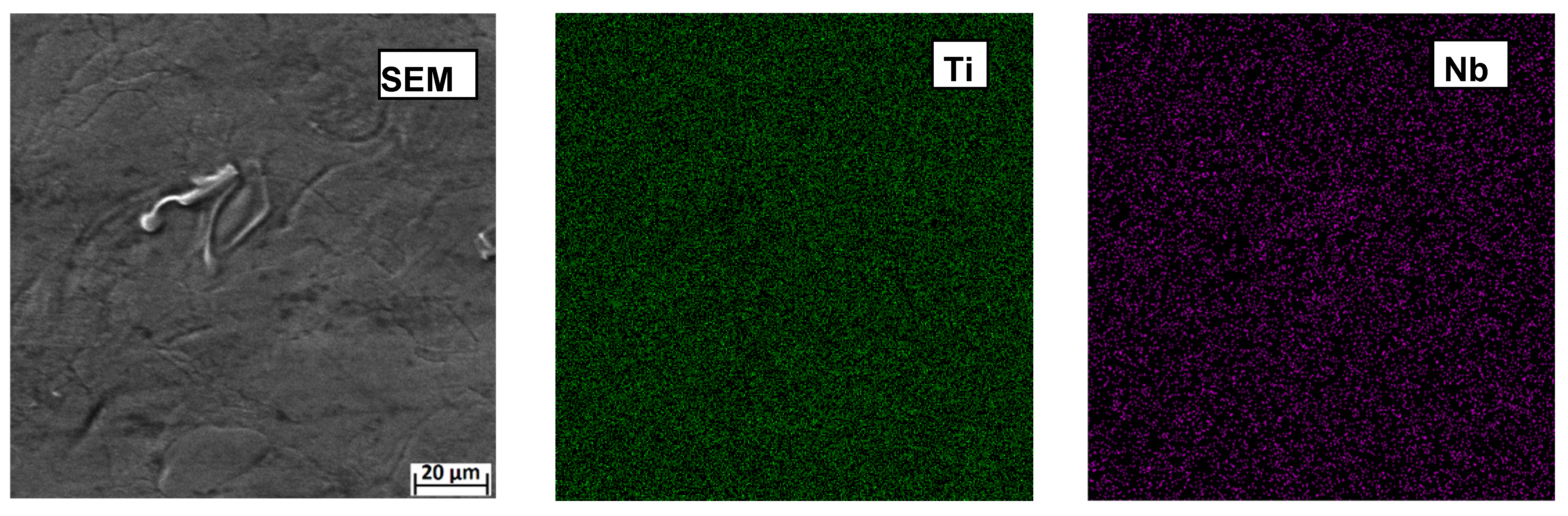

3.4. Microstructural Characterization and Phase Analysis

3.5. Mechanical Properties

4. Conclusions

- The Ti16Nb5Al3V2Hf alloy was successfully fabricated using two master alloys (Ti6Al4V and C-103) under various processing conditions.

- A total of 11 samples were produced using eight different energy density values. While nine samples exhibited porosity below 0.5%, two samples showed significantly higher porosity levels, ranging from 3.6% to 4.4%.

- The highest porosity was observed in a sample produced at 200 J/mm3, despite this being a relatively high energy density. This sample had the highest hatch spacing and the lowest scan speed, suggesting that low scan speeds combined with wide hatch spacing lead to decreased part density.

- Surface roughness measurements ranged from 3.14 to 4.89 μm for top surfaces, and from 6.97 to 7.91 μm for side surfaces. For top surfaces, higher energy densities resulted in smoother finishes. However, the effect of energy density on side surface roughness was less pronounced.

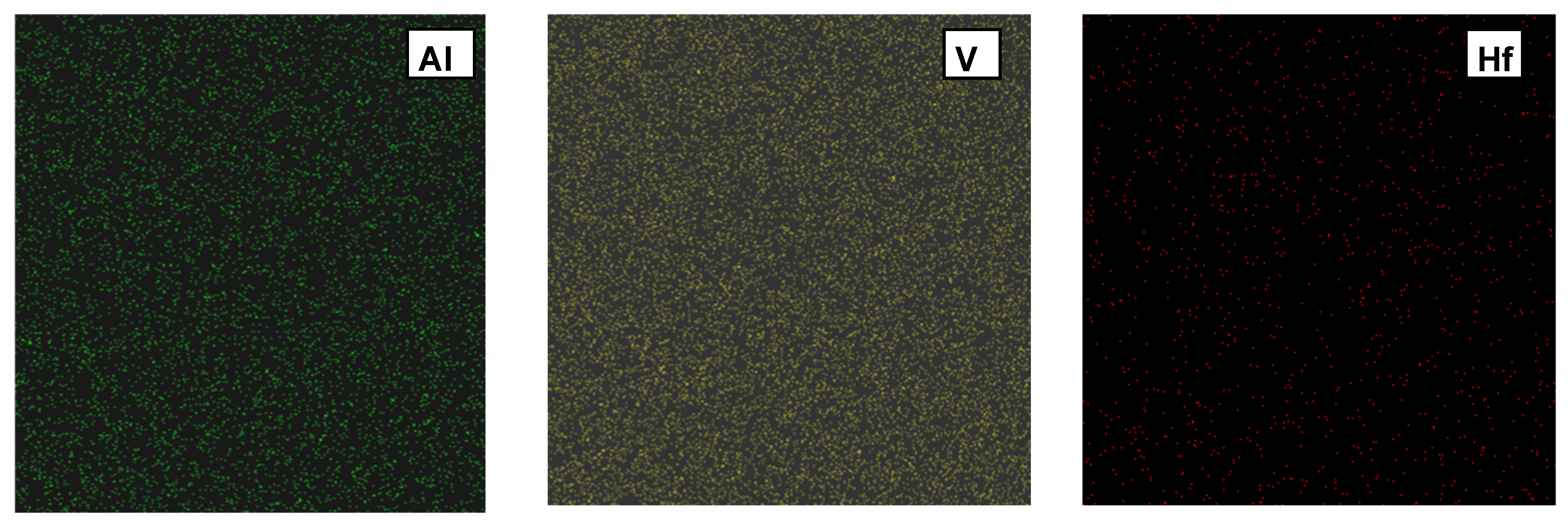

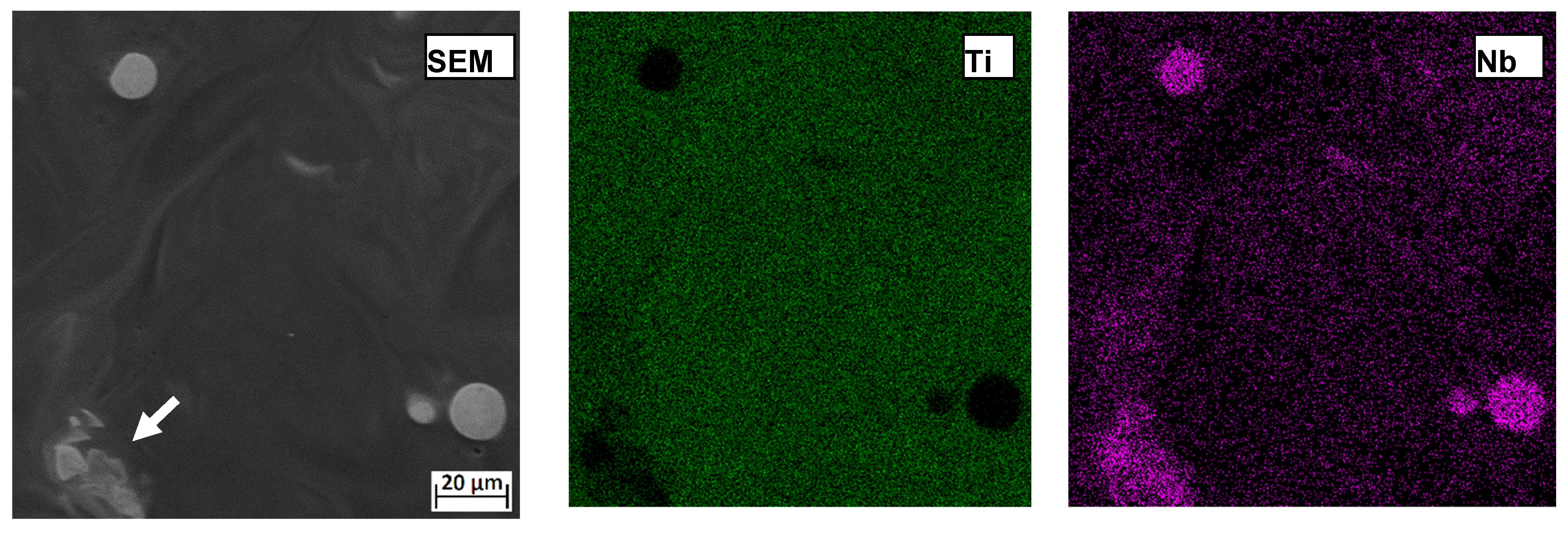

- Microstructural analysis of the samples produced with the lowest and highest energy densities showed a uniform distribution of Nb. Nevertheless, unmelted Nb particles were observed in all samples except the one produced using the highest energy density combined with low scan speed and narrow hatch spacing.

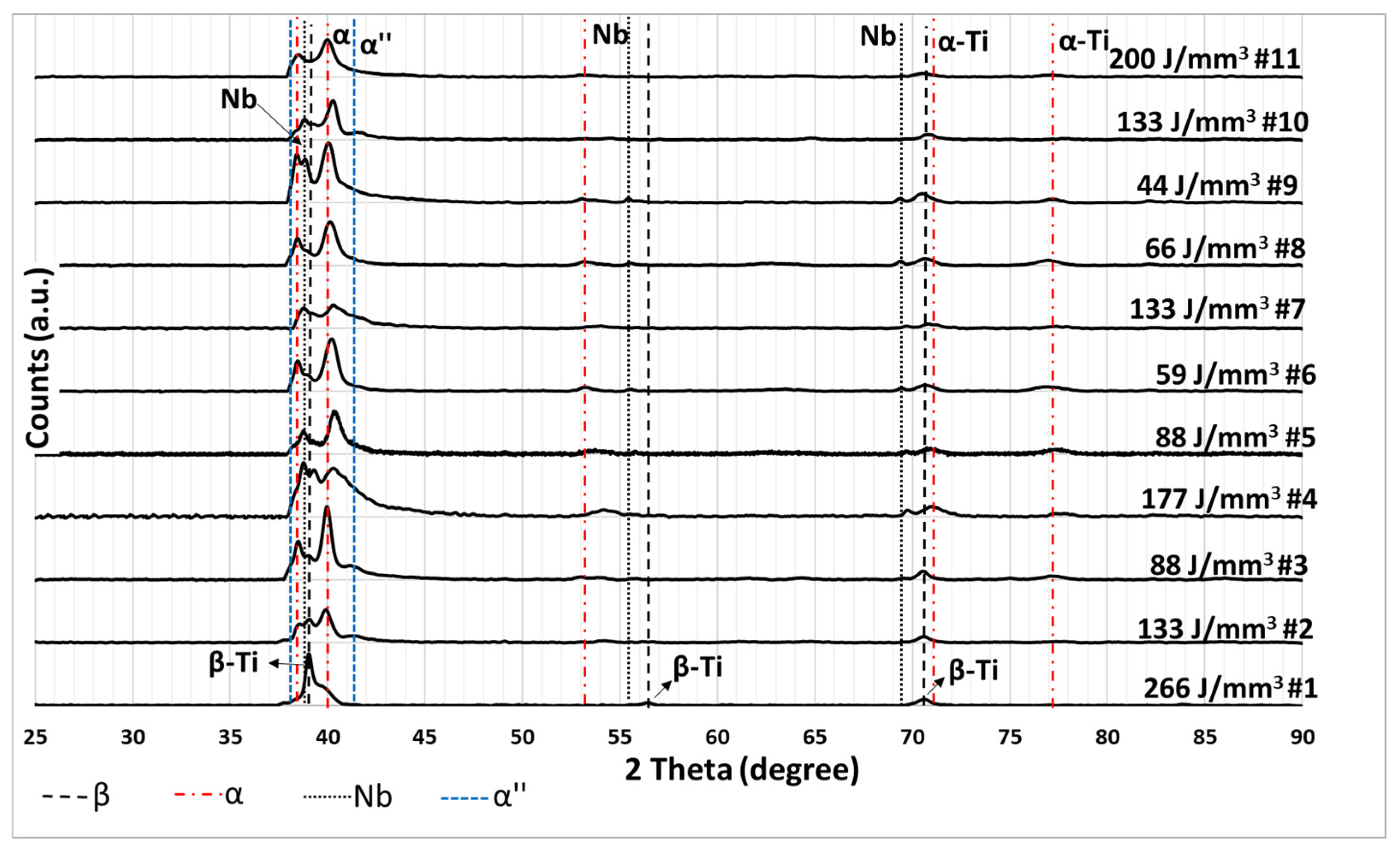

- XRD results showed that the β phase was dominant in the sample produced with the highest energy density, due to enhanced diffusion of Nb, a known β stabilizer. Conversely, the α phase was dominant in the sample produced with the lowest energy input.

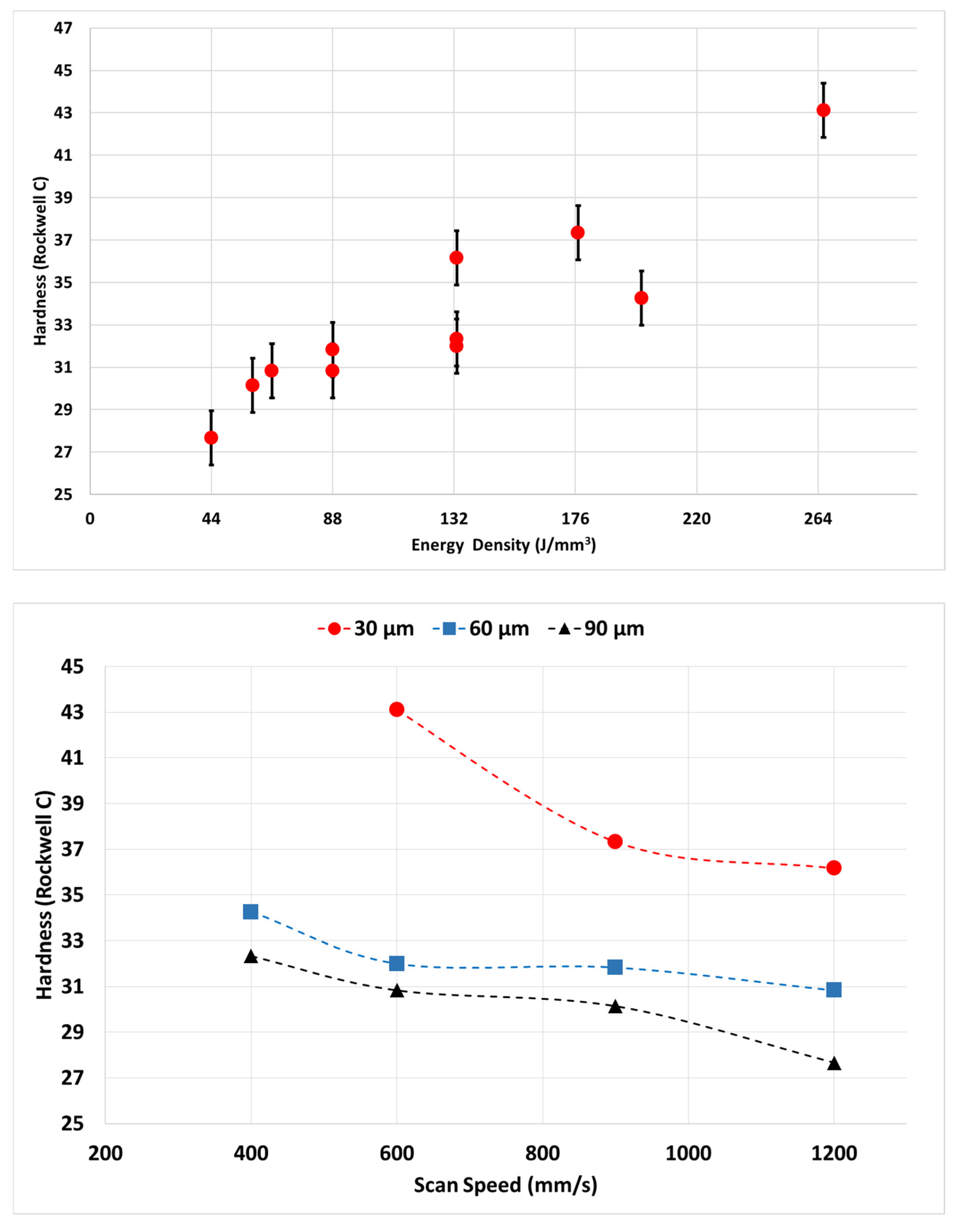

- The hardness values ranged from 28 to 43 HRC. The highest hardness was attributed to solid solution strengthening resulting from a finer and more uniform distribution of Nb. Elastic modulus values of 35.28 GPa and 38.23 GPa were measured for samples produced at the lowest and highest energy densities, respectively. These values are closer to that of human cortical bone than those of conventional Ti-Nb alloys.

- Overall, the findings demonstrate that L-PBF is an effective method for producing Ti-Nb-based alloys with improved microstructural and mechanical properties compared to traditional manufacturing techniques.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Niinomi, M. Mechanical Properties of Biomedical Titanium Alloys. Mater. Sci. Eng. A 1998, 243, 231–236. [Google Scholar] [CrossRef]

- Pilliar, R.M. Metallic Biomaterials. In Biomedical Materials; Springer: Boston, MA, USA, 2009; pp. 41–81. [Google Scholar] [CrossRef]

- Guo, S.; Meng, Q.; Zhao, X.; Wei, Q.; Xu, H. Design and Fabrication of a Metastable β-Type Titanium Alloy with Ultralow Elastic Modulus and High Strength. Sci. Rep. 2015, 5, 14688. [Google Scholar] [CrossRef] [PubMed]

- Meng, Q.; Zhang, J.; Huo, Y.; Sui, Y.; Zhang, J.; Guo, S.; Zhao, X. Design of Low Modulus β-Type Titanium Alloys by Tuning Shear Modulus C44. J. Alloys Compd. 2018, 745, 579–585. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, L. A Review on Biomedical Titanium Alloys: Recent Progress and Prospect. Adv. Eng. Mater. 2019, 21, 1801215. [Google Scholar] [CrossRef]

- Peters, M.; Kumpfert, J.; Ward, C.H.; Leyens, C. Titanium Alloys for Aerospace Applications. Adv. Eng. Mater. 2003, 5, 419–427. [Google Scholar] [CrossRef]

- Ridzwan, M.I.Z.; Shuib, S.; Hassan, A.Y.; Shokri, A.A.; Mohammad Ibrahim, M.N. Problem of Stress Shielding and Improvement to the Hip Implant Designs: A Review. J. Med. Sci. 2007, 7, 460–467. [Google Scholar] [CrossRef]

- Yamamoto, N.; Ohno, K.; Hayashi, K.; Kuriyama, H.; Yasuda, K.; Kaneda, K. Effects of Stress Shielding on the Mechanical Properties of Rabbit Patellar Tendon. J. Biomech. Eng. 1993, 115, 23–28. [Google Scholar] [CrossRef]

- Niinomi, M.; Nakai, M. Titanium-Based Biomaterials for Preventing Stress Shielding between Implant Devices and Bone. Int. J. Biomater. 2011, 2011, 836587. [Google Scholar] [CrossRef] [PubMed]

- Wachter, N.J.; Augat, P.; Krischak, G.D.; Mentzel, M.; Kinzl, L.; Claes, L. Prediction of Cortical Bone Porosity in Vitro by Microcomputed Tomography. Calcif. Tissue Int. 2001, 68, 38–42. [Google Scholar] [CrossRef]

- Prasad, K.; Bazaka, O.; Chua, M.; Rochford, M.; Fedrick, L.; Spoor, J.; Symes, R.; Tieppo, M.; Collins, C.; Cao, A.; et al. Metallic Biomaterials: Current Challenges and Opportunities. Materials 2017, 10, 884. [Google Scholar] [CrossRef]

- Yılmaz, E.; Gökçe, A.; Findik, F.; Gülsoy, H.Ö. Biomedical Porous Ti-16Nb-10Zr-(0–15)Ta Alloys. Int. J. Mater. Res. 2019, 110, 375–378. [Google Scholar] [CrossRef]

- Yılmaz, E.; Gökçe, A.; Findik, F.; Gulsoy, H.Ö. Metallurgical Properties and Biomimetic HA Deposition Performance of Ti-Nb PIM Alloys. J. Alloys Compd. 2018, 746, 301–313. [Google Scholar] [CrossRef]

- Kim, D.G.; Woo, K.D.; Kang, D.S.; Lee, T.; Lee, M.H. Fabrication and Biocompatibility Evaluation of Porous Ti-Nb-Based Biomaterials with Space Holder by Rapid Sintering. Mater. Res. Innov. 2015, 19, S1-301–S1-304. [Google Scholar] [CrossRef]

- de Oliveira, C.S.S.; Griza, S.; de Oliveira, M.V.; Ribeiro, A.A.; Leite, M.B. Study of the Porous Ti35Nb Alloy Processing Parameters for Implant Applications. Powder Technol. 2015, 281, 91–98. [Google Scholar] [CrossRef]

- Yılmaz, E.; Gökçe, A.; Findik, F.; Gulsoy, H.O.; İyibilgin, O. Mechanical Properties and Electrochemical Behavior of Porous Ti-Nb Biomaterials. J. Mech. Behav. Biomed. Mater. 2018, 87, 59–67. [Google Scholar] [CrossRef]

- Yılmaz, E.; Gökçe, A.; Fındık, F.; Gülsoy, H.Ö. Effects of Nb Content on the Microstructural and Mechanical Properties of the Biomedical PM Ti-Nb Alloys. Pamukkale Univ. J. Eng. Sci. 2017, 23, 945–948. [Google Scholar] [CrossRef][Green Version]

- Zhou, Y.L.; Niinomi, M.; Akahori, T. Mechanical Properties of Binary Ti-Ta Alloys for Biomedical Applications. Mater. Sci. Forum 2004, 449–452, 1089–1092. [Google Scholar] [CrossRef]

- Oliveira, N.T.C.; Aleixo, G.; Caram, R.; Guastaldi, A.C. Development of Ti–Mo Alloys for Biomedical Applications: Microstructure and Electrochemical Characterization. Mater. Sci. Eng. A 2007, 452–453, 727–731. [Google Scholar] [CrossRef]

- Upadhyaya, G.S. Sintered Metallic and Ceramic Materials—Preparation, Properties and Applications; Wiley: Hoboken, NJ, USA, 2001; p. 22. [Google Scholar] [CrossRef]

- Colaco, M.; Igel, D.A.; Atala, A. The Potential of 3D Printing in Urological Research and Patient Care. Nat. Rev. Urol. 2018, 15, 213–221. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Fischer, M.; Joguet, D.; Robin, G.; Peltier, L.; Laheurte, P. In Situ Elaboration of a Binary Ti–26Nb Alloy by Selective Laser Melting of Elemental Titanium and Niobium Mixed Powders. Mater. Sci. Eng. C 2016, 62, 852–859. [Google Scholar] [CrossRef]

- Schwab, H.; Prashanth, K.; Löber, L.; Kühn, U.; Eckert, J. Selective Laser Melting of Ti-45Nb Alloy. Metals 2015, 5, 686–694. [Google Scholar] [CrossRef]

- Wang, Q.; Han, C.; Choma, T.; Wei, Q.; Yan, C.; Song, B.; Shi, Y. Effect of Nb Content on Microstructure, Property and in Vitro Apatite-Forming Capability of Ti-Nb Alloys Fabricated via Selective Laser Melting. Mater. Des. 2017, 126, 268–277. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.-P.P.; Van Humbeeck, J. Microstructure and Mechanical Properties of a Novel β Titanium Metallic Composite by Selective Laser Melting. Acta Mater. 2014, 68, 150–158. [Google Scholar] [CrossRef]

- Fan, Z.; Feng, H. Study on Selective Laser Melting and Heat Treatment of Ti-6Al-4V Alloy. Results Phys. 2018, 10, 660–664. [Google Scholar] [CrossRef]

- Yılmaz, E.; Gökçe, A.; Findik, F.; Gülsoy, H.Ö. Characterization of Biomedical Ti-16Nb-(0–4)Sn Alloys Produced by Powder Injection Molding. Vacuum 2017, 142, 164–174. [Google Scholar] [CrossRef]

- Yılmaz, E.; Gökçe, A.; Fındık, F.; Gülsoy, H.Ö. Electrochemical Corrosion Behavior of Ti and Ti-16Nb Alloy for Implant Applications. In Proceedings of the 8th International Advanced Technologies Symposium (IATS’17), Elazığ, Turkey, 19–21 October 2017; Özdemir, N., Esen, H., Eds.; Fırat University/IATS: Elazığ, Turkey, 2017; Volume 8, pp. 2244–2251. [Google Scholar]

- Yılmaz, E.; Gökçe, A.; Findik, F.; Gulsoy, H.Ö. Assessment of Ti–16Nb–XZr Alloys Produced via PIM for Implant Applications. J. Therm. Anal. Calorim. 2017, 134, 7–14. [Google Scholar] [CrossRef]

- Yılmaz, E.; Gökçe, A.; Fındık, F.; Gülsoy, H.Ö. Influence of Zr Addition on the Corrosion Behavior of Biomedical PIM Ti-16Nb Alloy in SBF. Int. J. Mater. Res. 2019, 110, 379–381. [Google Scholar] [CrossRef]

- Yılmaz, E.; Çakıroğlu, B.; Gökçe, A.; Findik, F.; Gulsoy, H.O.; Gulsoy, N.; Mutlu, Ö.; Özacar, M. Novel Hydroxyapatite/Graphene Oxide/Collagen Bioactive Composite Coating on Ti16Nb Alloys by Electrodeposition. Mater. Sci. Eng. C 2019, 101, 292–305. [Google Scholar] [CrossRef]

- ASTM B212-17; Standard Test Method for Apparent Density of Free-Flowing Metal Powders Using the Hall Flowmeter Funnel. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM B527-20; Standard Test Method for Tap Density of Metal Powders and Compounds. ASTM International: West Conshohocken, PA, USA, 2020.

- Enneti, R.K.; Morgan, R.; Atre, S.V. Effect of Process Parameters on the Selective Laser Melting (SLM) of Tungsten. Int. J. Refract. Met. Hard Mater. 2018, 71, 315–319. [Google Scholar] [CrossRef]

- Nath, S.D.; Clinning, E.; Gupta, G.; Wuelfrath-Poirier, V.; L’Espérance, G.; Gulsoy, O.; Kearns, M.; Atre, S.V. Effects of Nb and Mo on the Microstructure and Properties of 420 Stainless Steel Processed by Laser-Powder Bed Fusion. Addit. Manuf. 2019, 28, 682–691. [Google Scholar] [CrossRef]

- Nath, S.D.; Irrinki, H.; Gupta, G.; Kearns, M.; Gulsoy, O.; Atre, S. Microstructure-Property Relationships of 420 Stainless Steel Fabricated by Laser-Powder Bed Fusion. Powder Technol. 2019, 343, 738–746. [Google Scholar] [CrossRef]

- Akilan, A.A.; Gökçe, A.; Nath, S.D.; Balla, V.K.; Kate, K.H.; Atre, S.V. Laser Powder Bed Fusion of In-Situ Composites Using Dry-Mixed Ti6Al4V and Si3N4 Powder. J. Manuf. Process. 2020, 59, 43–50. [Google Scholar] [CrossRef]

- ISO 4287; Geometrical Product Specifications (GPS), Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 1997.

- ASTM E8/E8M-16a; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- Tan, Y.; Zheng, J.; Gao, W.; Jiang, S.; Feng, Y. The Effect of Powder Flowability in the Selective Laser Sintering Process. In Proceedings of the 7th International Conference on Discrete Element Methods, DEM 2016, Dalian, China, 1–8 August 2016; 2016; pp. 629–636. [Google Scholar]

- Gibbons, D.W.; Govender, P.; van der Merwe, A.F. Metal Powder Feedstock Evaluation and Management for Powder Bed Fusion: A Review of Literature, Standards, and Practical Guidelines. Prog. Addit. Manuf. 2023, 9, 805–833. [Google Scholar] [CrossRef]

- Saker, A.; Cares-Pacheco, M.-G.; Marchal, P.; Falk, V. Powders Flowability Assessment in Granular Compaction: What about the Consistency of Hausner Ratio? Powder Technol. 2019, 354, 52–63. [Google Scholar] [CrossRef]

- Fitzpatrick, J. Powder Properties in Food Production Systems. In Handbook of Food Powders; Elsevier: Amsterdam, The Netherlands, 2013; pp. 285–308. [Google Scholar]

- Hong, I.-T.; Koo, C.-H. Vacuum-Furnace Brazing of C103 and Ti–6Al–4V with Ti–15Cu–15Ni Filler-Metal. Mater. Sci. Eng. A 2005, 398, 113–127. [Google Scholar] [CrossRef]

- Calignano, F.; Manfredi, D.; Ambrosio, E.P.; Iuliano, L.; Fino, P. Influence of Process Parameters on Surface Roughness of Aluminum Parts Produced by DMLS. Int. J. Adv. Manuf. Technol. 2013, 67, 2743–2751. [Google Scholar] [CrossRef]

- Han, M.K.; Kim, J.Y.; Hwang, M.J.; Song, H.J.; Park, Y.J. Effect of Nb on the Microstructure, Mechanical Properties, Corrosion Behavior, and Cytotoxicity of Ti-Nb Alloys. Materials 2015, 8, 5986–6003. [Google Scholar] [CrossRef]

- Mazumder, J.; Dutta, D.; Kikuchi, N.; Ghosh, A. Closed Loop Direct Metal Deposition: Art to Part. Opt. Lasers Eng. 2000, 34, 397–414. [Google Scholar] [CrossRef]

- Kaplan, A.F.H.; Groboth, G. Process Analysis of Laser Beam Cladding. J. Manuf. Sci. Eng. 2001, 123, 609. [Google Scholar] [CrossRef]

- Kruth, J.P.; Froyen, L.; Van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective Laser Melting of Iron-Based Powder. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Król, M.; Tański, T. Surface Quality Research for Selective Laser Melting of Ti-6Al-4V Alloy. Arch. Metall. Mater. 2016, 61, 1291–1296. [Google Scholar] [CrossRef]

- Chen, Z.; Lu, Y.; Luo, F.; Zhang, S.; Wei, P.; Yao, S.; Wang, Y. Effect of Laser Scanning Speed on the Microstructure and Mechanical Properties of Laser-Powder-Bed-Fused K418 Nickel-Based Alloy. Materials 2022, 15, 3045. [Google Scholar] [CrossRef]

- Zhang, L.C.; Klemm, D.; Eckert, J.; Hao, Y.L.; Sercombe, T.B. Manufacture by Selective Laser Melting and Mechanical Behavior of a Biomedical Ti–24Nb–4Zr–8Sn Alloy. Scr. Mater. 2011, 65, 21–24. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Levy, G.; Klocke, F.; Childs, T.H.C. Consolidation Phenomena in Laser and Powder-Bed Based Layered Manufacturing. CIRP Ann. 2007, 56, 730–759. [Google Scholar] [CrossRef]

- Malý, M.; Höller, C.; Skalon, M.; Meier, B.; Koutný, D.; Pichler, R.; Sommitsch, C.; Paloušek, D. Effect of Process Parameters and High-Temperature Preheating on Residual Stress and Relative Density of Ti6Al4V Processed by Selective Laser Melting. Materials 2019, 12, 930. [Google Scholar] [CrossRef]

- Torkamany, M.J.; Malek Ghaini, F.; Poursalehi, R. Dissimilar Pulsed Nd:YAG Laser Welding of Pure Niobium to Ti–6Al–4V. Mater. Des. 2014, 53, 915–920. [Google Scholar] [CrossRef]

- Borgman, J.M.; Wang, J.; Zani, L.; Conway, P.P.; Torres-Sanchez, C. The Effect of Energy Density and Nb Content on the Microstructure and Mechanical Properties of Selective Laser Melted Ti-(10-30 Wfile:///C:/Users/User/Downloads/1-S2.0-S1044580323000049-Main.Pdft.%) Nb. J. Mater. Eng. Perform. 2021, 30, 8771–8783. [Google Scholar] [CrossRef]

- Ren, Y.; Wu, H.; Du, J.; Liu, B.; Wang, X.; Jiao, Z.; Tian, Y.; Baker, I. Effect of Laser Scannings Speed on Microstructure, Tribological and Corrosion Behavior of Ti-23Nb Alloys Produced by Laser Metal Deposition. Mater. Charact. 2023, 197, 112647. [Google Scholar] [CrossRef]

- Li, Z.; Xu, H.; Dong, A.; Cai, X.; He, L.; Du, D.; Xing, H.; Zhu, G.; Sun, B. Mechanical Anisotropy of Laser Powder Bed Fusion Fabricated Ti-41Nb Alloy Using Pre-Alloyed Powder: Roles Played by Grain Morphology and Crystallographic Orientation. J. Alloys Compd. 2022, 925, 166572. [Google Scholar] [CrossRef]

- Li, Z.; Qiu, J.; Xu, H.; Dong, A.; He, L.; Zhu, G.; Du, D.; Xing, H.; Liu, X.; Sun, B. Characteristics of β-Type Ti-41Nb Alloy Produced by Laser Powder Bed Fusion: Microstructure, Mechanical Properties and in Vitro Biocompatibility. J. Mater. Sci. Technol. 2022, 124, 260–272. [Google Scholar] [CrossRef]

- Wang, J.C.; Liu, Y.J.; Qin, P.; Liang, S.X.; Sercombe, T.B.; Zhang, L.C. Selective Laser Melting of Ti–35Nb Composite from Elemental Powder Mixture: Microstructure, Mechanical Behavior and Corrosion Behavior. Mater. Sci. Eng. A 2019, 760, 214–224. [Google Scholar] [CrossRef]

- Hooper, P.A. Melt Pool Temperature and Cooling Rates in Laser Powder Bed Fusion. Addit. Manuf. 2018, 22, 548–559. [Google Scholar] [CrossRef]

- Foltz, J.W.; Welk, B.; Collins, P.C.; Fraser, H.L.; Williams, J.C. Formation of Grain Boundary α in β Ti Alloys: Its Role in Deformation and Fracture Behavior of These Alloys. Metall. Mater. Trans. A 2011, 42, 645–650. [Google Scholar] [CrossRef]

- Silva, L.M.d.; Claro, A.P.R.A.; Buzalaf, M.A.R.; Grandini, C.R. Influence of the Substitutional Solute on the Mechanical Properties of Ti-Nb Binary Alloys for Biomedical Use. Mater. Res. 2012, 15, 355–358. [Google Scholar] [CrossRef]

- Hein, M.; Lopes Dias, N.F.; Pramanik, S.; Stangier, D.; Hoyer, K.P.; Tillmann, W.; Schaper, M. Heat Treatments of Metastable β Titanium Alloy Ti-24Nb-4Zr-8Sn Processed by Laser Powder Bed Fusion. Materials 2022, 15, 3774. [Google Scholar] [CrossRef]

- Qi, L.; He, S.; Chen, C.; Jiang, B.; Hao, Y.; Ye, H.; Yang, R.; Du, K. Diffusional-Displacive Transformation in a Metastable β Titanium Alloy and Its Strengthening Effect. Acta Mater. 2020, 195, 151–162. [Google Scholar] [CrossRef]

- Wang, Y.B.; Zheng, Y.F. The Microstructure and Shape Memory Effect of Ti–16 at.%Nb Alloy. Mater. Lett. 2008, 62, 269–272. [Google Scholar] [CrossRef]

- Qiu, C.; Liu, Q. Multi-Scale Microstructural Development and Mechanical Properties of a Selectively Laser Melted Beta Titanium Alloy. Addit. Manuf. 2019, 30, 100893. [Google Scholar] [CrossRef]

- Motyka, M.; Kubiak, K.; Sieniawski, J.; Ziaja, W. Phase Transformations and Characterization of α + β Titanium Alloys. In Comprehensive Materials Processing; Elsevier: Amsterdam, The Netherlands, 2014; pp. 7–36. [Google Scholar]

| Composition (wt.%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Ti6Al4V | Ti | Al | V | Fe | O | C | Others | |

| Balance | 5.5 (max) | 3.5–4.5 | 0.25 (max) | 0.13–0.2 | 0.08 (max) | 0.4 (max) | ||

| C-103 | Nb | Hf | Ti | Zr | Ta | O | N | Others |

| Balance | 10 | 1 | 0.7 | 0.5 | 0.23 | 0.15 | 0.4 (max) | |

| Sample (#) | Layer Thickness (µm) | Power (W) | Scan Speed (mm/s) | Hatch Spacing (µm) | Energy Density (J/mm3) |

|---|---|---|---|---|---|

| 1 | 20 | 96 | 600 | 30 | 266 |

| 2 | 20 | 96 | 600 | 60 | 133 |

| 3 | 20 | 96 | 600 | 90 | 88 |

| 4 | 20 | 96 | 900 | 30 | 177 |

| 5 | 20 | 96 | 900 | 60 | 88 |

| 6 | 20 | 96 | 900 | 90 | 59 |

| 7 | 20 | 96 | 1200 | 30 | 133 |

| 8 | 20 | 96 | 1200 | 60 | 66 |

| 9 | 20 | 96 | 1200 | 90 | 44 |

| 10 | 20 | 96 | 400 | 90 | 133 |

| 11 | 20 | 96 | 400 | 60 | 200 |

| Powder | Density (g/cm3) |

|---|---|

| Ti6Al4V | 4.48 (+0.02–0.01) |

| C-103 | 8.86 (+0.01–0.03) |

| 18% C-103—82% Ti6Al4V | 4.91 (+0.01–0.02) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gökçe, A.; Balla, V.K.; Nath, S.D.; Akilan, A.A.; Atre, S.V. Laser Powder Bed Fusion of a Ti-16Nb-Based Alloy: Processability, Microstructure, and Mechanical Properties. Metals 2025, 15, 728. https://doi.org/10.3390/met15070728

Gökçe A, Balla VK, Nath SD, Akilan AA, Atre SV. Laser Powder Bed Fusion of a Ti-16Nb-Based Alloy: Processability, Microstructure, and Mechanical Properties. Metals. 2025; 15(7):728. https://doi.org/10.3390/met15070728

Chicago/Turabian StyleGökçe, Azim, Vamsi Krishna Balla, Subrata Deb Nath, Arulselvan Arumugham Akilan, and Sundar V. Atre. 2025. "Laser Powder Bed Fusion of a Ti-16Nb-Based Alloy: Processability, Microstructure, and Mechanical Properties" Metals 15, no. 7: 728. https://doi.org/10.3390/met15070728

APA StyleGökçe, A., Balla, V. K., Nath, S. D., Akilan, A. A., & Atre, S. V. (2025). Laser Powder Bed Fusion of a Ti-16Nb-Based Alloy: Processability, Microstructure, and Mechanical Properties. Metals, 15(7), 728. https://doi.org/10.3390/met15070728